Abstract

Self-healing technology is a new field within material technology. It represents a revolution in materials engineering and is changing the way that materials behave. Incorporating self-healing technology into the road design process has the potential to transform road construction and maintenance processes by increasing the lifespan of roads and eliminating the need for road maintenance. By decreasing the unnecessary premature ageing of asphalt pavements, self-healing asphalt can reduce the amount of natural resources used to maintain road networks, decrease the traffic disruption caused by road maintenance processes, decrease CO2 emissions during the road maintenance process and increase road safety. In addition to environmental savings, self-healing materials have the potential to deliver significant cost savings for road network maintenance across the EU. There are three main self-healing technologies available for asphalt pavement design: nanoparticles, induction heating and rejuvenation. This chapter reviews all three options and outlines the future development of self-healing asphalt technology.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The global road network spans 16.3 million kilometres [1], of which 5 million kilometres is in the EU, 4.4 million kilometres in the USA and 3.1 million kilometres in China [2]. Road networks fulfil a major economic and social goal by facilitating the movement of goods and people. The operational health of the road network is of the utmost importance for national and regional economic and social life. As a result, governments invest heavily in the development and maintenance of national and regional road networks. In 2009, EU governments invested 42% (€4.5 billion) of the EU transport network fund (€10.74 billion) into the development and maintenance of EU road networks [2]. The development and maintenance of the EU road network is crucial for the growth and competitiveness of the EU economy.

A typical modern road system comprises double or triple asphalt layers [3] with an expected lifespan of 20–40 years [4]. Recent research highlights the importance of developing long-life or perpetual pavements and has called for innovation to prolong pavement lifespan and reduce maintenance [5, 6]. The development of self-healing asphalt and its use in road paving is an innovation that could potentially double road lifespan to between 40 and 80 years and could significantly reduce road maintenance activity. In comparison with current maintenance processes, self-healing asphalt has the potential to improve traffic flow, reduce demand for fresh aggregate, reduce CO2 emissions and enhance road safety. The excellent durability of self-healing materials does not arise from the classical approach of minimizing damage but from the novel approach of designing materials with “self-healing” capabilities.

The objective of self-healing technology is to enable/assist material systems to heal after damage. It aims to reduce the level of damage and to extend or renew the functionality and lifetime of the damaged part [7]. Fisher defines the self-healing and self-repair of a material or system as “the ability to substantially return to an initial, proper operating state or condition prior exposure to a dynamic environment by making the necessary adjustments to restore to normality and/or the ability to resist the formation of irregularities and/or defects” [7].

The repair is, in principle, an automatic initiated response to damage or failure. To perform repair, any self-healing system must be capable of identifying and repairing damage. Fisher classifies repair into two categories:

Attributive repair: restoring the attributes of the system to its original state (i.e. to full capacity).

Functional repair: restoring the function of the system. If full functionality cannot be restored, the remaining available resources are employed/used to maximize the available functionality [7].

Attributive repair is the optimal solution. If the attempt to restore the system to its complete original condition fails, there is still significant benefit to be gained, in most instances, if the system continues to operate, even with reduced functionality. Living organisms possess intrinsic self-healing properties, enabling them to recover from damage or injuries. This repair or healing occurs with no external intervention. Some natural self-healing composite systems, such as bones, go beyond simple healing to continuous remodelling and strengthening [8]. Over the past decade, self-healing technology has entered the field of materials engineering [7]. Self-healing technology represents a revolution in materials engineering. Examples of engineering materials to which self-healing technology has been successfully applied are presented in Table 1.

1.1 Self-Healing Properties of Asphalt Pavement

Asphalt pavement is a self-healing material. When subjected to rest periods, asphalt pavement has the potential to restore its stiffness and strength by closing the micro-cracks that occur when the pavement is subjected to traffic loads. Research to date has focused on its autogenous healing properties (see Table 2).

Crack repair in an asphalt pavement system occurs as a result of the wetting and interdiffusion of material between the two faces of a micro-crack, to regain the properties of the original material [7, 33]. The three primary steps in the autonomous asphalt self-healing process are as follows:

-

1.

Wetting of the two faces of a micro-crack

-

2.

Diffusion of molecules from one face to the other

-

3.

Randomization of the diffused molecules to reach the level of strength of the original material

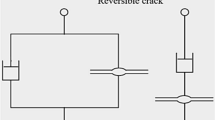

Binder is key to the self-healing process in an asphalt pavement. Self-healing takes place on a molecular level, when broken (non-associated) molecules are available to form links and chains via hydrogen bonds [7]. The process is termed “reversible hydrogen bonding” [34] and is achieved by bringing together the associated molecules to form both chains and crosslinks via hydrogen bonds [7]. A repaired molecular network can be formed by linking ditopic and tritopic molecules [35], which are able to associate with each other (see Fig. 1). This system, when broken or cut, can be simply repaired by bringing two fractured surfaces into contact [34–36].

Supramolecular network: Scheme of a reversible network formed by mixtures of ditopic (blue) and tritopic (red) molecules associating by directional interactions (represented by dotted lines) [35]

Qiu et al. [36] reported that self-healing in an asphalt pavement system is a viscosity-driven process, dependent on time (rest periods) and temperature. Qiu et al. [36] also demonstrated the self-healing time and temperature dependency of bituminous materials (see Fig. 2). A longer healing time and increased healing temperature lead to better healing [36]. Shorter time to heal results in the formation of fewer bridges across the interface and the development of a weaker bond across the break. However, if broken bonds are not healed immediately (i.e. if the fractured surfaces are not brought into contact with each other), the number of non-associated groups available for linking decreases (i.e. healing efficiency decreases) [35]. This is because, immediately after breakage, the free (non-associated) groups begin to seek other free groups within the broken part to link with [35].

Self-healing results of PBmas (asphalt mastic mix containing limestone filler and 70/100 pen bitumen) and SBSmas (asphalt mastic mix containing limestone filler and bitumen modified with styrene-butadiene-styrene polymer) [36]

Qiu et al. [36] successfully modelled the time–temperature dependence of the self- healing process in asphalt mastic using a time–temperature superposition principle, which can be expressed by the following formulation:

where the time–temperature superposition shift factor in Eq. (1) is based on the Arrhenius equation and is calculated using the following formulation:

where α T is the time–temperature superposition shift factor; m, n are the model parameters; ΔE a is the apparent activation energy, (J/mol) and R is the universal gas constant, 8.314 J/(mol K).

The healing of an asphalt pavement at high temperatures is governed by the so-called thixotropic effect, which describes the transformation of asphalt binder from a solid to gel state, allowing recovery from structural damage [30]. Wu reported that visible in-situ cracks within asphalt pavements disappear during periods of warm weather, only to reappear during cold weather [37]. At high temperatures, surface cracks close, but high temperatures dissipate quickly throughout the pavement depth [38], meaning that cracks 20–30 mm below the pavement surface do not heal and re-appear at lower temperatures or as a result of heavy traffic loading. Results presented in Fig. 2 show that the healing progress of two different asphalt mixtures (PBmas and SBSmas) is only 10% after healing at 10°C. The results from Qiu et al. [36] show that temperatures below 20°C are insufficient to initiate full recovery of asphalt pavements. However, the self-healing properties of asphalt can be enhanced either by heating the asphalt material or by adding modifiers or a healing agent (i.e. rejuvenator), as shown in Fig. 2.

2 Examples of Self-Healing Technology for Asphalt Pavements

The asphalt pavement design standards focus on enhancing asphalt pavement performance, that is, they aim to increase its durability and improve its load-carrying capability [39]. However, the authors consider that future of asphalt pavement design lies not with the enhancement of asphalt pavement properties, but in allowing it to repair itself to its original state.

As in nature, the self-healing performance of an asphalt pavement can be improved, for example, by introducing modifiers and additives to the asphalt mix to upgrade its self-healing properties. To function in an asphalt pavement system, the self-healing technology must have the capacity to survive the harsh conditions that prevail during asphalt pavement construction (mixing and compaction) and service life (traffic loading and environmental conditions such as rain, ice, snow, high temperatures, etc.). Qiu et al. [34] outlined five essential conditions for self-healing agents to be included into asphalt pavement design:

-

1.

Good compatibility with bitumen

-

2.

High temperature stability

-

3.

Ability to survive mixing and construction conditions

-

4.

Healing temperature between −30°C and 40°C

-

5.

Capable of continuous/multi-time healing

In this section, a number of existing self-healing approaches for asphalt pavement design are presented and critically analysed with respect to their functional design and performance.

Three self-healing methods for asphalt pavements have been reported to date, they are:

-

1.

Incorporation of nanoparticles

-

2.

Induction heating

-

3.

Rejuvenation

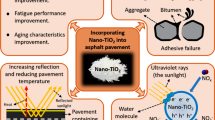

2.1 Nanoparticles

2.1.1 Nanoclay

Nanoclay materials are used in asphalt pavement design to improve the ageing, rheological and thermal properties of asphalt mixtures [40]. However, they also have the potential to repair micro-cracks in asphalt [34]. The nanoparticles tend to move towards the tip of the crack, driven by the high surface energy, and thus stop crack propagation and heal damaged asphalt material [34]. Tabatabee and Shafiee [15] studied the effect of rest periods on the fatigue life of organoclay-modified asphalt mixes and found that introduced rest periods at 3% and 5% strain level increased the fatigue resistance of these mixes. This finding demonstrates that nanoclay material can be used for improving the self-healing properties of asphalt mixtures. However, the nanoclay self-healing technique has not been researched in great detail to date and there is insufficient data available on the long-term effect of nanoclay particles on the performance of self-healing asphalt mixtures. This is an interesting area for future research.

2.1.2 Nanorubber

As with nanoclay materials, polymer and rubber modifiers are used in the bitumen mix to improve the physical and mechanical properties of the binders and, as such, to improve in-situ performance of an asphalt pavement [41–43]. Rubber modifiers in the form of nanoparticles have also been used to improve the healing properties of asphalt mastic [34]. Qiu et al. [34] studied the repair of asphalt mastic with nanorubber-modified binder (70/100 pen binder).Footnote 1 They conducted ductility self-healing tests to assess the self-healing capacity of asphalt mastics containing two different types of nanorubber modifier (NanoA and NanoB) and varying percentages of modifier (0–5%), where 0% was a control mix. The tests were performed on dog bone test specimens. The test specimens were cut at the centre, joined and left to heal for 4 h at room temperature (20–22°C). The test results showed good self-healing for non-modified asphalt mastic mixes, up to 70%. Recovery of the modified asphalt mixtures varied from 15% to 90%, depending on the type of nanorubber modifier and the amount added [34]. Unfortunately, the authors did not present the composition of the nanorubber modifier, so it is difficult to determine what type of healing mechanism activated the healing process and to understand the variability in the healing performance. Nevertheless, the study showed that nanorubber modifiers can be used to improve the self-healing properties of asphalt mixtures. Future studies should indicate the properties of the nanorubber modifiers used, that is, whether they are styrene-butadiene-rubber (SBR), styrene-isoprene-styrene (SIS) or olefinic rubber. This would enable determination of the type of healing mechanism that had occurred (i.e. whether it was reverse hydrogen bonding). The clear advantage of nanorubber as a modifier is its double role; it can improve asphalt mix durability and also act as self-healing modifier in the mix. However, the disadvantage of polymer-based modifiers is their thermodynamic incompatibility with asphalt binder as a result of the large differences in material density, polarity, molecular weight and solubility between the polymer and the asphalt [40]. This can result in delamination of the composite during thermal storage, which is not readily apparent and adversely affects the asphalt mix when it is used [40]. The thermodynamic incompatibility of nanomodifiers needs to be studied, because at high temperatures the separation of nanorubber modifier and binder could take place, resulting in deterioration of asphalt pavement performance.

The nano-effect and reverse hydrogen and ionic bonding are known for their multi-healing abilities [34], which is a benefit of this type of self-healing mechanism. However, the effect of healing time and temperature need to be further investigated to determine what effect time has on the healing of the asphalt mix. If ineffective at lower temperatures and without improvements in healing times relative to autonomous bitumen healing, the technology would be unsuitable for the self-healing of asphalt pavements.

Although nanoparticle self-healing technology has demonstrated its potential in asphalt pavement mix design, more substantial evidence of its performance must be demonstrated before it becomes acceptable as a viable self-healing technology.

2.2 Induction Heating

Induction heating in asphalt pavement design was pioneered by Minsk [44, 45]. He developed and patented the first electrically conductive asphalt pavement using graphite as a conductive medium for the purpose of melting snow and ice on roadway surfaces by induction heating. More recently, induction heating has regained popularity in asphalt pavement research for to improving self-healing in asphalt pavements [46–49]. Electrically conductive fibres and fillers (carbon fibres, graphite, steel fibres, steel wool and the conductive polymer polyaniline) were added to study the electrical conductivity in asphalt pavement. Results showed that the electrical resistivity significantly varied with the type, shape and size of fibres and fillers. Wu et al. [46] studied induction heating in asphalt pavement using conductive carbon fibres, carbon black and graphite as conductive media and demonstrated that adding conductive fibres to the mixture increases conductivity more effectively than adding conductive filler. Subsequent research by Garzia et al. [47] and Liu et al. [48] initiated the development of a self-healing asphalt pavement mix by inclusion of electrically conductive steel and wool fibres into the asphalt mix and activation of self-healing by induction heating.

The induction process operates by sending an alternating current through the coil and generating an alternating electromagnetic field. When the conductive asphalt specimen is placed under the coil, the electromagnetic field induces currents flowing along the conductive loops formed by the steel fibres [50]. This method can be repeated if damage returns. A schematic diagram of induction healing is illustrated in Fig. 3.

Induction healing in porous asphalt [51]

The major healing mechanism in induction healing is the capillary flow and diffusion of the asphalt binder (bitumen) at high temperatures. García [50] verified this healing mechanism using bitumen capillary flow tests. Liu [51] studied the induction healing effect of steel fibres and steel wool and characterized asphalt healing via the following equation:

where HI is the healing index (%), 100% indicating complete healing of damage and 0% indicating no healing at all; C 1 is the number of loading cycles for the first loading; and C 2 is the number of loading cycles for the second loading.

Figure 4 gives the results of a fatigue test performed by Liu [51], showing values of C 1 and C 2 for two loading cycles. The loading value C 2 illustrates the effect of induction healing.

Fatigue recovery of porous asphalt concrete cylinder for resilient modulus reduction to 80% [51]. C 1 and C 2 are loading cycles

Liu et al. [48] investigated the effect of long steel wool type 000 versus short steel fibre. The results showed that long steel wool is better than short steel fibre for making porous asphalt concrete electrically conductive.

Liu et al. [48] demonstrated that the addition of steel fibres reinforces the mastic (bitumen, filler and sand) of porous asphalt concrete, which can delay the ravelling effect in asphalt pavement. Liu et al. also demonstrated that the inclusion of steel fibres into the asphalt pavement mix prevents the drainage of bitumen from the surface of the asphalt pavement. The advantage of this is that it achieves a better bond between the large aggregates (stones) in the pavement.

Although induction healing can enhance the self-healing capacity of asphalt pavement, an adverse effect is that heating the asphalt mix ages the bitumen. Furthermore, overheating (>110°C) the asphalt mix can cause binder swelling and drainage, which adversely affects pavement performance. Liu et al. [48] suggested that the optimal heating temperature for a porous asphalt mix is 85°C. Liu [51] demonstrated that the degree of damage incurred by overheating also affects the healing ratio, (i.e. the heating should not be applied too early or too late). If applied too early (when resilient modulus is >80% of the original asphalt pavement stiffness value), the asphalt pavement can heal itself and heating is not required. However, if the asphalt is heated too late (when resilient modulus value is <80% of the original asphalt pavement stiffness value), the healing effect is poor, because structural damage such as permanent deformation or stone aggregate cracking can occur and is beyond the healing capacity of the induction healing process. Liu [51] further concluded that the best healing results were achieved when induction heating was combined with a rest period. This study demonstrated that healing can be improved by 15% if the autogenous healing process is aided by induction heating.

In December 2010, researchers from TU Delft in cooperation with the Dutch National Roads Authority resurfaced a road (the A58 in Netherlands) using an induction self-healing asphalt mix (i.e. an asphalt mix containing 1 cm long steel fibres) [52]. Testing of the self-healing process within the A58 motorway is ongoing at present [52].

Inductive heating is the most progressive self-healing technology for asphalt pavements reported to date. This technology has transitioned from laboratory to site in a short period of time (3 years). Although its ageing effect can be compensated for by the healing effect, a problem that has not been addressed by research is the loss of conductivity via oxidation (corrosion) of the steel wool and fibres. However, this should not be an insurmountable problem, as steel could be replaced by carbon fibres and/or conductive polymer [49, 53]. In addition, the piezoresistivity of conductive asphalt, which refers to the change in electrical resistivity with applied mechanical pressure, can be used for self-sensing of strain [54]. Self-sensing of damage for evaluating pavement distress is possible if there is a relationship between the electrical property and internal damage. Moreover, some conductive additives can improve the durability of asphalt concrete, thereby increasing the service life of the pavement system [48, 55, 56]. This aspect of self-healing induction technology needs to be further developed for the initiation of healing processes and also for self-health assessment of asphalt pavement.

2.3 Binder Healing Agent (Rejuvenation)

During the service life of a pavement, the volatile components of bitumen evaporate, and oxidation and polymerization can occur [57]. As a result, the bitumen ages and loses some of its viscoelastic properties. Asphalt binder is a combination of asphaltenes and maltenes (resins and oils). Asphaltenes are more viscous than either resins or oils and play a major role in determining asphalt viscosity [58, 59]. The oxidation of aged asphalt binder during construction and service causes the binder oils to convert to resins and the resins to convert to asphaltenes, resulting in age-hardening and a higher viscosity than for fresh binder [59, 60]. Although this process is irreversible, the viscoelastic state of the asphalt mix can be recovered through the addition of either bitumen with a high penetration value or a rejuvenating agent such as a cationic emulsion [61–63].

A rejuvenator is an engineered cationic emulsion containing maltenes and saturates. The primary purpose of a rejuvenator is to reduce the stiffness of the oxidized asphalt binder and to flux the binder to extend the pavement life by adjusting the properties of the asphalt mix [62]. Some commercially available rejuvenating agents are Reclamite, Paxole 1009, Cyclepave and ACF Iterlene 1000. A recent study by Su et al. [64] demonstrated that a by-product of waste cooking oil (WCO) can also be used as binder rejuvenator.

2.3.1 Self-Assembled Monolayers

When cracks within the surface layer of an asphalt pavement are still in an early phase, it is possible to apply a rejuvenator to the wearing course to prevent further crack propagation and pavement failure [65]. By applying the rejuvenator to the surface course, the lifespan of the asphalt pavement can be extended by several years; however, this only applies to the top few centimetres of the asphalt pavement. Shen et al. [66] reported the use of three different types of rejuvenators and found that none could penetrate further than 20 mm into asphalt concrete. A further issue encountered when applying these materials is the need for road closures for a period of time after the application. The rejuvenators can also cause significant reduction in the surface friction of the pavement and could also be harmful to the environment. Microencapsulation of the rejuvenators represents a potential means of overcoming these problems.

2.3.2 Microcapsulation Technique

The inclusion of a rejuvenator into the asphalt mix via microcapsules to restore the original binder properties is a self-healing method that has been studied by Su et al. [64, 67], Su and Schlangen [68] and García et al. [69]. The principle behind this approach is that when micro-cracks begin to form within the pavement system, they encounter a capsule in the propagation path. The fracture energy at the tip of the crack opens the capsule and releases the healing agent. The healing agent then mixes with the asphalt binder to seal the crack, thus preventing further propagation. This healing process is illustrated in Fig. 5. The process prevents the formation of micro-cracks within the pavement mix and prevents complete failure of the pavement system. Su and Schlangen [68] and García et al. [69] demonstrated that various types of capsules containing rejuvenator can be produced and that these capsules are sufficiently thermally and mechanically stable to survive the asphalt production process.

To date, the most successful microcapsule shells have been made of a prepolymer of melamine–formaldehyde modified by methanol (solid content 78.0%) and the rejuvenator was an oily product [17]. Figure 6 illustrates the fabrication process of double-shell microcapsules containing rejuvenator by two-step coacervation (TSC). The efficiency of microcapsule fabrication is measured by amount of rejuvenator retained within the microcapsule [68]. The highest efficiency achieved was 70% [67] using the following production conditions: core/shell ratio of 1:3, stirring speed 3,000 revolutions/min and 2.0–2.5% by weight styrene maleic anhydride (SMA) copolymer dispersant. Figure 7 shows the SEM morphology of dried microcapsules with a core/shell ratio of 1:3 and an average shell diameter of 25 μm.

Fabrication process for double-shell microcapsules containing rejuvenator by a two-step coacervation (TSC) method: (a) chemical structure of SMA alternating copolymer and hydrolysis polymer, (b–e) the first step coacervation, (f–h) the second step coacervation, and (i) microstructure of microcapsules produced by TSC method [68]

SEM morphologies of microcapsules containing rejuvenator [67]

The asphalt mortar films between aggregate particles in an asphalt pavement are found to be ≈ 50 μm thick [67]. To avoid being squeezed or pulverized during the asphalt pavement mixing and compaction processes, the size of the capsule needs to be less than 50 μm. However, Su et al. [67] stated that microcapsules of 10 μm and smaller are unsuitable for self-healing as they do not contain sufficient rejuvenator to rejuvenate the aged binder. The size of the capsule can be controlled by regulating the core/shell ratio (weight ratio between core and shell material). This can be achieved by modifying the prepolymer and the emulsion stirring rate [67]. Figure 8 shows the morphology of bitumen containing varying capsule content (10–30% of total binder volume) and capsules of varying size (10–30 μm). Figure 8a1, a2, shows that microcapsules with a mean size below 10 μm tend to congregate/attract as a result of the electrostatic attraction of tiny particles. In Figure 8b1, b2, microcapsules of 20 μm size have a homogeneously distributed, preventing from hard agglomeration of the capsules in the bitumen. Figure 8c1, c2 shows dispersion of larger microcapsules (30 μm size) with content of 10% and 30% in bitumen. Figure 8c2 shows that large micro capsules will occupy more space, where the capsule content in the bitumen is 30%. This phenomenon may lead to the interface separation between microcapsules and binder and may result in the formation of microcracks or other structural defects [67, 70]. This could result in poor mechanical performance of the asphalt pavement and premature pavement failure. In conclusion, the optimum content of microcapsules in bitumen must be no more than 30% of overall bitumen volume within an asphalt mix [67].

Fluorescence microscope images of morphology of bitumen samples with 10% (a 1 , b 1 , c 1 ) or 30% (a 2 , b 2 , c 2 ) microcapsule content and diameters of < 10 μm (a 1 , a 2 ), 20 μm (b 1 , b 2 ) or 30 μm (c 1 , c 2 ) [67]

More recently Su et al. [64] demonstrated that rejuvenators produced from recycled waste cooking oil (WCO) can be encapsulated and used in the asphalt self-healing technology. Capsules with high capsule shell strength of 1.0–1.52 GPa, core/shell ratio of 1:3 and good thermal stability (melting point 180°C) can survive the harsh asphalt production process. This research demonstrated that microencapsulated WCO rejuvenator can successfully penetrate and rejuvenate aged standard bitumen binder of 80/100 pen, and defuse it at low temperature (0°C) (see Table 3).

The microcapsule approach is favourable for asphalt self-healing in that it allows the rejuvenation of aged binder (i.e. returns it to its original physical and mechanical properties). However, the downside to this approach is that it works only once (i.e. once the healing material is released from the microcapsule it cannot be replenished) [34]. Nevertheless, this self-healing process is still in its early development stage and its full potential will be demonstrated in coming years. Methods for introducing a reasonable dose of microcapsules into the asphalt mix to achieve appropriate dispersion of capsules throughout the asphalt mix and enhancement of the multiphase self healing process need to be the focus of future research work in this field.

3 Towards New Generations of Self-Healing Asphalt Pavements

The key aim of research on self-healing asphalt pavements is to develop asphalt pavement material that is capable of healing itself without external intervention. Therefore, the ultimate goal for road designers is to develop an asphalt pavement material that can mimic nature itself. To achieve this, the self-healing processes embedded within the asphalt pavement system should be capable of self-assessment. This would enable the material to assess its structural and material health and to trigger a response to initiate self-healing where necessary [7].

To develop this new generation of self-healing asphalt pavements, based on findings of currently available self-healing technologies (presented in Sect. 2), three specific working areas are identified that need particular effort:

-

1.

Development/design of damage sensing and repair triggering elements. These elements are incorporated within pavement systems to give the capacity to trigger the self-healing process (i.e. signalling activation of the healing mechanism). This means that the sensory function should be enhanced and extended with an active learning functionality that is able to differentiate and detect damage, interpret the obtained information and trigger/stimulate the healing action on demand. These sensor elements should ideally be a structural component of the pavement system and not deteriorate the general functionality of the pavement system. Development of a sensory mechanism within the pavement system will allow healing-on-demand. Such an action could be triggered by a fall in current/resistivity in the pavement system or by a concentration of stress, which would initiate the repair action while activating an initiator (healing agent or heating).

-

2.

Development of multiple self-healing processes. To date, only a limited number of self-healing mechanisms for asphalt pavements have been developed, such as induction heating [16, 48] and rejuvenator encapsulation [17, 64, 68]. To explore the additional potential of self-healing asphalt technology, new self-healing mechanisms must be developed to respond to a broader range of performance demands, such as healing/rest time. All three self-healing mechanisms presented in Sect. 2 require at least 4 h of rest time in order for the asphalt pavement to achieve full recovery. On roads with high traffic flow, this is difficult to achieve. Perhaps technology can improve the repair times for self-healing asphalt pavements. Another, essential, part of the self-healing mechanism in asphalt pavements is multiphase self-healing. If a self-healing mechanism is “once off”, it is vulnerable to cracking after the first repair. This ultimately leads to asphalt pavement failure. This requirement of a self-healing mechanism is directly linked to the sensory/triggering mechanism. If a healing-on-demand technology can be achieved within asphalt pavements, the repair action can be re-activated and thus make self-healing asphalt more efficient.

-

3.

Development of self-healing assessment mechanisms. Such mechanisms are necessary to achieve self-assessment of the asphalt pavement system and to quantify the success of the self-healing process. To date there has been only limited understanding of how to quantify the success of self-healing, mostly done by measurement of mechanical performance, such as material strength [63]. This requires in-situ pavement evaluation, or a laboratory material evaluation of test samples obtained from site. Such evaluation requires traffic control and potential traffic delays, which increases the cost and reduces the benefit of self-healing asphalt pavements. A mechanism for the autonomous self-assessment of asphalt pavement system health and assessment of the self-healing process should be a focus for future research in this field.

If these developments in the self-healing process are accomplished, then it will be possible to create a truly smart asphalt pavement system that senses its internal state and external environment and responds in an appropriate manner to this information. The primary advantage of moving towards smart/self-healing technology is the potential cost benefit of condition-based maintenance strategies and the prospective long lifespan that can be achieved for asphalt pavement materials through in-situ health management.

The potential benefits of self-healing asphalt technology in material performance and environmental and social benefits will undoubtedly stimulate interest in the wider use of self-healing technology in asphalt pavement design and construction. However, for self-healing technology to become accepted as the industry standard, its superiority in the construction and maintenance of asphalt pavements must be demonstrated from functional, economic and environmental perspectives.

4 Cost and Environmental Benefits of Self-Healing Technology for Asphalt Pavement Design

To accurately assess the cost reductions that can accrue from self-healing materials, it would be best to compare the change (increase) in material costs with the change (decrease) in maintenance costs. Depending on the application, other costs such as operating costs, disposal costs and environmental costs could be factored in the cost–benefit analysis. It is expected that periods between road maintenance will extend when self-healing asphalt is employed, resulting in a decrease in traffic congestion and associated costs. For example, in the Netherlands the combined annual savings related to major repairs and traffic jam costs are approximately €65 million for an asphalt lifespan extension of 25%, and over €100 million for a lifespan extension of 50% for the entire porous asphalt pavement area in the Netherlands [71]. Even if the price of self-healing asphalt was double that of standard bitumen, the Netherlands would save approximately €90 million annually by investing in self-healing asphalt with a 50% extended lifespan, compared with traditional porous asphalt. The Netherlands is a fairly small country by European standards and represents only 3% of total European asphalt production, and only one third of this asphalt (1%) is used in surface layers [52]. If we extend the potential savings in the Netherlands to the EU as a whole, the potential savings could total €9 billion [52].

These figures outline the clear financial benefits to be accrued from self-healing technology in asphalt pavement design. However, the full potential benefits of self-healing technology in asphalt pavement design can only be understood when the full life cycle costs of asphalt pavements are known (financial, environmental and societal). Butt et al. [72] studied the effect of self-healing on the lifetime, energy and environment of asphalt pavements. Using a life cycle analysis (LCA) framework, performed in conjunction with a numerical model that simulates the self-healing capacity of asphalt pavements [73], they determined that self-healing asphalt pavements increased the lifetime of the pavement by 10% (from 20 years to 22 years) compared with asphalt pavements without any self-healing capacity. This increase in lifetime would result in a reduction in energy consumption of 3% (22 GJ) and CO2 emissions of 3% (1.5 Tonne). If the increased lifetime of an asphalt pavement is projected to 100% (from 20 years to 40 years, based on the assumption that self-healing technology can double asphalt pavement lifespan), the benefits in terms of reduced cost and reductions in energy consumption and CO2 emission would increase accordingly.

A greater insight into the potential of self-healing technology for the asphalt pavement industry can be achieved with full scale in-situ implementation of self-healing technology in asphalt pavement design, as in the A58 road in the Netherlands [52]. However, the clear benefits of self-healing asphalt materials, in the form of an extended lifespan of the asphalt pavement and reduced maintenance costs, only become apparent over time. Steyn explains [65]: “The important point to take from reality is that for any innovation to provide real benefit in the pavement engineering field, there has to be a real positive benefit/cost ratio.”

It is unlikely that decisions regarding implementation of self-healing technology in asphalt pavement design will be taken at a local level because of the high initial costs and long timeframe for savings. It requires regional (European) leadership, informed by a sound evidence base (i.e. research), to convince all that these technological advances are worth considering at a national and European level. Initial research results are positive, as shown in Sect. 2, and there is optimism that this technology has strong potential in the design of asphalt pavements.

5 Concluding Remarks

Roads . . . [are] the most ancient of human monuments, surpassing by many tens of centuries the oldest thing of stone that man has reared to mark his passing. The tread of time. . . has beaten only to a more enduring hardness the pathways that have been made throughout the world [74].

Throughout the centuries, a civilisation’s prosperity and economic development was measured and ensured by the quality of its road network, which was used for economic, social and military purposes. In its latest report Road Infrastructure – the backbone of transport system [75], the European Commission states: “Transport infrastructure influences both economic growth and social cohesion. A region cannot be competitive without an efficient transport network.”

Today, roads designs are sophisticated engineering creations. Despite this, the materials used in asphalt mixes have remained largely unchanged for the past 100 years. The main ingredient of a modern road is the bitumen. It is a co-product of crude oil, whose production is in decline [76], meaning that the financial and environmental costs of bitumen are on the rise [76, 77], which will result in an increase in the cost of road/asphalt pavements. Unless investment levels keep apace of increased costs, road networks of poorer standard could result.

Incorporating self-healing technology into asphalt pavement design presents a solution for some of the difficulties facing asphalt. Currently available self-healing road technologies are paving the way for the evolution of road design. Existing technologies have demonstrated their potential in repairing distressed asphalt pavements. They offer great opportunities for increased durability and reliability, reduced maintenance and lower overall cost of asphalt pavements. This includes a reduction in the material resources needed, because the usual over-design of materials is no longer required. The repair of an asphalt pavement is addressed in situ by its internal self-healing system at the very position of first appearance of damage, eliminating the need for classical in-situ maintenance processes.

However, the key objective of self-healing technology for asphalt pavement design is the development of a truly smart asphalt pavement system, capable of self-assessment and automatic response. Despite the progress made in the development of self-healing asphalt technology, further work is required to achieve truly smart asphalt pavements. Future work needs to focus on:

-

1.

Damage sensing and repair triggering elements

-

2.

Development of multiple self-healing processes

-

3.

Development of self-healing assessment mechanisms

The development of such areas of self-healing technology for asphalt pavements will truly revolutionize asphalt pavement design. This will also lead to another evolutionary step in road construction and design and bring the idea of self-healing roads from science fiction to reality.

Notes

- 1.

“pen” stands for penetration. Bitumen penetration test (EN 1426:2015) indicates the hardness of bitumen, lower penetration indicating a harder bitumen. Specifications for penetration graded bitumen normally state the penetration range for a grade, e.g. 70/100.

References

OECD (2013) Road traffic, vehicles and networks. In: Environment at a glance 2013: OECD indicators. OECD, Paris

European Union Road Federation (2012) European road statistics 2012. European Union Road Federation (ERF), Brussels

Sherwood PT (2001) Alternative materials in road construction, 2nd edn. Thomas Telford, London

Merill D (2005) Guidance on the development, assessment and maintenance of long-life flexible pavements. Transport Research Laboratory, Wokingham

FEHRL (2008) NR2C new road construction concepts; towards reliable, green, safe & smart and human infrastructure in Europe. Forum of European National Highway Research Laboratories (FEHRL), Brussels

World Road Association – PIARC (2014) Technical committees for road infrastructure. www.pirac.org

Fisher H (2010) Self repairing materials – dream or reality. Nat Sci 2(8):873–901

March DR, Li G (1999) The biology of fracture healing. Br Med Bull 55(4):856–869

Jin H et al (2012) Self-healing thermoset using encapsulated epoxy-amine healing chemistry. Polymer 53(2):581–587

Jonkers HM, Schlangen E (2009) A two components bacteria-based self-healing concrete. In: Alexander MG, Beushausen H-D, Dehn F, Moyo P (eds) Concrete repair, rehabilitation and retrofitting II. Tailor & Francis, London, pp 119–120

Dry C (1996) Procedure developed for self-repair of polymer matrix composite materials. Compos Struct 35(3):263–239

Wu M, Johnnesson B, Geiker M (2012) A review: self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr Build Mater 28:571–583

Boh B, Šumiga B (2008) Microencapsulation technology and its applications in building construction materials. Mater Geoenviron 55:329–344

Kishi T et al. (2007) Self-healing behaviour by cementitious recrystallization of cracked concrete incorporating expansive agent. In: 1st International conference on self-healing materials, Noordwijk aan zee, The Netherlands

Tabatabaee N, Shafiee MH (2012) Effect of organoclay modified binders on fatigue performance. In: 7th RILEM international conference on cracking in pavements. RILEM Bookseries, Delft, The Netherlands

García A, Schlangen E, van de Ven M (2011) Induction heating of mastic containing conductive fibers and fillers. Mater Struct 44(2):499–508

Su JF, Qiu J, Schlangen E (2013) Stability investigation of self-healing microcapsules containing rejuvenator for bitumen. Polym Degrad Stab 98(6):1205–1212

Wilson GO, Magnus H (2011) Self-healing systems for industrial and marine protective coatings. J Protect Coat Lin 28(8):18–21

Kirkby EL et al (2008) Embedded shape-memory alloy wires for improvements of self-healing. Adv Funct Mater 18:2253–2260

Lumley R (2007) Self healing in aluminium alloys. In: 1st international conference on self healing materials, Delft, The Netherlands

van Gooswiligen G, de Hilster E, Robertus C (1994) Changing needs and requirements for bitumen and asphalts. In: 6th Conference on asphalt pavement for South Africa, Cape Town, South Africa

Kim YR, Little DN (1991) SEM analysis on fracture and healing of sand-asphalt mixtures. ASCE J Mater Civil Eng 3(2):140–153

Lytton RL et al. (1993) Development and validation of performance prediction models and specifications for asphalt binders and paving mixes. Strategic Highway Research Program (SHRP), National Research Council, Washington

Ofori-Abebresse EK (2006) Fatigue resistance of hot-mix asphalt concrete mixtures using the calibrated mechanistic with surface energy measurements approach. Master’s thesis. Texas A&M University, Texas. http://oaktrust.library.tamu.edu/handle/1969.1/4136

Bhasin A et al (2011) Use of molecular dynamics to investigate self-healing mechanisms in asphalt binders. ASCE J Mater Civil Eng 23(4):485–492

Lee HJD, Daniel JS, Kim YR (2000) Laboratory performance evaluation of modified asphalt mixtures for Inchon airport pavements. Int J Pavement Eng 1(2):151–169

Kim B, Roque R (2006) Evaluation of healing property of asphalt mixture. In: 85th Annual meeting of the Transport Research Board, Washington, DC

Abo-Qudais S, Suleiman A (2005) Monitoring fatigue famage and crack healing by ultrasound wave velocity. Nondestruct Test Eva 20(2):125–145

Theyse HL, de Beer M, Rust FC (1996) Overview of the South African mechanistic pavement design analysis method. In: 75th Annual Transport Research Board meeting, Washington, DC

Verstraeten J (1991) Fatigue of bituminous mixes and bitumen thixotropy. In: 19th World road congress, AIPCR, Marrakech, Morocco

Castro M, Sanchez J (2006) Fatigue and healing of asphalt mixtures: discriminate analysis of fatigue curves. ASCE J Trans Eng 132(2):168–174

Hefer A, Little DN (2005) Adhesion in bitumen-aggregate systems and quantification of the effects of water on the adhesive bond. Ph.D. thesis, Texas A&M University, Texas

Kim YRL, Little DN, Lytton RL (2003) Fatigue and healing characterization of asphalt mixes. ASCE J Mater Civil Eng 15(1):75–83

Qiu J et al (2009) Investigation of self healing capability of bituminous binders. Road Mater Pavement Design 10(1):81–94, Special Issue on Asphalt Materials (ICAM 2009—China)

Cordier P et al (2008) Self-healing and thermoreversible rubber from supramolecular assembly. Nature 451:977–980

Qiu J et al (2012) Evaluating self healing capability of bituminous mastics. Exp Mech 52:1163–1171

Wu C (1998) Highway, heal thyself; cracking the code of self-healing asphalt could extend the life of roads. Sci News 153:60–63

Mallic RB et al (2012) Heating and its effect on hot in-place recycling of asphalt pavements with rejuvinator. Int J Pavement Res Technol 5(6):347–359

Newcomb DE, Buncher M, Huddleston IJ (2001) Concepts of perpetual pavements. Transport Research Circular, Transport Research Board, Washington, DC

Fang C et al (2013) Nanomaterials applied in asphalt modification: a review. J Mater Sci Technol 29(7):589–594

Manh HT, Viet AP (2013) Influence of fiber polymer reinforced asphalt concrete pavement in high temperature environment. In: Proceedings of the 2nd electronic international interdisciplinary conference (EIIC), Žilina, Slovak Republic. EICC, Žilina pp 465–468. http://www.eiic.cz/archive/?vid=1&aid=2&kid=20201-40

McNally T (2011) Polymer modified bitumen, PmB. In: Polymer modified bitumen properties and characteristics. Woodhead, Philadelphia

Abtahi SM, Sheikhzadeh M, Hejazi SM (2010) Fiber-reinforced asphalt-concrete – a review. Constr Build Mater 24:871–877

Minsk LD (1968) Electrically conductive asphalt for control of snow and ice accumulation. Trans Res Board 227:57–63

Minsk LD (1971) Electrically conductive asphaltic concrete. US patent 3,573,427

Wu S et al (2006) Self-monitoring electrically conductive asphalt-based composite containing carbon fillers. Trans Nonferrous Met Soc China 16:512–516

García A et al (2009) Electrical conductivity of asphalt mortar containing conductive fibers and fillers. Constr Build Mater 21(10):3175–3181

Liu Q et al (2010) Induction heating of electrically conductive porous asphalt concrete. Constr Build Mater 24:1207–1213

Zhang H, Wu XH, Wang XL (2011) Conductivity mechanism of asphalt concrete with the PANI/PP compound conductive fiber. Mater Sci Forum 689:69–73

García A (2012) Self-healing of open cracks in asphalt mastic. Fuel 93:264–272

Liu Q (2012) Induction healing of porous asphalt concrete. Ph.D. thesis, Faculty of Civil Engineering and Geosciences, TU Delft, The Netherlands

Schlangen E (2013) Other materials, applications and future developments. In: Rooij ME et al (eds) Self-healing phenomena in cement-based materials, RILEM series: state-of-the-art reports. Springer, Dordecht, pp 241–256

Wu S et al (2005) Investigation of the conductivity of asphalt concrete containing conductive fillers. Carbon 43(7):1358–1363

Liu XM, Wu SP (2009) Research on the conductive asphalt concrete’s piezoresistivity effect and its mechanism. Constr Build Mater 23(8):2752–2756

Wu S, Zhang Y, Chen M (2010) Research on mechanical characteristics of conductive asphalt concrete by indirect tensile test. In: Proceedings of the 4th international conference on experimental mechanics. Proc. SPIE 7522: 752265. doi:10.1117/12.851473

Liu X, Wu S (2011) Study on the graphite and carbon fiber modified asphalt concrete. Constr Build Mater 25(4):1807–1811

Gerardu JJA, Hendriks CF (1985) Recycling of road pavement materials in the Netherlands. Road Engineering Division of Rijkswaterstaat, Delft

Airey GD (2003) Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel 82(14):1709–1719

Wu S et al (2007) Investigation of temperature characteristics of recycled hot mix asphalt mixtures. Resour Conserv Recyc 51:610–620

Kandhal PS et al (1995) Performance of recycled hot mix asphalt mixtures. National Center for Asphalt Technology, Auburn

Silva HMRD, Oliveira JRM, Jesus CMG (2012) Are totally recycled hot mix asphalts a sustainable alternative for road paving? Resour Conserv Recycl 60:38–48

Brownridge J (2010) The role of an asphalt rejuvenator in pavement preservation: use and need for asphalt rejuvenation. In: 1st International conference on pavement preservation, Newport Beach, USA

Tabaković AG, Gibney A, McNally C, Gilchrist MD (2010) The influence of recycled asphalt pavement on the fatigue performance of asphalt concrete base courses. ASCE J Mater Civil Eng 22(6):643–650

Su JF et al (2015) Investigation the possibility of a new approach of using microcapsules containing waste cooking oil; in-situ rejuvenation. Constr Build Mater 74:83–92

Steyn W (2009) Potential application of nanotechnology in pavement engineering. ASCE J Trans Eng 135(10):764–772

Shen J, Amirkhanian S, Miller JA (2007) Effects of rejuvenating agents on superpave mixtures containing reclaimed asphalt pavement. ASCE J Mater Civil Eng 19(5):376–84

Su JF, Qiu J, Schlangen E, Wang Y-Y (2014) Experimental investigation of self healing behaviour of bitumen/microcapsule composites by modified beam on elastic foundation method. Materials and Structures doi:10.1617/s11527-014-0466-5

Su JF, Schlangen E (2012) Synthesis and physicochemical properties of high compact microcapsules containing rejuvenator applied in asphalt. Chem Eng J 198–199:289–300

García Á, Schlangen E, van de Ven M (2010) Two ways of closing cracks on asphalt concrete pavements: microcapsules and induction heating. Key Eng Mater 417–418:573–576

Su JF et al (2011) Interface stability behaviors of methanol– melamine–formaldehyde shell microPCMs/epoxy matrix composites. Polym Compos 32:810–820

NL Agency (2011) Self healing materials concept and application, 2nd edn. NL Agency, Dutch Ministry of Economic Affairs, Agriculture and Innovation, The Hague

Butt AA, Brigisson B, Kringos N (2012) Optimizing highway lifetime by improving the self-healing capacity of asphalt. Procidia – Soc Behav Sci, Transport Research Arena 48:2190–2200

Kringos N, Schmets A, Scarpas A, Pauli T (2011) Towards understanding of the self-healing capacity of asphalt mixtures. Heron 56(1/2):45–74. http://heron.tudelft.nl/56-12/4.pdf

O’Brien F (2007) The third policeman. Harper Collins, London (First published in Great Britain by MacGibbon & Kee in 1967)

Vita L, Marolda MC (2008) Road Infrastructure – the backbone of transport system. EU Directorate General for Research and Sustainable Surface Transport, Brussels, Belgium

Worth J (2014) Ending the oil age. In: New internationalist, Nov 2014, pp 12–16. http://newint.org/features/2014/11/01/extended-oil-keynote/

Leggett J (2014) Big oil’s looming bubble. In: New internationalist, Nov 2014, pp 20–21

Acknowledgements

This research has been conducted under the Marie Curie IEF research funding, research project Self-Healing Asphalt for Road Pavements (SHARP), project number 622863.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Tabaković, A., Schlangen, E. (2015). Self-Healing Technology for Asphalt Pavements. In: Hager, M., van der Zwaag, S., Schubert, U. (eds) Self-healing Materials. Advances in Polymer Science, vol 273. Springer, Cham. https://doi.org/10.1007/12_2015_335

Download citation

DOI: https://doi.org/10.1007/12_2015_335

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-32776-1

Online ISBN: 978-3-319-32778-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)