Abstract—

The size dependences of the melting and crystallization temperatures of silver nanoparticles are obtained by two alternative atomistic simulation methods, such as the molecular dynamics and Monte-Carlo methods. The simulation results are analyzed and compared with available experimental values and a melting temperature calculated using the well-known Thomson formula. Atomistic simulation reveals good coincidence between the data and satisfactorily conforms to the Thomson formula. However, the melting temperatures predicted through atomistic simulations exceeds the available experimental data.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

A study of the structural transformations in nanoparticles and their peculiarities in comparison with appropriate bulk phases is of great interest from the points of view of science and application. Despite numerous unsolved questions and problems, the melting and crystallization of nanoparticles, i.e., metal nanoclusters, are attributed to these structural transformations. As reported in [1], pioneering works on the atomistic simulation of the melting of metal nanoparticles composed of tens of atoms date back to the 1970s. The relevancy of using the definition of melting with reference to extremely small particles was questioned in [2]. Meanwhile, the differentiation of liquid and solid states for nanoparticles composed of hundreds to thousands of atoms and more, as well as detection of the phase melting transition and localization of the melting point Tm in direct experiments [3–9] and simulations [10–14], becomes quite adequate and reproducible.

FORMULATION OF THE TASK

According to earlier studies, the melting temperature decreases with decreasing particle radius r (Tm < T0, where T0 is the macroscopic melting temperature), and Tm is a linear function of the inverse particle radius r–1 in some approximation and, consequently, of N–1/3, where N is the number of atoms. This functional dependence coincides with the known Thomson formula:

where σsl is the interfacial tension at the crystal—melt boundary, \(\lambda _{{\text{m}}}^{{(\infty )}}\) is the specific heat of fusion of the corresponding bulk solid phase, \({{{v}}_{{\text{s}}}}\) is its specific volume. Formula (1) refers to spherical nanoparticles. The analogous expression:

taking into account the deviation of the particle shape from spherical was introduced in [15]. Here L = \({4 \mathord{\left/ {\vphantom {4 {3{{\sigma }_{{{\text{sl}}}}}{{{v}}_{{\text{s}}}}}}} \right. \kern-0em} {3{{\sigma }_{{{\text{sl}}}}}{{{v}}_{{\text{s}}}}}}\)/\(\lambda _{{\text{m}}}^{{(\infty )}}\) is the characteristic length, the physical meaning of which is discussed in [15], α is the asphericity factor defined as the surface area of a particle to that of a sphere with the same volume (α = S/S0).

As experimentally found by G. Zhdanov in the 1960–1970s [4], metal nanoparticles also exhibit melting–crystallization hysteresis, where the crystallization temperature Tc is below the melting point Tm, and their difference ΔT = Tm – Tc can be considered as a quantitative measure of this hysteresis. Unlike works dedicated to the fusion of nanoparticles, there are a very few items reporting their crystallization, especially those considering the melting—crystallization hysteresis. In this respect, one can mention the monograph [16] that combines the experimental data and the thermodynamic theory of melting—crystallization hysteresis, as well as the later work [17] where the melting–crystallization hysteresis has been monitored for lead nanoparticles via electron diffraction. Furthermore, the size dependences of Tm and Tc were found for nanoparticles of gold, copper, aluminum, nickel and other metals via the atomistic simulation of metal nanoparticles using the molecular dynamics (MD) and Monte-Carlo (MC) methods [2, 11–13, 18, 19]. The relationship between the size dependences of Tm and Tc was also inspected in the context of the thermodynamic approach in [20, 21].

There are no published studies of the melting and crystallization of silver nanoparticles, except some works [22, 23] dedicated to MD simulation of the melting of silver nanoparticles. Moreover, according to experimental data on the size dependence of the melting point of silver particles reported in [6–10], the value of Tm is much lower than that found via MD simulation [22, 23], and the causes of this divergence are still unclear.

MD simulation was performed in two independently developed programming codes (codes 1 [24] and 2 [25] hereinafter) aimed at applying a tight-binding potential [26], as well as the known open-access LAMMPS program, the implying the use of a multiparticle interatomic interaction potential [27] related to the embedded atom method. Furthermore, an original programming code suitable for the MD simulation of metal nanoparticles using the tight-binding potential was explored as well. The melting point of both MD and MC simulation methods was determined from a discounting in the temperature dependence in the potential (cohesive) term of the specific (per atom) internal energy. The method of simulating metal nanoparticles and the determination of melting points are detailed in [2, 12–15, 18, 19].

RESULTS AND DISCUSSION

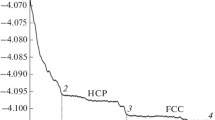

The size functions of the melting temperature of silver nanoparticles, plotted using atomistic simulation data, are shown in Fig. 1 by the closed symbols together with the MD simulation points [22]. The open symbols denote the dependences of the crystallization temperatures. As seen, the MD results for dependences 1 and 2 are consistent with the MC data (straight line 4) and the MD values obtained by other authors [22]. It is also worth noting that linear extrapolation to N–1/3 = 0 (N → ∞) in the atomistic simulation gives values of \(T_{{\text{m}}}^{{(\infty )}} = {{\lim }_{{N \to \infty }}}{{T}_{{\text{m}}}},\) that agree to a satisfactory degree with the experimental (reference) value of 1234 K of the melting point of silver [29]. Alongside this, the extrapolation of data obtained in the software 2 [25] via the MD simulation of metal nanoparticles using the tight-binding potential (Fig. 1, dependence 3) is associated with a value of \(T_{{\text{m}}}^{{(\infty )}}\) = 783 K that is much lower than the experimental macroscopic melting point Т0 = 1234 K. Of course, the Tm(N–1/3) dependence may deviate from linear with increasing N, as is shown in [22]. However, the deviation must be within the limits of allowed values.

Melting point \({{T}_{{\text{m}}}}\) and crystallization temperature \({{T}_{{\text{c}}}}\) versus \({{N}^{{ - {1 \mathord{\left/ {\vphantom {1 3}} \right. \kern-0em} 3}}}}\) for silver nanoparticles: 1—melting of initially spherical particles (the LAMMPS software used) (\(T_{{\text{m}}}^{{(\infty )}}\) = 1218 K); 2—melting of spherical particles (program 1 used) [24], MD simulation (\(T_{{\text{m}}}^{{(\infty )}}\) = 1119 K); 3—melting of icosahedral particles, (program 2 used) [25], MD simulation (\(T_{{\text{m}}}^{{(\infty )}}\) = 783 K); 4—melting of icosahedral particles, Monte-Carlo method (\(T_{{\text{m}}}^{{(\infty )}}\) = 1113 K); open symbols denote the crystallization temperatures; crosses are the MD simulation data (melting points) [22]; 5—calculation using the Thomson formula (1), the interfacial tension is taken from [28], other quantities in formula (1) were adopted from [29].

The results of MC (Fig. 1, line 4) and MD (linear dependence 3) simulations belong to nanoparticles with the initial icosahedral structure, while the primary configurations related to lines 1 and 2 correspond to spherical fragments of the fcc (face-centered cubic) lattice. The MC method usually gives somewhat higher values of the melting temperature. It is likely that the icosahedral shape of the particles makes the dependence 4 very close to the data 1 obtained by MD simulation. It can be assumed that the lower Tm values (line 3) are to some extent due to the icosahedral shape of the initial configurations. This conclusion is qualitatively consistent with formula (2). Nevertheless, the observed effect of asphericity of the initial icosahedral configuration seems overestimated. Unlike the melting of solid particles, the crystallization of nanodroplets is no more related to the initial shape of the particles exposed to melting. It is thus naturally that using different simulation approaches and different software ensures that data on the crystallization temperature roughly coincide with each other.

The known experimental size dependences of the melting point of silver nanoparticles were thoroughly analyzed as well with the values of Tm as a function of d–1, where d = 2r is the particle diameter, and as a function of N–1/3 were plotted. The values N were estimated from the density of the bulk phase, i.e., the correspondence in Fig. 2 between d and N is adequate but provisional. As obvious, all the experimental dependences in this figure are related to lower values Tm as compared to the atomistic simulation data [22] and the results of the present work (Fig. 1, lines 1, 2, and 4). Meanwhile, the linear dependence Tm(d–1) (and consequently Tm(N–1/3)), predicted by the Thomson formula (1) is also experimentally confirmed (Fig. 1, line 5). A comprehensive analysis of the experimental data, simulation results and theoretical estimations of other authors is summarized in Table 1. Silver icosahedral nanoclusters (at T = Tm) in the present molecular dynamics experiments and those simulated via the Monte-Carlo method exhibit sizes of d ~ 3 nm at N = 923 and d ~ 4.8 nm at N = 3871. As seen in Fig. 2, the extrapolation of experimental data to d–1 = 0 gives values \(T_{{\text{m}}}^{{(\infty )}}\) lower than the macroscopic melting point T0. For instance, quite coarse particles with diameters of 50 nm were studied in [7, 8]. In turn, it is unlikely the divergence between \(T_{{\text{m}}}^{{(\infty )}}\) and T0 is due to the deviation of the dependence Tm(d–1) from the linear type at small values of d–1.

CONCLUSIONS

Good coincidence was established between the melting points of silver nanoparticles, estimated via atomistic simulation, and the linear extrapolation results of the dependence Tm(N–1/3) to N–1/3 → 0 with the reference value of macroscopic melting temperature of silver. However, the cause of a pronounced divergence between the size dependences of the melting temperatures in direct and simulation experiments is still unclear. Taking into account the aforementioned as well as serious difficulties in the experimental study of nanoparticles, the results of direct measurements seem to not be completely reliable. In this respect, the prime cause of underestimation of the experimental melting points for silver nanoparticles is assumed to be due to the high thermal conductivity of Ag (429 W/m K [29]) that almost four times exceeds the thermal conductivity of most metals. The only exception is metals of the same subgroup, such as Au and Cu, but these also possess smaller thermal conductivities. It is thus likely that the experimentally recorded melting points of silver nanoparticles do not correspond entirely to their real temperatures.

REFERENCES

Yu. I. Petrov, Clusters and Small Particles (Nauka, Moscow, 1982) [in Russian].

V. M. Samsonov and A. G. Bembel’, Yad. Fiz. Inzhiniring 4, 578 (2013).

Ph. Buffat and J.-P. Borel, Phys. Rev. A: At., Mol., Opt. Phys. 13, 2287 (1976).

G. S. Zhdanov, Izv. Akad. Nauk SSSR, Ser. Fiz. 41, 1004 (1977).

K. Dick, T. Dhanasekaran, Z. Zhang, and D. Meisel, J. Am. Chem. Soc. 124, 2312 (2002).

N. H. Kim, J.-Y. Kim, and K. J. Jin, J. Nanosci. Nanotechnol. 7, 3805 (2007).

M. A. Asoro, J. Damiano, and P. J. Ferrera, Microsc. Microanal. 15, 706 (2009).

M. A. Asoro, D. Kovar, J. Damiano, and P. J. Ferrera, Microsc. Microanal. 16, 1802 (2010).

S. A. Little, T. Begou, R. W. Collins, and S. Marsillac, Appl. Phys. Lett. 100, 051107 (2012).

T. Castro, R. Reifenberger, E. Choi, and R. P. Andres, Phys. Rev. B: Condens. Matter Mater. Phys. 42, 8548 (1990).

Y. Qi, T. Çağin, W. L. Johnson, and W. A. Goddard, J. Chem. Phys. 115, 385 (2011).

V. M. Samsonov, S. S. Kharechkin, S. L. Gafner, et al., Crystallogr. Rep. 54, 526 (2009).

V. M. Samsonov, S. A. Vasilyev, I. V. Talyzin, and Yu. A. Ryzhkov, JETP Lett. 103, 94 (2016).

N. Yu. Sdobnyakov, P. V. Komarov, D. N. Sokolov, and V. M. Samsonov, Phys. Met. Metallogr. 111, 13 (2011).

V. M. Samsonov, S. A. Vasilyev, and A. G. Bembel, Phys. Met. Metallogr. 117, 749 (2016).

Skripov, V.P. and Koverda, V.P., Spontaneous Crystallization of Overcooled Liquids (Nauka, Moscow, 1984) [in Russian].

R. Kofman, P. Cheyssac, Y. Lereach, and A. Stella, Eur. Phys. J. D 9, 441 (1999).

N. Yu. Sdobnyakov, T. A. Vanyusheva, A. Yu. Kolosov, et al., Poverkhnost, No. 2, 60 (2015). N. Yu. Sdobnyakov, A. Yu. Kolosov, D. N. Sokolov, N. V. Novozhilov, A. S. Mikhailov, A. P. Andriychuk, and I. V. Kartashov, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 9, 164 (2015).

N. Yu. Sdobnyakov, V. M. Samsonov, A. N. Bazulev, and D. A. Kul’pin, Bull. Russ. Acad. Sci.: Phys. 72, 1371 (2008).

N. Yu. Sdobnyakov, D. N. Sokolov, A. N. Bazulev, et al., Russ. Metall. (Engl. Transl.) 2013, 100 (2013).

N. Yu. Sdobnyakov, S. V. Repchak, V. M. Samsonov, et al., J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 5, 508 (2011).

H. A. Alarifi, M. Atis, C. Özdogan, et al., J. Phys. Chem. C 117, 12289 (2013).

W. Luo, W. Hu, and S. Ziao, J. Phys. Chem. C 112, 2359 (2008).

V. M. Samsonov, A. G. Bembel’, and M. Yu. Pushkar’, PC Software Certificate No. 2013610101 (19.01.2013).

V. S. Myasnichenko, PC Software Certificate No. 2011615692 (20.01.2011).

F. Cleri and V. Rosato, Phys. Rev. B: Condens. Matter Mater. Phys. 48, 22 (1993).

J. B. Adams, S. M. Foiles, and W. G. Wolfer, J. Mater. Res. 4, 102 (1989).

M. A. Shebzukhova, Z. A. Shebzukhov, and A. A. Shebzukhov, Phys. Solid State 54, 185 (2012).

Physical Quantities. Handbook, Ed. by I. S. Grigor’ev and E. Z. Meilikhov (Energoatomizdat, 1991, Moscow, 1991) [in Russian].

C. C. Yang and S. Li, Phys. Rev. A: At., Mol., Opt. Phys. 75, 165413 (2007).

ACKNOWLEDGMENTS

This work was performed at Tver State University and was supported within the framework of the state research task (project no. 3.5506.2017/BCh) and by the Russian Foundation for Basic Research (grants nos. 17-53-04010, 18-38-00571, 16-33-60171 and 18-03-00132).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Maslova

Rights and permissions

About this article

Cite this article

Samsonov, V.M., Sdobnyakov, N.Y., Myasnichenko, V.S. et al. A Comparative Analysis of the Size Dependence of the Melting and Crystallization Temperatures in Silver Nanoparticles via the Molecular Dynamics and Monte-Carlo Methods. J. Surf. Investig. 12, 1206–1209 (2018). https://doi.org/10.1134/S1027451018050671

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451018050671