Abstract

The goal of this work is to confirm our earlier conclusion that the regularities observed during the electrodeposition of metallic lithium on copper and lithium electrodes can be associated with differences in the properties of the so-called solid electrolyte interphase formed at these electrodes in contact with the electrolyte. To do this, we analyzed the electrochemical impedance spectra measured during the above processes by using the method of the distribution of relaxation times. The electrolyte addition with surfactants (the cetyltrimethylammonium bromide and hexadecylpyridinium bromide) was shown to lead to a significant change in the properties of the solid electrolyte interphase layers and a noticeable increase in the values of the impedance components associated with the Faradaic processes at these electrodes. This indicates an inhibition of the lithium electrodeposition processes and the related process of dendrite formation under these conditions. At the same time, no such impedance components were observed at the fresh-formed deposit, which confirms our earlier conclusion that the effects of surfactants on the dendrite formation are associated with the changes in the properties of the solid electrolyte interphase layers in the presence of the surfactants, rather than the surfactants’ adsorption at lithium and blocking of the dendrite growth.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

In our preceding paper [1], we used the current transient and electrochemical impedance spectroscopy methods in our studying of processes occurring at copper and lithium electrodes during the lithium electrodeposition from nonaqueous solutions similar to those used in the commercial lithium-ion batteries. In particular, we concluded that some regularities observed upon the adding the electrolyte with some surfactants can be connected with the difference in the properties of the so-called solid electrolyte interphase (SEI) layer formed at these electrodes contacting the electrolyte. This conclusion was derived from the qualitative measurements of the electrochemical impedance spectra without their detailed analysis, however. In this work, we supplemented the conclusions drawn there and present results of the analysis of the electrochemical impedance spectra taken at copper and lithium electrodes, as well as lithium metal deposits obtained at these electrodes, with the using of the distribution of relaxation times (DRT) method.

The electrochemical impedance spectroscopy is a powerful instrument for the studying of the structure of interfaces and kinetics of electrochemical processes in many different areas. However, all too often the potential of the method is left untapped due to difficulties in the analyzing of obtained experimental data. The electrochemical impedance method is an integral one, that is, the response obtained within its resource is a sum of responses from the system’s individual components over the entire frequency spectrum. At the same time, the goal of the analysis used to be right the finding of responses of the system’s separate components, that is, it is the problem of the signal’s component reconstruction from an integral curve that must be solved.

The problem can be solved more or less reasonably when these components, their number, as well as their parameters can be estimated from independent data. In this case, the following procedure is to be applied. An equivalent electrical circuit is chosen whose elements are known or presumptive. Then, using nonlinear multivariable optimization (fitting), forcing the parameters of these elements and experimental data was performed to fit most accurately (with the least sum of mean-square deviations) the integral curve calculated in compliance with the chosen equivalent circuit. When no adequate fitting can be achieved, another equivalent circuit must be chosen, and the entire process is repeated until the fitting has been a success.

The procedure is a success when we know the equivalent circuit with a reasonable degree of accuracy. However, this narrows the field of the method application. If, however, we use the electrochemical impedance spectroscopy in the analysis of behavior of a system whose equivalent circuit is not known with certainty, and we intend determining or at least refining proceeding from the same impedance data (practically, this is the case in the vast majority of cases) we encounter serious limitations.

The first thing, because the matching curve is an integral one, it is not sensitive enough to the varying the contributions from its components. This situation is an ill-defined problem. As a result, the same integral response can be adequately described by several well different equivalent circuits. Correspondingly, it cannot be inferred by impedance measurements on the system using this procedure. Another limitation is connected with the nature of the studied systems which, in the vast majority of cases, are the ones with distributed parameters, whose frequency responses are mainly overlapped. Correspondingly, the best equivalent circuit most often is the one including one or more so-called constant phase elements whose appearance right corresponds to the response of a system with distributed parameters. Yet, the physical sense of these elements which are integral by nature, as well as their parameters, most commonly remained impervious for adequately interpreting with regard to their correspondence to the particular processes occurring in systems. As a result, the impedance measurements are considerably depreciated because the physical sense of thus determined parameters remained unclear.

Thus, the method of equivalent circuits is not appropriate for many practical systems. Therefore, it would be highly desirable to have an alternative procedure for the analysis of impedance data, which has enabled us to determine unambiguously and undependably, without using a priory information, at least the number (and, when possible, a type) of elements available in the system, which provided the obtained integral response. As already noted, this problem is an ill-defined problem whose solving by using a common adjustment does not seem possible. However, a number of approaches to the solving of ill-defined problems is at hand in literature. which are based on the so-called regularization, in particular, the Tikhonov regularization [2]. The principle of the regularization method lies in the fact that an ill-defined local minimum of the mean-square deviation is amplificated with the using of a specially adopted regularization parameters whose values are further optimized after the primal problem optimization. The using of the regularization method allows unambiguously determining the number of components of a certain type, which send a particular integral response. In particular, we note the relaxation time distribution method developed by the Italian researcher Ciucci [3–5] working in Hong Kong.

Within the frame of this method, the system’s response is represented as a sum of the so-called Voigt elements constituting a resistor and a capacitor connected in parallel and having relaxation times τ = RC, as well as a quantity R∞ corresponding to a system’s instant response (τ = 0). Notably, the relaxation times are somewhat distributed in time. The relaxation time distribution method used the Tikhonov regularization for the determination of the type of distribution in time in the logarithmic scale, γ(ln τ), where γ is the intensity of the distribution element with the characteristic time τ [3–5]. Here we look for such a distribution type which allowed reaching minimum of the mean-square deviation from the experimentally measured values of the real and imaginary components of the system’s impedance at the frequency f of the following function [4]:

Then, we look for the distribution function γ(ln τ) corresponding to the minimum of the mean-square deviation over all experimental points. It should be emphasized once more that here we deal with an ill-defined problem, hence, such a minimum must be found by using the Tikhonov regularization or like method. From a practical standpoint, this approach allows isolating from the system’s integral response the dominating components for some time/frequency range by determining the time/frequency dependence of the distribution function γ(ln τ). The method allows determining the number of such components (the distribution function peaks) and their relative intensities.

Basically, this information allows suggesting more substantiated equivalent circuits and continuing the analysis of experimental data using the method of equivalent circuits; however, even without this analysis the type of relaxation time distribution allows unambiguously concluding on the electrochemical system and processes occurring therein. For example, the method can be used for the cross-system comparison, the system evolution under certain conditions, etc. Often, of significant interest is the very fact of the presence of processes in a given relaxation-time range. For example, high-frequency processes in electrochemical systems used to include the electrical double layer charging; the low-frequency ones, diffusion impedance and Faradaic resistance of the charge-transfer stage. The medium-frequency range can include, e.g., the particle transport in ionic conductors. Also, the general appearance of the distribution curves can be used as “fingerprints,” as is done, e.g., with IR-spectra of complicated systems. Quite an advantage of the method is the fact that in the laboratory of F. Ciucci a program code [6] for the implementation of the relaxation-time distribution method was developed basing on the Matlab program medium. Its code is an open access.

In this work, we used the relaxation-time distribution method in the analyzing of the electrochemical impedance spectra obtained during studying the processes of the metallic lithium electrodeposition onto copper and lithium electrodes. This study was aimed at determining the effect of additions of some surfactants on the dendrite-formation processes in the systems. This study (carried out by electrochemical methods) is described in the preceding paper [1]; in the present work, we focus ourselves on the additional analysis of experimental data aiming at a confirmation of the conclusions drawn in work [1]. In particular, we confirmed the conclusion that the regularities observed during the metallic lithium electrodeposition onto copper and lithium electrodes can be connected with the difference in the properties of the so-called SEI (solid electrolyte interphase) layers formed at these electrodes in the contact with electrolyte.

EXPERIMENTAL

Electrodes

We studied electrodes made of copper and lithium metals. The electrodes were manufactured of copper (a sheet of the M1 grade copper, 99.9% Cu) and lithium metal (the band, 1.5 mm in thickness, 99.9% Li, Sigma-Aldrich). The lithium band was rolled into thin foil in a glove-box in argon atmosphere. Then, discs, 16 mm in diameter, were cut out of the foil. The lithium surface was mechanically cleaned. The copper discs, 16 mm in diameter, were cut out of the sheet, their surface was etched in 20%-sodium alkali for 20 min. Afterwards, the discs were washed thrice by twice-distilled water, oven-dried at T = 60°C for 30 min, and put into the glove-box. To remove the copper oxide traces that can be present at the electrode surface after its processing in air, prior to the measurements the copper electrodes were kept at the constant potential of +0.2 V vs. lithium electrode for 24 h.

Cells

We used standard two-electrode cells of the “coin cell” type with the 0.5 mm-thick fiberglass separators. The working electrodes were the above-described copper or lithium discs. The counter-electrodes were discs of metallic lithium, 16 mm in diameter. The electrolyte was the standard electrolyte (the Riol Chemie Co. production) composed of 1 М LiPF6 solution in the EC:DEC mixture (1 : 1), both surfactant-added and surfactant-free. The electrolyte volume in the cell was 0.125 mL. The cells were assembled in a MBraun Unilab glove-box in argon atmosphere.

Surfactants

The surface-active additives were: the cetyl(trimethyl)ammonium bromide (C16Me3Br, ≥98%) and hexadecylpyridinium bromide (C16PyBr, ≥97.0%). The substances were delivered by the Sigma-Aldrich Co. and used as received. The electrolyte solutions were prepared by adding 5.4 mg of C16Me3Br or 3.5 mg of C16PyBr to 1 mL of the standard electrolyte.

Electrochemical Measurements

Electrochemical measurements were carried out in a two-electrode configuration using a Biologic VMP-3 potentiostat–galvanostat with a EC-Lab software suite. The electrode potentials were measured (and given below) against the lithium counter-electrode. The impedance spectra were taken over the frequency range from 200 kHz to 100 mHz, with the potential modulation amplitude of 5 mV. The impedance was measured at the open-circuit potential that was settled at the electrode after the corresponding experiment and the following 5 min-exposure at open circuit.

The measurements were carried out both at the deposit-free copper and lithium electrodes and at the same electrodes after metallic lithium electrodeposition at different potentials. The procedure of the metallic lithium electrodeposition and measurements of electrochemical and impedance data is described at length elsewhere [1].

The Processing of the Electrochemical Impedance Spectra

The electrochemical impedance spectra were analyzed by the relaxation time distribution method with the using of the DRTtools program [6] developed in the Laboratory of F. Ciucci. The program was written for the Matlab medium, its initial code is an open access. The program version of 9.12.2021 was used. The following values of the ground parameters were used: the discretization method—a Gaussian one; the sort of data—a combined one, the real and imaginary parts, without using of inductive parameters; the type of derivative for the regularization—of the second order; the regularization parameter—usually, 5 × 10–4; the peak form control—the half-width.

RESULTS AND DISCUSSION

The Comparison of the Results of Analyses by the Relaxation-Time Distribution Method and the Equivalent-Circuit Method

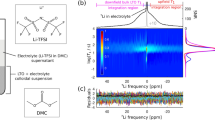

We begin with the comparison of the results of the impedance spectra analysis by the relaxation time distribution method and the results of the analysis by the traditional method of equivalent circuits. In Fig. 1а we show typical electrochemical impedance spectra measured with the metallic lithium deposited from the surfactant-free standard electrolyte (curve 2) and from the standard electrolyte added with one of the surfactants used in this work, hexadecylpy ridinium bromide (curve 1). At first site, the Nyquist plots have common form and can be described by the same equivalent circuit (also given in Fig. 1а). This equivalent circuit is typical for Faradaic processes complicated by mass transfer; it is a modified Ershler–Randles circuit with somewhat varied meaning of the principal parameters.

(а) Typical Nyquist plots for electrochemical impedance measured at electrodeposited metallic lithium whose electrodeposition was carried out (curve 1) in standard electrolyte added with hexadecylpyridinium bromide and (curve 2) in surfactant-free standard electrolyte. The measurements were carried out at the open-circuit potential in the same electrolyte as the electrodeposition. The electrodeposition conditions: (1) lithium electrode, potential –0.07 V; (2) copper electrode, potential –0.055 V. The lines are calculated by the model obtained using the distribution of relaxation times method. Insert: the equivalent circuit used in the analysis carried out by the distribution of relaxation times method. (b) The distribution of relaxation times obtained from the Nyquist plots (Fig. 1а) analysis. The deposition was carried out (1) in standard electrolyte added with hexadecylpyridinium bromide and (2) in surfactant-free standard electrolyte. (c) Frequency dependences of the real (1 ′, 2 ′) and imaginary (1 ′′, 2 ′′) parts of the impedance dependences (Fig. 1а). The lines are calculated by the model obtained using the distribution of relaxation times method.

The parameters R1 and C1 traditionally mean the high-frequency (Ohmic) resistance corresponding to the system’s instant response, and the capacitance of the electrical double layer at the electrode which is covered by the solid-electrolyte interphase (SEI). The parameter R2 meaning is also traditional one: here, the Faradaic resistance of the charge-transfer stage; the parameters Q3 and R3, some complex impedance Q3 of the ionic transport through the SEI layer

where f is the modulation frequency for the potential bypassed by the Ohmic (a low-frequency one) resistance R3 of the above-mentioned SEI layer, because it follows from the Nyquist plots that the electrodes are by no means blocking ones (in the limit of low frequencies, the imaginary impedance part tends to zero). The latter fact points to that the SEI layer is a conductor (it has ionic conductance, as it is known from literature [7, 8]). A relatively fast exchange by the lithium ions is established in the system between the electrolyte solution and the lithium-metal deposit. It should be emphasized once more that the discussed Nyquist plots were measured not directly in the electrodeposition process but after the electrodeposition, that is, at the electrodeposited lithium, upon its open-circuit exposure for 5 min.

The values of the parameters determined by the traditional fitting realized in the EC-Lab program pack (the simplex multidimensional optimization method) are given in Table 1.

Correspondingly, on the using of the traditional analysis with the equivalent circuits, the following conclusions were drawn:

(1) Both processes are adequately described by the same equivalent circuit, hence, passed by similar mechanisms.

(2) The adding of the surfactant does not change the process mechanism any notably, only the SEI layer parameters Q3 and R3 change. In particular, the charge transfer resistance R2 remained practically unchanged.

(3) With the adding of the surfactant, the SEI layer ionic resistance R3 grows. Also, the parameters of the complex impedance of the ionic transport through the SEI layer Q3 changed, however, the meaning of this parameter in the equivalent circuit remained unclear on the whole.

(4) Conspicuous is the fact that the values of the electrical double layer capacitance practically do not change upon the adding of the surfactant. This must be connected with the presence of the SEI layer at the metallic electrode surface, which is formed in both cases, that is, with and without the surfactant, and is an organic film with relatively low permittivity, which consisted of the products of a reaction between the electrolyte solution components and the metallic electrode [7, 8]. The obtained values of ~0.4…~0.5 μF grossly approximately correspond to the electrical double layer on the metallic electrodes covered by polymer films in organic electrolyte [9–12]. In particular, the value of capacitance for an electrode covered by a 20 nm-thick film with the relative permittivity of 10, calculated by the formula for parallel-plate capacitor, is 0.44 μF/сm2.

Now, we address the results of analysis of the same data (Fig. 1а) by using the distribution of relaxation times method. The corresponding distribution curves are given in Fig. 1b. They have peaks of different intensity and width; their maximums correspond to some relaxation times τ. Such an appearance follows from the chosen discretization method for the function of distribution in the Gaussian radial distribution functions [3–5]. Each peak in the distribution curves of Fig. 1b corresponds to a process in the system, which has a certain characteristic time. The peak intensity corresponds to the relative contribution from this process into the system’s total impedance.

Thus, the analysis by the distribution of relaxation times method, unlike that by equivalent circuits, allows evaluating the number of processes occurring in the system and comparing their intensities independently and without prejudice. Notably, the medium-frequency peak corresponding to the SEI layer impedance is broader and has satellite by-peaks in systems added with the surfactant. This is likely to correlate with the lower value of the α3 parameter obtained by the equivalent circuit method, which corresponds to broader distribution of the parameters described by the constant phase element.

The analysis of the distribution curves in Fig. 1b allowed concluding that the conclusions drawn from the analyzes made by the equivalent circuit method are in fact not entirely true. In particular, in the surfactant-free system we see only two ground processes corresponding, as judged by their characteristic values of the time/frequency, to the electrical double layer charging and ionic transport through the SEI layer. These processes are also present in the equivalent circuit of Fig. 1а; yet, the contribution of the third process (corresponding to the Faradaic stage of the lithium ion discharge–ionization) is missing in the relaxation time distribution spectrum. At the same time, the corresponding peaks at the times about 0.01 and 10 s are clearly seen in the distribution curve measured in the presence of a surfactant. Most likely, these peaks simply cannot be measured in the surfactant-free system because actually an equilibrium is established there between the lithium metal deposit (with a fresh non-passivated surface) and the lithium ions in the electrolyte solution. The adding of surfactant lowered the rate of exchange involving the lithium ions and brings to the forefront the presence of the corresponding processes at the curve.

It should be emphasized that the analysis by the equivalent circuit method gave us no reasons speaking on such a change in the process mechanism. Actually, either data is adequately described by the same equivalent circuit; the parameters, even if differ, yet, to a lesser extent. Moreover, taking into consideration the inevitable scatter of experimental points, the measured data yields no reasons for the adding/removal of the used equivalent circuit elements. Were no analyses by the relaxation time distribution method carried out, we have remained in the dark about the above-mentioned key-effect of the surfactants on the kinetics of the lithium ion ionization/discharge process at the electrode surface.

Important is also the fact that the analysis by the relaxation time distribution method provided good agreement between the experimental data and the values calculated from the model. This is illustrated by Fig. 1c where we presented frequency dependences of the real and imaginary impedance components (the curves of Fig. 1а) along with the dependences calculated from the distribution curves of Fig. 1b. We see that the relaxation-time distribution method described adequately the experimental data in both cases, despite the significant noisiness of the impedance data for low and medium frequencies. We also see from the figure that the general view of the frequency dependences obtained in the absence of and in the presence of the surfactant is remarkably similar; thus, we would not be aware of the basic difference between the intensity of the occurring processes judging only by the frequency dependences, without using the relaxation time distribution method.

The Effect of the Surfactant Additions on the Relaxation Time Distribution Character

Thus, with the using of the relaxation-time distribution method we are aware of the fact that the adding of surfactant to the electrolyte solution exerted a significant effect on the intensities of the processes in the system, as the relaxation time distribution method shows. In this section we shall analyze these regularities by example of the metallic lithium deposits obtained at copper and lithium electrodes both in the surfactant-free standard electrolyte and in the presence of the two cationic surfactants.

In Fig. 2 we show the relaxation time spectra obtained by the processing of experimental data for the metallic lithium deposits electrodeposited onto the copper and lithium electrodes. The dependences for the copper electrode are given in Fig. 2а; for the lithium electrode, in Fig. 2b. The electrodeposition was carried out in the presence of two surfactants, hexadecylpyridinium bromide (curves 1) and cetyltrimethylammonium bromide (curves 2), as well as in the surfactant-free standard electrolyte (curves 3). We see that, as in the above-mentioned case, the adding of the surfactants leads to the appearance of low-frequency components for the lithium deposits obtained both at the copper and lithium electrodes. This points to the hindering of the lithium ion discharge–ionization processes in the presence of the surfactants. The hindering is better pronounced on the adding of cetyltrimethylammonium bromide. It is also evident that the position of the low-frequency peaks is different for these two surfactants.

Relaxation time spectra obtained by the processing of impedance data for the lithium metal deposits electrodeposited onto (а) copper and (b) lithium electrodes in the presence of hexadecylpyridinium bromide (curves 1) and cetyltrimethylammonium bromide (curves 2), as well as in surfactant-free standard electrolyte (curves 3).

The reason for such a behavior still is unclear; it can be connected with the difference in the kinetic parameters of these processes, which leads to differences in their time constants. Also, we see the differences between the lithium and copper electrodes in the extremely low-frequency range (at the longest time periods). They are likely to be connected with differences in the SEI layer at these electrodes (see below). The curves obtained in the absence of the surfactant demonstrated no such processes which, as we have seen, pointed to the high lithium ion exchange rate under these conditions.

Thus, the results obtained from the electrochemical impedance spectra and the relaxation time distribution spectra can be summarized as follows:

(1) The low-frequency range of the impedance/the peaks of the relaxation time spectra (0.01–10 s) correspond to the Faradaic processes of the lithium metal deposition–dissolution under the SEI layer. These processes are very fast in the absence of the surfactants; are hindered, in their presence.

(2) The medium-frequency range of the impedance/the peaks of the relaxation time spectra (10–4–10–3 s) corresponds to ionic conductance of the SEI film at the electrode surface. These frequencies–times correspond to the arc in the impedance spectra, which in literature is associated with the ionic conductance of various organic ionic conductors/ion-conducting polymers.

(3) The high-frequency range of the impedance/the peaks of the relaxation time spectra (10–6–10–5 s) is associated with the processes characterized by a rather small value of the RC parameter. The capacitance corresponding to this frequency range can be estimated by the analyzing of the electrochemical impedance using the equivalent circuit method. It is about 0.25 μF/сm2. A close value was obtained from the estimate with the using relaxation time corresponding to the shortest-time peaks. Thus, this component should be connected with the charging of the electrical double layer capacitance at a metal electrode, taking into consideration the SEI layer thereat.

No unambiguous dependence of the peak height in this frequency range on the experimental conditions was established. The reason is likely to be that the surface of such an active material as lithium is poorly reproducible. It is to be noted, however, that the position of this component always is well reproducible.

The Effects of the Surfactant Additions and the Electrode Material on the Properties of the Solid Electrolyte Interphase (the SEI Layers)

The analysis of relaxation times in the medium-frequency range (2) allows judging on the properties of the solid electrolyte interphase (the SEI layers) formed in the corresponding conditions. In Fig. 3, highlighted are the segments of the relaxation time spectra that correspond to this frequency range. At that, we show both the spectra obtained from impedance data after the lithium metal electrodeposition onto copper and lithium electrodes and those measured at the corresponding electrodes prior to the electrodeposition, that is, at the copper or lithium original surfaces covered by the SEI layer. We dealt with SEI layers obtained in the surfactant-free standard electrolyte (Fig. 3а) and in that added with the hexadecylpyridinium bromide (Fig. 3b). No detailed analysis of the processes corresponding to the peaks in this relaxation time range was performed in this work; only general view of the relaxation time distribution in this time range was analyzed (the “fingerprint” method).

Relaxation time spectra in the medium-frequency range corresponding to the impedance of the solid-electrolyte interphase/SEI layers, obtained (а) in surfactant-free standard electrolyte and (b) in standard electrolyte added with hexadecylpyridinium bromide. (1, 3) Spectra of (1) lithium and (3) copper electrodes prior to electrodeposition; (2, 4) spectra of the lithium metal deposits electrodeposited onto (2) lithium and (4) copper electrodes.

We see that in the surfactant-free electrolyte the spectra of SEI layers formed at the copper and lithium electrodes differ markedly. Spectra of the SEI layers at the lithium electrode (curves 1 and 2) have a single well pronounced peak near 10–4 s, whereas at the copper electrode the spectra show two peaks: a less intensive one in the same time range and a more intensive, with the maximum near 4 × 10–3 s. What’s quite unexpected, the SEI layer spectra measured at the copper electrode prior to the lithium deposition were of the same kind as the SEI layer spectra obtained at the copper electrode after the metallic lithium electrodeposition, that is, at the quite different metal surface. While the spectra of the identical lithium deposit obtained at the lithium electrode were different: they corresponded to those obtained at the same lithium electrode, yet, prior to the lithium metal deposition. This proves the following:

(1) The electrodeposition occurred at the electrode surface, yet, under the SEI layer.

(2) The SEI layer is formed at the electrode surface prior to the electrodeposition has started; therefore, its properties depend on the nature of the electrode ground material, even when the electrode surface has been covered by other material (the electrodeposited metallic lithium).

(3) It follows therefrom that the SEI layer properties at the same material—the electrodeposited lithium—must differ depending on the material of the electrode onto which the electrodeposition was done.

(4) Hence, the SEI layer at the fresh-deposited lithium has not been formed to the full extent.

At the same time, in the presence of the surfactant the difference between the SEI layers formed at the copper and lithium are considerably levelled out (Fig. 3b) and the spectra of the SEI layers formed under these conditions are similar to those of the SEI layers formed at the copper electrode.

Correspondingly, the materials of this section allow drawing the following conclusions: a SEI layer is formed at the electrode surface prior to the beginning of the electrodeposition, rather than at the fresh-formed deposit; it remained there during the electrodeposition process. At that, its properties changed upon the surfactant adding to the electrolyte solution. The surfactant-free solution components interact in a different manner with the electrode material (at least, with such materials as the copper and lithium). In the presence of the surfactant, this difference is levelled out. The electrodeposition occurred under the SEI layer.

Adsorption of the Electrolyte Components during the Lithium Electrodeposition and Suppression of the Dendrite Formation

In our preseding paper [1] we found that, contrary to expectation, the surfactant additives were not able suppressing the dendrite formation processes during the lithium electrodeposition at rather large negative potentials. The analysis of impedance spectra by the relaxation time distribution method allowed causing the spotlight to be shone on the reasons of this behavior. In Fig. 4 we show evolution of the relaxation time spectra obtained during the lithium electrodeposition onto lithium electrode in the presence of the two surfactants. We see (Figs. 4а, 4b) that with the increasing of the negative potential the height of the relaxation-time peaks is lowered in the time range corresponding to the SEI layer impedance (10–4–10–3 s), which must be in all probability connected with the deposit growth inside the SEI layer and the corresponding thinning of the SEI layer over the deposit. Interestingly, here the peaks corresponding to the Faradaic process per se (the time range of 0.01–0.1 s) changed insignificantly. At the same time, with further increasing of the negative potential we obtained a drastic lowering of all peaks, which was accompanied with the qualitative change of the relaxation time spectra. In particular, the SEI layer impedance became practically non-observable. Moreover, the peaks of Faradaic processes observed earlier in the presence of the surfactants disappeared (Fig. 2).

Evolution of relaxation time spectra obtained by the processing of impedance data for the lithium metal deposits electrodeposited at different potentials onto substrates of (а, b) lithium and (c) copper. The electrolyte (а) added with cetyltrimethylammonium bromide; (b) added with hexadecylpyridinium bromide; (c) surfactant-free electrolyte. Potentials: (а) (1) –0.03, (2) ‒0.035, (3) –0.05, (4) –0.06 V; (b) (1) –0.065, (2) –0.07, (3) –0.08 V; (c) (1) –0.03, (2) –0.04, (3) –0.055 V. The impedance measured at the open-circuit potentials after the lithium electrodeposition.

Such a behavior must be connected with the deposit intergrowth through the SEI layer, with the further deposit outcropping onto the SEI surface. Here, the hazards of the dendrite formation increased significantly, which is attested to by steep increase in the current observed in the presence of both surfactants we have used (see the paper [1]). The dendrite formation not only has lowered the impedance corresponding to the SEI layer resistance but also completely suppressed the peaks at low frequency, which corresponded to the slowed-down Faradaic processes of the lithium deposition–dissolution. This points, in particular, to the fact that the additions of the surfactants alone cannot hamper the process, e.g., because of their adsorption at the growing deposit surface. Also, as mentioned above, no well-developed SEI layers are formed at the fresh-deposited metallic lithium because the formation of well accomplished SEI layers takes quite a time [7, 8].

The above-mentioned absence of any change in the electrical double layer capacitance upon the adding of the surfactants tells the same story. The surfactants are not adsorbed at the lithium metal electrode; hence, the capacitance is not changed. At the same time, the relaxation time spectra (Fig. 4) clearly show the lowering of the high-frequency peak height, which points to the capacitance increase in this time range (the impedance is inversely proportional to the capacitance) upon the deposit intergrowth through the SEI layer, which once again evidenced the absence of the surfactant adsorption at the fresh-formed deposit surface.

Correspondingly, the observed surfactants’ effect must be connected not with their adsorption at the lithium deposit but with the variations in the properties of the already-existing SEI layers formed prior to the beginning of the lithium metal electrodeposition processes. In the beginning of the electrodeposition process or over the entire period of time, provided the formed SEI layer is strong enough, the lithium metal electrodeposition occurs under the SEI layer that affects the electrodeposition kinetics by hindering them and preventing the dendrite formation. If, then, the deposit is outcropping at the SEI layer, the hindering disappeared and the dendrite formation goes on.

The dendrite formation probability is connected with the properties of the SEI layer formed at the electrode in the current terms. It follows from the data of Fig. 3 that the SEI layers formed at the copper and lithium electrodes differ in their properties. Moreover, the relaxation time spectra showed that upon the metallic lithium further deposition onto the copper electrode the properties of the SEI layer characteristic of the copper electrode are retained at the obtained lithium metal deposit as well. This may be just the reason of the fact emphasized in our preceding paper [1] that the adding of the surfactant prevents the dendrite formation at the copper electrode, while at the lithium electrode this effect is the case only at lower overvoltages. By contrast, with the increasing of the negative potential there existed a probability of the SEI layer breakdown with the involvement of the growing deposit, with the further dendrite formation. Indeed, in Fig. 4c presenting a potential dependence of the relaxation time spectra measured for the lithium deposition onto the copper electrode we observed only a change of the SEI layer impedance during the deposit growth; no SEI layer breakdown and the related disappearance of the corresponding components in the relaxation time spectra has been observed.

CONCLUSIONS

Thus, we conclude that the above-mentioned analysis with the using of distribution of relaxation times spectra of electrochemical impedance, obtained in the course of the metallic lithium electrodeposition in the presence of two surfactants, confirmed our earlier conclusions that (1) these surfactants are not able suppressing effectively the dendrite formation during the lithium electrodeposition despite their adsorption at the growing deposit surface, and (2) the observed surfactants’ effect is connected with their influence onto the properties of the SEI layers formed at the electrodes in their presence.

Alongside these conclusions, in this work, the analysis of relaxation time spectra showed that the properties of the SEI layer over the lithium metal deposits obtained by the electrodeposition onto copper and lithium electrodes differ from each other. Equally differ the relaxation-time spectra of the SEI layers formed at the lithium and copper substrates prior to the electrodeposition, that is, at the lithium and copper native surfaces covered with SEI layers. Notably, the spectrum of the SEI layer at the lithium deposition formed at a copper electrode practically does not differ from that of the SEI layer present at the copper electrode prior to the experiment. This means that the lithium deposition–dissolution at the copper electrode passed with the retention of the initial SEI layer formed at the copper electrode prior to the experiment. This has great possibilities in the controlling of electrodeposition and dendrite formation processes by controlling properties of the SEI layers formed at the electrodes involved in the electrodeposition. This conclusion is of special interest in connection with the now actively-developing concept of anode-free batteries [13, 14] in which the ground anodic process is the metallic lithium deposition–dissolution at the current-collector material which is the copper in the lithium current sources.

REFERENCES

Alpatov, S.S., Vasiliev, F.A., Aleshina, V.Kh., Vagramyan, T.A., and Semenikhin, O.A., Lithium Electrodeposition In The Presence Of surfactants, Russ. J. Electrochem., 2024, vol. 60, no. 5.

Tikhonov, A.N., On the regularization of incorrectly posed problems, Dokl. AN SSSR, 1963, vol. 153, p. 49.

Wan, T. H., Saccoccio, M., Chen, C., and Ciucci, F., Influence of the discretization methods on the distribution of relaxation times deconvolution: implementing radial basis functions with DRTtools, Electrochim. Acta, 2015, vol. 184, p. 483.

Ciucci, F. and Chen, C., Analysis of electrochemical impedance spectroscopy data using the distribution of relaxation times: A Bayesian and hierarchical Bayesian approach, Electrochim. Acta, 2015, vol. 167, p. 439.

Effat, M. B. and Ciucci, F., Bayesian and hierarchical Bayesian based regularization for deconvolving the distribution of relaxation times from electrochemical impedance spectroscopy data, Electrochim. Acta, 2017, vol. 247, p. 1117.

https://github.com/ciuccislab/DRTtools.

Heiskanen, S.K., Kim, J., and Lucht, B.L., Generation and Evolution of the Solid Electrolyte Interphase of Lithium-Ion Batteries, Joule, 2019, vol. 3, p. 2322.

Wu, H., Jia, H., Wang, C., Zhang, J.-G., and Xu, W., Recent Progress in Understanding Solid Electrolyte Interphase on Lithium Metal Anodes, Adv. Energy Mater., 2021, vol. 11, p. 2003092.

Alekseeva, E.Yu., Safonov, V.A., and Petrii, O.A., Zero-charge potentials and the electrical double layer structure at platinum and palladium in DMSO, Elektrokhimiya, 1984, vol. 20, p. 945.

Lonchakova, O.V., Semenikhin, O.A., Zakharkin, M.V., Sergeyev, V.G., and Antipov, E.V., Efficient gel-polymer electrolyte for sodium-ion batteries based on poly(acrylonitrile-co-methyl acrylate), Electrochim. Acta, 2020, vol. 334, article # 135512.

Semenikhin, O.A., Ovsyannikova, E.V., Alpatova, N.M., and Rotenberg, Z.A., Dynamic impedance measurements on a thin-film poly-3-methylthiophene electrode: memory effects and space charge formation, J. Electroanal. Chem., 1996, vol. 408, p. 67.

Semenikhin, O.A., Hossain, M.M.D., and Workentin, M.S., Photoelectrochemistry of Conducting Polymers Modified with Electron-Acceptor Moieties, J. Phys. Chem. B, 2006, vol. 110, p. 20189.

Su, L., Charalambous, H., and Cui, Z., High-efficiency, anode-free lithium–metal batteries with a close-packed homogeneous lithium morphology, Energy Environ. Sci., 2022, vol. 15, p. 843.

Tong, Z., Bazri, B., Hu, S.-F., and Liu, R.-S., Interfacial chemistry in anode-free batteries: challenges and strategies, J. Mater. Chem. A, 2021, vol. 9, p. 7396.

ACKNOWLEDGMENTS

Authors are grateful to Prof. V.G. Sergeyev, Head of the Chair of colloid chemistry, Department of Chemistry, Moscow State University, for the kindly procured surfactant samples.

Funding

This work was supported by the Russian Science Foundation, grant no. 22-23-00512, https://rscf.ru/project/22-23-00512/.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflict of interest.

Additional information

Translated by Yu. Pleskov

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alpatov, S.S., Vasiliev, F.A., Aleshina, V.K. et al. Analysis of the Electrochemical Impedance Spectra and the Structure of the Solid Electrolyte Interphase at the Electrodeposited Metallic Lithium Using the Distribution of Relaxation Times Method. Russ J Electrochem 60, 365–375 (2024). https://doi.org/10.1134/S1023193524050033

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193524050033