Abstract

A common technique for in vitro cartilage regeneration is to seed a porous matrix with cartilage cells and to culture the construct in static conditions or under medium perfusion in a bioreactor. An essential step toward the development of functional cartilage is to understand and control the tissue growth phenomenon in such systems. The growth process depends on various space- and time-varying biophysical variables of the environment surrounding the cartilage cells, primarily mass transport and mechanical variables, all involved in the cell biological response. Moreover, the growth process is inherently multiscale, since cell size (10 μm), scaffold pore size (100 μm), and cellular construct size (10 mm) pertain to three separate spatial scales. To obtain a quantitative understanding of cartilage growth in this complex multiphysics and multiscale system, advanced mathematical models and efficient scientific computing techniques have been developed. In this chapter, we discuss the existing knowledge in this field and we present the most recent advancements for the numerical simulation of cartilage tissue engineering.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Biomass Growth

- Discontinuous Galerkin

- Cartilage Tissue Engineering

- Engineer Cartilage

- Nutrient Diffusivity

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

A basic concept in the design of ex vivo tissue reconstruction is to provide a proper biophysical microenvironment to cells [38]. In cartilage regeneration (Fig. 1), mechanical stimulation is being extensively evaluated as a tool to modulate extra-cellular matrix (ECM) synthesis, coherently with the evidence that mechanical forces play an important role in cartilage homeostasis in vivo [14]. Mechanobiology models of engineered cartilage are currently addressed at optimizing the applied mechanical stimuli, by combining different stimuli, for example flow perfusion with cyclic pressurization (Fig. 2) [25, 26, 42, 46], as a means to better mimic the complex biophysical environment of chondrocytes within native cartilage.

Scanning electron micrographs of porous scaffolds seeded with cartilage cells. The scale bar equals 20 μm in all figures. a Polyurethane foam, b non-woven fiber mesh derived from hyaluronic acid, c polyurethane structure with regular spherical pores and d polystyrene regular grid. A coloured version of this figure is available on the online version of the book

Mechanical bioreactors for cartilage tissue engineering. During bioreactor culture, the cellular constructs may be subjected to a interstitial perfusion, b cyclic hydrostatic pressurization and c combined regimens of interstitial perfusion and cyclic hydrostatic pressurization. A coloured version of this figure is available on the online version of the book

To gain a better insight into the quantitative relationship between the applied culture conditions and cartilage growth, advanced computational models are currently applied to interpret the results from bioreactor studies. These attempts to calculate and control the balance of mass transport and mechanical stresses exerted on cells, have proven useful in capturing a rough understanding of the conditions favoring the development of engineered cartilage [36, 37, 39, 40, 42, 26, 44].

In mechanobiology models of engineered cartilage, comparison between the experimental findings and the computational results enable the local field variables to be correlated with specific cell responses. Only from the mastering of the complex biological phenomena (cell metabolism and proliferation, substrate degradation and remodeling of the ECM) that take place during the in vitro culturing process, one can control key aspects of tissue maturation.

2 Tissue Engineering: A Multiphysics/Multiscale Problem

Bioreactors for tissue culture are complex multiphase systems composed of a scaffold portion, a culture medium and a growing biomass. For their rational design, it is thus strongly required to have a quantitative understanding of the interplay between geometry, interstitial flow field, nutrient mass transfer and cellular behavior (proliferation, migration, biosynthetic activity). These variegated phenomena encompass a wide range of embedded scales.

Figure 3 shows five distinct scales at which (at least) the considered problem can be modeled, namely:

-

Macroscale: it is the scale at which the perfused scaffold is treated as a continuum and at which the Bioengineer sets the control parameters (inlet velocity, pressure drop). Its characteristic length is of the order of a few millimeters.

-

Mesoscale: it is the scale corresponding to a collection of a few functional sub-units (shortly, unit cells) of the scaffold. Its characteristic length spans from tens of microns to millimeters.

-

Microscale: it is the scale of the single unit cell of the polymeric scaffold, of the order of 100 microns.

-

Cellular scale: it is the scale at which cells cannot be treated as a continuum, but must be treated as single discrete entities. Its characteristic length is of the order of microns.

-

Sub-cellular scale: it is the scale accounting for all the mass transport and reaction processes that occur at the single cell membrane level. Its characteristic length is of the order of some nanometers.

We present here below a possible mathematical framework for the description of the bio-physical phenomena occurring in a bioreactor for tissue engineering. Let Ω be the bioreactor domain, composed by the time-invariant subdomains Ωsc, representing a non-biodegradable scaffold, and by its complement Ω e . This latter subdomain is, in turn, composed of a fluid portion Ωfl(t) and a biomass portion Ω b (t), both depending on time t. Notice that both Ωfl and Ω b may be, in general, composed by the union of complex, unconnected domains. The full scale approach consists of the coupled solution of the following multiphysics system:

-

1.

model for nutrient concentration: find c = c( x ,t) in Ω e such that

$$ \frac{\partial c}{\partial t} + \nabla \cdot \left( { - D\nabla c + \user2{v}c} \right) = Q\left( c \right) $$(1)where D is the nutrient diffusivity, equal to Dfl in Ωfl and to D b in Ω b , respectively, v is the velocity field and where the mass consumption term Q, due to cellular metabolism, is given by:

$$ Q\left( c \right) = \left\{ {\begin{array}{*{20}c} 0 & { {\text{in}}\;{{\Upomega}}_{\text{fl}} ,} \\ { - \frac{{V_{m} c}}{{K_{m} + c}}} & { {\text{in}} {{\Upomega}}_{b}\,({\text{Michaelis}}-{\text{Menten kinetics}}) _{ } } \\ \end{array} } \right. $$(2)V m being the maximal nutrient consumption and K m the half saturation constant,

-

2.

model for the fluid velocity:

-

v = 0 in Ω b

-

Navier-Stokes equations in Ωfl: find v = v(x , t) such that

$$ \left\{ {\begin{array}{*{20}c} {\frac{\partial \user2{v}}{{\partial {\text{t}}}} + \user2{v} \cdot \nabla \user2{v} - \eta \Updelta \user2{v} + \nabla p = 0} \\ {\nabla \cdot \user2{v} = 0.} \\ \end{array} } \right. $$(3)

-

-

3.

model for biomass growth (cell population and ECM accumulation):

$$ \Upomega_{b} = \Upomega_{b} \left( {t,c,\mathbf{v},{\text{ other biophysical parameters}}} \right) $$(4)

The interfaces between different materials and models have to be handled by means of suitable transmission conditions connecting the value of the variables and/or their fluxes from one domain to the other. At present, the computational challenge for solving the above three-dimensional (3D) time-dependent problem on the entire bioreactor domain with internal moving boundaries and spatial resolution at the cell (Microscale) level, is still a too demanding task, even for the more advanced numerical techniques and powerful machine resources. For this reason, computational models of cartilage tissue engineering have been proposed, addressing the problem at only a few of the above described scales, and often including only a restricted set of physical phenomena.

The biophysical admissibility of such models strongly depends on the culture time. As a matter of fact, the cell environment in the scaffold changes with culture time, at the beginning of culture there are only seeded cells, which later proliferate and synthesize ECM. Accounting for the interaction of the fluid flow with the growing biomass is a condition required to obtain a realistic simulation at high cell volume fractions, typical of long term culture. For this reason, single-physics/single-scale models might yield acceptable results for short culture times, while for longer culture times coupled multiphysics/multiscale simulations are required (Fig. 4).

In the following, we present a survey of such models, focusing on the coupling between nutrient mass transport with medium flow (Sect. 3) and biomass growth (Sect. 4). An overall description of these phenomena is provided in Sect. 5 under the perspective of homogenization, while in Sect. 6 we briefly address recent contributions to the multiscale modeling of the tissue engineering problem.

3 Coupled Models of Medium Flow and Mass Transport

A rough understanding of transport limitations in porous constructs has been obtained, in absence of flow, by Botchwey et al. [2, 3] and Sengers et al. [45] using homogeneous models of tissue-engineered constructs. This amounts to solving Eq. (1) with a constant nutrient diffusivity and v = 0 in the entire scaffold domain Ω, instead of considering the actual microscopic structure of the domain Ω e with its associated complex empty and filled substructures. In up-to-date recent tissue engineering bioreactors, the cell-seeded scaffold is immersed in a medium which is induced to flow through or around the scaffold surface in a perfusion flow apparatus. A simple strategy for increasing mass transport to cells would appear to be to increase the medium flow rate, but high flow rates induce high shear stresses on cells, which may be harmful instead of beneficial, at least at early stages of tissue growth.

This complexity presents serious hurdles in determining the appropriate values of flow rate and medium solute concentration. Flow around scaffolds in a concentric cylinder bioreactor has been studied by Williams et al. [49] by solving Eq. (2) coupled with Eq. (1) in the whole bioreactor domain. In this model, the biomass volume is not accounted for in the geometry, but an equivalent volumetric consumption rate is used at the right-hand side of Eq. (1). Such a model allowed to compute flow fields, shear stresses and oxygen profiles around the constructs.

Incorporating flow through the scaffold in a direct-perfusion configuration complicates the situation by establishing a velocity scale which is related to the actual fluid velocities in the scaffold, which are impossible to measure. This problem has been dealt with by using detailed pore-scale computational fluid-dynamic (CFD) simulations of fluid and chemical transport in tissue-engineering scaffolds populated with living cells [1, 10, 11, 31, 47]. In these models, the same set of equations is solved as in the above cited model, but considering only a few unit cells. This allows to obtain a much higher scale resolution and to represent the real local scaffold empty/filled structure. These simulations are able to capture flow, pressure and concentration fields resolved at the microscopic level. In particular, it is shown how the scaffold micro architecture influences the hydrodynamic shears imposed on cells within constructs. Calculations of nutrient flow indicate that inappropriately designed dynamic culture environments lead to regions of nutrient concentration insufficient to maintain cell viability. These studies provide a foundation for exploring the effects of dynamic flow on cell function and provide an important insight into the design and optimization of 3D scaffolds suitable in bioreactors for in vitro tissue engineering.

4 Coupled Models of Biomass Growth, Medium Flow and Mass Transport

A consistent mathematical description of tissue regeneration requires to provide a model of biomass growth, as indicated in Eq. (4). This is a very complex problem, involving several biophysical variables. Experimental observations and measurements [32] suggest that after seeding, cells undergo (i) a first period (5–7 days) of rapid proliferation, (ii) a second period (2–4 weeks) in which they start to significantly secrete the typical highly hydrated extracellular matrix (ECM), comprising proteoglycan monomers assembled with glycosaminoglycans (GAGs) anchored to hyaluronic acid chains, type II collagen and a small amount of other types of collagen. To our knowledge, there are no comprehensive models of (i), and (ii) in this application field, rather, only partial descriptions of (i) or (ii) have been developed.

4.1 Cell Population Dynamics

Computational tools known under the name of multicellular simulations can be used to model cell population dynamics. In these approaches, simple rules based on cell automata are adopted to describe cell behavior and the emergent trend of the cell populations is observed and analyzed. In particular, biased random walk techniques have found widespread use in biological applications like the simulation of angiogenesis [30] and, recently, have been applied to simulate cell populations that migrate, collide, and proliferate to build a tissue inside a 3D scaffold [7].

Simulation results show that the speed of cell locomotion modulates the rates of tissue regeneration by controlling the effect of contact inhibition and that the magnitude of this modulation strongly depends on the spatial distribution of the seeded cells. In our group, a strong effort has been devoted to integrate pore-scale CFD modeling and mass transport with multicellular simulation, developing computational models of cell proliferation under interstitial perfusion in a bioreactor [16, 17]. These models accounted for three physical phenomena: (1) cell proliferation and migration, simulated using established models of cell population dynamics [7, 28], (2) the hydrodynamic flow of culture medium, simulated using CFD modeling, and (3) oxygen transport from the flowing culture medium to the cells.

In these models, the increasing oxygen transfer from the culture medium to the growing cell biomass was included in the mass transport calculation, but the alteration of the fluid flow due to the growing cell volume was neglected, so that the simulation results were valid only for very low cell volume fractions, corresponding to initial culture conditions. An alternative perspective is based on homogeneous continuum approaches [29] or on porous medium representations, comprising motile cells and water inside a rigid scaffold material [8, 23]. In addition to cell growth kinetics, cell diffusion may be incorporated, to describe the effects of cell random walks. The values of some parameters used, such as the rate of cell ingrowth into the porous scaffold, are derived from the literature or by fit to published experimental data. Results suggest that the rate of tissue growth in porous scaffolds depends not only on the intrinsic rate of cell proliferation, but also on the balance of mechanical forces developed inside the tissue. This type of modeling also shows how the scaffold porosity or surface may be varied to reduce the tendency of cells to aggregate.

4.2 ECM Accumulation Dynamics

Mathematical models of ECM accumulation have been set up by treating the cell-scaffold construct either as a homogeneous continuum coupled with the nutrient field [27] or at the Microscale level [13]. In both these approaches, GAG concentration is assumed as the principal indicator of ECM secretion, distinguishing between soluble and bound GAG fractions. In Klein and Sah [21] an extension of the previous models is proposed, including in a phenomenological manner the effect of perfusion velocity on GAG release rate.

5 Homogenized Models of Biomass Growth, Medium Flow and Mass Transport

The difficulty of handling a domain with an internal time-dependent interface due to biomass growth with a robust numerical technique has brought many authors to propose homogenized-averaged approaches formulated at the Macroscale level. These approaches are aimed at accounting for the fact that the environment in a tissue-engineered construct is strongly heterogeneous. Multiphase models allow an explicit consideration of these interactions. Each constituent is considered as a distinct phase within the multiphase system with corresponding constitutive laws and interactions with neighbouring phases, the inherent complexity of this approach, compared to that of solving the complete problem of Eqs. (1–3) can be conveniently reduced by an averaging process, yielding a single equation which holds uniformly in the material, upon characterization of effective parameters such as nutrient diffusivity, biochemical reaction rates and construct permeability.

Derivation of multiphase models applied to a wide range of problems in computational biology has been given extensive treatment by many authors, including, for example, Marle [24], Whitaker [48] and Byrne et al. [6]. In the series of papers by Galban and Locke [15], a two phase (fluid and biomass) model for cell growth and nutrient diffusion in a polymer scaffold with no perfusion is presented. A single, averaged reaction–diffusion equation for the nutrient concentration in the two phase system is derived using the volume-averaging method of Whitaker [48], Wood et al. [50] and the effective diffusion coefficient and reaction rate are calculated as a function of the local cell volume fraction which evolves according to a cell population balance equation. In the paper by Chung et al. [9] a two-phase (fluid and biomass) model analogous to the one of Galban and Locke [15] is proposed, with the inclusion of a self-consistent computation of the fluid-dynamic field via an averaged Stokes-Brinkman model stemming upon volume averaging of Stokes equations [20]. To reflect the fact that cell growth into the scaffold reduces the effective pore size, Chung et al. [9] propose to include the dependency on the cell volume fraction via a Carman-Kozeny type relation for the permeability.

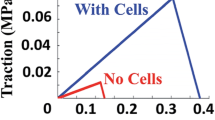

In our group, an homogenized approach in the line of the above cited literature has been recently investigated in Sacco et al. [44]. The main novel contribution of this work is the systematic inclusion of experimental data, in particular the dependence of the biomass growth rate on the local fluid-dynamical shear stress, and the inclusion of the effect of the solid scaffold fraction in the characterization of the effective parameters arising from the homogenization procedure (hydraulic permeability and nutrient diffusivity). The set of results presented in Fig. 5 are obtained adopting the same model as in Sacco et al. [44] but investigating the use of a modified biomass growth model based on two contributions: a promotion and an inhibition term. This latter term is calibrated with respect to the inlet velocity modulus, that is used as an indicator of the typical fluid-dynamical shear stress in the device. In this analysis, we track the spatial and temporal evolution of the nutrient concentration and fluid-dynamical variables as well as the volume fraction occupied by the growing biomass which modifies the porosity of the scaffold matrix, thus altering the fluid flow. Computations, corresponding to different time levels, refer to the same geometry discussed in Sacco et al. [44] enforcing a Poiseuille flow profile at the inlet. Simulations show that biomass growth is enhanced close to the inlet section of the scaffold, due to a larger local availability of nutrient. In turn, this results into a higher occlusion of the porous matrix in this area, giving rise to an increase in the local state of shear stress (represented in the model by the Darcy stress).

Simulation of biomass growth due to mass transport in an interstitially perfused disk-shaped scaffold computed with a modification of the homogenized model presented in [44]. a Time evolution of the total biomass fraction. Time snapshots of the distribution of: b biomass, c nutrient concentration and d Darcy stress. The medium flows from left to right

6 Multiscale Modeling

In the attempt of including in the mathematical description of the tissue-engineered construct a wider spectrum of phenomena, while keeping the computational complexity at an acceptable level, multiscale homogenization techniques have been applied in a certain number of recent studies. A first example in this direction is represented by the work of Cioffi et al. [11], where a Macroscale simplified model provides appropriate boundary conditions for a Microscale model. The former model is set in an axi-symmetric geometry and steady Navier-Stokes equations are solved coupled with a reaction-diffusion equation for the nutrient with a constant volumetric consumption rate. This model provides the velocity and nutrient concentration profiles at the inlet of the Microscopic model formulated on a small (sample) portion of the bioreactor which consists of the union of a few unit cells. In this Microscale computational domain the same equations as above are solved, but on the real geometry extracted from micro-CT images.

In Raimondi et al. [43], two complementary multiscale models are presented. The first approach follows a concept similar to the one described above. Namely, a 2D model of the whole scaffold seeded with a cell monolayer is considered, coupled with a 3D model of a functional sub-unit of such construct. The main novelty of this approach consists in the use of a moving boundary formulation originally proposed in Galban and Locke [15] and based on a phenomenological relation for the time evolution of the biomass-fluid interface, which consistently updates the geometry. To handle this time-evolving domains, an Arbitrary Lagrangian–Eulerian (ALE) formulation is adopted and periodic remeshing is applied to adapt the computational mesh to large deformations of the computational domain. In the second approach, a lumped discrete approximation to the problem of mass transfer, nutrient uptake and biomass growth at the Macroscopic scale of the scaffold is devised. In this description, the scaffold is represented by a simplified geometry characterized by piecewise constant biophysical parameters, whose values are extracted from the Microscale model. In turn, the Macroscale model supplies the nutrient concentration boundary condition to a discrete set of Microscale problems, whose solution is the nutrient distribution and biomass evolution at the pore-size level, to be compared with real-time microscopic data.

7 Scientific Computing Techniques in Multiphysics Modeling

The aforementioned models of the engineered tissue growth feature specific difficulties with respect to their numerical approximation, which determine significant criteria to select suitable numerical schemes to come up with computational solutions of flow and mass transport problems. Since the mathematical models representing such phenomena are based on partial differential equations, approximation methods such as the finite element method or the finite difference (or finite volume) methods may be equivalently applied. However, the forthcoming description will be biased in the direction of the finite element method, which is a highly flexible approach. The main challenges in modeling cellular constructs are represented by the need to solve problems with spatially heterogeneous physical parameters or to couple different mathematical models (viscous and inviscid flows, free flows and porous media) within a genuine multiphysics framework, including: Darcy’s, Brinkman’s or Stokes’ models for perfusion flow in the scaffold porous matrix with growing biomass, nutrient mass transport and delivery to growing cells, cell growth and metabolism. The interfaces between different materials and models have to be handled at the discrete level by a suitable treatment of the transmission conditions.

As an example, for the approximation of mass transport through heterogeneous media, which arises from the study of nutrient supply to cells, a correct quantification of the amount of nutrient reaching the target is achieved by properly capturing the balance of mass fluxes at the interface between the fluid and the growing tissue, as well as by accurately approximating the steep concentration gradients that arise in the neighborhood of the fluid/solid interface. For the former issue, an effective mathematical methodology is Domain Decomposition, for which we refer to Quarteroni and Valli [33].

Such family of methods splits a coupled multiphysics system in single sub-problems, which can be then solved by standard approximation techniques and software packages. The global solution accounting for their interaction is then recovered by means of iterative strategies. Domain decomposition techniques have already been successfully applied to analyze fluid dynamics and mass transfer through biological tissues [34, 35], D’Angelo and Zunino [12]. Another important issue in the simulation of heterogeneous problems is the development of robust and conservative schemes. For the case of nutrient transport, a conservative scheme would exactly preserve the local mass balance related to nutrient concentration. Robustness, in turn, refers to the stability of the numerical scheme, which is the fundamental property that quantifies at what extent the approximate solution is sensitive with respect to perturbations on the discrete problem data. A numerical method is called robust when its stability properties are affected neither by the magnitude of the problem coefficients nor by their variation. This is achieved by means of Discontinuous Galerkin finite elements (DG). However, a major drawback of DG schemes is their increased computational cost compared to standard (conforming) finite element formulations, that in some cases makes them unsuitable for large scale realistic problems.

The previous computational techniques allow for an accurate and efficient approximation of the partial differential equations that describe the phenomena governing artificial tissue growth. However, computational methods provide quantitative results only when they are applied on the basis of realistic data for the problem at hand, through a strong interaction between simulations and experiments. On the one hand, problem specific parameters such as nutrient diffusivity and consumption rates as well as fluid viscosities and hydraulic resistances of biomass should be provided. On the other hand, equations must be solved on realistic geometrical configurations, to allow for model validation based on direct comparison between simulations and observations.

Micro-CT and fluorescence microscopy images at the cell scale should be the starting point to reconstruct the geometrical models for numerical simulations. More precisely, the geometry of the scaffold matrix and the biomass available from images, has to be translated into quantitative terms in order to be exploited for the numerical approximation of fluid perfusion and transport processes. To address this task, several approaches are available. In principle, one can attempt to set up a parametric mathematical description of the domain boundaries or interfaces. However, the highly irregular shape of tissue-engineered constructs makes this task hardly achievable in the present context (Fig. 6). Alternatively, recent advances on numerical approximation schemes for PDEs have shown a promising way to override this difficulty. In particular, non-standard finite element schemes (such as the Extended Finite Element method, XFEM) have the ability to use Cartesian, non-boundary-fitted meshes to solve problems in complicated domains. Such approach, generally called the fictitious domain method [18], consists in embedding the computational domain into a fictitious volume with simple geometry, in such a way that the material interfaces do no longer need to be geometrically approximated. Recent developments in this direction Hansbo and Hansbo [19], Burman and Hansbo [4], Burman and Zunino [5] give rise to robust and efficient finite element schemes that are capable to approximate partial differential equations with interfaces separating between highly heterogeneous material properties even when the coefficient discontinuities are not exactly captured by the computational mesh.

(left) Fluorescence image of the engineered tissue growing on the fiber scaffold represented in Fig. 1b (scaffold fibers are visualized with blue, biomass with green). (middle) The outcome of image segmentation approach targeting the biomass. The contours of the biomass film are highlighted in red. (right) Numerical simulation of a diffusion problem where the biomass region features lower diffusivity than the surrounding fluid. Owing to the extended finite element technique, the computational mesh does not fit the complex contours of the fluid/biomass interface, although the computational accuracy is not significantly compromised

8 New Tools for Experimental Validation

In mechanobiology models of engineered cartilage, comparison between the experimental findings and the computational results enables the local field variables to be correlated with specific cell responses, a crucial step towards model validation. Generally this is a very complex procedure, as most variables to be measured are not experimentally accessible in 3D and in real time. To attack this problem, a first experimental set-up was developed and validated by our group in collaboration with the University of Basel. A geometrically-defined custom made scaffold was seeded with human chondrocytes and cultured inside a miniaturised perfusion chamber, so-called mini-bioreactor, that permitted time lapse imaging of the cellular construct in real time [41].

A step forward in this regard is a new optimized set up presented in Laganà and Raimondi [22]. The new perfusion mini-bioreactor was designed and rapid-prototyped taking advantage from microfluidic know-how, so it is easy to use, cost effective, potentially disposable, and wholly mounted on a standard microscope glass slide. The experimental set-up (Fig. 7) is composed of a syringe pump, a pipeline for cell feeding, a cell culture incubator and a fluorescence microscope equipped with an imaging system. To house the custom-made polystyrene scaffolds used (3D Biotek), the perfusion chamber thickness was set at 300 μm, i.e. over the traditional microfluidic scale (Fig. 8).

Micro-bioreactor set-up developed to validate multiphysics computational models of cartilage growth. Scheme (left) and photograph (right). a Syringes filled with complete cell culture medium and mounted on an infusion/withdrawal programmable syringe pump, b cell culture incubator (37°C, 5% CO2), c silicone rubber oxygenator tubes, d inverted microscope, e water-jacket heater used to maintain the micro-bioreactor chamber at 37°C, f cell culture medium reservoirs, and g laptop monitor showing a fluorescence image acquired directly on the live micro-construct with a high resolution camera. A coloured version of this figure is available on the online version of the book

Mini-bioreactor approach developed to validate multiphysics computational models of cartilage growth. a Exploded view showing (I) bottom side magnetic holder, (II) cover glass, (III) PDMS perfusion chamber (arrow), (IV) glass slide with CNC-milled perfusion channels, (V) top side magnetic holder. b Photograph of the mini-bioreactor placed on the microscope, c rendering of the polystyrene scaffold, d detail of the scaffold regular geometry and e fluorescence live image of the scaffold seeded with cells, in which cell nuclei stain blue and the cell cytoplasm stains orange. A coloured version of this figure is available on the online version of the book

The mini-bioreactor was successfully tested against leakage and used in cell culture experiments. We have used live fluorescence viable staining, DAPI (Sigma), in which the cell nuclei stain blue, and the Qtracker® Cell Labeling Kit (Invitrogen), in which the cell cytoplasm stains orange, to follow tissue growth during culture. We acquired fluorescence images at specific time points on live specimens, and we developed procedures to estimate the cell number and the biomass volume fraction non-destructively during culture. We are currently developing methods to compare these experimental observations to the computational predictions (Fig. 9), in the aim to approach a validation procedure for our more advanced multiphysics models of cartilage tissue engineering.

Integration between experiments and simulation in cartilage tissue engineering. Fluorescence images of cellular constructs marked with live staining, in which the cell nuclei stain blue and the cell cytoplasm stains orange, taken a at the beginning and b the end of culture, compared to c, d the numerical output of the multiphysics model [43]. In (c) and (d) the wall fluid shear stress is mapped on the biomass surface (c) at the beginning and (d) the end of culture. e The 3D domain modeled

9 Conclusion

In conclusion, the field of multiphysics computational modeling in cartilage tissue engineering is progressing rapidly. Here, we have reviewed several computational tools already available. Possible directions to improve these tools require to properly address the fundamental processes that induce growth of engineered tissue on scaffolds, i.e. cell adhesion, migration, proliferation and biosynthesis. This would open new avenues for engineering design using validated predictive tools in the field of tissue engineering.

References

Boschetti, F., Raimondi, M.T., Migliavacca, F., Dubini, G.: Prediction of the micro-fluid dynamic environment imposed to three-dimensional engineered cell systems in bioreactors. J. Biomech. 39(3), 418–425 (2006)

Botchwey, E.A., Pollack, S.R., El-Amin, S., Levine, E.M., Tuan, R.S., Laurencin, C.T.: Human osteoblast-like cells in three-dimensional culture with fluid flow. Biorheology 40, 299–306 (2003)

Botchwey, E.A., Dupree, M.A., Pollack, S.R., Levine, E.M., Laurencin, C.T.: Tissue-engineered bone: measurement of nutrient transport in three-dimensional matrices. J. Biomed. Mater. Res. A 67(1), 357–367 (2003)

Burman, E., Hansbo. P.: Fictitious domain finite element methods using cut elements: II. A stabilized Nitsche method. Appl. Numer. Math. (2011). doi:10.1016/j.apnum.2011.01.008

Burman, E., Zunino, P.: Numerical approximation of large contrast problems with the unfitted Nitsche method, frontiers in numerical analysis––Durham 2010. In: Blowey, J., Jensen, M. (eds.) Lecture Notes in Computational Science and Engineering, vol. 85, Springer, Heidelberg, Germany, (2012). ISBN 978-3-642-23913-7

Byrne, H.M., King, J.R., McElwain, D.L.S., Preziosi, L.: A two-phase model of solid tumor growth. Appl. Math. Lett. 16(4), 567–573 (2003)

Cheng, G., Youssef, B.B., Markenscoff, P., Zygourakis, K.: Cell population dynamics modulate the rates of tissue growth processes. Biophys. J. 90(3), 713–724 (2006)

Chung, C.A., Yang, C.W., Chen, C.W.: Analysis of cell growth and diffusion in a scaffold for cartilage tissue engineering. Biotechnol. Bioeng. 94(6), 1138–1146 (2006)

Chung, C.A., Chen, C.W., Chen, C.P., Tseng, C.S.: Enhancement of cell growth in tissue-engineering constructs under direct perfusion: modeling and simulation. Biotechnol. Bioeng. 97(6), 1603–1616 (2007)

Cioffi, M., Boschetti, F., Raimondi, M.T., Dubini, G.: Modeling evaluation of the fluid-dynamic microenvironment in tissue-engineered constructs: a micro-CT based model. Biotechnol. Bioeng. 93(3), 500–510 (2006)

Cioffi, M., Küffer, J., Ströbel, S., Dubini, G., Martin, I., Wendt, D.: Computational evaluation of oxygen and shear stress distributions in 3D perfusion culture systems: macro-scale and micro-structured models. J. Biomech. 41(14), 2918–2925 (2008)

D’Angelo, C., Zunino, P.: Robust numerical approximation of coupled Stokes and Darcy flows applied to vascular hemodynamics and biochemical transport. ESAIM: Math. Model. Numer. Anal. (M2AN) 45(3), 447–476 (2011)

DiMicco, M.A., Sah, R.L.: Dependence of cartilage matrix composition on biosynthesis, diffusion, and reaction. Transp. Porous Media 50(1–2), 57–73 (2003)

El Haj, A.J., Wood, M.A., Thomas, P., Yang, Y.: Controlling cell biomechanics in orthopaedic tissue engineering and repair. Pathol. Biol. 53(10), 581–589 (2005)

Galban, C.J., Locke, B.R.: Analysis of cell growth kinetics and substrate diffusion in a polymer scaffold. Biotech. Bioeng. 65(2), 121–132 (1999)

Galbusera, F., Cioffi, M., Raimondi, M.T., Pietrabissa, R.: Computational modelling of combined cell population dynamics and oxygen transport in engineered tissue subject to interstitial perfusion. Comput. Methods. Biomech. Biomed. Eng. 10(4), 279–287 (2007)

Galbusera, F., Cioffi, M., Raimondi, M.T.: An in silico bioreactor for simulating laboratory experiments in tissue engineering. Biomed. Microdevice 10(4), 547–554 (2008)

Glowinski, R., Pan, T.W., Périaux, J.: A fictitious domain method for Dirichlet problem and applications. Comput. Methods Appl. Mech. Eng. 111(3-4), 283–303 (1994)

Hansbo, A., Hansbo, P.: An unfitted finite element method, based on Nitsche’s method for elliptic interface problems. Comput. Methods Appl. Mech. Eng. 191(47-48), 5537–5552 (2002)

Hsu, C.T., Cheng, P.: Thermal dispersion in a porous medium. Int. J. Heat Mass Transfer 33(8), 1587–1597 (1990)

Klein, T.J., Sah, R.L.: Modulation of depth-dependent properties in tissue-engineered cartilage with a semi-permeable membrane and perfusion: a continuum model of matrix metabolism and transport. Biomech. Model Mechanobiol. 6, 21–32 (2007)

Laganà, M., Raimondi, M.T.: (2011) A miniaturized, optically accessible bioreactor for systematic 3D tissue engineering research. Biomedical Microdevices. doi:10.1007/s10544-011-9600-0

Lemon, G., King, J.R., Byrne, H.M., Jensen, O.E., Shakesheff, K.M.: Mathematical modelling of engineered tissue growth using a multiphase porous flow mixture theory. J. Math. Biol. 52(5), 571–594 (2006)

Marle, C.: On macroscopic equations governing multiphase flow with diffusion and chemical reactions in porous media. Int. J. Eng. Sci. 20(5), 643–662 (1982)

Mizuno, S., Tateishi, T., Ushida, T., Glowacki, J.: Hydrostatic fluid pressure enhances matrix synthesis and accumulation by bovine chondrocytes in three-dimensional culture. J. cell physiol. 193, 319–327 (2002)

Moretti, M., Freed, L.E., Padera, R.F., Laganà, K., Boschetti, F., Raimondi, M.T.: An integrated experimental–computational approach for the study of engineered cartilage constructs subjected to combined regimens of hydrostatic pressure and interstitial perfusion. Bio-Med. Mater. Eng. 18(4–5), 273–278 (2008)

Obradovic, B., Meldon, J.H., Lisa, E.F., Vunjak-Novakovic, G.: Glycosaminoglycan deposition in engineered cartilage: experiments and mathematical model. AIChE J. 46, 1860–1871 (2000)

Palsson, E.: A three-dimensional model of cell movement in multicellular systems. Future Gener. Comput. Sys. 17, 835–852 (2001)

Pisu, M., Lai, N., Cincotti, A., Concas, A., Cao, G.: Modeling of engineered cartilage growth in rotating bioreactors. Chem. Eng. Sci. 59, 5035–5040 (2004)

Plank, M.J., Sleeman, B.D., Jones, P.F.: A mathematical model of tumour angiogenesis, regulated by vascular endothelial growth factor and the angiopoietins. J. Theor. Biol. 229(4), 435–454 (2004)

Porter, B., Zauel, R., Stockman, H., Guldberg, R., Fyhrie, D.: 3-D computational modeling of media flow through scaffolds in a perfusion bioreactor. J. Biomech. 38(3), 543–549 (2005)

Potter, H.G., Linklater, J.M., Allen, A.A., Hannafin, J., Haas, S.: Magnetic resonance imaging of articular cartilage in the knee. An evaluation with use of fast-spin-echo imaging. J. Bone Joint Surg. (Am.) 80, 1276–1284 (1998)

Quarteroni, A., Valli, A.: Domain Decomposition Methods for Partial Differential Equations. Numerical Mathematics and Scientific Computation. Oxford Science Publications, The Clarendon Press, Oxford University Press, New York (1999), ISBN: 0-19-850178-1

Quarteroni, A., Veneziani, A., Zunino, P.: Mathematical and numerical modelling of solute dynamics in blood flow and arterial walls. SIAM J. Numer. Anal 39(2), 1488–1511 (2002)

Quarteroni, A., Veneziani, A., Zunino, P.: Domain decomposition methods for blood solute dynamics. SIAM J. Sci. Comput. 23(6), 1959–1980 (2002)

Raimondi, M.T., Boschetti, F., Falcone, L., Fiore, G.B., Remuzzi, A., Marinoni, E., Marazzi, M., Pietrabissa, R.: Mechanobiology of engineered cartilage cultured under a quantified fluid-dynamic environment. Biomech. Model. Mechanobiol. 1, 69–82 (2002)

Raimondi, M.T., Boschetti, F., Falcone, L., Migliavacca, F., Remuzzi, A., Dubini, G.: The effect of media perfusion on three-dimensional cultures of human chondrocytes: integration of experimental and computational approaches. Biorheology 41(3–4), 401–410 (2004)

Raimondi, M.T.: Engineered tissue as a model to study cell and tissue function from a biophysical perspective. Curr. Drug Discov. Technol. 3(4), 245–268 (2006a)

Raimondi, M.T., Moretti, M., Cioffi, M., Giordano, C., Boschetti, F., Laganà, K., Pietrabissa, R.: The effect of hydrodynamic shear on 3D engineered chondrocyte systems subject to direct perfusion. Biorheology 43(3–4), 215–222 (2006b)

Raimondi, M.T., Candiani, G., Cabras, M., Cioffi, M., Laganà, K., Moretti, M., Pietrabissa, R.: Engineered cartilage constructs subject to very low regimens of interstitial perfusion. Biorheology 45(3–4), 471–478 (2008)

Raimondi, M.T., Bridgen, D.T., Laganà, M., Tonnarelli, B., Cioffi, M., Boschetti, F., Wendt, D.: In-tegration of experimental and computational microfluidics in 3D tissue engineering. In: Berthiaume, F., Morgan, J. (eds.) Methods in Bioengineering––3D Tissue Engineering. Artech House, Boston, London (2010). ISBN: 978-1-59693-458

Raimondi, M.T., Bonacina, E., Candiani, G., Laganà, M., Rolando, E., Talò, G., Pezzoli, D., D’Anchise, R., Pietrabissa, R., Moretti, M.: Comparative chondrogenesis of human cells in a 3D integrated experimental-computational mechanobiology model. Biomech. Model. Mechanobiol. 10(2), 259–268 (2011a)

Raimondi, M.T., Causin, P., Mara, A., Nava, M., Laganà, M., Sacco, R.: Breakthroughs in computational modeling of cartilage regeneration in perfused bioreactors. IEEE Trans. Biomed. Eng. 58(12) (2011b). doi:10.1109/TBME.2011.2163405

Sacco, R., Causin, P., Zunino, P., Raimondi, M.T.: A multiphysics/multiscale numerical simulation of scaffold-based cartilage regeneration under interstitial perfusion in a bioreactor. Biomech. Model. Mechanobiol. 10(4), 577–589 (2011)

Sengers, B.G., van Donkelaar, C.C., Oomens, C.W., Baaijens, F.P.: Computational study of culture conditions and nutrient supply in cartilage tissue engineering. Biotechnol. Prog. 21(4), 1252–1261 (2005)

Schulz, R.M., Bader, A.: Cartilage tissue engineering and bioreactor systems for the cultivation and stimulation of chondrocytes. Eur. Biophys. J. 36, 539–568 (2007)

Singh, H., Teoh, S.H., Low, H.T., Hutmacher, D.W.: Flow modeling within a scaffold under the influence of uni-axial and bi-axial bioreactor rotation. J. Biotechnol. 119, 181–196 (2005)

Whitaker, S.: The Method of Volume Averaging Theory and Application of Transport in Porous Media. Kluwer Academic Publishers, Dordrecht (1999)

Williams, K.A., Saini, S., Wick, T.M.: Computational fluid dynamics modeling of steady-state momentum and mass transport in a bioreactor for cartilage tissue engineering. Biotechnol. Prog. 18(5), 951–963 (2002)

Wood, B.D., Quintard, M., Whitaker, S.: Calculation of effective diffusivities for bio films and tissues. Biotech. Bioeng. 77(5), 495–514 (2002)

Acknowledgments

This research is funded by Politecnico di Milano, under grant 5 per Mille Junior 2009 CUPD41J10000490001 “Computational Models for Heterogeneous Media. Application to Micro Scale Analysis of Tissue-engineered Constructs”, by the Italian Institute of Technology (IIT-Genoa), under grant “Biosensors and Artificial Bio-systems”, and by the Cariplo Foundation (Milano), under grant 2010 “3D Micro structuring and Functionalisation of Polymeric Materials for Scaffolds in Regenerative Medicine”.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2011 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Raimondi, M.T., Causin, P., Laganà, M., Zunino, P., Sacco, R. (2011). Multiphysics Computational Modeling in Cartilage Tissue Engineering. In: Geris, L. (eds) Computational Modeling in Tissue Engineering. Studies in Mechanobiology, Tissue Engineering and Biomaterials, vol 10. Springer, Berlin, Heidelberg. https://doi.org/10.1007/8415_2011_112

Download citation

DOI: https://doi.org/10.1007/8415_2011_112

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-32562-5

Online ISBN: 978-3-642-32563-2

eBook Packages: EngineeringEngineering (R0)