Abstract

Cavitation is defined as the sudden formation and collapse of bubbles in liquid by means of a mechanical force. As bubbles rapidly form and collapse, pressurized shock waves, localized heating events and tremendous shearing forces occur. As microscopic cavitation bubbles are produced and collapse, shockwaves are given off into the liquid, which can result in heating and/or mixing, similar to ultrasound. These shockwaves can provide breakthrough benefits for the heating of liquids without scale buildup and/or the mixing of liquids with other liquids, gases or solids at the microscopic level to increase the efficiency of the reaction.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Cavitation is defined as the sudden formation and collapse of bubbles in liquid by means of a mechanical force. As bubbles rapidly form and collapse, pressurized shock waves, localized heating events and tremendous shearing forces occur. As microscopic cavitation bubbles are produced and collapse, shockwaves are given off into the liquid, which can result in heating and/or mixing, similar to ultrasound. These shockwaves can provide breakthrough benefits for the heating of liquids without scale buildup and/or the mixing of liquids with other liquids, gases or solids at the microscopic level to increase the efficiency of the reaction.

One adverse effect of hydrodynamic cavitation has been the severe erosion of surfaces in contact with the fluid undergoing cavitation. This effect has been extensively documented, specifically on hydrofoils (Young, 1999). A unique design for equipment that induces fluid cavitation would allow the harnessing of destructive forces while eliminating equipment erosion and maximizing hydrodynamic cavitation in the product. The design of the ShockWave Power Reactor (SPR) system employed concentric cylinders with fluid in the annular space. The surface of the inner rotating cylinder contains multiple cavities where fluid was pressurized and depressurized many times, inducing hydrodynamic cavitation in the fluid. This type of cavitation was deemed “vortex” cavitation and occurs in the cavities of the rotor surface (Fig. 8.2). This novel design allows a continuous flow of fluid to replenish multiple cavities as the rotor spins, facilitating cavitation and product flow through the system. Centrifugal forces from the inner, rotating cylinder were countered with centripetal forces to avoid traveling cavitation, or cavitation that spills out of the cavity and travels through the system. Pressurizing the system during operation ensured continuous product contact with the inner rotor, resulting in the fluid undergoing controlled cavitation. As the product enters the SPR annular space with the rotor set at a specified operational speed (RPM), the mass rate of flow of the product dictats the frequency of cavitational events and, ultimately, the end exit temperature.

In recent decades, acoustic cavitation has given rise to new disciplines in chemistry such as sonochemistry and sonoluminescence. Mechanically induced cavitation is referred to as hydrodynamic cavitation. Hydrodynamic cavitation is induced mechanically when fluids are pressurized and depressurized while flowing around or through an obstacle in the flow field. Innovative hydrodynamic cavitation reactors offer logical applications in the food industry such as degassing of fluids, releasing intracellular enzymes and metabolites, enhanced microbial inactivation, mixing, emulsification and homogenizing of fluid foods (Balasundaram and Pandit, 2001; Mason and Lorimer, 2002; Middelberg, 1995; Save et al., 1997; Young, 1999).

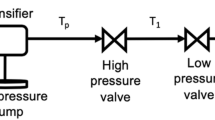

Cavitation is normally considered a very destructive force, known to damage pumps, boat impellers and water structures such as dams. Cavitation can destroy very durable substrates such as concrete and steel. Hydrodynamic cavitation is characterized for individual fluids by sanctioning a cavitation number, σ. The cavitation number, σ, is an index of the resistance of the flow to undergo cavitation and is denoted in Equation (8.1):

where P 0 = ambient static pressure, P v = vapor pressure, \((0.5) \times \rho \times \mu ^2 =\) dynamic pressure where ρ = density and μ = flow velocity. Cavitation is most likely to occur when the cavitation number is below a critical value characteristic of the fluid. The type of cavitation characterized by the cavitation number transpires in rotating cylinders, propellers, hydrofoils, fluid machinery and rapidly rotating rods (Young, 1999).

As fluid is forced through a configuration that induces formation of eddy currents such as flow around solid surfaces or small and large cross-sectional area in the flow stream, the fluid’s kinetic energy is converted into elevated velocities at the expense of a drop in fluid pressure. Localized high and low velocities in a fluid bulk develops momentary gradients of reduced vapor pressures, causing dissolved or trapped gases and fluid vapors to accumulate and expand, forming a bubble. Small particulates, such as dust, debris, or biological entities provide a physical surface for bubble nuclei to attach, expand, and collapse. Bubbles traveling instantaneously from regions of low to high pressure will implode. The collapse of a vapor-filled cavity is accompanied by intense pressure waves, vigorous shearing forces, localized heating events and, in some cases, the formation of free radicals (Earnshaw, 1998; Leighton, 1998; Mason and Lorimer, 2002; Young, 1999). Cavitation can also cause damage to pipes, turbines and pumps. Such uncontrolled cavitation can quickly destroy stainless steel, often requiring costly maintenance and replacement.

The majority of research investigating cellular disruption via hydrodynamic cavitation has employed some variation of a Venturi configuration or multi-orifice plate, which permits sample collection after one pass or one cavitation event. These studies examined the efficacy of hydrodynamic cavitation when disinfecting wastewater (Gogate, 2002; Jyoti and Pandit, 2001, 2004; Sivakumar and Pandit, 2002). In addition to wastewater treatment, increasing focus is being placed on hydrodynamic cavitation as a means of achieving cellular disruption or producing nano-sized suspended particles in large-scale operations with improved process control and reduced energy costs (Save et al. 1994, 1997).

One manufacturer of cavitation technology is Hydro Dynamics, Inc., who through the SPR has found a method to produce cavitation in a way that is not damaging to the equipment. Therefore, this powerful force can be used for mixing and heating applications in the food and consumer product industries.

8.1 How Cavitation Is Produced in the SPR

The SPR is a rotor–stator style device. The heart of the technology is a specialized rotor with cavities that spins. This novel design allows for a continuous flow of fluid to replenish multiple cavities as the rotor spins, facilitating cavitation and product flow through the system. Centrifugal forces from the inner rotating cylinder are countered with centripetal forces to avoid traveling cavitation, or cavitation that spills out of the cavity and travels through the system. Pressurizing the system during operation ensures continuous product contact with the inner rotor, resulting in the fluid undergoing controlled cavitation. As the product enters the SPR annular space with the rotor set at a specified operational speed (RPM), the mass rate of flow of the product dictates the frequency of cavitational events and, ultimately, the end exit temperature. As cavitation occurs, the fluid bulk receives energy dissipated by the bubbles in the vapor phase as the bubbles collapse; thus, the fluid in immediate contact with the bubbles before collapse will have instantaneous temperatures higher than the average temperature of fluid leaving the annular space. The exposure to temperatures exceeding that of the system’s average temperature allows microbial inactivation to exceed that, which can be predicted by using microbial inactivation kinetics based on the fluid transient time–temperature history in the annular space and the residence time after leaving the SPR prior to sampling. The amount of energy required to do this is the tensile strength or the maximum stress that a material can withstand from stretching the load without tearing. Stretching creates a low-pressure zone in the bottom of the holes. A slight back pressure assures that the device always remains full and that the cavities do not run dry. Eventually, the low-pressure zones can no longer maintain themselves and they collapse, releasing all of the mechanical energy required to create them in the form of a shockwave. The spinning action generates hydrodynamic cavitation within the cavities away from the metal surfaces. This is depicted in Fig. 8.1.

Because the cavitation is collapsing in the bulk fluid, and not against a metal surface, it is rendered harmless to the device. The cavitation is controlled, and therefore there is no damage. Shockwaves do strike the metal surfaces, but they are a small fraction of the energy of a cavitation bubble and cause no damage. The cavitation also has an ultrasonic effect that helps to keep the unit clean.

Cavitation is an exponential function with RPM as it is based upon tip speed. As RPMs increase, cavitational energy increases. Heat output is the heat energy imparted to the liquid by the SPR. ΔT is the difference between the liquid temperature at the SPR inlet and SPR outlet and can be used as a proxy for cavitational energy.

At higher speeds, the SPR induces cavitation in the processed liquid, which results as an input of heat energy into the liquid. Operational parameters that influence the amount of heat energy input are as follows:

-

1.

Rotor speed

-

2.

Rotor diameter

-

3.

Liquid flow rate

-

4.

Liquid properties, e.g., tensile strength, specific weight.

-

5.

Internal SPR geometry

A summary of the relationships between these parameters is noted below.

With all other variables remaining constant:

The SPR is generally coupled with an electric motor on a skid, although it is possible to couple it with other spin sources such as a diesel motor. A depiction of an SPR skid system can be seen in Fig. 8.2.

8.2 Scale-Free Heating

Temperature increase from fractional degrees to hundreds of degrees can be obtained in a single pass using cavitation. Because the heat is created inside the liquid rather than transferred through high temperature metal surfaces, there is no scaling of equipment and no scorching of product. This is particularly important in high fat dairy products such as cheese and puddings. Equipment shutdowns and maintenance problems are greatly reduced, improving product yield and product quality and reducing overall costs associated with production. Product taste is also improved.

Hydrodynamic cavitation applied to products eliminates scaling and generates heat instantaneously within the processed product. Eliminating scaling during heating allows for uniform processing of the product while minimizing the surface fouling commonly associated with conventional heating equipment. Cavitation can heat liquids in seconds. As cavitation occurs, the bulk fluid receives the energy dissipated by the bubbles in the vapor phase as the bubbles collapse; thus, the fluid in immediate contact with the bubbles before collapse has instantaneous temperatures higher than the average temperature of fluid leaving the annular space. This heating can be done with pinpoint accuracy and consistency by varying the RPMs through a temperature controller and variable frequency drive. There is no temperature gradient or hot or cold spots, as can be seen in Fig. 8.3. There is also no heat transfer surface, so there is no scaling or fouling. The system is flameless and can be totally automated.

Cavitation can heat liquids with no degradation in the heat transfer coefficient. This was demonstrated in work conducted with a major university on a scaling liquid in a heating test cell meant to mimic conventional heat exchangers and comparing that to an SPR system. The results of this study can be seen in Fig. 8.4.

Scaling comparison to conventional technology. Reproduced from Kazem et al. (2003)

Cavitation is excellent for heating eggs, pudding, gels, cheeses, sauces and high protein food products without scorching and for the pasteurization of high fat milk products and fruit juices. All of these substances can be processed without scaling.

The food industry has always pursued novel processing technologies that allow for reduced energy consumption and minimized product exposure to thermal treatments. Excessive thermal treatment of food, although necessary to render the product safe for consumption and extend shelf-life, was also a primary reason for reduced product quality and undesirable organoleptic properties. Table 8.1 depicts the energy consumption required for processing calcium-fortified apple juice using an SPR in comparison to conventional heating. Conventional pasteurization of apple juice required heating the product to 88˚C and holding for 15 s before cooling to eliminate spoilage and pathogenic microorganisms. Table 8.1 also portrays the amount of energy required to achieve a transient temperature change from 20°C to 65.6°C, 76.7°C and 88°C in order to achieve a 5-log reduction of Saccharomyces cerevisiae. Achieving target lethality at lower temperatures using an SPR resulted in a reduced energy requirement relative to that for conventional heat treatments to obtain a 5-log reduction of S. cerevisiae. The mean value of applied energy per unit weight of product to achieve 6.27 log cycles reduction of S. cerevisiae at SPR rotor speeds of 3,000 and 3,600 rpm at 65.6°C and 76.7°C were 173, 215, 173 and 215 kJ/kg, respectively. These values were considerably lower than the conventional heat treatment, which required the application of 258 kJ/kg to achieve the equivalent lethality of the SPR. Significant differences among mass flow rates and percentage energy efficiency at various SPR operating parameters suggested the use of SPR at rotor speeds of 3,600 rpm with an endpoint temperature of 65.6°C. These parameters required a mass flow rate of 0.044 kg/s and 173 kJ/kg of energy to induce a mean reduction of 6.27 log cycles with the lowest energy loss of 32 kJ/kg and highest energy efficiency of 84%. Operating the SPR at 3,600 rpm with an endpoint temperature of 76.7°C required a mass flow rate of 0.031 kg/s and 215 kJ/kg of energy to induce a mean reduction of 6.27 log cycles with an energy loss of 70 kJ/kg and an energy efficiency of 75%. SPR operation at 3,000 rpm with endpoint temperatures of 65.6 and 76.7°C required a mass flow rate of 0.026 and 0.019 kg/s and 173 and 215 kJ/kg of energy to induce a mean reduction of 6.27 log cycles with energy losses of 118 and 178 kJ/kg and energy efficiencies of 60 and 55%. These patterns suggested that the amount of energy lost to the system in the form of heat can be reduced by increasing the SPR rotational speed and product mass flow rates through the SPR system. Moreover, these data suggested a more efficient coupling of mechanical energy to the product when the SPR rotor speed was increased along with mass flow rate. As the specific heat of calcium-fortified apple juice was 3.792 (kJ/kg*K), excessive energy generated from hydrodynamic cavitation was lost as heat dissipated from the fluid to the SPR housing. Increasing the mass flow rate of the product through the system allowed energy to be coupled more efficiently to the product itself. These data supported the claim of utilizing an SPR to minimally heat treat apple juice, with benefits manifesting in the form of energy savings, superior organoleptic properties and increased retention of heat labile nutrients.

8.3 Mixing

Conventional batch mixing usually occurs in large tanks containing an impeller that constantly stirs the contents in order to achieve uniformity. Because the tanks are normally very large, long process times are required in order to achieve uniformity. In many cases, a completely homogeneous mixture cannot be achieved. Cavitation can often provide superior mixing because the powerful force of cavitation is applied to a limited volume of liquid.

When cavitation bubbles collapse and produce shockwaves, powerful forces are generated that cut the process material into microscopic sizes. This increases the surface contact area between the liquids, gases and/or solids being mixed and maximizes the efficiency of the procedure for processes such as hydration, emulsification and gas/liquid mixing. This procedure can be seen in Fig. 8.5.

Cavitation is a unique mixing mechanism and can often be used to effectively mix shear sensitive compounds. Cavitation can produce superior results when mixing liquids with gases, solids, or other liquids.

8.4 Pasteurization

Cavitation has an added benefit when used for pasteurization in that it allows a higher “kill” than what would be possible at a given temperature. A similar phenomenon for ultrasound is often referred to as manothermosonification.

The term “mano” is added when moderate to high pressures are employed during the temperature/ultrasound process. The term manothermohydrodynamic cavitation is perhaps more descriptive of what occurs in the SPR.

The final FDA 1998 final rule (63 FR 37030) for processing fruit and/or vegetable juice requires processors to label products with a warning of potential illness upon consumption of the product unless the product was processed to inactivate the most likely pathogenic bacteria in the product by 5-log. This rule caused processors to employ conventional heat treatments for pasteurization to ensure that a 5-log reduction has been achieved to avoid the use of a warning label. Processors fear that the warning label may negatively impact a consumer’s decision to purchase the product. More recently, the food processing industry has turned to non-thermal processing techniques to achieve the 5-log reduction of pathogens while minimizing heat exposure of the product (Morris, 2000). In essence, the product can be rendered microbially safe while maintaining the essential nutrients, the phytochemical-health-functional components and organoleptic properties of the original unprocessed juices (Rye and Mercer, 2003; Shomer et al., 1994). In light of these advantages of non-thermal processing technologies on quality, processors must acknowledge that today’s consumers are better educated about minimally processed juices and that there is increased consumer demand for health-functional foods (Deliza et al., 2005). Utilizing non-thermal processing techniques such as hydrodynamic cavitation and ultraviolet irradiation would inactivate pathogens, and because of the low temperature exposure, the nutritional/nutraceutical components in the product are preserved. Certain fruit juices known to be rich in phytochemicals with health-functional properties can be processed with minimal damage to the overall nutritional/functional properties of the product (Konja and Lovric, 1993; McLellan and Acree, 1993; Shahidi and Naczk, 2004; Shahidi, and Weerasinghe, 2004). In addition to the preservation of health-promoting phytochemicals, research has shown that declaring the use of an alternative food processing technology in conjunction with a brief explanation of the technology elicits a positive response in consumers’ decision to purchase a product (Deliza et al., 2005).

Innovative and novel equipment design for food applications must be validated for efficacy in producing safe and wholesome foods by microbial challenge tests using surrogates for pathogenic microorganisms. The Center for Food Safety and Applied Nutrition’s (CFSAN, 2000) report on kinetics of microbial inactivation under the conditions applied in alternative food processing technologies clearly states the rising need for more research on the validation of innovative food processing technology. The following sections address fundamental scientific principles that govern the action of hydrodynamic cavitation by itself and in conjunction with ultraviolet light. Microbial challenge protocols and results are discussed in subsequent chapters. The overall intent of this research is to lay the groundwork for eventual commercialization of this technology for food processing.

Physical stresses resulting from acoustic or hydrodynamic cavitation are understood to be the mechanisms responsible for cellular inactivation. Biological entities in the immediate area of a cavitation event endure stresses that induce severe damage to cell walls and ultimately inactivate the organism (Earnshaw, 1998; Earnshaw et al., 1995; Frizzell, 1988; Geciova et al., 2002; Piyasena et al., 2003; Young, 1999). Earnshaw (1998) cites research suggesting that larger cells such as yeast (5–20 μm) are more susceptible to the effects of cavitation due to their larger surface area. Gram-positive cells were once thought to be more resistant to cavitation than gram-negative bacteria due to additional layers of peptidoglycans in the former; however, more recent literature suggests no significant difference between gram-negative and gram-positive bacteria in their resistance to inactivation by cavitation. Spores of bacteria like Bacillus and Clostridium possess a higher tolerance to cavitational effects when compared to vegetative cells (Earnshaw, 1998). The SPR allows the inactivation of microorganisms through a combination of treatments, in this case cavitation in concert with temperature which exceeds that of temperature alone. This is demonstrated in Table 8.2.

8.5 Gum/Gel Hydration

Cavitation can be used to hydrate gums, gels and polymers in seconds. The process intensity helps to more completely hydrate the powders than with conventional mixers in a fraction of the time. The shockwaves can also break up dry powder agglomerates often referred to as “fish eyes.” This can result in raw powder savings, higher viscosity or higher quality due to more efficient use of the gum and a more uniform product.

The images in Fig. 8.6 show a carrageenan gum mixture that has been stained with methylene blue. Areas of the gum that are not well hydrated appear a darker blue. Cavitation creates a much more even gel. These gels can be made with reduced raw material, in reduced time, and are more homogeneous than those made with conventional technology.

8.6 Emulsification

Cavitation can emulsify liquids in seconds, whether in batch or a continuous system. Emulsification levels can be changed continuously and instantly by varying cavitation intensity and this can be accomplished in a small footprint.

Emulsification studies were conducted with water and canola oil (no surfactant). Varying amounts of horsepower were used as designated by Hz under the jars. As horsepower was increased, the time during which the emulsion was stable increased. This can be directly related to the particle size achieved. Cavitation can be used to “tune” particle size. Images from this study can be seen in Fig. 8.7.

The image above, taken a day after the emulsions were made, shows how changing the cavitation level changes particle size in an emulsion and, thus, the stability. This can be especially useful in products such as salad dressings.

8.7 Aeration

Gas/liquid mixing is one of the most widely used processes in the food industry. Since gases and liquids exist in two different phases, mixing them consistently and uniformly is not an easy task. Long retention times and excessive gas additions are often required and process inefficiencies are considered normal. The gas/liquid mixing ability of cavitation allows it to be used for aeration that is unperceivable by the consumer, which can directly increase profitability. A paste whipped with about 4% air can be seen in Fig. 8.8.

The gas–liquid mixing ability of the cavitation could also be used in other applications including hydrogenation, oxidation and ozonation. Gas–liquid ratios as high as 5:1 have been achieved in the SPR.

8.8 Mixing Thick Liquids

Cavitation is an excellent process for mixing thick and viscous liquids. The process intensity drives the mixing to be completely homogenous. The images in Fig. 8.9 show a paste mixed with a color. Cavitation creates a much more homogeneous gel as compared to a conventional technology such as a static mixer or homogenizer, which are often used to mix thick liquids.

8.9 Case Study of Cavitation Using the SPR

Several SPRs have been installed commercially for pasteurization and homogenization of egg products with excellent results. The main value of the SPR is heating without scaling while simultaneously homogenizing, because egg is a high scaling liquid.

Egg does not scale until it approaches its coagulation temperature, so it is possible to use a conventional heat exchanger to carry it to just before this level and then process it to completion with the SPR. For this pasteurization system, the SPR was used to add about 10°C in temperature after the conventional heating section.

The functionality of the product was tested by preparing a custard (% sag), a sponge cake (volume and consistency) and an omelet (color, aroma, taste and mouth feel). The first two products processed with the shock were a whole egg and a cholesterol-free egg white product. When compared with products processed under standard conditions, the products performed equally or better.

The second test studied replacing the high-pressure homogenizer. The product pasteurized with the SPR was compared with the same product that was pasteurized the previous day with the standard homogenizer. The product pasteurized without the SPR had an average aerobic plate count of 400–1,000 cfu/gr and a coliform count of 25–35. No aerobic bacteria or coliforms were detected in the product pasteurized with the SPR. The product was then tested by preparing a local cake that produced a cake 20% taller and with a better consistency than the cake prepared with standard product. The plant was able to pasteurize whole eggs for 8 h, until they ran out of product, without the need for cleaning, when before they could only achieve this result for 4 h.

The use of SPR potentially allows for pasteurization at higher temperatures for extended periods of time, which can result in better shelf-life and longer run time with gentler handling of the egg products.

8.10 UV Light Using Cavitation in the SPR

Higher surface refreshing photon-related reactions can result in higher mass transfer. Any process, such as UV, that must occur on a surface could benefit from the SPR surface refreshing technology. The extreme mixing forces in the SPR increase the rate of surface refreshing on the inner surface of the housing. The result is a concentration gradient at the surface, which cycles the process chemicals for the treatment. This action increases the mass transfer of photons. At any fixed point on the inner housing surface, the refreshing rate may be as high as several thousand times per second.

The adoption of germicidal UV treatment in water and waste water processing facilities has generated a number of studies validating the efficacy of UV for processing transparent fluids (Liltved and Cripps, 1999; NACMCF, 2004; Sommer et al., 2000). Germicidal ultraviolet light (UVC) at 200 to 280 nm wavelength has proved to be successful for inactivating pathogenic microorganisms like Escherichia coli O157:H7 and Cryptosporidium parvum in processed fruit juices such as apple juice and cider (Vasavada 2003; Wright et al., 2000). Interest in UV treatment of fluid food as an alternative to conventional heat treatment continues to grow. Processors concerned with product flavor and nutrient changes brought on by conventional heat treatment continue to view UV processing as a favorable alternative. In addition, the equipment required for effective thermal pasteurization may be too high-priced for small operations.

Ultraviolet (UV) radiation is considered to be a physical treatment for achieving disinfection of certain foods. Primarily used in water disinfection and waste water processing, the intended use is to disinfect, not sterilize. Disinfection refers to the inactivation of vegetative cells and, in some cases, the inactivation of pathogenic bacterial spores. Radiation is the emission and proliferation of energy through space or a given substance. UV radiation is defined as part of the electromagnetic spectrum displaying wavelengths shorter than the visible region (380–800 nm), but longer than X-rays (0.1–13 nm). In general, UV radiation wavelengths can range from 1 to 400 nm with subdivisions consisting of long-wave UV (UVA: 315–400), medium wave UV (UVB: 280–315 nm) and short-wave UV (UVC: 200–280 nm) (Lopez-Malo and Palou, 2005). Figure 8.10 displays the electromagnetic spectrum in its entirety. Figure 8.11 allows one to see the subdivisions among the UV radiation range. Bactericidal effects are observed closest to the wavelength of 260 nm (Jay, 1998).

Electromagnetic spectrum (taken from http://rst.gsfc.nasa.gov/Intro/emspec.jpg)

Electromagnetic spectrum subdivisions of ultraviolet region (taken from http://www.uvlp.ca/images/electromagneticspectrum40x.gif)

The energy provided by UV radiation is non-ionizing and is readily absorbed by proteins and nucleic acids. The photochemical changes at the cellular level are responsible for the bactericidal effect observed in microorganisms exposed to UV radiation. The cell does not die immediately, but rather procreates into a mutated form and is less suited for survival of offspring. The exposure to UV radiation results in cross-linking of thymine dimers within the DNA of the exposed organism. Figure 8.12 illustrates this photochemical effect.

Photochemical mutagenesis in DNA resulting in thymine dimer (taken from http://www.americanairandwater.com/images/DNA-UV.gif; accessed March 2007)

This photochemical reaction inhibits the microorganism’s capacity to effectively repair injury or successfully reproduce (Vasavada, 2003). UV light has been documented to produce ozone, a known antimicrobial agent, when processing fruits and vegetables (Jay, 1998). However, due to the weak penetration capacity of UV radiation, use of UV technology is limited to surface decontamination and sterilization applications. In addition, opaque fluid foods and/or fluid foods containing particulates, such as citrus juices, provide “shading effects,” which allow for microbial survival from UV radiation. Most UV applications can be found in waste water treatment plants, where the fluid is cleaned of any particulates before exposure to high-intensity UV radiation for decontamination and/or sterilization (CFSAN, 2000).

Currently available UV systems can effectively process only transparent fluids. Opaque fluids such as milk have been proven difficult to process with UVC because the depth of UVC penetration is small, and most microorganisms do not receive direct UVC exposure. In a well-mixed system, shadowing effects can be minimized and more of the target species would be exposed to UVC rays. Tables 8.3 and 8.4 illustrate the lethality effects of UV treatments in conjunction with SPR technology.

The UV-ShockWave Power Reactor (UV-SPR) is a non-immersive UV technology where the lamps do not come into contact with liquid. The bulbs are positioned outside a housing made of quartz to allow UV transmission. A depiction of the device can be seen in Fig. 8.13.

The reactor itself utilizes UV and cavitation for applications such as water disinfection, cold pasteurization and decolorization. Conventional UV technologies have attempted to find a way to improve the efficiency of existing systems by increasing UV lamp intensity. However, high-intensity lamps are not effective in opaque solutions; they are only effective in clear solutions. Conversely, the UV-SPR system utilizes a surface refreshing technique that brings microbials close to the lamp for improved exposure instead of using higher intensity bulbs to disinfect opaque solutions.

8.11 Conclusions

Cavitation can have many benefits over conventional technology. It can be used for heating and intense mixing. Cavitation could provide a paradigm shift for many applications in the food industry.

References

Balasundaram, B., and Pandit, A. B. (2001). Selective release of invertase by hydrodynamic cavitation. Biochemical Engineering Journal, 8, 251–256.

Center for Food Safety and Applied Nutrition. (2000). Kinetics of microbial inactivation for alternative food processing technologies. Retrieved July 1, 2004 from vm.cfsan.fda.gov on the World Wide Web: http://vm.cfsan.fda.gov/∼comm/ift-toc.htm

Deliza, R., Rosenthal, A., Abadio, F. B. D., Silva, C. H. O., and Castillo, C. (2005). Application of high pressure technology in the fruit juice processing: Benefits perceived by consumers. Journal of Food Engineering, 67, 241–246.

Earnshaw, R. G. (1998). Ultrasound: A new opportunity for food preservation. In: Povey, M. J. W., and Mason, T. J. (eds.), Ultrasound in food processing, pp. 183–192. London SE1 8HN, UK, Blackie Academic and Professional.

Earnshaw, R. G. Appleyard, J., and Hurst, R. M. (1995). Understanding physical inactivation processes: combined preservation opportunities using heat, ultrasound and pressure. International Journal of Food Microbiology, 28, 197–219.

Frizzell, L. A. (1988). Biological effects of acoustic cavitation. In: Suslick, K. S. (ed.), Ultrasound: Its chemical, physical, and biological effects, pp. 287–304. New York, NY, VCH.

Geciova, J., Bury, D., and Jelen, P. (2002). Methods for disruption of microbial cells for potential use in the dairy industry-a review. International Dairy Journal, 12, 541–553.

Gogate, P. R. (2002). Cavitation: an auxiliary technique in wastewater treatment schemes. Advances in Environmental Research, 6, 335–358.

Jay, J. (1998). Modern food microbiology, 5th edn, 661pp. Maryland, Aspen.

Jyoti, K. K., and Pandit, A. B. (2001). Water disnfection by acoustic and hydrodynamic cavitation. Biochemical Engineering Journal, 7, 201–212.

Jyoti, K. K., and Pandit, A. B. (2004). Ozone and cavitation for waster disinfection. Biochemical Engineering Journal, 18, 9–19.

Kazem, B., Armstead, D. A., Mancosky, D. G., Lien, S. J., and Verrill, C. J. (2003). Heating Black Liquor by partial oxidation with controlled cavitation as a means to reduce evaporator fouling. Chicago, IL, TAPPI Pulping Conference.

Konja, G., and Lovric, T. (1993). Berry fruit juices. In: Nagy, S, Chen, C. S., and Shaw, P. E. (eds.), Fruit juice processing technology, pp. 436–514. Auburndale, FL, Agscience.

Leighton, T. G. (1998). The principles of cavitation. In: Povey, M. J. W., and Mason, T. J. (eds.), Ultrasound in food processing, pp. 151–182. London SE1 8HN, UK, Blackie Academic and Professional.

Liltved, H., and Cripps, S. J. (1999). Removal of particle-associated bacteria by prefiltration and ultraviolet irradiation. Aquaculture Research, 30, 445–450.

Lopez-Malo, A., and Palou, E. (2005). Ultraviolet light and food preservation. In: Barbosa-Canovas, G. V., Tapia, M. S., and Cano, M. P. (eds.), Novel food processing technologies, pp. 405–422. Boca Raton, FL, CRC Press LLC.

Mason, T. J., and Lorimer, J. P. (2002). Applied sonochemistry: The uses of power ultrasound in chemistry and processing, 303 pp. Weinheim, Germany, Wiley-VCH Verlag GmbH.

McLellan, M. R., and Acree, T. (1993). Grape juice. In: Nagy, S., Chen, C. S., and Shaw, P. E. (eds.), Fruit juice processing technology, pp. 318–333. Auburndale, FL, Agscience.

Middelberg, A. P. J. (1995). Process-scale disruption of microorganisms. Biotechnology Advances, 13(3), 491–551.

Milly, P. J., Toledo, R. T., Chen, J., and Kazem, B. (2007a). Hydrodynamic cavitation to improve bulk fluid to surface mass transfer in a nonimmersed ultraviolet system for minimal processing of opaque and transparent fluid foods. Journal of Food Science, 72(9), M407–M413.

Milly, P. J., Toledo, R. T., Harrison, M. A., and Armstead, D. (2007b). Inactivation of food spoilage microorganisms by hydrodynamic cavitation to achieve pasteurization and sterilization of fluid foods. Journal of Food Science, 72(9), M414–M422.

Milly, P. J., Toledo, R. T., Kerr, W. L., and Armstead, D. (2008). Hydrodynamic cavitation: characterization of a novel design with energy considerations for the inactivation of Saccharomyces cerevisiae in apple juice. Journal of Food Science, 73(6), M298–M303.

Morris, C. E. (2000). US developments in non-thermal juice processing. Food Engineering and Ingredients, 25(6), 26–28.

National Advisory Committee on Microbiological Criteria for Foods. (2004). Requisite scientific parameters for establishing the equivalence of alternative methods of pasteurization: UV radiation, 66pp.

Piyasena, P., Mohareb, E., and McKellar, R. C. (2003). Inactivation of microbes using ultrasound: A review. International Journal of Food Microbiology, 87, 207–216.

Rye, G. G., and Mercer, D. G. (2003). Changes in headspace volatile attributes of apple cider resulting from thermal processing and storage. Food Research International, 36(2), 167–174.

Save, S. S., Pandit, A. B., and Joshi, J. B. (1994). Microbial cell disruption: Role of cavitation. Chemical Engineering Journal, 55, B67–B72.

Save, S. S., Pandit, A. B., and Joshi, J. B. (1997). Use of hydrodynamic cavitation for large scale microbial cell disruption. Trans IChemE, 75(C), 41–49.

Shahidi, F., and Naczk, M. (2004). Phenolics in food and nutraceuticals, 558pp. Boca Raton, FL, CRC Press.

Shahidi, F., and Weerasinghe, D. K. (2004). Nutraceutical beverages: An overview. In: Shahidi, F., and Weerasinghe, D. K. (eds.), Nutraceutical beverages: Chemistry, nutrition, and health effects, pp. 1–5. Washington, DC, American Chemical Society.

Shomer, R., Manheim, C. H., and Cogan, U. (1994). Thermal death parameters of orange juice and effect of minimal heat treatment and carbon dioxide on shelf-life. Journal of Food Processing and Preservation, 18(4), 305–315.

Sivakumar, M., and Pandit, A. B. (2002). Wastewater treatment: a novel energy efficient hydrodynamic cavitational technique. Ultrasonic Sonochemistry, 9, 123–131.

Sommer, R., Lhotsky, M., Haider, T., and Cabaj, A. (2000). UV inactivation, liquid-holding recovery and photoreactivation of Escherichia coli O157 and other pathogenic Escherichia coli strains in water. Journal of Food Protection, 63, 1015–1020.

Vasavada, P. C. (2003). Alternative processing technologies for the control of spoilage bacteria in fruit juices and beverages. In: Foster, T., and Vasavada, P. C. (eds.), Beverage quality and safety, pp. 73–93. Boca Raton, FL, CRC Press LLC.

Wright, J. R., Sumner, S. S., Hackney, C. R., Pierson, M. D., and Zoecklein, B. W. (2000). Efficacy of ultraviolet light for reducing Escherichia coli O157:H7 in unpasteurized apple cider. Journal of Food Protection, 63, 563–567.

http://www.americanairandwater.com/images/DNA-UV.gif. Accessed March 2007.

Young, F. R. (1999). Cavitation, 418 pp. London WC2H 9HE, Imperial College.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2011 Springer Science+Business Media, LLC

About this chapter

Cite this chapter

Mancosky, D.G., Milly, P. (2011). Controlled Cavitation for Scale-Free Heating, Gum Hydration and Emulsification in Food and Consumer Products. In: Feng, H., Barbosa-Canovas, G., Weiss, J. (eds) Ultrasound Technologies for Food and Bioprocessing. Food Engineering Series. Springer, New York, NY. https://doi.org/10.1007/978-1-4419-7472-3_8

Download citation

DOI: https://doi.org/10.1007/978-1-4419-7472-3_8

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4419-7471-6

Online ISBN: 978-1-4419-7472-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)