Abstract

Staphylococcal enterotoxin B (SEB), a potent enterotoxin produced by Staphylococcus aureus, has been implicated in incidences of Staphylococcal food poisoning in the Philippines. The use of lateral flow immunoassay devices to detect this toxin in solid food samples, like durian candy, at the point of sampling is constrained by the requirement for sample purification (e.g. centrifugation). This problem is also true with the other applications of LFIA devices on food samples. To overcome this challenge, a lateral flow immunoassay (LFIA) device capable of detecting SEB in unpurified durian candy sample was developed in this study. A modified LFIA device was assembled with three layers of glass fiber pads functioning as sample pads instead of a conventional cellulose fiber pad. Unlike with the cellulose fiber pad, the glass fiber sample pads acted as filter and allowed the flow of a 1:5 dilution of durian candy. The LFIA device applied to spiked 1:5 diluted durian candy samples achieved a visual limit of detection of 5 ng/mL for SEB, which is twofold lower than reported for previous LFIA devices designed to detect SEB in food samples.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Staphylococcus aureus is an ubiquitous microorganism that produces a multitude of toxins which include the Staphylococcal enterotoxin B (SEB), the most potent Staphylococcal enterotoxin. The toxin is a 28-kDa protein composed of 239 amino acids [1]. It has an oral ED50 value (effective dose) of 0.3 µg/kg, the dose at which it can exert symptoms of illness [2]. The main route of exposure of individuals to the toxin is through food consumption. Its heat stability and resistance to proteolytic digestive enzymes are attributes that contribute to its persistence in food and on its potency [1].

In the Philippines, staphylococcal enterotoxin was identified as second to Salmonella spp. as cause of foodborne poisoning outbreaks according to the data gathered from year 2005 to June 2018 [3]. One of these outbreaks occurred in the Caraga Region, Philippines where close to 2,000 people got sick after consuming contaminated durian candy. In this incident, it took around a week to identify S. aureus and its toxin to be the culprit [4].

This scenario illustrates the need for a reliable rapid screening for possible food contamination during food processing and for initial determination of the causes of food poisoning in order that proper medication can immediately be discharged. A tool that can be used for this purpose is the lateral flow immunoassay (LFIA) device. A popular example of this tool is the home pregnancy test kit, and more recently, the rapid antigen test for the diagnosis of COVID-19 infection. LFIA devices are the closest to satisfy the ASSURED point of care testing (POCT) criteria of the World Health Organization (WHO), which stands for affordable, sensitive, specific, user-friendly, rapid, and robust, equipment-free and deliverable to end-users [5].

In this regard, an LFIA device for the detection of the Staphylococcal enterotoxin, particularly SEB, in food samples prone to its contamination like durian candy, would be beneficial. There were already several studies on the development of LFIA devices to detect SEB but mainly using buffer and liquid milk samples. A gold nanoparticle-based LFIA device was made to detect SEB in milk samples [6]. Due to the tendency for milk proteins and lipids to block the pores of the nitrocellulose membrane, the sample was diluted several times. The LFIA device showed a decent sensitivity at 10 ng/mL. Another gold nanoparticle-based LFIA device was assessed to have a sensitivity of 0.5 ng/mL and 0.25 ng/mL in milk (with 2% fat) and 1:20 diluted and centrifuged purified yogurt samples, respectively [7]. On the other hand, solid foods such as baked macaroni and French fries contaminated with SEB were also analyzed using LFIA with gold nanoparticle-based detector probes [8]. The SEB sensitivity of the LFIA device ranged from 10 to 100 ng/mL for solid samples. To come up with an LFIA device for SEB with increased sensitivity, some studies went beyond the use of gold nanoparticles as signaling element and implemented innovative strategies. For instance, magnetic quantum dot (MagQD) conjugated anti-SEB antibodies were utilized as detector probe [9]. The magnetic probe enhanced the signal by its participation in the magnetic preconcentration which increased the concentration of the antigen and removed the physical and chemical interferences. The MagQD also improved the sensitivity of the LFIA device through its strong fluorescence when exposed to UV light. Because of these, the LFIA attained a detection limit of 0.05 ng/mL in liquid milk sample. Moreover, another study reported an LFIA for SEB with antibody labeled with rhodium (Rh) nanozymes as detector probe (Rh-mab) [10]. The accumulation of the Rh-mab on the test line appeared as distinct black color band. This signal was amplified by the application of H2O2/TMB, which the Rh nanozymes catalytically oxidized to yield ox-TMB, an insoluble colored product.

Almost all the LFIA devices for SEB from previous studies required a purification process in the preparation of liquid food samples and certainly, all would demand more intensive purification of solid food samples. This purification process normally involves centrifugation which can only be performed in the laboratory. This drawback extends to the other LFIA devices used to detect analytes other than SEB in solid food samples. Aside from the fact that intensive preprocessing entails additional capital investment, a limitation in resource-scarce settings, it restricts the conduct of the analysis at the point of sampling.

Hence, this study aimed to fabricate an LFIA device to detect SEB in a durian candy sample that eliminated the need for sample purification. This was made possible using a glass fiber pad instead of a cellulose fiber pad as a sample pad. Glass fiber pads are commonly employed as conjugate pads in conventional lateral flow assay devices, because of their low protein affinity [11]. Glass fiber pads are also more porous compared to cellulose fiber pads [12]. Previously, glass fiber pads were used as sample pads in lateral flow immunoassay devices but for a different purpose [13,14,15,16,17]. In this study, the porous property of the glass fiber pad was exploited for it to function as sample pad and at the same time as on-strip filtration component to permit the analysis of SEB contained in viscous homogenized durian candy samples with insoluble particulates. Equipping an LFIA device with this feature enables the in-field testing of durian candy samples for possible SEB contamination.

Experimental

Materials and instruments

The highly purified and lyophilized staphylococcal enterotoxin B (BT 202) was obtained from Toxin Technology Inc. (Sarasota, Florida, USA). The stabilized suspension of 40 nm gold nanoparticles in 0.1 mM PBS (OD 1) (753,637), anti-SEB antibody from rabbit (S 9008), and anti-rabbit IgG from goat (R 5506), cellulose fiber pads (CFSP 173000 and CFSP 203000) were purchased from Sigma-Aldrich Inc (St. Louis, Missouri, USA). The cellulose fiber pads (CSFSP 173000 and CFSP203000) were purchased from EMD Millipore (Burlington, Massachusetts, USA). The glass fiber pad (Ahlstrom 8964S2030) and nitrocellulose membrane (Whatman™ FF80HP) were procured from Ahlstrom-Munksjo (Helsinki, Finland) and Cytiva (Marlborough, Massachusetts, USA), respectively. The powdered skimmed milk and refined sugar, ingredients to make durian candy, were purchased from a local grocery store in Yokohama, Japan, while the fresh ripe durian was imported from the Philippines.

A Silhouette Cameo 3 cutting device (Graphtec, Kanagawa, Japan) was used for precutting the A4 nitrocellulose membrane sheets. A compact strip cutter SCM-100DX (Fuji Shoko Machinery, Saitama, Japan) was used to produce 4 mm wide strips of the sample- and conjugate pads, nitrocellulose membrane, and absorbent pad. Images of the LFIA devices ran with samples were taken using the Canon 9000F Mark II scanner (Canon, Tokyo, Japan). The ImageJ software (NIH, Bethesda, Maryland, USA) inverted the images and measured the color intensities of the capture antibody spots and background.

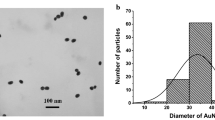

Preparation of detection probe

The detection probe was formed from gold nanoparticles and antibodies according to a previously published method with some modifications [18]. To 1 mL of gold nanoparticles (OD 1), 40 µL of 0.1 mg/mL of anti-SEB antibody from rabbit in 5 mM K2CO3, pH 8.5 was mixed. The solution was incubated for 1 h and blocked with 115 µL of 10% BSA and 15 µL of 0.01% Tween-20. The solution was further incubated for another 1 h and then centrifuged at 7000 × g for 10 min. The detection probe pellet (gold nanoparticle-antibody conjugate) was washed twice with 20 mM borate buffer, pH 8.5, containing 0.20% Tween-20. After washing, the detection probes were resuspended in 250 µL of 20 mM borate buffer, pH 8.5, containing 1% BSA, 0.25% Tween-20, 2% sucrose, and 0.02% NaN3.

Preparation of the sample pads

Two types of LFIA devices were assembled. Device design A was a conventional LFIA device with a cellulose fiber pad as a sample pad, while device design B used three layers of glass fiber pad as a sample pad. Supplementary Figs. 1, 2 show the illustrations of device designs A and B, respectively.

Effect of capture antibody concentration and SDS on the test spot signal visibility in device design A: a measured signal intensities (S/N) for blank and SEB-spiked (150 ng/mL) running buffer samples, and b representative scans of the corresponding LFIA devices; signal intensities are the averages of three replicates; results obtained in presence or absence of SDS are shown alternately in the order of increasing capture antibody concentration; a ( +) sign indicates a visually detectable test spot, while the (−) sign denotes the contrary; software-enhanced versions of scans supporting the naked eye visual perception are provided in Supplementary Fig. 5

The cellulose fiber pad (CSFSP 173000) was cut into 17 mm × 4 mm size and treated with 50 µL of sample pad blocking buffer composed of 20 mM borate buffer, pH 8.5, 1% BSA, 1.0% Tween-20, and 0.02% NaN3. The sample pads were dried for 2 h at 37 °C. On the other hand, glass fiber sample pads (Ahlstrom 8964) were cut into 4 mm × 16 mm size and used without any pretreatment.

Preparation of the conjugate pad

The glass fiber pad used as the conjugate pad was cut into 4 mm × 10 mm pieces. Each piece was pretreated with 20 µL of blocking buffer (20 mM borate buffer with 1% BSA, 0.25% Tween-20, 2% sucrose, and 0.02% NaN3). The pretreated pads were dried for 1 h at 65 °C, followed by deposition of 17.5 µL of the detection probe. The conjugate pads were dried at 37 °C for 2 h and immediately placed in a desiccator with < 20% relative humidity for overnight curing.

Preparation of the nitrocellulose membrane

The Whatman FF80HP was used as the nitrocellulose membrane. The A4-sized NC membranes were precut into strips of 25 mm width. These bare NC membrane strips were pasted on a backing card and then cut into 4 mm wide strips. 1 µL of the capture- and control antibody (0.5 mg/mL) solutions in 10 mM phosphate buffer (PB), pH 7.4, with 0.02% NaN3 were spotted onto separate positions of the nitrocellulose membrane to form the test and control spots. The capture and control antibodies used were the anti-SEB antibody from rabbit and the anti-rabbit IgG antibody from goat, respectively. Optimization of the composition of the capture antibody solution in device design A involved the use of different antibody concentrations at 0.5, 0.75, and 1.0 mg/mL dissolved in 10 mM PB solutions with and without 0.03% SDS. After spotting, the nitrocellulose strips were dried for 2 h at 37 °C.

Preparation of the absorbent pad

The cellulose fiber pad (CFSP203000, 20 mm × 300 mm) was used as the absorbent pad without pretreatment. It was cut into pieces with 4 mm × 20 mm size.

Assembly of the lateral flow immunoassay device

The individual components were joined together on the nitrocellulose membrane card strip to create the complete format of the lateral flow immunoassay device. For the device design A, the overlap between the cellulose fiber sample pad and the conjugate pad was 2 mm, while the overlap between the conjugate pad and the nitrocellulose membrane was 3 mm. The absorbent pad had a 5 mm overlap with the nitrocellulose membrane. On the other hand, with device design B, the 1st layer of glass fiber sample pad overlapped the conjugate pad for at least 3 mm. Then, the succeeding layers of sample pads were laid over at 15 mm overlap of their preceding layers. The devices were placed in plastic cassettes, which pressed the overlapping components of the LFIA devices to ensure adequate contact.

SEB assays in buffer solution

Devices of design A were run with blank and SEB-spiked running buffer samples. The running buffer consisted of 20 mM borate buffer with 1% BSA, 2% Tween-20, and 0.02% NaN3. The spiked sample contained 150 ng/mL of SEB. The assay was performed with three replicates per sample and at a sample volume of 150 µL. The run time was set at 15 min. The LFIA devices were visually inspected, and the signal intensities (S/N) were analyzed using the ImageJ software as shown in Supplementary fig. 3.

Detection of staphylococcal enterotoxin B in homogenized durian candy prepared at different dilutions: a representative scans of the corresponding LFIA devices ran with blank and spiked durian candy samples (150 ng/mL) at different dilutions, b measured test spot signal intensities (S/N); signal intensities are the averages of three replicates

SEB assays in durian candy

The durian candy sample was prepared as described in Supplementary Table 1. The capacity of device design A to analyze homogenized durian candy samples in running buffer (1:5 durian candy: running buffer dilution ratio) was investigated. LFIA devices of design A were ran with 150 µL of blank homogenized durian samples for 15 min. Meanwhile, the appropriate sample dilution of the homogenized durian candy sample for device design B was determined by testing the sample dilution ratios of 1:1, 1:2, 1:3, 1:4, and 1:5. Spiked samples which contained 150 ng/mL of SEB were incubated for an hour before use. Each blank or spiked sample per dilution was applied to three devices of design B. The optimum run time was determined from evaluating three run times: 15, 20, and 25 min. The sensitivities of both device designs A and B were assessed using running buffer and homogenized durian candy samples spiked with increasing concentrations of SEB (1, 5, 10, 20, 50, 100, and 150 ng/mL).

Results and discussion

A preliminary test with the LFIA device (results not shown here) produced a false positive signal. An approach to address this problem was acquired from the experience of a study by Zeng and co-researchers, where a high amount of capture antibody on the test line resulted in a high false positive signal [19]. This suggests that the false positive signal could be eliminated by decreasing the concentration of immobilized capture antibody on the NC membrane. Moreover, the effect of adding SDS, at 0.03% concentration, to the antibody solution used to prepare the test spot was evaluated. At < 0.1% w/v of concentration, SDS can be added safely into the capture antibody solution to curtail nonspecific binding and improve the rewetting of the capture antibody line or spot [20]. As an anionic surfactant, it disrupts hydrophobic and ionic interactions between protein molecules, which reduces nonspecific binding [21, 22]. As shown in Fig. 1a, the signal intensity (S/N) of the test spot of the device design A ran with blank and spiked samples in buffer increased with an increasing amount of deposited capture antibody. The LFIA devices prepared with 0.5 mg/mL of capture antibody solution containing 0.03% SDS produced the lowest signal intensities (S/N) for both the blank and spiked samples and did not exhibit false positive results as shown in Fig. 1b.

The LFIA devices spotted with 0.5 mg/mL of capture antibody in 10 mM PB, pH 7.4 without SDS produced a false positive signal for the blank sample (Fig. 1b). In fact, all LFIA strips spotted with capture antibody in 10 mM PB without SDS produced higher signal intensities for both blank and spiked samples compared to their counterparts including 0.03% SDS as a component in the capture antibody solution. Given the fact that results obtained with LFIA devices in the field are generally qualitatively interpreted by the naked eye, the appearance of false positive signals must by avoided by any means, even if the elimination of false positives is inherently accompanied by some reduction in the signal intensity of truly positive results. Hence, along with the decrease in the capture antibody concentration to 0.5 mg/mL, the incorporation of SDS achieved the complete removal of the false positive signal on LFIA devices when ran with blank samples in buffer.

Conventional LFIA devices (design A) with NC membranes treated with 1 µL of capture antibody solution (0.5 mg/mL in 10 mM PB with 0.03% SDS) as test spot were tested against a homogenized 1:5 durian candy: running buffer sample dilution. However, the attempt to run such durian candy sample failed, with the sample poorly taken up by the cellulose fiber sample pad and sample residues blocking the sample inlet. A previous study on the LFIA analysis of solid food samples dealt with this situation by further diluting the sample to reduce its viscosity and by centrifuging the sample to isolate the liquid component from solid or residual components [8]. Because these sample processing activities, particularly centrifugation, need to be conducted inside the laboratory, these prevent the use of the LFIA devices in the field, where needs are highest.

To enable the use of LFIA devices for on-site field testing, they must have the ability to analyze samples that did not undergo laboratory-based purification procedures, such as centrifugation. In this study, it was conceived that the replacement of the cellulose fiber pad with a glass fiber pad as a sample pad would be the answer to this necessity. Glass fiber pads generally possess more porous structures than cellulose fiber pads [12]. This is also evident from the SEM images comparing the two materials (Supplementary Figs. 4a, b). With this, the glass fiber pad was deemed to permit the passage of the liquid sample components, while filtering out the particulate residues. This possibility was demonstrated in a preliminary test, where a single layer of glass fiber pad was used (data not shown). As per the manufacturer’s specifications, the glass fiber pad was 0.43 mm thick with a liquid wicking rate of 5 s/2 cm and water absorption capacity of 70 mg/cm2 [24]. The glass fibers had a diameter of approximately 6 µm (Supplementary Fig. 4c). However, a single layer of the glass fiber pad was overwhelmed by the amount of the sample (150 µL) as indicated by its soaking and the leaking of the sample. To adequately contain the sample while also ensuring sufficient filtration capacity, three layers of glass fiber pads were fitted as the sample pad. Figure 2 shows the successful flow of a 1:5 homogenized durian candy blank sample through the LFIA device design B.

Unlike with running buffer as the sample (Fig. 1b), the durian candy sample left a moderate amount of detector probes at the sides of the device after 15 min of run time. This phenomenon is called the edge effect and arises when the sample flow rate is slow enough to be influenced by the preferential liquid evaporation at the edges, which pulls the gold nanoparticle labels from the interior region to the outer region of the device [20]. As long as the area covered by the edge effect does not overlap with the capture antibody test spot, such effect would be tolerable.

After sample pad modification to accommodate the analysis of the homogenized durian candy sample, the optimum sample dilution was determined. A higher overall sensitivity can be attained when analyzing less diluted samples. However, a high background signal can negate this advantage. For a positive capture antibody spot to be visually detected, there must be palpable contrast between it and its background. A high background signal lessens this contrast and consequently impairs detection of a positive signal. In the case of the trial to run 1:1 and 1:2 durian candy dilutions, the samples were mostly retained in the glass fiber sample pad and did not flow through the NC membrane. On the other hand, for 1:3, 1:4, and 1:5 dilutions, the LFIA devices applied with lower sample dilutions exhibited more intense edge effect, as shown in Fig. 3a. This can be attributed to the higher viscosity at lower sample dilutions [23]. At higher viscosity, the sample wicked slower [7], which stranded a significant amount of the conjugates not bound at the test spot mostly on the sides of the device by virtue of the edge effect [20]. Moreover, insoluble particles accounted for a bigger fraction of the sample's total volume at lower dilution, leaving a smaller liquid volume to flow through the entire device.

Meanwhile, results shown in Fig. 3a confirmed that the LFIA devices could positively detect SEB (150 ng/mL) in spiked 1:3 to 1:5 sample dilutions. The test spot signal intensity was found to be directly related to the sample dilution. Application of the more diluted samples resulted to stronger signal intensities with LFIA devices introduced with 1:5 sample dilutions attaining the strongest signal intensity. This was likely due to the lesser edge effect at higher sample dilutions leading to weaker background signals which translate into stronger signal intensities (S/N).

Aside from obtaining the lowest background signals and strongest signal intensity, only the devices applied with the 1:5 dilution of the spiked sample displayed recognizable clearance of the red background color around the test spot (capture antibody area). This clearance helps avoid incorrectly reading the results due to background signal interference. These outcomes established the viability of analyzing the durian candy at 1:5 dilution with homogenization as the only sample preparation step. A one-step sample preparation without requiring laboratory equipment renders the whole analytical process user-friendly and applicable for point-of-need analyses.

With the appropriate sample dilution already set, the study proceeded with the evaluation to find the optimum assay run time. The optimal run time would be the shortest time with no false positive results and with the highest possible positive signal intensity. A short run time, which characterizes an LFIA, is desired to obtain results in the quickest possible time. Presented in Fig. 4a are representative scans of the LFIA devices ran with spiked samples (150 ng/mL) for 15, 20, and 25 min. By visual inspection, it can be noted that the degree of the edge effect decreased with increased run time. The 20- and 25 min run times allowed greater amount of sample and gold nanoparticle-labeled detector probes to move across the nitrocellulose membrane. Because of this, the two longer run times developed stronger positive signal intensities than the 15 min run time (Fig. 4b). However, longer run times also elevate the risk of LFIA devices developing a false positive signal.

Fortunately, blank samples ran at different run times did not produce false positive results (data not shown). Considering that the strength of the positive signal intensity brought by the 20-min and 25-min run times were virtually the same, 20 min proved to be the optimal run time. The 20-min run time is slightly longer than the 10–15-min of most commercial LFIA devices [25].

Figure 5b shows representative LFIA devices of device design B used for sensitivity tests in the 1:5 homogenized durian candy as sample matrix. For the purpose of gauging the performance of device design B, sensitivity tests were also conducted for LFIA device design A (Fig. 5a). Running buffer served as sample matrix for device design A, because it was found to be incapable of analyzing homogenized durian candy samples. The visual limit of detection (vLOD) of both types of LFIA device was determined to be 5 ng/mL of SEB. Device design B gave a comparable sensitivity (vLOD) to device design A, despite running the test with a homogenized durian candy, a more complex sample matrix. This result affirms the applicability of device design B in detecting SEB in durian candy samples, which could not be achieved with device design A. When it comes to detecting SEB in a food sample, the vLOD of device design A is 1000–fold higher than the lowest vLOD of 5 pg/mL reported for an LFIA device for SEB detection [10]. But unlike the LFIA device that attained the highest sensitivity, the LFIA device design B in this study does not need an additional signal amplification step. Moreover, the LFIA developed in this study achieved a twofold lower vLOD than the 10 ng/mL described for the majority of the LFIA devices of previous studies. Finally, the test spot signals obtained for durian candy samples were generally higher than those with running buffer as sample as reflected in Fig. 6.

Spiked SEB concentration-dependent signal intensities (S/N) obtained with device design A (with cellulose fiber sample pad) and running buffer as sample matrix, and device design B (with glass fiber sample pad) and 1:5 homogenized durian candy as sample matrix; signal intensities are the averages of three replicates

While in most cases the matrix effect of a real sample causes a drop in the sensitivity of a lateral flow immunoassay device, the slower flow rate of the durian candy sample caused by its high viscosity compensated for the matrix effect. The slower flow rate of the durian candy sample extended the interaction time between the immobilized capture antibody and the sample antigen-detector antibody complex, resulting in stronger signal intensity.

Conclusions

The study successfully developed a lateral flow immunoassay device with integrated filtration capability imparted by the use of a glass fiber pad instead of a cellulose fiber pad as a sample pad. This LFIA device design permitted the detection of staphylococcal enterotoxin B in unpurified homogenized 1:5 dilution of durian candy with a visual limit of detection of 5 ng/mL. The utilization of a glass fiber pad solely or in combination with other materials to function as a sample pad and filter could be expanded to other LFIA devices to analyze other solid food samples at the point-of-need.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

B.C. Fries, A.K. Varshney, Bacterial toxins-Staphylococcal Enterotoxin B. Microbiol Spectr. (2012). https://doi.org/10.1128/microbiolspec.AID-0002-2012

Federal Department of Defense. Civil Protection and Sport. Fact sheet: staphylococcal enterotoxin B. FDDCPS (2009).

M.P.V. Azanza, B.N. Membrebe, R.G. Sanchez, E.E. Estilo, R.J. Dollete, U.G.M. Feliciano, N.K.A. Garcia, Foodborne disease outbreaks in the Philippines (2005–2018). Philipp. J. Sci. 148, 2 (2019)

J.Y. Geronimo, 'Poisoned' durian candy contaminated with bacteria – DOH, https://www.rappler.com/nation/99577-durian-candy-contaminated-bacteria. Accessed 20 February 2020.

K. Luojhjgk, H. Kimmjnj, M. . OHgky, Y. . Kimjgy., Paper-based lateral flow strip assay for the detection of foodborne pathogens : principles applications technological challenges and opportunities. Crit. Rev. Food Sci. Nutr. (2020). https://doi.org/10.1080/10408398.2018.1516623

S. Rong-hwa, T. Shiao-shek, C. Der-jiang, H. Yao-wen, Gold nanoparticle-based lateral flow assay for detection of staphylococcal enterotoxin B. Food Chem. 118(2), 462–466 (2010). https://doi.org/10.1016/j.foodchem.2009.04.106

T. Boyle, J.M. Njoroge, R.L. Jones, M. Principato, Detection of staphylococcal enterotoxin B in milk and milk products using immunodiagnostic lateral flow devices. J. AOAC Int. 93(2), 569–575 (2010). https://doi.org/10.1093/jaoac/93.2.569

P.Y. Tsui, D.J. Chiao, J.J. Wey, C. Liu, C.P. Yu, R.H. Shyu, Development of staphylococcal enterotoxin B detection strips and application of seb detection strips in food. J. Med. Sci. (Taiwan) 33(5), 285–291 (2013). https://doi.org/10.6136/JMS.2013.33(5).285

C. Wang, R. Xiao, S. Wang, X. Yang, Z. Bai, X. Li, Z. Rong, B. Shen, S. Wang, Magnetic quantum dot based lateral flow assay biosensor for multiplex and sensitive detection of protein toxins in food samples. Biosen. Bioelect. (2019). https://doi.org/10.1016/j.bios.2019.111754

X. Cai, Y. Luo, C. Zhu, D. Huang, Y. Song, Rhodium nanocatalyst-based lateral flow aimmunoassay for sensitivie detection of staphylococcal enterotoxin B. Sens. Actuators B Chem. (2022). https://doi.org/10.1016/j.snb.2022.132066

A. Sukumaran, T. Thomas, R. Thomas, R.E. Thomas, J.K. Paul, D.M. Vasudevan, Development and trouble shooting in lateral flow immunochromatography assays. Ind. J. Clin. Biochem. 36(2), 208–212 (2020). https://doi.org/10.1007/s12291-020-00887-5

N. Alam, L. Tong, Z. He, R. Tang, L. Ahsan, Y. Ni, Improving the sensitivity of cellulose fiber-based lateral flow assay by incorporating a water-dissolvable polyvinyl alcohol dam. Cellulose 28, 8641–8651 (2021). https://doi.org/10.1007/s10570-021-04083-3

J. Bhardwaj, A. Sharma, J. Jang, Biosensors and Bioelectronics Vertical fl ow-based paper immunosensor for rapid electrochemical and colorimetric detection of in fl uenza virus using a di ff erent pore size sample pad. Biosen. Bioelectronic. 126, 36–43 (2019). https://doi.org/10.1016/j.bios.2018.10.008

R. Pan, Y. Jiang, L. Sun, R. Wang, K. Zhuang, Y. Zhao, H. Wang, A. Ali, H. Xu, C. Man, Gold nanoparticle-based enhanced lateral flow immunoassay for detection of Cronobacter sakazakii in powdered infant formula. J. Dairy Sci. 101(5), 3835–3843 (2018). https://doi.org/10.3168/jds.2017-14265

J.H. Shin, J. Park, Functional packaging of lateral flow strip allows simple delivery of multiple reagents for multistep assays. Anal. Chem. 88(21), 10374–10378 (2016). https://doi.org/10.1021/acs.analchem.6b02869

W. Yang, X. Li, G.W. Liu, B.B. Zhang, Y. Zhang, T. Kong, J.J. Tang, D.N. Li, Z. Wang, A colloidal gold probe-based silver enhancement immunochromatographic assay for the rapid detection of abrina. Biosen Bioelectronic. 26(8), 3710–3713 (2011). https://doi.org/10.1016/j.bios.2011.02.016

W. Wen-de, L. Min, C. Ming, L. Li-Ping, W. Rui, C. Hai-Lan, C. Fu-Yan, M. Qiang, L. Wan-Wen, C. Han-Zhong., Development of a colloidal gold immunochromatographic strip for rapid detection of Streptococcus agalactiae in tilapia. Biosens. Bioelectron. 91, 66–69 (2017). https://doi.org/10.1016/j.bios.2016.11.038

L. Anfossi, G. D’Arco, M. Calderara, C. Baggiani, C. Giovannoli, Development of a quantitative lateral flow immunoassay for the detection of Aflatoxins in maize. Food Addit. Contam. 28(2), 2011 (2011). https://doi.org/10.1080/19440049.2010.540763

Q. Zeng, X. Mao, H. Xu, S. Wang, G. Liu, Quantitative immunochromatographic strip biosensor for the detection of carcinoembryonic antigen tumor biomarker in human plasma. Am. J. Biomed. Sci. 1(1), 70–79 (2009). https://doi.org/10.5099/aj090100070

E.M.D. Millipore, Rapid lateral flow test strips: considerations for product development (EMD Millipore Corporation, USA, 2013)

H. Hou, H. He, Y. Wang, Effects of SDS on the activity and conformation of protein tyrosine phosphatase from thermus thermophilus HB27. Sci. Rep. 10(1), 3195 (2020). https://doi.org/10.1038/s41598-020-60263-4

I. Buchwalow, V. Samoilova, W. Boecker, M. Tiemann, Non-specific binding of antibodies in immunohistochemistry: Fallacies and facts. Sci. Rep. 1, 1–6 (2011). https://doi.org/10.1038/srep00028

N. Upadhyay, S. Nara, Lateral flow assay for rapid detection of Staphylococcus aureus enterotoxin A in milk. Microchem. J. 137, 435–442 (2018). https://doi.org/10.1016/j.microc.2017.12.011

Ahlstrom, Our Solutios for Lateral Flow Immuno Assays: ReliaFlowTM High Performance Fiber-Based Materials (Ahlstrom 2024), https://ahlstrom-munksjo.showpad.com/share/F8zviFcyUFYbYiQtOIzUt. Accessed 20 July 2024.

S.J. Schulte, J. Huang, N.A. Pierce, Hybridization Chain Reaction Lateral Flow Assays for Amplified Instrument-Free At-Home SARS-CoV-2 Testing. ACS Infectious Diseases 9(3), 450–458 (2023). https://doi.org/10.1021/acsinfecdis.2c00472

Acknowledgements

This research project received financial support from the Department of Science and Technology – Science Education Institute through its Accelerated Science and Technology Human Resource Development Program (ASTHRDP) and Research Enhancement Program (REP) and the Davao del Norte State College. The authors thank Yuto Tanida of Keio University for the support related to the SEM pictures.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Relox, P.E., Israel, K.A.C., Hiruta, Y. et al. Lateral flow immunoassay device to detect staphylococcal enterotoxin B (SEB) in durian candy. ANAL. SCI. (2024). https://doi.org/10.1007/s44211-024-00665-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44211-024-00665-w