Abstract

The electric and electronic industry has experienced rapid growth in recent years, leading to high obsolescence rates and shorter product lifespans. Effective management of e-waste (EW) through reuse, refurbishment, remanufacturing, and recycling is essential for developing a circular economy. Recycling e-waste is critical for reducing environmental pollution, conserving valuable resources, and mitigating health risks associated with hazardous materials. While developed nations like the United States, the United Kingdom, and Germany have established efficient recycling practices across various product categories, developing countries such as India, Brazil, and China are still in the early stages. Indian states face numerous challenges in managing e-waste, and the key solution lies in engaging in recycling efforts to minimize waste. To facilitate recycling, it is crucial to identify and analyze the factors that affect e-waste management. This article leverages previously published literature and expert opinions to pinpoint these factors, employing interpretive structural modeling (ISM) and MICMAC to determine their contextual relationships and assess their driving and dependence power. Eleven critical factors have been identified. A pairwise comparison matrix, developed using expert responses, undergoes normalization and prioritization to establish the most influential factors. “Incentives for Adoption of Circular Economy (IC 3),” “Government Policies (GP 4),” and “Customer Awareness Towards Circular Economy (CA 9)” emerged as the most influential factors. These driving factors form the foundation of the e-waste recycling ecosystem, enabling other factors to function effectively. Implementing robust financial incentives and supportive policies is crucial for fostering a conducive environment for recycling initiatives in India.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The past few decades witnessed exponential progress in the electronics item industry, as a result of the consumer-oriented market and numerous technological advancements in recent times in the electronic industry, several products are becoming obsolete daily or are facing a continuous decline in the use and life of the product. The electrical and electronic products so discarded are termed EW [31]. The high rate of obsolesce, rapid growth of technology, short life span, attractive consumer design, and market compatibility issues are some of the key reasons for EW generation.

Nonetheless, circular economy (CE) minimizes resource utilization by encouraging reuse, recycling and recovery, resulting in monetary benefits, often by lengthening the product life cycle. In the year 1989, David. W. Pears and Kerry Turner originated the concept of circular economy. In a traditional “take-make-dispose” system, raw materials are extracted from nature, used for product manufacturing, and then disposed of via methods such as incineration or landfilling, constituting a linear economy. Conversely, in a circular economy, materials are recycled and reused in a closed-loop lifecycle, promoting sustainability by minimizing waste and conserving resources. The circular economy of e-waste aims to transform the traditional linear economic model into a more sustainable and resource-efficient system. This is achieved by reintroducing end-of-life electronic products back into the value chain through recycling and recovery processes. Clean and renewable technology is used, as innovative business concepts and the regulations that support them, the circular economy strives to design waste by optimizing product and material cycles to maintain them at their highest value and utility [50]. This approach not only reduces the environmental impact of electronic waste but also contributes to the conservation of natural resources and the mitigation of electronic pollution. Embracing a circular economy for e-waste management is crucial for achieving sustainable development, job creation, and inclusive societies while safeguarding biophysical resources.

EW recycling refers to the process of collecting, dismantling, and recovering valuable materials from electronic waste. Electronic waste includes rejected electrical devices such as CPUs, smartphones, TVs, and other electronic appliances. EW recycling is crucial for several reasons: (a) Resource conservation: Electronics contain valuable materials like copper, tin and precious metals (gold, silver) [23]. Recycling EW allows for the recovery of these resources, reducing the need for mining and conserving natural resources. (b) Environmental protection: Improper disposal of EW can lead to environmental pollution [25]. Developing nations often have a significant informal EW recycling sector where individuals, often in impoverished conditions, collect and dismantle electronic waste to extract valuable materials. While this sector provides livelihoods for many, it often involves unsafe and environmentally harmful practices. Informal recycling practices can lead to severe environmental pollution and health hazards due to the release of poisonous substances from EW, such as lead, mercury, and brominated flame retardants. Both workers and nearby communities are at risk of exposure to these hazardous materials. When not recycled properly, these toxins can leach into soil and water sources, posing a threat to ecosystems and human health [21]. Recycling minimizes the effect of these harmful elements into the environment. (c) Energy savings: Recycling EW consumes less energy compared to the extraction and refining of raw materials. Limited access to advanced recycling technologies and equipment can hinder efficient EW processing in developing nations. Investment in appropriate recycling technologies is often needed.

The recycling of electronic waste (e-waste) is crucial due to the rapid growth of this waste stream globally. E-waste contains valuable materials like precious metals found in printed circuit boards, making it a significant source for metal recovery. The identification and sorting of e-waste components are essential for effective recycling processes, with innovative technologies like high-speed hyperspectral imaging and Raman spectroscopy aiding in polymer identification for improved recovery rates and quality of recyclates. Proper recycling of e-waste not only helps in recovering valuable materials but also mitigates environmental and health risks associated with toxic substances present in electronic devices, contributing to sustainable waste management practices. Implementing efficient recycling methods for e-waste is crucial to reduce environmental impact, preserve natural resources, and promote the reuse of valuable materials in creating renewable energy technologies. The extraction of precious metals from e-waste is a critical component of the recycling process. E-waste, which includes discarded electronic devices such as smartphones, computers, and televisions, contains valuable metals like gold, silver, platinum, and palladium. Subsequently, chemical leaching or pyrometallurgical processes are employed to separate the precious metals from other materials. In India, the recycling of e-waste is a critical issue due to the significant amount generated annually, estimated at 3.5 lakh tons. Household residents play a crucial role in e-waste management, with attitudes, subjective norms, and perceived behavioral control influencing recycling intentions and behaviors [38]. Economic incentives have been found to contribute to e-waste recycling intentions among Indian urban households, alongside environmental concerns and attitudes. The country faces challenges in managing e-waste, leading to harmful environmental impacts, necessitating the implementation of effective policies and regulations to control e-waste generation and disposal. The growth of the informal e-waste recycling sector highlights the urgent need for organized and sustainable e-waste management strategies to mitigate health and environmental risks. According to the GEM report 2020, globally, 53.6 million metric tons (MT) of e-waste is generated annually, with only 20% of this waste being properly recycled; the remaining portion is typically sent for landfilling or incineration. In 2018, China recycled 1.546 MT of e-waste, while in 2017, America recycled 1.02 MT. India recycled approximately 0.03 MT of e-waste in 2016, and Japan recycled 0.54 MT in 2017. Brazil managed to recycle 0.14 MT of e-waste in 2012, and Russia recycled 0.09 MT in 2014. In 2017, Germany, the UK, and France recycled 0.83 MT, 0.87 MT, and 0.74 MT respectively [20]. The remaining 80% of global e-waste, sent for landfilling or incineration, contributes significantly to environmental pollution and health risks.

While previous studies have explored factors influencing e-waste (EW) recycling globally, there is a specific lack of comprehensive research focusing on the Indian context. Existing literature predominantly highlights practices and challenges in developed nations, leaving a gap in understanding the unique dynamics, barriers, and facilitators specific to EW recycling in India. Understanding how different factors interact and influence each other within the unique socio-economic, cultural, and technological context of India will provide a more nuanced picture of the recycling process. Existing research often qualitatively mentions the significance of various factors without quantitatively evaluating their relative driving and dependence power. Investigating the quantitative impact of each factor on EW recycling, along with their interdependencies, will enable a more accurate prioritization of efforts and resources for effective recycling initiatives. This article aims to bridge these gaps by systematically identifying, analyzing, and prioritizing factors crucial for enhancing EW recycling efforts in India, thereby contributing valuable insights to the field of sustainable waste management and circular economy development. The objective of this study is given below.

-

To identify the factors affecting recycling of EW in Indian context.

-

To develop the contextual relationship between the identified factors.

-

To determine the influence of the factors for EW recycling in Indian context.

To achieve the above objective intermittent structural modelling (ISM) and MICMAC analysis is used.

Literature Review

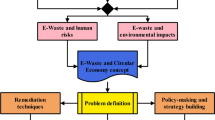

Electronic waste is the world's most rapidly rising waste stream, including a variety of elements that can affect people's health and pollute the environment if suitable disposal protocols are not followed for effective waste management. Ranjbari et al., [43] emphasized the need for a systemic approach and involvement of informal sectors to enhance WM practices post-pandemic. Seven main research themes were identified, including household and food waste, safety in waste handling, sustainability, plastic waste, healthcare WM practices, wastewater management, and infectious waste transmission. The authors proposed a research agenda addressing systemic WM frameworks, circular economy models, and decentralized municipal WM, particularly in developing countries [43]. Mahato et al., [36] discussed the effect of municipal solid waste burning in Jamshedpur Jharkhand. Authors determined the positive correlation between black carbon and PM2.5 concentration through pearson correlation coefficient in industrial, rural and urban waste-burning sites [36]. Jensen et al., [26] explored the recycling scenario in Colombia, however, workers who are directly engaged in handling electronic waste often lack awareness regarding the potential hazards of mercury exposure. The perception of risk among workers did not align well with their actual likelihood of being exposed to mercury. Instead, it often seemed to be influenced by a comparison with colleagues who had more direct contact with hazardous waste. The majority of recycling workers were men from lower-income families, and they were largely unaware of the dangers of mercury exposure on their health [26]. Tembhare et al., [53] provided an extensive analysis of current e-waste recycling methods, environmental implications, and technological advancements [19]. It emphasizes the significant environmental hazards posed by informal recycling practices, including the release of heavy metals and persistent organic pollutants. The review highlights various remediation techniques such as phytoremediation, soil washing, and the use of nanoparticles to mitigate these environmental risks. Additionally, it compares these methods and discusses their limitations when applied at a larger scale for real-contaminated sites, underscoring the need for innovative solutions to reduce the environmental impact of e-waste recycling [53]. Yang et al., [59] compared a control group in Ghana, evaluation of the effect of arsenic among EW workers. When informal recyclers are compared to the other control group, it is found that workers had higher median levels of arsenite As (III), As (V), methyl arsenate (MMA), dimethylarsinate (DMA), and the total concentration of arsenic. Over 80% of the employees involved in recycling exceeded the permissible concentration level of 14 g/L, which was much higher than the rate of 70% in the control group. In addition, 17.2% of the participants surpassed the acceptable concentration level of 40 g/L, indicating a statistically significant risk of acquiring cancer as a result of exposure to arsenic throughout their working lifespan [59]. Kiddee et al. [31] Determine the key drivers which will affect the EW management. Proper collection of used products, eco-design devices, disposal of used products with suitable techniques and customer awareness towards EW are the key drivers. Anju, and Naik (2020) find out the key drivers responsible for the reuse, refurbishing, remanufacturing and recycling of EW by using analytical method [52]. Regarding Malaysia, the potential obstacles in the field of recycling encompass: (a) Market dynamics and competitive landscape (b) Acquisition of raw materials (c) Availability of skilled workforce and expertise (d) Product design considerations (e) Influences from environmental and governmental factors (f) Technological approaches and methodologies. These barriers pose substantial obstacles to the successful enactment of recycling practices in Malaysia [48]. Customer awareness towards EW is one of the major drivers, without awareness recycling and remanufacturing cannot be processed with maximum efficiency. Collection center for used products is necessary to reduce the uncertainty in timing, quantity and quality [51]. Fengwang explored the dynamics of e-waste recycling in China. It contrasts the operational and economic aspects of formal and informal recycling sectors, highlighting their strengths and weaknesses. The analysis suggests that adopting deep-level manual dismantling with controlled environmental health safety (EHS) conditions is the optimal path for developing domestic recycling infrastructure. This approach is recommended to achieve high material recovery rates while ensuring environmental and health safety, emphasizing the need for a large-scale, efficient recycling system in China [35].

Gollakota et al., [18] discussed the urgent need for effective e-waste management strategies globally, highlighting the challenges faced by developing nations. The authors provided the statistics on e-waste generation across different continents, with Asia leading at 18.2 Mt, followed by Europe, America, Africa, and Oceania. The authors suggested the need to integrate formal and informal sectors, improving recycling facilities, and adopting eco-friendly technologies for better e-waste management [18]. In India, customer awareness towards EW recycling and inadequate rules addressing EW issues are identified as the root causes of EW bottlenecks[22]. The recycling of EW is significantly influenced by consumer attitudes towards disposal and recycling behavior. Moreover, challenges such as unclear policies and regulations, a lack of management anticipation, and carelessness towards the environment further hinder effective EW management [13]. EW, the rapidly expanding waste stream, sees a mere 15% recycling rate, with 20% of it being comprised of plastics. Recycling EW plastics faces challenges due to the presence of brominated flame retardants, rendering conventional methods inadequate. However, micro factories offer a promising solution by effectively transforming EW plastics into valuable products, addressing the limitations of traditional processes [14]. Generating local electronic waste (EW) presents significant challenges for developing countries, which grapple with inadequate management practices stemming from a lack of robust policies [55]. China and India, major EW producers, recently introduced legislation but face implementation issues [6]. Jaiswal et al., [23, 24] examined the recycling process, costs, and decision-making variables for exporting or recycling equipment. Scrap computers are found to be economically viable for domestic recycling, while other equipment might require subsidies. The importance of regulations, monitoring, and subsidies is emphasized, especially for low-value EW. Labor constitutes a significant portion of recycling costs, especially in countries with high labor costs [1]. Jaiswal et al., [23, 24] explores consumer attitudes and behaviors related to recycling of EW, highlighting the importance of public awareness campaigns and convenient recycling options [23]. Sharma et al., [50] identified and analyzed the influence of various enablers on e-waste management practices. It emphasized the importance of environmental management systems, collaboration with environmental partners, recovery of precious materials, and the implementation of subsidy benefits and deposit refund schemes as major drivers. Authors provided the valuable insights for policymakers and stakeholders aiming to enhance e-waste management and facilitate the transition towards a circular economy in developing countries [50]. Many studies conclude with calls for increased research, policy improvements, and collaboration among stakeholders to address the growing challenges of recycling of EW effectively.

Tools and Technique Modelling

“Multi-Criteria Decision Making (MCDM)” and related literature often utilize “structural modelling” to analyze critical constructs. Among these methods, “Interpretive Structural Modelling (ISM)” is widely employed to explore the relationships between variables and establish a hierarchy among them. ISM is one of the most frequently used structural modelling approaches for modeling crucial constructs [44]. ISM is one of the most prevalent structural modelling techniques used to analyze critical constructs across various research domains [22]. Alaboud & Alshahrani, [4] used ISM to establish a hierarchy of variables and analyze the dynamic interaction between them in the adoption of building information modelling (BIM) in the Saudi construction industry [4]. Goel et al., [17] used the ISM technique to identify and develop the relationship between challenges in adopting Green Human Resources Management (GHRM) practices in educational institutions [17]. Pramudya & Wibowo, [40] mentioned ISM to determine the hierarchy of risk events in BOT toll road investment projects in Indonesia [40]. Khan et al., [30] used ISM to analyze variables affecting employee turnover in humanitarian logistics and develop a model of hierarchy and interrelationships among these variables [30]. Kamble et al., [27] identified the potential barriers to adopting Industry 4.0 in Indian manufacturing industries and determined the driving and dependence power by using the ISM method [27].

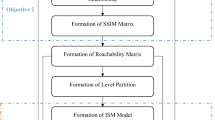

Interpretive Structural Modelling (ISM) is used to identify and summarize relationships among specific variables, often critical constructs within various domains. The ISM process begins with the identification and listing of elements relevant to the problem or system. Once the elements are identified, a structural self-interaction matrix (SSIM) is created to capture the perceived contextual relationships between pairs of elements [3]. These relationships are then converted into a reachability matrix. Through several iterations of matrix multiplication and adjustments, the reachability matrix is partitioned into different levels, resulting in a hierarchical structure that represents the relationships and dependencies among elements. The detailed mathematical procedure of Interpretive Structural Modeling (ISM) is explained in section “Interpretive Structural Modelling (ISM)”.

In many instances, ISM is succeeded by MICMAC analysis, which assesses the "driving and dependence power" of individual constructs and organizes them into appropriate categories based on their influence. Jaiswal et al., [23, 24] mentioned ISM and MICMAC to determine the contextual relationship among barriers affecting the circular economy of e-waste in the Indian context [23]. Farooq et al., [15] used ISM for modeling and MICMAC for analysis and classification. ISM is used to evaluate the determinants of sustainability of CPEC projects, while MICMAC is used to analyze and classify the determinants based on their interrelationships [15]. Rana et al., [42] mentioned ISM and MICMAC to develop a framework for the challenges and interrelationships of blockchain adoption in the public sector of India [42].

Methodology

In this study, authors identified the critical factors affecting recycling of EW in Indian context. Based on literatures and expert opinion factors are identified. Furthermore, interrelationship between factors is developed with the help of experts. The driving and dependence power of the factors were then determined using interpretive structural modeling (ISM) and MICMAC analysis. Figure 1 shows the flowchart of the research methodology.

Identification of factors

Firstly, authors searched different websites like science direct, google scholar and Scopus with keywords like EW, circular economy, and recycling of EW. Finally, using previous literature and expert opinion eleven factors have been identified viz, lack of technical skills in recycling product design (TS), High Investment Cost (HI), Lack of incentives for adoption of circular economy (IC), Lack of government policies (GP), Insufficient infrastructure (II), Uncertainty in quality of return products (QL), Uncertainty in quantity of return products (QN), Uncertainty in timing of return products (TR), Lack of customer awareness towards circular economy (CA), Lack of producer responsibility organizations (PR) and Lack of collection system (CS) which affect the EW recycling. Table 1 indicates a brief description of factors.

Interpretive Structural Modelling (ISM)

ISM is a statistical tool used to analyze the interrelationships between factors and determine the driving and dependency factors. It is a robust and tested method commonly employed to tackle complex problems by designing a problem structure and establishing a hierarchy. In this study, the authors first identified the factors influencing e-waste recycling through a literature survey and expert opinions. After identifying the barriers, a self-structured interaction matrix (SSIM) was developed. SSIM matrix involves creating a questionnaire and collecting responses from experts. In this process, we reached out to 34 individuals across 12 industries. However, only nine individuals from five organizations consented to share their opinions. Likewise, we contacted 15 academics, with six of them agreeing to participate in our study. Consequently, we formed a team comprising 15 members as shown in table 2. The matrix utilizes four symbols to show the interrelationships between factors: V, A, X, and O.

-

a)

'V' is used when “factor i impacts factor j”.

-

b)

'A' is used when “factor j impacts factor I”.

-

c)

'X' is used when both “factor i and factor j mutually impact each other”.

-

d)

'O' is used when “factor i and factor j have no impact on each other”.

Table 3 presents the SSIM matrix, which provides a visual representation of the interrelationships among the identified factors in the study. The matrix helps in understanding how factors influence each other and lays the foundation for further analysis and decision-making processes.

Furthermore, development of reachability matrix, in present matrix binary symbols are used to replace the codes of SSIM matrix. This matrix helps in identifying the hierarchical structure of the factors, indicating which factors are at the top of the hierarchy (more dependent) and which are at the bottom (more driving). If the response in SSIM matrix is ‘V’ then the value of i,j is 1 and j, i is 0. Similarly, for ‘A’, i, j is 0 and j, i is 1, if the response is ‘X’, then the value for both i, j and j, i is 1 and for ‘O’, the value is always 0. Table 4 shows the reachability matrix.

After creating the reachability matrix, the subsequent step involves creating level partitions. The level partition is presented in Table 5, where the reachability set and antecedent set for each factor are identified using the reachability matrix. These sets consist of the factors itself and the factors influenced by it. The process of level partitioning involves multiple iterations to determine the driving factors (those with significant impact) and the dependency factors (those influenced by other factors). Levels are assigned when the values of reachability and intersection set are the same. A total of five iterations were performed to assign levels to each critical factor. In the first iteration of level partitioning, the reachability set values were taken from the reachability matrix. The reachability set for a factor includes all elements marked as 1 in the corresponding row and contains the factor itself and any other factors it impacts. For example, the reachability set for TS 1 includes 1, 2, 4, 5, 6, 7, 8, and 10. Similarly, the antecedent set for a factor includes all elements marked as 1 in the corresponding column and contains the factor itself and all other factors that influence it. For TS 1, the antecedent set includes 1, 3, 4, 5, 9, and 10. The intersection set comprises the common elements from the reachability set and the antecedent set. For TS 1, the intersection set includes 1, 4, 5, and 10. Factors whose reachability set and intersection set are identical are considered at the top level of the ISM hierarchy. These top-level factors are achieved by all other factors at lower levels. Once these top-level factors are identified, they are removed from the set, and the process is repeated iteratively until all factors are assigned to an appropriate level. In the third iteration, TS 1 was assigned to the third level.

Last step is the formation of ISM model for determining the driving and dependence factors in the study. ISM model is developed using level partition as shown in figure 2. A total of five levels are assigned to eleven factors as indicated in table 6, top levels in the ISM model shows the dependence power of the factors and the bottom level shows the driving power of the factors.

MICMAC Analysis

Matriced’Impacts Croisés-Multiplication Appliquée à un Classement (cross-impact matrix multiplication applied to classification), or MICMAC, is an advanced analytical method. The purpose of this analysis is to evaluate the driving and dependence power of various barriers. This is accomplished by utilizing the reachability matrix outcomes, which provide the driving power (DRP) and dependence power (DEP) values for each barrier. These DRP and DEP values are then used as inputs for the MICMAC analysis. The inputs for the MICMAC analysis for TS1 (6,8) indicate that the dependence power is 6 and the driving power is 8, as derived from Table 4. Similarly, the coordinates for all other barriers have been determined. The MICMAC analysis categorizes the factors into four distinct groups based on their DRP and DEP values: Autonomous factors: Factors falling into quadrant one exhibit weak driving and weak dependence power. Dependent factors: Factors falling into quadrant second possess weak driving power but strong dependence power. Linkage factors: Factors falling into quadrant three demonstrate both strong driving and strong dependence power. Driving factors: Factors falling into quadrant four display strong driving power but weak dependence power. By classifying the factors into these four categories, the analysis provides valuable insights into the interrelationships and roles of the factors for implementation of EW recycling of e-waste as shown in figure 3.

Result and discussion

ISM Results

The objective of our ISM model was to establish a hierarchical structure to understand the interdependencies among the critical factors affecting e-waste recycling in India, to achieve a circular economy. This information will aid practitioners in devising appropriate strategies for the successful adoption of a circular economy. The results of the ISM model are notable, revealing a five-level hierarchy that illustrates the relationships between the identified constructs as shown in table 5 and 6. Level one of the hierarchy comprised “insufficient infrastructure (II 5), quality of return products (QL 6), quantity of return products (QN 7)” and “Timing of return products (TR 8)”. Level two consisted of “high investment cost (HI 2), producer responsibility organizations (PR 10)” and “collection system (CS 11)”. Level three of the hierarchy include “Technical skills in recycling product design (TS 1)”. Level four consisted of “Customer awareness towards circular economy (CA 9)”. Level five includes “incentives for adoption of circular economy (IC 3)” and “government policies (GP 4)” as indicated in figure 2.

The model indicated that "Incentives for Adoption of Circular Economy (IC 3)" and "Government Policies (GP 4)" are the most influential critical factors for e-waste recycling in India. These factors form the foundation of the ISM hierarchy. For incentives, the government can introduce tax benefits, subsidies, and financial support for businesses and individuals engaging in e-waste recycling and circular economy practices. This can be complemented by establishing recognition programs that reward companies and communities for their contributions to sustainability. For government policies, a robust regulatory framework should be developed to enforce stringent e-waste management standards, coupled with clear guidelines and compliance support. Policies should also encourage public-private partnerships to foster innovation and investment in recycling technologies and infrastructure [47].

“Insufficient infrastructure (II 5), quality of return products (QL 6), quantity of return products (QN 7)” and “Timing of return products (TR 8)”, are situated in the top level of ISM model and shows strong dependence power. These factors are crucial as they directly impact the efficiency and effectiveness of e-waste recycling processes. Insufficient infrastructure can hinder the collection, transportation, and processing of e-waste, making it challenging to achieve recycling targets. Without sufficient facilities, the entire recycling chain can be disrupted, leading to inefficiencies and increased costs. The lack of infrastructure can result in improper disposal methods, causing environmental pollution and health hazards. The quality of return products affects the feasibility and cost-effectiveness of recycling efforts, as higher quality returns lead to better resource recovery. The quantity of return products determines the scale at which recycling operations can be sustained, influencing the overall impact on the circular economy. Finally, the timing of return products is vital for ensuring a steady and manageable flow of e-waste, preventing bottlenecks and optimizing the use of recycling facilities. Addressing these factors is essential for creating a robust and sustainable e-waste management system that supports the circular economy.

In the ISM hierarchy, the Level Two factors "High Investment Cost (HI 2)," "Producer Responsibility Organizations (PR 10)," and "Collection System (CS 11)" are dependent on other foundational factors to function effectively. For instance, "High Investment Cost" is closely linked to "Incentives for Adoption of Circular Economy (IC 3)" and "Government Policies (GP 4)" from the foundational level. Financial incentives and supportive policies can mitigate the burden of high initial investments, making it more feasible for businesses to invest in e-waste recycling infrastructure. Similarly, the effectiveness of "Producer Responsibility Organizations (PR 10)" relies heavily on the regulatory framework established by government policies, which define the responsibilities and enforcement mechanisms for producers. Without strong policy support, PROs may lack the authority and resources to ensure compliance and efficiency. Lastly, the "Collection System (CS 11)" depends on adequate infrastructure (II 5) to establish and maintain a network of collection points and transportation logistics. The development of “technical skills” is intrinsically linked to the availability of "Incentives for Adoption of Circular Economy (IC 3)" and "Government Policies (GP 4)," which can drive investment in education and training programs. These incentives and policies can support the establishment of specialized courses, workshops, and certifications that enhance the technical capabilities of the workforce. Thus, the enhancement of technical skills in recycling and product design is contingent upon a supportive policy environment, robust infrastructure, effective collection systems, and collaborative industry practices, demonstrating the interconnected nature of these factors within the hierarchy.

MICMAC Results

The identified factors were categorized into four groups: autonomous, dependent, linkages, and driving.

-

A.

Autonomous region: In this region factors have “low driving and low dependence power”. Only one factor i.e. “high investment cost (HI 2)” falls in this region. Despite being a significant factor, high investment cost is categorized as autonomous because it neither strongly influences other factors nor is it heavily influenced by them. This indicates that while the high cost of investment is a challenge, it operates independently within the e-waste recycling ecosystem. Addressing this factor requires targeted financial strategies and incentives to reduce initial costs and encourage investment in recycling infrastructure and technology.

-

B.

Dependent region: Factors in the dependent region exhibit “low driving power but high dependence power”. This means they are significantly influenced by other factors but do not exert much influence themselves. In this study, the factors falling into this category are "insufficient infrastructure (II 5), quality of return products (QL 6), quantity of return products (QN 7)," and "timing of return products (TR 8)". These factors are crucial for the efficiency and effectiveness of e-waste recycling but are highly reliant on the foundational and driving factors for their improvement.

-

C.

Linkage region: Linkage factors are those who have “high driving and high dependence power”. Three factors fall under this region viz. “technical skills in recycling product design (TS 1), producer responsibility organizations (PR 10)," and "collection system (CS 11)". Addressing linkage factors involves a coordinated effort to improve both their driving and dependence aspects. Enhancing technical skills requires investment in education and training, supported by strong industry and government backing. Strengthening PROs demands robust policies and enforcement mechanisms, while an efficient collection system requires comprehensive infrastructure, public awareness, and participation.

-

D.

Driving region: These factors are those who have “high driving power but low dependence power”. "Incentives for adoption of circular economy (IC 3), government policies (GP 4)" and “customer awareness towards circular economy (CA 9)” these are the most influential factors for effective recycling of EW in India. These driving factors collectively create the foundation upon which the entire e-waste recycling system is built. By influencing consumer behavior, business practices, and regulatory environments, they play a pivotal role in shaping the effectiveness and sustainability of e-waste management in India. Ensuring robust incentives, strong government policies, and high levels of customer awareness is essential for driving the adoption of circular economy principles and achieving significant progress in e-waste recycling.

Conclusion

This study investigated the critical factors influencing e-waste recycling in India to facilitate the adoption of a circular economy. A total of eleven factors were identified through an extensive literature review and consultations with domain experts from industry and academia. Further, these factors were modelled through ISM and MICMAC analysis to evaluate the contextual relationship between the factors and determined the hierarchy among the critical factors. The result shows that "Incentives for Adoption of Circular Economy (IC 3)", "Government Policies (GP 4)" and “customer awareness towards circular economy (CA 9)” emerged as the most influential factors. These driving factors form the bedrock of the e-waste recycling ecosystem, enabling other factors to function effectively. The implementation of robust financial incentives and supportive policies is crucial for fostering a conducive environment for recycling initiatives in India. Government policy plays a crucial role for development of sustainable environment, countries like USA, UK and Japan have a strict policy for EW management which encourage the company to develop a sustainable product. Governments set specific recycling targets or quotas that industries, businesses, or municipalities must achieve. This encourages greater recycling efforts and diverts more waste from landfills. A high level of customer awareness is essential for fostering sustainable consumption patterns, promoting responsible product use, and encouraging participation in circular economy initiatives. Customer awareness is necessary so that the end user know about the harmful effects of EW, some of which fall in the human, environment and economy. This paper will assist organizations and policymakers in building a sustainable recycling strategy to achieve circular economy.

“Insufficient infrastructure (II 5), quality of return products (QL 6), quantity of return products (QN 7)” and “Timing of return products (TR 8)”, are situated in the top level of ISM model and shows strong dependence power. These factors are crucial as they directly impact the efficiency and effectiveness of e-waste recycling processes. To address the top-level factors, a multi-faceted approach is required. Enhancing insufficient infrastructure (II 5) can be achieved through increased investments in recycling facilities, supported by government grants and public-private partnerships. Improving the quality of return products (QL 6) necessitates consumer education programs and incentives for proper disposal practices, ensuring e-waste is returned in a usable condition. Addressing the quantity of return products (QN 7) involves developing a comprehensive and accessible collection system, alongside awareness campaigns to encourage public participation in recycling initiatives. For the timing of return products (TR 8), establishing regular and convenient e-waste collection schedules, possibly integrated with existing waste management systems, can help maintain a consistent flow of materials. These solutions, supported by strong policy frameworks and incentives, will collectively enhance the operational efficiency of e-waste recycling.

Similar to prior studies, this research is not without limitations and lays the foundation for future explorations. This study's scope is confined to eleven factors, offering room for future investigations to delve deeper into the recycling landscape in India. The exclusion of a fuzzy approach to account for subjective expert responses presents another limitation. To enhance result clarity, a fusion of the ISM approach with a fuzzy technique could be considered. Additionally, future prospects include integrating the structural equation modeling (SEM) technique for statistical model validation. Despite these constraints, the findings of this study provide a well-structured path toward comprehending the successful implementation of EW recycling initiatives in Indian context, the findings might be useful for other developing countries.

References

Aboelmaged M (2021) E-waste recycling behaviour: An integration of recycling habits into the theory of planned behaviour Mohamed. J Clean Prod 278:124182. https://doi.org/10.1016/j.jclepro.2020.124182

Agrawal A, Mukti SK (2020) Knowledge management & it’s origin, success factors, planning, tools, applications, barriers and enablers: a review. Int J Knowl Manag (IJKM) 16(1):43–82

Agrawal A, Kumar C, Mukti SK (2021) Role of Information and communication technology (ICT) to enhance the success of knowledge management (KM): a study in a steel plant. J Knowl Econ 12(4):1760–1786

Alaboud N, Alshahrani A (2023) Adoption of Building Information Modelling in the Saudi Construction Industry: An Interpretive Structural Modelling. Sustainability (Switzerland), 15(7). https://doi.org/10.3390/su15076130

Arner Güerre MA (2020) Extended producer responsibility for waste oil, e-waste and end-of-life vehicles. International Journal of Economics and Financial Research 6.10(2020):223–235

ASSOCHAM-NEC (2018) India among the top ve countries in e-waste generation: ASSOCHAM-NEC study 2018–2020. www.assocham.org/newsdetail-print.php?id==5725

Awasthi AK, Li J (2017) Management of electrical and electronic waste: a comparative evaluation of China and India. Renew Sustain Energy Rev.https://doi.org/10.1016/j.rser.2017.02.067

Baragde DB, Jadhav AU (2020) Circular economy model for the E-waste management sector. Handbook of research on entrepreneurship development and opportunities in circular economy. IGI Global, pp 216–230. https://doi.org/10.4018/978-1-7998-5116-5.ch011

Barapatre S, Rastogi M (2021) e-Waste management: a transition towards a circular economy. https://doi.org/10.1007/978-981-16-4230-2_68

Bhatia MS, Srivastava RK (2018) Analysis of external barriers to remanufacturing using grey-DEMATEL approach: aan Indian perspective. Resour Conserv Recycl 136:79–87

Bilal M, Khan KIA, Thaheem MJ, Nasir AR (2020) Current state and barriers to the circular economy in the building sector: towards a mitigation framework. J Clean Prod 276:123250

Bridgens B, Hobson K, Lilley D, Lee J, Scott JL, Wilson GT (2019) Closing the loop on E-waste: a multidisciplinary perspective. J Ind Ecol 23(1):169–181

Cao J, Chen X, Zhang X, Gao Y, Zhang X, Kumar S (2020) Overview of remanufacturing industry in China: government policies, enterprise, and public awareness. J Clean Prod 242:118450

Dutta D, Goel S (2021) Understanding the gap between formal and informal e-waste recycling facilities in India. Waste Manag 125:163–171. https://doi.org/10.1016/j.wasman.2021.02.045

Farooq M, ur-Rehman Rao Z, Shoaib M (2023) Analyzing the determinants of sustainability of China Pakistan economic corridor (CPEC) projects: an interpretive structural modelling (ISM) approach. Environ Sci Pollut Res 30(5):12385–12401. https://doi.org/10.1007/s11356-022-22813-3

Ghosh BK, Mekhilef S, Ahmad S (2022) A Review on global emissions by e-products based waste : technical management for reduced effects and achieving sustainable development goals. 1–19. https://doi.org/10.3390/su14074036

Goel P, Mehta S, Kumar R, Castaño F (2022) Sustainable green human resource management practices in educational institutions: an interpretive structural modelling and analytic hierarchy process approach. Sustainability (Switzerland), 14(19). https://doi.org/10.3390/su141912853

Gollakota ARK, Gautam S, Shu CM (2020) Inconsistencies of e-waste management in developing nations – facts and plausible solutions. J Environ Manage 261:110234. https://doi.org/10.1016/j.jenvman.2020.110234

Islam MT, Huda N (2018) Reverse logistics and closed-loop supply chain of waste electrical and electronic equipment (weee)/e-waste: a comprehensive literature review. Resour Conserv Recy 137:48–75

Islam MT, Huda N, Baumber A, Shumon R, Zaman A, Ali F, Hossain R, Sahajwalla V (2021) A global review of consumer behavior towards e-waste and implications for the circular economy. J Clean Prod 316:128297

Jaiswal SK, Mukti SK (2023a) External barriers affecting e-Waste remanufacturing in the indian context. In Sustainable approaches and strategies for e-waste management and utilization (pp. 61–73). IGI Global. https://doi.org/10.4018/978-1-6684-7573-7.ch004

Jaiswal SK, Mukti SK (2023b) ISM model for factors affecting e-waste remanufacturing in indian context. In Phanden RK, Kumar R, Pandey PM, Chakraborty A (eds) Advances in industrial and production engineering. Springer Nature, Singapore, pp. 125–133

Jaiswal SK, Mukti SK, Agrawal A (2023) Circular economy of e-waste: a critical analysis in indian context. AIP Conf Proc 3006(1). https://doi.org/10.1063/5.0186573

Jaiswal SK, Mukti SK, Rath KC (2023) E-Waste control and its recycling to build sustainable society in the global context. In Handbook of research on applications of ai, digital twin, and internet of things for sustainable development. IGI Global, pp. 200–222. https://doi.org/10.4018/978-1-6684-6821-0.ch012

Jaiswala SK, Muktib SK (n.d.) E-waste remanufacturing in Indian context. In Recent advances in material, manufacturing, and machine learning. CRC Press, pp. 997–1002 https://doi.org/10.1201/9781003370628-26

Jensen M, CombarizaBayona DA, Sripada K (2021) Mercury exposure among E-waste recycling workers in Colombia: Perceptions of safety, risk, and access to health information. Int J Environ Res Public Health 18(17):9295

Kamble SS, Gunasekaran A, Sharma R (2018) Analysis of the driving and dependence power of barriers to adopt industry 4.0 in Indian manufacturing industry. Comput Ind 101:107–119. https://doi.org/10.1016/j.compind.2018.06.004

Kazancoglu Y, Ozkan-Ozen YD, Mangla SK, Ram M (2020) Risk assessment for sustainability in e-waste recycling in circular economy. Clean Technol Environ Policy, 1–13. https://doi.org/10.1007/s10098-020-01901-3

Kerdlap P, Low JSC, Ramakrishna S (2019) Zero waste manufacturing: A framework and review of technology, research, and implementation barriers for enabling a circular economy transition in Singapore. Resour Conserv Recy 151:104438. https://doi.org/10.1016/j.resconrec.2019.104438

Khan M, Sarmad M, Shah SFA, Han BJ (2020) Extent of employee turnover in humanitarian logistics: An interpretive structural modelling approach. Int J Supply Chain Manag 9(4):107–121

Kiddee P, Naidu R, Wong MH (2013) Electronic waste management approaches : an overview. 33:1237–1250https://doi.org/10.1016/j.wasman.2013.01.006

Koshta N, Patra S, Singh SP (2021) Sharing economic responsibility: assessing end user’s willingness to support E-waste reverse logistics for circular economy. J Clean Prod, 130057. https://doi.org/10.1016/j.jclepro.2021.130057

Kuah ATH, Wang P (2020) Circular economy and consumer acceptance: an exploratory study in East and Southeast Asia. J Clean Prod 247:119097

Kumar S (2010) Waste management. BoD–Books on Demand.

Lara P, Sánchez M, Herrera A, Valdivieso K, Villalobos J (2019) Modeling reverse logistics networks: A case study for e-waste management policy. international conference on advanced information systems engineering, pp 158–169. https://doi.org/10.1007/978-3-030-21297-1_14

Mahato DK, Sankar TK, Ambade B, Mohammad F, Soleiman AA, Gautam S (2023) Burning of municipal solid waste: an invitation for aerosol black carbon and PM2. 5 over mid–sized city in India. Aerosol Sci Eng 7(3):341–354

Mohammadi E, Singh SJ, Habib K (2021) How big is circular economy potential on Caribbean islands considering e-waste? J Clean Prod 317:128457

Parajuly K, Kuehr R, Awasthi AK, Fitzpatrick C, Lepawsky J, Smith E, Widmer R, Zeng X (2019) Future E-waste scenarios. https://hdl.handle.net/10344/8262

Paulraj CRKJ, Bernard MA, Raju J, Abdulmajid M (2019) Sustainable waste management through waste to energy technologies in India-opportunities and environmental impacts. Int J Renew Energy Res (IJRER) 9(1):309–342

Pramudya AA, Wibowo A (2022) Ranking risks of BOT Toll road investment projects in indonesia using fuzzy interpretive structural modelling. Constr Econ Build 22(4):59–80. https://doi.org/10.5130/AJCEB.v22i4.8091

Priyadarshini P, Abhilash PC (2020) Circular economy practices within energy and waste management sectors of India: A meta-analysis. Bioresour Technol 304:123018

Rana NP, Dwivedi YK, Hughes DL (2022) Analysis of challenges for blockchain adoption within the Indian public sector: an interpretive structural modelling approach. Inform Technol Peopl 35(2):548–576. https://doi.org/10.1108/ITP-07-2020-0460

Ranjbari M, Shams Esfandabadi Z, Gautam S, Ferraris A, Scagnelli SD (2023) Waste management beyond the COVID-19 pandemic: Bibliometric and text mining analyses. Gondwana Res 114:124–137. https://doi.org/10.1016/j.gr.2021.12.015

Raut RD, Narkhede B, Gardas BB (2017) To identify the critical success factors of sustainable supply chain management practices in the context of oil and gas industries: ISM approach. Renew Sustain Energy Rev 68:33–47. https://doi.org/10.1016/j.rser.2016.09.067

Safdar N, Khalid R, Ahmed W, Imran M (2020) Reverse logistics network design of e-waste management under the triple bottom line approach. J Clean Prod 272:122662

Sarkar B, Ullah M, Sarkar M (2022) Environmental and economic sustainability through innovative green products by remanufacturing. J Clean Prod 332:129813. https://doi.org/10.1016/j.jclepro.2021.129813

Schroeder P, Anggraeni K, Weber U (2019) The relevance of circular economy practices to the sustainable development goals. J Ind Ecol 23(1):77–95

Shamee A, Shamsuddin A (2019a). End-of-life electrical and electronic equipment remanufacturing prospects in Malaysia end-of-life electrical and electronic remanufacturing prospects in Malaysia. https://doi.org/10.1088/1757-899X/530/1/012033

Shamee A, Shamsuddin A (2019) End-of-life Electrical and Electronic Equipment Remanufacturing Prospects in Malaysia. IOP Conf Ser: Mater Sci Eng 530(1):12033

Sharma M, Joshi S, Kumar A (2020) Assessing enablers of e-waste management in circular economy using DEMATEL method: an Indian perspective. Environ Sci Pollut Res 27(12):13325–13338

Shi J, Wang R, Chen W, Xing L, Jin M (2020) Bi-objective design of household E-waste collection with public advertising and competition from informal sectors. Waste Manag.https://doi.org/10.1016/j.wasman.2019.10.018

Singh A, Panchal R, Naik M (2020) Circular economy potential of e-waste collectors, dismantlers, and recyclers of Maharashtra: a case study. Environ Sci Pollut Res 27(17):22081–22099. https://doi.org/10.1007/s11356-020-08320-3

Tembhare SP, Bhanvase BA, Barai DP, Dhoble SJ (2022) E-waste recycling practices: a review on environmental concerns, remediation and technological developments with a focus on printed circuit boards. Environ Dev Sustain 24(7). https://doi.org/10.1007/s10668-021-01819-w

Tura N, Hanski J, Ahola T, Ståhle M, Piiparinen S, Valkokari P (2019) Unlocking circular business: A framework of barriers and drivers. J Clean Prod 212:90–98

Vats MC, Singh SK (2014) Status of e-waste in India-a review. Transportation 3(10): 16917-16931

Xavier LH, Ottoni M, Lepawsky J (2021) Circular economy and e-waste management in the Americas: Brazilian and Canadian frameworks. J Clean Prod 297:126570

Xia X, Zhang C (2019) The impact of authorized remanufacturing on sustainable remanufacturing. Processes 7(10):1–12. https://doi.org/10.3390/pr7100663

Yaduvanshi NR, Myana R, Krishnamurthy S (2016) Circular economy for sustainable development in India. Ind J Sci Technol 9(46):1–9

Yang J, Bertram J, Schettgen T, Heitland P, Fischer D, Seidu F, Felten M, Kraus T, Fobil JN, Kaifie A (2020) Arsenic burden in e-waste recycling workers–A cross-sectional study at the Agbogbloshie e-waste recycling site, Ghana. Chemosphere 261:127712

Acknowledgements

The authors would like to express their sincere gratitude to the following individuals and organizations for their valuable contributions and support throughout the research. We extend our appreciation to Dr. Suraj Kumar Mukti for their expert guidance and invaluable insights, which greatly enriched the quality of this study. Our thanks go to the participants who generously shared their time and perspectives, without which this research would not have been possible.

Funding

Not applicable

Author information

Authors and Affiliations

Contributions

All authors have read and approved the final version of the manuscript. Each author contributed significantly to the research and the development of this article

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

The author consents to publication.

Availability of Data and Materials

On request it should be available.

Competing Interests

The author declares no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jaiswal, S.K., Mukti, S.K. Prioritizing Factors Affecting E-Waste Recycling in India: A Framework for Achieving a Circular Economy. Circ.Econ.Sust. (2024). https://doi.org/10.1007/s43615-024-00423-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43615-024-00423-0