Abstract

An expansive soil (black cotton soil) treated with up to 10 % cement kiln dust (CKD), a waste obtained from the manufacture of cement, was evaluated for use as a flexible pavement construction material. Laboratory tests were carried out on specimens compacted with British Standard light, British Standard light or standard Proctor (relative compaction = 100 %) energy. Results obtained show that the index properties of the soil improved with CKD treatment. Peak unconfined compressive strength of 357.07 kN/m2 and California bearing ratio (CBR) of 7 % as well as resistance to loss in strength of 44 % were recorded at 10 % CKD treatment. Reduction in the particle sizes with curing period was observed when samples were viewed through the scanning electron microscope. The study showed that CKD can be beneficially used to improve the subgrade of lightly trafficked roads and as admixture in lime stabilization during construction of flexible pavements over expansive soil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Black cotton soils, which are among the types of expansive soils, are in the group of problem soils encountered by geotechnical engineers. They are so named because the cotton plant thrives well on them. The swelling and shrinkage properties exhibited by black cotton soils have caused damage to various civil engineering structures constructed with or on these deposits. The costs of these damages have not been properly documented in Nigeria.

The most vulnerable engineering structure susceptible to damage due to shrink–swell potential (volume change) of black cotton soil is highway pavements because of their light weights and very shallow foundations. The multi-layered flexible road pavement is a complex structure made up of materials which engineering properties are very much affected by the loading to which they are subjected and also by the environmental conditions (Aitken 1971). A road pavement is expected to fulfil two basic functions: to remain structurally sound to satisfy the engineer’s design and to provide a satisfactory ride to the road user during its design life. Unfortunately and very frequent in practice, road pavements do not fulfil their basic functions, especially when they are constructed on expansive soils. There is, therefore, a need to incorporate an economical soil stabilization process before these roads are constructed to forestall these unfortunate results, because experience has clearly shown that the cost of repairs (of bad roads) is very much higher than the cost of a proper initial design, and the results are much less satisfactory (Krazynski 1980).

Cement kiln dust (CKD) is formed in the kiln during the production of cement clinker. The dust is a particulate mixture of partially calcined and unreacted raw feed, clinker dust and ash, enriched with alkali sulphates, halides and other volatiles. These particles are captured by the exhaust gases and collected in particulate matter control devices such as cyclones, baghouses and electrostatic precipitators. Several factors influence the chemical and physical properties of CKD. Because plant operations differ considerably with respect to raw feed, type of operation, dust collection facility and type of fuel used, the dust from each plant can vary markedly in chemical, mineralogical and physical composition (Wayne and Donald 2008).

Over the years, extensive research has been carried out to improve deficient soils. The two most commonly used stabilizers for expansive clays are cement and lime. Researchers (Ola 1983; Balogun 1991; Osinubi 1995) reported that the stabilization of this soil with cement or lime admixture is effective but very costly. The overdependence on cement and lime stabilization of deficient soils have kept the cost of constructions of stabilized roads financially high. This hitherto has continued to deter the underdeveloped and developing nations of the world from providing accessible roads to meet the need of the people. Due to the high costs of cement and lime, effort is being intensified by engineers/researchers (Osinubi 2000; Osinubi and Medubi 1997; Ramzi et al. 2001; Medjo and Riskowiski 2004; Osinubi and Stephen 2006; Alhassan and Mustapha 2007; Osinubi et al. 2011; Moses 2008; Musa 2008; Suhail et al. 2008; Oriola and Moses 2010; Akshaya 2012; etc.) to investigate the possibilities of utilizing potentially cost-effective locally available industrial and agricultural wastes for the modification and stabilization of deficient soils. Thus, the possible use of industrial waste (such as CKD) will not only reduce the cost of disposal but also will reduce or eliminate the environmental hazards caused by such wastes.

In recent years, there has been growing interest in the research of soil microstructure. From the image of soil microstructure, some micro-parameters such as porosity and soil particle orientation degree could be extracted (Wei 2010). The new generation scanning electron microscope (SEM), utilizing energy dispersive X-ray spectrometers (EDS), incorporate computer automation and detector technology that allow for rapid elemental analyses of small particles or inclusions. Automated SEM–EDS analyses remove biases inherently present in manual optical analyses and provide elemental and morphological information. This technique allows for a more complete characterization of particulate within a sample in a time-efficient manner. If the analysis involves searching a sample for specific materials of interest, or classification of all particulate within a sample, automated SEM–EDS can provide rapid and accurate results (Brian 2013). The SEM is designed primarily for producing electron images, but can also be used for element mapping and even point analysis, if an X-ray spectrometer is added. There is thus a considerable overlap in the functions of these instruments making them useful in the complete analysis of both the structural and elemental composition of natural and stabilized soil samples.

2 Materials and Methods

2.1 Materials

2.1.1 Soil

The black cotton soil sample used for this study was collected from a deposit at Deba (latitude 10°13′N and longitude 11°23′E) in Gombe State, Nigeria, using the method of disturbed sampling. The samples were taken at depth of 0.6 m from the natural earth surface to avoid organic matter influence.

2.1.2 Cement Kiln Dust

The CKD was obtained from Sokoto Cement Factory, Sokoto, Nigeria. The chemical composition of CKD was determined by using the method of energy dispersive X-ray fluorescence.

2.2 Methods

Laboratory tests were performed to determine the index properties of the natural soil and CKD-treated black cotton soil in accordance with BS 1377 (1990) and BS 1924 (1990), respectively.

2.2.1 Compaction

The compaction tests were performed on the natural soil and the stabilized soils (0, 2, 4, 6, 8 and 10 % CKD treatment by dry weight of soil); using the British Standard light (BSL) energy.

2.2.2 Strength

Tests performed were used to determine unconfined compressive strength (UCS), California bearing ratio (CBR) values. The UCS test specimens were compacted at BSL energy and cured for 7, 14 and 28 days before testing. The CBR tests were carried out in accordance with Nigerian General Specifications (1997) which specifies that specimens be cured in the dry for 6 days and then soaked for 24 h before testing

2.2.3 Durability

The durability assessment (which is simulation of some of the adverse field conditions) of the soil sample was determined by resistance to loss in strength of the soil samples when immersed in water. It is expressed as the ratio of UCS of the specimen wax-cured for 7 days and de-waxed top and bottom before being soaked for another 7 days to the UCS of the specimen cured for 14 days.

2.2.4 Microscopy

The properties of the clay sub-fractions in the soil/CKD-treated samples were studied by two analytical methods, scanning electron microscopy (SEM) and EDS. The SEM analysis was done using a SEM model “Tecan Vega SEM.” Individual analyses from different zones of the sample were performed by EDS. Since the electron probe analyses only to a shallow depth, specimens were well polished so that surface roughness does not affect the results.

3 Results and Discussion

3.1 Properties of Materials

The index properties of the natural soil show that it is an A-7-6 (16) soil according to AASHTO classification system (AASHTO 1986) and low plasticity clay (CL), using the Unified Soil Classification System, USCS (ASTM 1992). The soil has a liquid limit value of 48.2 %, plastic limit of 27.2 %, plasticity index of 21.0 %, linear shrinkage of 16.9 % and free swell value of 80 % with 73.6 % passing the BS No. 200 sieve (75 µm aperture). The predominant clay mineral is montimorillonite (Ola 1991; Balogun 1991; Osinubi 2000). Nigerian Building and Road Research Institute, NBRRI (1983), classifies the soil as high swell potential soil. The test results show that the soil in its natural state is not suitable for the construction of a flexible road pavement. The properties of the natural soil are summarized in Table 1, while its particle size distribution curve is shown in Fig. 1. The oxide composition of the CKD used in the study is given in Table 2. The CaO content and loss on ignition (LOI) values are relatively high.

3.2 Compaction Characteristics

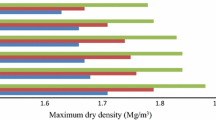

3.2.1 Maximum Dry Density

The variation of maximum dry density (MDD) of black cotton soil with CKD content is shown in Fig. 2. The MDD increased to a peak value at 6 % CKD content and thereafter decreased with higher CKD content. This initial increase in MDD could be due to CKD with a higher specific gravity (2.55) compared to that of soil (2.33) occupying the voids within the soil matrix as well as the flocculation and agglomeration of the clay particles due to exchange of ions (Osinubi 2000; Oriola and Moses 2010). The observed reduction in MDD may be probably due to the fact that for any soil-additive reaction, there is always a water content required to produce maximum strength (Osinubi 1999). The trend is in agreement with the findings reported by Lees et al. (1982), Ola (1991) and Iorliam et al. (2012).

3.2.2 Optimum Moisture Content

The variation of optimum moisture content of black cotton soil with CKD content is shown in Fig. 3. The OMC increased to a peak value at 6 % CKD content and thereafter decreased with higher CKD content. This trend is in conformity with results reported by Ola (1978), Gidigasu (1976) and Osinubi (1999). An explanation for this trend was the increased demand for water commensurate with the higher amount of CKD required for its hydration reaction and dissociation needed for cation exchange reaction. The subsequent decrease in OMC with increase in CKD content might be due to cation exchange reaction that caused the flocculation of clay particles.

3.3 Strength Characteristics

3.3.1 Unconfined Compressive Strength

The variation of UCS of black cotton soil with CKD content for 7-, 14- and 28-day curing periods together with that of 7 days curing and 7 days soaking are shown in Fig. 4. The UCS values generally increased with increase in CKD content. The observed trends can be attributed to ion exchange at the surface of clay particles. The Ca2+ in CKD reacted with the lower valence metallic ions in the clay microstructure which resulted in agglomeration of the clay particles (Moses and Saminu 2012). The increase in the UCS values was primarily due to the formation of various compounds, such as calcium silicate hydrates (CSH) and calcium aluminate hydrates (CAH) and micro-fabric changes, which are responsible for strength development (Jones and Holtz 1973; Osinubi et al. 2011).

Although UCS values increased with increase in CKD content for all curing periods considered, however, it was generally observed that strength decreased with curing age. This was primarily due to the high LOI value (39.28 %) of the CKD (long-dry kiln dust) used for this study. The high LOI of the CKD used may imply that it contains a large amount of CaCO3 and/or that it has been exposed to moisture. When kiln dust is exposed to moisture, alkali sulphates rapidly go into solution, and free lime and some cementitious phases, if present, undergo hydration. As a result, the availability of calcium ions is dictated by the equilibrium achieved through the solubility limit of Ca(OH)2 and gypsum (CaSO4·2H2O), if present. Evaporation of moisture from an open stockpile will result in the formation of gypsum and alkali hydroxides. Each of these compounds contributes to higher LOI. However, LOI of kiln dust that has not been exposed to moisture may be related to the CaCO3 content that undergoes decarbonation when ignited (Bhatty et al. 1996; Talal and Awad 1999; Miller and Zaman 2000; Wayne and Donald 2008).

The gradual release of the (high content) bound water within the chemical structure of CKD and the high slow-reacting calcium carbonate content were responsible for the decreased UCS values or loss of strength with curing period. In other words, the same mechanism (increased free moisture) that caused the decrease in UCS value when cured for 7 days and soaked for 7 days (compared with 14-day curing period) was responsible for the decrease in strength with curing age (Bhatty and Todres 1996; Miller and Zaman 2000; Wayne and Donald 2008).

3.3.2 California Bearing Ratio

The variation of unsoaked and soaked (24 h soaking) CBR values of the soil with CKD content is shown in Fig. 5. Generally, the CBR values recorded increased with higher CKD content. This increase could be due to the presence of adequate amounts of calcium required for the formation of CSH and CAH, which are the major compounds responsible for strength gain. Peak CBR values did not meet the 20–30 % requirement for subbase reported by Gidigasu and Dogbey (1980), for materials compacted at the optimum moisture content.

3.3.3 Durability

Durability assessment of soil samples involves the simulation of some of the worst conditions that could occur in the field. In this study, durability was evaluated by the immersion of specimens in water to determine resistance to loss in strength which is more acceptable for tropical regions like Nigeria (Ola 1974). Conventionally, an allowable 20 % loss in strength (80 % resistance to loss in strength) is recommended for a specimen cured for 7 days and immersed in water for 4 days (Ola 1974; Osinubi 1999).

The variation of resistance to loss in strength of the soil with CKD content is shown in Fig. 6. Resistance to loss in strength of the treated soil increased with higher CKD content.

Although the peak value did not satisfy the allowable value requirement, regardless of the harsher condition the samples were subjected to in the laboratory (7 days soaking instead of the conventional 4 days), the 10 % CKD-treated soil may be used as an improved subgrade for the construction of flexible pavements.

4 Microanalysis of Specimens

4.1 7 Days Curing Period

The results of microscopic/elemental analysis of specimens of black cotton soils treated with 0 and 10 % CKD and cured for 7 days are shown on Figs. 7a–c and 8a–c, respectively.

The EDS elemental analyses of the natural soil shows the usual composition of the aluminosilicate minerals (Reyes et al. 2007) consisting of Si, Al, Fe, with traces of Ca, Mg, Ti and k as shown in Fig. 7b and c. On the other hand, due to the CKD content in sample analysed in Fig. 8a, the Si content reduced while the Ca content highly increased (see Fig. 8b, c). The presence of elemental carbon in the EDS is due to the carbon tape at the background of sample holder.

The untreated sample (see Fig. 7a) formed aggregates of particles with smaller sized distribution than the treated sample (see Fig. 8a). The more active and higher valent cation (i.e., Ca2+) in the mixtures replaced the weakly bonded ions in the clay structure. The larger particle sizes formed in the soil treated with 10 % CKD were responsible for the higher strength values recorded.

4.2 28 Days Curing Period

The coarseness of soil–CKD mixture specimens reduced after 28 days curing (see Figs. 9a, 10a) when compared with the images of specimens cured for 7 days. This was probably due to the high LOI value of CKD used that liberated bond water at the outer layers. Consequently, the UCS values reduced at 28-day curing period when compared to the 7-day curing period values. The EDS elemental analysis patterns for specimens cured for 28 days (see Figs. 9b, c, 10b, c) are similar to those recorded for specimens cured for 7-day curing period discussed above.

5 Conclusion

The black cotton soil (expansive soil) classifies as an A-7-6 (16) soil using the AASHTO classification system and CL using the USCS. Although the properties of the natural soil improved, peak UCS, CBR and resistance to loss in strength values of 357.07 kN/m2, 7 and 44.37 % recorded for soil treated with 10 % CKD content did not meet the requirement for its use as a subbase material. The microscopy/EDS elemental analysis results of the 0 and 10 % CKD-treated samples when cured for 7 and 28 days show reduction in particle sizes with higher curing period as observed for UCS specimens. The study showed that CKD can be beneficially used to improve the subgrade of lightly trafficked roads and in admixture stabilization during construction of flexible pavements over expansive soil. However, CKD with high LOI should be avoided in the treatment of expansive soils.

References

AASHTO (1986) Standard specifications for transport materials and methods of sampling and testing, 14th edn. American Association of State Highway and Transport Officials (AASHTO), Washington

Aitken DH (1971) Transportation of geomechanics to roads and bridges. Proceedings of the 1st Australia–New Zealand conference on geomechanics, Melbourne, vol 2, p 489

Akshaya KS (2012) Utilization of bagasse ash and lime sludge for construction of flexible pavements in expansive soil areas. Electron J Geotech Eng 17:1037–1046

Alhassan M, Mustapha AM (2007) Effect of rice husk ash on cement stabilized laterite. Leonardo Electron J Pract Technol 6(11):47–58

ASTM (1992) Annual book of standards, vol 04.08. American Society for Testing and Materials, Philadelphia

Balogun LA (1991) Effect of sand and salt additives on some geotechnical properties of lime stabilized black cotton soil. Niger Eng 26(2):15–24

Bhatty JI, Todres HA (1996) Use of cement kiln dust in stabilizing clay soils. Portland Cement Association, Skokie

Bhatty JI, Bhattacharja S, Todres HA (1996) Use of cement kiln dust in stabilizing clay soils. RP 343, PCA serial no. 2035, Portland Cement Association, Skokie, Illinois

Brian JB (2013) Automated SEN/EDS analysis and classification of forensic samples. Forensic magazine. February/March 2013

BS 1377 (1990) Methods of testing soil for civil engineering purposes. British Standards Institute, London

BS 1924 (1990) Methods of tests for stabilized soils. British Standards Institute, London

Gidigasu MD (1976) Laterite soil engineering: pedogenesis and engineering principles. Elsevier, Amsterdam

Gidigasu MD, Dogbey JLK (1980) Geotechnical characterization of laterized decomposed rocks for pavement construction in dry sub-humid environment. Proceedings of the 6th South East Asian conference on soil engineering, Taipei, vol 1, pp 493–506

Iorliam AY, Agbede IO, Joel M (2012) Effect of cement kiln dust on some geotechnical properties of black cotton soil. Electron J Geotech Eng 17:967–976

Jones D, Holtz J (1973) Expansive soils: hidden disaster. Civ Eng ASCE 43:54

Krazynski LM (1980) Expansive soils in highway construction: some problems and solutions. Proceedings of the 4th International Road Federation African Highways Conference, Nairobi, Kenya

Lees G, Addelkader MO, Hamdani SK (1982) Sodium chloride as additive in lime–soil stabilization. J Inst Highw Eng 29(11):8–16

Medjo E, Riskowiski G (2004) A procedure for processing mixtures of soil, cement and sugar cane bagasse. Agric Eng Int J Sci Res Dev Manuscript BC 990 III: 1–6

Miller A, Zaman R (2000) Utilization of cement kiln dust in cement mortar and concrete. Resour Conserv Recycl 48(4):315–338

Moses G (2008) Stabilization of black cotton soil with ordinary Portland cement using bagasse ash as admixture. IRJI J Res Eng 5(3):107–115

Moses GK, Saminu A (2012) Cement kiln dust stabilization of compacted black cotton soil. IRJI J Res Eng 17:826–834

Musa A (2008) Potential of rice husk ash for soil stabilization. Assumpt Univ J Technol 11(4):246–250

NBRRI (1983) Engineering properties of black cotton soils of Nigeria and related pavement design. Nigerian Building and Road Research Institute, Research Paper No 1, p 22

Nigerian General Specifications (1997) Roads and bridges. Federal Ministry of Works, Abuja

Ola SA (1974) Need for estimated cement requirement for stabilizing lateritic soil. J Transp Div ASCE 17(8):379–388

Ola SA (1978) The geology and geotechnical properties of the black cotton soils of North Eastern Nigeria. Eng Geol 12:375–391

Ola SA (1983) The geotechnical properties of black cotton soils of North Eastern Nigeria. In: Ola SA (ed) Tropical soils of Nigeria in engineering practice. Balkama, Rotterdam, pp 160–178

Ola SA (1991) Laboratory testing and geotechnical characterization of black cotton soil and expansive shales in Nigeria. Proceedings of the 9th regional conference for Africa on Soil Mechanics and Foundation Engineering, Balkema, Rotterdam, pp 991–995

Oriola F, Moses G (2010) Groundnut shell ash stabilization of black cotton soil. Electron J Geotech Eng 15:415–428

Oriola F, Moses G (2011) Compacted black cotton soil treated with cement kiln dust as hydraulic barrier material. Am J Sci Ind Res (AJSIR) 2(4):521–530

Osinubi KJ (1995) Lime modification of black cotton soils. Spectr J 2(1):112–122

Osinubi KJ (1999) Evaluation of admixture stabilization of Nigerian black cotton soil. Niger Soc Eng Tech Trans 34(3):88–96

Osinubi KJ (2000) Laboratory trial of soil stabilization using pulverised coal bottom ash. Niger Soc Eng Tech Trans 35(4):13–21

Osinubi KJ, Medubi AB (1997) Evaluation of cement and phosphatic waste admixture on tropical black clay road foundation. Proceedings of 4th international conference on structural engineering analysis and modeling (SEAM 4), Kumasi, Ghana, 9–11 July, vol 2, pp 297–307

Osinubi KJ, Stephen TA (2006) Effect of bagasse ash content on particle size distribution and plasticity characteristics of black cotton soil. Proceedings of the 5th Nigerian Materials Congress “NIMACON 2006”, Abuja, Nigeria, 17–19 November, pp 214–220

Osinubi KJ, Eberemu AO, Oyelakin MA (2011) Improvement of black cotton soil with ordinary Portland cement—locust bean waste ash blend. Electron J Geotech Eng Bund F 16: 619–627

Ramzi T, Amer A, Ali A, Hilia A (2001) Use of cement kiln dust in soil stabilization. EJUQ 14:61–76

Reyes LRG, Remoro ETG, Cabral AP, Rodriguez RC (2007) Characterization of chromium in contaminated soil studied by SEM, EDS, XRD and Mossbauer spectroscopy. J Miner Mater Charact Eng JMMCE 7(1):59–70

Suhail AAA, Khawla AKA, Ibrahaim MAA (2008) Strength durability and hydraulic properties of clayey soil stabilized with lime and industrial waste lime. Al-Rafidain Eng 16(1):102–116

Talal OA, Awad AA (1999) Experimental study on the utilization of cement kiln dust for ground modification. J King Saud Univ (JKSU) 11:218–230

Wayne SA, Donald HT (2008) Beneficial uses of cement kiln dust. In: 50th cement industry technical conference, paper no. 1627, Miami, USA, May 2008

Wei W (2010) Analysis of soil microstructure parameters based on image mosaic technology. Xiao-Yuan He Conf Publ 1:286–289

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salahudeen, A.B., Eberemu, A.O. & Osinubi, K.J. Assessment of Cement Kiln Dust-Treated Expansive Soil for the Construction of Flexible Pavements. Geotech Geol Eng 32, 923–931 (2014). https://doi.org/10.1007/s10706-014-9769-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-014-9769-0