Abstract

There is considerable potential for pulmonary gene therapy as a treatment for a number of conditions for which current treatment is inadequate. Delivering genes directly to the lungs by dry powder inhalers (DPIs) have attracted much attention due to better stability of genes. Formulating genes as powders for aerosol delivery is a challenge as it requires not only flowability and dispersibility of the powders but also maintaining gene stability and biological activity during manufacturing and delivery. In this review, we aim to provide an overview about the potentials of spray-freeze-drying (SFD) for the development of inhalable dry gene powders for pulmonary drug delivery. We will discuss the main steps involved within the production process (i.e., spraying, freezing and drying) and introduce different SFD methods which can successfully be used for the production of porous particles whose physical and aerosol characteristics are considered to be ideal for use in pulmonary drug delivery.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In recent years, the lungs have been studied as a very attractive target for drug delivery [1]. Pulmonary drug delivery offers several advantages over injectable, transdermal or oral methods of delivery. Inhalables provide a non-invasive method of delivering drugs into the bloodstream, they enable effective drug targeting to the lungs for relatively common respiratory tract diseases and provide very rapid absorption similar to the intravenous route because of an enormous surface area and a relatively low enzymatic, controlled environment for the systemic absorption of medications. Delivering drug to the lungs can also help avoid gastrointestinal tract problems such as poor solubility, low bioavailability, gut irritability, unwanted metabolites, food effects and dosing variability [2, 3].

Gene therapy has as its central principle the addition of gene function through gene transfer. It has been the subject of a great deal of information, and misinformation, over the past decades [4]. However, there is considerable potential for pulmonary gene therapy as a treatment for a number of conditions for which current treatment is inadequate [5]. Gene delivery in humans requires carriers that will transfer genes into the nuclei of target cells. These carriers (viral or non-viral systems) first must be safe for human use, they must be efficient in transfection, and protect the genes from degradation before arriving at the target cell. Both viral and non-viral gene delivery systems have been used in the lungs, however, both have limitations associated with their biological properties [5]. Viral vectors are highly effective delivery agents, but their high immunogenicity has led researchers to seek safer alternatives [6]. Very popular non-viral delivery systems are biodegradable and biocompatible poly (D,L-lactide-co-glycolide) (PLGA) polymers, cationic liposomes, polyethyleneimine (PEI) etc. They are much safer than viral delivery systems, but their transfection efficiency in vivo is limited [7].

Pulmonary administration is a powerful tool for achieving effective pulmonary gene therapy against several lung diseases, such as cystic fibrosis, α1-antitrypsin deficiency, and lung cancer [8]. These diseases could be treated by high-level and long-term expression of the corresponding gene of interest [6]. The lungs possess inherent advantages for gene therapy since they are easily accessible via the airways, offer a large surface area for transfection and reduce the risk of systemic side effects. The most important thing in pulmonary gene therapy is to deliver a therapeutic gene to the lungs. To achieve this goal, several intravenous formulations have been developed. However, delivery to the lungs via intravenous injection is limited since genes are rapidly degraded by endonucleases in the systemic circulation. Another problem is nontargeted distribution, subsequently leading to poor therapeutic effects and adverse effects [8, 9]. Delivering genes directly to the lungs by nebulizers, pressurized metered-dose inhalers (pMDIs), or dry powder inhalers (DPIs) can solve these problems. Among these aerosol inhalation systems, DPIs have attracted much attention due to their low cost, portability, no propellant, and ease of handling [10]. Dry powder formulation also offers the better stability of genes by minimizing the exposure to high shear stress (during nebulization) and avoids the compatibility issues with propellants (in metered dose inhaler (MDI) [11]. Particle engineering methods that are suitable for preparing inhaled powder formulation of genes are spray drying, spray-freeze-drying and supercritical fluid technology [12]. Spray-freeze-drying (SFD) is powderization technique used to produce highly porous low-density powders, with high dispersibility and reachability to the lungs.

2 Spray-Freeze-Drying (SFD)

Spray-freeze-drying is biopharmaceutical powder production method, which has been attracting increasing interest in various areas of research [13]. The process has been widely used in pharmaceutical research, as well as food science and technology [14]. This technology can enhance the apparent solubility of poorly water-soluble drugs [15,16,17,18]. It is used as an approach that facilitates the development of dosage forms for alternative delivery pathways (pulmonary, nasal routes and delivery to the epidermis by needle-free injection) [19]. Some research groups have used SFD for preprocessing the protein/peptide ingredient prior to encapsulation in poly (lactic-co-glycolic acid) (PLGA) microspheres [20, 21]. It is also used very successfully to improve the storage stability of protein/peptide active ingredients [13, 22]. Spray-freeze-drying is preferred over classical spray-drying or freeze-drying for many reasons. First, it is possible to produce very porous powders with controlled particle-size distributions, and the technology offers the possibility to process thermosensitive active ingredients.

The term “spray-freeze-drying” (SFD) refers to processes with three steps in common: dispersion of bulk liquid solutions into droplets, droplet freezing, and sublimation drying of the frozen material. Schematic diagram of the spray-freeze-drying process is shown in Fig. 1. The first step in SFD is the dispersion of bulk liquid and the formation of droplets by using various types of nozzles and droplet stream generation systems. In the next step, droplets are being frozen either by transfer of thermal energy from the liquid to a cold gas, another immiscible liquid or a solid in contact with the droplet surface or by the diffusion of energy rich volatiles into the surroundings at low vapor pressure. The final step of the process is sublimation drying in which mobile solvent molecules separate from the surface of the frozen solid when they have acquired sufficient energy. This final step is significantly different from sublimation drying of frozen solutions in vials during freeze-drying because the specific surface area of frozen droplets exceeds the ratio of the surface area available for the escape of solvent molecules [19].

Schematic diagram of the spray-freeze-drying process [11]

Spray-freeze-drying covers different production methods: atmospheric freezing, spray-freezing into vapor over a liquid cryogen (SFV), spray-freezing into liquid cryogen (SFL), spray-freezing onto solid surfaces (thin film freezing, TFF) [13, 19]. Spray freezing into vapor over liquid cryogen (SFV) was first reported in 1948 and was performed by Benson and Ellis to investigate the surface area of protein particles [23]. The liquid feed was atomized into the vapor over a cryogenic liquid, such as liquid nitrogen or propane using either two-fluid or ultrasound nozzles. The droplets begin to freeze during the time of flight through the cold vapor phase and completely freeze upon contact with the cryogenic liquid phase itself [13]. Spray-freezing into liquid cryogen (SFL) is one of the most commonly used spray-freeze-drying techniques and it involves the atomization of a drug solution mostly via a two-fluid or an ultrasonic nozzle into a spray chamber filled with a cryogenic liquid [24]. The spraying process can be performed beneath or above the surface of the cryogenic liquid, depending on the position of the nozzle. Upon contact with the cryogenic liquid, the droplets solidify rapidly (in milliseconds) because of the high heat-transfer rate. After the spray freezing process is completed, the whole content can be lyophilized, with conventional freeze-drying. The frozen solvent is removed, as in the case of freezing with cryogenic liquids, by vacuum or atmospheric freeze-drying. The large surface area of the frozen powder and loose porous structure of the powder allow relatively fast and homogeneous drying compared with a standard lyophilization process [25].

Spray-freeze-drying is highly promising technology for the production of porous particles whose physical and aerosol characteristics are considered to be ideal for use in pulmonary drug delivery. The particles produced by SFD are typically amorphous and homogeneous. Spray freeze-dried particles can be engineered to the desired respiratory size range (below 5 µm) or even down to nano-scale [25]. The large porous particles have relatively small aerodynamic diameters usually smaller than 5 μm and large geometrical diameters usually larger than 10 μm.

Spray-freeze-drying has become very popular for processing of biologicals such as therapeutic proteins, monoclonal antibodies, and vaccines because of its ability to produce highly porous particles at sub-ambient temperatures with or without excipients. Spray-freeze-drying has been used to formulate a significant number of thermolabile and highly potent therapeutic proteins/peptides into dry powder inhalation products, including recombinant-derived humanized anti-IgE monoclonal antibody [26], recombinant human deoxyribonucleases [26], insulin [27], small interfering RNA (siRNA) [11] and plasmid DNA pSG5lacZ [28]. It is important to mention that the application of SFD is not limited to the production of porous materials; the technique is equally capable of producing high-density particles. It is also worth noting that the application of SFD is not only limited to aqueous solutions because most volatile organic solvents can be processed [25]. Despite all, SFD methods have many disadvantages. Almost all SFD methods are still highly experimental and only scaled for laboratory purposes [13]. Methods are not as well established due to their high complexity and high cost.

3 Development of Dry Gene Powders by SFD

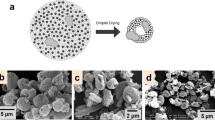

Formulating genes as powders for aerosol delivery is a challenge as it requires not only flowability and dispersibility of the powders but also maintaining gene stability and biological activity during manufacturing and delivery [29]. Development of inhalable aerosol systems for pulmonary gene delivery is critical for clinical use. The mean problem in the formulation is destabilization of the gene or delivery system caused by several stresses: heating, freezing, spraying and shearing stress in the nozzle [8, 9]. These forms of physical stress during the preparation might cause a critical loss of the gene. Therefore, a stable preparation of dry gene powder is necessary to achieve the clinical application of pulmonary gene therapy. Critical factors that can affect inhalability of the particles are also morphology and particle size of prepared powders [11]. To allow efficient lung deposition, prepared powders must have optimal particle size. Only particles that exhibited aerodynamic diameter between 1 and 5 µm can reach the deep lung. Aerodynamic diameter is affected by the geometric diameter as well as the density of the particles. Particles with a geometric diameter of 1–5 µm usually have poor flowability and dispersibility due to the strong cohesion force. On the other hand, porous particles with large geometric size tend to have small aerodynamic size because of the low density. These types of particles are desirable for inhalation due to the good flowability and dispersibility. In general, aerosol particles with aerodynamic diameters between 1 and 5 μm can achieve good lung deposition and the choice of inhaler device, therefore plays an important role in determining the success of aerosol delivery [1, 25].

Very porous particles produced by spray-freeze-drying has made this technology an attractive method for preparing inhaled powders. Porous particles with large physical size and low density exhibit small aerodynamic size, which can promote high flowability. In addition, porous particles have high specific surface area, thereby enhancing dissolution rate in the lungs. The porosity of the particles could be controlled by altering the solute concentration of the feed solution for spray-freeze-drying [11].

In one of the first studies, Maa et al. successfully used spray-freeze-drying to produce protein powders containing recombinant human desoxyribonuclease (rhDNase) and anti-IgG monoclonal antibody (anti-IgG Mab) for dry powder inhalation. Maa et al. revealed that a dry powder produced by SFD had superior inhalation characteristics compared to dry powders prepared by spray drying. Spray-freeze-drying can also guarantee the high-level recovery of produced dry powders, even if the initial amount of the formulation is small, which is very important for the study of dry gene powders on a laboratory scale since the employed genes are relatively expensive [26].

Kuo and Hwang first reported about the dry gene powders prepared by SFD. However, its gene transfection characteristics in vivo have remained unknown [30]. Mohri et al. successfully prepared inhalable dry plasmid DNA (pDNA) powders by SFD. They examined the stability of pDNA obtained through SFD and the morphology of prepared dry pDNA powders. All powders had spherical and highly porous particles about 20–40 μm in diameter. The ternary structure of pDNA was evaluated by electrophoresis to investigate the integrity of pDNA in the powders prepared by SFD. In the preparation without chitosan, the pDNA was almost completely degraded through SFD. However, the addition of chitosan improved the destabilization of pDNA caused by the physical stress during SFD. Chitosan has been reported to show high tolerability in the body. Unfortunately, on the other hand, it has been reported that the transfection efficiency of chitosan is low compared to that of polyethyleneimine (PEI), a non-biodegradable polycation [9]. Kuo and Hwang also reported the destabilization of pDNA through SFD and a protective effect of polyethyleneimine, a polycation, but not mannitol, supporting their results in part [30].

Okuda et al. also used SFD to prepare inhalable dry gene powders. In order to achieve higher gene transfection efficiency, authors have synthesized poly(aspartamide) derivatives with an ethylenediamine unit as a side chain (poly{N[N-(2-aminoethyl)-2-aminoethyl]aspartamide} (PAsp(DET)) and their block copolymers with poly(ethylene)glycol (PEG-PAsp(DET)) as vectors. These novel biodegradable polycations have superior efficiencies with minimal cytotoxicity compared to PEI. The final product had spherical and porous structures with a 5–10 μm diameter, and they showed that the integrity of plasmid DNA could be maintained during powder production. Both PAsp(DET)- and PEG-PAsp(DET)-based dry gene powders could achieve higher gene transfection efficiencies in the lungs compared with chitosan-based dry gene powders [8].

Liang et al. demonstrated in their study that dry gene powder could be stably prepared by SFD without the loss of plasmid DNA integrity and that the powder exhibited a gene expressing effect in the lungs of mice following pulmonary administration [31]. For clinical application, however, a higher gene transfection efficiency in the lungs is necessary. In their last study, Liang et al. employed spray-freeze-drying to prepare dry powder of small interfering RNA (siRNA) to treat lung diseases. Mannitol and herring sperm DNA were used as bulking agent and model of small nucleic acid therapeutics, respectively. The gel retardation and liquid chromatography assays showed that the siRNA remained intact after spray-freeze-drying even in the absence of delivery vector. The powder formulation exhibited a high emitted fraction (EF) of 92.4% and a modest fine particle fraction (FPF), of around 20%. Authors successfully demonstrated that spray-freeze-drying can be used to produce naked siRNA formulation with intact integrity [11].

4 Conclusion

Spray-freeze-drying is powderization technique used to produce a highly porous low-density powders. The powders produced by SFD are considered more suitable for inhalation compared with those produced by conventional techniques. Spray-freeze-drying involves multiple steps: liquids are first sprayed into a cryogen such as liquid nitrogen and the droplets, which are frozen immediately, are then transferred into a freeze dryer to allow the sublimation of ice, resulting in the formation of highly porous powders. Spray-freeze drying has shown to be a feasible method if good particle size control, spherical particle shape and a high product yield are essential. The porous particles produced by spray-freeze-drying has made this technology an attractive method for preparing inhaled gene powders. Many authors reported the use of spray-freeze-drying technology to produce dry powder of gene complexes that are suitable for inhalation. These dry powders produced by SFD could very successfully reach to intrapulmonary region and exhibit gene expression in the lungs. Since the aerosol performance of a powder formulation is also affected by the design of inhaler, a careful selected inhaler device could improve the delivery efficiency.

References

Labiris, N., Dolovich, M.: Pulmonary drug delivery. Part I: Physiological factors affecting therapeutic effectiveness of aerosolized medications. Br. J. Clin. Pharmacol. 56(6), 588–599 (2003a)

Patton, J., Byron, P.: Inhaling medicines: delivering drugs to the body through the lungs. Nat. Rev. Drug Discov. 6(1), 67–74 (2007)

Swarbirck, J., Boylan, J.: Encyclopedia of Pharmaceutical Technology, 3rd edn, pp. 1279–1287. M. Dekker, New York (2000)

West, J., Rodman, D.M.: Gene therapy for pulmonary diseases. Chest 119(2), 613–617 (2001)

Jenkins, R.G., McAnulty, R.J., Hart, S.L., Laurent, G.J.: Pulmonary gene therapy. Realistic hope for the future, or false dawn in the promised land? Monaldi Arch. Chest. Dis. 59, 17–24 (2003)

Bivas-Benita, M., Romeijn, S., Junginger, H.E., Borchard, G.: PLGA–PEI nanoparticles for gene delivery to pulmonary epithelium. Eur. J. Pharm. Biopharm. 58(1), 1–6 (2004)

Roth, J.A., Cristiano, R.J.: Gene therapy for cancer: what have we done and where are we going? J. Natl. Cancer Inst. 89(1), 21–39 (1997)

Okuda, T., Suzuki, Y., Kobayashi, Y., Ishii, T., Uchida, S., Itaka, K., Kataoka, K., Okamoto, H.: Development of biodegradable polycation-based inhalable dry gene powders by spray freeze drying. Pharmaceutics 7(3), 233–254 (2015)

Mohri, K., Okuda, T., Mori, A., Danjo, K., Okamoto, H.: Optimized pulmonary gene transfection in mice by spray-freeze dried powder inhalation. J. Control. Release 144(2), 221–226 (2010)

Labiris, N., Dolovich, M.: Pulmonary drug delivery. Part II: The role of inhalant delivery devices and drug formulations in therapeutic effectiveness of aerosolized medications. Br. J. Clin. Pharmacol. 56(6), 600–612 (2003b)

Liang, W., Chan, A., Chow, M., Lo, F., Qiu, Y., Kwok, P., Lam, J.: Spray freeze drying of small nucleic acids as inhaled powder for pulmonary delivery. Asian J. Pharm. 13(2), 163–172 (2017)

Pfeifer, C., Hasenpusch, G., Uezguen, S., Aneja, M.K., Reinhardt, D., Kirch, J., Schneider, M., Claus, S., Friess, W., Rudolph, C.: Dry powder aerosols of polyethylenimine (PEI)-based gene vectors mediate efficient gene delivery to the lung. J. Control. Release 154, 69–76 (2011)

Schiffter, H.: Spray-freeze-drying in the manufacture of pharmaceuticals. Eur. Pharm. Rev. 3, 1–7 (2007)

Ishwarya, S.: Spray-freeze-drying: a novel process for the drying of food and bioproducts. Trends Food Sci. Technol. 41, 161–181 (2015)

Rogers, T.L., Overhoff, K.A., Shah, P., Yacaman, M.J., Johnston, K.P.: Micronized powders of a poorly water soluble drug produced by a spray-freezing into liquid-emulsion process. Eur. J. Pharm. Biopharm. 55, 161–172 (2003)

Kondo, M., Niwa, T., Okamoto, H., Danjo, K.: Particle characterization of poorly water-soluble drugs using a spray-freeze drying technique. Chem. Pharm. Bull. 57(7), 657–662 (2009)

Leuenberger, H.: Spray-freeze-drying—the process of choice for low water soluble drugs. J. Nanoparticle Res. 4, 111–119 (2002)

Hu, J., Johnston, K., Williams, R.: Rapid dissolving high potency danazol powders produced by spray freezing into liquid process. Int. J. Pharm. 271(1–2), 145–154 (2004)

Wanning, S., Süverkrüp, R., Lamprecht, A.: Pharmaceutical spray freeze drying. Int. J. Pharm. 488(1–2), 136–153 (2015)

Costantino, H., Johnson, O., Zale, S.: Relationship between encapsulated drug particle size and initial release of recombinant human growth hormone from biodegradable microspheres. J. Pharm. Sci. 93(10), 2624–2634 (2004)

Leach, W., Simpson, D., Val, T., Anuta, E., Yu, Z., Williams, R., Johnston, K.: Uniform encapsulation of stable protein nanoparticles produced by spray-freezing for the reduction of burst release. J. Pharm. Sci. 94(1), 56–69 (2005)

Wang, S.H., Kirwan, S.M., Abraham, S.N., Staats, H.F., Hickey, A.J.: Stable dry powder formulation for nasal delivery of anthrax vaccine. J. Pharm. Sci. 101(1), 31–47 (2012)

Benson, S., Ellis, D.: Surface areas of proteins. I. Surface areas and heats of absorption 1. J. Am. Chem. Soc. 70(11), 3563–3569 (1948)

Rogers, T.L., Johnston, K.P., Williams III, R.O.: Solution based particle formation of pharmaceutical powders by supercritical or compressed fluid CO2 and cryogenic spray-freezing technologies. Drug Dev. Ind. Pharm. 27, 1003–1015 (2001)

Chow, A., Tong, H., Chattopadhyay, P., Shekunov, B.: Particle engineering for pulmonary drug delivery. Pharm. Res. 24(3), 411–437 (2007)

Maa, Y.F., Nguyen, P.A., Sweeney, T., Hsu, C.C.: Protein inhalation powders: spray drying versus spray freeze drying. Pharm. Res. 16, 249–254 (1999)

Bi, R., Shao, W., Wang, Q., Zhang, N.: Spray-freeze-dried dry powder inhalation of insulin-loaded liposomes for enhanced pulmonary delivery. J. Drug Target. 16(9), 639–648 (2008)

Yu, Z., Garcia, A.S., Johnston, K.P., Williams III, R.O.: Spray freezing into liquid nitrogen for highly stable protein nanostructured microparticles. Eur. J. Pharm. Biopharm. 58, 529–537 (2004)

Lam, J., Liang, W., Chan, H.: Pulmonary delivery of therapeutic siRNA. Adv. Drug Deliv. Rev. 64(1), 1–15 (2012)

Kuo, J.H., Hwang, R.: Preparation of DNA dry powder for non-viral gene delivery by spray—freeze-drying: effect of protective agents (polyethyleneimine and sugars) on the stability of DNA. J. Pharm. Pharmacol. 56, 27–33 (2004)

Liang, W., Kwok, P.C.L., Chow, M.Y.T., Tang, P., Ma-son, A.J., Chan, H.K., Lam, J.K.W.: Formulation of pH responsive peptides as inhalable dry powders for pulmonary delivery of nucleic acids. Eur. J. Pharm. Biopharm. 86, 64–73 (2014)

Conflict of Interest

The authors have no conflicts of interest to disclose.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Vranić, E., Sirbubalo, M., Tucak, A., Hadžiabdić, J., Rahić, O., Elezović, A. (2020). Development of Inhalable Dry Gene Powders for Pulmonary Drug Delivery by Spray-Freeze-Drying. In: Badnjevic, A., Škrbić, R., Gurbeta Pokvić, L. (eds) CMBEBIH 2019. CMBEBIH 2019. IFMBE Proceedings, vol 73. Springer, Cham. https://doi.org/10.1007/978-3-030-17971-7_79

Download citation

DOI: https://doi.org/10.1007/978-3-030-17971-7_79

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-17970-0

Online ISBN: 978-3-030-17971-7

eBook Packages: EngineeringEngineering (R0)