Abstract

From the last few decades, environmental pollution is one of the major problems of the modern world. Increased industrialization has caused a serious problem of water pollution as it has led to the discharge of toxic and hazardous chemicals into the water bodies. Dyes are the main class of organic compounds that pollute the water. Hence, their effective removal is inescapable. The presence of metal ions is also a serious problem. Due to low volatility, chemical stability, and chelating abilities of ionic liquids, the application of functionalized ionic liquids can effectively reduce the amount of these pollutants.

In this chapter, the properties of ionic liquids which make them suitable for wastewater treatment are presented, and design ability of the functionalized ionic liquids/task-specific ionic liquids provides better opportunities to change the structures in cation and anion to achieve functionalized ionic liquid for specific pollutant removal. Therefore, recent applications of functionalized ionic liquids for the treatment of metal ions and different dyes are discussed. Later, a case study on the photodegradation with possible mechanisms of organic dyes, namely, methylene blue and congo red using a synthesized polymer-supported ionic liquid Fe-porphyrin complex is presented. Catalyst loadings of 10 mg and 12.5 mg at constant time of 60 min are found to be a better choice for the photodegradation of methylene blue and congo red dyes, respectively. The highest photodegradations of methylene blue and congo red are found to be ~78% and ~ 99%, respectively.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Wastewater treatment

- Functionalized ionic liquids

- Photodegradation

- Organic dyes

- Polymer supported ionic liquid iron porphyrin

12.1 Introduction

Approximately 7,00,000 tons of dyes are manufactured worldwide annually; wherein about 60% is azo dye out of which 10–15% of azo dyes is passed in the water system (Langhals 2004). Azo dyes are classified as acidic, basic, disperse, reactive, direct, and solvents/food dyes. An azo dye which is derived from benzidine, C12H12N2 is the main segment of carcinogenicity. Textile industries use a huge amount of freshwater for dyeing and processing, which discharge large amount of chemical pollutants like organic surfactants, dyes, dispersants, alkalis, acids, solvents, and various salts into the water bodies. The presence of dyes in water creates acute aesthetic and aquatic problems by disturbing the photosynthetic reaction due to light penetration. So, it is essential to focus on wastewater treatment technologies for its reuse and recycle. From the view of an environment, severe problems such as toxicity to water bodies and foremost to carcinogenic and mutagenic effects on humans are created by the textile-based industries (Dalvand et al. 2011; Du et al. 2017). The removal/treatment of dyes from polluted wastewater is comparatively more significant than the other soluble polluted compounds, which also add the portion of biochemical oxygen demand (Holkar et al. 2016). Many methods exist to eradicate harmful dyes from wastewater such as coagulation, an electrochemical process, membrane separation process, chemical oxidation, adsorption, reverse osmosis, and biodegradation. But most of these processes are not so acceptable due to additional chemical demand, producing large amount of secondary by products with their disposal problem and monetary disadvantages. A massive amount of such dyes in wastewater is nonbiodegradable because of their complex and stable molecular structures.

The drawback with the conventional biological methods (Shankar et al. 1999) is the treatment period. Treatment period typically varies from 1 day to 6 days. In addition, traditional processes (physical and chemical) are found to be comparatively expensive and may also lead to other secondary pollution due to the requirement of additional chemicals (Oller et al. 2011). Conventional biological procedures in association with physical/chemical processes to obtain improved decolorization of effluents may generally be costly and limited applicable. The adsorption processes using suitable adsorbents (activated carbons, charcoals, clays, diatomaceous earth, microbial biomass, compost, unmodified and modified lignocellulose, etc.) for the wastewater treatment have disadvantage of regeneration, which also increases the cost of the process. At times, it demands a very long time, and it may be ineffective for low concentrations of pollutants. Oxidation can be used to decolorize the dye effluent using various oxidizing agents such as hydrogen peroxide and ozone activated with Fe(II) salts. However, the pollutant removal mechanisms involve flocculation, and contaminants are shifted from the wastewater to the sludge, which further demands disposal in landfill (Boczkaj and Fernandes 2017; De Lima et al. 2017). Hence, the abovementioned techniques may not provide sustained solution with ecological point of view. Very recently, electrochemical treatment methods have achieved a good position as effective and efficient treatment technologies for dye effluents. However, the application of electrochemical techniques warrants a higher investment in equipment and energy requirement (Vaghela et al. 2005; Butler et al. 2011; Gautam et al. 2019).

In the recent years, researchers have used ionic liquids for various applications such as biocatalytic transformation, chemical synthesis, electrochemistry, analytical chemistry, and separation processes, because of the green characteristics of ionic liquids (Wasserscheid and Keim 2000; van Rantwijk et al. 2003; Pandey 2006; Hernández-Fernández et al. 2015). Main advantages of ionic liquids are the better possibilities of reusing and relatively easy recovery of ionic liquids. Therefore, application of ionic liquids effectively reduces the amount of waste generated during treatment process. The photodegradation of dye molecules using ionic liquids (ionic liquids), also regarded as green solvents, has advantageous over other processes with the view of environment protection. However, ionic liquids are still quite expensive. Hence, regeneration and recycling of ionic liquids are important to make a technology economically viable (Fernández et al. 2010). The scheme to reduce the amount of pollutants from industrial effluents using ionic liquids and potential sources of environmental release is presented in Fig. 12.1.

12.2 Ionic Liquids

An ionic liquid is a molten salt comprising of positive charged ions, cations and negative charged ions, anions having melting point below 100 °C. Combination of bulky and asymmetrical cations such as imidazolium, pyrrolidinium, and pyridinium and evenly shaped symmetrical anions such as halides, triflate, and nitrate lowers the lattice energy which is accounted for low melting points. Ionic liquids are also known as liquid electrolytes, room temperature molten salts, low temperature molten salts, ambient temperature molten salts, ionic melts, ionic fluids, fused salts, liquid salts, ionic glasses, or neoteric solvents (Wilkes 2002). Room temperature ionic liquids are salts which are in liquid state at or below room temperature. The structures of common cations and anions of ionic liquids are presented in Fig. 12.2. Ionic liquids are gaining worldwide acknowledgement from researchers as well as people in the industries for a large number of applications (Heintz and Wertz 2006).

Structure of common cations and anions of ionic liquids. (Sun and Armstrong 2010)

Depending on the cation and anion, the characteristics of ionic liquids, e.g., viscosity, solubility, and cloud point, may differ. The main benefit of ionic liquids is the provision of the replacement of anion that enables developing compounds with characteristics necessary for specific application. These tuned salts are referred to as task-specific ionic liquids/functionalized ionic liquids. Moreover, non-volatility, non-flammability, and better thermal stability make ionic liquids very attractive for industrial applications. Ionic liquids also have excellent features for removal of organic pollutants and metal ions because of its low volatility, chemical stability, and chelating abilities (Domanska and Rekawek 2009; Egorov et al. 2010; Regel-Rosocka and Wisniewski 2011). Ionic liquids consist of loosely coordinating bulky ions with the polarities comparable to alcohols. In addition to negligible vapor pressure, ionic liquids are nonexplosive and nonflammable. Ionic liquids have application in fields such as electrochemical, photo-degradation of organic compounds, catalysis and/or reaction media, drug delivery, biotransformation, solar cells, and various areas of separations (Patel and Lee 2012). The tailored ionic liquids used in reaction media and separation processes are reported to show better activity, selectivity, yields, stability, and environmental safety than conventional solvents (Dietz 2006; Han and Row 2010; Bollin and Viamajala 2012). An overview of physical properties such as density and viscosity of selected ionic liquids used in separations are presented in Table 12.1 (Han and Row 2010). The design ability of the functionalized ionic liquids/task-specific ionic liquids provides better opportunities to change the structures in cation and anion, and the length of the side chain can also be altered to the organic cation to achieve tailored/ functionalized ionic liquid of special properties.

12.3 Functionalization of Ionic Liquids

The chemo-physical properties of ionic liquids depend on the cation-anion combination and the length of alkyl chain. The functionality of ionic liquids also has a strong effect on the properties. Thus, the synthesis of functionalized ionic liquids is generally performed by the integration of functional groups into the cation of ionic liquid. Till date, mostly, the imidazolium cations are functionalized, and a few functionalized anions are known. Imidazolium cations can be modified using functionalized groups such as alkyl halides, hydroxyl groups, carboxylic groups, thiol groups, alkene groups, diene groups, and so on (Ye and Shreeve 2004; Fei et al. 2005). Using the quaternization method, most of the functional groups directly added imidazolium moiety and give the desired functionalized ionic liquids. Certain functionalities require other synthetic routes to be connected to the imidazole backbone (Liddle and Arnold 2005). The imidazolium salts with SiOMe3 groups can also be synthesized with greater yield using direct quaternization. The hydrophilicity of these imidazolium salts may be controlled on the surfaces of Si/SiO2 by anion exchange (Gao et al. 2004).

Less attention was given on the synthesis of pyridinium-based functionalized ionic liquids rather than imidazolium systems. Pyridinium-based ionic liquids are successfully functionalized as the nitrile salt, 1,2,4-substitute-triazolium salts, and phosphazene-based ionic liquids. Other low melting salts have also been formed using quaternization of pyrazine and pyrimidine with alkyl and polyfluoroalkyl halides. Functionalized ammonium ionic liquids, also known as ammonium salts, have been synthesized with ether groups. The ammonium salts show enhancement in cathodic and anodic stability and provide larger electrochemical window (Zhao 2007).

12.4 Applications of IL in Wastewater Treatment

Ionic liquids have excellent features for extraction of metal ions/organic pollutants from aqueous solutions because of its low volatility, chemical stability, and chelating abilities. In this section, few recent studies are discussed particularly extraction of heavy metals/others from wastewater using functionalized and modified ionic liquids as presented in Table 12.2. Major findings of the study appeared in the literature are presented in this table.

12.5 Degradation of Dyes Using Functionalized Ionic Liquids

Ionic liquids have found the recent applications in fields such as electrochemical, photo-degradation of organic compounds, catalysis and/or reaction media, drug delivery, biotransformation, and various areas of separations (Patel and Lee 2012). In this section of the chapter, recent and selected studies have been presented in Table 12.3 for the degradation of various dyes such as methyl orange, methylene blue, rhodamine B, indigo blue, and Sudan III using the functionalized ionic liquids. Applicable ionic liquids are also assisted by incorporating different nanoparticles such as Ag and TiO2. It is clear from Table 12.3 that ionic liquids can be effectively used for the effective removal of the dyes. The following section describes a case study on the photodegradation of organic dyes, namely, methylene blue and congo red, using a polymer-supported ionic liquid Fe-porphyrin complex.

12.6 Case Study: Photodegradation of Organic Dyes, Methylene Blue, and Congo Red Using a Polymer-Supported Ionic Liquid Fe-Porphyrin Complex

In this case study, a polymer-supported ionic liquid Fe-porphyrin complex was synthesized using the procedure described below. Ionic liquid complex was tested for the photodegradation of the organic dyes, namely, methylene blue and congo red. Results were analyzed using several characterization techniques.

12.6.1 Synthesis of a Polymer-Supported Ionic Liquid Fe-Porphyrin Complex

-

Synthesis of Poly 1-(4-(sec-butyl) benzyl)-3-(3-formyl-4-hydroxybenzyl)-1H-benzo [d] imidazol-3-ium chloride, 1-A

For the synthesis of a polymer-supported ionic liquid Fe-porphyrin complex, firstly, equal moles of poly 1-(4-s-butyl) benzyl)-1H-benzo[d]imidazole, 0.02 mol/5.284 g and 5-(chloromethyl)-2-hydroxybenz-aldehyde, 0.02 mol/3.411 g were taken and mixed in the round bottle flask of 100 mL with acetonitrile of 25 mL. The complete reaction mixture was agitated 24 h using a magnetic stirrer at ambient temperature. After completion of reaction, a new compound was formed and washed using a solvent, diethyl ether to acquire white powder form of 1D (Balinge et al. 2017, 2018). The yield and melting point of the resultant compound were determined as 68.99% and 180–198 °C, respectively.

1H NMR (400 MHz, DMSO-d6): δ 0.52 (s, 1H), 0.74 (br. 1H), 1.08 (br. 1H), 1.29 (s, 1H), 1.92 (s, 1H), 5.65 (s, 4H), 7.36 (br. 6H), 7.73 (br. 1H), 10.13 (d, 2H, J = 8.97 Hz), 15.79 (br. 1H). 13C NMR (100 MHz, DMSO-d6): 190.77, 161.74, 159.18, 136.94, 135.46, 131.29, 129.18, 127.15, 122.94, 118.64, 114.49, 49.76. FT-IR – (KBr, v/cm−1): 3377.36, 3018.60, 2926.01, 1654.92, 1612.49, 1558.48, 1487.12, 1444.68, 1371.39, 1282.66, 1249.87, 1188.15, 1151.50, 1016.49,929.69, 842.89, 744.52, 698.23, 632.65, 540.07, 497.63, 424.34.

-

Synthesis of 3-(2-carboxyethyl)-1-(3-formyl-4-hydroxybenzyl)-1H-benzo[d]imidazol-3-ium bromide, 1-B

The synthesis of 3-(2-carboxyethyl)-1-(3-formyl-4-hydroxybenzyl)-1H-benzo[d]imidazol-3-ium bromide was carried out according to the procedure given in (Muskawar et al. 2013; Khiratkar et al. 2016) with slight modification. 5-(1-H-benzo[d]imidazole-1-yl) methyl)-2-hydroxybenzaldehyde-(BMSA), 7.56 g/30 mmol was stirred for 1 h in toluene solution of 50 ml at 60 °C. Then, 3-bromopropionic acid of 6.08 g/40 mmol in toluene was added drop wise for 30 min and stirred for next 14 h at 85 °C. After this, the whitish solid product was obtained, after the decantation of toluene and washing with ethyl acetate, 3 × 20 mL and diethyl ether, 3 × 25 mL with yield of 73.33%, and melting point of 205 °C.

1H NMR (400 MHz, DMSO-d6): δ 2.63 (s, 2H), 4.33 (s, 2H), 5.35 (s, 2H), 6.67 (s, 1H),7.15 (s, 1H), 7.29 (s, 1H), 7.50 (d, 1H, J = 19.52 Hz), 7.75 (s, 1H), 9.24 (s, 1H), 9.58 (s, 1H), 9.88 (s, 1H), 10.55 (s, 1H), 12.32 (1H, br), 15.58 (1H, br), 13C NMR (100 MHz, DMSO-d6): 190.97, 172.31, 161.49, 161.32, 142.40, 142.57, 136.53, 129.55, 127.12, 126.01, 125.24, 122.90, 118.48, 116.31, 114.47, 114.34, 113.51, 65.36, 49.56, 33.21, 15.63. FT-IR – (KBr, v/cm−1): 3360, 3120, 1720, 1560, 1440, 1249, 1184, 1128, 989, 823, 744, 626, 495.

-

Synthesis of 1,1′1″-(((20-(5-((3-(4-(sec-butyl)benzyl)-1H-benzo[d]imidazole-3-ium-1-yl)methyl)-2-hydroxyphenyl)porohyrin-5,10,15-triyl)tris(4-hydroxybenzene-3,1-diyl))tris (methylene))tris(3-(2-carboxyethyl)-1H-benzo[d]imidazole-3-ium) tribromide chloride, (PSILPP) ligand 1-C

1-(4-(sec-butyl)benzyl)-3-(3-formyl-4-hydroxybenzyl)-1H-benzo[d]imidazol-3-ium chloride, 1-A of 1.01 g/2.5 mmol and 3-(2-carboxyethyl)-1-(3-formyl-4-hydroxybenzyl)-1H-benzo[d]imidazol-3-ium bromide, and 1-B of 3.039 g/7.5 mmol were mixed thoroughly in propionic acid, 20 mL at 60 °C for 30 min. To the mixture, pyrrole of 0.67 g/10 mmol in propionic acid of 15 mL was fed gradually for 30 min with controlled stirring for next 60 min at 130–140 °C. The purple solid product was then obtained. This was separated by removal of 2/3 propionic acid using rotary evaporator and finally washing with methanol followed by diethyl ether, 3 × 25 mL. The NH protons inside the ring of porphyrins acquired acidic character and therefore can get deprotonated to provide porphyrin to ions (Rabbani et al. 2016; Min et al. 2019). %Yield = 71.99% and melting point = above 250 °C were found.

1H NMR (400 MHz, DMSO-d6): δ −1.006 (s, 2H), 0.05(t, 5H, J = 7.62 Hz), 0.24(s, 2H), 1.21(q, 3H, J = 7.88 Hz), 1.54(s, 3H), 1.99(q, 2H, J = 6.1 Hz), 3.74(q, 3H, J = 7.21 Hz), 4.72(brs, 5H), 6.17(s, 7H), 6.57(m, 9H), 6.69(q, 4H, J = 3.17 Hz), 6.84(q, 7H, J = 3.00 Hz), 6.98(d, 4H, J = 8.58 Hz), 7.07(q, 4H, J = 3.19 Hz), 7.10(s, 5H), 8.49(s, 6H), 8.86(s, 2H), 12.21(s, 2H). FT-IR – (KBr, v/cm−1): 3026, 2929, 1712, 1610, 1560, 1502, 1438, 1330, 1255, 1182, 991, 827, 744, 601, 464.

-

Synthesis of 1,1′1″-(((19-(5-((3-(4-(sec-butyl)benzyl)-1H-benzo[d]imidazole-3-ium-1-yl)methyl)-2-hydroxyphenyl)-12,13-dihydro-112H,32H-11λ2–1(12,3)-1λ2–5,8-(azeno)pyrrolo[1,2-b][1]zinc[2,11]diazacycloundecina-3(5,2)-pyrrolacycloheptaphan-5-ene-14,2,4-triyl)tris(4-hydroxybenzene-3,1-diyl))tris(methylene))tris(3-(2-carboxyethyl)-1H-benzo[d]imidazole-3-ium) tribromide chloride, polymer supported ionic liquid iron porphyrin complex 1-D

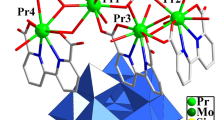

Polymer-supported ionic liquid iron porphyrin complex was successfully prepared and characterized by the different methods. The complex ligand 1-C of 0.903 g/0.5 mmol and FeCl3 of 0.097 g/0.6 mmol were charged to methanol and stirred initially for 30 min at atmospheric temperature. Later, above mixture was subjected to reflux at a temperature of 75 °C for 5 h in the inert atmosphere of nitrogen. The synthesized product was then isolated by periodic washing using methanol, and it was dried in the oven for 2 h at a temperature of 80 °C. Finally, a purple color powder of polymer-supported ionic liquid iron porphyrin complex was obtained as given in Fig. 12.3 with yield of 79.93% and melting point of above 250 °C.

FT-IR – (KBr, v/cm−1): 3248, 1714, 1608, 1562, 1506, 1438, 1259, 1189, 1132, 993, 829, 746, 592, 505, 422.

12.6.2 Photodegradation of Methylene Blue and Congo Red

The synthesized polymer-supported ionic liquid iron porphyrin catalyst was used to photodegrade the two azo dyes, methylene blue and congo red under the simulated light and normal air at specific values of pH. The photodegradation results are shown in Figs. 12.4 and 12.5. The process parameters used in photodegradation were optimized to maximize the degradation. In the process of optimization, photodegradation of dyes in visible light was investigated by changing one variable, and remaining variables were kept constant. After getting one optimum parameter, next parameter study was carried out keeping fixed other variables to find optimum photodegradation. First, the photodegradation of methylene blue using this catalyst with different quantities was optimized under simulated light at temperature of 25 °C. The results are presented in Table 12.4 as serial numbers 1–5 and Fig. 12.4, 1B.

It was found from Table 12.4 as serial number 12 and Fig. 12.4, 1D that only 22.42% of methylene blue was degraded in 60 min without using catalyst, under atmospheric air irradiation. On the other hand, 46.78% degradation efficiency of methylene blue was obtained with 5 mg catalyst as shown in Table 12.4, serial number 1 and Fig. 12.4, 1B. The improvement in the degradation efficiencies was observed as 65.31% and 77.76% with higher catalyst loadings of 7.5 mg and 10 mg, respectively, as given in Table 12.4, serial numbers 2–3 and Fig. 12.4, 1B. Comparatively less improvement was observed in photodegradation of methylene blue with the catalyst loading above 10 mg as shown in Table 12.4, serial numbers 4–5, and Fig. 12.4, 1B. This implies that the photo-induced electrons and holes are produced at lesser rate with high catalyst loadings and leads to a limiting factor for degradation. Catalyst loading of 10 mg is found to be a better choice for the photodegradation of methylene blue.

The photodegradation of congo red using polymer-supported ionic liquid iron porphyrin with different amounts of catalyst at atmospheric temperature of 25 °C under simulated sunlight was studied as given in Table 12.5 from serial numbers 1–5 and Fig. 12.5, 2B. Without catalyst, 21% of congo red was only able to degrade under atmospheric air irradiation in 60 min, whereas 41.7% removal was accomplished with 5 mg of catalyst as presented in Table 12.5 and Fig. 12.5, 2B. The increased removal was noticed at higher loadings of the catalyst, where −8.41% and 51.76% degradation were observed with catalyst loadings of 7.5 mg and 10 mg, respectively, as represented in Table 12.5, serial numbers 2–3, and Fig. 12.5, 2B. The negative value of degradation efficiencies may be attributed to the formation of few chromophore groups during the photodegradation. Similar findings were obtained by Kharazi et al. (2018); Khajone et al. (2019).

The rate of improvement was enhanced with 12.5 mg photocatalyst but found lesser thereafter, in serial numbers 4–5 of Table 12.5 and Fig. 12.5, 2B, which means that the photodegradation rate can be controlled by the production rate of photo-induced electrons and holes at these higher catalyst dosages. Next, the influence of duration was also influenced on photodegradation of congo red using the optimized catalyst loading of 12.5 mg in 25 mL at 10 ppm concentration. The progress in the degradation efficiencies was detected from 41% to 98.82% with respect to duration from 15 min to 75 min as presented in Table 12.5, s. no. 6–10. However, there was no appreciable enhancement with more duration, Table 12.5 at s. no. 11. It was found that there was no significant degradation in absence of photocatalyst as given in Table 12.5, s. no. 12–17.

12.6.3 Possible Mechanism

The possible mechanism of the dye degradation by polymer-supported ionic liquid iron porphyrin catalyst is given in Fig. 12.6. When exposed to replicated sunlight, electrons could reduce O2 to O2−· and the OH− and OH· radicals could be formed with the photo-generated holes. More radicals are generated due to the higher separation efficacy of electron–hole pairs in the developed photocatalyst. These generated radicals such as · OH· and O2− and 1O2 were found to be responsible for the photodegradation of methylene blue and congo red. Equations (12.1, 12.2, 12.3, 12.4, 12.5, 12.6, 12.7, and 12.8) illustrate the creation of radicals.

12.7 Conclusions

This study presents the recent applications of functionalized ionic liquids for the removal of metal ions and different dyes. An up-to-date review of the recent articles is presented in the first part. Later, a case study focusing on the application of a polymer-supported ionic liquid Fe-porphyrin complex for the photodegradation of organic dyes, namely methylene blue and congo red, is presented. It was observed that a polymer-supported ionic liquid Fe-porphyrin complex could be effectively used for the removal of organic dyes. This may pave a way for the efficient removal of the organic pollutants from the wastewater.

References

Archana V, Meera KM, Begum S, Anantharaman N (2016) Studies on removal of phenol using ionic liquid immobilized polymeric micro-capsules. Arab J Chem 9:371–382. https://doi.org/10.1016/j.arabjc.2013.03.017

Balinge KR, Khiratkar AG, Bhagat PR (2017) Polymer supported Zn-salen complexes: an effective one-pot oxidative esterification of aldehydes to carboxylic esters. J Mol Liq 242:1085–1095. https://doi.org/10.1016/j.molliq.2017.07.105

Balinge KR, Khiratkar AG, Muskawar PN, Thenmozhi K, Bhagat PR (2018) Facile access to polymer supported zinc–salen complex: highly efficient heterogeneous catalyst for synthesizing hydantoins, thiohydantoins and Schiff bases in aqueous medium. Res Chem Intermed 44:2075–2097. https://doi.org/10.1007/s11164-017-3215-x

Boczkaj G, Fernandes A (2017) Wastewater treatment by means of advanced oxidation processes at basic pH conditions: a review. Chem Eng J 32:608–633. https://doi.org/10.1016/j.cej.2017.03.084

Bollin PM, Viamajala S (2012) Reactive extraction of triglycerides as fatty acid methyl esters using Lewis acidic chloroaluminate ionic liquids. Energy Fuels 26:6411–6418. https://doi.org/10.1021/ef301101d

Butler E, Hung YT, Yeh RL, Suleiman Al Ahmad M (2011) Electrocoagulation in wastewater treatment. Water SA 3:495–525. https://doi.org/10.3390/w3020495

Dalvand A, Gholami M, Joneidi A, Mahmoodi NM (2011) Dye removal, energy consumption and operating cost of electrocoagulation of textile wastewater as a clean process. Clean-Soil Air Water 39:665–672. https://doi.org/10.1002/clen.201000233

De Lima LB, Pereira LO, de Moura SG, Magalhães F (2017) Degradation of organic contaminants in effluents-synthetic and from the textile industry-by Fenton, photocatalysis, and H2O2 photolysis. Environ Sci Pollut Res 24(7):6299–6306. https://doi.org/10.1007/s11356-016-6973-x

Dietz M (2006) Ionic liquids as extraction solvents: where do we stand? Sep Sci Technol 41:2047–2063. https://doi.org/10.1080/01496390600743144

Domanska U, Rekawek A (2009) Extraction of metal ions from aqueous solutions using Imidazolium based ionic liquids. J Solut Chem 38:739–751. https://doi.org/10.1007/s10953-009-9402-7

Du C, Xue Y, Wu Z (2017) Microwave-assisted one-step preparation of macadamia nut shell-based activated carbon for efficient adsorption of reactive blue. New J Chem 41:15373–15383. https://doi.org/10.1039/C7NJ03208K

Egorov VM, Djigailo DI, Momotenko DS, Chernyshov DV, Torocheshnikova II, Smirnova SV, Pletnev IV (2010) Task-specific ionic liquid trioctylmethylammonium salicylate as extraction solvent for transition metal ions. Talanta 80(3):1177–1182. https://doi.org/10.1016/j.talanta.2009.09.003

Fei Z, Zhao D, Geldbach TJ, Scopelliti R, Dyson PJ, Antonijevic S, Bodenhausen G (2005) Angew Chem Int Ed 44:5720. https://doi.org/10.1002/anie.200500207

Fernández JF, Neumann J, Thöming J (2010) Regeneration, recovery and removal of ionic liquids. Curr Org Chem – in press, Alexander K (ed), (InTech) ISSN 1385-2728

Ferreir AM, Coutinho JAP, Fernandes AM, Freire MG (2014) Complete removal of textile dyes from aqueous media using ionic-liquid-based aqueous two-phase systems. Sep Purif Technol 128:58–66. https://doi.org/10.1016/j.seppur.2014.02.036

Fuerhacker M, Haile TM, Kogelnig D, Stojanovic A, Keppler B (2012) Application of ionic liquids for the removal of heavy metals from wastewater and activated sludge. Water Sci Technol 65(10):1765–1773. https://doi.org/10.2166/wst.2012.907

Gao Y, Twamley B, Shreeve JM (2004) Inorg Chem 43:3406. https://doi.org/10.1021/ic049961v

Gautam K, Kamsonlian S, Kumar S (2019) Removal of reactive black 5 dye from wastewater using electro-coagulation: equilibrium isotherms and kinetic study. J Water Chem Technol. https://doi.org/10.1515/zpch-2017-1044

Han D, Row KH (2010) Recent applications of ionic liquids in separation technology. Molecules 15:2405–2426. https://doi.org/10.3390/molecules15042405

Hao M, Zhiguo J, Kong J (2013) Hydrophobic poly(ionic liquid) for highly effective separation of methyl blue and chromium ions from water. Polymers 5:1203–1214. https://doi.org/10.3390/polym5041203

Hayouni S, Robert A, Maes C, Conreux A, Marin B, Mohamadou A, Bouquillon S (2018) New dendritic ionic liquids (DILs) for the extraction of metallic species from water. New J Chem 42:18010–18020. https://doi.org/10.1039/C8NJ01921E

Heintz A, Wertz C (2006) Ionic liquids: a most promising research field in solution chemistry and thermodynamics. Pure Appl Chem 78:1587–1593. https://doi.org/10.1351/pac200678081587

Hernández-Fernández F, de los Ríos PJ, Mateo-Ramírez AF, Godínez C, Lozano-Blanco LJ, Moreno JI, Tomás-Alonso F (2015) New application of supported ionic liquids membranes as proton exchange membranes in microbial fuel cell for waste water treatment. Chem Eng J 279:115–119. https://doi.org/10.1016/j.cej.2015.04.036

Holkar CR, Jadhav AJ, Pinjari DV, Mahamuni NM, Pandit AB (2016) A critical review on textile wastewater treatments: possible approaches. J Environ Manage 182:351–366. https://doi.org/10.1016/j.jenvman.2016.07.090

Khajone VB, Balinge KR, Patle DS, Bhagat PR (2019) Synthesis and characterization of polymer supported Fe-phthalocyanine entangled with carboxyl functionalized benzimidazolium moiety: a heterogeneous catalyst for efficient visible-light-driven degradation of organic dyes from aqueous solutions. J Mol Liq 288:111032. https://doi.org/10.1016/j.molliq.2019.111032

Kharazi P, Rahimi R, Rabbani M (2018) Study on porphyrin/ZnFe2O4@polythiophene nanocomposite as a novel r adsorbent and visible light driven photocatalyst for the removal of methylene blue and methyl orange. Mater Res Bull 103:133. https://doi.org/10.1016/j.materresbull.2018.03.031

Khiratkar AG, Muskawar PN, Bhagat PR (2016) Polymer-supported benzimidazolium based ionic liquid: an efficient and reusable Brønsted acid catalyst for Biginelli reaction. RSC Adv 6:105087–105093. https://doi.org/10.1039/C6RA23781A

Langhals H (2004) Color chemistry. Synthesis, properties and applications of organic dyes and pigments. By Heinrich Zollinger, Wiley Online Library. Liddle ST, Arnold PL Organometallics. 24, 2597 https://doi.org/10.1002/anie.200385122

Liddle ST, Arnold PL (2005) Synthesis of heteroleptic cerium(III) anionic amido-tethered N-heterocyclic carbene complexes. Organometallics. 24:2597–2605. https://doi.org/10.1021/om050061b

Mathews C, Bhosale VK, Kulkarni PS, Kamble SP (2019) Removal of phenol from organic system using ionic liquids. Curr Environ Eng 6:1. https://doi.org/10.2174/2212717806666190408154507

Min KS, Kumar RS, Lee JH, Kim KS, Lee SG, Son YA (2019) Synthesis of new TiO2/porphyrin-based composites and photocatalytic studies on methylene blue degradation. Dyes Pigments 160:37–47. https://doi.org/10.1016/j.dyepig.2018.07.045

Muskawar PN, Kumar SS, Bhagat PR (2013) Carboxyl-functionalized ionic liquids based on Benzimidazolium cation: study of Hammett values and catalytic activity towards one-pot synthesis of 1-amidoalkyl naphthols. J Mol Liq 380:112–117. https://doi.org/10.1016/j.molcata.2013.09.026

Oller I, Malato S, Sa’nchez-Pe’rez JA (2011) Combination of advanced oxidation processes and biological treatments for wastewater decontamination-a review. Sci Total Environ 409:4141–4166. https://doi.org/10.1016/j.scitotenv.2010.08.061

Pandey S (2006) Analytical applications of room-temperature ionic liquids: a review of recent efforts. Anal Chim Acta 556:38–45. https://doi.org/10.1016/j.aca.2005.06.038

Park H, Shamim AH, Nallal M, Park S, Park KH (2019) Synthesis of silver nanostructures in ionic liquid media and their application to photodegradationof methyl orange. Nanomater Nanotech 9:1–9. https://doi.org/10.1177/1847980419836500

Patel DD, Lee JM (2012) Applications of ionic liquids. Chem Rec 12:329–355. https://doi.org/10.1002/tcr.201100036

Pei YC, Wang JJ, Xuan XP, Fan J, Fan M (2007) Factors affecting ionic liquids based removal of anionic dyes from water. Environ Sci Technol 41:5090–5095. https://doi.org/10.1021/es062838d

Pilli SR, Mohanty K, Banerjee T (2014) Extraction of Phthalic Acid from Aqueous Solution by Using Ionic Liquids: A Quantum Chemical Approach. International Journal of Thermodynamics 17(1):42–51. https://doi.org/10.5541/ijot.482

Qi L, Yu J, Jaroniec M (2013) Enhanced and suppressed effects of ionic liquid on the photocatalytic activity of TiO2. Adsorption 19:557–561. https://doi.org/10.1007/s10450-013-9478-7

Rabbani M, Heidari-Golafzani M, Rahimi R (2016) Synthesis of TCPP/ZnFe2O4@ZnO nanohollow sphere composite for degradation of methylene blue and 4-nitrophenol under visible light. Mater Chem Phys 179:35–41. https://doi.org/10.1016/j.matchemphys.2016.05.005

Ravishankar TN, Sureshkumar K, Dupont J, Ramakrishnappa T, Nagaraju G (2015) Ionic liquid-assisted hydrothermal synthesis of TiO2 nanoparticles and its applications towards the photocatalytic activity and electrochemical sensor. J Exp Nanosci 10. https://doi.org/10.1080/17458080.2015.1014870

Regel-Rosocka M, Wisniewski M (2011) Ionic liquids in separation of metal ions from aqueous solutions, applications of ionic liquids in science and technology, Prof. Scott Handy (ed), (InTech) ISBN: 978-953-307-605-8. https://doi.org/10.5772/23909

Rodríguez CB, Rodríguez PI, Corchero R, Rodil R, Rodil E, Arce A, Soto A (2017) Photocatalytic degradation of methyl orange, methylene blue and rhodamine B with AgCl nanocatalyst synthesised from its bulk material in the ionic liquid [P6 6 6 14]Cl. Water Sci Technol 75(1–2):128–140. https://doi.org/10.2166/wst.2016.499

Saleem S, Saqib ANS, Mujahid A, Hanif M, Mustafa G, Mahmood T, Waseem A, Khan AR (2014) Extraction of Pb(II) from water samples by ionic liquid-modified silica sorbents. Desalin Water Treat 52:40–42. https://doi.org/10.1080/19443994.2014.922497

Sergi D, Gemma E, Claudia F (2019) System for mercury preconcentration in natural waters based on a polymer inclusion membrane incorporating an ionic liquid. Journal of Hazardous Materials 371:316–322. https://doi.org/10.1016/j.jhazmat.2019.03.017

Shankar M, Sekaran G, Sadullah S, Ramasami T (1999) J Chem Tech Biotechnol 74:337. https://doi.org/10.1002/(SICI)1097-4660(199904)74:4<337::AID-JCTB39>3.0.CO;2-U

Sun P, Armstrong DW (2010) Ionic liquids in analytical chemistry. Anal Chim Acta 661:1–16. https://doi.org/10.1016/j.aca.2009.12.007

Vaghela SS, Jethva AD, Mehta BR, Dave SP, Ramachandriah G (2005) Environ Sci Technol 39:2848. https://doi.org/10.1021/es035370c

van Rantwijk F, Madeira LR, Sheldon RA (2003) Biocatalytic transformations in ionic liquids. Trends Biotechnol 21. https://doi.org/10.1016/S0167-7799(03)00008-8

Wasserscheid P, Keim W (2000) Ionic liquids:new “solutions” for transitionmetal catalysis. Angew Chem Int Ed 39:3772–3789. https://doi.org/10.1002/1521-3773(20001103)39:21<3772::AID-ANIE3772>3.0.CO;2-5

Wilkes JS (2002) A short history of ionic liquids-from molten salts to neoteric solvents. Green Chem 4:73–80. https://doi.org/10.1039/b110838g

Ye C, Shreeve JM (2004) J Org Chem 69:8561. https://doi.org/10.1021/jo048383x

Zhao D (2007) Design, synthesis and applications of functionalized ionic liquids, (Thesis) M.Sc. in Chemistry, Xinan Petroleum University, Nanchong, Chine et de nationalité chinoise. https://doi.org/10.5075/epfl-thesis-3531

Acknowledgments

The authors acknowledge SIF DST-VITFIST, the SEM facility at SBST, and RGEMS (VIT, Vellore) for allowing them to use the analytical instruments.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Patle, D.S., Khajone, V., Bhagat, P.R., Jaiswal, A.K., Kumar, S. (2021). Functionalized Ionic Liquids for the Photodegradation of Dyes. In: Inamuddin, Ahamed, M.I., Lichtfouse, E. (eds) Water Pollution and Remediation: Photocatalysis. Environmental Chemistry for a Sustainable World, vol 57. Springer, Cham. https://doi.org/10.1007/978-3-030-54723-3_12

Download citation

DOI: https://doi.org/10.1007/978-3-030-54723-3_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-54722-6

Online ISBN: 978-3-030-54723-3

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)