Abstract

Nanotechnology is currently being applied in pavement engineering and, in particular, asphalt mixtures. This emerging technology can enhance materials’ properties and in recent years there has been research carried out on the influence of modifications through different nanomaterials. Hydrotalcite, which is a type of layered double hydroxide (LDH), has been regarded as a promising modifier, particularly on account of its ability to reflect UV radiation (improving UV aging resistance), delay oxygen permeability and retard the loss of volatile components. Such properties can actively contribute to enhance the aging resistance of the asphalt binder, and consequently of the asphalt mixtures. The objective of this paper is to present the effect of nano hydrotalcite modification in the mechanical behavior of Stone Mastic Asphalt with an 8 mm upper sieve size of the aggregate (SMA 8). The gap-graded aggregate skeleton bounded with a mastic mortar that is very rich in modified bitumen (7.5%), and contains 0.5% of natural cellulose fibers, are special characteristics that are able to induce a more significant effect of the nanomodification. The dosage of hydrotalcite was 3% by mass of asphalt binder. The study of the mechanical behavior comprised laboratory tests of resistance to permanent deformation (EN 12697-22), indirect tensile strength (EN 12697-23), water sensitivity (EN 12697-12), stiffness (EN 12697-26), and resistance to fatigue (EN 12697-24). The main conclusions were established by comparing the results obtained with those of an unmodified SMA 8. Although the unmodified SMA 8 already exhibited good mechanical performance, it was possible to observe that the nanomodified SMA 8 also showed an adequate behavior for application in surface layers. The most relevant enhancement was obtained in the evaluation of water sensitivity by the indirect tensile strength test, achieving a 100% indirect tensile strength ratio. In general, the results revealed the potential of hydrotalcite for the modification of asphalt mixtures, indicating positive effects in terms of durability.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

Technological innovations in pavement engineering are currently being explored to improve materials’ performance from the mechanical, economic, and environmental points of view. In the case of surface layers, the asphalt mixtures have to withstand a wide range of environmental and traffic conditions and, at the same time, provide special and more exigent conditions of skid and rutting resistance, among other characteristics. In addition to this, bitumen is a material that is sensitive to aging, and its properties deteriorate over time also affecting the performance of asphalt mixtures (Sirin et al. 2018). Aging is a particularly important factor in surface layers because those pavement layers are exposed directly to environmental conditions such as ultraviolet (UV) radiation, moisture, oxygen, and greater temperature variations. New asphalt mixtures have been developed, such as Porous Asphalt (PA) and Stone Mastic Asphalt (SMA), using a wide variety of additives in order to enhance the performance of asphalt mixtures during the pavement’s life cycle. In recent years, different additives were developed for different purposes: adhesion improvers, fibers, rubber, warm mix asphalt additives, rejuvenators, and polymers (Behnood 2019, 2020; Caputo et al. 2020; Gupta et al. 2019; Habbouche et al. 2020; Picado-Santos et al. 2020; Rossi et al. 2017; Slebi-Acevedo et al. 2019). These new asphalt materials not only provide more resistant and resilient, and longer life pavements but also protect the environment and reduce maintenance costs.

Self-healing is aimed at increasing the lifespan of road pavements by reducing the aging effect on asphalt pavements. Three main self-healing technologies are currently available for asphalt pavement construction and maintenance: nanoparticles, induction heating, and rejuvenation (Behnood 2019 Crucho et al. 2019; Pasupunuri et al. 2017; Tabaković and Schlangen 2016; Vo et al. 2020).

The application of nanomaterials as an additive in asphalt mixtures is being considered today as an option in pavement technology. Indeed, like other additives, nanomaterials are suitable for asphalt binder modification with a view to improving asphalt mixtures’ performance. Several studies have demonstrated the benefits of the modifications with nanomaterials – such as nanosilica, nanoclays, and nanoiron – on the mechanical performance and aging resistance (Crucho 2018; Crucho et al. 2018, 2019; Filippi et al. 2018; Martinho and Farinha 2017; Yanga and Tigheb 2013).

Hydrotalcite is a type of layered double hydroxide (LDH) (Evans and Slade 2005; Wang and O’Hare 2012). LDHs are ionic lamellar compounds made up of positively charged brucite-like layers of organic-inorganic or inorganic-inorganic nanomaterials. Compared to clays mineralogical structure, LDHs are less prone to delamination due to stronger interactions interlayers. The substance has already been considered to be a promising modifier for construction materials, particularly on account of its ability to reflect UV radiation (improving UV aging resistance), delay oxygen permeability, and retard the loss of volatile components. There are research studies on potential applications of LDH in concrete materials with very positive results (Duan et al. 2013; Xu et al. 2009). The application of LDH in asphalt mixtures has also been studied in recent years mainly thanks to its ability to be a physical barrier against UV and, as a consequence thereof, to delay the aging of bitumen (Cui et al. 2016; Liu et al. 2014; Pang et al. 2014; Peng et al. 2015; Xu et al. 2015, 2016, 2017; Zhao et al. 2015; Zhu et al. 2019).

We believe that these properties of nano hydrotalcite can actively contribute to enhancing the aging resistance of an asphalt binder, and consequently of asphalt mixtures. The influence could be more effective in the case of binder-rich asphalt mixtures. The innovative objective of this paper is to present a study on the feasibility of the nano hydrotalcite modification of SMA 8. The paper describes a preliminary laboratory study on the mechanical behavior characterized by indirect tensile strength and water sensitivity, stiffness, and resistance to fatigue and permanent deformation.

2 Methodology

2.1 Materials

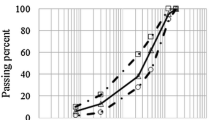

An SMA 8 asphalt mixture was used in this study. The aggregates mixture consisted of the following percentages (relative to the total mass of aggregates mixture) of the three fractions based on the minimum and maximum nominal sizes (d/D): 20% of 6/12 fraction; 54% of 2/6 fraction; and 19% of fraction 0/6. Figure 1 shows the grading curve of the aggregates mixture. Aggregates were obtained from crushed gabbro rock.

The SMA was made up of 7% (relative to the total mass of aggregates mixture) of filler (limestone) and 0,5% (relative to the total mass of asphalt mixture) of natural cellulose fibers. This mixture was designed in accordance with EN 13108-5. The asphalt mixture was made up of 7.5% (relative to the total mass of asphalt mixture) of PMB 45/80-65 modified bitumen (control binder). Table 1 presents the main Marshall properties of the asphalt mixture.

The asphalt mixture was modified with 3% (relative to the total mass of asphalt binder) of nano hydrotalcite. Crucho (2018) describes the modification procedure followed in this study. The properties of penetration (EN 1426) and softening point (EN 1427) of the control and modified binders are presented in Table 2. Two similar asphalt mixtures were produced in the study: the control mixture (unmodified with hydrotalcite), and the modified mixture (modified with 3% of hydrotalcite).

2.2 Laboratory Tests

Table 3 lists the properties and test standards followed in the laboratory study according to the European specification framework in EN 12697 for hot mix asphalt. Indirect tensile strength and water sensitivity were determined according to EN 12697-23 and EN 12697-12, respectively. Stiffness evaluation was based on EN 12697-26 and adopting the four-point bending beam equipment, under controlled strain, at 20°C. Resistance to fatigue was determined using the four-point bending beam equipment, under controlled strain, at 20°C and with 10 Hz sinusoidal loading, in accordance with EN 12697-24. Evaluation of permanent deformation was based on EN 12697-22 (wheel-tracking), using the small-size device and specimens conditioned in air.

3 Results and Discussion

3.1 Indirect Tensile Strength and Water Sensitivity

The mixture modified with 3% hydrotalcite presented good performance in the indirect tensile strength (ITS) and indirect tensile strength ratio (ITSR). Compared with the control mixture, the modified mixture presented 3% increase in ITSdry (under dry conditions, with no water sensitivity conditioning) and 9% increase in ITSwet (after water sensitivity conditioning). The results of ITS and ITSR of the control and modified mixtures are presented in Fig. 2. The control mixture also presented a good performance for these parameters, indicating no problems with ITS or ITSR. This means that the margin for enhancement using the modification was limited. Nevertheless, in the modified mixture the increase in ITSwet superior to the increase in ITSdry led to an increase in ITSR, with the modified mixture presenting a ratio of 100%. Such results provide a good indication of the positive effect of the modification with hydrotalcite on ITS and water sensitivity.

3.2 Stiffness

The modification with hydrotalcite had some effect on the stiffness of the asphalt mixture. Compared with the control mixture, the modified mixture presented a slightly lower stiffness modulus, with a variation dependent on the loading frequency. The reduction in stiffness modulus of the modified mixture was 20% and 4% at 1 Hz and 30 Hz respectively, and for the intermediate frequencies, the observed reduction was approximately linear. With regard to phase angle, the modified mixture presented slightly higher values than the control mixture. At 1 Hz the increase in phase angle was 7% and at 30 Hz the increase in phase angle was 18%, meaning the values of the intermediate frequencies were within these two extremes. The results of the stiffness modulus and phase angle of the control and modified mixtures are presented in Fig. 3 and Fig. 4 respectively.

The elastic slopes (slope of the regression line of the natural logarithms of the loading frequency and elastic modulus) calculated from the stiffness data were 0.316 and 0.377 for the control and modified mixtures respectively. The elastic slope alone is not an accurate indicator of the aging level of the asphalt mixture; nevertheless, this parameter does decrease as the aging increases (Crucho 2018). As the modified binder presented a lower penetration value and higher softening point, one possible explanation for the higher elastic slope of the modified mixture, in line with a slightly lower stiffness modulus and slightly higher phase angle, could be that it is an effect of aging protection of the asphalt binder and mixture, particularly in the mixing and compaction stages. This property requires further investigation.

3.3 Resistance to Fatigue

The modification with hydrotalcite had an effect on fatigue resistance. However, the differences observed were relatively small considering the high dispersion commonly observed in fatigue tests. The fatigue lines of the control and modified mixtures are presented in Fig. 5. The strain corresponding to the application of one million loading cycles (ε6) was 255 µm/m for the control mixture and 224 µm/m for the modified mixture. Thus, the modified mixture presented a reduction in ε6 of 12%. The slopes of the fatigue lines were −5.0 and −5.7 for the control and modified mixtures respectively. In the case of the slope of the fatigue line, the modified mixture presented an increase of 13%.

3.4 Permanent Deformation

The parameters obtained with the wheel-tracking tests, i.e. rut depth in air (RDair), proportional rut depth in air (PRDair), and wheel-tracking slope in air (WTSair), for the control and modified mixtures are presented in Table 4. For each parameter, the respective value of standard deviation is presented in brackets. The modified mixture presented higher values for all parameters, indicating a softer behavior, which to some extent, is in line with the results for stiffness. Nevertheless, the results obtained can be considered within the range expected for SMA 8 mixtures.

4 Conclusions

This paper presents and discusses the results of a laboratory study aimed at assessing the effect of nano hydrotalcite modification on the mechanical behavior of an asphalt mixture. The selected mixture, a binder-rich (with 7.5% bitumen) Stone Mastic Asphalt with 8 mm upper sieve size of the aggregate (SMA 8), was modified with 3% hydrotalcite. The unmodified and the modified asphalt mixture were tested for indirect tensile strength, water sensitivity, stiffness, resistance to fatigue and permanent deformation.

The results obtained from the experimental study allow for the conclusion that nano modified SMA 8 presents in general an adequate mechanical performance for application in surface layers. The modification with hydrotalcite had effects on the mechanical performance of the SMA 8. The most important enhancement was obtained in the evaluation of water sensitivity by the indirect tensile strength test, achieving 100% indirect tensile strength ratio. The hydrotalcite modification gave positive indications regarding a potential effect in terms of aging protection and consequent improvements in durability.

References

Behnood, A.: Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: a review. J. Clean. Prod. 231, 171–182 (2019). https://doi.org/10.1016/j.jclepro.2019.05.209

Behnood, A.: A review of the warm mix asphalt (WMA) technologies: effects on thermo-mechanical and rheological properties. J. Clean. Prod. 259 (2020). https://doi.org/10.1016/j.jclepro.2020.120817

Caputo, P., et al.: The role of additives in warm mix asphalt technology: an insight into their mechanisms of improving an emerging technology. Nanomaterials 10, 1202 (2020). https://doi.org/10.3390/nano10061202

Crucho, J.: Development of an accelerated asphalt concrete aging method and utilization of nano-modifiers to improve durability of asphalt concrete. Ph.D. Thesis, Instituto Superior Técnico, Universidade de Lisboa, Portugal (2018)

Crucho, J., et al.: Mechanical performance of asphalt concrete modified with nanoparticles: nanosilica, zero-valent iron and nanoclay. Constr. Build. Mater. 181, 309–318 (2018). https://doi.org/10.1016/j.conbuildmat.2018.06.052

Crucho, J., et al.: A review of nanomaterials’ effect on mechanical performance and aging of asphalt mixtures. Appl. Sci. 9, 3657 (2019). https://doi.org/10.3390/app9183657

Cui, P.Q., et al.: Characteristics of using layered double hydroxides to reduce the VOCs from bituminous materials. Constr. Build. Mater. 123, 69–77 (2016). https://doi.org/10.1016/j.conbuildmat.2016.06.117

Duan, P., et al.: Influence of layered double hydroxides on microstructure and carbonation resistance of sulphoaluminate cement concrete. Constr. Build. Mater. 48, 601–609 (2013). https://doi.org/10.1016/j.conbuildmat.2013.07.049

Evans, D.G., Slade, R.C.T.: Structural aspects of layered double hydroxides. In: Duan, X., Evans, D.G. (eds.) Layered Double Hydroxides. Structure and Bonding, vol. 119, pp. 1–87. Springer, Heidelberg (2005). https://doi.org/10.1007/430_005

Filippi, S., et al.: Effect of nanoadditives on bitumen aging resistance: a critical review. J. Nanomater. 2018, 2469307 (2018). https://doi.org/10.1155/2018/2469307

Gupta, A., Rodriguez-Hernandez, J., Castro-Fresno, D.: Incorporation of additives and fibers in porous asphalt mixtures: a review. Materials 12, 3156 (2019). https://doi.org/10.3390/ma12193156

Habbouche, J., et al.: A critical review of high polymer-modified asphalt binders and mixtures. Int. J. Pavement Eng. 21(6), 686–702 (2020). https://doi.org/10.1080/10298436.2018.1503273

Liu, X., et al.: Fatigue properties of layered double hydroxides modified asphalt and its mixture. Adv. Mater. Sci. Eng. 2014, 868404 (2014). https://doi.org/10.1155/2014/868404

Martinho, F., Farinha, J.: An overview of the use of nanoclay modified bitumen in asphalt mixtures for enhanced flexible pavement performances. Road Mater. Pavement Des. (2017). https://doi.org/10.1080/14680629.2017.1408482

Pang, L., et al.: Effect of LDHs on the aging resistance of crumb rubber modified asphalt. Constr. Build. Mater. 67, 239–243 (2014). https://doi.org/10.1016/j.conbuildmat.2013.10.040

Pasupunuri, S.K. et al.: Self-healing pavements: a revolution in pavement materials. In: 18th Crossroads World Road Meeting 2017, India (2017). https://www.researchgate.net/publication/327838600_SELF-HEALING_PAVEMENTS_A_REVOLUTION_IN_PAVEMENT_MATERIALS

Peng, C., et al.: Preparation and properties of a layered double hydroxide deicing additive for asphalt mixture. Cold Reg. Sci. Technol. 110, 70–76 (2015). https://doi.org/10.1016/j.coldregions.2014.11.013

Picado-Santos, L., et al: Crumb rubber asphalt mixtures: a literature review. Constrt. Build. Mater. 247. https://doi.org/10.1016/j.conbuildmat.2020.11857

Rossi, C.O., et al.: Adhesion promoters in bituminous road materials: a review. Appl. Sci. 7, 524 (2017). https://doi.org/10.3390/app7050524

Sirin, O., et al.: State of the art study on aging of asphalt mixtures and use of antioxidant additives. Adv. Civil Eng. 2018, 3428961 (2018). https://doi.org/10.1155/2018/3428961

Slebi-Acevedo, C.J., et al.: Mechanical performance of fibers in hot mix asphalt: a review. Constr. Build. Mater. 200, 756–769 (2019). https://doi.org/10.1016/j.conbuildmat.2018.12.171

Tabaković, A., Schlangen, E.: Self-healing technology for asphalt pavements. In: Hager, M.D., van der Zwaag, S., Schubert, U.S. (eds.) Self-Healing Materials. APS, vol. 273, pp. 285–306. Springer, Cham (2016). https://doi.org/10.1007/12_2015_335

Yanga, J., Tigheb, S.: A review of advances of nanotechnology in asphalt mixtures. In: 13th COTA International Conference of Transportation Professionals (CICTP 2013). Procedia - Social and Behavioral Sciences, vol. 96, pp. 1269–1276. https://doi.org/10.1016/j.sbspro.2013.08.144

Xu, S., et al.: Facile preparation of pure CaAl-layered double hydroxides and their application as a hardening accelerator in concrete. Chem. Eng. J. 155(3), 881–885 (2009). https://doi.org/10.1016/j.cej.2009.08.003

Xu, S., et al.: Investigation of the ultraviolet aging resistance of organic layered double hydroxides modified bitumen. Constr. Build. Mater. 96, 127–134 (2015). https://doi.org/10.1016/j.conbuildmat.2015.08.019

Xu, S., Yu, J., Zhang, C., Yao, T., Sun, Y.: Effect of salicylic acid intercalated layered double hydroxides on ultraviolet aging properties of bitumen. Mater. Struct. 49(4), 1235–1244 (2015). https://doi.org/10.1617/s11527-015-0573-y

Xu, S., et al.: Performance evaluation of asphalt containing layered double hydroxides with different zinc ratio in the host layer. Pet. Sci. Technol. 35(2), 127–133 (2017). https://doi.org/10.1080/10916466.2016.1248774

Vo, H.V., et al.: Effects of asphalt types and aging on healing performance of asphalt mixtures using induction heating method. J. Traffic Transport. Eng. (English Edition) 7(2), 227–236 (2020). https://doi.org/10.1016/j.jtte.2018.10.009

Wang, Q., O’Hare, D.: Recent advances in the synthesis and application of layered double hydroxide (LDH) nanosheets. Chem. Rev. 112(7), 4124–4155 (2012). https://doi.org/10.1021/cr200434v

Zhao, Z.J., et al.: The aging resistance of asphalt containing a compound of LDHs and antioxidant. Pet. Sci. Technol. 33(7), 787–793 (2015). https://doi.org/10.1080/10916466.2015.1014965

Zhu, K., et al.: Flame-retardant mechanism of layered double hydroxides in asphalt binder. Materials 12, 801 (2019). https://doi.org/10.3390/ma12050801

Acknowledgments

The authors acknowledge the Laboratory of Transport Infrastructures (Department of Civil Engineering, Architecture and Georesources, Instituto Superior Técnico, University of Lisbon) and CERIS – Civil Engineering Research and Innovation for Sustainability – for the support of this study.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Crucho, J., Neves, J., Pedro, A. (2021). Mechanical Behavior of SMA 8 Modified with Nano Hydrotalcite. In: Tapase, A., Lee, J., Zhang, L. (eds) Infrastructure Sustainability Through New Developments in Material, Design, Construction, Maintenance, and Testing of Pavements. GeoChina 2021. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-030-79644-0_1

Download citation

DOI: https://doi.org/10.1007/978-3-030-79644-0_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-79643-3

Online ISBN: 978-3-030-79644-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)