Abstract

Expansive black cotton soil (BCS) exhibits dual nature (swelling/shrinkage) predominantly when it is exposed to moisture fluctuation. This behavior renders the BCS unsuitable for use in geoengineering applications. The present study emphasizes the polypropylene and glass fiber based soil reinforcement with a traditional cement binder and envirosafe alkali-activated binders (AAB). Cement stabilization is one of the most popular methods for reducing swelling properties of BCS. However, the production of cement leads to the emission of greenhouse gases, which is a threat to modern society. Hence the present study aims to compare the geomechanical strength between AAB and cement binder with inclusions of various discrete fibers. AAB is generated by the reaction between an aluminosilicate precursor (Fly ash and/or GGBS) and an alkali activator solution of sodium hydroxide and sodium silicate. The water to solids ratio is maintained at 0.4 in the present study. Mineralogical and microstructural characterization are performed for both cement and AAB treated BCS as well as untreated BCS through stereomicroscope, X-ray diffraction (XRD), Fourier-transform infrared (FTIR) spectroscopy, scanning electron microscope (SEM), and energy dispersive x-ray spectroscopy (EDS). The unconfined compressive strength (UCS), indirect tensile strength (ITS), California Bearing Ratio (CBR) and consolidation characteristics of both untreated and binder treated BCS are carried out at different combinations of cement-fiber and AAB-fiber in the clay. It is observed that the proposed treatment method shows a significant improvement in geoengineering properties and aids in enhancing the shear strength and ductility properties. An addition of 5% AAB with 0.3% of polypropylene fiber reduces the plasticity and swelling pressure by 17–25%, while CBR and ITS values are increased by 28–33%. Recommendations on the practical implementation of this technique for stabilization of expansive soils are proposed based on findings of the present study.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Stabilization of expansive soil

- Alkali Activated Binder

- Geotechnical characterization

- Fiber

- Microstructural analysis

1 Introduction

Expansive clayey soil has high vulnerability to volume change and exhibits low strength bearing ratio, due to the existence of smectite group and soil moisture imbalance (Ola 1978; Ackroyd and Husain 1986; Chen 1988; Oren 2014). Low volumetric soil stability may lead to cause severe destruction of structures founded on them (Katti 1978; Petry and Little 2002; Phani kumar and Sharma 2004). To overcome the problem of shrinkage, heave, and settlement, cementitious chemical binders are used as an additive to stabilize the expansive soil (Das 2003; Sivapullaiah et al. 2009). Lime and cement are identified as the most usable traditional binders for stabilizing the expansive clay (Bell 1996; Yong et al., 1996; Chen and Wang 2006). However, production of these binders leads to the emission of carbon dioxide and nitrous oxide. Also, excessive use of binders may lead to soil shrinkage cracks due to rapid sulfate reaction (Gartner 2004; Al-Rawas 2005; Ouhadi and Yong 2008; Pourakbar et al., 2015). Industrial by-products such as fly ash, rice husk ash (RHA), Ground Granulated Blast Furnace Slag (GGBS), bagasse ash, pond ash, volcanic ash, cement kiln dust has also gained popularity in stabilizing expansive soil (Kumar et al. 2007; Tang et al. 2007; Eberemu and Sada 2013; Lin et al. 2013; Salahudeen et al. 2014; Ural 2015; Kolay et al. 2016; Miao et al. 2017; Gupta et al. 2018). This technique minimizes the disposal of industrial by-products and maintains the green sustainable environment in an economic and efficient way (Gupta et al. 2018; Mazhar et al. 2018). Numerous research is carried out to improve the geomechanical behavior of BCS with a combination of cementitious binder and fiber (Kaniraj and Gayathri 2003; Yetimoglu et al. 2005; Kuamr et al. 2007; Babu and Vasudevan 2008; Tang et al. 2007, 2010, 2014). However, limited studies are reported on the mechanism of fiber bonding with cement and fly ash based binders.

The present study proposes a method of geopolymerisation of expansive black cotton soil by alkali activated binders (AAB) prepared by blending Class-F fly ash, an industrial by-product, with a solution of sodium silicate and sodium hydroxide. The water to solids ratio is maintained at 0.4. The primary objective of this paper is to compare the microstructure and geoengineering characteristics of BCS reinforced with glass and polypropylene fiber in AAB and cement treated BCS individually. The brittle nature of BCS blended with cement and AAB mixture can be overcome through reinforcing with short discrete Polypropylene and glass fibers intrusion.

2 Materials

2.1 Black Cotton Soil (BCS)

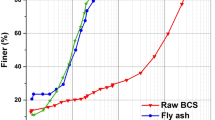

BCS is collected in this study from Nalgonda district of Telangana State in the southern part of India. The soil is dark brown to black in color and excavated at 30 cm depth from the natural ground surface in order to avoid the collection of vegetation. The soil is classified as highly plasticity clay (CH) according to the Unified Soil Classification System. The different physical and mechanical properties of raw BCS are provided in Table 1. Particle size distribution curves for both untreated and AAB treated BCS are shown in Fig. 1.

2.2 Alkali Activated Binder (AAB)

Class-F fly ash, used in the present study, is obtained from National Thermal Power Corporation (NTPC), Ramagundam city, Telangana, India. Sodium silicate solution and sodium hydroxide pellets are obtained from Hychem Chemicals Laboratories, Hyderabad. The purity of sodium hydroxide pellets is 99%. The sodium silicate solution is composed of 55.9% water, 29.4% SiO2 and 14.7% Na2O. The mass ratio of sodium hydroxide to sodium silicate to fly ash is 10.57:129.43:400 (Gupta et al. 2018).

2.3 Cement

Ordinary Portland cement of grade 53, used in this study, was sourced from JSW Cement Limited, Nandyal, Andhra Pradesh.

2.4 Fibers

Polypropylene fiber (PPF) and Glass fiber (GF) used in this study are obtained from Kanaka Durga Industries Pvt. Ltd., Hyderabad. Both fiber lengths of 12 mm are adopted in the entire test. Figure 2 shows the physical appearance of both PPF and GF.

2.5 Preparation of Soil Sample

Raw BCS is mixed separately with 5% of AAB paste and same 5% of dry cement (with respect to the total weight of soil) satisfying optimum binder requirement for both dry cement and AAB paste. The w/s ratio for AAB paste is maintained by 0.4. Both cement and AAB mixed soil are compacted in three layers with 9 kg rammer and a fall height of 30 cm. For continuous curing, cement and AAB compacted BCS are covered with moist jute bag minimum for 24 h. Prior to random mixing of different percentages of polypropylene and glass fiber (0%, 0.1%, 0.2%, 0.3% and 0.4% by mass of BCS) individually in both cement and AAB mixed soil. The glass, polypropylene fiber reinforced with cement and AAB treated soil specimens are designated as BCS+C+GF, BCS+C+PPF, BCS+AAB+GF, BCS+AAB+PPF and where C denotes cement.

3 Results and Discussions

3.1 Microstructure Analysis

Influence of fly ash based AAB, cement and randomly oriented polypropylene and glass fibers on the microstructure analysis of expansive black cotton soil is investigated by conducting x-ray diffraction, Fourier transfer infrared spectroscopy, stereomicroscope, scanning electron microscope and energy dispersive x-ray spectroscopy.

X-Ray Diffraction (XRD)

Powder X-ray diffraction analyses are performed using a RIGAKU Ultima-IV diffractometer to identify the minerals crystallinity in BCS. Both cement and AAB treated samples are examined through CuKα rays generated at 40 mA and 40 kV. The operating 2θ range is from 0o to 80o with a step of 0.02o for 2θ values and integrated at the rate of 2 s per step. Figure 3 shows the X-ray diffraction patterns of untreated BCS and fiber reinforced cement and AAB treated BCS. The raw BCS consisted of clay minerals such as Montmorillonite (M), Quartz, (Q) and Muscovite (Ms) (Sharma et al. 2012; Miao et al. 2017). After addition of fly ash based AAB to BCS, negligible changes take place in the peak intensities, as is evident from the diffractograms. It is observed that the crystalline peak of Montmorillonite (M) is reduced significantly, which may be attributed towards the alteration of clay minerals (Sivapullaiah et al. 2009; Ural Ural 2015; Rios et al. 2015; Sekhar and Nayak 2017). The diffractogram for fiber-AAB treated BCS shows additional peaks corresponding to Quartz (Q), and Mullite (Mu) which are characteristic to the hardened AAB paste (Mia et al. 2017; Mazhar et al. 2018). Moreover, the XRD pattern of fiber-cement treated BCS reveals crystalline peaks of Calcite (C), and Calcium silicate hydrate (CSH) (Saride and Dutta 2016). The formation of this mineral can be related to the cementitious reaction induced between BCS and binder. A flatter portion in the Xrd patterns indicates an amorphous phase of both hardened cement and AAB paste.

Fourier Transforms Infrared (FTIR) Spectroscopy

Fourier transform infrared (FTIR) molecular bond spectroscopy of the untreated and treated BCS are performed using a JASCO FTIR 4200 setup with KBr pellet arrangement. Transmittance spectral range is chosen from 4000–500 cm−1 for all the samples. Figure 4 shows the IR transmittance spectra of untreated BCS and fiber reinforced cement and AAB treated BCS. The spectrum curve of untreated BCS shows O-H stretching vibrations around 3616 cm−1 which is the general characteristics of montmorillonite (Madejova and Komadel 2001). For all selected samples, the broadband is found at 3450 cm−1 correspondings to O-H stretching of the hydroxyl group. Moreover, the peaks corresponding to C–H asymmetric stretching is detected between 2950–2875 cm−1. The peak around 1710 cm−1, representing the C=O carbonyl bond, is also detected. The bending vibration peak of =CH2 group is observed at 1460 cm−1. After cement and AAB-treatment, the =CH2 peak in the BCS shows a chemical shift of about 10 cm−1. Another main peak at 1033 cm−1 is attributed to Si-O-Si antisymmetric stretching, which is visible in both cement and AAB treated soil. Similarly, Al-O stretching bonds and Si-O-Al bending vibration bonds are found at 785 cm−1 and 527 cm−1 for both treated and untreated BCS, but most of them show chemical shifts, indicating impermeable nature of BCS.

Stereomicroscopic Images

Stereomicroscopic images are visualized using an Olympus SXZ7 setup having least dimension of 20 μm. Physical surface characteristics for both untreated BCS and fiber reinforced cement and AAB treated BCS samples are captured at various magnifications. Figure 5a shows the image of untreated BCS, which consists of light red and yellow grain particles indicating the presence of iron oxide and brown colored region indicating the presence of Illite and smectite group. The presence of iron and manganese is generally associated with montmorillonite mineral of clay. Figure 5b shows a deposit of hardened AAB paste with polypropylene fiber matrix around the clay surfaces. In addition, bright and shiny regions exhibit mica from the aluminosilicate precursors and dark colored patches reflect the voids left by the evaporation of water from hardened AAB paste. Figure 5c shows the discrete glass fiber embedded in the cement treated BCS, which act as a bridge surface by holding the clay particles strongly around the fiber.

Scanning Electron Microscope (SEM) and Energy Dispersive X-Ray Spectroscopy (EDS)

Surface morphology and elemental analysis of soil are examined using a Thermo Scientific Apreo SEM provided by FEI (Field Electron and Ion Company). Target locations are chosen randomly through Gentle beam of electromagnetic lenses which screens the surface through the small aperture by maintaining 20 kV excitation voltage with spot size 9. Energy dispersive x-ray spectra (EDS) are recorded using Aztec analyzer system provided by Oxford Instruments with a probe current of 65.4 μA at a working distance of 10 mm. Micrographs of untreated BCS and fiber reinforced AAB and cement treated BCS are presented in Fig. 6(a, b and d). The surface morphology of raw BCS reveals the flocculated flaky microstructure, which corresponds to montmorillonite and smectite group of clay (Fig. 6a). The hollow spheres varying from small to large particles in Fig. 6b may indicate the presence of unreacted fly ash in the soil. This significant change in surface morphology of BCS may be attributed towards the formation of flocculated network with more cementitious structure (Sekhar and Nayak 2017). Figure 6c shows a discrete fiber matrix bonded with cement and AAB around the irregular aggregated clayey surfaces, which act as spatial thread groove network by interlocking the clayey particles. EDS provides the elemental composition in terms of weight percent (wt%) and atomic percent (at.%) of treated BCS. Figure 6c and d show the volumetric chemical characteristics for glass fiber reinforced AAB and cement treated BCS. Peak intensities of Silica (Si), Calcium (Ca), Oxygen (O) and Alumina (Al) become relatively stronger in AAB and cement treated BCS, which may indicate the increase in the quantity of sodium aluminosilicate and cementitious compounds. The detailed elemental analyses are tabulated in Table 2. This finding corroborates that from the SEM images.

3.2 Geoengineering Characteristics

A series of compaction, shear strength, indirect tensile strength and California bearing ratio tests are performed for both untreated BCS and AAB treated BCS at the different fiber content. All the soil specimens are prepared with respect to their MDD and OMC values. These experimental results are used to assess the effectiveness of binder and durability of fiber reinforced in the BCS. The details of the tests performed and the discussion of test results are given in the following sections.

Compaction

A series of standard Proctor compaction tests are performed according to ASTM D-698 standard. Figure 7 shows the MDD and OMC of untreated BCS and fiber reinforced cement and AAB treated BCS. MDD of raw BCS is 1.65 g/cc and the corresponding OMC is 24.5%, indicating highly compressible clay. Compared with the raw BCS, the addition of cement and AAB increased the MDD values from 1.65 to 1.82 g/cc; however, the OMC values decreased from 24.5 to 18.6%. The variation of dry density and moisture content can be attributed to the particle flocculation and reduction of specific surface area in the soil (Sridharan and Sivapullaiah, 2005. Sharma et al. 2012; Ural 2015). Thus the increase in MDD and decrease in OMC is an indicator of improving the mechanical properties of soil.

Consolidation and Swelling Pressure

One dimensional consolidation and constant volume swelling pressure tests are conducted in an one-dimensional consolidometer according to ASTM D-2435 and D-4546 standards. Untreated BCS, as well as cement and AAB, treated BCS samples are statically molded at MDD and OMC in a consolidation ring of 20 mm height and 60 mm diameter. Figure 8a shows the void ratio versus logarithmic effective stress (e-log p) curve of treated and untreated BCS. The e-log p of raw BCS attains the highest equilibrium void ratio and the cement treated BCS attains least void ratio on saturation. Under the confined condition, as the effective stress increases, the void ratio and swelling pressure of soil decrease upon their saturation (Sivapulliah et al. 2009). The reduction in the settlement may attribute to interlocking particles, density and encapsulation of clayey surfaces by deposition of hardened AAB paste and cementitious materials (Vitale et al. 2017; Miao et al. 2017). Figure 8b shows the variation of swelling pressure with time for untreated BCS as well as cement and AAB treated BCS. From the time-swell curves, it is interesting to note that that the raw BCS takes maximum time to attain the equilibrium swelling pressure when compared to cement and AAB treated the soil. The main mechanisms that govern the reduction of swelling pressure of cement and AAB modified soil are morphological changes (pozzolanic reaction, flocculation, and mineralogical alteration) and physicochemical forces (interlocking density, suction, and cation exchange) (Zhao et al. 2008, 2013).

Unconfined Compressive Strength (UCS)

Unconfined compressive strength tests are performed as per ASTM D-2166 standard. Treated and untreated soil samples are molded in 38 mm diameter and 76 mm height under a fixed strain rate of 1.25 mm/min. Figure 9a shows the UCS values of untreated BCS and fiber reinforced cement and AAB treated BCS. From the results, it is noticed that the addition of fiber in raw BCS does not have a significant effect on compressive strength. The inclusion of glass and polypropylene fibers with cement or AAB treated soil show significant improvement in shear resistance property. The enhancement of geomechanical characteristics of BCS may be due to significant interfacial friction between the fiber and soil matrix with confinement bonding (Anagnostopoulos et al. 2014). Figure 9b shows the stress-strain curve of BCS stabilized with different cementitious binders and fibers. Raw BCS attains a low peak strength at around 2.3% of strain and PP fiber reinforced with AAB treated BCS attains highest shear strength with the lowest strain. The drastic improvement in compressive strength can be because of geopolymeric reaction induced between the sodium aluminosilicate and pozzolanic additives in the clay particles (Malik and Priyadarshee 2018).

Indirect Tensile Strength (ITS)

Indirect tensile tests are conducted as per ASTM D4123-1995 standard on cement and AAB treated soil incorporated with different fibers. The soil specimens are prepared by maintaining 80 mm height and 100 mm diameter with the loading strip of 12.5 mm at a constant strain rate of 50.5 mm/min in a Marshall stability machine. The samples are preserved for 24 h in the humidity chamber before testing (Emesiobi 2001; Eberemu and Sada 2013). Figure 10a shows the variations of ITS values of untreated BCS, as well as fiber, reinforced cement, and AAB, treated BCS. It can be observed that the tensile strength of cement and AAB treated BCS increases with increase in glass and polypropylene fiber content. Upon comparison, it can be seen that the AAB treated BCS reinforced with polypropylene fiber achieves the highest tensile strength. This drastic improvement in ductile properties and stretching resistance is majorly due to fiber surface morphology and pozzolanic reaction (Tang et al. 2007; Moghal et al. 2017). Figure 10b shows the typical arrangement of indirect tensile soil strength specimen under the loading strip frame. Hence the fiber-AAB compound mixture can effectively reduce the brittleness behavior and control the formation of the tensile cracks.

California Bearing Ratio (CBR)

Soaked and unsoaked CBR tests are performed for both treated and untreated BCS using ASTM D-1883 standard. Figure 11 shows the variations of CBR results for both soaked and unsoaked values at 2.5 mm penetration. As seen from the graph, the soaked CBR value of raw BCS is 1.96, indicating low strength and bearing. It is also noticed that the CBR value of cement and AAB treated soil increases with an increase in fiber content. In addition, the highest soaked and unsoaked CBR values are found at 0.3% polypropylene fiber with 100% fly ash based AAB treated BCS when compared to the fiber-cement mixture. Blending of cementitious and pozzolanic compounds with fiber in the BCS, aid to upgrade the strength bearing ratio of soil through hydration and geopolymerisation reaction during the period of soaking (Das 2003; Kumar et al. 2007; Malik and Priyadarshee 2018).

4 Summary and Conclusions

The present study compares the microstructure and geoengineering characteristics of glass and polypropylene fiber based soil reinforcement with a traditional cement binder and envirosafe alkali-activated binders (AAB). Fly ash based geopolymer binder serves a dual benefit of preventing the disposal of industrial by-product and at the same time maintaining a green sustainable environment. The important findings and main conclusions can be summarized as follows.

-

Microanalysis results confirm the formation of new crystalline phases and molecular vibrations in the cement and AAB treated BCS. In addition, stereomicroscopic images of glass and polypropylene fiber reinforced with cement or AAB show improved bonding behavior.

-

Micrographs of fiber-cement and fiber-AAB treated BCS shows strong interfacial surface interaction between the fiber matrix and soil through the formation of cementitious structure in the soil mass.

-

The geotechnical results show that AAB treated BCS with polypropylene fiber shows the most significant improvement in tensile, bearing capacity and shear strength properties of BCS when compared to glass fiber- AAB treated and cement-fiber treated BCS.

-

Void ratio and swelling pressure of cement treated BCS is significantly reduced by 36%, whereas AAB treated BCS reduces the same by about 32%. The volumetric stability and tensile resisting properties of BCS is greatly enhanced by blending 0.3% of polypropylene fiber with AAB.

-

Strength bearing ratio in terms of CBR, compaction, and shear strength values of glass and polypropylene fiber reinforced AAB treated BCS increases by 46% and 58%, whereas cement treated BCS increases by 38% and 45% respectively.

References

Ackroyd, L.W., Husain, R.: Residual and lacustrine black cotton soils of north-east Nigeria. Geotechnique 36(1), 113–118 (1986)

Al-Rawas, A.A., Hago, A.W., Al-Sarmi, H.: Effect of lime, cement and Sarooj (artificial pozzolan) on the swelling potential of an expansive soil from Oman. J. Build. Environ. 40, 681–687 (2005)

Anagnostopoulos, C.A., Tzetzis, D., Berketis, K.: Shear strength behaviour of polypropylene fibre reinforced cohesive soils. Geomech. Geoeng. 9(3), 241–251 (2014)

Bell, F.G.: Lime stabilization of clay minerals and soils. Eng. Geol. 42(4), 223–237 (1996)

Chen, F.H.: Foundations on Expansive Soils. Elsevier Scientific Publishing Co., Amsterdam (1988)

Chen, H., Wang, Q.: The behaviour of organic matter in the process of soft soil stabilization using cement. Bull. Eng. Geol. Environ. 65(4), 445–448 (2006)

Das, B.M.: Chemical and mechanical stabilization. Transportation Research Board (2003)

Davidovits, J.: Properties of geopolymer cements. In: First International Conference on Alkaline Cements and Concretes, Kiev State Technical University, Scientific Research Institute on Binders and Materials, Ukraine, vol. 1, p. 13 (1994)

Eberemu, A.O., Sada, H.: Compressibility characteristics of compacted black cotton soil treated with rice husk ash. Niger. J. Technol. 32(3), 507–521 (2013)

Gartner, E.: Industrially interesting approaches to ‘low-CO2’ cements. Cem. Concr. Res. 34(9), 1489–1498 (2004)

Gupta, S., GuhaRay, A., Kar, A., Komaravolu, V. P.: Performance of alkali-activated binder-treated jute geotextile as reinforcement for subgrade stabilization. Int. J. Geotech. Eng. 1–15 (2018)

Kaniraj, S.R., Gayathri, V.: Geotechnical behavior of fly ash mixed with randomly oriented fiber inclusions. Geotext. Geomembr. 21, 123–149 (2003)

Katti, R.K.: Search for solutions to problems in black cotton soils. Indian Institute of Technology, Bombay (1978)

Kumar, A., Walia, B.S., Bajaj, A.: Influence of fly ash, lime, and polyester fibers on compaction and strength properties of expansive soil. J. Mater. Civ. Eng. 19(3), 242–248 (2007)

Lin, B., Cerato, A.B., Madden, A.S., Elwood Madden, M.E.: Effect of fly ash on the behavior of expansive soils: microscopic analysis. Environ. Eng. Geosci. 19(1), 85–94 (2013)

Madejova, J., Komadel, P.: Baseline studies of the clay minerals society source clays: infrared methods. Clays Clay Miner. 49(5), 410–432 (2001)

Malik, V., Priyadarshee, A.: Compaction and swelling behavior of black cotton soil mixed with different non-cementitious materials. Int. J. Geotech. Eng. 12(4), 413–419 (2018)

Mazhar, S., GuhaRay, A., Kar, A., Avinash, G.S.S., Sirupa, R.: Stabilization of expansive black cotton soils with alkali activated binders. In: Proceedings of China-Europe Conference on Geotechnical Engineering, pp. 826–829. Springer, Cham (2018)

Moghal, A.A.B., Chittoori, B., Basha, B.M., Al-Shamrani, M.A.: Target reliability approach to study the effect of fiber reinforcement on UCS behavior of lime treated semiarid soil. J. Mater. Civ. Eng. 29, 04017014 (2017). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001835

Miao, S., Shen, Z., Wang, X., Luo, F., Huang, X., Wei, C.: Stabilization of highly expansive black cotton soils by means of geopolymerisation. J. Mater. Civ. Eng. 29(10), 04017170 (2017)

Ural, N.: Effects of additives on the microstructure of clay. J. Road Mater. Pavement Des. 10, 1–16 (2015)

Ola, S.A.: Geotechnical properties and behavior of some stabilized Nigerian lateritic soils. Q. J. Eng. Geol. Hydrogeol. 11(2), 145–160 (1978)

Oren, A.H.: Estimating compaction parameters of clayey soils from sediment volume test. Appl. Clay Sci. 101, 68–72 (2014)

Ouhadi, V.R., Yong, N.R.: Ettringite formation and behaviour in clayey soils. Appl. Clay Sci. 42, 258–265 (2008)

Phani Kumar, B.R., Sharma, R.S.: Effect of fly ash on engineering properties of expansive soils. J. Geotech. Geoenviron. Eng. 130(7), 764–767 (2004)

Petry, T.M., Little, D.N.: Review of stabilization of clays and expansive soils in pavements and lightly loaded structures—history, practice, and future. J. Mater. Civ. Eng. 14(6), 447–460 (2002)

Rios, S., Cristelo, N., Viana da Fonseca, A., Ferreira, C.: Structural performance of alkali-activated soil ash versus soil cement. J. Mater. Civ. Eng. 28(2), 04015125 (2015)

Saride, S., Dutta, T.T.: Effect of fly-ash stabilization on stiffness modulus degradation of expansive clays. J. Mater. Civ. Eng. 28(12), 04016166 (2016)

Salahudeen, A.B., Eberemu, A.O., Osinubi, K.J.: Assessment of cement kiln dust-treated expansive soil for the construction of flexible pavements. Geotech. Geol. Eng. 32(4), 923–931 (2014)

Sharma, N.K., Swain, S.K., Sahoo, U.C.: Stabilization of a clayey soil with fly ash and lime: a micro level investigation. Geotech. Geol. Eng. 30(5), 1197–1205 (2012)

Sekhar, D., Nayak, S.: SEM and XRD investigations on lithomargic clay stabilized using granulated blast furnace slag and cement. Int. J. Geotech. Eng. 13, 1–15 (2017)

Sivapullaiah, P.V., Prasad, B.G., Allam, M.M.: Effect of sulfuric acid on swelling behavior of an expansive soil. Soil Sediment Contam. 18(2), 121–135 (2009)

Tang, C., Shi, B., Gao, W., Chen, F., Cai, Y.: Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 25(3), 194–202 (2007)

Vitale, E., Russo, G., Dell’Agli, G., Ferone, C., Bartolomeo, C.: Mechanical behaviour of soil improved by alkali activated binders. Environments 4(4), 80 (2017)

Yetimoglu, T., Inanir, M., Inanir, O.E.: A study on bearing capacity of randomly distributed fiber-reinforced sand fills overlying soft clay. Geotext. Geomembr. 23(2), 174–183 (2005)

Zhao, H., Ge, L., Petry, T., Sun, Y.-Z.: Effects of chemical stabilizers on an expansive clay. J. Civ. Eng. KSCE 10, 1–9 (2013)

Acknowledgements

The authors would like to express their sincere gratitude to the Central Analytical Laboratory Facilities at BITS-Pilani, Hyderabad Campus for providing the setup for the XRD, FTIR, and SEM-EDS analyses.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Syed, M., Guharay, A. (2020). Stabilization of Expansive Soil Reinforced with Polypropylene and Glass Fiber in Cement and Alkali Activated Binder. In: Hoyos, L., Shehata, H. (eds) Advancements in Unsaturated Soil Mechanics. GeoMEast 2019. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-030-34206-7_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-34206-7_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-34205-0

Online ISBN: 978-3-030-34206-7

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)