Abstract

A piezoelectric sensor with a recognition layer based on magnetic carbon nanocomposites, including multi-walled carbon nanotubes, magnetic Fe3O4 nanoparticles, and polymer nanospheres with molecular imprints of erythromycin and azithromycin, obtained by the “core–shell” method, is developed. Silicon dioxide particles are used as cores, on the surface of which a shell molecularly imprinted with macrolides is synthesized by free radical polymerization or the sol–gel method. SiO2 particles are obtained by the Stober method by varying the ratio of reagents during the synthesis. The size of the cores and nanoparticles of molecularly imprinted polymers (MIP) is determined by atomic force microscopy, and the density and uniformity of the layer on the surface of magnetic carbon nanocomposites (MCNC) are determined by the piezoelectric quartz crystal microbalance method. The optimal ratio of the reagents (template : functional monomer : cross-monomer) is established by a spectrophotometric method during the synthesis of “core–shell” nanostructures by free radical polymerization. A thin shell of SiO2 with imprints of an antibiotic based on organosilicon compounds used in the synthesis of the core is formed by the sol–gel method on the surface of the silicon dioxide core. The sensor recognition layer is formed under the action of an external magnetic field. The dependence of the analytical signal of the sensor based on MIP@SiO2/MCNC on concentration is linear in the range 5–160 µg/mL for azithromycin and 10–160 µg/mL for erythromycin, and with a recognition layer based on SiO2@SiO2/MCNC, in the concentration range 20–400 µg/mL for erythromycin.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Piezoelectric gravimetric sensors have proved themselves well in the determination of toxicants in mixtures of complex composition with high sensitivity and selectivity virtually without sample preparation [1–4]. Most often, antibodies, antigens, and aptamers are used as recognition elements in piezoelectric sensors; they are characterized by a high specificity of interaction and allow obtaining information about the course of a biochemical reaction in almost real time [5–8]. However, their instability during storage, exposure to organic solvents, and high concentrations of electrolytes, as well as the difficulty of preparation [9], stimulates the search for “synthetic” antibodies, which can be molecularly imprinted polymers (MIP), which have a number of undeniable advantages over natural receptors. Molecularly imprinted polymers can be obtained by the copolymerization of a functional monomer and a cross monomer in the presence of template molecules (templates), which are most often the analytes. After the removal of the template molecule, an imprint is formed in the polymer matrix, which corresponds to the molecule to be determined in shape and chemical functionality, and the analyte can be selectively rebound to it [10, 11]. However, at present, there are no standard procedures for obtaining MIP with the necessary characteristics.

Molecularly imprinted polymers can be obtained by block polymerization and used after grinding and screening [12, 13]. However, regular-shaped imprinted polymers, especially in the nanoscale region, find wider application in sensorics [14, 15]. The MIP nanoparticles exhibit higher surface area to volume ratios; therefore, the imprints are more accessible to templates, which improves the kinetics of rebinding with template molecules. The most popular methods for the synthesis of MIP nanoparticles, such as micro- and miniemulsion polymerization, the precipitation method, and the core–shell method (core–shell, core–shell by grafting), carried out in two stages, should be noted [16–20]. At the first stage, a spherical core is formed, and at the second stage, a thin-layer polymer shell with imprints of analyte molecules is synthesized. In this case, the imprints are concentrated in a rather thin layer, which accelerates the rebinding of the template with the MIP. Magnetic Fe3O4 nanoparticles, chitosan nanoparticles, activated polystyrene beads, quantum dots, and SiO2 nanoparticles are used as cores [21–23]. For the shell synthesis, microemulsion and free radical polymerization (FRP), as well as the sol–gel method (SGM) are most often used [24, 25]. An earlier study on the use of Fe2O3 particles as cores showed that the high mass of MIP particles contributed to narrowing the range of analyte concentrations determined using a gravimetric piezoelectric sensor [26].

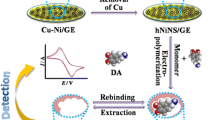

In the development of piezoelectric sensors, the method of forming a recognition layer is of paramount importance. Previously, we proposed obtaining a recognition layer of an immunosensor based on magnetic carbon nanocomposites (MCNC) under the action of an external magnetic field [27]. The carbon nanotubes (CNT) present in the nanocomposite contributed to an increase in the specific surface area of the electrode, i.e., made it possible to place a larger number of recognizing molecules, and magnetic particles (MNP) significantly reduced and simplified the procedure for preparing a piezoelectric sensor for analysis. In forming the receptor coating of a piezoelectric sensor based on MIP nanoparticles, it is necessary to limit the mass of polymer particles in order not to make the recognition layer heavier. More promising is the use of MIP obtained by the core–shell method based on light SiO2 cores as recognition structures, which can be modified in various ways, thus changing and improving their properties [28]. This will reduce the cost of analysis, increase the range of the determined analyte concentrations, but at the same time retain a possibility of fixing the recognition layer under the action of magnetic forces.

The aim of this work was to study the conditions for the synthesis of polymer particles with molecular imprints of macrolides by the core–shell method with silicon dioxide cores and a possibility of their use in the recognition layer of a piezoelectric sensor based on magnetic carbon nanocomposites for the determination of antibiotics in liquid media.

EXPERIMENTAL

Materials and equipment. For the synthesis of polymers with molecular imprints we used the following substances: functional monomer—methacrylic acid (MAA) (Vekton, Russia), crosslinking monomer—ethylene glycol dimethacrylate (EGDMA) (Aldrich Chemistry, United States), and polymerization initiator—azobisisobutyronitrile (Labtekh, Russia). Macrolides of the erythromycin series were used as templates (Scheme 1): erythromycin (Sintez, Russia), azithromycin (Production of medicines, Russia).

Scheme 1 . Structural formulas of (a) erythromycin and (b) azithromycin.

The solvents were as follows: acetonitrile, toluene (Vekton, Russia), ethanol (Ekos1, Russia), acetic acid (NevaReaktiv, Russia), acetone (98%, Qumica, Spain), hydrochloric acid (density 1.198 g/cm3, NevaReaktiv, Russia). Triton X-100 (Sigma–Aldrich, United States) was used to transfer particles to a dispersed state. SiO2 nanospheres were synthesized using tetraethoxysilane (TEOS) (Komponent-Reaktiv, Russia), (3-aminopropyl)triethoxysilane (APTES) (Sigma–Aldrich, United States), and a 25% aqueous NH3 solution (Khimreaktivsnab, Russia). The obtained SiO2 particles were hydrophobized with polyvinylpyrrolidone (Aplichem, Germany).

Solutions of macrolide antibiotics in ethyl alcohol of a concentration of 40 µg/mL were used for reembedding in MIP. To construct calibration dependences, solutions with concentrations of 0.1, 0.5, 5, 10, 20, 40, 100, 160, 200, and 400 µg/mL, obtained by diluting a concentrated solution with ethyl alcohol, were used.

The surface morphology of the nanoparticles was studied by atomic force microscopy (Solver P47-PRO scanning probe microscope, Nanotechnology-MDT, Russia) in the semicontact mode in air at a scanning rate of 1.34 Hz. The nature of functional groups on the surface of SiO2 particles was determined by IR spectrometry (Iraffinity-1 FTIR spectrometer, Japan), as well as the nature of bonds formed during the synthesis of MIP by free radical polymerization and the sol–gel method.

Piezoelectric AT-cut resonators 8 mm in diameter with a natural oscillation frequency of 10 MHz, with gold electrodes located on both sides of the quartz plate (ZAO “ETNA”, Russia) were used as sensors. The analytical signal was recorded on a CPNA-330 setup (ZAO “ETNA”, Russia).

The ratio of the template, functional and crosslinking monomers was determined by the spectrophotometric method in the UV region of the spectrum (Fluorat-02-Panorama, Russia).

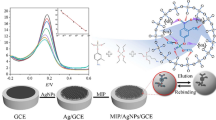

Synthesis of nanoparticles with molecular imprints. Two procedures for the synthesis of nanoparticles with a core–shell structure were used: in the first case, a polymer shell was synthesized on the surface of a silicon dioxide core by the FRP method—SiO2@MIP. The second method consisted in obtaining a shell on the surface of the silica core by the sol–gel method using siloxanes—SiO2@SiO2 (Fig. 1).

The synthesis of SiO2 cores was carried out according to the Stober method. For work, we chose the procedures described in the literature, which differed in the ratio of reagents during the synthesis (Table 1).

The synthesis of a polymer shell by free radical polymerization requires the preliminary hydrophobization of the SiO2 core. For this, 0.3 g of SiO2 nanoparticles were added to 50 mL of an aqueous solution of polyvinylpyrrolidone (60 mg/mL) and the mixture was stirred with a magnetic stirrer at 25°C for 12 h. The resulting particles were separated, washed to pH 7, and dried at 70°C to a constant weight [31]. To synthesize a polymer shell on the surface of hydrophobized silicon dioxide cores, 0.06 g of a macrolide was dissolved in 18 mL of a porogenic solvent, an acetonitrile–toluene mixture (3 : 1, by volume). Next, 0.1 mmol of MAA was introduced, and the resulting mixture was kept for 2 h at 4°C to form the template–monomer prepolymerization complex. A 0.015-g portion of SiO2 particles and 0.8 mmol of EGDMA were added, sonicated for 10 min, the polymerization initiator azobisisobutyronitrile (0.0985 g) was added, and the resulting solution was continuously stirred at 50°C. The resulting SiO2@MIP particles were dried to a constant weight.

The sol–gel method consisted in the formation of macrolide surface imprints in a silica shell [32]. For this, 0.6 mL of TEOS, 9 mL of ethanol, and 0.9 mL of distilled water were mixed, 0.4 mL of a 25% ammonia solution was added, and the mixture was stirred with a magnetic stirrer for 1 h at 25°С. Next, 0.3 mL of APTES (as a functional monomer), 10 mg of erythromycin (template), and 0.5 mL of TEOS (crosslinker) were added, and the mixture was stirred for another 1 h. The particles were separated by centrifugation and washed with ethanol to remove template molecules.

Templates were not used in the synthesis of non-imprinted polymer particles (SiO2@NIP) by the FRP and SGM methods.

Synthesis of composite nanomaterials and formation of a receptor layer. We used magnetic carbon nanocomposites described in [27]. Fe3O4 nanoparticles were immobilized on the surface of multi-walled carbon nanotubes synthesized at the Institute for Problems of Microelectronics Technology and High-Purity Materials, Russian Academy of Sciences, Chernogolovka [33]. The CNT–MNP ratio was chosen by piezoelectric quartz crystal microbalancing [34] taking into account the mass of the coating, because an overload led to a breakdown of the analytical signal of the sensor, and a decrease in the amount of MNP in the composite led to a decrease in the strength of binding to the sensor under the action of an external magnetic field. It was found that the optimal ratio was 3 : 1. Transfer to the dispersed state was carried out according to the scheme proposed earlier [35]: 1 mg of MCNC was added to 1 mL of a 1% aqueous solution of Triton X-100 and subjected to ultrasonic treatment for 1 h.

Recognizing elements (MIP@SiO2 and SiO2@SiO2) were immobilized on the surface of MCNC by physical sorption; to do this, 1 mg of activated MCNC and 1 mg of MIP nanoparticles were added to 1 mL of a 1% aqueous solution of Triton X-100, heated to 90°C for 15 min, and sonicated for 1 h.

A receptor layer based on composite materials (MIP@SiO2/MCNC and SiO2@SiO2/MCNC) was formed by dosing 2 μL of the dispersion onto a sensor electrode preliminarily purified with a 1 mM hydrochloric acid solution, acetone, and ethanol, placed above a neodymium magnet in the detection cell described in [27].

Evaluation of the quality of the receptor coating. The recognition layer based on MIP@SiO2/MCNC or SiO2@SiO2/MCNC composites was characterized by the piezoelectric quartz crystal microbalance method similar to that described in [16, 17]. As an analytical signal, we used the change in the oscillation frequency of the resonator before and after the application of a nanocomposite dispersion, as well as before and after the desorption and sorption of template molecules.

The mass of the recognition coating ∆mMIP (μg) was calculated based on the Sauerbrey equation: ∆mMIP = (SΔF)/(2.3 × 106\(F_{0}^{2}\)), where ∆F = F1 – F2 (F1 is the oscillation frequency of the pure sensor, Hz; F2 is the oscillation frequency of the sensor with the MIP film, Hz); F0 is the natural oscillation frequency of the quartz crystal, MHz; S is the electrode surface area (0.10066 cm2). The influence of nonspecific surface sorption was taken into account by measuring the analytical signal of the sensor ∆Fan (Hz) relative to the NIP: ∆Fan = ∆FMIP – ∆FNIP. The mass of the removed (∆mMIP) and re-embedded template molecules (∆mEMB) was determined from the difference between the mass of the MIP layer before and after the removal of the templates. The molar concentration of macrolide surface imprints R (µmol/cm2) on the sensor electrode surface was determined as follows: R = ∆mEMB/SM, where M is the molar mass of the template.

The selectivity of the recognition layer was calculated from the cross response coefficients: CR, % = ΔFint/ΔFanalyte, where ΔFanalyte and ΔFint are the analytical signals of the sensor in solutions of the analyte and the interfering substance.

RESULTS AND DISCUSSION

Synthesis of polymer particles with molecular imprints of macrolides by the core–shell method. Synthesis of cores. The size and morphology of the silica particles used as cores are largely determined by the ratio of reactants during the synthesis. The procedures that provide the formation of particles with active functional groups on the surface of the core were chosen as the basis [28–30]. The cores were synthesized according to the Stober method, including the hydrolysis and subsequent condensation of organosilicon compounds [36]. The TEOS and APTES used in the work ensured the formation of surface active hydroxyl and amino groups (Table 1). The average diameters of the synthesized SiO2 cores were determined by atomic force microscopy (Fig. 2).

The influence of the SiO2 particle diameter on the density and uniformity of the layer on the surface of magnetic carbon nanocomposites was established by the piezoelectric quartz crystal microbalance method. Thus, particles synthesized by method 2 and having a smaller diameter (77 ± 3 nm) were more compactly arranged on the MCNC surface, forming a uniform layer with a sufficiently large surface area. When particles of larger diameters (157 ± 7 and 148 ± 7 nm) obtained by methods 1 and 3 were used, an accumulation of large morphologically inhomogeneous structures was observed on the MCNC surface, which sterically hindered interaction with the surface layer.

Synthesis of the polymer shell was carried out by free radical polymerization or the sol–gel method. In the first case, because of the use of hydrophobic functional and cross monomers in the preparation of the shell, preliminary hydrophobization of SiO2 nanospheres with a solution of polyvinylpyrrolidone was carried out in order to enhance bonding between the polymer layer and the core, reduce particle aggregation, and increase their stability. In synthesizing the polymer shell by SGM, hydrophobization was not carried out, because the stages of the formation of the core and surface shell were carried out sequentially using the same reagents.

In the synthesis of MIP by the FRP method, MAA and EGDMA were used as functional and cross monomers, which proved themselves well earlier [18–20]. An important condition for the successful synthesis is the choice of the ratio of reagents in the polymerization mixture that provides the maximum number of available surface imprints. The optimal ratios of template : functional monomer and template : functional monomer : cross monomer were determined taking into account the maxima in the absorption spectra in the UV region (180–380 nm) by varying the amount of the reagents in the polymerization mixture (Fig. 3).

The maximum absorbances were recorded in the absorption spectra at the following molar ratios of templates : functional monomer : cross monomer: for erythromycin 1 : 8 : 60, for azithromycin 1 : 4 : 30. Different ratios of reagents in the synthesis of MIP of individual macrolides are probably associated with differences in the structures of their molecules. In view of the fact that the nonspecific sorption of the template is possible on the surface of a silica core, and molecular imprints are formed in a thin polymer layer, the concentration of the template used in the synthesis of MIP was additionally increased. It was found that the maximum signal in the absorption spectra in the UV region was observed at a template : SiO2 ratio of 4 : 1; therefore, in synthesizing the shell by the FRP method, a polymerization mixture with the composition template : functional monomer : cross monomer 4 : 32 : 240 (for erythromycin) and 4 : 16 : 120 (for azithromycin) was used.

A comparison of the IR spectra of the macrolide and MIP obtained by the FRP method (Fig. 4a) showed a shift of the peak of carbonyl groups to the shorter wavelengths from 1747 to 1722 cm–1, which indicated the formation of hydrogen bonds between methacrylic acid (functional monomer) and template molecules during the formation of the prepolymerization complex. Also, the higher intensity of the –C–OH peak in the MIP spectra as compared to NIP ones indicates the presence of the carbonyl group of the lactone ring of macrolides in the imprinted polymer (988 cm–1). The broadening of this band in the MIP spectra compared to the spectrum of the antibiotic was noted, which confirms the involvement of the hydroxyl groups of the macrolide in the hydrogen bonds with the functional monomer.

Similar changes in IR spectra were also observed during the formation of the shell by SGM (Fig. 4b). The presence of the macrolide lactone ring was indicated by a peak at 950 cm–1, which is characteristic of antibiotics of this series. The formation of bonds between the template and the shell was confirmed by the broadening and shift of the band of the carbonyl group from 1747 to 1706 cm–1 compared to the spectrum of the macrolide. A comparison of the spectra of the SiO2 shell sorbed by the macrolide and the desorbed shell made it possible to prove the successful removal of the template molecules.

Characteristics of an affine piezoelectric sensor based on composite nanomaterials. For the repeated use of the recognition layer of a gravimetric piezoelectric sensor based on MIP nanoparticles, it is important to carry out regeneration that ensures the removal of the maximum number of template molecules from the molecular imprints and a stable polymer structure. Due to the fact that macrolides in general are poorly soluble in water, but are easily soluble in ethanol, acetone, and some other polar organic solvents, a possibility of using ethanol; an ethanol–acetonitrile mixture (1 : 3); and an acetic acid–ethanol mixture (1 : 6) as regenerating solutions was studied. Experimental data have shown that the use of acetonitrile–ethanol and acetic acid–ethanol mixtures led to a significant destruction of the polymer already after the first regeneration cycle. Only the use of ethanol made it possible to achieve satisfactory results in the desorption and resorption of macrolide molecules.

An most important characteristic is the duration of a contact of the receptor layer based on MIP particles with the regenerating solution, which ensures the most complete removal and subsequent incorporation of antibiotic molecules. Using the piezoelectric quartz crystal microbalance method, it was found that the complete recovery of erythromycin molecules by ethanol from the SiO2@MIP polymer matrix occurred within 4 min, and the maximum incorporation of antibiotics into the formed imprints was after 3 min (Fig. 5), which indicates a high availability of the imprints in the MIP structure to template molecules. The duration of the complete extraction of the template from the SiO2@SiO2 structure was 10 min, while the maximum incorporation occurred in 6 min, which indicates the lower availability of the imprints to the template molecules in the polymer shell obtained by the sol–gel method.

Table 2 presents analytical characteristics of the piezoelectric sensor based on composite nanomaterials. It was noted that, during the synthesis, the mass of antibiotics (mtemplate, μg) incorporated in the SiO2@SiO2 or SiO2@MIP structures significantly exceeded the similar characteristic obtained upon repeated embedding (∆mEM1 and ∆mEM2), which is explained by the partial destruction of the matrix adjacent to the imprint during primary regeneration. However, as a result of subsequent procedures of the desorption–sorption of antibiotics into molecular imprints, the masses of the re-embedded template molecules, as well as the concentrations of surface imprints (R1 and R2), almost coincided, which indicates the formation of a constant number of available imprints on the particle surface and the stability of the developed sensor.

It was found that the sensor signal based on MIP@SiO2/MCNC was linear in the range 5–160 μg/mL for azithromycin and 10–160 μg/mL for erythromycin. For the sensor based on SiO2@SiO2/MCNC, an increase in the upper limit of the determined erythromycin concentration to 400 μg/mL was observed, which indicates a higher concentration of surface imprints in the shell obtained by the sol–gel method.

The developed sensors were tested in the determination of macrolides in pork and chicken meat (Table 3). It was found that in all samples the concentrations of antibiotics did not exceed the maximum allowable level of the drugs (0.2 mg/mL) [37]. The RSD values indicate a high reproducibility of the measurement results.

The selectivity of the sensor based on molecularly imprinted particles was evaluated using the cross-reactivity coefficient CR (%) (Table 4). It was found that molecularly imprinted particles synthesized by the FRP and SGM methods have high selectivities with respect to antibiotics of other classes. However, the CR values for other macrolides exceed 70% or more, which suggests that MIP with individual macrolide imprints can be used to determine the amount of erythromycin antibiotics.

Sensors based on magnetic carbon nanocomposites and molecularly imprinted polymers synthesized by FRP and SGM methods can be recommended for determining the amount of macrolides in the presence of other antibiotics in liquid media.

CONCLUSIONS

A procedure for forming the receptor layer of a piezoelectric sensor based on magnetic carbon nanocomposites with molecularly imprinted core–shell polymers for the determination of macrolide antibiotics in liquid media was proposed. The influence of the diameter of SiO2 cores on the density and uniformity of the layer on the surface of magnetic carbon nanocomposites was established. It was noted that the sensor based on MIP synthesized by free radical polymerization is characterized by a linear dependence of the analytical signal on the analyte concentration in the range 5–160 μg/mL for azithromycin and 10–160 μg/mL for erythromycin. The results of the determination of macrolides using a piezoelectric sensor coated on the basis of MIP@SiO2/MCNC are comparable in sensitivity to the well-known method of analysis by HPLC–UV with preliminary solid-phase extraction [38] (LOD = 0.45 μg/mL) and voltammetric method [39] (LOD = 1.4 μg/mL). The developed piezoelectric sensors ensure the determination of macrolides in a wider concentration range. In using MIP obtained by the sol–gel method, the upper limit of the analytical range increased to 400 µg/mL. The sensors were tested in the determination of macrolides in pork and chicken meat.

REFERENCES

Guliy, O.I., Zaitsev, B.D., Smirnov, A.V., Karavaeva, O.A., and Borodina, I.A., Biosens. Bioelectron., 2022, vol. 12, p. 100274.

Skladal, P., TrAC, Trends Anal. Chem., 2016, vol. 79, no. 5, p. 127.

Ermolaeva, T.N., Kalmykova, E.N., and Shashkanova, O.Yu., Russ. J. Gen. Chem., 2008, vol. 78, no. 12, p. 2430.

Chauhan, R., Singh, J., Solanki, P.R., Basu, T., O’Kennedy, R., and Malhotrae, B.D., Biochem. Eng. J., 2015, vol. 103, no. 15, p. 103.

Gupta, B.K., Yadav, A., Koch, P., and Mishra, P., in Biosensors in Food Safety and Quality, Boca Raton: CRC, 2022, p. 10.

Zhang, J., Zhang, X., Wei, X., Xue, Y., Wan, H., and Wang, P., Anal. Chim. Acta, 2021, vol. 1164, p. 338321.

Guliy, O.I., Zaitsev, B.D., Alsoveidi, A.K.M., Karavaeva, O.A., Lovtsova, L.G., and Borodina, I.A., Biophysics (Moscow), 2021, vol. 66, no. 4, p. 555.

Alsoveidi, A.K.M., Karavaeva, O.A., Gulii, O.I., Antibiot. Khimioter., 2022, vol. 67, nos. 1–2. p. 53.

Poma, A., Guerreiro, A., Whitcombe, M.J., Piletska, E.V., Turner, A.P.F., and Piletsky, S.A., Adv. Funct. Mater., 2013, vol. 23, p. 2821.

Kupai, J., Razali, M., Buyuktiryaki, S., Kecili, R., and Szekely, G., Polym. Chem., 2017, vol. 8, p. 666.

Sharma, P.S., Iskierko, Z., Pietrzyk-Le, A., D’Souza, F., and Kutner, W., Electrochem. Commun., 2015, vol. 50, p. 81.

Refaat, D., Aggour, M.G., Farghali, A.A., Mahajan, R., Wiklander, J.G., Nicholls, I.A., and Piletsky, S.A., Int. J. Mol. Sci., 2019, vol. 20, no. 24, p. 6304.

He, J.X., Pan, H.Y., Xu, L., and Tang, R.Y., J. Chem. Res., 2020, vol. 45, no. 5, p. 1.

Ma, J., Yan, M., Feng, G., Ying, Y., Chen, G., Shao, Y., She, Y., Wang, M., Sun, J., Zheng, L., Wang, J., and El-Atyde, A.M.A., Talanta, 2021, vol. 225, p. 122031.

Thobakgale, L., Ombinda-Lemboumba, S., and Mthunzi-Kufa, P., Nanomaterials, 2022, vol. 12, no. 15, p. 2688.

Karaseva, N., Ermolaeva, T., and Mizaikoff, B., Sens. Actuators, B, 2016, vol. 225, p. 199.

Karaseva, N.A., Pluhar, B., Mizaikoff, B., Beliaeva, E.A., and Ermolaeva, T.N., Sens. Actuators, B, 2019, vol. 280, p. 272.

Ermolaeva, T.N., Farafonova, O.V., and Bessonov, O.I., Sorbtsionnye Khromatogr. Protsessy, 2019, vol. 19, no. 6, p. 682.

Ermolaeva, T.N., Farafonova, O.V., Chernyshova, V.N., Zyablov, A.N., and Tarasova, N.V., J. Anal. Chem., 2020, vol. 75, no. 10, p. 1270.

Ermolaeva, T.N., Chernyshova, V.N., and Bessonov, O.I., Sorbtsionnye Khromatogr. Protsessy, 2015, vol. 15, no. 3, p. 345.

Shi, J., Zhang, X., Zhang, Q., and Yang, P., Bull. Environ. Contam. Toxicol., 2022, vol. 108, p. 379.

Malik, S., Khan, A., Rahman, G., Ali, N., Khan, H., Khan, S., and Sotomayor, M.D.P.T., Environ. Res., 2022, vol. 212, p. 113209.

Yun, G., Koo, K.M., and Kim, Y., Polymer, 2021, vol. 215, p. 123389.

Ladj, R., Bitar, A., Eissa, M.M., Fessi, H., Mugnier, Y., Le Dantec, R., and Elaissari, A., Int. J. Pharm., 2013, vol. 458, p. 230.

Bakeeva, I.V. and Morozova, I.V., Sovremennye nanokompozitnye materialy—organo-neorganicheskie gibridnye geli. Uchebnoe posobie (Modern Nanocomposite Materials—Organic-Inorganic Hybrid Gels: Handbook), Moscow: Mosk. Inst. Tonkikh Khim. Tekhnol., 2006, p. 40.

Bizina, E.V., Farafonova, O.V., Tarasova, N.V., and Ermolaeva, T.N., Sorbtsionnye Khromatogr. Protsessy, 2021, vol. 21, no. 2, p. 177.

Bizina, E.V., Farafonova, O.V., Zolotareva, N.I., Grazhulene, S.S., and Ermolaeva, T.N., J. Anal. Chem., 2022, vol. 77, no. 4, p. 375.

Gendrikson, O.D., Zherdev, A.V., and Dzantiev, B.B., Usp. Biol. Khim., 2006, vol. 46, p. 149.

Liu, Y.N., Zhang, Z., and Zhang, M., Chin. J. Appl. Chem., 2013, vol. 30, no. 3, p. 316.

Liu, S.M., Wei, M.X., Fu, X., and Zhang, X.B., Chin. J. Chem. Phys., 2018, vol. 31, no. 2, p. 229.

Huang, Y., Li, F., Qiu, L., Lin, F., Lai, Z., Wang, S., Lin, L., Zhu, Y., Wang, Y., Jiang, Y., and Chen, X., ACS Appl. Mater. Interfaces, 2019, vol. 11, no. 29, p. 26384.

Yu, D., Hu, X., Wei, S., Wang, Q., He, C., and Liu, S., J. Chromatogr. A, 2015, vol. 1396, p. 17.

Grazhulene, S.S., Zolotareva, N.I., Red’kin, A.N., Shilkina, N.N., Mitina, A.A., and Khodos, I.I., Russ. J. Appl. Chem., 2020, vol. 93, no. 1, p. 57.

Bizina, E.V., Efrosinina, A.V., Roldugina, A.S., Farafonova, O.V., and Ermolaeva, T.N., Abstracts of Papers, IV S”ezd Analitikov Rossii (IV Meeting of Analytical Chemists of Russia), Moscow, 2022. http://www.analystscongress.ru/iv/Shared%20Documents/2022-IVCъeздAP-Teзиcы-v9.pdf. Accessed April 20, 2023.

Bizina, E.V., Farafonova, O.V., Zolotareva, N.I., Grazhulene, S.S., and Ermolaeva, T.N., J. Anal. Chem., 2023, vol. 78, no. 4, p. 514.

Blaaderen, A., Geest, J.V., and Vrij, A., J. Colloid Interface Sci., 1992, vol. 154, no. 2, p. 481.

Decision of the Board of the Eurasian Economic Commission dated February 13, 2018, no. 28 “On the maximum permissible levels of residues of veterinary medicinal products (pharmacologically active substances) that may be contained in unprocessed food products of animal origin, including raw materials, and methods for their determination.” https://docs.cntd.ru/document/556522984. Accessed June 20, 2021.

Song, S., Wu, A., Shi, X., Li, R., Lin, Z., and Zhang, D., Anal. Bioanal. Chem., 2008, vol. 390, p. 2141.

Vajdle, O., Guzsvány, V., Škoric, D., Csanádi, J., Petkovic, M., Avramov-Ivic, M., Konya, Z., Petrovic, S., and Bobrowski, A., Electrochim. Acta, 2017, vol. 229, p. 334.

Funding

The study was carried out with the financial support of the Russian Foundation for Basic Research and the Lipetsk Region within the framework of the scientific project no. 20-43-480001. At IPTM RAS, the work was carried out within the framework of State Assignment no. 075-01304-23-00.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by V. Kudrinskaya

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bizina, E.V., Efrosinina, A.V., Farafonova, O.V. et al. Nanocomposites Based on Multi-Walled Carbon Nanotubes, Magnetite Nanoparticles, and Core–Shell Molecularly Imprinted Polymers in Piezoelectric Sensors for the Determination of Macrolide Antibiotics. J Anal Chem 78, 1566–1574 (2023). https://doi.org/10.1134/S1061934823110035

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061934823110035