Abstract

The present study introduces an eco-friendly approach to repurpose waste from the paper and wood industry as a construction material. The method involves a unique combination of lignosulfonate (LS) and fly ash (FA) to address the limitations of using fly ash / lignosulfonate as a stand-alone stabilizer for expansive soil. Two synthetic soils, namely, Soil A (20% bentonite and 80% sand, by weight) and Soil B (20% bentonite and 80% fly ash, by weight) were chosen to represent the soil of high plasticity. A different dosages of calcium LS (1–3%, in the interval of 1%) was mixed with synthetic soils to understand the efficacy of LS and FA in stabilising montmorillonite-based clay soils. Several geotechnical properties of untreated and treated swelling clays, including plasticity, swelling pressure, consolidation parameters, and unconfined compressive strength were examined followed by microstructural studies. The results conclude that the combination of FA and LS has significantly improved the geotechnical properties of swelling clays and is quite effective compared to lignosulfonate and fly ash as a standalone stabilizer. Moreover, the presence of fly ash has reduced the lignosulfonate requirement to stabilize the swelling clays.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The volumetric instability of expansive soils owing to the sensitive nature of clay minerals to moisture variation has been recognized as a global issue. In particular, the presence of montmorillonite significantly enhances the ability of soil to retain moisture but could cause significant swelling. The subsequent moisture evaporation induces considerable shrinkage, causing severe damage to overlying structures and leading to great financial loss. The swelling of expansive soils can cause distress to foundations, walls, and floors of buildings. Additionally, the shrinkage of expansive soils can cause cracking to the pavements and other structures, leading to continuous repairs and maintenance [1, 2]. Pavements, canals, and other lightweight structures are more susceptible to such damage. Moreover, the damage caused by expansive soils is not only limited to buildings and infrastructure but also have significant impacts on the environment. For example, the swelling of soils can cause landslides, erosion, and other natural hazards, while the shrinking of soils can lead to cracking of the soil surface, making it difficult for vegetation to grow and potentially leading to desertification [3]. The simultaneous occurrence of swelling and shrinkage process can lead to structural damage and even collapse if not addressed in a timely manner. Moreover, in worldwide, the damages incurred by the swell-shrink response of expansive soils is significantly higher than the damages caused by natural calamities like earthquakes, floods, hurricanes, etc [4].

In the past few decades, various physical and chemical stabilization methods have been proposed to counter the damages incurred by expansive soils. Replacing problematic soils with non-expansive soil, prewetting the soil before construction, and laying horizontal and vertical moisture control barriers are some of the physical methods that have been widely implemented in the field [5, 6]. Alternatively, traditional chemical admixtures such as hydrated lime and Portland cement have been proven efficient in reducing the swell potential and increasing the mechanical strength of soils through various research studies [7,8,9,10,11,12,13,14]. Despite its remarkable benefits in stabilizing expansive soil, applying these pozzolanic materials in the field has few detrimental effects. The energy required in the production of these materials, increased solubility due to increased pH levels in stabilized soils, and lime leaching have an adverse impact on the environment causing serious problems [15,16,17,18]. Recently, industrial by-products such as fly ash (FA), ground granulated blast furnace slag, cement kiln dust, lime kiln dust, and coal ash have also been studied extensively for expansive soil stabilization [19,20,21,22,23]. Phanikumar and Sharma [24] focused on the improvement of expansive soils in terms of free swell index, swell potential, swelling pressure, plasticity, compaction, strength, and hydraulic conductivity with different proportion of FA. Nalbantoglu [25] mentioned that with the addition of optimum dosage of FA, there is a reduction in swell potential, clay particles, plasticity, and CEC (cation exchange capacity) of expansive soils. The reduced CEC suggest that the treatment with FA alters the mineralogy of the treated soils, leading to the formation of new secondary reaction minerals. Volume change behaviour of bentonite with different proportion of FA was examined by Pal and Ghosh [26]. The use of FA to stabilize soil with high sulphate and high plasticity soils works better than cement and lime. Zha et al. [27] compared the performance of combined effect of fly ash and lime stabilization of expansive soil. With the increase in the dosage of fly ash and lime-fly ash, there is a reduction in the plasticity index, free swell, swell potential, swelling pressure, axial shrinkage percentage, optimum water content and the maximum dry unit weight. Additionally, as the curing time for the treated soil increases, swell potential and swelling pressure continue to decline but with increased unconfined compressive strength. Saride et al. [28] studied the effect of lime of on the swell-shrink behavior of clay soils. Jallu and Saride [29] explored the alkali-activation response of FA in reclaimed asphalt pavement, finding that 28-day cured samples were durable against wetting-drying cycles. Mypati et al. [30] investigated the impact of deep mixing FA-geopolymer binder on expansive soils. SEM images revealed that the layered structure of expansive soils disappeared when reacting with alkali-activated fly ash stabilized soils.

In parallel, the development and application of non-traditional chemical admixtures (polymer, enzyme, lignin, ionic compound, salt) for stabilizing expansive soil has gathered attention among researchers. Biopolymers class of non-traditional stabilizer is an organic polymer having many constituents as polysaccharides, made from available crops. Dagliya et al. [31] used biopolymers focussing on stabilization with the help of hydrophillic part of the compound. One of such material is lignosulfonate (LS), which is a lignin-based organic compound extracted as a by-product of the paper industry. Around 50 million tonnes of LS are generated annually from the wood and paper industries [32, 33]. Based on the manufacturing unit, it can be obtained as a bio-based compound that is primarily calcium, magnesium, or aluminium. It is an anionic surfactant composed of multiple hydroxyl methyl ether functions that form a three-dimensional structure. The utilisation of LS in enhancing the geotechnical properties of soils, like, silty sand, silt clayey soil, and low-plastic clays is fairly established by several researchers but the potential usage of LS as an expansive soil stabilizer is not explored adequately [18, 33,34,35,36,37,38,39,40,41]. Alazigha et al. [34] conducted swelling and durability tests to assess the performance of LS in stabilizing expansive soils. A considerable reduction in swell was observed for LS-treated soils at an optimum dosage of 2%. Also, the addition of LS did not alter the pH level of the soil, which was one of the major limitations of cement and lime stabilization. Moreover, LS stabilization is dependent on intermolecular interaction rather than chemical reaction as compared to traditional stabilisers. Ta’negonbadi and Noorzad [43] investigated the effect of LS on compaction and mechanical strength properties of highly plastic clays. It was reported that by treating soil with 0.75% LS has decreased the liquid limit by 29% and increased the unconfined compressive strength by 44%. However, exceeding 0.75% dosage of LS has increased the liquid limit and decreased unconfined compressive strength. Notably, some researchers observed a reduction in Atterberg limit and swell properties till optimum dosage of LS, while no significant changes beyond the optimal dosage [18, 44, 45]. Hence, there is a need to explore the reasons for such disparity in the characteristics of LS stabilised expansive soils.

Although FA has been proven to mitigate the swelling of soils, the FS treated soils may not provide the adequate strength required for geostructures, hence, there is a need to introduce other chemical stabiliser to address this issue. This made researchers to blend FA with lime and/or cement in improving the strength characteristics of expansive soils. However, the brittle mechanical response and the geoenvironmental issues associated with traditional stabilisers has made researchers to explore alternate combinations. As noticed from the literature, the LS stabilised expansive soil possesses high strength with enhanced ductility characteristics, which made, few researchers to utilise the benefit of FA and LS in enhancing the characteristics of expansive soils. In parallel, the beneficial effect of combined action of FA and LS in engineered cementitious composite (ECC) and cement concrete is gaining attention. Atmajayanti et al. [35] observed that the 7-day compressive strength of FS based ECC has increased by 20% with the inclusion of LS (2%) but with negligible changes in the tensile strength. Moreover, at higher LS content, the beneficial influence of LS in reducing the drying shrinkage gradually decreased, hence optimum LS dosage needs to be estimated accurately. Lekha et al. [38] explored the combined effect of FA and LS in stabilising expansive soils. It was reported that the index and engineering properties of the expansive soils have improved significantly with the addition of LS and FA when compared to standalone stabilisers. A similar response was noticed for expansive soils treated with LS and lime [37]. It is interesting to note that the enhancement is better at longer curing period but the reasoning for such responses is not adequately understood. Possibly, addition of LS and FA with expansive soil binds the soil matrix with complex cementitious and organic compound interaction leading to changes in the physicochemical and colloidal processes, which could enhance the soil properties.

From the review of literature, it can be noticed that the effectiveness of FA and LS in improving the characterises of expansive soils was explored by several researchers but the efficacy of combined effect of FA and LS in enhancing the response of expansive soil yet to be understood in terms of improvement and the stabilisation mechanism. The addition of FA to expansive soil increases the silt size fractions. However, LS alone does not provide cementitious bonding to the soil due to the absence of pozzolanic compounds. A combination of FA and LS can stabilize clay fractions or clay minerals present in the soil, similar to the studies attempted by Lekha [38] and Ijaz [37]. Also, the blend of FA and LS would not only utilize industrial by-products but also reduces the amount of FA required for soil stabilization. Hence in the present study, an attempt is made to investigate the effectiveness of the use of FA–LS blends to improve the engineering properties of swelling clays. As the clay content and the clay mineral present in the expansive soil dictate the engineering response and stabilisation mechanism, in the present study, montmorillonite present in the sodium bentonite was chosen as primary clay mineral. A different dosages of calcium LS was mixed with synthetic soils, namely, Soil A (20% bentonite and 80% sand, by weight) and Soil B (20% bentonite and 80% fly ash, by weight) to understand the efficacy of LS and FA in stabilising montmorillonite-based clay soils. Several geotechnical properties of untreated and treated synthetic soils, including plasticity, swelling pressure, consolidation parameters, and unconfined compressive strength were examined followed by microstructural studies.

Materials Used and Methodology

Preparation of Swelling Clays

Two synthetic swelling clays (Soil A and Soil B) were prepared in the laboratory by mixing bentonite (B) with sand (S) or fly ash in definite proportions. The mix proportions of bentonite and fly ash/sand were chosen based on the liquid limit, plasticity index, free swell index, and swell potential. The synthetic soil made of 20% bentonite with 80% fly ash/sand, by weight, is sufficient to make the soil mixes represent the soil with high compressibility/plasticity. The behavior of chosen synthetic soils has been addressed by various researchers and for various applications but the effectiveness of LS in reducing the expansive nature is not yet completely understood [24, 46,47,48,49,50,51]. In most of the listed references, the synthetic soil made of 20% bentonite with 80% fly ash/sand were chosen as materials representing clayey soils (for landfill liner materials). The expansive nature of the synthetic mix is primarily because of the montmorillonite clay mineral present in the sodium bentonite. In the present study, a commercially available sodium bentonite having a primary clay mineral of montmorillonite was used for the preparation of swelling clay. The uniformly graded fine sand (S) of size between 0.212 mm and 0.425 mm (425 μm passed and 212 μm retained) was chosen as an inert material. Class C grade fly ash (FA), passing through 1 mm sieve was used in the study. The grain size distribution of soils was determined as per ASTM D422-63 [52]. The clay size fractions in both soils remain the same, whereas silt and sand contents vary. The Atterberg limits of the soils were determined as per ASTM D4318-17e1 [53]. As the chosen synthetic soil comprises of 20% bentonite, a free swell index test was performed. 10 g oven dry soil samples were poured in two 100 ml graduated cylinders, in which one cylinder is filled with kerosene oil and the other with distilled water. The initial and the equilibrium volume in the two cylinders are measured. The free swell index is defined as the ratio of the difference in the volume of the samples in distilled water and kerosene to volume of the sample in kerosene. Table 1 provides the summary of the test results of untreated soils. As per Indian classification, IS 1498 (1970) [54] of expansive soils, the synthetic soils have medium to high degree of expansion, while according to USCS classification system soil A and soil B are classified as SC with high plasticity. The medium to high swelling and higher plasticity is possibly because of the presence of sodium bentonite (20%, by weight).

Ca-LS Treated Swelling Clays

Lignosulfonate is available in three different cations: Ca, Na, and Mg, of which, calcium-based lignosulfonate (Ca-LS) is chosen in the present study. The reason is attributed to high cation charge (divalent) of calcium as compared to monovalent ions of sodium and potassium lignosulfonate. The lignosulfonate solutions were prepared by mixing different mass percentages of Ca-LS with the required amount of deionized (DI) water. The solution was stirred mechanically to completely dissolve Ca-LS in DI water and make it into a homogeneous mixture. The treated specimens were prepared by mixing Ca-LS: DI water solution with oven-dried soil at varying mass percentages of 1%, 2%, and 3%.

Laboratory Tests

The index properties of the stabilised soils were determined by preparing the soil sample of a required size and allowed the sample to cure. After the curing period, samples were crushed by a mechanical crusher and sieved as per the test protocol. Atterberg limits, grain size distribution (using wet-sieve analysis and sedimentation analysis), compaction behaviour of treated samples was determined from the cured soil mixture. However, swell-consolidation and strength tests were done on treated cured samples directly without crushing and recompacting it. This was done to avoid irregularities in the engineering response as recompacting the soils could change the volumetric and mechanical responses.

Atterberg limit tests were conducted on swelling clays treated with different percentages of LS solutions. Oven dried soil was mixed with a predetermined quantity of LS: DI water solution to make a uniform paste of treated soils. These mixtures were allowed to attain moisture equilibrium by curing them for 24 h in a sealed container. Then, liquid limit of the mixtures was determined using the cone penetrometer method, starting from a wet state of the mixture to a dry state and the plastic limit is determined using the hand rolling method as specified in ASTM D4318-17e1 [53].

Compaction characteristics of soil samples were determined using the standard effort compaction test (ASTM D698-12 [55]). The test was conducted in a standard 101.6 mm diameter mould, by dropping a hammer from 305 mm height, thereby creating a compaction effort of 600 kN-m/m3. The dry density of soil and water content relation (compaction curve) was obtained from which optimum moisture content and maximum dry density of the sample are determined.

One-dimensional swell potential test was performed on untreated and treated soil specimens according to IS 2720-41 (1977) [56]. For treated soil, oven-dried soils were first mixed with LS: DI water solution at optimum moisture content. Specimens of diameter 60 mm and 20 mm in height were prepared in two layers by moist-tamping compaction method and after that cured for 28 days at room temperature (25–28 °C) by wrapping it in plastic films. Moisture equilibrated specimens were placed in standard oedometers, inundated with DI water and loaded axially under a 5 kPa surcharge load. Specimens were allowed to swell under the applied load until equilibrium and readings were taken in periodic time intervals. One-dimensional consolidation test was carried out as per ASTM D2435-04 [57] on treated and untreated specimens. Specimen dimensions and preparation procedure were the same as that of the swell potential test. The 28-day cured samples were placed in oedometers and confined laterally by inundating DI water. An axial seating load of 5 kPa was applied initially and then loaded subsequently by various stress increments. The effective vertical stress and corresponding void ratio were plotted to examine the compressibility characteristics of treated soils.

Unconfined compression strength (UCS) test was performed on specimens of 38 mm diameter and 76 mm height. The specimens were prepared in three layers using the moist-tamping technique at optimum moisture content and maximum dry density. Compacted specimens were then cured and tested for UCS according to ASTM D2166-06 [58]. The prepared soil specimens are named in a unique format for ease of usage (Example: A_1LS_28D corresponds to Soil A treated with 1% of LS and cured for 28 days.

Once the optimum dosage of chemical was decided based on the macro-mechanical tests results, microstructural analysis were performed to understand the reasoning for the enhancement at the optimum dosages of LS. XRD analysis was performed on specimens using Rigaku Miniflex 600 polycrystalline system diffractometer to examine the various minerals present in the untreated and treated soils. SEM analysis was performed using Carl Zeiss 8.5 mm beam WSEM imaging at 15 kV with an aperture size of 30 nm.

Results and Discussion

The response of the LS stabilised soil A is the actual response of the LS with the clay mineral present in the bentonite (montmorillonite) because of the unreactive nature of sand particles. The expansive nature of the synthetic mix is primarily because of the montmorillonite clay mineral present in sodium bentonite. For the same clay content and the clay minerals, the enhanced response of LS stabilised soil B in comparison with the LS stabilised soil A illustrates the benefit of adding LS as the secondary chemical stabiliser with fly ash as primary chemical stabiliser.

Atterberg Limits

The liquid limit, plastic limit and shrinkage limit of sodium bentonite is 501%, 69% and 7.5% respectively. With the proportion of 20B and 80 S/FA, the liquid limit has drastically reduced because of lesser clay fraction. Of the untreated soils, soil B was observed to have a relatively higher liquid limit than soil A due to the binding characteristics of fly ash with clay particles, resulting in an increased hydrophilic behavior of the soil. After a curing period of 28 days, LS treated soils were tested for liquid and plastic limits. Figure 1 shows the change in liquid limit with varying LS content. It can be noticed that the liquid limit has decreased with an increase in the LS dosage, irrespective of the soil type. The addition of LS has increased the attraction between clay particles and thus binds the colloidal particles together. Furthermore, the calcium ion (Ca2+) present in the LS replaces the exchangeable ions on the expansive soil surface, eventually reducing the thickness of diffuse double layer [59, 60]. The liquid limit for both soils at 1% of LS dropped to almost 50% of the respective untreated soils. The liquid limit of soil A decreased from 84 to 50% at 1% of LS, while liquid limit of soil B decreased from 108 to 65% at 1% of LS. These results are in agreement with earlier research that showed a decreasing trend in the liquid limit with an increase in stabilizer content [14, 27, 34, 43, 61, 62]. The liquid limit for soil A observed a slight increase beyond 3% LS, while for soil B a continuous decrease was noticed. It is speculated that a cementitious reaction occurs in soil B between FA and LS, altering the arrangement of clay particles into a more compact manner and leading to a continuous decrease in liquid limit. Whereas in soil A, beyond 3% of LS, further addition of LS leads to flocculation of clay particles and thus increases the repulsive forces. Both soils do not show any significant change in the plastic limit with increasing LS content. But since the liquid limit has been greatly reduced, the plasticity index eventually decreased considerably. Ijaz et al. [37] observed 55% reduction in plasticity index with combination of 2.65%lime and 0.875% LS. Also, Alazigha et al. [34] observed a 50% reduction in liquid limit and plasticity index. Figure 2 shows the plasticity chart as per IS 1498–1970 [54] along with the changes in the soil classification of treated soils upon increasing LS content. Interestingly, with the increase in the LS content, the soil classification has changed from high plastic clay (CH) to medium plastic clay (CI) for soil A, but to high plastic silty soil (MH) for soil B. The classification transformation is in agreement with the previous work done with the Ca-LS stabilizer for expansive soils [34, 43, 63]. Thus, LS addition has considerably improved the plasticity characteristics of swelling clays.

Compaction Characteristics

Figure 3 shows the compaction curves for LS treated soils with varying dosages. The treated soils exhibited higher maximum dry density than the untreated soil. At 2% of LS dosage, the maximum dry density of soil A has increased to 1.65 g/cm3 from 1.72 g/cm3, with the optimum moisture content (OMC) changing from 16.1 to 21.4%. Beyond 3% of LS dosage, the effect on the maximum dry density and OMC becomes insignificant (not shown). For soil B, which contains FA as one of its components, the maximum dry density increased from 1.2 g/cm3 to 1.28 g/cm3 at a 3% of LS dosage. The effect of presence of FA can be seen in Fig. 3(b) as shift towards left with increase in LS content. The reason can be attributed to steep increase in density of the soil due to agglomeration of FA particles. The figure also revealed that the compaction curves for stabilized soils were much steeper than those of untreated soils, an effect that becomes more pronounced with increasing LS content. This suggests that the sensitivity of the dry density characteristics is highly dependent on the variation in moisture content. For field application at the highway subgrade, the moisture content of the stabilized soils should be controlled strictly to obtain the required degree of compaction. This observation agrees with available literature [34, 39]. Alazigha [34] observed left shift in compaction curve with increase in LS content. The increase in density can be attributed to the formation of the LS cementing property, which occupies the voids between soil particles and increases soil density. The higher density of soil A compared to soil B is possibly due to the presence of sand.

Swell Potential

The volumetric expansion capacity of soils can be inferred from the swell potential under certain surcharge pressure. The swell potential is defined as the percentage increase in the thickness due to swelling of a compacted, laterally confined sample, which has been inundated with de-ionized water under a surcharge pressure of 5 kPa. Figure 4 shows the temporal variation of percent swell of untreated and treated soils. For both the untreated soils, it was observed over time that the percentage swell has increased steadily, followed by a steep rise to a maximum value where it becomes constant. Despite having the same bentonite content, the swell potential of soil B was lower than that of soil A due to the presence of fly ash. The percent swell of soil A decreased with an increase in LS content. A significant reduction in the percent swell was observed for both the treated soil samples. With an increase in the dosage from zero to 3% of LS, the swell potential of soil A has decreased from 23 to 0.6%. As previously mentioned, a decline in the plasticity index of treated soils indicates that the hydrophilic nature of clay particles has reduced, resulting in a fall in the swell potential. The continues decrease in percent swell corroborates well with the published literature [45, 63] having higher clay content. Fernandez et al. [63] observed a 30% reduction in percent swell at optimum dosage of LS. The strong bond of LS with clay particles constrains the water permeation into the soil, ultimately decreasing the soil swell potential. Interestingly, swell potential decreased from 12 to 0% for all the treated soil B samples. The cementitious gel formed due to the reaction between FA-LS-clay minerals could have resulted in increased resistance towards the swell potential of soil. The soils with high silt amount in expansive soils showed a reduction in swell potential till optimum dosage of LS [34, 43, 63], further increase in amount of LS has led to the reversal trend due to repulsion of LS particles with each other. The fly ash proves to be an advantage for reducing the swell potential in such cases.

Consolidation Characteristics

The relationship between void ratio and effective consolidation stress (e-log P) for both soils in the presence of various dosages of LS after a 28-day curing period is shown in Fig. 5. As noticed, soil B has a steeper slope compared to soil A due to the high amount of FA, which is highly compressible. However, with the addition of LS, the slope of treated soil A was steeper than soil B. The void ratio has decreased significantly in the case of soil B due to the relatively higher density of the soil with increasing chemical content. This decrease is due to the cementitious nature of FA, in contrast to soil A. Also, the slope of soil A does not vary much with an increase in chemical content under increasing surcharges.

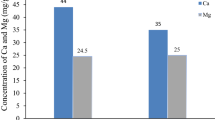

Figure 6 shows the variation of swell pressure, preconsolidation pressure and compression index of the chosen soils at various dosage of chemical stabilisers. The swell pressure of soil A treated with LS has significantly decreased from 300 kPa to 10 kPa for 2% of LS, while for soil B, it has reduced to zero due to reaction with FA. The preconsolidation pressure of the chosen soils and chosen chemical dosage was in the range of 85–105 kPa. The compression index of soil A was higher than soil B due to agglomeration of FA particles. The compression index for soil A at 2% of LS was 0.286, while for soil B, it was 0.145 at 1% of LS. The reduction in void ratio for soil A was observed from 0.9 to 0.45 at 1% of LS, and 0.62 to 0.5 for 2% of LS. However, for soil B, at 1% of LS, it has decreased from 1.05 to 0.75, while at 3% of LS, it has reduced from 0.88 to 0.78, which is relatively less. Roshan et al. [64] observed a reduction in compressibility index of soil from 2.4 to 0.3 at 3% LS. The decrease in void ratio due to consolidation pressure was higher for soil B due to the presence of fly ash, while the overall compression decreased with increasing LS content. With the increase in LS content in the pore fluid, a large number of Ca2+ cations diffuse into the interlayer of montmorillonite. The dispersive nature of clay particles has caused a decrease in the inter-particle repulsive stresses between montmorillonite particles, resulting in a lower void ratio.

The variation of coefficient of permeability of the untreated and treated soils under various vertical stresses is shown in Fig. 7. It can be noticed that with the increase in the vertical stress from 50 kPa to 800 kPa, the coefficient of permeability of the treated and untreated soil samples has decreased by two orders. With the addition of LS to the soil A, a relatively higher values of coefficient of permeability were observed in comparison with untreated soil, irrespective of the magnitude of vertical stress. The permeability of the soil A samples treated with 1% and 2% of LS is comparable. Similar observations were noticed for soil B samples. The coefficient of consolidation (Cv) is a fundamental geotechnical parameter used to characterize the rate at which a saturated soil layer undergoes consolidation under an applied load. Figure 8 shows the variation of coefficient of consolidation of the untreated and treated soils under various vertical stresses. It can be noticed that treated soil A shows a relatively higher value of the Cv when compared to untreated soil samples. Moreover, with the increase in the vertical stress, a fairly uniform value of Cv was observed for untreated and treated soil. However, soil B showed some variation with the vertical stress, but the nature of variation does not follow any identical pattern. Ta’negonbadi and Noorzad [43] observed a negligible change in permeability and durability of soils with cycles after treatment with LS.

Unconfined Compressive Strength

The unconfined compressive strength (UCS) of the soil samples were determined to evaluate the effectiveness of LS on the mechanical strength of 28-day cured soil samples prepared at optimum moisture content and corresponding dry unit weight. Figure 9 shows the axial stress - strain curves of all the tested specimens. Table 2 provides the summary of initial modulus and secant modulus of soils treated with different dosages of LS. The UCS of the untreated soil B was 70% higher than untreated soil A. The addition of LS has considerably increased the compressive strength of both soil A and B, but the rate of increase depends on the chemical dosage. At 1% of LS, UCS of soil A has increased from 120 to 200 kPa. Further increase in the dosage of LS has resulted in the marginal reduction in the UCS of soil A. It has reduced to 85 kPa at 3% of LS. It is to be noted that at 3% of LS, UCS of soil A was 31.8% lesser than untreated soil (A) Similarly, beyond 2% LS, a reduction in initial and secant modulus of soil A was noticed. With the increase in LS dosage beyond 2%, the skeletal structure between soil particles could have been broken because of the high quantity of calcium lignosulfonate. This caused a rise in porosity, leading to a loss of cohesion and reduced compressive strength. Soil B also showed an increase in UCS with a 1% addition of LS. It increased from 417 to 453 kPa showing an 8.75% increase. Further addition of LS did not alter the UCS significantly, while initial modulus and secant modulus has reduced marginally. Interestingly, for the soil A sample treated with 1% LS, the maximum strength was attained at higher axial strain, whereas for soil B, it was achieved at a lower axial strain compared to the untreated samples. Moreover, soil A treated with 1% of LS showed ductile behaviour than soil (B) Also, the percentage increase in UCS of treated soil B is comparatively lesser than treated soil A.

Optimum Dosage

The parameters used to fix the optimum dosage of LS are liquid limit, plasticity index, percent swell, swelling pressure, compression index, preconsolidation pressure and unconfined compressive strength. For soil A with 3% of LS, the liquid limit reduced to 38%. The plasticity index was higher for soil A as compared to soil B. Beyond 3% of LS, increase in plasticity index was observed while for soil B there was a continuous decrease. The percent swell for soil A has decreased to 0.5% at 2% of LS while it was zero for soil B with 1% of LS. The swell pressure for soil B was higher than soil A. The swell pressure for soil A has decreased to 20 kPa at 1% of LS and 10 kPa at 2% of LS while zero for soil B treated with 1% of LS. The compression index of soil A has decreased from 0.5 to 0.286 at 2% of LS, while for soil B with 1% of LS, it has decreased from 0.35 to 0.145. The UCS for soil A has increased from 120 to 200 kPa at 1% of LS, while for soil B, it has increased from 380 to 450 kPa. Considering the obtained results, the optimum dosage of LS for soil A and soil B is chosen as 2% of LS and 1% of LS, respectively.

Microstructural Analysis

Figure 10 shows SEM micrographs of untreated sample and treated samples at an optimum chemical dosage (at 28-day curing period). Figure 10 (a) and (b) shows the SEM images of lignosulfonate and fly ash respectively. From the images showing the texture of the particles, it can be observed that the lignosulfonate showed matrix form, while fly ash showed the ball-like structure of silica compound. Figure 10 (c) and 10 (d) shows the SEM images of the untreated and treated samples of soil A and soil B. Before treatment, soil A showed sand fractions were coated with bentonite, but with soil B, cementitious matrix due to the chemical reaction between bentonite and fly ash can be witnessed. This shows the significance of fly ash-based stabilisation of expansive soil. With the addition of optimum dosage of LS, soil A shows a change in the clay structure. The particles of bentonite form a flocculated structure after treatment, and the sand particles associated with the bentonite are brought together. For soil B, at optimum dosage (1% LS), a tendril like structure, indicating the presence of Illite can be noticed. Also, floc formation due to the reactions of bentonite, fly ash, and LS leads to cementitious component. The soil samples have a flocculated structure that is porous in nature. These morphological changes can be attributed to the adsorption phenomenon and cation exchange mechanism between the soil minerals and the LS organic molecules.

XRD, a mineralogical analysis, was employed to study the mineral changes in the soil due to the presence of LS stabilizer. It aids in understanding the interaction between clay minerals and the LS stabilizer. The diffractogram patterns of the untreated and treated specimens for optimum dosages of soil A and soil B are shown in Fig. 11. The patterns were analyzed based on new peak formation, changes in refractive angle (2θ) and atomic planes separation distance (d-spacing). Montmorillonite (2θ = 5.780), illite (2θ = 20.027, 26.914, 45.571 and 61.982), kaolinite (2θ = 21.96°, 31.5°) and quartz (2θ = 27.20) minerals were identified to be present in both the untreated soil samples. The signature position of montmorillonite is 2θ = 5.780 at which peaks are observed to reduce for soil A, while no peaks are observed for soil B with increasing LS dosages. The quartz signature position at 27.20 for soil A and soil B was observed to rise in peaks compared to untreated soils, though the peak is higher for soil B due to the presence of fly ash. The peak area is found to be small in comparison to the treated, resulting in a smaller surface area. This is due to a decrease in the size of the crystallite. The hump-shaped peaks of montmorillonite reflect amorphicity due to the coating of LS on clay particles (as noticed in Fig. 10). This observation aligns well with the literature on clay and lignosulfonate reaction [18, 45]. The coating of the LS on particles reduces the diffraction of light due to the widening area under the peak [65]. The formation of calcium silicate aluminate is observed for the optimum dosage of soil B at positions. There are no changes in peak intensities of minerals such as kaolinite and illite. The d-spacing of these minerals in the specimens with and without treatment was the same (12.10, 200, 250, 360, 520), and their associated intensities decreased. This is due to peripheral adsorption, which causes the intensities of non-swelling minerals to decrease.

Conclusions

The study investigates the effectiveness of the use of FA–LS blends to improve the engineering properties of expansive soils. As the clay content and the clay mineral present in the expansive soil dictate the engineering response and stabilisation mechanism, in the present study, montmorillonite present in the sodium bentonite was chosen as primary clay mineral. Several experimental tests were conducted on treated and untreated soil samples to determine the optimum dosage of LS to be employed for efficient stabilization. The microstructural analysis were performed to understand the reasoning for the enhancement at the optimum dosages of LS. The main conclusions of the study are as follows:

-

1.

The plasticity index for soil A at 2% of LS has decreased to 18%, further increase in LS content caused only marginal changes. For soil B, the presence of fly ash reduced the lignosulfonate requirement to stabilize the soil. The plasticity index has decreased to 13% at 1% LS, beyond which the slope of plasticity index with chemical content decreased. With an increase in the LS dosage from zero to 3%, the swell potential of soil A has decreased from 23 to 0.6%. A significant reduction in the percent swell was observed for soil B samples.

-

2.

Under standard Proctor compaction energy, addition of LS had marginal effects on maximum dry density, but the optimum moisture content has increased for soil A but decreased for soil B compared to untreated soils.

-

3.

The swell pressure of soil A has decreased from 300 kPa to 10 kPa at 2% of LS, while decreased to zero for soil B with 1% of LS. The preconsolidation pressure of the chosen soils and chosen chemical dosage was in the range of 85–105 kPa. The compression index of soil A was higher than soil B due to agglomeration of FA particles. The compression index for soil A at 2% of LS was 0.286, while for soil B, it was 0.145 at 1% of LS.

-

4.

The permeability of the treated and untreated soil samples has decreased by two orders with the increase in the vertical stress from 50 kPa to 800 kPa. With the addition of LS to the soil A, relatively higher values of permeability were observed in comparison with untreated soil, irrespective of the magnitude of vertical stress. Similar observations were noticed for soil B samples.

-

5.

The coefficient of consolidation of the treated soil A samples showed relatively higher values compared to untreated soil samples. A fairly uniform value of Cv was observed for untreated and treated soil with the increase in the vertical stress. However, soil B shows some variation with the vertical stress, but the nature of variation does not follow any identical pattern.

-

6.

Calcium lignosulfonate caused significant changes in the strength characteristics of the soil. The unconfined compressive strength of treated swelling soils has increased with different percentages of LS at a 28-day curing period compared to untreated soils. The UCS for soil A without fly ash increased from 120 to 200 kPa, while for soil B it has increased from 417 kPa to 453 kPa for 1% of LS respectively.

-

7.

The untreated soil A shows sand fractions coated with bentonite, but with soil B, cementitious matrix due to the chemical reaction between bentonite and fly ash can be witnessed. This shows the significance of fly ash-based stabilisation of expansive soil. With the addition of optimum dosage of LS, soil A showed a change in the clay structure. The particles of bentonite form a flocculated structure after treatment, and the sand particles associated with the bentonite are brought together. For soil B, at optimum dosage (1% LS), a tendril-like structure, indicating the presence of Illite can be noticed.

The results concluded that the combination of fly ash and calcium lignosulfonate has significantly improved the geotechnical properties of swelling clays and is quite effective compared to lignosulfonate and fly ash as a standalone stabilizer. The improvement of the soil with fly ash and lignosulfonate can be understood in terms of decrease in liquid limit by 41%, plasticity index by 80%, and percent swell by 100% with increase in unconfined compressive strength by 10%. Moreover, the presence of fly ash has reduced the lignosulfonate requirement to stabilize the swelling soils. The effect of the proposed combination needs to be explored for extreme climatic conditions, cycles of the climate, and also leachate issues.

Data Availability

All data, models, and codes generated or used in this study are presented in the paper. All associated data and other relevant information have been embedded in the paper.

References

Wang G, Wei X (2014) Modeling swelling-shrinkage behavior of compacted expansive soils during wetting-drying cycles. Can Geotech J 52(6):783–794. https://doi.org/10.1139/cgj-2014-0059

Mishra PN, Zhang Y, Bhuyan MH, Scheuermann A (2020) Anisotropy in volume change behaviour of soils during shrinkage. Acta Geotech 15:3399–3414. https://doi.org/10.1007/s11440-020-01015-6

Adem HH, Vanapalli SK (2015) Review of methods for predicting in situ volume change movement of expansive soil over time. J Rock Mech Geotech Eng 7(1):73–86

Jones DE, Holtz WG (1973) Expansive soils, the hidden disaster. Am Soc Civil Eng J 31:87–89

Nelson JD, Chao KC, Overton DD (2006) Foundation Engineering for expansive soil. Wiley, Hoboken, N.J

Nelson JD, Chao KC, Overton DD, Nelson EJ (2015) Foundation Engineering for Expansive Soils, problems and Practice in Foundation and Pavement Engineering. John Wiley & Sons Inc, Hoboken, New Jersey

Prusinski J, Bhattacharja S (1999) Effectiveness of Portland cement and lime in stabilizing clay soils. Transp Res Rec 1652–1628

Al-Rawas AA (2002) Microfabric and mineralogical studies on the stabilization of an expansive soil using cement by-pass dust and some types of slags. Can Geotech J 39(5):1150–1167

Kolias S, Kasselouri-Rigopoulou V, Karahalios A (2005) Stabilisation of clayey soils with high calcium fly ash and cement. Cem Concrete Composition 27(2):301–313

Tonoz MC, Gokceoglu C, Ulusay R (2003) A laboratory scale experimental investigation on the performance of lime columns in expansive Ankara (Turkey) clay. Bull Eng Geol Environ 62(2):91–106

Estabragh AR, Moghdas M, Javadi AA (2013) Effect of different types of wetting fluids on the behavior of expansive soil during wetting and drying. Soil Found 53(5):617–627

Khemissa M, Mahamedi A (2014) Cement and lime mixture stabilization of an expansive overconsolidated clay. Appl Clay Sci 95:104–110

Dayioglu M, Cetin B, Nam S (2017) Stabilization of expansive Belle Fourche Shale clay with different chemical additives. Appl Clay Sci 146:56–59

Mahedi M, Cetin B, White DJ (2020) Cement, Lime, and fly ashes in stabilizing expansive soils: performance evaluation and comparison. J Mater Civ Eng 32(7):04020177

Eades JL, Grim RE (1966) A quick test to Determine Lime requirements for Lime Stabilization. Highway Res Rec 139

Rollings RS, Burkes JP, Rollings MP (1999) Sulfate attack on cement-stabilized sand. J Geotech GeoEnviron Eng 125(5):364–372

Bhattacharji TK, Ghosh A, Tripathi HS, Das SK (2003) Solid state sintering of lime in presence of La2O3 and CeO2. Bull Mater Sci 26(7):703–706

Alazigha DP, Indraratna B, Vinod JS, Heitor A (2018) Mechanisms of stabilization of expansive soil with lignosulfonate admixture. Transp Geotechnics 14:81–92. https://doi.org/10.1016/j.trgeo.2017.11.001

Brooks RM (2009) Soil stabilization with fly Ash and Rice Husk Ash International. J Res Reviews Appl Sci 1(3):209–217

Celik E, Nalbantoglu Z (2013) Effects of ground granulated blastfurnace slag (GGBS) on the swelling properties of lime-stabilized sulfate-bearing soils. Eng Geol 163:20–25. https://doi.org/10.1016/j.enggeo.2013.05.016

Sharma AK, Sivapullaiah PV (2016) Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer. Soil Found 56(2):205–212

Behnood A (2018) Soil and clay stabilization with calcium- and non-calcium based additives: a state-of-the-art review of challenges, approaches and techniques. Transp Geotechnics 17A:14–32

Ogila WAM (2021) Effectiveness of fresh cement kiln dust as a soil stabilizer and stabilization mechanism of high swelling clays. Environ Earth Sci 80:283. https://doi.org/10.1007/s12665-021-09589-4

Phanikumar BR, Sharma RS (2007) Volume change behavior of fly ash-stabilized clays. J Mater Civ Eng 19(1):67–74

Nalbantoglu Z (2004) Effectiveness of Class C fly ash as an expansive soil stabilizer. Constr Build Mater 18(6):377–381

Pal SK, Ghosh A (2014) Volume change behavior of fly ash-montmorillonite clay mixtures. Int J Geomech 14(1):59–68

Zha F, Liu S, Du Y, Cui K (2008) Behavior of expansive soils stabilized with fly ash. Nat Hazards 47:509–523

Saride S, Puppala AJ, Chikyala SR (2013) Swell-shrink and strength behaviors of lime and cement stabilized expansive organic clays. Appl Clay Sci 85:39–45

Jallu M, Saride S (2024) Performance of alkali-activated fly ash stabilized high percentage RAP aggregates as a pavement base course: Laboratory and field perspectives. Int J Geosynthetics Ground Eng 10:15. https://doi.org/10.1007/s40891-024-00523-9

Mypati VNK, Saride S, Challapalli S (2024) Durability of fly-ash geopolymer binder in deep-mixed expansive soils. Proc Institution Civil Eng - Ground Improv 177(2):116–128

Dagliya M, Satyam N, Garg A (2023) Desert sand stabilization using biopolymers: review. Smart Constr Sustainable Cities 1. https://doi.org/10.1007/s44268-023-00001-7

Gandini A, Belgacem MN (2008) The State of the Art. Monomers, Polymers and Composites from Renewable Resources 1–16

SankaraNarayanan M, Rajesh S (2024) A state-of-the-art review on sustainable chemical stabilizers for expansive soils. Indian Geotech J 54:998–1016. https://doi.org/10.1007/s40098-023-00858-6

Alazigha DP, Indararatna B, Vinod JS, Ezeajugh LE (2016) The swelling behaviour of lignosulfonate-treated expansive soil. Proc Inst Civil Eng- Ground Improv 169(3):182–193

Atmajayanti AT, Hung CC, Yuen TYP, Shih R-C (2021) Influences of sodium lignosulfonate and high-volume fly ash on setting time and hardened state properties of engineered cementitious composites. Materials 14:4779. https://doi.org/10.3390/ma14174779

Cai Y, Ou M (2023) Experimental study on expansive soil improved by lignin and its derivatives. Sustainability 15(11):8764

Ijaz N, Dai F, Meng L, Rehman Z, Zhang H (2020) Integrating lignosulphonate and hydrated lime for the amelioration of expansive soil: a sustainable waste solution. J Clean Prod 254(119985):0959–6526

Lekha BM, Sarang G, Shankar AUR (2005) Effect of electrolyte lignin and fly ash in stabilizing black cotton soil. Transp Infrastructure Geotechnology 2:87–101. https://doi.org/10.1007/s40515-015-0020-0

Puppala AJ, Hanchanloet S (1999) Evaluation of a new chemical treatment method on strength and resilient properties of a cohesive soil. Transportation Research Board. Paper 99038

Roshana K, Choobbastia AJ, Kutanaei SS (2020) Evaluation of the impact of fiber reinforcement on the durability of lignosulfonate stabilized clayey sand under wet-dry condition. Transp Geotechnics 23:10059, 1–12

Sarkar D, Apu SO, Kumar N, Wang JX, Lynam GJL (2023) Sustainable lignin to enhance engineering properties of unsaturated expansive subgrade soils. J Mater Civ Eng 35(8):15008–15020

Singh AK, Sahoo JP (2022) Experimental modelling for time dependent strength behavior of lignosulfonate-treated high plasticity clay. J Mater Civ Eng 34(7):01–11

Ta’negonbadi B, Noorzad R (2017) Physical and geotechnical long-term properties of lignosulfonate-stabilized clay: an experimental investigation. Transp Geotechnics 17:41–50

Vinod JS, Indararatna B (2011) A conceptual model for lignosulfonate treated soils. In:Khalili N, Oeser M(eds) 13th International Conference of the International Association for Computer Methods and Advances in Geomechanics Australia 296–300

Zhang T, Cai G, Liu S (2018) Application of lignin-stabilized silty soil in highway subgrade: a macroscale laboratory study. J Mater Civ Eng 30(4):1–16

Kolay PK, Ramesh KC (2016) Reduction of expansive index, swelling and compression behavior of Kaolinite and Bentonite clay with sand and class C fly ash. Geotech Geol Eng 34(1):87–101

Chapuis RP, Lavoie J, Gerard D (1992) Design, construction and repair of the soil-bentonite liners of two lagoons. Can Geotech J 29:638–649

Rashid HMA, Sardar A, Ismail A (2021) Geotechnical characterization of bentonite-fly ash mixtures for their application as landfill liner in Pakistan. Arab J Geosci 14:1306,1–12. https://doi.org/10.1007/s12517-021-07663-6

Mollamahmutoğlu M, Yilmaz Y (2001) Potential use of fly ash and bentonite mixture as liner or cover at waste disposal areas. Environ Geol 40(11–12):1316–1324

Pal SK, Ghosh A (2013) Hydraulic conductivity of fly ash–montmorillonite clay mixtures. Indian Geotech J 43(1):47–61

Younus MM, Sreedeep S (2012) Evaluation of bentonite-fly ash mix for its application in landfill liners. J Test Eval 40(3):357–362

ASTM D422-63 (2018) Standard Test Methods for Particle-Size Analysis of Soils. West Conshohocken, PA https://doi.org/10.1520/D6913-04R09.2

ASTM D4318-17 (2017) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. West Conshohocken, PA https://doi.org/10.1520/D4318-10

IS 1498–1970 (1970) Classification and identification of soils for general engineering purposes. Bureau of Indian Standards

ASTM D698 (2012) Test method for laboratory compaction characteristics of soils using standard effort (12.400 ft-lbf / ft 3 (600 kN-m / m 3)). ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D0698-12E01.1

IS 2720-41 (1977) Methods of test for soils, Part 41: measurement of swelling pressure of soils [CED 43. Soil and Foundation Engineering]

ASTM D2435-04 (2011) Standard test methods for one-dimensional consolidation properties of soils using incremental loading. https://doi.org/10.1520/D4546-08.2. West Conshohocken, PA

ASTM D2166-16 (2016) Standard test method for unconfined compressive strength of cohesive soil. ASTM International, West Conshohocken, PA

Li J, Yin ZY, Cui YJ, Liu K, Yin JH (2019) An elasto-plastic model of unsaturated soil with an explicit degree of saturation-dependent CSL. Eng Geol 260:105240

Xu YS, Zhou XY, Sun DA (2022) Thermal properties of GMZ bentonite pellet mixtures subjected to different temperatures for high-level radioactive waste repository. Acta Geotech 17:981–992. https://doi.org/10.1007/s11440-021-01244-3

Al-Swaidani AM (2016) Prediction of compressive strength and some permeability-related properties of concretes containing volcanic scoria as cement replacement. Romanian J Mater 46(4):505–514

Dayioglu M, Cetin B, Nam S (2017) Stabilization of expansive Belle Fourche Shale clay with different chemical additives. Appl Clay Sci 146:56–69

Fernández MT, Orlandi S, Codevilla M, Piqué TM, Manzanal D (2021) Performance of calcium lignosulfonate as a stabilizer of highly expansive clay. Transp Geotechnics 27:100469. https://doi.org/10.1016/j.trgeo.2020.100469

Roshan K, Choobbasti A, Soleimani Kutanaei S (2020) Evaluation of the impact of fiber reinforcement on the durability of lignosulfonate stabilized clayey sand under wet-dry condition. Transp Geotechnics 23:100359

Russell JD (1994) and A.R.Fraser. Infrared methods. Clay mineralogy: Spectroscopic and chemical determinative methods. M.J.Wilson, 11–67. Dordrecht, Netherlands:Springer

Funding

The work in this paper was supported substantially by the Science and Engineering Research Board, Department of Science and Technology, India (Project No. CRG/2018/004612).

Author information

Authors and Affiliations

Contributions

All authors (Richa Mudliar, Sathiyamoorthy Rajesh) contributed to the conception, design of experiments and data analysis. Richa Mudliar performed material preparation, experiments, analysis and the initial draft of the manuscript. The manuscript was reviewed, written-rewritten, and edited by Sathiyamoorthy Rajesh. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest that link to the research. Authors are not employed or paid by any organisation which can have financial benefits or damages from the paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mudliar, R., Rajesh, S. Assessment of Combined Effects of Lignosulfonate and Fly ash in Enhancing the Geotechnical Characteristics of Swelling Clays. Int. J. of Geosynth. and Ground Eng. 10, 83 (2024). https://doi.org/10.1007/s40891-024-00591-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-024-00591-x