Abstract

Agricultural waste (ACW) and agro-industrial waste (AIW) are been produced in big amounts worldwide. Approximately 147.2 million metric tonnes of fiber sources are found worldwide, and around 89 million tonnes of biomass (from the agricultural production, postharvest, and processing stages) are wasted annually. In Europe, the disposal of 1 tonne of solid waste or 1 m3 of effluent costs $28–60 dollars. Regarding some estimations, about 815 million people of the 7.3 billion people in the world were suffering from chronic undernourishment. This is one of the reasons why the AIW must be used in the most efficient way and be valorized through its healthy and functional potential. Valorization of AIW is currently focused on composting, livestock feeding, and other products with low-added value. Regarding that, this chapter is aimed to remark cases where the valorization is going forward, taking advantage from scientific studies to create new products with added value from AIW. The present chapter reviews different valorization strategies of AIW and the use of technologies to extract bioactive compounds and elaborate added value products with health benefits. Currently, the agro-industry is not only valorized by their productivity but also because of their relationship with the environment, which made them reduce the waste volume and avoid the waste dispose in landfills.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Agro-industrial waste

- Bioactive compounds

- Biorefinery

- Techno-economics

- Agro-industrial waste valorization

1 Current Context in Both Agricultural Waste (ACW) and Agro-Industrial Waste (AIW)

As definition, agricultural waste (ACW) comes from the agricultural phase of the cultivation of certain species, while agro-industrial waste (AIW) results from the industrial processing of biomass (Portugal-Pereira et al. 2015). This is the base to quantify and identify the ways to face the problem. In the European Union, taking into account both ACW and AIW, around 89 million tonnes of biomass (from the agricultural production, postharvest, and processing stages) are wasted annually (Stenmarck et al. 2016), and this value is expected to increase by 40% in 2020. However, this chapter is mainly focused in postharvest and processing stages, excluding the end of the food supply chain (retail and final consumption), which relates to retailers and consumers behavior.

If we analyzed just the AIW, this causes a serious disposal problem. For example, the juice industries produced a huge amount of waste as peels, the coffee industry produced coffee pulp as a waste, and cereal industries produced husks (Sadh et al. 2018). All over the world approximately 147.2 million metric tonnes of fiber sources are found, whereas 709.2 and 673.3 million metric tonnes of wheat straw residues and rice straws were estimated, respectively, in the 1990s (Belewu and Babalola 2009).

Specifically related to fruit processing industry, the proportion of AIW is significant, for example, depending on the location and method of harvest, the AIW is 30–50% for mango, 20% for banana, 40–50% for pomegranate, and 30–50% for citrus (Laufenberg et al. 2003; Parfitt et al. 2010). These percentages are clear and represent a relative number of wastes. However, if we think in terms of the scale of companies, the approaches could be different. For example, in micro and small-scale companies, processing waste is considered to be of negligible value compared to the processed material. On the contrary, for big companies the problem of waste is a priority, because they are paying to dispose their vegetable and food wastes in landfills. For example, in the case of an specific AIW (fruit processing wastes) in Europe, the disposal of 1 tonne of solid waste or 1 m3 of effluent costs $28–60 dollars which includes a landfill tax of $10 (Gendebien et al. 2001). On the other hand, in developing countries such as India, the average transportation cost was found to be $11–15 dollars per tonne per trip (FICCI 2010) which may indicate $300 million dollars for total landfilling cost. If we add the environmental impact and the concept of corporate social responsibility, it is necessary to take into account that landfilling is also associated with risks of greenhouse gas emissions (Roggeveen 2010). For example, global food processing waste-related greenhouse gas emission was found to be the third highest contributor after total emissions for China and the USA.

On the other hand, the United Nations Food and Agriculture Organization estimates that about 815 million people of the 7.3 billion people in the world were suffering from chronic undernourishment in 2016 (FAO 2017). This is the reason why the AIW and ACW must be used in the most efficient way and be valorized through its healthy and functional potential. Regarding that, in developing countries the majority of the fruit and vegetable processing information was found to be fragmented and insufficient, focusing on the execution of projects about biogas or compost production to obtain biofertilizer, which unfortunately does not take into account the complete potential of AIW. On the contrary, in developed countries, the fruit and vegetable processing waste was found to be fifth highest contributor (8% of total food waste) to overall food waste (Fava et al. 2015), allowing carried out studies focused on AIW recovery (Pfaltzgraff et al. 2013).

Finally, a key factor to recognize the opportunities of AIW and its valorization or added value is to identify the main sources or industries of each country or region. In the case of Chile, for example, AIW are generated in companies that produce fruit pulps, avocado oil, ready-to-eat salads, ready-to-eat meals, canned fruit, canned vegetables, and fruit juice, among others. Regarding this AIW, it is important to know which types of bioactive compounds are able to be extracted from them and how much is their value. This is also a key factor to take into account when a company must decide to invest in a new process or a new product. Table 1 shows some bioactive compounds found in vegetable sources from AIW.

The focus is clear; however, the way to achieve the aforementioned goals is not simple. Some modifications are needed to stabilize the AIW before to be processed. Some researchers are investigating both aerobic and anaerobic digestions as a tool to stabilize the AIW (Fernandez-Bayo et al. 2018). On the other hand, if the goal is the functional compound from AIW, the stabilization must play the role of decreasing the biochemical reactions into the AIW and at the same time keep the benefits of the bioactive compounds. Some studies of AIW drying to recover bioactive compounds are focused in technologies as spray drying, freeze drying, and supercritical CO2 drying (Santos-Rezende et al. 2018; Plazzotta et al. 2018). The cost of the abovementioned technologies is relatively high; however, conventional drying or drying using equipment like roller drum driers could be a most cost-efficient alternative to stabilize AIW in order to obtain its bioactive compounds as a potential added value.

2 Valorization Approaches of AIW

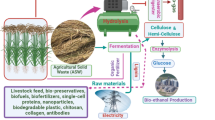

Valorization of AIW is currently focused on composting, livestock feeding, and other products with low-added value, as shown in Table 1. There are many ways to decrease the amount of waste generated in this industry, some of them are reuse and recycle. However, in general both of them are options to valorize the residues into the same companies. Regarding that, this section is aimed to remark cases where the valorization is going forward, taking advantage from scientific studies to create new products with added value from AIW.

Some of the alternatives to valorize the AIW are the reuse and recycle. Reuse indicates the use of waste materials for other purposes without or with minor modification of their properties (Manzocco et al. 2016). Direct reuse of AIW for soil amendment has been investigated by Clemente et al. (2015). However, it is difficult to put into practice due to the high biological instability of waste (Ajila et al. 2012). On the other hand, recycle is a strategy based on the recovery of waste materials after a major modification of their characteristics (Williams and Anderson 2006), which offers more possibilities than its reuse. Recycle strategies can be divided into strategies in which the whole waste mass is recycled and strategies in which specific compounds are extracted. Hence, the valorization on this chapter will be focused on the recycle strategies to extract specific bioactive compounds from AIW.

2.1 Valorization from the Process

The AIW contribution related with fruit and vegetable processing is more than 0.5 billion tonnes worldwide (Banerjee et al. 2017). The potential of those AIW in terms of bioactive compounds, antioxidant activity, and some other micronutrients makes this feedstock an important source of detailed studies. Some examples are the study of resveratrol from grape seeds and peels from wine industry (Fernández-Mar et al. 2012) and the valorization of pomace fractions from tomato paste to extract lycopene (Allison and Simmons 2017).

In the case of lycopene extraction, there are many factors to be considered: drying method of the pomace, tomato varieties, and the characteristics of the cultivars, among others. In Table 2, the influence of different extraction methods in maximum lycopene recovery is presented.

Despite the abovementioned and the technologies used at laboratory level, the commercial technology to produce lycopene extract is solvent extraction using a mixture of ethanol and water. The commercial price of lycopene is 80–90 US$/kg, the commercial format is a red microencapsulated powder with 10% of lycopene, and the final powder is oil soluble.Footnote 1

The case of grape pomace valorization has been very important in the recent years because of the growing of wine industry. Since grape pomace can be regarded as an excellent and affordable source of polyphenolic compounds, some researchers have been studying technologies and strategies to extract the antioxidants from that source (Tournour et al. 2015). Figure 1 shows the antioxidant activity (ORAC value) extracted from grape pomace from different cultivars of grapes in Portugal.

Extraction of antioxidant activity from grape pomace from different grape cultivars: TR Tinta Roriz; TF Touriga Franca; TNac Touriga Nacional; Mix mix red grape pomace. Gray columns represent the ethanol/water extracts (80:20 v/v); and black columns represent the aqueous suspension (Tournour et al. 2015). ORAC (oxygen radical absorbance capacity) represents the value of antioxidant activity

Another example of valorization is the case of producing succinic acid from natural resources (Dessie et al. 2018), which use AIW to carry out a solid-state fermentation. The succinic acid produced represents an added value product, which could be used in food, agricultural, and pharmaceutical industries. Other studies focused on the AIW valorization to produce succinic acid, explore the characteristics of the biomass feedstock and evaluate if mixed food waste is especially appealing as it represents less resource competition than more homogenous food waste fractions (Rex et al. 2017).

The AIW could be also a by-product from the process. For instance, the defatted soybean meal from the soybean oil industry could be used to obtain isolated soy protein. The high amount of protein of defatted soybean meal is interesting for the current market taking into account the food trends to plant-based diet. The protein content of defatted soybean meal is 45.7% w/w. There are several types of products derived from isolated soybean protein: dairy-based products including infant formula, beverages including liquid soy milk and fruit drinks, soups and sauces, energy bars, meat analogs including vegetarian food products, breads and pastries, breakfast cereals and other nutritional food products, and protein drink for muscle building and weight-gaining purposes (Lai et al. 2017). On the other hand, there is another type of applications of added value products from AIW. For instance, in the last few years, there is a growing interest to encompass from material as bioabsorbent (Sud et al. 2008) to rhizobial inoculant production (Ben Rebah et al. 2007).

Also, there are some bioactive compounds that are demanded for the market, and they could be included in AIW, for example, pectin, dietary fiber, polyinsaturated lipids, essential oils, flavonoids, and peptides, among others (Banerjee et al. 2017). Also structuring agents, mainly referring to colloidal polymers with interesting gelling or viscosant properties, can also be selectively extracted from AIW (McCann et al. 2011). Some recent studies relevant to bioactive extraction (e.g., carotenoids, essential oils, polyphenols, anthocyanins) from AIW using novel technologies include the use of ultrasounds, supercritical carbon dioxide, microwaves, and pulsed electric fields (Amiri-Rigi et al. 2016; Jacotet-Navarro et al. 2015; Rabelo et al. 2016; Zhou et al. 2015). For these reasons, extraction of specific compounds from AIW could be an affordable, sustainable, and profitable strategy for industries (Galanakis 2012; Laufenberg et al. 2003).

On the other hand, before to extract bioactive compounds or structuring agents from AIW, the strategy to stabilize them is drying. Flours can be obtained from drying processes, and they can be used as an ingredient for the formulation of products rich in functional compounds such as polyphenols and fiber (Ferreira et al. 2015). The main advantage of this recycle strategy is that valuable products such as adsorbents and functional flours are obtained from low-cost raw materials. However, the main issue is the high cost required for AIW drying, due to the high water content. As a consequence, the production of AIW flour is affordable only if high value-added ingredients and products are developed (Ratti 2001). To have an estimation of the cost to dry AIW, Karam et al. (2016) have stablished the energy consumption of different drying technologies, for example, diseccant drying (6 KW/kg of AIW), freeze drying (15–20 KW/kg of AIW), and vaccum drying (5 KW/kg of AIW).

Another example of valorization is rice bran , which was previously being considered as an AIW, as the rice kernel (white rice) is an important product where the major income from rice comes from this part. Rice germ and bran are usually being considered as by-products, until researchers found that rice bran oil has good composition of monounsaturated and polyunsaturated fatty acids which turns to be health beneficial to humans (Kochhar and Gunstone 2002). Rice bran, a part of the rice kernel that contains pericarp, aleurone, and subaleurone fractions, is a by-product of rice milling. It is estimated that the world annual production of rice bran amounts to 76 million tonnes (Chiou et al. 2013). Rice bran oil has been commercialized now in India, the USA, Thailand, and many more. The benefits of rice bran oil have been discussed by many researchers, which have been summarized by Friedman (2013): anti-allergic activities, anti-cholesterol activities, anti-diabetic activities, producing liquid-solid or semisolid form of product from rice bran oil (e.g., shortening or spreads), and regulation of the immune system. These benefits are related to rice bran composition in terms of bioactive compounds, which is summarized in Table 3.

2.2 Valorization from the Artisanal Fishery to Food Industry

From a social point of view, fisheries and aquaculture industry provide employment to a major part of the population in several coastal provinces of many countries. This activity is physically demanding and in many cases is not well remunerated in developing countries. On the other hand, a big amount of waste is obtained from the cleaning process of fishery products, which could be used for other food applications. Hence, valorization of the underutilized and invasive species along with fishery by-products and wastes generated from these industries can enhance the industry’s value chain, which can improve the profitability of the products. Also, valorization and production of various high-value pharmaceuticals/nutraceuticals (marine oils, omega-3 fatty acids, proteins, amino acids, enzymes, chitin, chitosan, and astaxanthin) from these resources can maximize the economic viability of the industry while addressing issues of waste management and environmental sustainability. Currently, polyunsaturated fatty acids mainly omega-3 fatty acids are obtained from marine fishes with high fat content. Specifically, fish oil derived from blue fish is rich of both eicosapentaenoic acid (EPA, C20:5n-3) and docosahexaenoic acid (DHA, C22:6n-3) (Ciriminna et al. 2017). High demand has motivated researchers to pursue new sources of these fatty acids, improve existing extraction methods, and develop more efficient methods for mass production and commercialization (Dave and Routray 2018).

The situation of valorizing residues in artisanal fisheries also can reach other applications. For instance, the production of seafood generates great amounts of seashells. Regarding that and in order to reduce the dependency on virgin materials for construction, efforts have been made to incorporate by-products and wastes from different industries as alternatives in concrete. Hence, an opportunity has been visualized from the fishery industry. Seashell waste , such as oyster shells, mussel shells, and scallop shells, among others, is available in huge quantities in certain regions and is usually dumped or landfilled without any reuse value. Over seven million tonnes of mollusk discards are produced every year worldwide, being mainly shells, which can be reused due to their high content of calcium carbonate (approximately 95%).Footnote 2 For example, in Europe, France has an important fishing and shellfish farming industry that produces nearly 200,000 tonnes of shells from shellfish breeding and nearly 50,000 tonnes of shellfish per year from fishing (Nguyen et al. 2013). The use of seashell waste as a partial replacement for conventional materials in concrete and other related cement-based products is a possibility. The characteristics of different types of seashell waste, as well as the effects of incorporating the seashells on the fresh and hardened properties of concrete, have been studied (Moa et al. 2018). The results of this study show that despite the reduction in the workability and strength, it is suggested that seashell waste could still be utilized as a partial aggregate at a replacement level of up to 20% for adequate workability and strength of concrete for nonstructural purposes.

Chitin and chitosan are other examples of products obtained from marine waste from crustacean shells such as shrimp, crabs, lobsters, and krill. In the study of Kumari et al. (2015), chitin from marine sources is converted to chitosan and characterized through different methodologies. On the other hand, there is the case of compounds from the fishery waste industry used in applications like packaging (Leceta et al. 2015). That investigation was focused on the manufacture of sustainable films by using chitosan derived from wastes of fishery industry. Since chitosan is a hydrophilic polymer, moisture sorption behavior was analyzed in order to provide novel knowledge related to the best use conditions for chitosan as packaging films. The results revealed that chitosan films show a great potential to be used as packaging films for food products with intermediate moisture sorption. The main importance of these findings are the suitable design of chitosan-based sustainable food packaging films, valorization of waste product, maintenance of food quality, and, thus, reduction of food waste and environmental impact caused by conventional packaging systems.

3 Approaches to Optimize the Valorization of Wastes with Conventional and New Technologies

Agro-industrial wastes are often underutilized and pose a major disposal problem to the concerned parties. Food processing wastes are promising sources of valuable compounds such as dietary fiber, antioxidants, essential fatty acids, antimicrobials, and minerals because of their favorable technological, nutritional, and functional properties (Schieber et al. 2001). However, the higher-value products may be developed through various modification methods and technologies. Here, the conventional and new technologies used for valorization or extracting processes from food waste or by-products will be analyzed.

3.1 Solvent Extraction

In solvent extraction, the solvent acts as a physical carrier to transfer the target molecules between different phases of solid, liquid, and vapor (Galanakis 2012). Various compounds can be isolated using solvent extraction, which are tocopherols, flavonoids, and related compounds such as coumarins, cinnamic acid derivatives, and chalcones, phenolic diterpenes, and phenolic acids (Oreopoulou and Tzia 2007). Nonpolar solvents (hexane, petroleum ether) can be used for the recovery of tocopherols and certain phenolic terpenes. Ethyl ether and ethyl acetate are very efficient for the recovery of flavonoid aglycons, low molecular weight phenolics, and phenolic acids. Solvents of higher polarity (ethanol or ethanol water mixtures) additionally can extract flavonoid glycosides and higher molecular weight phenolics, resulting in higher yields of total extracted polyphenols. Organic solvents, such as acetone and ethyl acetate, are used for the extraction of carotenoids, and acetone results in the highest yield compared to ethanol, petroleum ether, and hexane (Calvo 2005). From the regulatory point of view, solvents permitted for use in the preparation of food ingredients in the European Union are ethanol, ethyl acetate, and acetone (Marriott 2010). Pectin extraction is accomplished by the use of mineral acids, usually hydrochloric or nitric acid (Oreopoulou and Tzia 2007). The extract is separated from the solid residue, and pectin is precipitated by the addition of ethanol or AlCl solution. Extraction of defatted soy flake with aqueous alcohol improves the flavor and color of soy protein isolate as well as markedly improved its foaming and gelling properties by removing phospholipids and other alcohol-soluble materials. Hence, it is clear that solvent extraction is a versatile way to selectively extract several types of compounds from vegetable and animal sources but is also a scalable technology and, in terms of costs, depends on the selected solvent and the downstream purification processes.

3.2 Supercritical Fluid Extraction (SFE)

Supercritical fluid extraction involves the use of gas above its critical temperature and pressure (Galanakis 2012). Supercritical fluid is defined as a state where the liquid and gas are indistinguishable from each other above its critical point or a state where the fluid is compressible and has a similar density and solvating power to liquid. Supercritical fluid extraction has several advantages over the conventional methods, including faster processing times, high selectivities (i.e., high quality extract), and high extraction yields (Farías-Campomanes et al. 2013; Herrero et al. 2006); however, energy cost to operate at high pressure is elevated. Carbon dioxide is the most commonly used fluid in SFE due to its low critical point (304.2 K/7.4 MPa), favorable environmental characteristics, and low costs. CO2 can be easily separated by depressurization and, thus, can be recovered and reused (Farías-Campomanes et al. 2013). Numerous vegetable matrices have been used as natural sources for compressed fluid extraction. Legumes, spices, aromatic plants, and even fruit beverages, such as natural orange juice (Señoráns et al. 2001), have been processed to obtain natural antioxidant compounds.

Several applications have been developed using SFE in the recovery of value-added components from grape residues, including oil from seeds, tannins from seeds, and polyphenols from both skins and seeds (Farías-Campomanes et al. 2013). The recovery of catechin and other phenolic compounds was found to be higher during isolation of phenolic compounds from grape seeds using supercritical carbon dioxide (Murga et al. 2002; Louli et al. 2004). The use of supercritical fluid extraction after ethyl acetate extraction of wine industry by-products caused higher antioxidant activity, allowing odorless and clearer extracts.

Some authors analyzed the economic feasibility of obtaining different bioactive molecules from plant matrices. In the case of oil extraction from pre-pressed seeds, it was possible to determine that the lowest cost of manufacture (COM) is in the order of 4.08 USD/kg of oil recovered from pre-pressed seeds (by-products of the oil extraction process by cold pressing). Considering the cost of raw materials, inputs such as CO2 and co-solvent, energy costs, manpower, among others, it allows establishing the feasibility of using this type of process for the valuation of vegetable matrices (del Valle et al. 2014). Prado et al. (2012) reported that the production cost for grape seeds depended on the operating conditions, taking into account that by increasing the scale of the process it becomes economically viable. COM values ranging from 290.17 US $/kg extract for a scale process of 5 L and operational time of 60 min, up to 11.93 US $/kg for a scale process of 500 L and 300 min of operation. It is even possible to estimate the global cost of obtaining extracts using SFE, using rapid estimation models that allow establishing that the recovery process is economically feasible (Rosa and Meireles 2005). The case of lycopene recovery from tomato processing waste have also been reported, determining that COM value is close to 1.8 M€/kg lycopene when using supercritical CO2, while this value can be improved when it uses supercritical ethane given the higher the extraction speed, therefore the shorter the process cycle, and the higher the productivity, therefore the lower the COM (Silva et al. 2014); for its part, the recovery of oil from depleted coffee beans through supercritical fluid technology reports annual productivities up to 454 tonnes/year (extraction conditions 2 h, 300 bar, 50 ° C, 30 kg CO2/kg raw material h) with COM of 2.4 M€ and net economic income of 56.6 M€ (Melo et al. 2014). It is important to consider that the cost of manufacture will depend basically on the raw material to be used, if there is a use of co-solvent or not, and on the scale of the extraction process and therefore of the productivity process (Veggi et al. 2014), determining, for example, variations of the COM between 1300 and 833 USD/kg crude extract rich in polyphenols from bean when CO2 was used and considering the lower value for the greater scale of process. The data provided allows establishing the variability in the cost of manufacturing extracts from different plant matrices and therefore the potential use of AIW. This cost is associated with different variables, especially the scale and operational conditions of the process; in addition, the costs are associated with the molecule to be recovered (a crude extract or a specific compound) and are increasing with the purity required for the final product; however, it is still technically and economically feasible to take advantage of different plant matrices, with high net returns.

3.3 Subcritical Water Extraction (SWE)

Subcritical water extraction (SWE), an extraction which uses hot water under pressure, has recently emerged as a useful and environmentally friendly tool to replace the traditional extraction methods. Basically, the instrumentation consists of a water reservoir coupled to a high-pressure pump to introduce the solvent into the system, where the extraction cell is placed and extraction takes place and a restrictor or valve to maintain the pressure. Extracts are collected in a vial at the end of the extraction system. Subcritical water extraction has been widely used to extract different compounds from several vegetable matrices such as rosemary (Arvanitoyannis and Kassaveti 2008; Herrero et al. 2006).

Although at present there are no economic analyzes in the literature regarding the feasibility of the extraction process with subcritical water, different authors point out that it is an economically viable technology, given the fact that traditional organic solvents are replaced by water, the extraction product would not require desolventization, among other things (Zakaria and Kamal 2016; Gbashi et al. 2016; Tian et al. 2017). On the other hand, it is also necessary to consider that in general it has been reported that different green technologies, such as extraction by supercritical fluids (as seen in the previous point), microwave-assisted extraction, or electric pulse, among others, are economically feasible to be applied for the recovery of extracts with bioactive molecules (Bromberger et al. 2018).

3.4 Solid-State Fermentation (SSF)

Solid-state fermentation (SSF) is gaining wide interest these days for the production of organic acids such as citric, lactic, and oxalic acids, enzymes, and other biotechnological products, which could be extracted from AIW, which are generally considered the best substrates for this fermentation processes, especially for enzyme production (Dhillon et al. 2013). The presence of lignin and cellulose/hemicellulose acts as natural inducers, and most of these residues are rich in sugar, promoting better fungal growth and thus making the process more economical especially for the cellulo- and ligninolytic enzymes. Other potential applications of AIW through SFF technology are the production of fructooligosaccharides, bioactive compounds, and bio-insecticides, among others (Mussatto et al. 2012). For example, apple pomace undergone solid fermentation to produce organic acids, heteropolysaccharide (i.e., xanthan, chitosan), flavor and aroma compounds, bioethanol, enzymes, edible mushroom (Pleurotus ostreatus), antioxidants, and nutritional enrichment among others. Several factors making apple pomace suitable as a raw material for biotechnological products are the high content of polysaccharides (mainly cellulose, starch, and hemicelluloses); presence of mono-, di-, and oligosaccharides, citric acid, and malic acid, which can be metabolized by microorganisms; and richness in vitamins and other mineral ions which could limit the cost of nutrient supplementation for fermentation media (Dhillon et al. 2013). Also there is great potential for coffee pulp and coffee husk used as substrates to microbial aroma production by solid-state fermentation using two different strains of C. fimbriata (Murthy and Naidu 2012).

3.5 Extrusion

Extrusion combines a number of unit operations, i.e., mixing, cooking, shearing, puffing, final shaping, and drying in one energy-efficient rapid continuous process (Harper et al. 1989), and can be used to produce a wide variety of starchy foods including snacks, ready-to-eat (RTE) cereals, confectioneries, and extruded crisp breads (Suknark et al. 1997). This process of high-temperature short-time extrusion brings gelatinization of starch, denaturation of protein, modification of lipid, and inactivation of enzymes, microbes, and many antinutritional factors (Bhattacharya and Prakash 1994). Extruded foods are able to provide nutritious products, by means of combine quality ingredients and nutrients to produce processed foods that are formulated to contain specific amounts of each required nutrient (Cheftel 1986). The fruit wastes, defatted hazelnut flour, and durum clear flour can be used in combination with cereal flours for production of nutritionally balanced convenient extruded snack foods due to their valuable characteristics.

4 Conclusion: Biorefinery Concept from AIW

The use of AIW for its use as a source of bioactive compounds can be associated with two different concepts, the biorefinery and the circular economy. The processes based on agro-industrial wastes can consider different steps and technologies that allow the recovery of bioactive compounds of interest in a better way. As shown in Fig. 2, it is possible to consider a first stage of wet milling that allows reducing the particle size, facilitating both the development of later extractive processes and the release of different compounds through the syneresis process. Depending on the raw material, it is possible to remove soluble molecules (low molecular weight) such as minerals or sugars of low molecular weight, among others. In this aspect, also AIW can be an important source of macromolecules such as fibers (soluble and insoluble) and proteins, so that a fractionation of these molecules would allow a better use of waste as a raw material. In the case of proteins, these can be solubilized by the addition of an alkaline solution that is then removed by centrifugation or pressing, which allows obtaining a solid residue rich in fibers, which can contain molecules as antioxidants. In this way, the solid can be treated by different technologies for the recovery of these compounds, for example, direct extraction for the recovery of antioxidants, leaving an expended solid fraction rich in fibers; the application of SFF as a technology for the generation of enzymes or other compounds; or the application of different treatments prior to the extraction itself (such as an enzymatic treatment, or physicochemical treatments), obtaining a final residue rich in fiber that can be used by the food industry or a solid with a better metabolism capacity of the raw material and that can be used in the generation of bioenergy.

References

Ajila CM, Brar SK, Verma M, Prasada Rao UGS (2012) Sustainable solutions for agro processing waste management: an Overview. In: Malik A, Grohmann E (eds) Environmental protection strategies for sustainable development. Springer, Dordrecht, pp 65–109

Allison BJ, Simmons CW (2017) Valorization of tomato pomace by sequential lycopene extraction and anaerobic digestion. Biomass Bioenergy 105:331–341

Amiri-Rigi A, Abbasi S, Scanlon MG (2016) Enhanced lycopene extraction from tomato industrial waste using microemulsion technique: optimization of enzymatic and ultrasound pre-treatments. Innov Food Sci Emerg Technol 35:160–167

Arvanitoyannis IS, Kassaveti A (2008) Dairy waste management: treatment methods and potential uses of treated waste. In: Waste management for the food industries. Food science and technology, pp 801–860

Banerjee J, Singh R, Vijayaraghavan R, MacFarlane D, Patti AF, Arora A (2017) Bioactives from fruit processing wastes: Green approaches to valuable chemicals. Food Chem 225:10–22

Belewu MA, Babalola FT (2009) Nutrient enrichment of some waste agricultural residues after solid state fermentation using Rhizopus oligosporus. J Appl Biosci 13:695–699

Ben Rebah F, Prevost D, Yezza A, Tyagi RD (2007) Agro-industrial waste materials and wastewater sludge for rhizobial inoculant production: a review. Bioresour Technol 98:3535–3546

Bhattacharya S, Prakash M (1994) Extrusion of blends of rice and chick pea flours: a response surface analysis. J Food Eng 21:315–330

Bromberger M, de Marsillac L, Peixoto C (2018) Green technologies for the extraction of bioactive compounds in fruits and vegetables. CyTA J Food 16(1):400–412. https://doi.org/10.1080/19476337.2017.1411978

Calvo MM (2005) Lutein: a valuable ingredient of fruit and vegetables. Crit Rev Food Sci Nutr 45:671–696

Clemente R, Pardo T, Madejón P, Madejón E, Bernal MP (2015) Food byproducts as amendments in trace elements contaminated soils. Food Research International 73:176–189

Cheftel JC (1986) Nutritional effects of extrusion-cooking. Food Chem 20:263–283

Chiou TY, Ogino A, Kobayashi T, Adachi S (2013) Characteristics and antioxidative ability of defatted rice bran extracts obtained using several extractants under subcritical conditions. J Oleo Sci 62:1–8

Ciriminna R, Meneguzzo F, Delisi R, Pagliaro M (2017) Enhancing and improving the extraction of omega-3 from fish oil. Sustain Chem Pharmacy 5:54–59

del Valle JM, Núñez GA, Aravena RI (2014) Supercritical CO2 oilseed extraction in multi-vessel plants. 1. Minimization of operational cost. J Supercrit Fluids 92:197–207

Dave D, Routray W (2018) Current scenario of Canadian fishery and corresponding underutilized species and fishery byproducts: a potential source of omega-3 fatty acids. J Clean Prod 180:617–641

Dessie W, Zhanga W, Xina F, Donga W, Zhanga M, Maa J, Jiang M (2018) Succinic acid production from fruit and vegetable wastes hydrolyzed by onsite enzyme mixtures through solid state fermentation. Bioresour Technol 247:1177–1180

Dhillon GS, Brar SK, Kaur S, Verma M (2013) Bioproduction and extraction optimization of citric acid from Aspergillus niger by rotating drum type solid-state bioreactor. Ind Crop Prod 41:78–84

FAO (2017) The state of food security and nutrition in the world 2017. http://www.fao.org/state-of-food-security-nutrition/en/

Farías-Campomanes AM, Rostagno MA, Meireles MAA (2013) Production of polyphenol extracts from grape bagasse using supercritical fluids: yield, extract composition and economic evaluation. J Supercrit Fluids 77:70–78

Fava F, Totaro G, Diels L, Reis M, Duarte J, Beserra-Carioca O, Poggi-Varaldo HM, Sommer-Ferreira B (2015) Biowaste biorefinery in Europe: opportunities and research & development needs. N Biotechnol 32(1):100–108

Fernandez-Bayo JD, Yazdani R, Simmons CW, VanderGheynst JS (2018) Comparison of thermophilic anaerobic and aerobic treatment processes for stabilization of green and food wastes and production of soil amendments. Waste Manag 77:555–564

Fernández-Mar MI, Mateos R, García-Parrilla MC, Puertas B, Cantos-Villar E (2012) Bioactive compounds in wine: Resveratrol, hydroxytyrosol and melatonin: a review. Food Chem 130:797–813

Ferreira JPA, Miranda I, Gominho J, Pereira H (2015) Selective fractioning of Pseudotsuga menziesii bark and chemical characterization in view of an integrated valorization. Ind Crop Prod 74(15):998–1007

FICCI (2010) Bottlenecks in Indian Food Processing Industry. http://ficci.in/sedocument/20073/Food-Processing-bottlenecks-study.pdf

Friedman M (2013) Rice brans, rice bran oils, and rice hulls: composition, food and industrial uses, and bioactivities in humans, animals, and cells. J Agric Food Chem 61:10626–10641

Galanakis CM (2012) Recovery of high added-value components from food wastes: conventional, emerging technologies and commercialized applications. Trends Food Sci Technol 26(2):68–87

Gbashi S, Adebo OA, Piater L, Madala NE, Njobeh PB (2016) Subcritical water extraction of biological materials. Separ Purif Rev 46:21–34. https://doi.org/10.1080/15422119.2016.1170035

Gendebien R, Ferguson J, Brink H, Horth M, Davis R, Brunet HPJ (2001) Survey of wastes spread on land—final report study contract. http://ec.europa.eu/environment/waste/studies/compost/landspreading.pdf

Harper JM, Linko P, Mercier C (1989) Extrusion cooking. American Association of Cereal Chemists, St. Paul, MN

Herrero M, Cifuentes A, Ibañez E (2006) Sub- and supercritical fluid extraction of functional ingredients from different natural sources: plants, food-by-products, algae and microalgae: a review. Food Chem 98(1):136–148

Jacotet-Navarro M, Rombaut N, Fabiano-Tixier AS, Danguien M, Bily A, Chemat F (2015) Ultrasound versus microwave as green processes for extraction of rosmarinic, carnosic and ursolic acids from rosemary. Ultrason Sonochem 27:102–109

Karam MC, Petit J, Zimmer D, Djantou EB, Scher J (2016) Effects of drying and grinding in production of fruit and vegetable powders: a review. J Food Eng 188:32–49

Kochhar S, Gunstone F (2002) Sesame, rice-bran and flaxseed oils. In: Vegetable oils in food technology: composition, properties and uses. Blackwell, Oxford, pp 297–326

Kumari S, Rath P, Kumar ASH, Tiwari TN (2015) Extraction and characterization of chitin and chitosan from fishery waste by chemical method. Environ Technol Innov 3:77–85

Kundu TK, Vikru RSB, Annavarapu HK., Kempegowda M (2011) Site-specific inhibitors of histone methyltransferase (HMTASE) and process of preparation thereof. Patent No. 8,003,698, U.S.

Lai WT, Khong NMH, Lim SS, Hee YY, Sim BI, Lau KY, Lai OM (2017) A review: modified agricultural by-products for the development and fortification of food products and nutraceuticals. Trends Food Sci Technol 59:148–160

Laufenberg G, Kunz B, Nystroem M (2003) Transformation of vegetable waste into value added products: (A) the upgrading concept; (B) practical implementations. Bioresour Technol 87:167–198

Lavecchia R, Zuorro A (2010) Process for the extraction of lycopene misc. Google Patents. http://www.google.com/patents/US20100055261

Leceta I, Uranga J, Arana P, Cabezudo S, De la Caba K, Guerrero P (2015) Valorisation of fishery industry wastes to manufacture sustainable packaging films: modelling moisture-sorption behavior. J Clean Prod 91:36–42

Liker H (2014) Method of using pomegranate extracts for increasing prostate specific antigen doubling time. Patent No. US 2014/0044809, U.S.

Louli V, Ragoussis N, Magoulas K (2004) Recovery of phenolic antioxidants from wine industry by-products. Bioresour Technol 92(2):201–208

Mackler A (2014) Methods and compositions for treatment of urinary tract infections. Patent No. US 2016/9,248,154. U.S.

Manzocco L, Alongi M, Sillani S, Nicoli MC (2016) Technological and consumer strategies to tackle food wasting. Food Eng Rev 8(4):457–467

Marriott RJ (2010) Greener chemistry preparation of traditional flavour extracts and molecules. Agro Food Ind Hi Tech 21:46–48

McCann TH, Fabre F, Day L (2011) Microstructure, rheology and storage stability of low-fat yoghurt structured by carrot cell wall particles. Food Res Int 44(4):884–892

Melo MMR, Barbosa HMA, Passos CP, Silva CM (2014) Supercritical fluid extraction of spent coffee grounds: measurement of extraction curves, oil characterization and economic analysis. J Supercrit Fluids 86:150–159

Moa KH, Alengaram UJ, Jumaat MZ, Lee SC, Goh WI, Yuen CW (2018) Recycling of seashell waste in concrete: a review. Construct Build Mater 162:751–764

Murga R, Sanz MT, Beltrán S, Cabezas JL (2002) Solubility of some phenolic compounds contained in grape seeds, in supercritical carbon dioxide. J Supercrit Fluids 23(2):113–121

Murthy PS, Naidu MM (2012) Sustainable management of coffee industry by-products and value addition—a review. Resour Conserv Recycl 66:45–58

Mussatto SI, Ballesteros LF, Martins S, Teixeira JA (2012) Use of agro-industrial wastes in solid-state fermentation processes. In: Show KY (ed) Industrial waste. IntechOpen, Rijeka. https://doi.org/10.5772/36310. https://www.intechopen.com/books/industrial-waste/use-of-agro-industrial-wastes-in-solid-state-fermentation-processes

Nafisi-Movaghar K, Druz LL, Victoria CP (2013) Conversion of citrus peels into fiber, juice, naringin, and oil. Patent No. US 2013/0064947 A1, U.S.

Nguyen DH, Boutouil M, Sebaibi N, Leleyter L, Baraud F (2013) Valorization of seashell by-products in pervious concrete pavers. Construct Build Mater 49:151–160

Oreopoulou V, Tzia C (2007) Utilization of plant by-products for the recovery of proteins, dietary fibers, antioxidants, and colorants. In: Utilization of by-products and treatment of waste in the food industry. Springer, Berlin

Parfitt J, Barthel M, Macnaughton S (2010) Food waste within food supply chains: quantification and potential for change to 2050. Philos Trans R Soc Lond B Biol Sci 365(1554):3065–3081

Pfaltzgraff LA, De bruyn M, Cooper EC, Budarin V, Clark JH (2013) Food waste biomass: a resource for high-value chemicals. Green Chem 15(2):307–314

Plazzotta S, Calligaris S, Manzocco L (2018) Innovative bioaerogel-like materials from fresh-cut salad waste via supercritical-CO2-drying. Innov Food Sci Emerg Technol 47:485–492

Portugal-Pereira J, Soria R, Rathmann R, Schaeffer R, Szklo A (2015) Agricultural and agro-industrial residues-to-energy: technoeconomic and environmental assessment in Brazil. Biomass Bioenergy 81:521–533

Prado JM, Dalmolin I, Carareto NDD, Basso RC, Meirelles AJA, Vladimir Oliveira J, Batista EAC, Meireles MAA (2012) Supercritical fluid extraction of grape seed: process scale-up, extract chemical composition and economic evaluation. J Food Eng 109:249–257

Rabelo RS, Machado MTC, Martínez J, Hubinger MD (2016) Ultrasound assisted extraction and nanofiltration of phenolic compounds from artichoke solid wastes. J Food Eng 178:170–180

Ratti C (2001) Hot air and freeze-drying of high-value foods: a review. J Food Eng 49(4):311–319

Rex E, Rosander E, Røyne F, Veide A, Ulmanen J (2017) A systems perspective on chemical production from mixed food waste: the case of bio-succinate in Sweden. Resour Conserv Recycl 125:86–97

Roggeveen K (2010) Tomato journey from farm to fruit shop: greenhouse gas emissions and cultural analysis. University of Wollongong, Wollongong

Rosa PTV, Meireles MAA (2005) Rapid estimation of the manufacturing cost of extracts obtained by supercritical fluid extraction. J Food Eng 67:235–240

Sadh PK, Duhan S, Duhan JS (2018) Agro-industrial wastes and their utilization using solid state fermentation: a review. Bioresour Bioprocess 5:1. https://doi.org/10.1186/s40643-017-0187-z

Santos-Rezende RR, Pedreira-Nogueira J, Narain N (2018) Microencapsulation of extracts of bioactive compounds obtained from acerola (Malpighia emarginata DC) pulp and residue by spray and freeze drying: chemical, morphological and chemometric characterization. Food Chem 254:281–291

Schieber A, Stintzing FC, Carle R (2001) By-products of plant food processing as a source of functional compounds—recent developments. Trends Food Sci Technol 12(11):401–413

Señoráns FJ, Ruiz-Rodrıguez A, Ibañez E, Tabera J, Reglero G (2001) Optimization of countercurrent supercritical fluid extraction conditions for spirits fractionation. J Supercrit Fluids 21(1):41–49

Silva AF, de Melo MMR, Silva CM (2014) Supercritical solvent selection (CO2 versus ethane) and optimizationof operating conditions of the extraction of lycopene from tomato residues: innovative analysis of extraction curves by a response surface methodology and cost of manufacturing hybrid approach. J Supercrit Fluids 95:618–627

Stenmarck A, Jensen C, Quested T, Moates G (2016) Estimates of European food waste levels. Stockholm, Sweden. ISBN 978-91-88319-01-2

Sud D, Mahajan G, Kaur M (2008) Agricultural waste material as potential adsorbent for sequestering heavy metal ions from aqueous solutions: a review. Bioresour Technol 99:6017–6027

Suknark K, Phillips RD, Chinnan MS (1997) Physical properties of directly expanded extrudates formulated from partially defatted peanut flour and different types of starch. Food Res Int 30(8):575–583

Taboada E, Siacor FD (2013) Preparation of pectin and polyphenolic compositions from mango peels. Misc, Patent No. WO2013/141723 A1, Talamban

Tian Y, Wang Y, Ma Y, Zhu P, He J, Lei J (2017) Optimization of subcritical water extraction of resveratrol from grape seeds by response surface methodology. Appl Sci 7:321. https://doi.org/10.3390/app7040321

Tournour HH, Segundo MA, Magalhães LM, Barreiros L, Queiroz J, Cunha LM (2015) Valorization of grape pomace: extraction of bioactive phenolics with antioxidant properties. Ind Crop Prod 74:397–406

Veggi PC, Cavalcanti RN, Meireles MAA (2014) Production of phenolic-rich extracts from Brazilian plants using supercritical and subcritical fluid extraction: experimental data and economic evaluation. J Food Eng 131:96–109

Williams PJ, Anderson PA (2006) Technical bulletin: operational cost savings in dairy plant water usage. Int J Dairy Technol 59(2):147–154

Zakaria SM, Kamal SMM (2016) Subcritical water extraction of bioactive compounds from plants and algae: applications in pharmaceutical and food ingredients. Food Eng Rev 8:23–34

Zhou Y, Zhao X, Huang H (2015) Effects of pulsed electric fields on anthocyanin extraction yield of blueberry processing by-products. J Food Process Preserv 39(6):1898–1904

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Caballero, E., Soto, C. (2019). Valorization of Agro-Industrial Waste into Bioactive Compounds: Techno-Economic Considerations. In: Bastidas-Oyanedel, JR., Schmidt, J. (eds) Biorefinery. Springer, Cham. https://doi.org/10.1007/978-3-030-10961-5_10

Download citation

DOI: https://doi.org/10.1007/978-3-030-10961-5_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-10960-8

Online ISBN: 978-3-030-10961-5

eBook Packages: EnergyEnergy (R0)