Abstract

In recent decades, micro and nanotechnology have received increasing attention with a multitude of applications across disciplines. These technologies have been applied to the field of transportation vehicles (automotive industry) extensively. This paper reviews the current state of the art in micro/nano-technology in the automotive industry including how this technology can be employed to improve the comfort, safety, and efficiency of transportation vehicles. In addition, this paper focuses on recent developments and applications of nanotechnology in the transportation vehicle industry, including nanocoating’s, carbon nanotubes (CNT), graphene, nanocomposites, aluminium-CNT nanocomposites, silicon carbide, nanofluids, nano steel, carbon black for tires, electric vehicles, fuel cells vehicles, scratch and wear resistance paint, nanostructured coatings, ultra-thin layers for mirrors and reflectors, micro-/nano-technologies for improved engine performance, automotive sensors, light weighting of bodies/hoods, lubricants, etc. It is possible that several nanomaterials may be potential candidates for use in future environment friendly transportation vehicles since they have demonstrated outstanding performance and have been theoretically researched. We anticipate that this paper will contribute to further sustainable research and greater potential applications of environmentally friendly nanomaterials in transportation vehicles to improve the automobile industry worldwide.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanotechnology is defined as the manipulation of matter with a size range between 0.1 and 100 nm, as illustrated in Fig. 1. It is employed in industry around the world due largely to the unique physical and chemical characteristics of nanomaterials (Malik et al. 2023; Ricci and Dietz 2023; Omietimi et al. 2023) resulting in products with high mechanical strength, long durability, super-hydrophobicity in paint, sensors for different kinds of gases and molecules. These characteristics could include miraculously transformed (photo) catalysis, optical sensitivity and mechanical strength of materials at nano sizes, facilitating applications in energy storage and sensors among others (Malik et al. 2023; Omietimi et al. 2023). These interesting physical properties of nanomaterials result from the fact that at the nanoscale, electrostatic forces and quantum effects overcome other classical forces such as gravity (Rodríguez-Sevilla et al. 2018; Mohammad et al. 2022). Several fields such as chemistry, biology and engineering have been impacted by the nanotechnology revolution. As a result of their superior performance, nanotechnology applications are increasing in various fields, including automobiles (Shafique and Luo 2019), medicine (Kumar et al. 2016a), and catalysis (Kumar et al. 2016b), robotics, electronics, and the civil engineering industry (Kumar et al. 2011, 2017b; Shafique and Luo 2019; Pokrajac et al. 2021; Malik et al. 2023) resulting in significant benefits.

The automotive industry anticipates that future vehicles will be able to further harness the power of this technology to become safer and more fuel-efficient. There has been a steady increase in greenhouse gases in our ecosystem and there is therefore a global demand for lowering the greenhouse gas emissions by designing more fuel-efficient transportation (van Vuuren et al. 2017; Leach et al. 2020). This has led to a new market for low-cost, lightweight, and durable materials for better fuel efficiency. Given diminishing returns with classical techniques for fuel efficiency improvement, nanotechnology could give a much needed boost for step changes in this domain (Manu and Manoj 2020). Nanotechnologies such as lightweight nanomaterials, scratch-resistant paints, sensors and nanofluids are crucial to the development of smart, speedy and efficient vehicles (Shafique and Luo 2019). There has been a rapid development of nanoscale materials in recent years (Kumar et al. 2013, 2022a, 2023). Some components of the automotive industry are now being designed using nanomaterials.

This literature review aims to provide an overview of state-of-the-art research in nanotechnology applications in the automobile industry. We begin by reviewing articles and patents published in reputed journals and proceedings that are directly related to nanotechnology in the transportation and automobile industries. In the first instance, papers were identified using specific criteria in scientific databases (e.g., Web of Science, Google Scholar, Sci-Finder). It is the purpose of this review to examine recent advancements in nanotechnology applications in transportation as well as the attendant concerns of the automobile industry between the years 2019 and 2023 (Shafique and Luo 2019; Mathew et al. 2019; Manu and Manoj 2020; Leach et al. 2020; Dericiler et al. 2022; Malik et al. 2023). Overall, 250–300 were found, which are closely related to the automotive industry in terms of safety, animal/human health and no impact on the environment. There has been a rapid development of nanoscale materials in recent years (Kumar and Mohanta 2011; Kumar et al. 2015, 2017a, 2019, 2023; Bhooshan Kumar et al. 2016). Some parts of the automotive industry are now being designed using nanocomposite materials for lower gas emissions and more fuel-efficient vehicles (Goyal et al. 2014; Dericiler et al. 2022; Wazeer et al. 2023).

Recent literature reviews have summarized the potential benefits of nanotechnology in transportation vehicles. According to the literature review, there are few comprehensive studies examining nanotechnology applications in the automotive industry in the light of sustainability. This study aims to provide a recent literature review of nanotechnology applications in transportation vehicles, which may provide useful information in the development of sustainable and environmentally friendly nanomaterials in the near future. In this study, it is emphasized that implementing environmentally friendly nanomaterials into vehicles in the near future may provide long-term benefits. The purpose of this paper is to present a vision and prospect for the application of nanotechnology and nanoscale materials in different parts of the automotive industry.

Currently Used Nanomaterials in Automotive Industry

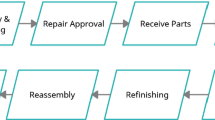

The use of nanotechnology can be found in a variety of automotive components, including paint, batteries, fuel cells, tires, mirrors, and windows (Tomar 2012; Kumar et al. 2016c, d; Sadiku et al. 2018; Masias et al. 2021; Wazeer et al. 2023). Nanotechnology typical enhances the performance of existing of materials due to its size effect and confinement of electron movement. Therefore, nanomaterials offer advantages to automobiles in that they provide lighter, stronger body parts (to enhance safety and fuel efficiency), improved fuel efficiency and longer-lasting performance (Tomar 2012). In order to fill that gap, this nanotechnology-based study provides a comprehensive overview of nanotechnology’s application in the automotive industry as illustrated in Fig. 2. In this study, we review recent literature related to the application of nanotechnology in transportation vehicles that provides valuable information for the development of sustainable and environmentally friendly nanomaterials in the near future. The study presents several environmentally friendly nanomaterials used in the automobile industry such as: graphene, carbon nanotubes, nano steel, aluminum carbon nanotube, silicon carbide, Zinc oxide, etc.

Graphene

As a form of carbon, graphene consists of a single layer of atoms arranged in a hexagonal lattice in two-dimensional space (Fig. 2). It is possible that each atom has four bonds, one pi bond with each of its three neighbors and three sigma bonds with each of its three neighbors (Stankovich et al. 2006; Wu et al. 2007; Fuhrer et al. 2010; Wang and Shi 2015). Layers of graphene are held together by Van Der Wall Forces and have numerous advantages that make it unique among other materials (Geim and Novoselov 2007; Wu et al. 2007; Wang and Shi 2015). Automobile parts that utilize graphene are lighter and stronger than those using steel or carbon fiber (200 times stronger) (Geim and Novoselov 2007). It also provides for innovative self-cleaning car interiors. Graphene is used in tires and provides high mechanical strength and thermal conductivity. In addition, graphene could be used to make energy-efficient batteries that could replace or improve lithium-ion batteries.

Carbon Nanotubes (CNT)

A CNT consists of carbon whose diameter is measured in nanometers. Shortly, we refer to carbon nanotubes as “CNTs” (De Volder et al. 2013). A carbon nanotube is equivalent to a one-dimensional or two-dimensional graphene sheet, which is rolled into a tube and can either be single walled or multiwalled as shown in Fig. 2. Carbon nanotubes exhibit a number of extraordinary properties, including an elastic modulus close to 1000 GPa, a strength of 30–100 GPa and a low thermal expansion coefficient. CNTs are of three types: single-walled CNT (SWCNT), multi-walled CNT (MWCNT) and double-walled CNT (DWCNT) (De Volder et al. 2013; Wang and Strano 2013). Using CNT in the automobile industry allows for weight reduction, which reduces fuel consumption. It is also used for electrostatic discharge in the fuel system, reducing the risk of fuel system explosions (Wang and Strano 2013; Wang and Shi 2015). CNTs are useful because they are capable of forming covalent bonds. In the automobile industry, CNT has a number of potential applications. Due to their exceptional physical and chemical properties (mostly surface functionalization, surface bonding) they can be used to make automobile parts such as chassis, head shields, rubber tires, engine blocks, etc., and to produce hydrogen fuel cells.

Interface of Graphene and Carbon Nanotubes

Recently, these two nanomaterials have demonstrated some remarkable physical, chemical and biological properties. There are some similarities between them as well as some differences. Both materials possess a SP2 hybridization bond between their carbon atoms, which explains their strength. It is because of the sp2 bond that they are stronger than diamond, one of the most demanding materials. Because of their unique molecular arrangement, they have the highest tensile strength as well as the ability to conduct heat and electricity (Fuhrer et al. 2010; De Volder et al. 2013). The only difference between the two is that graphene is a zero-gap semiconductor, whereas carbon nanotubes can either behave as semiconductors with a band gap or as metallic materials, depending on their structure.

Aluminum-CNTs Nanocomposites

It is also known as Al-CNT composites, which came into existence following the discovery of CNT. This is a modified version of CNT that offers improved physical and chemical properties including mechanical strength. Al-CNT composites are capable of enhancing the deformation resistance of composites at high temperatures. The Al-CNT composites have improved upon yield strength and tensile strength by 104.7% and 51.8%, respectively, while their electrical conductivity is comparable to pure Al (Zhang et al. 2021). A further advantage of Al-CNT is its ability to perform at high temperatures. However, AI-CNT has some limitations. It can be observed that there is some instability when it is subjected to higher strain rates and low temperatures.

Silicon Carbide

Silicon Carbide is a composite made of silicon-infiltrated carbon that is used for the manufacture of high-performance ceramics (Tanaka et al. 2001). They are capable of performing well at high temperatures. As an example, brake discs are used in automobiles such as race cars, bicycles, etc. A sintered form of Si–C is also used for diesel particulate filters. In the automotive industry, SiC components have great potential in electric power supplies, especially in high-power ones, and by 2025 they will account for 25% of the power semiconductors used there (Racka-Szmidt et al. 2022). However, the main issue at present is the high cost of these components as well as their limited availability.

Nanofluid

Recently, the word “nanofluid” has attracted the attention of a wide range of scientists and researchers interested in the use of nanofluids to increase the efficiency of thermal systems in automobiles (Hafeez et al. 2021). Nanofluids have the potential to improve the thermophysical properties of conventional fluids such as water and oil that are used to dissipate thermal loads in automobile thermal absorption systems (Hafeez et al. 2021). Recent research has investigated the effects of nanoparticle size, weight, and distribution in coolant on heat transfer rates in the automobile industry. As a result of using nanofluids instead of conventional fluids in systems such as automobile radiators, the thermal conductivity, the heat capacity and the size of the heat transfer area of the fluid can be improved (Shrikhande and Kriplani 2014; Hafeez et al. 2021). There are several carbon-based nanomaterials demonstrating extreme thermal conductivity, including graphene, carbon nanotubes, and carbon quantum dots (Kumar et al. 2022b).

Nano Steel

It is imperative that crash safety and lightweight are addressed as the two major concerns. Nanotechnology can be used to produce a high-strength and lightweight car body material (Madadi et al. 2022). It has been reported that embedded nanoparticles of metallic carbon nitride can significantly increase the strength of steel. It has been found that 0.002 percent finely dispersed carbon can significantly increase the stability of steel over long-term loading by up to 10,000 h. This is due to the small size of carbon nitride, which is between five and ten nanometers in diameter. In the last few years, several third-generation advanced high-strength steels have been proposed and developed, but only two classes are currently in series production by several steel makers: quenching and partitioning and transformation-induced-plasticity assisted bainitic-ferritic steels (Madadi et al. 2022). The production of nano steel on a coil scale has only been achieved recently. Additionally, the 2015 Ford Edge provides an example of an efficient design of nanoscale materials that utilizes a variety of steel grades, which is similar to nano steel in terms of optimizing the performance and mass of the vehicle (Reed 2015). Based on Fig. 3, the material distribution for automobiles is composed of approximately 50% advanced high-strength steels and 20% high-strength steel (Reed 2015; Madadi et al. 2022). Advanced high-strength steels grades used in the Edge include dual-phase, martensitic and hot-stamped steels.

In the 2015 Ford Edge, a variety of steel grade body-in-white is utilized to create an efficient design. Reprint with permission from Ref. Reed (2015)

Applications of Nanotechnology in Automotive

In the field of transportation vehicles, nanotechnology has a wide range of potential applications. Nanomaterials, nanostructures, and nanodevices provide new ways to develop sustainable vehicles. Using nanotechnology, automobile bodies can be protected against corrosion and abrasion. Figure 4 illustrates the impact of and need for nanotechnology applications in transportation vehicles.

In order to accomplish this objective, Shafique and Luo (2019) have identified the most significant factors that have an influence on the performance of transportation vehicles over an extended period of time. Accordingly, Fig. 4 lists those factors. According to them, nanotechnology applications in transportation can be optimized by segmenting them into four groups according to demand and impact upside (Shafique and Luo 2019). It includes the segment “must do”, which consists of the use of more innovative, cost-effective and environmentally friendly nanomaterials for safe and sustainable transportation. The segment “need to do” refers to applications with high impact and demand in the automotive industry (Fig. 5). Among these advancements are the optimization of nanotechnology for lighter weight, the optimization of nanomaterials for self-cleaning and self-healing and the advancement of high-resolution sensors and equipment. Furthermore, “do case-by-case” and “can do” segments could also have a high impact with moderate demand in the transportation industry (Shafique and Luo 2019). It is also important to select multifunctional nanomaterials and optimize nanocomposite insulation in the near future so as to make transportation systems safer and more durable. Furthermore, there is a high demand for the selection of environmentally friendly nanomaterials in transportation since this will result in a more reliable and sustainable environment for the nano-industry.

Impact versus demand for micro-/nano-technology applications in the transportation vehicle industry. Reprint with permission from Ref. Shafique and Luo (2019)

Nanotechnology in Electric Vehicles (EVs)

Due to the global trend of reducing CO2 emissions and fossil fuel consumption, electric vehicles and hybrid vehicles are becoming more popular (Wazeer et al. 2023). As of today, there are more than 25 different EV models available on the global market and more models are expected to be introduced in the near future (Lu et al. 2013). In today’s electric vehicles, lithium-ion batteries are the most suitable energy storage devices because of their attractive properties, which include high energy efficiency, lack of memory effect, long cycle life, high energy density and high power density. Since graphene has a high surface area to volume ratio, stable chemical properties and satisfactory electrical and thermal conductivity, it has been used in lithium-ion batteries (both anode and cathode materials) to improve the performance, rate and stability of LIBs (Chen et al. 2021). The coating of silicon oxide SiO2/C nanoparticles with graphene as anode material for LIBs, demonstrated by Al Ja’farawy et al., improved the cycle life and provided efficient conductive pathways (Al Ja’farawy et al. 2021). The researchers wrapped LiFePO4 (LFP) with 2% graphene and graphene nanoribbons (GNRs) into LFP using spray deposition and vacuum filtration techniques, enabling a conductive network to be formed (Li et al. 2014). According to Kumar et al. (2016c) a derivative of graphene would make an effective anode for LIBs. Figure 6 illustrates a LIB-based electric vehicle with wireless charging (Aghajan-Eshkevari et al. 2022).

Static inductive charging of an electric vehicle. Reprint with permission from Ref. Aghajan-Eshkevari et al. (2022)

The proper design of nanoscale-based materials for new LIBs can enhance the performance of the batteries at the end of life cycle (Dunn et al. 2011). The increase in current density and specific strength is more pronounced than the regular LIB battery in electric vehicles and can result in a significant increase in range owing to their reduced weight. Improved LIB based energy storage devices are possible by incorporating graphene and reducing fabrication times (Li et al. 2014; Chen et al. 2021; Al Ja’farawy et al. 2021). Even though considerable research has been conducted on improving the performance of lithium-ion batteries and graphene-based nanocomposites, the fabrication of these components on an industrial scale needs further improvement.

Nanotechnology in Fuel Cells Vehicles

In the transition from fossil fuel-based vehicles to fully electric and hydrogen-powered vehicles, nanotechnology plays a pivotal role in advanced fuel cell technology. In recent years, the demand for cleaner fuels and energy has increased globally due to a number of factors, such as increased transportation, population growth, and climate change (Karthik Pandiyan and Prabaharan 2020). Thus, alternative sources of energy are becoming increasingly popular and fuel cell technologies are receiving much-needed attention as they can replace internal combustion engines in vehicles due to their high efficiency and low emissions (Karthik Pandiyan and Prabaharan 2020). They can also be used in portable and stationary power applications due to their low emissions. Fuel cells complement other electricity generation technologies (Kang et al. 2006; Karthik Pandiyan and Prabaharan 2020). Fuel cell electric vehicle provide a low-carbon alternative to conventional fuel vehicles when hydrogen gas is produced from renewable sources (Rajalakshmi and Gopalan 2021). In a fuel cell, the chemical energy of a fuel reacts with oxygen from the surrounding environment and the reduction and oxidation reactions occurring in the electrodes separated by a membrane generates electricity (). Unlike batteries, they require a constant supply of oxygen and fuel to maintain a chemical reaction. The automobile industry could potentially store hydrogen in a semi-solid state for storing more hydrogen as compared to hydrogen tanks that are used today (more distance travel) (Qian et al. 2006; Li et al. 2015). The use of nanotechnology and low platinum group metal with carbon nanomaterials will enable this to be achieved (Karthik Pandiyan and Prabaharan 2020; Xiao et al. 2022). Fuel cells infused with nanoparticles may offer an efficient and more affordable method for the manufacture of hydrogen-powered vehicles.

Nanotechnology for Chassis and Tires

A primary concern of automobile manufacturers is the reduction of overall automobile weight. By reducing the weight of the automobile, fuel consumption and emissions are reduced (Wellbrock et al. 2020). Through the incorporation of nanoparticles or the control of structure at the nanoscale, nanotechnologies can allow materials to be lighter and more abrasion resistant with good grip (Agarwal et al. 2021). It is possible to achieve the same mechanical strength with less and lighter material while enhancing performance. Silica, organosilane and soot are found to improve the properties of natural rubber in a significant manner. Silica and soot are the most important chemical ingredients used in tire reinforcement (Na and Cebon 2022). It was carbon black that was the first nanomaterial to be used in tires as a pigment and reinforcement material (Agarwal et al. 2021). One-third of the cover is composed of reinforcing filler, which provides desired properties such as abrasion resistance, grip, tear resistance and low rolling resistance (Na and Cebon 2022). These tire properties, which partially contradict each other in terms of reducing the rolling resistance and comparable wet grip, are primarily caused by the chemical and physical interactions between the rubber and the filler. It is possible to increase the fuel efficiency and durability of tires by using nanostructured soot as filler. The presence of nanoparticles results in an increase in surface energy, which in turn increases the interaction with the molecules of natural rubber (Mohan et al. 2012). Consequently, inner friction is reduced and the rolling resistance is improved. As a result, strain vibrations within the material at high speeds are reduced (Formela et al. 2017; Neethirajan et al. 2022). This results in superior traction, particularly on wet roads. It is becoming increasingly important to reduce the weight of the engine/chassis in order to reduce fuel consumption and emissions of harmful exhaust fumes. Through the incorporation of nanoparticles or by controlling chassis structure at the nanoscale, nanotechnology offers solutions in terms of lighter and better materials (Paduvilan et al. 2021). In this regard, polymers reinforced with nano clays play an important role (Mohan et al. 2012; Paduvilan et al. 2021). It is sufficient to add a small amount of nanoparticles, about 2–5%, to achieve significant improvements in properties such as resistance, elasticity, and dimensional stability, as well as specific properties like fire resistance in interior parts and weather resistance in exterior parts. In the future, nanotechnology will play an important role in the chassis and tires of automobiles, as shown in Fig. 7 (Presting and König 2003).

Nanotechnology will play an important role in the chassis and tires of future automobiles. Reprint with permission from Ref. Presting and König (2003)

Scratch and Wear Resistance Paint

Nanomaterials are applied to vehicle bodies in the form of nanosized layers applied over vulnerable surfaces so that they can combat harsh environmental conditions and promote self-repair. The nanomaterials prevent, or rather repel, dirt and grime, resulting in a cleaner appearance for the vehicle without the need for much manual intervention. Nano-varnishes that offer scratch resistance and maintain paint brilliance for a long period of time are now available (de Queiroz et al. 2022). It is possible to achieve this property due to the embedded ceramic particles in the final varnish layer. A conventional paint consists of a binder and cross-linking agent, while a nano paint is composed of an organic binder with high elasticity and an inorganic nanoparticle with high strength. In order to make the paint scratch-resistant, nanomaterials are tightly packed. An illustration of the conventional and nano paint structures can be found in Fig. 8a, b (de Queiroz et al. 2022).

The structural differences between conventional paint and nano paint, as well as the thickness of the films that are formed after the paint is applied. Reprint with permission from Ref. de Queiroz et al. (2022)

Modern cars process a large amount of glass, the majority of which is used in the windscreens and window panes. Due to the small size of nanomaterials and even distribution of the filler particles, the glass can be highly transparent. Currently, new developments are happening on the topic of orientable surface particles that will enable owners to change the outer color of the paintwork by controlling the electrical charge (de Queiroz et al. 2022).

Nanostructured Coatings

The most widely used nanotechnology in automotive engineering involves the application of nanocoating to improve the surface characteristics of materials and parts for the automobile industry (Farooq et al. 2022). Incorporating nanoparticles into polymer coatings improves scratch resistance as well as wear resistance from repeated friction (Farooq et al. 2022). The addition of nanoscale SiO2 to polymer coatings has been well established; however, SiC, ZrO2, ZnO, Al2O3, and TiO2 have also been used in this way.

Ultra-Thin Layers for Mirrors and Reflectors

In recent years, ultra-reflecting layers with thicknesses less than 100 nm have been developed for mirrors and headlights. In addition, nanotechnology applications are used to equip surfaces with features that repel water, oil and dirt. This layer offers good dynamic friction properties and, as a result, is more durable. A layer of this nature consists of molecular chains with an anchor group at one end that forms a chemical bond on the surface of the substrate. In addition, at the other end, a functional group is responsible for causing the water, oil, and dirt to be repelled. During the day and at night, thin-film reflective mirrors reduce glare from sunlight and other vehicles’ headlights. A thin film of Al2O3, deposited by chemical vapor deposition (CVD) can provide a water- and dust-resistant surface for windows and mirrors.

Micro-/Nano-technologies for Automotive Sensors

Sensors based on micro- or nanotechnology are typically small, have a high bandwidth, and are extremely sensitive, and can therefore be used directly to measure desired force from the road on a wheel rather than inferring data through indirect measurements (Walther et al. 2018). Controlling the interface between the micro- and nano-systems and/or between the nanoscale device and the microscale packaging is the key to maximizing the capabilities of micro- and nano-systems (Walther et al. 2018). Device performance and processing and integration costs are largely determined by these interfaces. In light of various types of sensors employed in various applications, the effect of probe dimensions on sensing performance is discussed (Walther et al. 2018; Kim et al. 2021). Research has made possible the fabrication of submicron and nanoscale devices through the modification of conventional techniques and the development of modern approaches. Nevertheless, it remains a challenge in certain situations to manufacture such high-performance surfaces with the desired topology (Paladiya and Kiani 2018). A modern, inexpensive laser ablation method for fabricating porous and fibrous thin-films primarily for silicon is discussed, as well as the effect of various control parameters on the topology of porous silicon surfaces, as well as the theoretical limitations regarding the minimum diameter of nanofibers used in sensing applications. Furthermore, another sensor-based device is micro-electro-mechanical systems (MEMS), which is the integration of mechanical elements, sensors, actuators, and electronics on a common silicon substrate through microfabrication technology. MEMS promises to revolutionize nearly every product category by bringing together silicon-based microelectronics with micromachining technology, making possible the realization of complete systems-on-a-chip. MEMS is an micro/nano technology concept base deices, which are allowing the development of smart products in automotive industry.

The Following are Other Potential Applications of Nanotechnology in the Automobile Industry

-

Nanotechnology under the hood

-

Engine and transmission nanotechnology

-

Durability of the engine

-

The use of nanomaterials in engine coolants has been reported

-

Reduced engine size and increase compression ratio

-

Cost of coolant in relation to fuel efficiency

-

The application of nanotechnology to engines and transmissions

Nanotechnology Goals in Automotive Industry

Goals for the application of nanotechnology in automobiles are:

Environment

-

Resource efficiency

-

Catalysts

-

Fuel cells

-

Sensors

-

Lithium-ion rechargeable battery

Comfort

-

Product quality

-

Ease of operation

-

Passenger convenience

Safety

-

Active and passive safety

-

No environmental impact on nature

-

Nontoxic to humans and animals

-

Easy to degrade and use to design new parts

-

Easy maintenance

Future Prospective Research on Nanotechnology in Automobile Industry

Nanotechnology exhibits several attractive properties for a safer and more sustainable vehicle industry. However, there are still research gaps and opportunities for future research. In this section, we list the most important research gaps and future directions in the field of nanotechnology in the automobile industry. As shown in Fig. 9, there are six major research gaps that require attention for future applications. The potential for interdisciplinary collaboration in advancing nanotechnology applications in automotive design and manufacturing could be a more value-added product and a circular economy for our nation (i.e. India). Developing high-performance multifunctional nanomaterials, such as carbon nanotubes, carbon nanofibers, graphene, and metal oxide nanowires, allows for the creation of more efficient energy storage devices, batteries, fuel cell vehicles, and high-strength engine materials. The advancement of this nanotechnology has enabled electric vehicles to extend their range, making them a viable and sustainable alternative to conventional combustion engines.

Summary and Conclusions

Nanotechnology is becoming one of the most important and cost-effective fields of research in the automotive industry, especially since scientists are constantly finding new ways to manipulate nanomaterials and apply these new materials in production. Nanotech is predicted to create cleaner, quieter, more energy-effective and aesthetically pleasing vehicles in the future, so everyone from everyday drivers to automotive scientists, aficionados, collectors and investors have something to look forward to in the years in front of us.

Researchers are presented with a wide array of opportunities in the application of nanotechnology to vehicles. The introduction of nanotechnology to the transportation industry will enable us to improve the efficiency, strength, and durability of vehicles. In this paper, we review the literature regarding enhancements in transportation vehicles that have been achieved by introducing nanotechnology, as well as the associated concerns regarding environmental health and safety for future large-scale applications of nanotechnology in the automobile industry. Various nanomaterials like graphene, carbon nanotubes, ceramic nanoparticles (ZnO, TiO2, SiO2, etc.) and carbon black are used in the automotive industry to enhance paint coatings, engines, body parts, mirrors, tires, etc. Moreover, nanomaterials can enhance strength, light weight, flame and fire resistance, as well as the UV resistance of aerospace materials. Furthermore, nanomaterial coatings are capable of reducing corrosion and fouling in ships. There are many factors that remain unknown despite the many great features associated with nanotechnology applications, such as the exact mechanisms through which nanomaterials achieve these results. As nanomaterials are new products in the transportation vehicle industry, it is essential to understand their potential impacts on air, soil, and water. Multidisciplinary research cooperation and collaboration are imperative for dealing with environmental challenges. More in-depth research is needed on environmentally friendly nanotechnology. A future study could focus on the adoption of environmentally friendly nanotechnology in a variety of industries. In order to accomplish this goal, it is necessary to consider the multiple aspects of nanotechnology applications in the real world. It would be beneficial for communities to identify which nanotechnology applications are environmentally friendly and safe for future development if an honest analysis of the nanotechnology application methodologies, services, and environmental impact could be conducted. In addition, there is no regulatory framework pertaining to the use of nanotechnology in the workplace. A very limited amount of knowledge is also available about the long-term effects of nanotechnology products in a variety of fields in real-world applications. Developing an understanding of how nanomaterials affect multiple scenarios is crucial. Our goal is to ensure safe and sustainable applications of nanotechnology in the automotive industry through the development of an effective impact assessment system. Based on the findings of this review study, we expect that future research on the topic will be encouraged.

References

Agarwal AK, Singh AP, Thipse SS, Goswami G (2021) A review on energy, environment, and emissions issues in Indian road transport sector. Trans Indian Natl Acad Eng 6:595–611. https://doi.org/10.1007/s41403-021-00232-z

Aghajan-Eshkevari S, Azad S, Nazari-Heris M et al (2022) Charging and discharging of electric vehicles in power systems: an updated and detailed review of methods, control structures, objectives, and optimization methodologies. Sustainability (switzerland) 14:2137

Al Ja’farawy MS, Hikmah DN, Riyadi U et al (2021) A review: the development of SiO2/C anode materials for lithium-ion batteries. J Electron Mater 50:6667–6687

Bhooshan Kumar V, Gouda L, Porat Z, Gedanken A (2016) Sonochemical synthesis of CH3NH3PbI3 perovskite ultrafine nanocrystal sensitizers for solar energy applications. Ultrason Sonochem 32:54–59. https://doi.org/10.1016/j.ultsonch.2016.02.012

Chen Y, Kang Y, Zhao Y et al (2021) A review of lithium-ion battery safety concerns: the issues, strategies, and testing standards. J Energy Chem 59:83–99

de Queiroz MN, de Oliveira Lima AM, Winkler MEG et al (2022) Conductive nanopaints: a remarkable coating. In: Nanotechnology in the automotive industry. Elsevier, London, pp 429–449

De Volder MFL, Tawfick SH, Baughman RH, Hart AJ (2013) Carbon nanotubes: present and future commercial applications. Science 339:535–539. https://doi.org/10.1126/science.1222453

Dericiler K, Aliyeva N, Mohammadjafari Sadeghi H et al (2022) Graphene in automotive parts. In: Nanotechnology in the automotive industry. Elsevier, London, pp 623–651

Dunn B, Kamath H, Tarascon J-M (2011) Electrical energy storage for the grid: a battery of choices system power ratings, module size. Science 334:928

Farooq SA, Raina A, Mohan S et al (2022) Nanostructured coatings: review on processing techniques corrosion behaviour and tribological performance. Nanomaterials 12:1323

Formela K, Hejna A, Zedler Ł et al (2017) Structural, thermal and physico-mechanical properties of polyurethane/brewers’ spent grain composite foams modified with ground tire rubber. Ind Crops Prod 108:844–852. https://doi.org/10.1016/j.indcrop.2017.07.047

Fuhrer MS, Lau CN, MacDonald AH (2010) Graphene: materially better carbon. MRS Bull 35:289–295. https://doi.org/10.1557/mrs2010.551

Geim AK, Novoselov KS (2007) The rise of graphene. Nat Mater 6:183–191. https://doi.org/10.1038/nmat1849

Goyal R, Sharma M, Kumar Amberiya U (2014) Innovative nano composite materials and applications in automobiles. Int J Eng Res Technol 3:3001–3009

Hafeez MB, Amin R, Nisar KS et al (2021) Heat transfer enhancement through nanofluids with applications in automobile radiator. Case Stud Therm Eng. https://doi.org/10.1016/j.csite.2021.101192

Kang SJ, Lee JY, Lee JK et al (2006) Influence of Bi modification of Pt anode catalyst in direct formic acid fuel cells. J Phys Chem B 110:7270–7274

Karthik Pandiyan G, Prabaharan T (2020) Implementation of nanotechnology in fuel cells. In: Materials today: proceedings. Elsevier, London, pp 2681–2685

Kim I, Martins RJ, Jang J et al (2021) Nanophotonics for light detection and ranging technology. Nat Nanotechnol 16:508–524

Kumar VB, Mohanta D (2011) Formation of nanoscale tungsten oxide structures and colouration characteristics. Bull Mater Sci 34:435–442. https://doi.org/10.1007/s12034-011-0117-1

Kumar VB, Kar KK, Paik P (2011) Advanced functional polymers nanoparticles and its composites: synthesis and applications. Research Publishing Services, Singapore, pp 1–34. ISBN number: 978-981-08-3711-2

Kumar KS, Kumar VB, Paik P (2013) Recent advancement in functional core-shell nanoparticles of polymers: synthesis, physical properties, and applications in medical biotechnology. J Nanoparticles 2013:1–24. https://doi.org/10.1155/2013/672059

Kumar VB, Pulidindi IN, Gedanken A (2015) Selective conversion of starch to glucose using carbon based solid acid catalyst. Renew Energy 78:141–145. https://doi.org/10.1016/j.renene.2014.12.070

Kumar VB, Medhi H, Yong Z, Paik P (2016a) Designing idiosyncratic hmPCL-siRNA nanoformulated capsules for silencing and cancer therapy. Nanomedicine. https://doi.org/10.1016/j.nano.2015.10.007

Kumar VB, Mishra RK, Pulidindi IN et al (2016b) Preparation and catalytic activity of thermosensitive Ga2O3 Nanorods. Energy Fuels 30:7419–7427. https://doi.org/10.1021/acs.energyfuels.6b01568

Kumar VB, Pol V, Tang J et al (2016c) In situ sonochemical synthesis of luminescent Sn@C-dots and hybrid Sn@C-dots@Sn anode for lithium-ion batteries. RSC Adv 6:66256–66265. https://doi.org/10.1039/C6RA09926B

Kumar VB, Sanetuntikul J, Ganesan P et al (2016d) Sonochemical formation of Ga–Pt intermetallic nanoparticles embedded in graphene and its potential use as an electrocatalyst. Electrochim Acta 190:659–667. https://doi.org/10.1016/j.electacta.2015.12.193

Kumar VB, Perkas N, Porat Z, Gedanken A (2017a) Solar-light-driven photocatalytic activity of novel Sn@C-dots-modified TiO2 catalyst. ChemistrySelect 2:6683–6688. https://doi.org/10.1002/slct.201701375

Kumar VB, Sahu AK, Mohsin ASM et al (2017b) Refractive-index tuning of highly fluorescent carbon dots. ACS Appl Mater Interfaces 9:28930–28938. https://doi.org/10.1021/acsami.7b08985

Kumar VB, Kumar R, Gedanken A, Shefi O (2019) Fluorescent metal-doped carbon dots for neuronal manipulations. Ultrason Sonochem 52:205–213. https://doi.org/10.1016/j.ultsonch.2018.11.017

Kumar VB, Porat Z, Gedanken A (2022a) Synthesis of doped/hybrid carbon dots and their biomedical application. Nanomaterials 12:898

Kumar VB, Sahu AK, Bhanu K, Rao S (2022b) Development of doped carbon quantum dot-based nanomaterials for lubricant additive applications. Lubricants 10:144

Kumar VB, Gedanken A, Porat Z (2023) Sonochemistry of molten gallium. Ultrason Sonochem 95:106364. https://doi.org/10.1016/j.ultsonch.2023.106364

Leach F, Kalghatgi G, Stone R, Miles P (2020) The scope for improving the efficiency and environmental impact of internal combustion engines. Transp Eng 1:100005

Li X, Li T, Zhang Y et al (2014) Graphene nanoribbon-wrapping LiFePO4 by electrostatic absorbing with improved electrochemical performance for rechargeable lithium batteries. Electrochim Acta 139:69–75. https://doi.org/10.1016/j.electacta.2014.06.157

Li Q, Wen X, Wu G et al (2015) High-activity PtRuPd/C catalyst for direct dimethyl ether fuel cells. Angew Chem 127:7634–7638

Lu L, Han X, Li J et al (2013) A review on the key issues for lithium-ion battery management in electric vehicles. J Power Sources 226:272–288. https://doi.org/10.1016/j.jpowsour.2012.10.060

Madadi M, Yeganeh M, Eskandari M (2022) Nano-steels in the automotive industry. In: Nanotechnology in the automotive industry. Elsevier, London, pp 287–313

Malik S, Muhammad K, Waheed Y (2023) Nanotechnology: a revolution in modern industry. Molecules 28:661

Manu A, Gupta MK (2020) Application of nanomaterials in automobile industry. Appl Innovative Res 2:107–113

Masias A, Marcicki J, Paxton WA (2021) Opportunities and challenges of lithium ion batteries in automotive applications. ACS Energy Lett 6:621–630

Mathew J, Joy J, George SC (2019) Potential applications of nanotechnology in transportation: a review. J King Saud Univ Sci 31:586–594

Mohammad ZH, Ahmad F, Ibrahim SA, Zaidi S (2022) Application of nanotechnology in different aspects of the food industry. Discov Food 2:12

Mohan TP, Kuriakose J, Kanny K (2012) Water uptake and mechanical properties of natural rubber–styrene butadine rubber (nr–sr)—nanoclay composites. J Ind Eng Chem 18:979–985. https://doi.org/10.1016/j.jiec.2011.10.010

Na X, Cebon D (2022) Quantifying fuel-saving benefit of low-rolling-resistance tyres from heavy goods vehicle in-service operations. Transp Res D Transp Environ. https://doi.org/10.1016/j.trd.2022.103501

Neethirajan J, Parathodika AR, Hu G-H, Naskar K (2022) Functional rubber composites based on silica-silane reinforcement for green tire application: the state of the art. Funct Compos Mater. https://doi.org/10.1186/s42252-022-00035-7

Omietimi HB, Afolalu SA, Kayode JF et al (2023) An overview of nanotechnology and its application. In: E3S web of conferences. EDP Sciences

Paduvilan JK, Velayudhan P, Amanulla A et al (2021) Assessment of graphene oxide and nanoclay based hybrid filler in chlorobutyl-natural rubber blend for advanced gas barrier applications. Nanomaterials. https://doi.org/10.3390/nano11051098

Paladiya C, Kiani A (2018) Nano structured sensing surface: significance in sensor fabrication. Sens Actuators B Chem 268:494–511

Pokrajac L, Abbas A, Chrzanowski W et al (2021) Nanotechnology for a sustainable future: addressing global challenges with the international network4sustainable nanotechnology. ACS Nano 15:18608–18623. https://doi.org/10.1021/acsnano.1c10919

Presting H, König U (2003) Future nanotechnology developments for automotive applications. Mater Sci Eng C 23:737–741. https://doi.org/10.1016/j.msec.2003.09.120

Qian W, Wilkinson DP, Shen J et al (2006) Architecture for portable direct liquid fuel cells. J Power Sources 154:202–213

Racka-Szmidt K, Stonio B, Żelazko J et al (2022) A review: inductively coupled plasma reactive ion etching of silicon carbide. Materials 15:123

Rajalakshmi N, Gopalan R (2021) Recent trends in science and technology of hydrogen and polymer electrolyte membrane fuel cells. Trans Indian Natl Acad Eng 6:189–218. https://doi.org/10.1007/s41403-021-00206-1

Reed J (2015) Advanced High-Strength Steel Technologies in the 2015 Ford Edge

Ricci F, Dietz H (2023) The harmony of form and function in DNA nanotechnology. Nat Nanotechnol 18:541–542

Rodríguez-Sevilla P, Prorok K, Bednarkiewicz A et al (2018) Optical forces at the nanoscale: size and electrostatic effects. Nano Lett 18:602–609. https://doi.org/10.1021/acs.nanolett.7b04804

Sadiku ER, Agboola O, Agboola O et al (2018) Nanotechnology in paints and coatings. In: Advanced coating materials. Wiley, London, pp 175–233

Shafique M, Luo X (2019) Nanotechnology in transportation vehicles: an overview of its applications, environmental, health and safety concerns. Materials 12:2493

Shrikhande NS, Kriplani VM (2014) Heat transfer enhancement in automobile radiator using nanofluids: a review. Int J Eng Res Technol 3:174–177

Stankovich S, Dikin DA, Dommett GHB et al (2006) Graphene-based composite materials. Nature 442:282–286. https://doi.org/10.1038/nature04969

Tanaka S, Rajanna K, Abe T, Esashi M (2001) Deep reactive ion etching of silicon carbide. J Vac Sci Technol B Microelectron Nanometer Struct Process Meas Phenom 19:2173–2176. https://doi.org/10.1116/1.1418401

Tomar S (2012) Innovative nanotechnology applications in automobiles. Int J Eng Res Technol 1:1–5

van Vuuren DP, Stehfest E, Gernaat DEHJ et al (2017) Energy, land-use and greenhouse gas emissions trajectories under a green growth paradigm. Glob Environ Chang 42:237–250. https://doi.org/10.1016/j.gloenvcha.2016.05.008

Walther DC, Lin L, Pisano AP et al (2018) Micro-and nano-technologies for automotive sensor research. https://doi.org/10.4271/2007-01-1012. ISSN: 0148-7191, e-ISSN: 2688-3627

Wang X, Shi G (2015) An introduction to the chemistry of graphene. Phys Chem Chem Phys 17:28484–28504. https://doi.org/10.1039/c5cp05212b

Wang QH, Strano MS (2013) Carbon nanotubes a bright future for defects. Nat Publ Group 5:812–813. https://doi.org/10.1038/nchem.1768

Wazeer A, Das A, Abeykoon C et al (2023) Composites for electric vehicles and automotive sector: a review. Green Energy Intell Transp 2:100043

Wellbrock W, Ludin D, Röhrle L, Gerstlberger W (2020) Sustainability in the automotive industry, importance of and impact on automobile interior—insights from an empirical survey. Int J Corp Soc Responsib. https://doi.org/10.1186/s40991-020-00057-z

Wu J, Pisula W, Müllen K (2007) Graphenes as potential material for electronics. Chem Rev 107:718–747

Xiao F, Wang Y, Xu GL et al (2022) Fe–N–C boosts the stability of supported platinum nanoparticles for fuel cells. J Am Chem Soc 144:20372–20384. https://doi.org/10.1021/jacs.2c08305

Zhang S, Chen G, Qu T et al (2021) A novel aluminum–carbon nanotubes nanocomposite with doubled strength and preserved electrical conductivity. Nano Res 14:2776–2782. https://doi.org/10.1007/s12274-021-3284-4

Acknowledgements

The author would like to thank Advanced Engineering and Product Development teams at Ashok Leyland, Chennai, India.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

No conflict of interest has been declared by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Subramanian, K., Kumar, V.B. Micro-/Nano-technology in the Automotive Industry: A Review. Trans Indian Natl. Acad. Eng. 9, 323–334 (2024). https://doi.org/10.1007/s41403-024-00476-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41403-024-00476-5