Abstract

Heavy metal enters into the ecosystem from natural and anthropogenic sources. Heavy metals are toxic which leads to various types of diseases in the living organisms. Hence, the removal of heavy metals from water is very essential to minimize the toxic effects of heavy metals. This chapter explains the sources, toxic effects and treatment methods of various heavy metals. Adsorption technique seems to be the best technique for heavy metal remediation. Activated carbon (AC) is the promising adsorbents for the removal of heavy metal from water. Hence, this chapter mainly focused on AC derived from different wastes like agriculture wastes, biological wastes, fruit wastes, vegetable wastes, plastic wastes and electronic waste (e-waste) materials for heavy metal removal. Various adsorption influencing conditions which were optimized for heavy metal removal are discussed in detail. A possible mechanism for heavy metal removal is also given. A comparison of heavy metal adsorption capacity of AC derived from various waste materials is discussed in detail.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

3.1 Introduction

Water is one of the most important resources present in the universe which is responsible for the existence of all the living organisms. For the past ten decades, water has been affected by a lot of pollutants such as heavy metals (Carolin et al. 2017; Awual et al. 2016), organic matter, domestic wastes, industrial wastes , etc. (Staples et al. 2011). Among them, heavy metals are highly dangerous because these are stable and non-biodegradable in nature which causes the serious threats and diseases to living community (Periyasamy et al. 2017). Aluminium (Al), arsenic (As), chromium (Cr), cadmium (Cd), lead (Pb), cobalt (Co), iron (Fe), copper (Cu), magnesium (Mg), molybdenum (Mo), mercury (Hg), manganese (Mn), uranium (U), nickel (Ni) and zinc (Zn) are the important toxic heavy metals which enter into the drinking water sources from various natural and man-made activities (Gopalakannan et al. 2018; Duruibe et al. 2007; Godt et al. 2006). As industrialization and civilization have grown over the last century, there has been an increase in the release of various toxic contaminants and other waste products into the water system. Although some of these metals are essential at lower concentration, the same metals cause various diseases if they exceed the tolerance limit. Hence, the World Health Organization (WHO) has assigned the tolerance limit of various toxic heavy metals in drinking water. It is also mandatory to remove the excess heavy metal ions present in water to minimize their toxic effects.

The different techniques have been reported for the removal of heavy metal such as adsorption, chemical precipitation, electrochemical precipitation, chemical oxidation, ion-exchange, membrane process, activated sludge process, electrocoagulation, electrodialysis and anaerobic process (Naushad et al. 2015; Bushra et al. 2015; Nag et al. 2017). Among them, adsorption is one of the best techniques for the remediation of heavy metal due to its unique advantages like economical , simple operation and high adsorption capacity (Aswin Kumar and Viswanathan 2018; Pandi et al. 2017).

Nowadays, the different adsorbents like polymers, inorganic materials, graphene oxide(GO), clays, activated carbon (AC) , carbon nanotube (CNT), magnetic materials, covalent organic frameworks (COFs) and metal organic frameworks (MOFs) are employed for the heavy metal removal from aqueous solution (Alqadami et al. 2017). Among the adsorbents, AC and their modified materials are considered as the most effective adsorbents for the removal of various contaminants from aqueous solution because they possess large specific surface area and high micropore volume. AC is carbon fabricated from the carbonaceous sources such as coconut husk, bamboo, coir, wood, etc. In the last few decades, AC was prepared from various waste materials such as agricultural wastes, biological wastes, fruit wastes, electronic wastes, vegetable wastes and plastic wastes (Mohan et al. 2005). AC prepared from the above-mentioned waste materials has been utilized for heavy metal removal because AC materials have many attractive functional groups such as carbonyl, polyhydroxy, phenolic, acetamido, alcoholic, amido, amino, sulphydryl, etc. (Forgacs et al. 2004; Dias et al. 2007; Demirbas 2008). These functional groups are attracted by heavy metal ions via electrostatic attraction or surface metal complexation. The heavy metal adsorption mechanism has been followed by physical adsorption, chemical adsorption, complexation, diffusion and ion exchange (Babel and Kurniawan 2003; Al-Othman et al. 2011).

3.2 Sources and Toxic Effects of Heavy Metals

Heavy metals are entering into the environment by both natural and anthropogenic activities. The important natural sources of heavy metals are weathering of minerals, volcanic activity, soil erosion, ores, forest fires and bio-fertilizers (Alloway 2013). Commonly, soils have various metal minerals and ores like chalcopyrite (Cu), gold veins in rock (Au), hematite (Fe), molybdenite (Mo) and sphalerite (Zn). The anthropogenic sources of heavy metals are industrial effluents, inorganic fertilizers, sewage wastes and fossil fuels (Periyasamy et al. 2018; Luo et al. 2015). Due to the rapid industrialization and commercial life style, the anthropogenic sources of environmental pollution have increased day by day. The list of anthropogenic sources, tolerance limit and toxic effects of heavy metals is demonstrated in Table 3.1.

3.3 Heavy Metal Removal by Various Methods

Nowadays, numerous types of chemical , physical and biological methods have been utilized for heavy metal removal from water. However, they have their own advantages and disadvantages which are listed in Table 3.2 (Gunatilake 2015; Azimi et al. 2017; Malik et al. 2017).

3.4 Advantages of Heavy Metal Adsorption

Adsorption is one of the best methods for the technological decontamination of water because it is effective, economical and eco-friendly (Sharma et al. 2017). In addition, the various adsorbents prepared for adsorption process can be highly regenerated than the other methods (Aswin Kumar and Viswanathan 2018; Pandi et al. 2017; Gopalakannan and Viswanathan 2015). It is a process which is strong enough to realize the water reuse requirement and high run-off standards in the industries. Adsorption of heavy metal is a mass transfer process in which the metal ion is transferred to the surface of the adsorbent and becomes bounded by the physical or chemical interactions (Kousalya et al. 2010). In addition, the bonding nature in the adsorption of heavy metals are shown in a clear manner. The physical and chemical adsorption process can occur in the environment at low temperature with appropriate pH condition.

Many adsorbent materials such as inorganic, organic, polymeric, MOF, COF, clay, AC , biomass and waste carbon source materials have been utilized for heavy metal removal . Among the adsorbents examined for heavy metal removal, AC from various waste materials due to be low cost and also a very efficient material. This chapter is focused on the development of AC from the inexpensive waste materials and its unique properties like high affinity, selectivity and high adsorption capacity towards heavy metal removal were discussed. The potential of various agricultural and industrial waste materials has received the most attention for heavy metal removal from the water/wastewater.

3.5 Origin of Activated Carbon

Initially, AC has been used by Egyptians as adsorbent for the medicinal purposes and as purifying agent in 1500 BC. Sweden Chemist, Karl Wilhelm Scheele, has utilized the charcoal for the adsorption of gases in 1773. A few years later, AC was utilized in the sugar industry as a decolourizing agent. In the twentieth century, the first AC plant was developed in Germany, and it was utilized as sugar-purifying/decolourization agent. In 1900, the production of AC from various plants was applied as the decolourization agent for both pharmaceutical and food products. Nowadays, AC plays a vital role in various applications such as water purification , sewage treatment, medicine, air purification, fuel storage, metal extraction, hydrogen storage and decaffeination.

3.6 Preparation of Activated Carbon-Supported Materials

AC has been broadly applied in air purification, energy storage and water treatment especially for the removal of toxic metal ions owing to its abundant pore textural properties like large specific surface area, average pore width, micropore volume and assets of the exterior oxygen containing active functional groups (Ayranci and Duman 2009). AC was synthesized from various carbonaceous materials such as agriculture wastes, biological wastes, fruit wastes, vegetable wastes, plastic wastes, e-wastes, etc., by the carbonization process followed by physical or chemical activation (Abioye and Ani 2015; Skodras et al. 2007; Shehzad et al. 2015; Kumar et al. 2018).

3.6.1 Physical Activation

Physical activation is one of the pyrolysis processes which mainly occurred at high temperature. This process involves two steps, namely, carbonization of carbonaceous materials in an inert atmosphere and the activation of the resulting materials in the presence of carbon gasification reactants such as carbon dioxide, stream or air. Physical activation process is involved between the carbon atom and the oxidizing gas. Fatima Salgado et al. have synthesized AC from babassu endocarpunder (Brazilian palm) using physical activation method. They also reported the efficiency of AC product as 79.09, 80.94 and 83.72% at 700, 750 and 800 °C, respectively. The BET surface area of babassu endocarpunder AC was found to be 543.56, 480.74 and 542.19 m2/g at 700, 750 and 800 °C, respectively (Fatima Salgado et al. 2018).

3.6.2 Chemical Activation

Chemical activation is one of the chemical processes occurring in a single-step reaction in which the raw carbon source materials are impregnated with the suitable chemicals. In this method, the solid activation agents like alkali, alkaline earth metal containing salts and some acid/bases such as sulfuric acid, hydrochloric acid, nitric acid, phosphoric acid, potassium hydroxide and sodium hydroxide have been utilized for the production of AC (Hui et al. 2009). The temperature employed in chemical activation is lower than that of physical activation. In addition, the chemical activation process offers a higher surface area of AC (>3000 m2/g) than physical activation. Limousy et al. have synthesized AC from the phosphoric acid-activated olive stone and successfully utilized it for amoxicillin removal from aqueous solution. The obtained specific BET surface area and pore volume of AC by olive stone were found to be 1174 m2/g and 0.46 cm3/g, respectively (Limousy et al. 2017). Tran et al. have prepared an efficient AC from the golden shower tree flower via chemical activation which provides the high surface area of 1413 m2/g (Tran et al. 2017).

3.7 Activated Carbon from Different Waste Materials for Toxic Metal Removal

AC is the promising adsorbent for the removal of heavy metals from water. The AC prepared from the waste materials seems to be cost-effective and possess high removal capacity. The sources of AC-based waste materials can be divided into two categories: natural and man-made wastes. The natural wastes are created by the usage of natural materials such as agriculture products, vegetables, fruits, woods and seeds. The man-made wastes created by human activities include industrial, municipal, plastic and e-wastes. These waste materials can be utilized for the synthesis of AC which can be applied in various wastewater treatments especially the removal of heavy metal. In addition, the large surface area and the high micro-mesoporous structure of AC can be prepared by either physical or chemical activation of AC which helps to enhance the heavy metal adsorption capacity . The derived AC from different sources of waste materials developed for the removal of various heavy metals from water is discussed as follows.

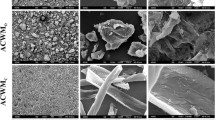

3.7.1 Activated Carbon from Agricultural Wastes

Agricultural waste is unsalable or unwanted materials produced entirely from the results of various agricultural operations which directly related to the growing of crops. Agricultural waste materials could be used as the resource materials in many fields such as engineering, medical, wastewater treatment, etc. A lot of agricultural wastes such as rice husk , tamarind seeds, corn cobs, groundnut shell, etc. have been produced day by day in various agricultural processes. These waste materials are biodegradable and can be easily converted into AC which is often applied for heavy metal removal from water.

Shrestha et al. have developed the agricultural waste product seed-generated AC, namely, Lapsi (Choerospondias axillaris), which is available in the subcontinent of India. The major purpose of their work was to improve the easiest chemical method which is adopted for the chemical activation of Lapsi seed and carbonization for Pb(II) and Ni(II) removal. The higher adsorption capacity of AC which derived from Lapsi seed occurred by the use of chemical carbonization process. The experimentally observed adsorption capacities of Pb(II) and Ni(II) were found to be 424 and 70 mg/g, respectively (Shrestha et al. 2013).

Kadirvelu et al. have prepared AC from the numerous solid wastes obtained from agricultural such as sago waste, coconut tree sawdust, silk cotton hull and maize cob for Ni(II) adsorption from aqueous solution. The adsorption of Ni(II) requires a very diminutive time period and gives the quantitative removal as well. The experimental result of AC obtained from the agriculture waste materials was effective in Ni(II) removal from water. Since all the solid wastes applied in this exploration are locally available and abundant in nature, this ensuing AC was projected as an inexpensive material for the wastewater treatment. These biowaste materials were collected from the agricultural processing industries in and around Coimbatore, Tamilnadu, India. These materials were converted into AC using concentrated H2SO4. The removal of Ni(II) was carried out in batch scale using coconut tree sawdust, sago waste, silk cotton hull and maize cob which was found to be 81, 100, 58 and 100%, respectively (Kadirvelu et al. 2003).

The effluent treatment at various water sources is necessary for any industry to overcome the problems of adverse public health, economic and environmental impacts caused by excess Cd(II) in water. The pretreatment of Cd(II) effluent up to the safe limit can only resist the hazardous Cd(II) to reach the water bodies and natural environment. Nag et al. have developed the naturally obtainable agriculture waste materials, viz. rubber plants, mango leaves and jackfruit leaves, which have been utilized for the preparation towards the toxic Cd(II) removal from aqueous medium. The surface characteristic properties like porous morphology and high surface area facilitate the adsorption process. The adsorption of Cd(II) was controlled by intraparticle diffusion, mass transport and chemical adsorption process. Jackfruit leaf showed the best adsorption performance of 20.37 mg/g for Cd(II) removal. In addition, the prepared AC from jackfruit leaf performed satisfactorily when tested for the collected industrial wastewater as well (Nag et al. 2018). Recently, microwave heating method has been utilized for AC synthesis toward the removal of heavy metal by low-cost vegetable wastes. The conservative heating process was adopted frequently for AC synthesis which involves the fabrication of electrical energy heater and involves elevated energy use and long-time processes; thereby, microwave technology was improved for the preparation of AC (Wang et al. 2012a, b).

In addition, olive stone (OS) waste residue is a raw material used for AC fabrication which can be considered as the better material because it is abundant and quite cheap. The International Olive Council has reported that the annual invention of olive oil worldwide in the year 2012 was almost more than 3 million tons, and approximately 15 million tons of olive cakes are gained (Vossen 2007). Taking these into consideration, Alslaibi et al. have developed the microwave technology for the synthesis of olive stone (OS)-generated AC (OSAC) towards Cd(II) removal (Alslaibi et al. 2013). The removal percentage of 95.32% was observed for Cd(II) adsorption using OSAC, and also the microwave-applied OSAC can be applied for the efficient Cd(II) adsorption from wastewater at field condition. The carbonization process of carbon-containing raw materials is the requirement step for the easiest preparation of AC. However, the carbon porosities are not efficiently improved for the need of practical applications. So, carbonization followed by thermal activation has applied for the preparation of AC in which the process occurred under the flow of CO2 or steam.

Chand et al. have synthesized the porous AC materials from the agro-waste barley straw (BS) and wheat straw (WS) by applying the carbonization process, and the prepared AC has been utilized for Cr(VI) removal from aqueous solution (Chand et al. 2009). The Cr(VI) adsorptive removal investigation occurred at a carbonization temperature of 800 °C at pH 2. The carbonized barley straw (CBS) and carbonized wheat straw (CWS) materials obtained from the agro-wastes were found to have the higher Cr(VI) adsorption capacities of 44.89 and 43.75 mg/g respectively. In addition, it requires the equilibrium time of 1 h for Cr(VI) removal. Chun-Shui et al. have developed an agricultural by-product called peanut hull which is most abundant in nature and utilized for Cu(II) removal from aqueous solution (Chun-Shui et al. 2009) (Fig. 3.1 ).

The Cu(II) adsorption was pH-dependent and maximum at pH 5.5 at 2 h of equilibrium time. The activation energy (Ea) of Cu(II) adsorption was found to be 17.02 kJ/mol which shows that peanut hull bioadsorbent has been activated with chemical method, and the adsorption capacity for Cu(II) was observed as 21.25 mg/g at 30 °C. Mohan et al. have focused on the decontamination of Cr(III) from drinking water using low-cost AC which was synthesized from the coconut shell fibres. The coconut shells that are the current grim disposal trouble in the environment were collected from Lucknow, India. In this study, AC was synthesized by treating 2 g of coconut shell fibres with 20 mL of concentrated sulfuric acid, and this mixture was kept in an oven at 150–165 °C for 24 h. Finally, the carbonized material was washed well with double distilled water to remove the excess acid and dried at 105–110 °C for 24 h. The dried coconut shell fibres were get in through the removal of Cr(III) from water, and the adsorption capacity was observed as 39.56 mg/g (Mohan et al. 2006).

Hegazi has focused on utilizing the possible sources of agro-based inexpensive rice husk adsorbent for the feasible removal of heavy metals from water. He focused on contributing less expensive adsorbents for various agricultural waste products, which are also pollution sources. In this study, Fe(II), Pb(II), Cd(II), Cu(II) and Ni(II) ion solutions of 20, 30, 40, 50 and 60 mg/L were taken for adsorption studies. Fe, Pb, Cd, Cu and Ni removal using rice husk has the percentage removal efficiency of 99.25, 87.17, 67.91, 98.18 and 96.95%, respectively (Hegazi 2013).

3.7.2 Activated Carbon from Biological Wastes

The biological waste materials that exist in nature are capable of self-replication and may produce the effects upon biological organisms. The important biological waste materials include buffing dust, bovine skin obtained from leather industries, etc., which may cause itself a serious problem until it gets disposed or reused. Hence, the preparation of AC from these biological waste materials has been taken into account in which it is applied in the environmental remediation (Gil et al. 2014) (Fig. 3.2).

Lopez-Anton et al. have studied AC of biowastes obtained from the vegetable tanning process and demonstrated for the adsorption of Hg(II) capture in oxy-combustion process. The high proportion of Hg oxidizes to Hg(II) under AC is very important to consider that the cost-effective mode , in order to diminish Hg(II) emissions during coal combustion process and 60% of Hg(II) removal was observed (Lopez-Anton et al. 2015).

3.7.3 Activated Carbon from Fruit Wastes

Fruit wastes occur when sorting and selecting are done during the fruit production processes. The development of fruits may produce two types of waste as the solid waste of peel/skin, seeds, stones, etc. and the liquid waste of juice and its wash waters. The various solid fruit wastes like orange peels, banana peels, grape seeds, pomegranate peels, palm shells, medlar seeds, etc. are utilized for the preparation of AC for pollutant removal from water (Guo and Lua 2000; Issabayeva et al. 2006). In recent years, the attention to palm shell has improved as it can be an exceptional source for the preparation of high-quality AC. A study also showed that the palm shell AC has elevated adsorption capacity to capturing Pb(II) ion compared with other types of AC (Daud and Ali 2004). Issabayeva et al. have focused on the preparation of column packed palm shell assisted AC for the continuous adsorption of Pb(II), and the adsorption capacities are found to be 90.2 mg/g at pH 5 (Issabayeva et al. 2008). Likewise, Choong et al. have synthesized the magnesium silicate-impregnated palm shell waste powdered AC for the removal of Pb(II) from water, and the adsorption capacity of 419.9 mg/g was observed (Choong et al. 2018).

Awwad et al. have prepared AC derived from date seeds (DS) via physical and chemical activation. The raw DS material was activated under pure steam with N2 gas, and the chemically activated DS was prepared by the addition of 10% calcium acetate. The prepared AC was studied for the removal of assorted metal ions like Co(II), Fe(III), Pb(II) and Zn(II) from water, and almost 95% removal percentage of all the toxic metals was observed. The high removal of the toxic metal ions can be explained through the chemical or physical activation as follows: (i) AC by steam pyrolysis process and (ii) AC by single-step steam pyrolysis at 700 °C with N2 activation. The adsorption capacities of Co(II), Fe(III), Pb(II) and Zn(II) were found to be 1317, 1555, 1261 and 1594 mg/g, respectively (Awwad et al. 2013) (Fig. 3.3).

An additional solid waste with a large potential for the synthesis of AC is medlar seed waste. Medlar (Mespilus germanica) is an apple-shaped fruit with a reddish-tinged colour which carries different sizes (diameter, 1.5–3 cm; weight, 10–80 g). Medlar has been used in the form of jam, marmalade and jellies which has been commercially observed by food industries. In addition, it has been applied for the treatment of diuretic, bladder and kidney stones (Gruz et al. 2011). Solgi et al. have focused on the characterization of novel AC from medlar seed for Cr(VI) removal. The obtained medlar seed (Mespilus germanica) was chemically activated using KOH, and the carbonization process occurred at different temperatures of 450, 550, 650 and 750 °C. The maximum adsorption capacity of Cr(VI) on AC obtained from medlar seed was observed as 200 mg/g (Solgi et al. 2017). Likewise, Silva et al. have prepared AC from Malpighia emarginata grinded seeds for the removal of Cd(II) and Cu(II) in aqueous solution. The adsorption capacities of Malpighia emarginata seeds were found to be 103 and 98 mg/g for Cd(II) and Cu(II), respectively (Silva et al. 2017).

Gupta and Gogate have investigated the application of ultrasound technique on the activated watermelon shell-based bioadsorbent for the adsorption of Cu(II) from aqueous solution. The observed watermelon shells were let to dry under the sunlight for 48 h. Further, the shells were heated in the hot air oven at 120 °C overnight. Then, the dried watermelon shells were then powdered and then sieved in order to get the uniform particles of size, and the sieved watermelon shell powder was then mixed with stock 0.1 M citric acid solution. Considering the significant effects of the sonochemical processes, the effect of ultrasonic power indulgence on the adsorption rate has also been investigated. In order to attain the intensified adsorption by the combination of ultrasound with AC has been studied. The result shows that the watermelon treated with calcium hydroxide and the watermelon treated with citric acid adsorbents were utilized for the removal of Cu(II) from water, and the adsorption capacities were found to be 31.25 and 27.02 mg/g, respectively (Gupta and Gogate 2015).

3.7.4 Activated Carbon from Vegetable Wastes

These waste materials mainly comprised of the various vegetable matters. These vegetable waste materials can be easily decomposed by microorganisms. Nowadays, a lot of vegetable wastes such as soybean hulls, pumpkin stem waste, putrescible vegetables, etc. have been utilized for the preparation of AC towards toxic metal removal from water. Generally, they are burnt in the air to attain the function of the rapid removal of soil and water pollution in the environment (Nahil and Williams 2010).

At present, the different types of vegetable waste materials have been utilized for the adsorption of various toxic metal ions from water. One of them is carrot residue (CR) which is readily available in nature, and their use as adsorbents seems appropriate. Nasernejad et al. have developed the comparison studies for the adsorption modelling of heavy metals like Cr(III), Cu(II) and Zn(II) from wastewater by CR. CR is composed of lignin and cellulose with the removal capacity to bind metal cations due to the available functional groups like carboxylic and phenolic groups (Dhiman et al. 2017). The attained CR was dried overnight at 60 °C, and the obtained AC was chemically modified for the use of adsorption process. The adsorption capacities of AC obtained from CR residue were found to be 32.74, 45.09 and 29.61 mg/g for Cu(II), Cr(III) and Zn(II), respectively (Nasernejad et al. 2005). The use of different chemically modified cassava waste biomass for the enhancement of the adsorption of metal ions such as Cd(II), Cu(II) and Zn(II) from aqueous solution was reported by Abia et al. Cassava as garri, foofoo and starch is considered as a fast food in Nigeria which generates the large amounts of wastes and which has been often creating the environmental trouble in the region. The cassava waste biomass was chemically modified by thiolation and applied for the adsorption studies, and it possesses the adsorption capacities of 0.94, 1.01 and 0.95 mg/g for Cd(II), Cu(II) and Zn(II) compared to the unmodified cassava waste biomass which possesses slightly lower adsorption capacities of 0.87, 0.89 and 0.92 mg/g for Cd (II), Cu (II) and Zn (II), respectively (Abia et al. 2003).

Marshall et al. have proposed the enhanced metal adsorption by soybean hulls modified with citric acid for Cu(II) removal. Soybean hulls have been modified with citric acid (CA) at 120 °C for 90 min. The result shows that CA-modified hulls possess the adsorption capacities of 2.44 mmole/g for Cu(II) adsorption which was much greater than the unmodified soybean hulls which hold the removal capacities of 0.39 mmole/g (Marshall et al. 1999). Similarly, Horsfall and Abia have developed cassava waste biomass (Manihot sculenta Cranz) for the adsorption of two divalent ions Cd(II) and Zn(II) under untreated and differentially acid-treated conditions. The Cd(II) and Zn(II) adsorption capacities were found to be 86.68 and 55.82 mg/g for untreated and 647.48 and 559.74 mg/g for acid-treated biomass, respectively (Horsfall and Abia 2003) (Fig. 3.4).

3.7.5 Activated Carbon from Plastic Wastes

Plastic waste is a waste that refers to a wide range of synthetic organic amorphous solid materials which derived from natural gas and oil. The numerous plastic waste materials such as polyethylene terephthalate bottles, rubber tyres, polystyrene tyres, etc. are converted into AC and utilized for heavy metal removal from water. The precursor, namely, polyethylene terephthalate (PET), from bottle waste has been utilized for the synthesis of AC by chemical activation with potassium hydroxide (KOH) and physical activation with steam under limited heating levels and atmospheric condition. Wang et al. have reported on the preparation of chelating fibres with waste PET fibres for the various heavy metal ion removal from water (Wang et al. 2012a, b). To extend the application of PET in the adsorption system, Mendoza-Carrasco et al. have synthesized the high-quality AC from PET bottle waste for Fe(III) removal, and PET-derived AC holds the adsorption capacity of 659 mg/g (Mendoza-Carrasco et al. 2016) (Fig. 3.5).

3.7.6 Activated Carbon from Electronic Wastes (e-Wastes)

Electronic waste or e-waste refers to discarded electronic or electrical devices. The sources of e-wastes are mobile phones, discarded computers, entertainment device electronics, office electronic equipment, refrigerators and television sets which are destined for resale, reuse, recycling, salvage or disposal , etc. A low-cost AC material derived from many e-wastes such as printed circuit boards and disposal of printed track boards has been utilized for heavy metal removal from water. In electronic industries, e-waste materials have become the most important problems raised by the public in the past few years. With more common information of the various electronic equipments, the product life has been reduced, and more outmoded products are becoming superseded, thus lifting the serious environmental trouble when disposed into the water system (Xiang et al. 2006).

The printed circuit boards (PCBs) are centre constituents in the electronic products. The most eco-friendly technologies presently utilized for PCB recycling split the PCBs into a metallic and non-metallic powder (Wong et al. 2007). Xu et al. have focused on the idea of recycling the e-waste material in order to develop the AC for the treatment of the various heavy metals especially in Cd(II)-mixed wastewater. The maximum uptake capacity of the newly derived PCB material for Cd(II) has reached 2.1 mmole/g. This value shows that this material can effectively remove Cd(II) from the effluents (Xu et al. 2014) (Fig. 3.6).

The huge disposal of printed track boards (PTBs) worldwide leads to the ecological threats for adequate solution. Mainly, the modified non-metallic fraction of this waste develops nano-AC material with the suitable functionalization. Hadi et al. have developed AC derived from PCB which acts as the attractive adsorbent material for capturing the toxic metals from effluents especially the removal of Cu(II), Pb(II) and Zn(II) in single-component solutions, and the adsorption capacities of 92.94, 112.17 and 64.10 mg/g were observed, respectively. Furthermore, the limited selectivity was attained in the binary solution of Pb(II) and Cu(II), whereas a complete selectivity in the Zn(II)-containing binary solution was demonstrated using AC generated from PTB (Hadi et al. 2014).

3.8 Development of Functionalized Activated Carbon for Heavy Metal Removal

Functionalization is the progress of adding fresh functions, properties or capabilities to the adsorbent by changing the surface nature of the adsorbents . It also plays a vital role in various fields such as textile engineering, material chemistry, biological engineering and nanotechnology. To enhance the adsorption capacities of AC towards heavy metal, the functionalization of various active functional groups has been introduced on AC. The functional groups such as -COOH, -OH, amine, thiol, etc., have been focused on the functionalization of AC derived from waste materials (Yao et al. 2016). The incorporation of these functional groups possibly enhances the number of active sites on AC surface which increases the interaction of toxic pollutants, thereby enhancing the adsorptive capacity. Recently, Lalhmunsiama et al. have focused on the simultaneous removal of Hg(II) using succinic anhydride-functionalized AC derived from areca nut waste, and the removal capacity was found to be 11.23 mg/g (Lalhmunsiama et al. 2017). The comparison of adsorption capacities of AC derived from various waste materials for the removal of heavy metal are shown in Table 3.3. The AC derived from various waste materials possesses the appreciable heavy metal removal capacity (Fig. 3.7).

3.9 Conclusions

This chapter discussed the activated carbon obtained from the different natural waste materials for the assorted toxic metal removal from drinking/wastewater:

-

A wide range of AC derived from various waste materials like vegetable, agricultural, fruit, electronic, plastic and biological wastes for heavy metal removal is presented in detail.

-

AC derived from waste materials possesses advantages like inexpensiveness, high microporosity, local availability and high surface area and selectivity towards heavy metal removal.

-

A comparison results in the adsorption capacity of AC derived from various waste materials was given in detail.

-

The development of AC is frequently reported by worldwide researchers. However, to control the influence of multisteps in the synthesis of AC for the adsorption studies should be focused in the near future.

-

Fabrication, optimization and application of AC which derived from the various waste materials are needed to concentrate at the industrial scale.

-

The significant features such as the preparation techniques, the modification of the surface properties, and the regeneration studies of AC should be improved in order to make AC material as a cost-effective one.

-

AC should be mixed with suitable binding materials which help to convert into usable shapes like membranes, beads, etc., for developing the heavy metal removal technology.

References

Abia AA, Horsfall M Jr, Didi O (2003) The use of chemically modified and unmodified cassava waste for the removal of Cd, Cu and Zn ions from aqueous solution. Bioresour Technol 90:345–348. https://doi.org/10.1016/S0960-8524(03)00145-7

Abioye AM, Ani FN (2015) Recent development in the production of activated carbon electrodes from agricultural waste biomass for supercapacitors: a review. Renew Sust Energ Rev 52:1282–1293. https://doi.org/10.1016/j.rser.2015.07.129

Alloway BJ (2013) Sources of heavy metals and metalloids in soils. Environ Pollut 22:11–50. https://doi.org/10.1007/978-94-007-4470-7-2

Al-Othman ZA, Inamuddin, Naushad M (2011) Determination of ion-exchange kinetic parameters for the poly-o-methoxyaniline Zr(IV) molybdate composite cation-exchanger. Chem Eng J 166:639–645. https://doi.org/10.1016/j.cej.2010.11.036

Alqadami AA, Naushad M, Alothman ZA, Ghfar AA (2017) Novel metal-organic framework (MOF) based composite material for the sequestration of U(VI) and Th(IV) metal ions from aqueous environment. ACS Appl Mater Interfaces 9:36026. https://doi.org/10.1021/acsami.7b10768

Alslaibi TM, Abustan I, Ahmad MA, Foul AA (2013) Cadmium removal from aqueous solution using microwaved olive stone activated carbon. J Environ Chem Eng 1:589–599. https://doi.org/10.1016/j.jece.2013.06.028

Aswin Kumar I, Viswanathan N (2018) Development and reuse of amine-grafted chitosan hybrid beads in the retention of nitrate and phosphate. J Chem Eng Data 63(1):147–158. https://doi.org/10.1021/acs.jced.7b00751

Awual MR, Hasan MM, Eldesoky GE et al (2016) Facile mercury detection and removal from aqueous media involving ligand impregnated conjugate nanomaterials. Chem Eng J 290:243–251. https://doi.org/10.1016/j.cej.2016.01.038

Awwad NS, El-Zahhar AA, Fouda AM, Ibrahium HA (2013) Removal of heavy metal ions from ground and surface water samples using carbons derived from date pits. J Environ Chem Eng 1(3):416–423. https://doi.org/10.1016/j.jece.2013.06.006

Ayranci E, Duman O (2009) In-situ UV-visible spectroscopic study on the adsorption of some dyes onto activated carbon cloth. Sep Sci Technol 44(15):3735–3752. https://doi.org/10.1080/01496390903182891

Azimi A, Azari A, Rezakazemi M, Ansarpour M (2017) Removal of heavy metals from industrial wastewaters: a review. ChemBioEng Rev 4(1):37–59. https://doi.org/10.1002/cben.201600010

Babel S, Kurniawan TA (2003) Low-cost adsorbents for heavy metals uptake from contaminated water: a review. J Hazard Mater 97(1–3):219–243. https://doi.org/10.1016/S0304-3894(02)00263-7

Brown P, Jefcoat IA, Parrish D, Gill S, Graham E (2000) Evaluation of the adsorptive capacity of peanut hull pellets for heavy metals in solution. Adv Environ Res 4(1):19–29. https://doi.org/10.1016/S1093-0191(00)00004-6

Bushra R, Naushad M, Adnan R et al (2015) Polyaniline supported nanocomposite cation exchanger: synthesis, characterization and applications for the efficient removal of Pb2+ ion from aqueous medium. J Ind Eng Chem 21:1112–1118. https://doi.org/10.1016/j.jiec.2014.05.022

Carolin CF, Kumar PS, Saravanan A et al (2017) Efficient techniques for the removal of toxic heavy metals from aquatic environment: a review. J Environ Chem Eng 5(3):2782–2799. https://doi.org/10.1016/j.jece.2017.05.029

Chand R, Watari T, Inoue K, Torikai T, Yada M (2009) Evaluation of wheat straw and barley straw carbon for Cr(VI) adsorption. Sep Purif Technol 65:331–336. https://doi.org/10.1016/j.seppur.2008.11.002

Choong CE, Ibrahim S, Yoon Y, Jang M (2018) Removal of lead and bisphenol A using magnesium silicate impregnated palm-shell waste powdered activated carbon: comparative studies on single and binary pollutant adsorption. Ecotoxicol Environ Saf 148:142–151. https://doi.org/10.1016/j.ecoenv.2017.10.025

Chun-Shui Z, Li-Ping W, Wen-bin C (2009) Removal of Cu(II) from aqueous solution by agricultural by-product: peanut hull. J Hazard Mater 168:739–746. https://doi.org/10.1016/j.jhazmat.2009.02.085

Daud WMA, Ali WS (2004) Comparison on pore development of activated carbon produced from palm shell and coconut shell. Bioresour Technol 93(1):63–69. https://doi.org/10.1016/j.biortech.2003.09.015

Demirbas E (2008) Heavy metal adsorption onto agro-based waste materials: a review. J Hazard Mater 157(2–3):220–229. https://doi.org/10.1016/j.jhazmat.2008.01.024

Dhiman P, Naushad M, Batoo KM et al (2017) Nano FexZn1−xO as a tuneable and efficient photocatalyst for solar powered degradation of bisphenol A from aqueous environment. J Clean Prod 165:1542. https://doi.org/10.1016/j.jclepro.2017.07.245

Dias JM, Alvim-Ferraz MCM, Almeida MF, Rivera-Utrilla J, Sanchez-Polo M (2007) Waste materials for activated carbon preparation and its use in aqueous-phase treatment: a review. J Environ Manag 85(4):833–846. https://doi.org/10.1016/j.jenvman.2007.07.031

Duruibe JO, Ogwuegbu MOC, Egwurugwu JN (2007) Heavy metal pollution and human biotoxic effects. Int J Phys Sci 2(5):112–118. doi: 59CA35213127

Fatima Salgado M, Abioye AM, Junoh MM, Santos JAP, Ani FN (2018) Preparation of activated carbon from babassu endocarpunder microwave radiation by physical activation. IOP Conf Ser Earth Environ Sci 105:012116. https://doi.org/10.1088/1755-1315/105/1/012116

Forgacs E, Cserhati T, Oros G (2004) Removal of synthetic dyes from wastewaters: a review. Environ Int 30(7):953–971. https://doi.org/10.1016/j.envint.2004.02.001

Gil RR, Ruiz B, Lozano MS, Martin MJ, Fuente E (2014) VOCs removal by adsorption onto activated carbons from biocollagenic wastes of vegetable tanning. Chem Eng J 245:80–88. https://doi.org/10.1016/j.cej.2014.02.012

Godt J, Scheidi F, Grosse-Siestrup C, Esche V, Brandenburg P, Reich A, Groneberg DA (2006) The toxicity of cadmium and resulting hazards for human health. J Occup Med Toxicol 1:22. https://doi.org/10.1186/1745-6673-1-22

Gopalakannan V, Viswanathan N (2015) Development of nano-hydroxyapatite embedded gelatin biocomposite for effective chromium (VI) removal. Ind Eng Chem Res 54(50):12561–12569. https://doi.org/10.1021/acs.iecr.5b01224

Gopalakannan V, Periyasamy S, Viswanathan N (2018) Fabrication of magnetic particles reinforced nano-hydroxyapatite/gelatin composite for selective Cr(VI) removal from water. Environ Sci Water Res Technol 4(6):783–794. https://doi.org/10.1039/C8EW00027A

Gruz J, Ayaz FA, Torun H, Strnad M (2011) Phenolic acid content and radical scavenging activity of extracts from medlar (Mespilus germanica L) fruit at different stages of ripening. Food Chem 124(1):271–277. https://doi.org/10.1016/j.foodchem.2010.06.030

Gunatilake SK (2015) Methods of removing heavy metals from industrial wastewater. J Multidiscip Eng Sci Technol Methods 1(1):12–18. doi: JMESSP13420004

Guo J, Lua AC (2000) Preparation and characterization of adsorbents from oil palm fruit solid wastes. J Oil Palm Res 12(1):64–70

Gupta H, Gogate PR (2015) Intensified removal of copper from waste water using activated watermelon based biosorbent in the presence of ultrasound. Ultrason Sonochem 30:113–122. https://doi.org/10.1016/j.ultsonch.2015.11.016

Hadi P, Barford J, McKay G (2014) Selective toxic metal uptake using an e-waste based novel sorbent-single, binary and ternary systems. J Environ Chem Eng 2:332–339. https://doi.org/10.1016/j.jece.2014.01.004

Hanafiah MAK, Ibrahim SC, Yahya MZA (2006) Equilibrium adsorption study of lead ions onto sodium hydroxide modified Lalang (Imperata cylindrica) leaf powder. J Appl Sci Res 2:1169–1174

Hegazi HA (2013) Removal of heavy metals from wastewater using agricultural and industrial wastes as adsorbents. HBRC J 9(3):276–282. https://doi.org/10.1016/j.hbrcj.2013.08.004

Horsfall M Jr, Abia AA (2003) Sorption of cadmium(II) and zinc(II) ions from aqueous solutions by cassava waste biomass (Manihot sculenta Cranz). Water Res 37:4913–4923. https://doi.org/10.1016/j.watres.2003.08.020

Hui D, Le Y, Tao G, Dai J (2009) Preparation and characterization of activated carbon from cotton stalk by microwave assisted chemical activation-application in methylene blue adsorption from aqueous solution. J Hazard Mater 166(2–3):1514–1521. https://doi.org/10.1016/j.jhazmat.2008.12.080

Issabayeva G, Aroua MK, Sulaiman NMN (2006) Removal of lead from aqueous solutions on palm shell activated carbon. Bioresour Technol 97(18):2350–2355. https://doi.org/10.1016/j.biortech.2005.10.023

Issabayeva G, Aroua MK, Sulaiman NM (2008) Continuous adsorption of lead ions in a column packed with palm shell activated carbon. J Hazard Mater 155(1–2):109–113. https://doi.org/10.1016/j.jhazmat.2007.11.036

Junior OK, Gurgel LVA, de Melo JCP, Botaro VR, Melo TMS, de Freitas Gil RP, Gil LF (2006) Adsorption of heavy metal ion from aqueous single metal solution by chemically modified sugarcane bagasse. Bioresour Technol 98:1291–1297. https://doi.org/10.1016/j.biortech.2006.05.013

Kadirvelu K, Kavipriya M, Karthika C, Radhika M, Vennilamani N, Pattabhi S (2003) Utilization of various agricultural wastes for activated carbon preparation and application for the removal of dyes and metal ions from aqueous solutions. Bioresour Technol 87(1):129–132. https://doi.org/10.1016/S0960-8524(02)00201-8

Kenawy E-R, Ghfar AA, Naushad M et al (2017) Efficient removal of Co(II) metal ion from aqueous solution using cost-effective oxidized activated carbon: kinetic and isotherm studies. Desalin Water Treat 70:220–226. https://doi.org/10.5004/dwt.2017.20534

Kousalya GN, Gandhi MR, Viswanathan N (2010) Preparation and metal uptake studies of modified forms of chitin. Int J Biol Macromol 47(5):583–589. https://doi.org/10.1016/j.ijbiomac.2010.07.014

Kumar U, Gaikwad V, Sahajwalla V (2018) Transformation of waste toner to iron using E-waste plastics as a carbon resource. J Clean Prod 192:244–251. https://doi.org/10.1016/j.jclepro.2018.05.010

Lalhmunsiama LSM, Choi SS, Tiwari D (2017) Simultaneous removal of Hg(II) and phenol using functionalized activated carbon derived from Areca nut waste. Metals 7:1–15. https://doi.org/10.3390/met7070248

Leyva-Ramos R, Bernal-Jacome LA, Acosta-Rodriguez I (2005) Adsorption of cadmium(II) from aqueous solution on natural and oxidized corncob. Sep Purif Technol 45:41–49. https://doi.org/10.1016/j.seppur.2005.02.005

Limousy L, Ghouma I, Ouederni A, Jeguirim M (2017) Amoxicillin removal from aqueous solution using activated carbon by chemical activation of olive stone. Environ Sci Pollut Res 24(11):9993–10004. https://doi.org/10.1007/s11356-016-7404-8

Lopez-Anton MA, Gil RR, Fuente E, Diaz-Somoano M, Martinez-Tarazona MR, Ruiz B (2015) Activated carbons from biocollagenic wastes of the leather industry for mercury capture in oxy-combustion. Fuel 142:227–234. https://doi.org/10.1016/j.fuel.2014.11.018

Luo XS, Xue Y, Wang YL, Cang L, Xu B, Ding J (2015) Source identification and apportionment of heavy metals in urban soil profiles. Chemosphere 127:152–157. https://doi.org/10.1016/j.chemosphere.2015.01.048

Malik DS, Jain CK, Yadav AK (2017) Removal of heavy metals from emerging cellulosic low-cost adsorbents: a review. Appl Water Sci 7(5):2113–2136. https://doi.org/10.1007/s13201-016-040-8

Marshall WE, Wartelle LH, Boler DE, Johns MM, Toles TA (1999) Enhanced metal adsorption by soybean hulls modified with citric acid. Bioresour Technol 69:263–268. https://doi.org/10.1016/S0960-8524(98)00185-0

Mendoza-Carrasco R, Cuerda-Correa EM, Alexandre-Franco MF, Fernandez-Gonzalez C, Gomez-Serrano V (2016) Preparation of high quality activated carbon from polyethylene terephthalate (PET) bottle waste its use in the removal of pollutants in aqueous solution. J Environ Manag 181:522–535. https://doi.org/10.1016/j.jenvman.2016.06.070

Mohan D, Singh KP, Singh VK (2005) Removal of hexavalent chromium from aqueous solution using low-cost activated carbons derived from agricultural waste materials and activated carbon fabric cloth. Ind Eng Chem Res 44:1027–1042. https://doi.org/10.1021/ie0400898

Mohan D, Singh KP, Singh VK (2006) Trivalent chromium removal from wastewater using low cost activated carbon derived from agricultural waste material and activated carbon fabric cloth. J Hazard Mater 135(1–3):280–295. https://doi.org/10.1016/j.jhazmat.2005.11.075

Nag S, Mondal A, Bar N, Das SK (2017) Biosorption of chromium (VI) from aqueous solutions and ANN modeling. Environ Sci Pollut Res 24(23):18817–18835. https://doi.org/10.1007/s11356-017-9325-6

Nag S, Mondal A, Roy DN, Bar N, Das SK (2018) Sustainable bioremediation of Cd(II) from aqueous solution using natural waste materials: kinetics, equilibrium, thermodynamics, toxicity studies and GA-ANN hybrid modeling. Environ Technol Innov 11:83–104. https://doi.org/10.1016/j.eti.2018.04.009

Nahil MA, Williams PT (2010) Activated carbons from acrylic textile waste. J Anal Appl Pyrolysis 89:51–59. https://doi.org/10.1016/j.jaap.2010.05.005

Naiya TK, Chowdhury P, Bhattacharya AK, Das SK (2009) Saw dust and neem bark as low-cost natural biosorbent for adsorptive removal of Zn(II) and Cd(II) ions from aqueous solutions. Chem Eng J 148:68–79. https://doi.org/10.1016/j.cej.2008.08.002

Nasernejad B, Zadeh TE, Pour BB, Bygi ME, Zamani A (2005) Comparison for biosorption modeling of heavy metals (Cr(III), Cu(II), Zn(II‑ adsorption from wastewater by carrot residues. Process Biochem 40:1319–1322. https://doi.org/10.1016/j.procbio.2004.06.010

Naushad M, ALOthman ZA, Awual MR et al (2015) Adsorption kinetics, isotherms, and thermodynamic studies for the adsorption of Pb2+ and Hg2+ metal ions from aqueous medium using Ti(IV) iodovanadate cation exchanger. Ionics (Kiel) 21:2237–2245. https://doi.org/10.1007/s11581-015-1401-7

Pandi K, Periyasamy S, Viswanathan N (2017) Remediation of fluoride from drinking water using magnetic iron oxide coated hydrotalcite/chitosan composite. Int J Biol Macromol 104:1569–1577. https://doi.org/10.1016/j.ijbiomac.2017.02.037

Parlayici S, Pehlivan E (2017) Removal of metals by Fe3O4 loaded activated carbon prepared from plum stone (Prunus nigra): kinetics and modelling study. Powder Technol 317:23–30. https://doi.org/10.1016/j.powtec.2017.04.021

Periyasamy S, Gopalakannan V, Viswanathan N (2017) Fabrication of magnetic particles imprinted cellulose based biocomposites for chromium(VI) removal. Carbohydr Polym 174:352–359. https://doi.org/10.1016/j.carbpol.2017.06.029

Periyasamy S, Gopalakannan V, Viswanathan N (2018) Enhanced chromium sorption and quick separation of magnetic hydrotalcite anchored biopolymeric composites using the hydrothermal method. J Chem Eng Data 63(5):1286–1299. https://doi.org/10.1021/acs.jced.7b00906

Rehman H, Shakirullah M, Ahmad I, Shah S, Hamedullah (2006) Sorption studies of nickel ions onto sawdust of Dalbergia Sissoo. J Chin Chem Soc 53:1045–1052. https://doi.org/10.1002/jccs.200600139

Sharma G, Naushad M, Kumar A et al (2017) Efficient removal of coomassie brilliant blue R-250 dye using starch/poly(alginic acid-cl-acrylamide) nanohydrogel. Process Saf Environ Prot 109:301–310. https://doi.org/10.1016/j.psep.2017.04.011

Shehzad A, Bashir MJK, Sethupathi S, Lim J-W (2015) An overview of heavily polluted landfill leachate treatment using food waste as an alternative and renewable source of activated carbon. Process Saf Environ Prot 98:309–318. https://doi.org/10.1016/j.psep.2015.09.005

Shrestha RM, Varga I, Bajtai J, Varga M (2013) Design of surface functionalization of waste material originated charcoals by an optimized chemical carbonization for the purpose of heavy metal removal from industrial waste waters. Microchem J 108:224–232. https://doi.org/10.1016/j.microc.2012.11.002

Silva ACP, Jorgetto AO, Wondracek MHP, Galera RM, Schneider JF, Saeki MJ, Pedrosa VA, Zara LF, Castro GR (2017) Properties, characteristics and application of grinded Malpighia emargiata seeds in the removal of toxic metals from water. Ground Water Sustain Dev 6:50–56. https://doi.org/10.1016/j.gsd.2017.10.006

Skodras G, Diamantopoulou I, Zabaniotou A, Stavropoulos G, Sakellaropoulos GP (2007) Enhanced mercury adsorption in activated carbons from biomass materials and waste tires. Fuel Sci Technol 88(8):749–758. https://doi.org/10.1016/j.fuproc.2007.03.008

Solgi M, Najib T, Ahmadnejad S, Nasernejad B (2017) Synthesis and characterization of novel activated carbon from Medlar seed for chromium removal: experimental analysis and modeling with artificial neural network and support vector regression. Resour Eff Technol 3(3):236–248. https://doi.org/10.1016/j.reffit.2017.08.003

Staples CA, Dome PB, Klecka GM, Oblock ST, Harris LR (2011) A review of the environmental fate, effects, and exposures of bisphenol A. Chemosphere 36(10):2149–2173. https://doi.org/10.1016/S0045-6535(97)10133-3

Tan I, Ahmad A, Hameed B (2008) Optimization of preparation conditions for activated carbons from coconut husk using response surface methodology. Chem Eng J 137:462–470. https://doi.org/10.1016/j.cej.2007.04.031

Tran HN, You SJ, Chao HP (2017) Fast and efficient adsorption of methylene green 5 on activated carbon prepared from new chemical activation method. J Environ Manag 188:1–14. https://doi.org/10.1016/j.jenvman.2016.12.003

Vossen P (2007) Olive oil: history, production, and characteristics of the world’s classic oils. Hortic Sci 42(5):1093–1100

Wang Y, Wang XJ, Liu M, Wang X, Wu Z, Yang LZ, Xia SQ, Zhao JF (2012a) Cr(VI) removal from water using cobalt-coated bamboo charcoal prepared with microwave heating. Ind Crop Prod 39:81–88. https://doi.org/10.1016/j.indcrop.2012.02.015

Wang J, Xu L, Cheng C, Meng Y, Li A (2012b) Preparation of new chelating fiber with waste PET as adsorbent for fast removal of Cu2þ and Ni2þ from water: kinetic and equilibrium adsorption studies. Chem Eng J 193–194:31–38. https://doi.org/10.1016/j.cej.2012.03.070

Wen T, Wang J, Yu S, Chen Z, Hayat T, Wang X (2017) Magnetic porous carbonaceous material produced from tea waste for efficient removal of As(V), Cr(VI), humic acid, and dyes. ACS Sustain Chem Eng 5(5):4371–4380. https://doi.org/10.1021/acssuschemeng.7b00418

Wong MH, Wu SC, Deng WJ, Yu XZ, Luo Q, Leung AO, Wong CS, Luksemburg WJ, Wong AS (2007) Export of toxic chemicals – a review of the case of uncontrolled electronic-waste recycling. Environ Pollut 149:131–140. https://doi.org/10.1016/j.envpol.2007.01.044

Xiang D, Mou P, Wang J, Duan G, Zhang HC (2006) Printed circuit board recycling process and its environmental impact assessment. Int J Adv Manuf Technol 34:1030–1036. https://doi.org/10.1007/s00170-006-0656-6

Xu M, Hadi P, Chen G, McKay G (2014) Removal of cadmium ions from wastewater using innovative electronic waste-derived material. J Hazard Mater 273:118–123. https://doi.org/10.1016/j.jhazmat.2014.03.037

Yao S, Zhang J, Shen D, Xiao R, Gu S, Zhao M, Liang J (2016) Removal of Pb(II) from water by the activated carbon modified by nitric acid under microwave heating. J Colloid Interface Sci 463:118–127. https://doi.org/10.1016/j.jcis.2015.10.047

Zhu Y, Zhang H, Zeng H, Liang M, Lu R (2012) Adsorption of chromium (VI) from aqueous solution by the iron (III)-impregnated sorbent prepared from sugarcane bagasse. Int J Environ Sci Technol 9:463–472

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Periyasamy, S., Kumar, I.A., Viswanathan, N. (2020). Activated Carbon from Different Waste Materials for the Removal of Toxic Metals. In: Naushad, M., Lichtfouse, E. (eds) Green Materials for Wastewater Treatment. Environmental Chemistry for a Sustainable World, vol 38. Springer, Cham. https://doi.org/10.1007/978-3-030-17724-9_3

Download citation

DOI: https://doi.org/10.1007/978-3-030-17724-9_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-17723-2

Online ISBN: 978-3-030-17724-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)