Abstract

Solid waste management is a severe challenge in India due to massive and rapid growth in waste generation rates, environmental difficulties, and financial constraints for proper treatment. Poorly managed municipal solid waste (MSW) has substantial negative consequences for society, including financial and aesthetic harm, contamination of natural resources, environmental pollution, and severe health danger. Both qualitative and quantitative factors are required to select the appropriate solid waste treatment and disposal technologies. Multi-Criteria decision-making tools helped in analyzing solid waste in terms of qualitative and quantitative factors. In this paper, seven criteria and their sub-criteria are selected for ranking solid waste treatment and disposal technology using fuzzy-analytic hierarchy process. The results showed that composting is the most suitable option for solid waste treatment and disposal technology, followed by refuse-derived fuel. The incineration and sanitary landfills are the least preferred MSW management alternatives. The sensitivity analysis reveals a high consistency, robustness, and stability level.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Urbanization, industrialization, economic integration, and population growth have increased the huge quantity of municipal solid waste (MSW) [1]. As the population increases, the MSW generation in India also increases the additional pressure on existing resources and infrastructure for appropriate and safe disposal [2, 3]. In India, about 143,449 metric tons of MSW is generated per day, of which 111,000 metric tons were collected and only 35,602 metric tons received treatment [4]. There was an exponential increase in solid waste generation rate from 0.24 kg to 0.85 kg of solid waste per person per day from 2001 to 2018 [5]. Waste generation continues to grow at an alarming rate, and MSW is concerned about hygienic and safe disposal [4]. If it is not appropriately managed, the enormous amount of MSW will negatively affect the environment, such as air, water, and soil pollution [6], food chain contamination with bacteria & viruses, etc. [7].

Biological treatment and thermal conversion technologies are commonly used to handle solid waste in India [8,9,10]. The biological treatment method, mainly composting, can convert organic wastes and residual sludge into compost (manure) or methane (waste to energy). Thermal conversion technologies include incineration of MSW with or without heat recovery, pyrolysis, gasification, and refuse-derived fuel (RDF) production. Solid waste is sometimes disposed off in sanitary landfills, either directly without treatment or indirectly, i.e., after treatment.

Solid waste management and disposal are complex problems that involve political, social, economic, technological, and environmental considerations. A series of trade-offs hamper reaching the best treatment technology among various stakeholders with differing objectives and viewpoints. As a result, technical, economic, environmental, managerial, and social issues must be assessed, which can be done using quantitative, qualitative, or mixed methodologies. The appropriate solid waste treatment technology and disposal choice vary from country to country. It is influenced by various factors, including the types and composition of waste, land availability, labor requirement, capital cost, public awareness, the calorific value of waste, energy availability, policy and subsidy, employment and environmental impact. Thus, MSW management must be considered a task requiring Multi-Criteria Decision Making (MCDM) for appropriate management. Many researchers have worked on various aspects of solid waste management and disposal methods using various MCDM tools, such as Delphi method, analytic hierarchy process (AHP) method, technique for order preference by similarity to ideal solution (TOPSIS) method, and rapid impact assessment matrix (RIAM) method [11,12,13].

In several areas of environmental management, the AHP technique is recommended as an excellent technique for solving multi-criteria decision-making [14]. Apart from environmental management, there are many applications, such as the selection of waste management strategies for hospitals [15], municipal wastes [16], hazardous waste transportation [17], sites [18], waste collection [19], and waste allocation [20]. Interestingly, decision-making in AHP involves judgment based on the expert's knowledge; however, different opinions and decision-making modes cannot reflect the same thinking [21]. As a result, AHP has always been criticized for various reasons, including being unrealistic, not covering all ranges of human thinking templates, and the uncertainty in the analysis [22].

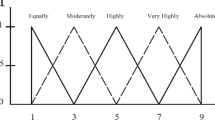

The development of fuzzy set theory proposes more flexible methods and addresses the typical difficulties mentioned above. The crisp set has only two states: non-membership and full membership, so in fuzzy theory, a crisp set is expanded, allowing for more accurate real-time decision modeling and comparative membership [23]. Mikhailov and Tsvetinov were the first to combine AHP with fuzzy theory, termed FAHP (fuzzy analytic hierarchy process) modeling, which is frequently utilized in many management modeling projects to address uncertainty, lack of knowledge, and the presence of non-statistical information [24]. For the first time, Van Laarhoven and Pedrycz employed FAHP to compare fuzzy ratios given by the triangular fuzzy [25]. To optimize and analyze various environmental concerns, such as urban solid waste management, site selection, and ocean disposal sites, fuzzy sets are combined with multi-criteria decision-making approaches, especially AHP. FAHP determines the relative importance of every criterion through pairwise evaluation given utilizing area experts or selection makers [26]. Fuzzy computing in FAHP is used to describe and address uncertainties by simulating human intelligence. Consequently, modified FAHP is adopted in this paper to select the best option among MSW treatment and disposal systems with seven criteria and 21 sub-criteria.

Materials and methodology

Selection of solid waste treatment and disposal technology

This study considers six alternatives: composting, sanitary landfill, gasification, incineration, RDF, and pyrolysis for solid waste treatment and disposal. These alternatives are briefly explained as follows:

-

1.

Composting: the biochemical process of creating biogas through microbial decomposition of organic material in the presence of oxygen is known as the composting process [27]. The operating process involves pre-treatment, separation of non-digestible materials, shredding, digestion, and residue treatment.

-

2.

Incineration: incineration is a controlled and complete combustion process that burns solid wastes. The temperature of the incinerators ranges from 980 °C to 2000 °C [28]. The ability to reduce the original volume of combustible solid waste by 90% is one of the most attractive characteristics of the incineration process [29].

-

3.

Gasification: this is a thermochemical process that uses heat and low-oxygen [30] to partially oxidize carbonaceous materials like biomass or MSW, and converts them into flammable gases [31]. Gasification, unlike incineration, converts solid or liquid waste feedstock into a gaseous product by exposing it to a range of high temperatures (>700 °C) in a controlled supply of oxygen. The gasification occurs in a sealed stainless-steel vessel-filled plasma reactor with air. Gasification can reduce volume by up to 90% while producing almost no toxic emissions.

-

4.

Pyrolysis: pyrolysis is the thermochemical decomposition of organic waste at high temperatures in an oxygen-free environment or with too little oxygen for combustion or gasification.

-

5.

RDF: RDF is a combustible fraction of MSW that has been separated. The flammable percentage of the waste is compressed into fuel pellets or shredded and converted into fluff, which is then increased in organic content by removing inorganic materials and moisture.

-

6.

Sanitary landfill: open, uncontrolled, and poorly managed dumps regularly occur in many metropolitan areas, resulting in considerable environmental deterioration. For the final disposal of MSW, sanitary landfilling is a viable and recommended option. Because all other solutions produce some residue that must be disposed off through landfilling, it is a necessary component of MSW management. However, landfilling appears to be the most generally adopted practice in the upcoming years, and at that time, will require various adjustments to ensure sanitary landfilling.

Selection of criteria and sub-criteria

Evaluation of each technology depends on the application of the main criteria and sub-criteria, with the opinion of the expert, field engineers, and literature, the seven main criteria and 21 sub-criteria identified for the FAHP study as presented in Table 1. The details of the criterion and sub-criteria with references to data collection are as follows.

-

1.

Waste quality and quantity: the quantity and quality of waste generation play a vital role in selecting waste processing technologies. It has three sub-criteria. (a) Desirable moisture content (b) Waste acceptance: waste acceptance criteria are the technical criteria that must accept waste at storage, treatment, or disposal facilities for Indian MSW conditions. (c) Suitability (quantity): the higher capacity of treatment technology to tackle solid waste, the higher preference should be given.

-

2.

Environmental criteria: the treatment and disposal technology application should be free from environmental safety. It is critical to meet this condition since waste constitutes a severe concern in these areas and one of the primary requirements of treatment technologies is to eliminate this risk. Four sub-criteria are selected under environmental criteria: (a) Greenhouse gas emission: lesser emissions of \({\mathrm{CO}}_{2}\) greenhouse gases are given higher preference. (b) Adverse impacts: all qualitative impacts of treatment technology considered. The lower the impact is, the higher the priority. (c) Land requirement: technology that requires less land area should be given higher prioritized and (d) Leachate pollution: less leachate pollution from technology is preferred.

-

3.

Opportunities criteria: technology prominence/establishment and Generation/ recovery of other valuable products are selected as sub-criteria of opportunities for the selection of MSW treatment and disposal technology.

-

4.

Managerial criteria: there is a need for expertise and labor to operate technology. There is a massive scarcity of expertise in India. The managerial criteria have two sub-criteria; these are labor requirements and technical expertise.

-

5.

Technical criteria: the overall system efficiency, retention time, volume reduction and power generation are selected as technical sub-criteria for choosing the best treatment technology for MSW.

-

6.

Economic criteria: the three Sub-criteria are used to address the economic aspects:(a) Capital cost, (b) Operating cost, (c) Pre-treatment costs. Capital cost is the cost required to establish a plant, including all costs associated with the project's construction and implementation. Operating cost is the total amount of money spent on the plant's operation over its entire lifetime.

-

7.

Social and political criteria: local support and community participation are the most critical factors for the sustainable functioning of technology in any locality. The process of selecting social criteria is complicated, and in this study, three factors were considered: policy & subsidy, employment and public acceptability. The policy and subsidy play a significant role in selecting solid waste treatment and disposal technology. In many cases, MSW management programs have failed due to a lack of funds. Currently, the number of employees is a significant indicator.

FAHP methodology

The FAHP is a well-known and tested methodology used worldwide. However, the problem lies where the steps are lengthy and consumes time. Due to the lengthy calculation, there is a risk of error. For this reason, we used two calculation methods to find the priority of criteria/sub-criteria and the priority of alternatives based on each sub-criteria: one using MS Excel software and the software package RStudio. If the final result from both approaches is not the same, the methods must be rechecked and labeled for mismatches and the overall approach of the study is presented in Fig. 1. The FAHP method on the enhanced extent analysis approach has the following steps and is briefly shown in Fig. 2.

Step 1: Developing a decision Model.

The FAHP solves the problem using a hierarchy of four levels and a schematic diagram represented in Fig. 3 to select optimal treatment and disposal technology. The top or first level of the hierarchy is the goal, i.e., ranking of MSW treatment and disposal technology. The intermediate or second level of the hierarchy is based on relevant evaluation criteria. In this study, seven criteria are considered: waste quality & quantity, environmental, managerial, economical, technical, opportunity and social & political. The third level consists of sub-criteria of evaluation criteria mentioned in level second. Here, 21 sub-criteria are as follows: 3 sub-criteria for waste quality and quantity, 4 sub-criteria for environmental, 2 sub-criteria for managerial, 3 sub-criteria for economic, 4 sub-criteria for technical, 2 sub-criteria for opportunity criteria, and 3 sub-criteria of social & political criteria. Finally, the hierarchy's lowest or fourth level comprises alternatives or options; in this work, six alternatives are considered, i.e., composting, RDF, incineration, gasification, pyrolysis and sanitary landfill.

The hierarchical structure for the prioritization of treatment and disposal technology for solid waste management. WQQ Waste quality and quantity, DEMC Desirable Moisture Content, WAAC Waste ASTE Acceptance, SUQU Suitability Quantity; ENV Environmental criteria, GHEM GHG Emission, ADIM Adverse impacts, LANRE Land requirement, LEPO Leachate Pollution; MNG Managerial criteria, LARE Labour Requirement, LORTE Lack of resources/Technical expertise; ECO Economic Criteria, CACO Capital cost, OPCO Operating cost, PTCO Pre-treatment costs; TEC Technical criteria, OVSE Overall system efficiency, RETI Residence time, POGE Power Generation, VORE Volume reduction; OPP Opportunities criteria, TEPE Technology prominence/establishment, ROVP Generation/recovery of other valuable products; SPI Social and Political impact Criteria, POSU Policy & subsidy, EMPL Employment, PUAC public acceptability; COM Composting, RDF Refuse-derived fuel, INC Incineration, GAS Gasification, PYR Pyrolysis, SLF Sanitary landfill

Step 2: Formulation of fuzzy pairwise comparison decision matrix.

The comparison between criteria and sub-criteria is based on the AHP scale given from the opinion of the expert, field engineers and literature review. The comparison between treatment and disposal technology concerning criteria was made with the help of collected data and a literature review. The fuzzy comparison is generated by transforming the AHP pairwise comparison matrix into a triangular fuzzy number matrix represented in Table 2.

Step 3: According to [43], the geometric mean of fuzzy comparison values of each criterion is calculated by Eq. (1). Here, \({\widetilde{r}}_{l}\), “tilde” represents the triangular number demonstration.

Step 4: The fuzzy priorities of each criterion can be found in Eq. (2) with the help of steps 4a, 4b, and 4c.

Step 4a: Find the vector summation of each \({\widetilde{r}}_{l}\).

Step 4b: Find the (−1) power of the summation vector, which replaces the fuzzy triangular number, to make it in increasing order.

Step 4c: Find the fuzzy priority of criterion i(\({\widetilde{w}}_{l}\)) multiply each \({\widetilde{r}}_{l}\) with this reverse vector.

Step 5: Defuzzify the fuzzy priorities:

Defuzzification is the process of obtaining a single crisp number from the fuzzy set to convert the fuzzy set output into a crisp output. The defuzzification is done using center of area method proposed by [44] by applying the Eq. (3)

Step 6: After defuzzification, \({M}_{i}\) is a non-fuzzy number. However, it needs to be normalized by Eq. (4). The 6 steps are performed to find the normalized priorities of criteria, sub-criteria, and alternatives.

Step 7: Consistency check.

First, find the largest eigenvalue of the decision matrix to check the consistency decision matrix (\({\lambda }_{\mathrm{max}}\)). It is computed by Eq. (5)

The consistency check is calculated using Eqs. (6) and (7)

where CR is the consistency ratio, CI is the consistency index and RI is the random index. \({\lambda }_{\mathrm{max}}\) is the largest eigenvalue decision matrix, and n is the number of criteria. The value of RI depends on the dimension (order) of the comparison matrix. Table 3 shows the random index values for the matrix up to size 15 and the acceptable limit of CR value presented in Table 4.

Step 8: Global priority.

The results of the global fuzzy number are derived by multiplying the local fuzzy number of each sub-criteria by their respective fuzzy number of the criteria.

Results and discussion

The selection of the most appropriate technology from six technology alternatives is evaluated by considering 7 main criteria and 21 sub-criteria for the FAHP study. It is evaluated by the use of MS Excel software and the software package RStudio as:

Comparison matrix of criteria and their priorities

The first step is to use an MS Excel data sheet to import a pairwise comparison matrix. Then, using the fuzzy package's command "pairwise comparison Matrix()", an AHP comparison matrix is created. Following that, using the command "fuzzyPairwiseComparisonMatrix()" the pairwise is turned into a triangular fuzzy number, as shown in Table 5.

Consistency check

After forming the consistency of the fuzzy pairwise comparison matrix, it is necessary to check the result. The command "consistency index ()" is used to determine the consistency index. The consistency ratio is determined using the fuzzy AHP package command "consistency Ratio()". The fuzzy pairwise comparison matrix is consistent for calculations when the consistency ratio is smaller than 0.1. Table 5 shows the results of the consistency index and consistency ratio of the fuzzy AHP pairwise comparison matrix between different criteria.

Priority vectors (synthetic degree value)

Equation 1 is used to obtain the geometric mean of the fuzzy comparison values of each criterion after the first three steps of the process have been completed. The order of the numbers in the last row is modified since the fuzzy triangular number should be in increasing order. Table 6 shows the result of the relative fuzzy priorities of each criterion by both manual calculation using MS Excel software and with the software package RStudio.

The synthetic degree value of the FAHP criterion (fnMin, fnModal, fnMax) was generated using the RStudio Fuzzy AHP package software. "calculateWeights()" is the code that is used to find synthetic degree values; then, the priority score is defuzzified as indicated, and synthetic degree value of the FAHP criterion (fnMin, fnModal, fnMax) is shown in Table 6. Taking the average of fuzzy numbers for each criterion, the relative non-fuzzy priority value of each criterion (Mi) is calculated using the non-fuzzy Mi normalized priority value of each criterion.

After prioritizing the main criteria, the sub-criteria within each main criterion are prioritized in the same way. The consistency ratio of each comparison matrix that was found to be less than 0.1 is acceptable. The six solid waste management technologies are then individually compared for each of the 21 sub-criteria, resulting in 21 pairwise comparison matrices of order 18×6 representing priority vectors of each technology within each sub-criterion.

The global priority value of sub-criteria is evaluated by multiplying each of the main criteria priority values by the local priority of the sub-criteria in the respective main criteria category. The local priority and global priority of sub-criteria are shown in Table 7. In waste quality and quantity criteria, waste acceptance is considered the essential sub-criterion at the local level, whereas desirable moisture content is regarded as the least important. If a single form of alternative cannot handle all types of waste, other types of alternatives are needed. All types of waste should be accepted to rely on one type of alternative. Because the moisture content of solid waste can be changed by drying in sunlight, it is given less priority. This is why the expert has been given more priority to waste acceptance compared to the other two sub-criteria of waste quality and quantity criteria for the selection of solid waste treatment and disposal technology. Greenhouse gas emission is given the highest priority in environmental criteria, followed by leachate pollution, adverse impacts and land requirements. Lack of resources/technical expertise has given higher priority to labor requirements due to new technology requiring expertise to operate and scarcity of expertise while labor is readily available. Capital cost is favored in terms of economic factors. Volume reduction, retention time, power production, and overall system efficiency are technical criteria with priority values of 0.430, 0.264, 0.154 and 0.152, respectively. Regarding social and political impact, policies and subsidies, employment and public acceptance. The greenhouse gas emission had the highest global priority of 0.153, while the desired moisture content had the lowest priority of 0.0039, for MSW treatment and disposal technology selection.

The overall priority is determined in terms of the fuzzy number to reduce information loss and avoid questionable outcomes during defuzzification. The priority of alternatives concerning sub-criteria is multiplied by their respective global priority of sub-criteria. Then, the fuzzy impact of alternatives is obtained by adding synthetic degree values Si priority value by corresponding fuzzy composite relative priorities of parent node criterion shown in Table 8. After that, a fuzzy impact on the alternative is obtained by adding the composite relative synthesis value summation. Then, the final ranking is obtained as represented in Table 9, after defuzzification and the normalization of fuzzy values. Composting is the most recommended technology for treating and managing solid waste, with a priority of 0.2308, while incineration and sanitary landfills are the least preferred MSW management alternatives. RDF comes second with a priority score of 0.1970 for solid waste treatment. Gasification and pyrolysis are ranked third and fourth, with priority scores of 0.1584 and 0.1537, respectively.

According to a similar study based on the AHP model, composting is the most preferred technology, followed by RDF, while sanitary landfills and incineration are the worst options for solid waste treatment and disposal. The third favored technology is gasification [47, 48].

Sensitivity analysis for FAHP

The sensitivity analysis is required to find the sensitive parameter or criterion in FAHP analysis. For that, eight cases are formed based on (i) each criterion having an equal priority of 14.29, and (ii) one criterion being 50% and 50% for other criteria with an equal priority value. Case 1: providing an identical priority of 14.29% to each criterion. Case 2: social and political impact has been given a priority of 50%, while the remaining priority value is equally divided among other criteria. Case 3: the opportunity criterion has a priority value of 50%, while the remaining priority value is equally divided into other criteria. Case 4: technical criterion has a priority value of 50%, while the remaining priority value is equally divided into other criteria. Case 5: economical criterion has a priority of 50%, while the remaining priority value is equally divided into other criteria. Case 6: managerial criterion has a priority of 50%, while the remaining priority value is equally divided into other criteria. Case 7: environmental criterion has a priority of 50%, while the remaining priority value is equally divided into other criteria. And Case 8: the waste quality and quantity criterion has a priority of 50%, while the remaining priority value is equally divided into other criteria.

The results of the sensitivity analysis shown in Fig. 4 represent the priorities of different cases. Composting is ranked first among other alternatives in all cases with varying priority values. RDF is second except in Case 8, with priority values varying between 0.15 and 0.22. Finally, in terms of solid waste treatment and disposal technology, incineration and sanitary landfills are considered the last alternative in most cases.

Figure 5 shows the "What if Analysis" results to check whether any treatment options ranking changed. The results show no changes in the ranked results, indicating that the composting alternative is still the best option for treating solid waste treatment and disposal technology. Except in Case 8, RDF is the second-best technology for solid waste treatment. The sanitary landfilling and incineration technology ranked last in most of cases. It should be emphasized that the rank of solid waste treatment and disposal systems may vary depending on the system's progress.

Conclusions

The selection of solid waste treatment/disposal technology is a complex multi-criteria decision-making process, with the essential characteristics being uncertainty, complexity and hierarchy. The FAHP approaches present a realistic way to select and prioritize solid waste treatment and disposal technology problems. In this study, the FAHP method is used in two ways: manually with the MS Excel software and with the RStudio software package, and the results from both are consistent, proving the accuracy of the final results. Out of seven criteria, the environmental criterion has demonstrated great importance compared to the other criteria. In contrast, a pairwise comparison revealed that the waste quality and quantity criterion is the least important of the criteria. The most favored solid waste treatment technology for the treatment and disposal of solid waste is composting. The organic component of solid waste is significant; hence, this technology is ideal. Gasification, pyrolysis and incineration are not favored technologies due to a large amount of organic waste, environmental issues, and strong public opposition due to perceptions relevant to human health risks. In many places in India, open landfilling is still performed, with massive piles of rubbish piled around the landfilling in the most unsanitary manner. Sanitary landfilling is the least preferred alternative due to associated disadvantages such as the need for a huge amount of land, negative impacts on surrounding communities, and a long residence duration of solid waste. In this context, the established methodology will aid planners and policymakers in selecting India's most appropriate solid waste treatment technologies.

The study was limited to seven criteria and only six treatment and disposal technologies. Since gasification and pyrolysis are still in the early stages of commercialization, their application to MSW in India should be investigated further, with real evidence from technology. Other multiple criterion methods, such as AHP-GIS, Picture fuzzy AHP, Pythagorean fuzzy AHP, Fuzzy TOPSIS and ELECTRE, etc., can be employed in future studies to evaluate the MSW treatment process.

References

Khoshand, A., Rahimi, K., and Ehteshami, M. 2019. Fuzzy AHP approach for prioritizing electronic waste management options: A case study of Tehran, Iran. Environmental Science and Pollution Research 26: 9649–9966.

Rawal, N. 2019. An approach for selection of solid waste disposal sites by rapid impact assessment matrix and environmental performance index analysis. International Journal of Environment and Pollution 66 (1/2/3): 127.

Sharma, A., and Rawal, N. 2022. Life cycle costing assessment-based approach for evaluation of solid waste management options. Journal of Hazardous, Toxic, and Radioactive Waste 26: 04022023-1.

Kumar, S., Smith, S.R., Fowler, G., et al. 2017. Challenges and opportunities associated with waste management in India. Royal Society Open Science 4: 160764.

Central Pollution Control Board (CPCB). 2019. Annual Report Information on Solid Waste Management Scenario in the Country for the year 2018-2019. Available at: https://cpcb.nic.in/status-of-implementation-of-solid-waste-rules/. Accessed 8 July 2022.

Weidemann, E., and Boily, L.L.J.F. 2016. Thermal decomposition of municipal solid waste fly ash and desorption of polychlorinated dibenzo-p-dioxins and furans from fly ash surfaces. Journal of Environmental Science and Pollution Research 23 (22): 22843–22851.

Giusti, L. 2009. A review of waste management practices and their impact on human health. Waste Management 29: 2227–2239.

UNEP. 2005. Solid waste management. Nairobi, Kenya: United Nations Environment Programme.

Tchobanoglous, G. 2003. Solid waste management. In Environmental engineering, 5th ed., Salvato, J.A., Nemerow, N.L., and Agardy, F.J. (eds.). New York, NY, USA: Wiley.

CPCB. 2016. Selection criteria for waste processing technologies. Available at: https://cpcb.nic.in/uploads/MSW/SW_treatment_Technologies.pdf. Accessed on 8 July 2022.

Sharma, A., and N. Rawal. 2021. The selection of wastewater treatment units based on analytical hierarchical process. In: Recent Trends in Civil Engineering. Lecture Notes in Civil Engineering, Pathak, K.K., Bandara, J.M.S.J., Agrawal, R. (eds.), vol 77, pp. 1003–1019. Singapore: Springer. https://doi.org/10.1007/978-981-15-5195-6_73

Rawal, N., Rai, S., and Duggal, S. 2017. An approach for the analysis of the effects of solid waste management in slum areas by rapid impact assessment matrix analysis. International Journal of Environmental Technology and Management 20 (3–4): 225–239.

Rawal, N., Singh, R.M., and Vaishya, R.C. 2012. Optimal management methodology for solid wastes in urban areas. Journal Hazardous, Toxic, and Radioactive Waste 16 (1): 26–38.

Saaty, T.L. 1994. Highlights and critical points in the theory and application of the analytic hierarchy process. European Journal of Operational Research 74 (3): 426–447.

Karamouz, M. 2007. Developing a master plan for hospital solid waste management: A case study. Waste Management 27 (5): 626–638.

Pires, A., Chang, N., and Martinho, G. 2011. An AHP-based fuzzy inter val TOPSIS assessment for sustainable expansion of the solid waste management system in Setúbal Peninsula, Portugal. Resources, Conservation and Recycling 56 (1): 7–21.

Gumus, A.T. 2009. Evaluation of hazardous waste transportation firms by using a two step fuzzy-AHP and TOPSIS methodology. Expert Systems with Applications 36 (Part 2): 4067–4074.

Önüt, S., and Soner, S. 2009. Transshipment site selection using the AHP and TOPSIS approaches under fuzzy environment. Waste Management 8 (9): 1552–1559.

Wang, G.Q. 2008. Optimizing the collection and transportation of municipal solid wastes based on AHP. Journal of Harbin Institute of Technology 28 (9): 838–842.

Li, R.Z., Wang, J.Q., and Qian, J.Z. 2005. Delphi-AHP method for allocation of waste loads in a region. Harbin Gongye Daxue Xuebao/Journal of Harbin Institute of Technology 37 (1): 84–88.

Kahraman, C., Cebeci, U., and Ulukan, Z. 2003. Multi-criteria supplier selection using fuzzy AHP. Logistics Information Management 16 (6): 382–394.

Deng, H. 1999. Multicriteria analysis with fuzzy pairwise comparison. International Journal of Approximate Reasoning 21 (3): 215–231.

Ertugdrul, I., and Karakasoglu, N. 2007. Comparison of fuzzy AHP and fuzzy TOPSIS methods for facility location selection. International Journal of Advanced Manufacturing Technology 39: 783–795.

Mikhailov, L., and Tsvetinov, P. 2004. Evaluation of services using a fuzzy analytic hierarchy process. Applied Soft Computing 5: 23–33.

Laarhoven, P.V., and Pedrycz, W. 1983. A fuzzy extension of Saaty’s priority theory. Fuzzy Sets and Systems 11 (1–3): 199–227.

Zhu, G.-N., Hu, J., and Ren, H. 2020. A fuzzy rough number-based AHP-TOPSIS for design concept evaluation under uncertain environments. Applied Soft Computing 91: 106228. https://doi.org/10.1016/j.asoc.2020.106228.

Gumisiriza, R., Hawumba, J., Okure, M., et al. 2017. Biomass waste-to-energy valorisation technologies: A review case for banana processing in Uganda. Biotechnology for Biofuels 10: 1–29.

Hoang, Q.N., Vanierschot, M., Blondeau, J., et al. 2021. Review of numerical studies on thermal treatment of municipal solid waste in packed bed combustion. Fuel Communications 7: 100013. https://doi.org/10.1016/j.jfueco.2021.100013

CPHEEO. 2017. Waste to Wealth, Ministry of House and Urban Affairs. Available at: http://cpheeo.gov.in/upload/5abc86de40012WastetoWealth2Oct.pdf. Accessed 8 July 2022.

Hu, Z., Xiao, B., Li, J., et al. 2009. Hydrogen-rich gas from catalytic steam gasification of municipal solid waste (MSW): Influence of catalyst and temperature on yield and product composition. International Journal of Hydrogen Energy 34 (1): 195–203.

Sheth, P.N., Bab, B.V. 2009. Experimental studies on producer gas generation from wood waste in a downdraft biomass gasifier. Bioresource Technology 100: 3127–3133.

Sebastian, R.M., and Alappat, B. 2016. Thermal properties of Indian Municipal Solid Waste over the past, present and future years and its effect on thermal waste to energy facilities. Civil Engineering and Urban Planning: An International Journal 3 (2): 97–106.

Gupta, M., Srivastava, M., Agrahari, S.K., et al. 2018. Waste to energy technologies in India: A review. Journal of Energy and Environmental Sustainability 6: 29–35.

CPHEEO. 2016. Municipal Solid Waste Management Manual. New Delhii, India: Central Public Health and Environmental Engineering Organisation.

Yap, H.Y., and Nixon, J.D. 2015. A multi-criteria analysis of options for energy recovery from municipal solid waste in India and the UK. Waste Management 46: 265-277

Clearance, E. 2010. Technical EIA guidance manuals for common Municipal Solid Waste Management facilities. The Ministry of Environment and Forest Government of India. Available at: http://environmentclearance.nic.in/writereaddata/form-1a/homelinks/TGM_%20Comman%20Municipal%20Sold%20Waste%20Management_160910_NK.pdf. Accessed 7 July 2022.

Malav, L.C., and Yadav, K.K. 2020. A review on municipal solid waste as a renewable source for waste-to energy project in India: Current practices, challenges, and future opportunities. Journal of Cleaner Production 277: 123227.

Chakraborty, M., Sharma, C., Pandey, J., et al. 2013. Assessment of energy generation potentials of MSW in Delhi under different technological options. Energy Conversion and Management 75: 249–255.

Nixon, J.D., Dey, P.K., Ghosh, S.K., et al. 2017. Evaluation of options for energy recovery from municipal solid waste in India using the hierarchical analytical network process. Energy 9, 215–223.

Prakasam, V., and Thirugnanam, G. 2013. Refused Derived Fuel to Electricity. International Journal of Engineering Research & Technology 2 (9): 2930–2932.

Saini, S., Rao, P., and Patil, Y. 2012. City based analysis of MSW to energy generation in India calculation of state-wise potential and tariff comparison with EU. Procedia-Social and Behavioral Sciences 37: 407–416.

Thengane, S.K. 2018. Assessment of different technologies for managing yard waste using analytic hierarchy process. Process Integration and Optimization for Sustainability 3, 255–272.

Buckley, J.J. 1985. Fuzzy Hierarchical analysis. Fuzzy Sets and Systems 17: 233–247.

Chou, S.W., and Chang, Y. 2008. The implemementation factors that influence the ERP (enterprise Resource Planning) benefits. Decision Support Systems 46 (1): 149–157.

Odu, G. 2019. Weighting methods for multi-criteria decision making technique. Journal of Applied Sciences and Environmental Management 23 (8): 1449–1457.

Saaty, T.L. 2008. Decision making with the analytic hierarchy process. International Journal of Services Sciences 1: 83–98.

Kharat, M.G., Raut, R.D., Kamble, S.S., et al. 2015. The application of Delphi and AHP method in environmentally conscious solid waste treatment and disposal technology selection. Management of Environmental Quality: An International Journal 27 (4): 427–440.

Kansal, A. 2002. Solid waste management strategies for India. Indian Journal of Environmental Protection 22: 444–448.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, A., Sharma, A. & Rawal, N. An approach for selection of solid waste treatment and disposal methods based on fuzzy analytical hierarchy process. Waste Dispos. Sustain. Energy 4, 311–322 (2022). https://doi.org/10.1007/s42768-022-00117-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42768-022-00117-z