Abstract

Cartilage is a fundamental tissue to ensure proper motion between bones and damping of mechanical loads. This tissue often suffers damage and has limited healing capacity due to its avascularity. In order to replace surgery and replacement of joints by metal implants, tissue-engineered cartilage is seen as an attractive alternative. These tissues are obtained by seeding chondrocytes or mesenchymal stem cells in scaffolds and are given certain stimuli to improve the establishment of mechanical properties similar to the native cartilage. However, tissues with ideal mechanical properties were not obtained yet. Growth and remodelling (G&R) computational models of tissue-engineered cartilage are invaluable to interpret and predict the effects of experimental designs. The current model contribution in the field will be presented in this chapter, with a focus on the response to mechanical stimulation, and the development of fully coupled modelling approaches incorporating simultaneously solute transport and uptake, cell growth, production of extracellular matrix and remodelling of mechanical properties.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

Articular cartilage is a fundamental tissue that resides in the surface of bones, providing a smooth and lubricated surface for relative bone motion in the joints and for transmission of loads with low friction [1, 2]. Articular cartilage is generally between 2 and 4 mm thick. Unlike other tissues, it does not have surrounding blood vessels or nerves [2]. The cartilage is populated by chondrocytes, specialized cells for the production of extracellular matrix (ECM). This matrix is mostly composed of collagen fibres, proteoglycans, water and other less present components, such as noncollagenous proteins and glycoproteins. The ECM components are fundamental for water retention in the tissue, promoting a softer load transfer and motion [1, 2]. Water is the most abundant component of articular cartilage, generally accounting for 65–80% of the total tissue weight. The collagen of the articular cartilage is mostly type II, and it is related to the tensile resistance of cartilage. Collagen accounts for 10–20% of the total cartilage mass. The proteoglycans are composed of a protein core with glycosaminoglycans (GAGs) attached, being 5–10% of the cartilage mass. The GAGs have a global negative charge that helps to control the hydration of cartilage and to provide resistance to compression and shear. When under a mechanical load, the proteoglycans promote a redistribution of water in cartilage, leading to an increase in osmotic pressure with water flow. The osmotic pressure becomes larger than the applied load, which is fundamental to protect bones from loading [1, 2]. A fundamental characteristic of articular cartilage is the depth-dependent organization, with three zones with distinct functions and collagen architectures: the superficial zone, responsible for protection against shear stress and with collagen fibres parallel to the surface of the tissue; the middle zone, with oblique collagen fibres and providing the first resistance to compression and the deep zone, with the highest resistance to compressive forces with collagen fibres oriented perpendicularly to the cartilage surface. The cartilage is anchored to the subchondral bone by the calcified layer [1].

The most common pathology associated with articular cartilage is osteoarthritis (OA), a degenerative disease that causes loss of the smooth surface of cartilage with pain, inflammation and loss of motion amplitude. The highest risk factor for OA is increasing age, while other factors such as obesity, genetics and gender are also associated [3]. The worldwide prevalence of OA was estimated to be 3.8% in 2010 [4], and the direct and indirect costs of the disease are very high. In the USA only, the annual medical care expenditures with OA are of about $185 billion [5]. While traditionally seen as a disease of the cartilage only, more recently, OA has been identified as a multi-organ pathology, causing subsequent damage in bone marrow and bone, tendons, ligaments, muscles and neural tissues [6].

Since cartilage is an avascular tissue, the intrinsic regeneration capacity of articular cartilage is very limited, leading to increasing severity of damage. The current therapeutic solutions are the total joint replacement by a metal implant, which is more common in older patients with very advanced damage. Other solutions for younger patients are the microfracture and autologous chondrocyte implantation to promote the formation of new cartilaginous tissue in the injury site. These solutions have moderate short-term success rates, while long-term results are not satisfactory. The failure of these therapies is related with the formation of tissue with inferior mechanical properties to the native tissues, with possible fibrocartilage formation [7].

Tissue-engineered (TE) cartilage has been proposed as a prospective new treatment for osteoarthritis by the in vitro production of cartilaginous tissue with more similar structure, composition and properties to the native articular cartilage. TE cartilage is obtained by seeding chondrocytes or mesenchymal stem cells (MSCs) with chondrogenic cues, on a porous and biocompatible scaffold that is able to provide a favourable environment to maintain the differentiated phenotype of chondrocytes and to enable the production of extracellular matrix (ECM). Although promising, the translation of this approach to products has been hindered by some factors, such as insufficient mechanical properties, mainly due to the inability of the engineered tissues to have a type II collagen content similar to the native cartilage, difficulty in creating an anisotropic tissue structure with three layers with collagen fibres oriented as found in the native tissue, and heterogeneous mechanical properties with stiffer peripheries and softer cores [8,9,10,11].

In order to better predict the experimental conditions to subject the growing tissue to, either by mechanical, electrical and/or chemical stimuli, computational models of tissue-engineered cartilage are invaluable. Mathematical modelling in the context of TE cartilage has provided good insights on the nutrient distribution in the growing tissues [12,13,14,15], cell proliferation and death [12,13,14], synthesis of the main components of ECM, such as proteoglycans and collagen [16,17,18] and remodelling of biphasic mechanical properties [12, 14, 17, 19]. Most of these models attempt to solve one or two variables responsible for the full remodelling of TE cartilage. Recently, a new approach that couples all these factors in order to simulate spatiotemporal patterns of metabolic activity, biomass growth and remodelling properties simultaneously was developed with results for both unloaded and mechanical stimulated constructs [20,21,22].

This chapter aims to review the body of work in the computational modelling of tissue-engineered cartilage with a focus on metabolic, biomass growth and mechanical remodelling. It is organized into several sections that emphasize different relevant aspects of the biomechanical behaviour of the growing cartilaginous tissues. Thus, Sect. 2 emphasizes the transport, uptake and production of relevant metabolites or growth factors that impact the biosynthetic activity of chondrocytes or mesenchymal stem cells, and how thee mechanisms are affected by external stimuli. A particular focus will be given to the main metabolites involved in chondrocyte metabolism: glucose, oxygen and lactate. Then, Sect. 3 is related to the different models proposed to modulate the proliferation, death and migration of chondrocytes and in the case of MSCs, the proliferation of these and their differentiation into chondrocytes and other possible lineages. Section 4 is concerned with to the models of synthesis of the main components of the extracellular matrix (ECM), glycosaminoglycans (GAGs) and collagen taking into account the impact of different stimuli on the production rates, binding and degradation of the matrix, as well as the alignment of collagen fibres to establish the anisotropy of the cartilaginous tissue. Afterwards, Sect. 5 describes the models of the mechanical behaviour of cartilage and the remodelling of the mechanical properties of tissue-engineered cartilage based on the produced biomass and ECM. Section 6 presents the models that couple all the aforementioned concepts into simultaneous metabolic, biosynthetic and mechanical remodelling models.

2 Models for Solute Transport, Uptake and Release

In order to obtain tissue-engineered cartilage with a sufficient amount of extracellular matrix, cells need to consume high amounts of nutrients to support their anabolic activity. However, there are serious limitations to nutrient transport across the tissues, which become hindered by the increase of matrix accumulation and decrease of the tissue porosity. This limitation is particularly seen in the cores of the tissues, where supply of nutrients is limited and accumulation of toxic byproducts leads to increased heterogeneities in the growing tissues. As a consequence, tissues with cores with lower cell viability and ECM content are formed, leading to inferior mechanical properties [11, 12, 23, 24]. It has been postulated that, apart from the diffusive transport present in free swelling and unstrained constructs, advective nutrient transport may be helpful to reduce heterogeneities in nutrient supply, with a higher positive contribution for the transport of large solutes over small solutes [23, 25, 26].

The simplest modelling approach for solute transport is based on the diffusion-reaction equation, where solute diffuses through a porous tissue with a diffusivity that is a fraction of the diffusivity in the fluid phase, and with a reactive term correspondent to the consumption or release of solutes depending on the amount of solute and the cell density in the tissue. A typical way to demonstrate the decrease of diffusivity across a porous tissue is given by the Mackie–Mears relationship. The most common representation of the reactive term is based on the Michaelis–Menten kinetics, as shown below [12, 25, 27–30].

When dynamic loading is involved, an advective term is included to represent the fluid flow mediated transport [27, 30–33].

In the equations above, c represents the concentration of the nutrient, \( D_{\text{tissue}} \) represents the diffusion coefficient of the nutrient in the tissue, R the flux of the metabolite, \( \rho_{\text{cell}} \) the cell density, \( V_{\hbox{max} } \) the maximum uptake rate, and \( K_{\text{m}} \) is the half-maximum-rate concentration and \( n_{\text{f}} \) the fluid volume fraction. The solutes consumed by the cells that are typically simulated in previous works are glucose and oxygen, and several studies used this simplified assumption for consumption with good results [12, 22, 27, 29, 32]. However, particularly in cases where the culture medium has a high content in glucose, the deleterious effect of lactate production in cell proliferation cannot be ignored, and the release of lactate to the culture media is also modelled, considering both anaerobic and aerobic degradation of glucose depending on the experimental lactate to glucose ratios [12, 34]. Under dynamic loading conditions, deformation affects solute transport in several ways. In the first place, the diffusion coefficient depends on the porosity of the scaffold used for cell support. As stated before, a common law used in previous modelling contributions is the Mackie–Mears diffusion law. Another effect of dynamic loading in the cellular metabolism is related to the variation of cell density. Assuming, as a simplification, that the number of cells in a given volume is constant, under loading, the cell density is affected due to the change of volume of the constructs in a compressible scaffold. This volume change is described by the determinant of the deformation gradient tensor (J). This value describes the ratio between the volume of the deformed configuration and the undeformed configuration. Therefore, the deformed cell density is obtained as such [35, 36].

3 Models for Cellular Dynamics

The cell population in tissue-engineered cartilage is highly dynamic and dependent on several metabolic and physical cues. The main mechanisms associated with cells populating the newly formed tissue are [37]:

-

Proliferation—A fundamental factor to obtain ECM in proper amounts. However, the higher the cell population, the more likely the nutrient depletion and inhomogeneity in cell distributions across the tissue.

-

Differentiation—When the tissue is seeded with mesenchymal stem cells (MSCs), an important factor to control besides their proliferation is the differentiation into chondrocytes. Since MSCs can also give rise to adipocytes and osteocytes, a precise control of the biochemical and biomechanical cues to favour differentiation into a given precise lineage is fundamental.

-

Migration—spatial redistribution of cells in the scaffold can both occur due to random walks without a preferential direction or can happen directionally towards chemoattractants. In high-density scaffolds, cells can form colonies.

-

Death—Apart from the regular lifespan of chondrocytes, lack of nutrients or aggressive external physical cues will speed up the process of death.

The typical model for cell dynamics in a tissue-engineered cartilage takes into account these factors as follows:

A diffusion coefficient, \( D_{\text{cell}} \), is introduced due to the assumption that new chondrocytes have mobility due to random walks [38]. While the death rate per cell, \( R_{\text{death}} \), is assumed constant, the proliferation rate, \( R_{\text{prol}} \), is modulated both by metabolic and mechanical factors that decrease the actual proliferation from the maximum proliferation rate, \( \mu_{\hbox{max} } \). The simplest model for nutrient-limited cell proliferation (accounted for in \( R_{\text{prol}} \)) in tissue-engineered cartilage is given by the Monod kinetics. In this model, similar to the Michaelis–Menten kinetics for nutrient dynamics, growth is limited by the availability of a nutrient, for which a half-rate concentration controls the steepness until maximum growth.

Several models based on the Monod kinetics have good results in comparison with experimental data, either by using one solute only, such as glucose [39, 40] or oxygen [14, 41–44], or a combination of solutes, like models with glucose and collagen [45], or models inhibited by pH decrease simplified as accumulation of lactate [34].

Another model that is commonly used in the literature to describe the limitation of chondrocyte growth by substrate is the Contois kinetics. This representation differs from the Monod kinetics because the growth in the Contois kinetics is also inhibited by the cell density, implying saturation of growth due to spatial competition of cells for resources, as shown below:

The Contois kinetics has also provided good agreement to the growth of chondrocytes in different scaffolds, using glucose [13, 22, 38, 39], oxygen [46, 47], a combination of glucose and lactate [48] and a combination of glucose and lactate accounting for pH negative effects [49].

In terms of the metabolic modulation of cell growth, other less used equations are reported, such as the Heaviside step function [50, 51], the Moser or heterogeneous n-th order model [39] and logistic function [32].

In order to incorporate the impact of mechanical stimulation in cell growth, some models have built up from the aforementioned mechanical factors and introduced the impact of shear stress in cell growth. It was shown experimentally that articular chondrocytes show a dose and time-dependent response to shear stress [52, 53]. Two main modelling contributions have been proposed to incorporate this effect in mathematical models thus far. In the first place, a simple linear model of a linearly increase in the growth rate with increasing shear stress was proposed [14, 34]. An extension of this equation was proposed as a polynomial dependence with a non-integer factor by [47]. A more recent contribution resides in a piecewise function with shear stress, accounting for a maximum stimulatory range of shear stresses between 0.1 and 0.6 Pa as determined experimentally and assuming suppression of growth for stresses above 1 Pa [15].

All the models presented thus far consider growth on a homogeneous cell population with the same characteristics. Other models have focused on particular compartments of the cell population for modelling, with a cell in a given state having a different role in tissue homeostasis. A model reporting a proliferative, an extracellular matrix producing and a quiescent cell fraction was proposed with interchangeability between these compartments [54], having been recently expanded to include a transitional state between proliferative and ECM producing states and the possibility of quiescence and apoptosis [44]. Another compartmental modelling approach is related to the influence of the phase of the cell cycle during mitosis on the maturity of the cell and the possibility of undergoing protein synthesis [54]. While these contributions are valuable and in closer agreement with the inherent biology of the chondrocytes, the previously reported general chondrocyte growth models have shown good agreement with experiments and are, in most cases, a reasonable modelling approach.

4 Models for ECM Growth

The extracellular matrix of articular cartilage is a collagen fibre network, mainly composed by type II collagen, and of glycosaminoglycans (GAGs) that provide mechanical support to chondrocytes and resistance to the mechanical stimuli that cartilage is subjected to An and Martin [1, 16, 17]. In tissue-engineered cartilage, it is highly required to stimulate the new tissues to produce a network similar to the native cartilage, with a content of 5–10% of the total mass in GAGs and 10–20% of the total mass in collagen [1]. While there are reported studies able to produce GAGs in a concentration similar to the native cartilage, the collagen content is much lower than the native values, being this one of the most significant hurdles to surpass to obtain viable tissue for implantation [9, 55].

The main mechanisms behind ECM dynamics are

-

Synthesis—Synthesis models are focused on the total cell population as a whole, assuming that all cells have the ability to produce ECM or on an ECM producing cell compartment, depending on the model for cell growth used. Synthesis rates may depend on the availability of a given substrate or on the mechanical stimuli that cells face.

-

Binding—The newly synthesized ECM composing molecules are released into the media and then linked to the ECM.

-

Degradation—Bound ECM molecules are degraded and diffused into the culture media at a given rate due to several forms of damage.

The first models appearing in the literature on this matter started to consider the ECM as a whole and did not provide distinction between collagen and proteoglycans. These models considered a linear synthesis rate modulated by the difference between current ECM concentrations and the steady-state concentration of ECM, due to the experimental observation that synthesis rates decay with the accumulation of ECM [16]. This model formulation was later adapted to include the impact of cell density in the growth rates and a separation by type of ECM component, the differentiation between bound and unbound ECM, and the rates of degradation [17, 18, 22, 56–59]. The typical formulation for these three ECM mechanisms is depicted in the equations below:

In the equations above, the unbound \( \left( {{\text{ECM}}_{\text{ub}} } \right) \), bound \( \left( {{\text{ECM}}_{\text{b}} } \right) \) and the degradation products \( \left( {{\text{ECM}}_{\text{d}} } \right) \) are controlled by the respective diffusion coefficients and by the synthesis \( \left( {k_{\text{s}} } \right) \), binding \( \left( {k_{\text{b}} } \right) \) and degradation rates \( \left( {k_{\text{d}} } \right) \). It is assumed that, in tissue-engineered cartilage, ECM growth will saturate at a given concentration, hence the dependence of the synthesis rate on the steady-state concentration \( {\text{ECM}}_{{{\text{b}},{\text{ss}}}} \). Apart from the commonly used linear dependence of the synthesis rate on the concentration of the specific ECM entity to model, other dependences were reported, such as a logistic dependence on the unbound GAG concentration [44, 60, 61] or the impact of levels of relevant solutes, like glucose [20, 62] and oxygen [20, 44, 60, 61], on the synthesis rates of GAG. For collagen, a dependence on the cell proliferation time derivative, instead of the typical linear dependence on cell density, was also reported [11].

The impact of mechanical stimuli on the synthesis rates of extracellular matrix has been less explored so far, but some contributions are provided in the literature. Fluid velocity levels were considered in a previous level to directly affect the GAG synthesis rate, based on experimental observations that fluid velocity has a stimulatory effect on GAG synthesis, while for collagen, an attempt in the same work was performed considering augmented synthesis when the maximum principal strain is above a given threshold value [63]. The dependence on fluid velocity for GAG synthesis and on maximum principal strain for collagen synthesis was implemented in previous research works [20, 21] although with a different formulation. Fluid velocity and shear stress were also considered as stimulatory for cartilage growth above a given threshold for both proteoglycans and collagen [64]. More recently, a modular function assuming that there is an optimal cell volume for synthesis of GAG by chondrocytes was implemented as a function of tissue deformation [65].

Another factor that is relevant for the establishment of extracellular matrix and of the anisotropic properties is the remodelling and reorientation of the collagen fibres. It is known that collagen fibres align in preferred directions between the maximum principal strain directions [10, 59, 66]. Therefore, the application of mechanical stimuli can be used to drive the desired orientation of tissue-engineered cartilage. The first work that applied the remodelling theory of collagen fibres in cartilage assumed that collagen fibres rotated with an angular velocity controlled by the angle between the collagen fibre directions in the undeformed configuration and the preferred fibril directions, taking into account the magnitude of the three possible spatial principal strains to establish these directions [66]. Another approach to computational modelling of fibre reorientation was provided through an anisotropic tensor describing the degree of structural anisotropy and an ellipsoid representation for the fibre material parameters. Here, the reorientation is described through the angle between the current anisotropic tensor and the Cauchy–Green strain tensor and mediated through a time constant [18]. Furthermore, a probability density approach for the distribution of collagen fibres that can change over time with respect to the mechanical stimuli was also proposed [67]. These concepts are inherently coupled with the constitutive relationship used to describe the mechanical behaviour of growing cartilage.

5 Models for Description of the Mechanical Behaviour and Remodelling of Mechanical Properties

Cartilaginous tissue obtained through support of a porous scaffold is a material with a very high water content, like the native articular cartilage. For this reason, a simple monophasic constitutive material is not sufficient to explain the viscoelastic behaviour of cartilage, caused by fluid flow-dependent and independent mechanisms inherent to the properties of the solid material [68]. For this reason, mixture models based on the biphasic theory were proposed. These models describe the total stress in the tissue with a solid stress \( \sigma^{\text{S}} \) and a hydraulic pore pressure component p [20,21,22, 68,69,70].

Fluid flow is governed by the Darcy’s law, which states that fluid velocity, \( v^{\text{f}} \) (m s−1), relative to the solid matrix, \( v^{\text{s}} \), is proportional to the gradient of the pore pressure Vp (Pa) and controlled by the permeability, k (m2), of the porous scaffold, accounting as well for the porosity, n, of the material [56].

Due to the very high fluid content of these native cartilage, both the solid and fluid phases are generally described as incompressible or nearly incompressible for simplicity (that is, with a Poisson’s ratio close to 0.5). However, in the tissue-engineered cartilage, some polymers are described as compressive solids in equilibrium with an incompressible fluid [8, 10, 22, 71]. These models can partly describe the fluid flow-related viscoelasticity related to the low permeability of the material.

As an extension to the biphasic model for cartilage behaviour, triphasic models were developed to take into account the swelling behaviour due to gradients in osmotic pressure. This model accounts for a fluid with ionic particles, inducing or limiting chemical expansion of the negatively charged proteoglycan chains due to electrostatic repulsion. The osmotic pressure gradient \( \left( {\Delta \pi } \right) \) and the chemical potential of the fluid \( \left( {\mu f} \right) \) that drive the ionic phase stress contribution are caused by differences in ion concentrations of the cartilage and the surrounding fluid [68].

For the solid phase of these models, several constitutive relationships were proposed to describe the mechanical behaviour. The simples theory to describe the behaviour of porous and viscoelastic materials is the poroelastic theory, where the solid phase is linear elastic and the fluid is viscous. In this model, the stress–strain relationship of the solid phase is provided by the Hooke’s Law:

In the equation above, \( H_{\text{a}} \) is the aggregate modulus, which is a measure of the stiffness of the material in equilibrium when fluid flow through the material ceases. This quantity is related to the Young’s modulus (E) and the Poisson’s ratio \( \left( \upsilon \right) \) through the following relationship:

For mechanical modelling of scaffolds impregnated with chondrocytes, the poroelastic theory has been widely used [22, 23, 71, 72]. Another reported theory for modelling of the solid phase is the porohyperelastic theory. Similarly, to the poroelastic theory, the fluid is viscous but the solid phase has an hyperelastic constitutive relationship, such as the stress–strain behaviour is modelled by a nonlinear relationship dependent on the strain energy (W) and on the deformation gradient tensor (F) and its determinant, J.

Models with a solid phase described by the neo–Hookean hyperelastic relationship have been widely used to modulate the mechanical behaviour of articular cartilage [25, 70, 73, 74]. Modelling of the hydrogel solid phase has used either the neo–Hookean law or the Odgen law [75, 76].

The mentioned hyperelastic models until now are isotropic with the same mechanical properties in all dimensions. However, articular cartilage is an anisotropic material, with stress–strain behaviour dependent on the orientation of the collagen fibres [68]. Therefore, it is more appropriate in long-term studies of cartilage growth to model the growing tissue with an anisotropic model with augmented tensile response in the loading directions equal to the fibre directions. A proposed model for this is the Holzapfel–Gasser–Odgen model [69], which divided the ECM into a non-fibrilar component, explained by the neo–Hookean model, and a fibrilar component with strain energy dependent on material parameters and the degree of anisotropy of the tissue. A similar relationship was reported, with the difference of taking into account a continuous exponential angular fibre distribution [18, 67].

Another theory reported to describe the mechanical behaviour of hydrogels is the poroviscoelastic model, with a non-viscous fluid and a viscoelastic solid phase [77, 78]. This model is not used, to our knowledge, to model hydrogels with growing cartilage.

A highly relevant parameter for the description of the biphasic behaviour of cartilage is the hydraulic permeability. This parameter is related to changes in the porosity and void ratio of the material. Several exponential relationships between the permeability and porosity or void ratio were presented, with two of the most common ones being the Holmes and Mow law [33, 79, 80] and the Carman–Kozeny law [14, 22] for isotropic permeability remodelling. However, with the growth of collagen fibres, the permeability also becomes anisotropic, with different values according to the orientation parallel or perpendicular to the fibres. Studies for modelling of articular cartilage explants have already included this dependency [67, 69].

While the newly formed tissue is growing and ECM is deposited, the mechanical properties of the tissue are changing. The target average values of mechanical properties of tissue-engineered cartilage are between 450 and 800 kPa of compressive Young’s modulus and 10−16 to 10−15 m4. N−1 s−1 in hydraulic permeability [81]. A tissue that combines these two ranges of mechanical parameters has not yet been established. In long-term tissue-engineered cartilage modelling, establishing remodelling algorithms to simulate and account for the change of the mechanical properties is fundamental to determine with accuracy the intrinsic mechanical response of the tissues to external stimuli.

Few studies have reported relationships for the modelling of the solid matrix properties under linear elastic assumptions. The Young’s modulus remodelling was previously described by a linear model for the aggregate modulus with the concentration of GAGs and collagen derived from experimental data on bovine cartilage in different ages [19]. An extension of this relationship was reported as well with a fourth-order polynomial dependence on the collagen concentration [22]. If the Poisson’s ratio is assumed constant, the Young’s modulus can be derived directly from such relationships. However, a possible remodelling relationship for the Poisson’s ratio related to the porosity of the material was adapted from [82] since a compressible material, with the growth of ECM, tends to approach incompressibility.

In anisotropic models, the remodelling of the non-fibrilar part is controlled by the concentration of GAGs and the remodelling of fibrilar part controlled by the concentration of collagen. One reported relationship relates the rate of remodelling with the ratio of the current concentrations to the expected steady-state concentrations [18]. Regarding the remodelling of permeability, the lower availability of experimental permeability measurements compared to the modulus measurements hinders the fitting to mechanistic models. However, as a proper simplification, previously reported models relate the decrease of permeability with the increase of the volumetric fraction of cells and ECM throughout the construct, leading to a decrease in porosity [11].

6 Coupled Metabolic and Mechanical Remodelling Models

Currently, most of the modelling contributions for tissue-engineered cartilage are focused in up to three of the modelling dimensions presented. While all these contributions are very valuable, for a complete description of the behaviour of the tissue and the time and spatial evolution of mechanical properties, all four dimensions need to be included. The creation of a validated model with explanatory and predictive power with the dimensions of solute transport and consumption, cell dynamics, extracellular matrix growth and remodelling of mechanical properties will allow to explain in a more quantitative way the histologically observed differences in the distribution of the modelled quantities across the tissues, as well as being invaluable to recommend changes to the processes of tissue culture in order to obtain better results. Finally, the complete coupled model can be used to predict the impact of envisioned changes to the culture protocol, such as the type and geometry of the scaffold material, dynamic loading, culture exchange, seeding densities, among others. The general full modelling scheme flow is represented in Fig. 1.

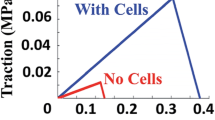

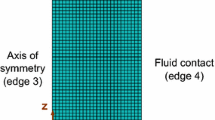

For the simulation of free swelling constructs with different scaffold geometries, the model was applied to simulate short-term effects in the Young’s modulus and hydraulic permeability of constructs with cylindrical and cubic geometries, either solid or with a central channel [83]. Despite the short culture period of 72 h, it was possible to determine that the channelled constructs had a large increase of nutrient availability related to the solid counterparts, with an up to 136-fold increase in minimum glucose concentrations and up to 220-fold increase in minimum oxygen concentrations. Under the model assumptions, ECM matrix synthesis increased up to 50% in the constructs with channel, favouring already a small positive impact on the mechanical properties after 72 h as a result of improved homogeneity across the tissues (Fig. 2).

Impact of several construct geometrical configurations in free swelling culture conditions on the radial distribution of biphasic mechanical properties after 72 h in culture. Reprinted from [83]

This work was expanded to a long-term culture case by simulating an experiment with both a solid and a channelled 2% w/w agarose construct with chondrocytes during 56 days. The model was calibrated with solid construct data on GAG and collagen concentrations, as well as on the compressive Young’s modulus and validated by reproducing well the experimental data for the channelled construct [22]. This modelling effort allowed to gain quantitative insights on the spatial heterogeneity of the constructs, showing that the degree of spatial heterogeneity of the Young’s modulus the constructs with a central diffusion channel is 23% of the control value, while for permeability, the heterogeneity is 27% of the control one, showing a significant improvement for the channelled condition (Fig. 3). The degree of spatial heterogeneity and the insufficient permeability remodelling in the simulated solid constructs affects significantly the mechanical response to compressive strain, with nominal stresses for the simulated heterogeneous TE cartilage 57% lower than for native articular cartilage and pore pressures 53% lower than the native case. Therefore, permeability is the main parameter to be improved to get a more similar mechanical response, calling for new scaffold material designs and stimulation protocols.

Spatial distributions of Young’s modulus at a 14 days, b 28 days, c 42 days, d 56 days. Reprinted Bandeiras and Ramos [22]

The developed complete model was also applied to simulate dynamic loading conditions. A model parameterized with the literature parameters was used to simulate the distribution of cell density and ECM in cubic constructs subjected to either compression, shear or bending at 5% of height, 1 Hz for 6 h continuously [20]. While the simulation time is very short for relevant differences in the mechanical properties to be seen, bending was, under these conditions, the more favourable regime for cell proliferation and the spatial distributions are relevant with the establishment of cartilage with different structural organizations due to different maximum principal strain directions (Fig. 4). Current work is related to the model validation for the estimation of cell proliferation, ECM growth and mechanical properties remodelling under several different regimes of cyclic unconfined compressive loading.

Values of the cell density, GAG and COL outputs for the compression (left), shear (centre) and bending (right) stimulus. Values obtained for the x = 0 plane. Reprinted from Bandeiras et al. [20]

All the reported works until now have been focused on articular cartilage. However, the complete modelling scheme was also successfully applied to estimate the remodelling of temporomandibular joint disc, an area where tissue engineering is still in a very early phase. The application of static hydrostatic pressure for 72 h on PEDGA-condylar constructs promoted a very slight improvement of the mechanical properties. This preliminary study provided a future basis to estimate the impact of long-term static or dynamic hydrostatic pressure on the growth of new temporomandibular joint discs [21].

The presented model applications for simulation of growth and remodelling under dynamic loading represent short-term loading with limited differences in the mechanical properties between conditions. Future work involves the simulation of long-term intermitted compressive loading. On long-term regimes, the collagen content is relevant in terms of fibre organization, and therefore, the expansion of the constitutive relationships to include the anisotropic behaviour of tissue-engineered cartilage and its time dynamics is a future goal.

7 Concluding Remarks

This chapter provided an overview of the current state of the computational models used for simulation of growth of tissue-engineered cartilage, namely the models based in mixture theory. The several individual contributions for the underlying phenomena, such as solute transport and uptake, cell growth, production of extracellular matrix and remodelling of mechanical properties, were presented, with a focus on, when applicable, the models that incorporate the impact of mechanical stimulation on these phenomena. Several constitutive relationships to model the mechanical behaviour of tissue-engineered cartilage have been proposed and integrated into these models. A fully coupled modelling approach was developed to accommodate all these phenomena in a simultaneous fashion for a more realistic representation of the biomechanical phenomena and used to estimate the growth and remodelling of mechanical properties under free swelling and mechanical loading of tissues. Future challenges on this area include refinement of the developed equations through validation with experimental studies with proper measurements of all the underlying variables when possible, study the degree of robustness and/or specificity with different cell-matrix systems, simulation of long-term mechanical loading cultures and the incorporation of anisotropic models with reorientation of collagen fibres in the fully coupled formulation.

References

An YH, Martin KL (2003) Handbook of histology methods for bone and cartilage. Springer

Fox AJS, Bedi A, Rodeo SA (2009) The basic science of articular cartilage: structure, composition, and function. Sports Health: A Multidisciplinary Approach 1(6):461–468

Loeser RF, Collins JA, Diekman BO (2016) Ageing and the pathogenesis of osteoarthritis. Nat Rev Rheumatol

Cross M, Smith E, Hoy D, Nolte S, Ackerman I, Fransen M, Bridgett L, Williams S, Guillemin F, Hill CL et al (2014) The global burden of hip and knee osteoarthritis: estimates from the global burden of disease 2010 study. Annals of the rheumatic diseases pp.annrheumdis–2013

Hiligsmann M, Reginster J (2013) The economic weight of osteoarthritis in Europe. Medicographia 35:197–202

Martin JA, Buckwalter JA (2002) Aging, articular cartilage chondrocyte senescence and osteoarthritis. Biogerontology 3(5):257–264

Kock L, van Donkelaar CC, Ito K (2012) Tissue engineering of functional articular cartilage: the current status. Cell Tissue Res 347(3):613–627

Mesallati T, Buckley CT, Nagel T, Kelly DJ (2013) Scaffold architecture determines chondrocyte response to externally applied dynamic compression. Biomech Model Mechanobiol 12(5):889–899

Bian L, Angione S, Ng K, Lima E, Williams D, Mao D, Ateshian G, Hung C (2009) Influence of decreasing nutrient path length on the development of engineered cartilage. Osteoarthritis Cartilage 17(5):677–685

Khoshgoftar M, Wilson W, Ito K, van Donkelaar CC (2013) The effect of tissue-engineered cartilage biomechanical and biochemical properties on its post-implantation mechanical behavior. Biomech Model Mechanobiol 12(1):43–54

Bandeiras C, Completo A (2015) Comparison of mechanical parameters between tissue-engineered and native cartilage: a numerical study. Comput Methods Biomech Biomed Eng 18(S1):1876–1877

Sengers BG, Heywood HK, Lee DA, Oomens CW, Bader DL (2005) Nutrient utilization by bovine articular chondrocytes: a combined experimental and theoretical approach. J Biomech Eng 127(5):758–766

Chung C, Chen C, Chen C, Tseng C (2007) Enhancement of cell growth in tissue-engineering constructs under direct perfusion: Modeling and simulation. Biotechnol Bioeng 97(6):1603–1616

Sacco R, Causin P, Zunino P, Raimondi MT (2011) A multiphysics/multiscale 2d numerical simulation of scaffold-based cartilage regeneration under interstitial perfusion in a bioreactor. Biomech Model Mechanobiol 10(4):577–589

Nava MM, Raimondi MT, Pietrabissa R (2013) A multiphysics 3d model of tissue growth under interstitial perfusion in a tissue-engineering bioreactor. Biomech Model Mechanobiol 12(6):1169–1179

Wilson CG, Bonassar LJ, Kohles SS (2002) Modeling the dynamic composition of engineered cartilage. Arch Biochem Biophys 408(2):246–254

Haider MA, Olander JE, Arnold RF, Marous DR, McLamb AJ, Thompson KC, Woodruff WR, Haugh JM (2011) A phenomenological mixture model for biosynthesis and linking of cartilage extracellular matrix in scaffolds seeded with chondrocytes. Biomech Model Mechanobiol 10(6):915–924

Nagel T, Kelly DJ (2011) Mechanically induced structural changes during dynamic compression of engineered cartilaginous constructs can potentially explain increases in bulk mechanical properties. J R Soc Interf 9(69):777–789

Bandeiras C, Completo A (2017) A mathematical model of tissue-engineered cartilage development under cyclic compressive loading. Biomech Model Mechanobiol 16(2):651–666

Bandeiras C, Completo A, Ramos A (2014) Compression, shear and bending on tissue-engineered cartilage: a numerical study. Comput Methods Biomech Biomed Eng 17(S1):2–3

Bandeiras C, Completo A, Ramos A (2014) Simulation of remodeling of tissue engineered condylar cartilage under static hydrostatic pressure. Biodental Engineering III p 83

Bandeiras C, Completo A, Ramos A (2015) Influence of the scaffold geometry on the spatial and temporal evolution of the mechanical properties of tissue-engineered cartilage: insights from a mathematical model. Biomech Model Mechanobiol 14(5):1057–1070

Mauck RL, Hung CT, Ateshian GA (2003) Modeling of neutral solute transport in a dynamically loaded porous permeable gel: implications for articular cartilage biosynthesis and tissue engineering. J Biomech Eng 125(5):602–614

Aristotelous AC, Haider MA (2014) Use of hybrid discrete cellular models for identification of macroscopic nutrient loss in reaction–diffusion models of tissues. Int J Numer Method Biomed Eng 30(8):767–780

Zhang L, Szeri A (2005) Transport of neutral solute in articular cartilage: effects of loading and particle size. In: Proceedings of the royal society of London A: mathematical, physical and engineering sciences, vol 461. The Royal Society, pp 2021–2042

Chahine NO, Albro MB, Lima EG, Wei VI, Dubois CR, Hung CT, Ateshian GA (2009) Effect of dynamic loading on the transport of solutes into agarose hydrogels. Biophys J 97(4):968–975

Zhou S, Cui Z, Urban JP (2004) Factors influencing the oxygen concentration gradient from the synovial surface of articular cartilage to the cartilage–bone interface: a modeling study. Arthritis Rheum 50(12):3915–3924

Zhou S, Cui Z, Urban JP (2008) Nutrient gradients in engineered cartilage: metabolic kinetics measurement and mass transfer modeling. Biotechnol Bioeng 101(2):408–421

Devarapalli M, Lawrence BJ, Madihally SV (2009) Modeling nutrient consumptions in large flow-through bioreactors for tissue engineering. Biotechnol Bioeng 103(5):1003–1015

Unnikrishnan G, Unnikrishnan V, Reddy J (2012) Finite element model for nutrient distribution analysis of a hollow fiber membrane bioreactor. Int J Numer Method Biomed Eng 28(2):229–238

Evans RC, Quinn TM (2006) Dynamic compression augments interstitial transport of a glucose-like solute in articular cartilage. Biophys J 91(4):1541–1547

Shakeel M (2013) 2-d coupled computational model of biological cell proliferation and nutrient delivery in a perfusion bioreactor. Math Biosci 242(1):86–94

Urciuolo F, Imparato G, Netti P (2008) Effect of dynamic loading on solute transport in soft gels implication for drug delivery. AIChE J 54(3):824–834

Hossain MS, Bergstrom D, Chen X (2015) Modelling and simulation of the chondrocyte cell growth, glucose consumption and lactate production within a porous tissue scaffold inside a perfusion bioreactor. Biotechnol Rep 5:55–62

Kam KK (2011) Poroelastic finite element analysis of a heterogeneous articular cartilage explant under dynamic compression in abaqus

Malandrino A, Noailly J, Lacroix D (2011) The effect of sustained compression on oxygen metabolic transport in the intervertebral disc decreases with degenerative changes. PLoS Comput Biol 7(8):e1002112

Sengers BG, Taylor M, Please CP, Oreffo RO (2007) Computational modelling of cell spreading and tissue regeneration in porous scaffolds. Biomaterials 28(10):1926–1940

Chung C, Yang C, Chen C (2006) Analysis of cell growth and diffusion in a scaffold for cartilage tissue engineering. Biotechnol Bioeng 94(6):1138–1146

Galban CJ, Locke BR (1999) Analysis of cell growth kinetics and substrate diffusion in a polymer scaffold. Biotechnol Bioeng 65(2):121–132

Cheng G, Markenscoff P, Zygourakis K (2009) A 3d hybrid model for tissue growth: the interplay between cell population and mass transport dynamics. Biophys J 97(2):401–414

Croll TI, Gentz S, Mueller K, Davidson M, O’Connor AJ, Stevens GW, Cooper-White JJ (2005) Modelling oxygen diffusion and cell growth in a porous, vascularising scaffold for soft tissue engineering applications. Chem Eng Sci 60(17):4924–4934

Malda J, Brink PVD, Meeuwse P, Grojec M, Martens D, Tramper J, Riesle J, Blitterswijk CV (2004) Effect of oxygen tension on adult articular chondrocytes in microcarrier bioreactor culture. Tissue Eng 10(7–8):987–994

Flaibani M, Magrofuoco E, Elvassore N (2009) Computational modeling of cell growth heterogeneity in a perfused 3D scaffold. Ind Eng Chem Res 49(2):859–869

Lelli C, Sacco R, Causin P, Raimondi MT (2015) A poroelastic mixture model of mechanobiological processes in tissue engineering. part i: Mathematical formulation. arXiv preprint arXiv:1512.02182

Chung C, Ho SY (2010) Analysis of collagen and glucose modulated cell growth within tissue engineered scaffolds. Ann Biomed Eng 38(4):1655–1663

Coletti F, Macchietto S, Elvassore N (2006) Mathematical modeling of three-dimensional cell cultures in perfusion bioreactors. Ind Eng Chem Res 45(24):8158–8169

Liu D, Chua CK, Leong KF (2013) A mathematical model for fluid shear-sensitive 3d tissue construct development. Biomech Model Mechanobiol 12(1):19–31

Yan X, Bergstrom D, Chen X (2012) Modeling of cell cultures in perfusion bioreactors. IEEE Trans Biomed Eng 59(9):2568–2575

Chung C, Chen C, Lin T, Tseng C (2008) A compact computational model for cell construct development in perfusion culture. Biotechnol Bioeng 99(6):1535–1541

Lewis MC, MacArthur BD, Malda J, Pettet G, Please CP (2005) Heterogeneous proliferation within engineered cartilaginous tissue: the role of oxygen tension. Biotechnol Bioeng 91(5):607–615

Landman KA, Cai AQ (2007) Cell proliferation and oxygen diffusion in a vascularising scaffold. Bull Math Biol 69(7):2405–2428

Lane Smith R, Trindade M, Ikenoue T, Mohtai M, Das P, Carter D, Goodman S, Schurman D (2000) Effects of shear stress on articular chondrocyte metabolism. Biorheology 37(1,2):95–107

Raimondi MT, Moretti M, Cioffi M, Giordano C, Boschetti F, Laganà K, Pietrabissa R (2006) The effect of hydrodynamic shear on 3d engineered chondrocyte systems subject to direct perfusion. Biorheology 43(3,4):215–222

Sengers B, Oomens C, Nguyen T, Bader D (2006) Computational modeling to predict the temporal regulation of chondrocyte metabolism in response to various dynamic compression regimens. Biomech Model Mechanobiol 5(2–3):111

Byers BA, Mauck RL, Chang IE, Tuan RS (2008) Transient exposure to TGF-β3 under serumfree conditions enhances the biomechanics and biochemical maturation of tissue-engineered cartilage. Tissue engineering Part A 14(11):1821

Sengers B, Van Donkelaar C, Oomens C, Baaijens F (2004) The local matrix distribution and the functional development of tissue engineered cartilage, a finite element study. Ann Biomed Eng 32(12):1718–1727

van Donkelaar C, Chao G, Bader D, Oomens C (2011) A reaction–diffusion model to predict the influence of neo-matrix on the subsequent development of tissue-engineered cartilage. Comput Methods Biomech Biomed Eng 14(05):425–432

DiMicco MA, Sah RL (2003) Dependence of cartilage matrix composition on biosynthesis, diffusion, and reaction. Transport Porous Med 50(1–2):57–73

Baaijens F, Bouten C, Driessen N (2010) Modeling collagen remodeling. J Biomech 43(1):166–175

Nikolaev N, Obradovic B, Versteeg HK, Lemon G, Williams DJ (2010) A validated model of GAG deposition, cell distribution, and growth of tissue engineered cartilage cultured in a rotating bioreactor. Biotechnol Bioeng 105(4):842–853

Obradovic B, Meldon JH, Freed LE, Vunjak-Novakovic G (2000) Glycosaminoglycan deposition in engineered cartilage: experiments and mathematical model. AIChE J 46(9):1860–1871

Myers K, Ateshian GA (2014) Interstitial growth and remodeling of biological tissues: tissue composition as state variables. J Mech Behav Biomed Mater 29:544–556

Yamauchi KA (2012) Prediction of articular cartilage remodeling during dynamic compression with a finite element model

Ficklin TP, Davol A, Klisch SM (2009) Simulating the growth of articular cartilage explants in a permeation bioreactor to aid in experimental protocol design. J Biomech Eng 131(4):041008

Gao X, Zhu Q, Gu W (2015) Analyzing the effects of mechanical and osmotic loading on glycosaminoglycan synthesis rate in cartilaginous tissues. J Biomech 48(4):573–577

Wilson W, Driessen N, Van Donkelaar C, Ito K (2006) Prediction of collagen orientation in articular cartilage by a collagen remodeling algorithm. Osteoarthritis Cartilage 14(11):1196–1202

Federico S, Herzog W (2008) On the anisotropy and inhomogeneity of permeability in articular cartilage. Biomech Model Mechanobiol 7(5):367–378

Julkunen P, Wilson W, Isaksson H, Jurvelin JS, Herzog W, Korhonen RK (2013) A review of the combination of experimental measurements and fibril-reinforced modeling for investigation of articular cartilage and chondrocyte response to loading. Comput Math Methods Med 2013

Pierce DM, Ricken T, Holzapfel GA (2013) A hyperelastic biphasic fibre-reinforced model of articular cartilage considering distributed collagen fibre orientations: continuum basis, computational aspects and applications. Comput Methods Biomech Biomed Eng 16(12):1344–1361

Bandeiras C, Completo A (2013) Comparison between constitutive models for the solid phase of biphasic agarose/chondrocytes constructs for knee cartilage engineering. Comput Methods Biomech Biomed Eng 16(S1):262–263

Tasci A, Ferguson SJ, Büchler P (2011) Numerical assessment on the effective mechanical stimuli for matrix-associated metabolism in chondrocyte-seeded constructs. J Tissue Eng Regen Med 5(3):210–219

Sengers BG, Oomens CW, Baaijens FP (2004) An integrated finite-element approach to mechanics, transport and biosynthesis in tissue engineering. J Biomech Eng 126(1):82–91

Wu J, Herzog W (2000) Finite element simulation of location-and time-dependent mechanical behavior of chondrocytes in unconfined compression tests. Ann Biomed Eng 28(3):318–330

Vahdati A, Wagner DR (2012) Finite element study of a tissue-engineered cartilage transplant in human tibiofemoral joint. Comput Methods Biomech Biomed Eng 15(11):1211–1221

Khoshgoftar M, van Donkelaar CC, Ito K (2011) Mechanical stimulation to stimulate formation of a physiological collagen architecture in tissue-engineered cartilage: a numerical study. Comput Methods Biomech Biomed Eng 14(02):135–144

Chen J, Irianto J, Inamdar S, Pravincumar P, Lee D, Bader DL, Knight M (2012) Cell mechanics, structure, and function are regulated by the stiffness of the three-dimensional microenvironment. Biophys J 103(6):1188–1197

Kalyanam S, Yapp RD, Insana MF (2009) Poro-viscoelastic behavior of gelatin hydrogels under compression-implications for bioelasticity imaging. J Biomech Eng 131(8):081005

Roberts JJ, Earnshaw A, Ferguson VL, Bryant SJ (2011) Comparative study of the viscoelastic mechanical behavior of agarose and poly (ethylene glycol) hydrogels. J Biomed Mater Res B Appl Biomater 99(1):158–169

Gu W, Yao H, Huang C, Cheung H (2003) New insight into deformation-dependent hydraulic permeability of gels and cartilage, and dynamic behavior of agarose gels in confined compression. J Biomech 36(4):593–598

Holmes M, Mow V (1990) The nonlinear characteristics of soft gels and hydrated connective tissues in ultrafiltration. J Biomech 23(11):1145–1156

Mansour JM (2003) Biomechanics of cartilage. Kinesiology: the mechanics and pathomechanics of human movement, pp 66–79

Wilson W, Huyghe J, Van Donkelaar C (2007) Depth-dependent compressive equilibrium properties of articular cartilage explained by its composition. Biomech Model Mechanobiol 6(1–2):43–53

Bandeiras C, Completo A, Ramos A (2014) Scaffold geometry influences the mechanical properties of tissue engineered cartilage. In: Proceedings of the 11th World Congress on Computational Mechanics (WCCM XI), Barcelona, 20–25 July 2014

Acknowledgements

This work is supported by the project POCI-01-0145-FEDER-028424, funded by Programa Operacional Competitividade e Internacionalização (COMPETE 2020) on its component FEDER and by funding from FCT—Fundação para a Ciência e Tecnologia on its component OE.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Bandeiras, C., Completo, A.M.G. (2020). Computational Modelling of Tissue-Engineered Cartilage Constructs. In: Belinha, J., Manzanares-Céspedes, MC., Completo, A. (eds) The Computational Mechanics of Bone Tissue. Lecture Notes in Computational Vision and Biomechanics, vol 35. Springer, Cham. https://doi.org/10.1007/978-3-030-37541-6_8

Download citation

DOI: https://doi.org/10.1007/978-3-030-37541-6_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-37540-9

Online ISBN: 978-3-030-37541-6

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)