Abstract

The expansive clay soils, which cover most of the new urbanized areas in Egypt, create major damages in most of the engineering structures and infrastructures such as buildings, roads, bridges, pipelines and others due to bad human activities, e.g. lack of maintenance for sewage and drinking lines, and flood irrigation of golf areas which causes fluctuation of water content through the foundation clay layers associated with shrink-swell behavior. These geotechnical challenges and their treatment solutions consume most of the urbanized project budget and delay the development plan. Therefore, in this study the high plasticity and soft to firm clay soils were stabilized using various dosages of fresh cement kiln dust (CKD) as an economical alternative to the other expensive stabilizing agents (stabilizers or binders) such as lime, cement and other chemical stabilizers. The effectiveness of this type of CKD as a stabilizing agent, soil stabilization mechanism, and changes in mineralogical and microstructural characteristics of stabilized soils due to this stabilization process were evaluated through Atterberg limits, unconfined compressive strength (UCS), stiffness (stress–strain behavior, Es), pH, electrical conductivity (EC), total dissolved solids (TDS), X-Ray diffraction (XRD) and scanning electron microscope (SEM) investigations. The present study revealed that by adding CKD, the workability of the treated clays was increased by decreasing the liquid limit and plasticity index as well as increasing the bearing capacity and decreasing the settlement by increasing UCS and Es. This study also showed that by adding CKD, the initial pH, EC, and TDS of CKD-clay system increased, creating favorable conditions for dissolution of edges and surfaces of clay flakes. The active montmorillonite clay flakes adsorbed the soluble calcium cation and sulfate anion on their surfaces that are rich in soluble silica and alumina and then the cation exchange and flocculation–agglomeration processes began. With curing, the pozzolanic products grew on the surfaces and edges of clay flakes and extended into the voids of the agglomerated inter-clay particles resulting in the filling of these micro-voids. The present investigation also found that, the progressive decreasing in pH, EC, and TDS values of CKD-clay systems through different curing periods is a good indicator for pozzolanic activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

From a geotechnical point of view, the high population growth in the area lying northwest of the Egyptian Nile Delta is mostly followed by new urbanization areas with various types of engineering structures and infrastructures. In the last years, the ground and underground engineering structures constructed on the soft to firm silt and clay soils in the newly urbanized areas along the borders of the Nile Delta and around the Nile Valley were subjected to various types of cracks and damages (Ismail and Ryden 2012; Ismaiel 2013; Ismail and Belal 2016). This forced the construction engineers to lay different civil engineering structures on the very high plasticity and/or soft to firm foundation clay layers. The undesirable properties of these clay soils, such as low strength, low bearing capacity, high swelling potential, high compressibility, and high settlement (Elkhouly et al. 2005; Hamza et al. 2006; Sakr et al. 2009; Ismail and Ryden 2012, 2014; Stanley and Clemente 2014; Ismail and Belal 2016; Hamed et al. 2017; Zaid et al. 2019) offer no other choice than soil stabilization before the construction of the different engineering structures such as pavements, buildings, factories, pipelines, tunnels, and bridges to avoid severe damage and/or tilting of the established engineering structures.

Soil stabilization is the process by which the geotechnical properties are altered to satisfy the engineering requirements (Attoh-Okine 1995). Many types of stabilizers are used as soil binders to improve their engineering properties, such as lime, cement, cement kiln dust and fly ash. Their effectiveness mainly depends on their chemical reactions with the soil elements in the presence of water (Mallela et al. 2004; Ramadas et al. 2011; Azadegan et al. 2012).

In Egypt and from an environmental point of view, the rapid urbanization developments and the technological advances in cement industry result in waste generation and environmental aggressions that affect the public health (El-Abssawy et al. 2011; Darweesh 2017).

Being at the forefront of adopting technological innovations, the cement industry is growing at a significant pace. According to Ali et al. (2016), the Egyptian cement industry produces about 1.5% of the total world production with an amount of about 38 million tons per year from dry kilns as well as small amounts from seven wet kilns. The total amount of cement kiln dust (CKD) as a waste byproduct of Portland Cement manufacturing is about 3.5 million tons yearly, that are mostly dumped-off in unoccupied areas near the Portland Cement factories (Ali et al. 2016). Due to the very fine particle size of this dust, it can fly and spread all over the factories surrounding areas by very weak winds. Accordingly, it causes harmful effects for most of the bio-ecosystems (El-Abssawy et al. 2011; Darweesh 2017). In addition to these environmental negative effects of CKD, it causes a very serious and great financial loss to all cement production companies due to the transportation of very huge amounts of CKD behind the kiln filters and water required to granulate it. Therefore, intensive efforts are carried out worldwide to mitigate such dangerous effects (Ali et al. 2016).

In Egypt, few studies were carried out to study the effect of cement industry on the atmosphere and human health in the industrial neighboring (El-Abssawy et al. 2011; Ali et al. 2016; Darweesh 2017). These studies reveal that cement plants are the main emission sources of pollution of organic and inorganic chemicals as well as harmful metals such as antimony, arsenic, lead, cadmium, chromium, cobalt, copper, manganese, nickel, thallium, tin, vanadium, zinc, beryllium, selenium, tellurium, and mercury that are considered just as toxic to humans and ecosystems (Pizzol et al. 2011) causing many respiratory system diseases, digestive system diseases, infection diseases, skin lesions diseases, and finally, brain, liver, kidneys and stomach cancer. Therefore, safe handling, proper disposal, and utilization of CKD represents a very challenging task. It is also considered as an obstacle to the sustainable development plans of developing countries.

However, this paper suggests that it is possible to utilize such cement industrial waste material (CKD) in soil stabilization as a binder agent, which could consume considerable amounts of this harmful material with good economical feedback and positive environmental impacts. This is highly applicable in Rashid area (Egypt) due to the low bearing capacity and compressive strength, and high compressibility behaviors of its foundation clays.

The main objectives of this study are: (1) to investigate the effectiveness of CKD in the stabilization of these problematic clays, (2) to study the mineralogical and microstructural modifications of treated clays due to CKD stabilization, (3) to compare them with untreated clays to interpret the CKD-clay stabilization mechanism.

Ground improvement of the engineering structures in these newly urbanized areas is mostly carried out by mixing the problematic soils with CKD that is often more economical than other traditional materials (Solanki et al. 2007; Jegandan et al. 2010; Rahman et al. 2011; Hashad and El-Mashad 2014; Ismail and Belal 2016). The addition of a chemical stabilizer (binder) such as CKD altered the geotechnical properties of the existing problematic soils to create new site materials with high shear strength and bearing capacity, and low swelling potentiality and compressibility that are required to support the different engineering structures and infrastructures (Miller and Azad 2000; Sreekrishnavilasam et al. 2007; Peethamparan and Olek 2008; Hossain and Mol 2011).

Many researchers studied the usage of CKD in stabilization of high expansive clay soils (e.g. Baghdadi 1990; Miller and Azad 2000; Sreekrishnavilasam et al. 2007; Peethamparan and Olek 2008; Hossain and Mol 2011). They suggested that the stabilization potentiality of the different types of CKDs is the most economical and environmental alternative to the chemical soil stabilizer agents such as lime and cement. Economically, CKD is considered as a waste material that is mostly dumped-off in the vacant spaces near industrial areas resulting in causing considerable damage to the sustainable development plans of developing countries and significant financial losses. Therefore, in different countries, recycling this waste material in different construction and geotechnical sites works for saving storage and disposal costs, not to mention that this material is considered as a no-price material compared to other chemical stabilizer agents (Baghdadi and Rahman 1990; Baghdadi et al. 1995; Freer-Hewish et al. 1999; Al-Aghbari et al. 2009; Carlson et al. 2011; Hossain and Mol 2011; Ogila 2014; Kumar and Janewoo 2016; Mosa et al. 2017; Abdel-Ghani et al. 2018). The field implementation study conducted by the FHWA at the Oklahoma PRA-CHIC12 project revealed that the treatment of the project area with 10% CKD, compared with lime, resulted in an estimated cost savings of approximately $25,000 for 18,000 m2 of treated project area (Miller and Azad 2000). On the other hand, environmentally, the use of this waste material mostly decreases the disposed amounts in the surrounding environment resulting in eliminating its hazardous impact on human health.

Elbaz et al. (2019) reviewed the beneficial uses of CKD in the field of soil stabilization, agriculture, waste treatment, concrete and cement industry. They suggested that recycling CKD in these fields has the potential to provide economic and environmental benefits. Economic benefits include a reduction of cost associated with CKD disposal, an increase in revenue caused by selling CKD, and cost savings due to CKD replacing other more-costly materials. Environmental benefits include reducing greenhouse gas emissions, reducing the need for disposing CKD in landfills, and the usage of virgin resources.

These studies also revealed that the treatment of high expansive clay soils with CKD binder increases the compressive strength and deformation modulus values, enhancing the workability of treated soils as well as reducing the swelling potentiality and plasticity index properties. Most of these studies found that fresh CKDs with high free-lime content (high free-lime CKDs) were more effective in soil stabilization than landfill CKDs with low free-lime content. Besides soil and CKD types, the percentages of CKD added to untreated soils and duration of curing were the main factors in the soil stabilization process (Sreekrishnavilasam et al. 2007).

Soil treatment factors in CKD stabilizing agent are mainly the free-lime content (CaO) as well as the other cement forming minerals as parawollastonite, portlandite, and larnite minerals as discussed later in the studied CKD (Solanki et al. 2007; Peethamparan et al. 2009). Choquette et al. (1987) studied the mineralogical and microstructural changes due to stabilization of clay soils by lime. They suggested that there are two important phenomena occurring when clay soil was mixed with lime. These two phenomena are: (1) rapid improvement of soil physical properties, immediate or short-term treatment, by changes in moisture water content "moisture sensitivity" of treated clays that was resulting in enhancement of their Atterberg limits and increasing their workability through reduction of adsorbed water and decrease in plasticity index, and (2) long-term treatment by increasing the strength of treated soil through producing new cementitious minerals. They also disclosed that four proposed mechanism stages, three in short-term and one in long-term, are responsible for these transformations. These soil stabilization mechanism stages are replacement of the main exchangeable clay cations by calcium ions provided by lime (cation exchange stage), flocculation–agglomeration stage of clay particles, reaction between lime and air carbon dioxide to form calcium carbonate (lime carbonation stage), and finally chemical reactions between lime and soluble silica and alumina cations liberated from clay minerals to produce cementing minerals (pozzolanic reactions stage) as hydrated calcium silicates (CSH), hydrated calcium aluminates (CAH), and hydrated calcium alumino-silicates (CASH) that are the main indicators for insuring the effectiveness of lime-soil stabilization process.

Bell (1996) studied the stabilization of different clay soils with lime and mentioned that the stabilization process of clay soils depends mainly on the types of clay minerals and length of curing time. In addition, he found that in lime-treated clays the calcium ions initially adsorbed by clay minerals that are responsible for improvement of soil workability and decreasing the plasticity index values but not increasing the soil strength. This amount of calcium ions is called as lime fixation point, after this fixation point the excess of lime added to clay soils is utilized in cementation process (pozzolanic reactions); whereas, the effectiveness of lime stabilization is mainly depended on these chemical reactions between lime and existing clay minerals.

Miller and Azad (2000) investigated the effectiveness of CKD for stabilizing different plasticity soils (low and high plasticity soils). Three different soils CH, CL, and ML were treated using different dosages of CKD (5, 10, 15, 20, 25, 30, 35, 40, 50%). They found that in all cases the UCS values of treated soils are more than untreated soils, the most significant strength gains mostly occurred during the first 14 days and the low plasticity soils gain strength significantly than high plasticity soils especially after 28 curing days. They also suggested that the increasing in UCS of soils with the same content of CKD is dramatically higher for low plasticity soils than high plasticity soils. In addition, with increasing the saturation degree of treated soil (immersed in water for 48 h), the soil strength increases with about 50–100% of the same treated soils not immersed in water.

Solanki et al. (2007) studied the effect of different amounts of CKD (5, 10, 15%) at 28 days curing time on the geotechnical properties of subgrade fine grained low plasticity clay and silt soils. They revealed that by increasing CKD content in treated soils, the maximum dry density (MDD) decreased from 17.7 to 17.1 kN/m3, the optimum moisture content (OMC) increased from 14.6 to 15.3%, resilient modulus substantially improved to 35–425% at 15% CKD, UCS increased from 0.034 to 1.323 MPa with increasing in UCS by a factor of 5, 27, and 39 for 5, 10, 15% CKD, and elasticity modulus improved by 327, 1400, and 2247% due to the addition of 5, 10, and 15% CKD, respectively. They also found that, the crystalline-hydrated product (ettringite mineral) produced from the chemical reaction between CKD and treated soil is filling the soil void spaces and considered as the major factor contributing to strength improvement.

Sreekrishnavilasam et al. (2007) evaluated two fresh and one landfilled CKDs for soil treatment. They revealed that the fresh CKD with free lime 2–5% was considered as good soil stabilizer while the fresh and landfill CKDs with low free-lime contents may be used in treating the wet subgrades or wet-logged areas. They also suggested that the suitability using CKD as a soil stabilizer depends mainly on the free-lime content present. More reactive CKD with considerable amount of free lime produces more change in Atterberg limits that is considered as a good indicator of CKD stabilization potentiality, as well as the addition levels between 8 and 20% of high free-lime CKD increases the UCS with percentage between 35 and 50% while the addition of the other low free-lime CKDs reduces the UCS with about 20–50%. They measured the swelling behavior of treated soil with 15% high free–lime CKD and found that the CKD decreases the swelling strain associated with immersion in water from 0.7 to 0.1%.

Peethamparan et al. (2009) studied the stabilization of Na-Montmorillonite clay with 25% of high free-lime content CKD and with 7% of lime. They found that the 25% CKD was considered as reasonably well stabilizer where the unconfined compressive strength increases from 1.0 MPa at 1 day to 2.40 MPa at 90 days. They also discovered that the morphological modifications in clay particles treated by CKD was similar to the morphological changes which induced by CaO treatment; whereas, the calcium hydroxide derived from hydration of free lime within CKD was adsorbed on the surfaces of clay flakes where the pozzolanic reactions occurred. They also found that new minerals as gypsum, ettringite, and CSH reaction products were produced in addition to much of clay was left unreacted, but the produced microstructure of reactant clay particles disclosed that a significant clay mineral modification in response of CKD treatment as lime treatment. This study revealed that the pH of the clay–CKD mixture was initially raised to more than 13.0 and then dropped to 12.5 and was maintained at this level despite absence of detectable Ca(OH)2 which characterized the saturated calcium hydroxide solution.

Carlson et al. (2011) studied the geotechnical properties of CKD-modified silty soils (5, 10, 15, 20% CKD) with curing 7 days. They suggested that the engineering behaviors of treated soils enhanced with adding a considerable amount of CKD (15–20%); whereas, the workability of treated soils enhanced with slightly decreasing plasticity index as well as the OMC increase from 27 to 32% and MDD is mostly constant with increasing the amount of CKD. They also revealed that, the UCS increased from about 0.24 MPa to about 0.75 MPa and the peak axial strain decreased from 4.5 to 2% as well as modulus of elasticity increased from 27.7 to 59.7 MPa. Therefore, using the CKD as a stabilizing agent may provide sustainable geotechnical construction with cost saving and reducing the need for landfill construction to store excess CKD as well as the cost for soils removal and replacement are eliminated.

Solanki and Zaman (2012) investigated the microstructural and mineralogical characteristics of high plasticity clay stabilized using 9% hydrated lime with free lime of about 46.7% or 15% CKD with free lime 6.7% or 15% coal fly ash (CFA) with free lime 0.2%. They found that the mechanical characteristics of treated soils were enhanced where the modulus of elasticity increased from 69 MPa to 137, 134, 202 MPa with treating of lime, CFA, and CKD, respectively. They also revealed that the formation of new cementation minerals as CSH, CASH, and ettringite are contributed to strength development of stabilized clay. The X-Ray Diffraction (XRD) revealed that the peak intensities of the clay minerals generally are reduced in all treated clay soils, which indicate that the effectiveness of these calcium-based stabilizers in stabilization process of high expansive soils.

El-mashad and Hashad (2013) studied the effectiveness of CKD in improving sandy silt soils. They mixed the studied soils with 10, 15, and 30% of CKD and they found that the specific gravity increased from 2.56 to 2.70 at 30% CKD. They suggested that the CKD significantly improves the shear resistance of treated soils and canal embankment soil slope stability where California Bearing Ratio (CBR) increased from 7.3 to 165% at 30% CKD and wet UCS increased with increasing CKD percentage and curing time. They also found that the shear strength parameters (cohesion and internal friction angle) increased from 12 KN/m2 to 104 KN/m2 and from 13° to 16° at 30% CKD. Therefore, the safety factor of canal embankment soil slope side increased two times by adding 30% CKD that is more effective than soil reinforcement technique using nine geo-grid layers.

Abd El-Aziz and Abo-Hashema (2018) studied the impact of CKD (2–10%) on enhancing the durability and workability of subgrade clayey soils. They revealed that the increasing of CKD accompanied with significant increasing of CBR values (increasing 4 times than untreated soils) and shear strength parameters, as well as decreasing liquid limit values with reduction of about 56% by using 10% CKD as well as the plasticity index reduced between 40 and 65% when using 2–10% CKD, swelling percent decreases from 50 to 13% by addition of 10% CKD, and MDD was decreased by 12% when 10% CKD added. They also suggested that the effect of CKD on shear strength starts to appear when CKD was added by above 6%. So that, using CKD in treatment of clayey subgrade soils is considered as a viable and innovative method to enhance their geotechnical design parameters.

Jala and Sharma (2019) investigated the impact of CKD (with 5, 10, 15% of dry soil weight) on high plasticity clay at subgrade level. They found that the UCS increasing from 0.088 to 0.1395 MPa after 28 curing days and unsoaked CBR increasing from 1.65 to 4.35% at 15% CKD as well as compression index decreased from 0.378 to 0.117 at 15% CKD and 4% (Road Building International Grade 81, RBI 81) and void ratio from 0.53 to 0.41. Therefore, they suggested that the treatment of subgrade clayey soils in pavements with CKD was accompanied with increasing the durability and workability of the treated soils with time due to the formation of new CSH and CAH cementation compounds that partially fill voids and reduce the volume of treated soils resulting in increasing soil strength.

Adeyanju and Okeke (2019) treated the clayey soil extracted from the failed road of Sango, Ota using cheap CKD waste product. They used different dosage of CKD (7.5, 10, 12.5, and 15%) to investigate the optimum CKD stabilizer content. They found that the 10% CKD showed the best mechanical improvement where the unsoaked CBR increased from 1.49 to 28.6% after 7 days of curing. Also, they revealed that the other geotechnical properties as Atterberg limits, Proctor compaction and free swelling enhanced. Therefore, the 10% CKD was the more economical and environmentally beneficial as well as the use of CKD in soil stabilization is considered as sustainable waste management practices.

Materials and methods

Untreated clay samples

Three soft to firm clay samples are used in the present study. These investigated clay samples were obtained from the shallow foundation layers of new engineering structures west of Rashid City, northern Nile Delta, Egypt (Fig. 1). The investigated clay samples are started at a depth of about 2 m below the ground surface and extended down to about 15 m, these clays are generally overlained by silty sand layer and underlained by medium-to-coarse sand layer. In this study, the clay samples (1a, 2a, and 3a) represent the natural, undisturbed/cored, untreated clays while (1b, 2b, and 3b) represent the CKD-clay treated mixtures or treated clay samples, respectively.

The grain size analysis according to ASTM D422-63 (2003) was carried out on the untreated clay samples and the gradation curves are represented in Fig. 2 as well as grain size distribution results are shown in Table 1. The results revealed that the clay samples are ranging from silty clay for clay samples (1a) and (2a) to silty sandy clay with 3% gravel fraction for clay sample (3a).

The consistency or Atterberg limits (Table 1) were carried out on the untreated clay samples according to ASTM D4318-00 (2000). The results disclosed that the liquid limit values of untreated clay samples are ranging from 80 to 195%, plastic limit values are ranging from 32 to 55%, and plasticity index values from 48 to 140%. Based on the liquid and plastic limits as well as plasticity index, the untreated clay samples are classified as high plasticity clay (CH) according to Unified Soil Classification System (USCS, ASTM D2487-00 2000), and are classified as high to very high swelling potential clays (Holtz and Gibbs 1956; Snethen et al. 1977; Chen 1988).

Dakshanamurthy and Raman (1973) classified the degree of swelling into six classes according to their liquid limit values. Based on this classification, the studied clay samples are ranging from very high to extremely high swelling clays. The knowledge of Atterberg limits is often used to determine the main clay minerals in the fine-grained soils, and according to Michell and Soga (2005) classification, the predicted clay minerals in the studied clay samples based on the values of liquid and plastic limits, are montmorillonite and illite minerals as confirmed by XRD analysis.

The unconfined compressive strength tests are carried out on natural undisturbed cylinder clay specimens, 6.3 cm in diameter and 12.7 cm in height; whereas, the specimens at their natural moisture contents and bulk densities were tested for their compressive strengths under rate of strain equal to 1.00 mm/min according to ASTM D2166-00 (2000). The unconfined compressive strength (UCS) values (Table 1) of natural untreated clay samples are varied from 0.0667 to 0.1267 MPa.

The undisturbed and untreated studied clay samples are classified as soft to firm clays according to Bell (2007) and as medium-stiff to stiff clays according to Terzaghi et al. (1996).

The pH values of extracted water of natural untreated clay samples were measured at 20 °C using an electronic Pometer pH009 (II) ATC portable pH meter according to ASTM D 4972-01 (2007). The pH values of natural clays (Table 1) are ranging from 7.23 to 7.63 and the clay samples are classified as neutral soils.

The mineralogical composition of two natural untreated clay samples (2a and 3a) were investigated by powder X-Ray Diffraction (XRD). The XRD was carried out using a BRUKER X-Ray Diffractometer model AXSD8 Advance (BRUKER-D8) with CuKα target (λ = 1.54 Å and n = 1) at 40 kV and 40 mA, which is available at the Central Metallurgical Research and Development Institute, Egypt. The powdered samples were analyzed using XRD with scanning speed of 2°/min in the range from 4° to 70°. Types of the phases in the clay samples were identified using the X-ray powder data files published by the American Standard for Testing Material (ASTM Cards). The XRD patterns for the studied clay samples are represented in Fig. 3. The XRD result disclosed that the untreated clay sample (2a) is composed mainly of montmorillonite clay mineral, in addition to quartz, labradorite and calcite non-clay minerals. On the other hand, the XRD result of untreated clay sample (3a) revealed that the montmorillonite, illite and kaolinite clay minerals are represented in order according to their abundances in addition to quartz, feldspars (albite and microcline), and calcite non-clay minerals. According to Lambe and Whitman (1969) the swelling ability is depending mainly on the types and amounts of clay minerals in the clay soils where the swelling ability increases in montmorillonite, illite and decreases in kaolinite and depends on exchangeable ions.

The visual observation of natural untreated clay samples (1a, 2a, and 3a) showed that, the clay samples (1a and 3a) have small amounts of iron oxide materials while the clay sample (2a) has no iron oxide materials (Fig. 4). These small amounts of iron oxide materials were not detected by XRD analysis but were detected by visual observation as small porphyritic iron oxide materials (clay sample, 1a) and by reflected homogenous yellowish color of the clay sample (3a).

The microstructural investigation of natural untreated clay samples (2a and 3a) was carried out using SEM model Quanta 250 FEG (Field emission Gun) attached with EDX unit (Energy Dispersive X-ray Analyses) with accelerating voltage 30 kV, magnification 14 × up to 1,000,000 × and resolution for Gun-1n. This SEM investigation is available at the Central Laboratories Sector of the Egyptian Mineral Resources Authority, Ministry of Petroleum, Egypt. The SEM micrographs at different spots through the studied untreated clay samples were used to represent the qualitative identification of their mineralogical and microstructural characteristics before CKD treatment and then are compared with the other SEM micrographs of CKD-clay treated mixtures. The remolded untreated clay samples (2a and 3a) at the values of their liquid limits, cured for 28 days, oven-dried at 65 °C for approximately 12 h and air-dried for 48 h to remove the absorbed water content without distortion of their existing microstructural characteristics were investigated. Tiny fresh and non-fractured pieces were mounted on multi-stub holder and coated using EMITECH K550X sputter coater to increase the conductivity of spin-coated samples, and then the clear fresh surfaces investigated by SEM.

The high-resolution SEM micrographs obtained from the untreated remolded clay samples are shown in Figs. 5 and 6. Figure 5a for remolded clay sample (2a) reveals that an assemblage of undulating fluffy film-like structure or flaky wavy texture of foliated montmorillonite clay mineral in addition to overall open microstructures were clearly visible. The montmorillonite clay particles clearly described and diagrammed as very thin plates with quite sharp outlines of clay particles. Figure 5b shows the highly magnification view of clay particles that appear as a cotton appearance with foliated texture of montmorillonite clay particles with more visible inter-clay particle voids. This SEM investigation confirms the XRD analysis and revealed that the clay sample (2a) is composed mainly of high expansive montmorillonite clay mineral.

The SEM investigation of remolded clay sample (3a) as shown in Fig. 6 reveals that this clay sample is characterized by flocculated texture of montmorillonite clay mineral (Fig. 6a). This texture pattern was mostly due to the montmorillonite particles that are usually thin with curved flakes which bonded by high valance interlayer cations, as Mg2+, Ca2+, Fe2+, and Fe3+, to act as on thick unit (Grim 1968).

The presence of iron oxides as observed in visual observation might have added the flocculated texture to this clay sample. The clay sample is also composed of microcline particles confirmed by XRD analysis (Fig. 3). Figure 6b shows the presence of undulating fluffy film-like structure and cotton appearance with foliated texture of montmorillonite clay particles as well as thin laths morphology of authigenic illite clay mineral particles that are observed under highly magnification SEM as confirmed by XRD analysis (Fig. 3). Various studies (Inoue et al. 1988; Inoue and Kitagawa 1994; Środoń et al. 2000) suggested that the thin lath-like forms represent the earliest stages of illite formation, then by further growth the illite was converted into irregular platy forms and finally into well-developed hexagonal forms.

According to the SEM and XRD investigations of clay sample (3a), this clay sample is composed mainly of mixed montmorillonite–illite clay as well as kaolinite clay mineral with different swelling potential degrees.

The XRD and SEM investigation results were confirmed by the results of Atterberg limits, where the untreated clay sample (2a) has swelling potentiality than the untreated clay sample (3a). Comparing between the Atterberg limits, XRD and SEM results of investigated untreated clay samples with the classifications of Michell and Soga (2005) revealed that the studied clay sample (1a) is considered as extremely swelling potential clay, the studied sample (2a) is considered as very high swelling potential clay composed mainly of montmorillonite clay, and the studied clay sample (3a) is considered as high swelling potential clay composed of mixed montmorillonite–illite layer as well as kaolinite clay minerals.

According to the XRD and SEM results, and according to many researchers (e.g. Miller and Azad 2000; Michell and Soga 2005; Peethamparan et al. 2009; Solanki and Zaman 2012) the high swelling clays that contains a considerable amount of montmorillonite clay mineral are suitable for CKD treatments due to their high activity, cation exchange capacity and surface area, as well as the presence of main cations which are necessary to complete the pozzolanic reactions.

Cement kiln dust (CKD)

The CKD is a by-pass product derived from the Portland cement industry carried in air stream of cement kiln and removed by the plant’s air pollution control system. The chemical and mineralogical compositions of CKDs derived from different cement kilns are mostly depending on the types of raw materials, type of cement production operation, the fuel used in cement industry, and dust collection facility. Therefore, the CKDs generated from different plants vary in chemical and mineralogical compositions (Peethamparan et al. 2009; Abdel-Ghani et al. 2018). In general, the composition of CKD is similar to that of Portland cement with relatively high amounts of sulfates and chlorides and generates relatively highly alkaline pH levels when mixed with water.

Peethamparan and Olek (2008) and Rahman et al. (2011) suggested that the effectiveness of CKD as a stabilizer or binder material in soil stabilization depends on both its physical and chemical characteristics as well as the particle size distribution, percentage of CaO, SiO2, alkali and sulfate content. Many researchers investigated the possibility of using CKD in soil stabilization (e.g. Peethamparan et al. 2006; Peethamparan and Olek 2008). The results indicated that all the types of CKDs enhanced the geotechnical characteristics of kaolinite and Na-montmorillonite clays especially the high free-lime CKDs. Therefore, before using the CKD in soil stabilization, the chemical and mineralogical compositions of CKD must be investigated to ensure the effectiveness suitability of CKD in soil treatment.

The used cement kiln dust with high free lime-content (fresh CKD or high free-lime CKD) was obtained directly from the electrostatic precipitators of Tourah Portland Cement Factory and stored in airtight plastic bags to reduce the CKD hydration. The gradation curve of CKD is shown in Fig. 2 and is revealed that the CKD has a wide grain distribution scale from fine sand to clay (0.3 mm to less than 0.005 mm) and it can be considered as silt size material.

The bulk chemical composition of CKD was carried out at the Raw Building Materials and Processing Technology Research Center, Egypt, and the results are given in Table 2. The results revealed that the combined amounts of silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3) are approximately 19% by weight. The CKD contained a high content of CaO, 56.94% by weight, with high content of unreacted CaO or free-lime content (13.94%) which plays a major role in the stabilization of high expansive clays. The CKD is characterized by high alkali content (about 5% of Na2O and K2O) confirmed by the presence of considerable amounts of soluble alkali salts as sylvite and halite minerals as confirmed in XRD analysis of CKD (Fig. 3). It is characterized by high TDS content (7.25%) and high amounts of Cl− and SO3− (3.18% and 2.01% for water extraction method, and 3.45% and 2.99% for acid extraction method, respectively). When the CKD mixed with water, the CKD produced a highly alkaline pH of about 13.16 which was greater than the pH value (12.5) of CaO or Ca(OH)2 solutions that is the main indicator of effectiveness of CKD in expansive clay stabilization process. This pH result agrees with Peethamparan and Olek (2008).

The XRD pattern of studied CKD (Fig. 3) is obviously dominated by the characteristic peaks of portlandite Ca(OH)2, larnite (Ca2SiO4), parawollastonite (CaSiO3), anhydrite (CaSO4), sylvite KCl, and halite NaCl. Due to the wide range of the chemical and mineralogical compositions of different CKDs, the chemical and mineralogical compositions of this CKD should not be considered as a main characteristic composition of different types of CKDs.

The SEM micrographs of CKD (Fig. 7) illustrates that the studied CKD particles considered as undispersed or agglomerated particles with poorly defined shapes.

Clay-CKD treated mixtures

Previous studies have shown that the treatment of expansive soils with 8–40% CKDs can improve their geotechnical properties, but the optimum CKD content in soil stabilization, to obtain the high degree of enhancement of soil properties, is depending on the type of treated soils (montmorillonite, illite, kaolinite clays) and the chemical and mineralogical compositions of CKDs especially the percentage of free lime content that considered as the main factor of soil stabilization (Baghdadi and Rahman 1990; Zaman et al. 1992; Santagata and Bobet 2002; Peethamparan and Olek 2008; Peethamparan et al. 2009; Solanki and Zaman 2012). The effectiveness of CKD stabilization amount added to stabilized soil can be studied by measuring the changes in Atterberg limits, swelling potentiality, and UCS. Hence, it is important to evaluate the effectiveness of CKD as soil stabilizer, based on its chemical composition (free lime content). Dash and Hussain (2012), Ciancio et al. (2013), and Jha and Sivapullaiah (2020) studied the lime stabilization of soils and revealed that the optimum lime content in soil stabilization process is ranging from 4 to 6% that enhanced the workability, durability and other geotechnical characteristics of stabilized soils. Relying on previous studies, for each of the current studied clay samples, five CKD concentrations (8%, 16%, 24%, 32%, and 40% of dry soil weight, with free lime contents 1.12%, 2.23%, 3.35%, 4.46%, and 5.58%, respectively) were mixed with the clay soil.

The moisture content through the treated soil system dramatically influences the manner of lime diffusion and lime reaction during lime stabilization in lime–clay system, where the high moisture content enhances the efficiency of lime diffusion and provides sufficient water to produce the pozzolanic hydrated minerals in the long term (Bell 1988; Barker et al. 2007). Sreekrishnavilasam et al. (2007) mixed the CKD-clay mixtures with water content that measured at 15 blows consistency. Peethamparan and Olek (2008) measured Atterberg limits of CKD-clay mixtures after mixing with water content equivalent to 25–35 blows needed to close groove of liquid limit device to attain uniform water content. As well as, Ismail and Belal (2016) mixing the CKD-clay mixtures with water content at plastic limit and curing 24 h. to ensure the homogenous distribution of sufficient water through the mixtures. Therefore, in this study the water content value at zero-time curing liquid limit for each CKD-clay mixture was used to ensure the uniform water distribution and sufficient water to carry out the stabilization pozzolanic reactions. The two dry components are firstly combined and homogenized by manual mixing and then the identical water content (water content equal to liquid limit value at zero-time curing for each mixture) was added. After the homogenous mixing of these components with the identical water content, the mixed CKD-clay treated mixture was hermetically sealed in plastic cylinder (12 cm long and 6.4 cm diameter) for curing at 24 °C, average temperature of laboratory room during curing time of specimens. The CKD-clay treated mixture was stored for curing periods of 0, 1, 7, 14, and 28 days to investigate the immediately impact of CKD in soil stabilization, stabilization stages from hydration stage of free lime into mostly completing the pozzolanic reactions stage that can be used in evaluation of CKD effectiveness. After designated curing periods, the CKD-clay treated mixture were oven-dried at 65 °C for approximately 12 h and air-dried for 48 h and then various Atterberg limits, SEM and XRD analyses were carried out.

The investigation testing program to evaluate the effectiveness of CKD as a stabilizer or binder material in soil stabilization as well as the mechanism of CKD-clay stabilization, including measure of the CKD-clay treated mixtures pH values, using Pometer pH009 (II) ATC portable pH meter; measure of the total dissolved salts (TDS) values using pocket standard TDScan2 tester; and measure of the electrical conductivity (EC) using digital EC conductivity meter model EC-1383 according to test method reported in ASTM D4972-01 (2007). This investigation program was carried out on the treated clay samples (2b and 3b) with 24% CKD for 0, 7, 14, 28, 42, and 56 curing days. The study of unconfined compressive strengths (UCS, according to ASTM D2166-00 2000) for moist CKD-treated clays were also conducted in the present study for 1, 7, 14, and 28 curing days.

The Atterberg limits of Nile Delta clays treated with 8%, 16%, 24%, 32%, and 40% of CKD were determined with different curing periods. On the other hand, the UCS, TDS, pH, EC, XRD, and SEM were carried out on the optimum added CKD percentage in the present study (24% CKD by dry weight of clay samples).

Results and discussion

According to ASTM D 4609-02 (2002), the effectiveness of soil stabilizer agent is assessed by comparing the Atterberg limits, UCS, and resistance to moisture between treated and untreated clay samples. In this standard method, the significant reduction of liquid limit and plasticity index as well as the increase of the UCS of treated clays at least of about 0.345 MPa or more are indication of effectiveness of stabilizer agent in soil stabilization.

Atterberg limits

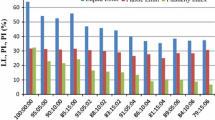

To evaluate the effectiveness of CKD in reducing the Atterberg limits and plasticity index that result in improving the durability and workability of clays, a series of liquid limit and plastic limit tests according to ASTM D 4318-00 (2000) were carried out at four curing periods (immediately after mixing at zero time, 7, 14, and 28 days) for treated clay samples with different five CKD percentages (8, 16, 24, 32, and 40 of CKD) and these obtained results were compared with Atterberg limits and plasticity index values of untreated clay samples.

Figure 8 shows the impact of different CKD percentages and curing periods on liquid and plastic limits and then on plasticity index. The obtained results revealed that the addition of CKD to the studied clay samples significantly decreases both the liquid limit and plasticity index values, and slightly increases the plastic limit values. The obtained results of this study show that the percentage of 24% CKD is the optimum mixing percentage for effective treatment of expansive clays with maximum dropping in liquid limit and plasticity index values. A further increasing in the CKD content after this optimum mixing percentage didn’t significantly influence the liquid limit and the plasticity index values of treated clay samples. Also, the figure shows that in the present investigation, the 28 days curing time is the optimum curing time for stabilization of expansive clay samples by CKD. The obtained results revealed that, the liquid limit values decreasing from 195 to 144.5% (for clay samples 1a and 1b, respectively) with reduction percent of about 25.9%, from 108 to 75% (for clay samples 2a and 2b, respectively) with reduction percent of about 30.56%, and from 80 to 52.5% (for clay samples 3a and 3b, respectively) with reduction percent of about 34.38%, when mixing with 24% CKD and cured for 28 days. These reduction percent values suggest that the untreated clay samples converted from extremely high swelling potential clays into very high or high swelling potential clays specially for clay samples (2a and 3a) when treated with CKD (clays samples 2b and 3b, respectively), according to Dakshanamurthy and Raman classification (1973). On the other hand, the plastic limit values are slightly increased from 55 to 63.54% (for clay samples 1a and 1b, respectively), from 39 to 44% (for clay samples 2a and 2b, respectively), and from 32 to 36.54% (for clay samples 3a and 3b, respectively) with increasing percent of about 15.5%, 12.82%, and 14.19%, respectively, that result in decreasing the plasticity index values and then increasing the durability and workability of treated clay samples. The plasticity index values also decreasing from 140 to 80.96% (for clay samples 1a and 1b, respectively), from 69 to 31% (for clay samples 2a and 2b, respectively), and from 48 to 15.96% (for clay samples 3a and 3b, respectively) with reduction percent of about 42.17%, 55.07%, and 66.75%, respectively, converted the studied clay samples from very high plastic clays into high or medium plastic clays specially for clay samples (2a and 3a) when treated with CKD (clays samples 2b and 3b, respectively).

The results of the present study accord with the Peethamparan and Olek (2008) study, which suggested that the effectiveness of CKD in remediation of high expansive clay samples was directly proportional with free lime, alkali and sulfate content of the CKD that is high in the studied CKD.

Unconfined compressive strength and stiffness behaviors

The unconfined compressive strength, UCS, is a very important key indicator in the evaluation of CKD effectiveness and in improving the bearing strength and stiffness of treated clays. The unconfined compressive strength tests were carried on 24% CKD-clay treated saturated mixtures through different curing periods (1, 7, 14, and 28 days). The obtained results of UCS (Fig. 9) reveal that the UCS values of treated clay samples increased with curing time. The UCS of treated clay samples was increased from 0.0667 to 0.260 MPa (for clay samples 1a and 1b, respectively), from 0.0926 to 0.524 MPa (for clay samples 2a and 2b, respectively), and from 0.1267 to 0.6236 MPa (for clay samples 3a and 3b, respectively) with increasing percent of about 290%, 466%, and 392%, respectively, after one-day curing time and then was increased to 1.1065 MPa, 2.30 MPa, and 2.706 MPa with increasing percent of about 1558% (15.5 times), 2383.26% (23.8 times), and 2035.48% (20.3 times) for clay samples (1b, 2b, and 3b), respectively, after 28 days of curing time. This increasing in UCS due to treatment with 24% CKD and curing to 28 days converted the studied soft to firm clays (Bell 2007) into weak rock (Egyptian code 2007) with increasing durability and workability of treated clays as confirmed by enhancement of Atterberg limits as discussed above. The wide range of the UCS increasing for the different three studied clay samples especially at 28 days curing time may be due to their difference in sand contents, clay percentages and clay types; whereas, the soil with high sand content has high UCS than the soils that has high clay content as shown from grain size distribution of studied clay samples. Thus, treating the high expansive clay samples with an appropriate amount of high free-lime CKD and allowing them to cure for a sufficient curing time extraordinarily increases the UCS and bearing strength of treated clays. These results are validated by the study of Peethamparan and Olek (2008) that suggested the UCS values of treated expansive clays significantly impacted by free lime, alkali and sulfate contents in CKD stabilizing agent that are presented with high contents in the studied CKD.

The measured stress–strain curves of 24% CKD-treated clay samples with different curing periods revealed that with increasing curing time, the peak stress increased reflecting the increase of UCS and decrease the peak strain from 11 to 2.5% (for clay samples 1a and 1b, respectively), from 9 to 2.5% (for clay samples 2a and 2b, respectively), and from 8 to 3% (for clay samples 3a and 3b, respectively) with reduction percent of about 77.27%, 72.2%, and 62.5%, respectively, that induced substantially brittle behaviors for the treated clay samples (Fig. 10).

The settlement magnitude and stiffness of clay soil depend on its Young’s modulus. The estimation of soil stiffness at any strain level is important for foundation engineering practice specially when building on problematic soils (Vardanega and Bolton 2013). In this study, the initial tangent modulus (Es), which is the slope of the initial straight-line portion of stress–strain curve obtained from the unconfined compressive strength test, is used as an indicator for the increase of the stiffness of treated CKD-clay mixtures. Generally, in the present study the addition of 24% CKD into soft to firm clays with short curing period (one-day curing time) increases the initial tangent modulus from 1.44 to 7.38 MPa (for clay samples 1a and 1b, respectively), from 1.58 to 10.65 MPa (for clay samples 2a and 2b, respectively), and from 4.42 to 10.1 MPa (for clay samples 3a and 3b, respectively), with increasing percent of about 512.5%, 674%, and 228.5%, respectively. With increasing the curing time, the initial tangent modulus increased as shown in Fig. 11; whereas, the initial tangent modulus of 24% treated CKD-clay mixture at 28 days curing period was increased between 33 and 82 times compared to untreated clay samples (increasing percent ranging between 3201 and 8114%). This enhancement in the stress–strain behaviors of treated clays was confirmed by the enhancement of their Atterberg limits. By increasing the CKD content and curing time, higher initial stiffness, reduced strain at failure, and overall more brittle behaviors are achieved. These treatment behaviors of treated clays with CKD stabilizer or binder material are similar to observations that have been made in the case of cement-treated clay according to the investigation carried out by Sreekrishnavilasam et al. (2007). Therefore, based on these physical and mechanical characteristics (physico-mechanical characteristics) of untreated and treated Nile Delta clay samples, it can be suggested that the studied high free-lime CKD binder material is an effective, economical, and commercially successful soil stabilizer agent.

CKD-clay stabilization mechanism

pH, TDS, EC, XRD, and SEM investigations for the optimum CKD stabilizer or binder percentage in the present study (24% CKD-clay treated mixtures for clay samples 2b and 3b) were carried out to understand the clay stabilization mechanism that was responsible of improving the geotechnical characteristics of high expansive clays. In the present study, the CKD-clay chemical reactions have four main stages that are initial rapid hydration of CKD (Stage 1), cation exchange between soluble cations (Stage 2), flocculation and agglomeration of clay particles (Stage 3), and pozzolanic reactions between CKD and clay (Stage 4). This agrees with the studies that were carried out by Eades and Grim (1960), Diamond et al. (1964), and Beetham et al. (2015) on the attack of the calcium hydroxide on clay minerals in lime–clay stabilization system and clay mineral modifications.

Beetham et al. (2015) introduced the context of lime stabilization and principles of lime–clay reactions. They revealed that the lime–clay reactions are divided into four stages. The first drying stage is removing the excess water from the lime–clay system by rapid hydration of CaO into Ca(OH)2 which is considered as exo-thermal reaction that generate substantial heat and increase the pH to maximum value of about 12.45, the typical time required for this stage is immediately after the addition of lime. The second stage is cation exchange/clay mineral aggregation. In this stage rapid cation exchange process occurs on the surface of clay particles. By this rapid cation exchange between divalent (Ca2+) cation and monovalent cations (Na+ and K+), the diffuse double layers around the clay particles shrink and the electro-static charges on the edges and faces of clay particles are balanced resulting in flocculation and positive/negative charge (edge-to-face) arrangement (Fig. 12). This causes aggregation of clay particles to silt size aggregations (Bell, 1996). The time required for this stage ranges from 0 to 72 h. At the same time of the second stage, the third stage begins. The third stage (cation exchange/clay aggregation) reduces clay mineral effective surface area and the early pozzolanic reactions restrict subsequent dispersion of aggregations. The required time of this stage ranges from 0 to 72 h. In this stage, an increase in micro-porosity and a change of meso-porosity (intra-aggregate and inter-aggregate to flocculated particles, respectively) reduces the effective surface area of clay minerals in contact with inter-aggregate pore water that results in the decreasing of plasticity and shrink/swell behaviors, promotion of brittle/friable behavior, and increasing permeability (Fig. 12). At the end of this stage, early-formed pozzolanic reaction products localize at the contact points between clay particles (Fig. 12). The final fourth stage is pozzolanic reactions stage, which starts at 72 h., continuing for months/years. With new minerals growth and by increasing curing time the engineering properties, strength, stiffness, and durability of treated clay samples are achieved (Beetham et al. 2015).

Sequence of early lime–clay reactions (Beetham et al. 2015). a Diffuse double layer, b substitution of Ca2+ cations for Na+ and K+ cations reduces diffuse double layer thickness, c aggregation of clay particles results in repulsion of like charges on clay particles, and d aggregations of larger particles with inter-aggregate pore space

Eades and Grim (1960) and Diamond et al. (1964) suggested that the lime–clay reactions occur in three steps which are exchange of calcium ions for those held by the clay minerals, formation of new pozzolanic minerals, and finally carbonation of any excess lime when stabilization soil system is subjected to atmospheric air condition and/or dissolved carbon dioxide in mixing water.

As lime, the calcium hydroxide carbonation process was carried out if the CKD-clay system with high content of calcium hydroxide (free lime dissolved in water) is subjected to atmospheric air and/or dissolved carbon dioxide in mixing water. In this case, the calcium hydroxide reacted with carbon dioxide to form calcium carbonate as the following chemical equation. Therefore, the studied CKD-clay treated mixtures were saved and cured in sealed plastic bags to prevent this carbonation process:

In the first stage, initial rapid hydration, the free calcium oxide "free lime" rapidly absorbed water from the saturated media and hydrated with releasing a thermal energy based on the following equation as a hydration reaction result:

The thermal energy released from the initial rapid hydration of the studied pure CKD and treated 24% CKD-clay mixtures (for clay samples 2b and 3b) were measured and represented in Fig. 13. The rapid hydration reactions of these studied slurries revealed that the temperature of hydrated pure CKD elevated from the initial pre-hydration temperature, 24 °C of water temperature, into 40 °C between 20 and 30 min. For the CKD-clay (2b) system, the temperature elevated into 38 °C in a time ranging from 5 to 15 min, while for the CKD- clay (3b) mixture was elevated into 37.5 °C between 8 and 15 min. The temperature values of initial rapid hydration reactions decreased into initial pre-hydration temperature in a time ranging between 100 and 120 min. Hence, it can be suggested that the complete hydration process for treated clay samples required time ranging between 15 and 30 min (the first stage of rapid hydration process). The temperature is considered as the most important factor in clay stabilization; whereas, at the beginning of rapid hydration process, temperature and pH values increased and the CKD gel is formed along the edges of clay particles resulting in rapid consumption of free lime and a breakdown of clay phase. This hydration process agrees with the study of stabilization of different soils by cement that was carried out by Mitchell and El Jack (1966). Miller (1960) and Leontakianakos et al. (2010) suggested that the hydration temperature is affected by the particle size and the activity of calcium hydrated particles; whereas, the increase in hydration temperature is mostly associated with fine particle and high activity Ca(OH)2 particles. This reason could explain the variation in temperature values and hydration reaction time for the studied treated CKD-clay mixtures and pure CKD raw material.

Immediately after completing the rapid hydration stage of free lime content in CKD, the maximum concentration of calcium hydroxide quickly raises the pH value of the CKD-clay slurry into 12.81–12.86 which was substantially greater than the pH value that is produced by CaO or Ca(OH)2 (pH 12.5, Peethamparan et al. 2009). This creates a favorable alkaline environment for local dissolution of clay particles at their surfaces and edges resulting in the release of aluminum and silica into solution and then further CKD-clay system chemical reactions. The pH values of the studied CKD-treated clay samples (2b and 3b) are increased from 7.41 and 7.23 to 12.86 and 12.81, respectively. This increasing in pH values of the studied CKD-clay systems is the main indicator of the effectiveness of CKD as a stabilizer agent. This pH increasing provided a favorable condition for dissolving the silica and alumina from the clay structure and promoting the chemical reactions of released soluble silica and alumina cations with the calcium hydroxide liberated from hydration of free lime.

The cation exchange and flocculation–agglomeration processes (stages 2 and 3) are carried out immediately after complete hydration stage. In cation exchange process, the monovalent cations in lattice structure of clay minerals as well as monovalent cations between interlayered structure of clay minerals (Na+, and K+) are replaced by bivalent calcium ions liberated from CKD to balance the charge deficient on the surfaces and edges of clay particles. These calcium ions linked the clay particles together by reducing the repulsion forces and thickness of the double-diffused water layer between clay particles (change the electrolyte content of water in CKD-treated clay system) resulting in increasing the strengthening bond between clay particles and causing change in the clay texture (flocculation–agglomeration appearance) (Beetham et al. 2015).

In light of the above-mentioned, the variation in pH, EC, and TDS values due to the addition of CKD into clay system was measured in this study. Zhang et al. (2000) found that the initial rapid increasing in pH value of the modified treated clay was followed by decreasing of this value through curing time which is a good indicator of pozzolanic reactions.

The present study discovered that the pH, EC, and TDS values of treated clay samples by CKD are decreased with curing time which proved the effectiveness of CKD in clay treatment and represented the four stages of CKD stabilization mechanism (Fig. 14). The results of pH, EC, and TDS revealed that the complete hydration stage took about several minutes with maximum values of pH, EC, and TDS (with average values of about 12.835, 28.26 mS/cm, and 12,449 ppm, respectively). The cation exchange and flocculation–agglomeration stages took about several hours and could extend to few days (rapidly change or decreasing in pH, EC, and TDS values). In this study, they began from about 30 min and extended into twenty-four hours, or may have even extended into seven days where the pH, EC, and TDS values were mostly constant with minor changes (at average values of about 11.55, 14.25 mS/cm, and 6100 ppm for pH, EC, and TDS; respectively). The pozzolanic reactions stage in this study began immediately after the abrupt decreasing of pH, EC, and TDS values that was mostly associated with the cation exchange and flocculation–agglomeration stages (24 h. after the beginning of CKD-clay system reaction) and continued with increasing curing time until the pH of CKD-clay system created unfavorable conditions. In the present investigation, this value of pH is 11.06 with 7 mS/cm EC and 3700 TDS that was achieved after 56 curing days. In the pozzolanic reactions stage, the soluble silica, alumina, sulfate, and calcium ions reacted together to produce the cementitious materials as calcium silicate hydrates (tobermorite CSH mineral, as confirmed by XRD and SEM investigations) and calcium aluminum sulfate hydrates (ettringite mineral, as confirmed by XRD and SEM investigations), in addition to recrystallization of poorly defined minerals in CKD as portlandite and parawollastonite minerals that was confirmed by XRD and SEM analyses. The portlandite mineral is mostly coming from recrystallization of existing poorly defined portlandite mineral in CKD and/or from crystallization of calcium hydroxide liberated from complete hydration of free lime in CKD-clay system. By increasing the curing period of treated clays, these cementitious minerals increase in size and fill the micro-pores between aggregated clay particles resulting in the increase of the bulk density and then the increase of the mechanical characteristics of treated clay samples.

The macro-textural, mineralogical, and microstructural changes due to CKD treatment of Nile Delta clay samples were determined by visual observations, XRD, and SEM investigations as well as compared with the corresponding natural clay samples.

The visual observations of 28 days curing clay specimens treated with 24% CKD show that the formation of porphyritic texture in addition to granular texture with aggregated and dispersive textures of treated clays that was indicated by a rough touch rather than a smooth touch of natural clays (Fig. 15). This figure shows that there are two types of porphyritic materials, the essential type is the black porphyritic materials which is padded by white materials, while the secondary type is the white porphyritic powdered materials. The XRD analysis was carried out on the black porphyritic materials (Fig. 16), while the acidic solubility test by using 10% hydrochloric acid solution was carried out on the white porphyritic powdered materials.

The XRD results revealed that the mineral composition of the black porphyritic materials is mainly goethite, illite, kaolinite, and quartz minerals; while the acidic solubility test results revealed that the main composition of the white porphyritic powdered materials is calcite mineral that give high effervescence with 10% dilute hydrochloric acid solution. These observations can be attributed to the porphyritic materials composed mostly of inactive minerals (unreacted minerals) and/or residual product of stabilization process. The calcite mineral may be derived from the calcite mineral that is included within the studied clay samples or from the slight carbonation of calcium hydroxide by dissolved carbon dioxide within the treated water. The black porphyritic materials are mainly inactive minerals that migrated through the CKD-clay slurry, concentrated, and deposited in large voids to form the porphyritic texture of treated clay samples. These observations are indirect good indicators of stabilization reactions in treated CKD-clay mixture that mainly occurred between the very active montmorillonite clay mineral and the soluble calcium and sulfate ions liberated from CKD in CKD-clay system.

The change in mineralogical composition of stabilized Nile Delta clay samples using CKD binder material is shown in Fig. 16. The mineralogical investigation revealed that the treated clay samples have the same mineralogical composition of natural untreated clay samples in addition to CKD minerals (as parawollastonite, portlandite, and sylvite minerals) and cementitious minerals of pozzolanic reactions (as tobermorite and ettringite minerals). The XRD patterns of the treated clays revealed the disappearance of some montmorillonite clay peaks and a decrease in the peak intensity of others, as well as an increase in the intensity of CKD-minerals phases and pozzolanic cementing minerals. This observation shows that the montmorillonite clay mineral was attacked in alkaline environment by calcium hydroxide to produce hydrated calcium silicate minerals (as tobermorite), and by soluble sulfate ion liberated from anhydrite and sylvite salt in CKD to produce hydrated calcium aluminum sulfate minerals (as ettringite). This observation also shows the recrystallization of the anhedral crystals "poorly defined shape particles" of CKD minerals (Fig. 7). This was confirmed by the SEM investigation for treated CKD-clay samples. The constant intensities of feldspar peaks such as albite, microcline, and labradorite revealed that the main source of soluble silica and alumina cations that are required to carry out the pozzolanic reactions in the CKD-clay system is montmorillonite and other clay minerals.

The mineralogical composition and microstructural changes through CKD-treated clay samples were confirmed by SEM observations. The representative SEM micrographs at different spots through the treated 24% CKD-clay mixtures that had been subjected to 28 days curing, oven-dried at 65 °C for 12 h., and then air-dried for 48 h. are represented in Figs. 17 and 18.

Figure 17a shows the significant changes in the microstructure of treated clay sample (2b) when mixed with CKD and cured for 28 days. These microstructure modifications revealed that the flaky texture of montmorillonite clay mineral (as shown in Figs. 5, 6) almost disappeared and most of the clay particles were converted in fact into cemented clay agglomerations (silt-sized aggregations) that are closely separated by an inter-aggregate porosity. Besides, a new cementitious calcium hydroxide (CH) flaky mineral "portlandite" was observed. The figure also shows that there are no preferential orientations of clay flakes (random structure of treated clay), and the secondary porosities between silt-sized aggregations that are observed as micro-pores. This SEM micrograph also reveal that the porphyritic materials were covered with a reaction shell of cemented clay particles with new cementitious products resulting from the chemical pozzolanic reactions.

Figure 17b shows that the new cementitious minerals with characteristic crystal shapes are presented. The non-developed needle forms of hydrous calcium silicate "CSH" tobermorite mineral with reticulated structure or honeycomb structure is found on the surface of montmorillonite clay "cotton appearance" and developed in the inter-aggregate voids. In addition, small lamellar crystals that presumably hydrous calcium aluminum sulfate mineral "ettringite" is also found on the surface of montmorillonite clay, extending in the direction of inter-aggregate voids.

Figure 17c discloses the inter-aggregate voids that are filled with cementitious minerals. The lath-shape or flaky habit of portlandite, the rose-shape or sheet-like structure of tobermorite, and thin lamellar crystals of ettringite minerals fill these inter-aggregate voids.

Figure 18, for 24% CKD-treated clay sample (3b) that was cured for 28 days, reveals that the aggregation texture with several micro-pores (inter-aggregate voids) between the aggregated clay particles are filled by new pozzolanic cementitious minerals with special new microstructure morphologies "rose texture" (Fig. 18a). This figure also discloses the recrystallized lamellar parawollastonite mineral, unreacted microcline grains and unreacted montmorillonite clay particles.

Figure 18b shows a close-up view of the new microstructure morphology which reveals that the montmorillonite clay particles are considered as a center "a nucleus" of pozzolanic reactions between the soluble calcium and sulfate ions liberated from CKD on one side and the soluble silica and alumina cations dissolved from montmorillonite clay mineral on the other side. Based on this figure, it is concluded that the high concentration of exchangeable and reacted cations on the montmorillonite clay edges/faces have a favorable condition for completing the pozzolanic reactions that results in precipitation of new cementitious minerals. These cementitious minerals are observed on the edges/faces of high activity montmorillonite clay particles within the treated clays. The non-developed CHS mineral "tobermorite" is observed on the upper clay surface with special rosy texture and/or web texture. In addition, developed thin lamellar and/or needle-shape crystals of ettringite mineral are observed as growth columns from the base and edges of montmorillonite clay particles and extended to fill the void spaces between treated clay particles (inter-aggregate voids). This figure also shows the core of unreacted montmorillonite clay particles with the original cotton appearance, as well as recrystallized parawollastonite mineral.

Figure 18c is a close-up view of the new microstructure appearance that is developed in inter-clay particle voids particles (inter-aggregate voids), where the cotton appearance of montmorillonite clay mineral observed with needle-shape crystals of ettringite that grow as radiated crystals from the edges of montmorillonite clay flakes.

Generally, the SEM investigation of treated CKD-clay mixtures suggested that the montmorillonite clay mineral attacked at its edges and faces by calcium hydroxide and soluble sulfate anion that was liberated from hydrated CKD forming new cementitious tobermorite and ettringite minerals that filled the inter-clay particle voids (inter-aggregate voids) resulting in the appearance of the compacted structure of treated clay samples resulting in infilling the inter-aggregate pore space, strength increase, and permeability decrease by pore blocking as suggested by Wild et al. (1987). The un-attacked montmorillonite clay particles or unreacted core of montmorillonite clay particles did not suffer appreciable loss of crystallinity and have the original cotton appearance with original foliated clay texture.

Finally, the author can postulate after the addition of CKD into clay, the progressive dissolution of the montmorillonite edges and faces in strong alkaline environment "pH ≈12.8" is produced by liberated Ca(OH)2 from rapid hydration process of CKD. The dissolution of these clay edges and faces are resulting in high concentration of soluble silica and alumina cations on these faces and edges of clay particles. After that in the presence of soluble calcium hydroxide and sulfate anion in the CKD-clay system, the pozzolanic reactions between these ions begin at these edges and faces. These pozzolanic reactions resulted in precipitation of the new cementitious products filling the inter-aggregate voids. Then by increasing the curing times, these new cementitious products enhance the geotechnical properties of treated clay samples as increasing the workability, durability and mechanical strength characteristics.

Conclusions

This paper has covered the suitability of CKD as a clay stabilizer or binder material as well as the stabilization mechanism of CKD-clay system including the change in the mineralogical and microstructural characteristics. Three clay samples representing the high plasticity and soft to firm north Nile Delta clays are selected to achieve the objectives of the present study. In this study, five CKD-clay mixtures (8%, 16%, 24%, 32%, and 40% CKD by weight of dry soil) with different curing times (1, 7, 14, 28 days) were investigated. The following list summarizes the key points discussed in this paper that may be useful for future studies.

-

1.

The addition of CKD into expansive clays converts the very high plastic clays into high-to-medium plastic clays, and converts the soft-firm clays into weak rock. These enhancements in swelling and mechanical strength behaviors of treated clays revealed that the studied clay samples became stiffer and had more brittle behavior and a higher bearing capacity strength. Therefore, finally these improvements result in increasing the durability and workability of treated clays and reveal that the CKD is considered as an effective soil stabilizer agent.

-

2.

In general, mineralogical and SEM investigations confirmed that the addition of CKD-binder material to clays induced some beneficial pozzolanic reactions where the montmorillonite clay particles served as nucleation sites for growth of the cementitious minerals resulting in filling the inter-aggregation voids affecting the pore size distribution. These modifications in mineralogical and microstructure behaviors of treated clay samples are contributed to significant enhancement of the geotechnical characteristics of unsuitable clays under the engineering structures.

-

3.

Based on the results of temperature, pH, EC, and TDS as well as XRD and SEM observations of untreated and treated clay samples, the soil stabilization mechanism is carried out through four stabilization stages. These stages are: (1) by adding CKD to untreated clays, the rapid hydration process of free lime (rapid hydration stage) raises the pH of CKD-clay system that creates a favorable condition for local dissolution of the clay particles at their faces and edges releasing a considerable amount of soluble silica and alumina into solution with high concentration of calcium hydroxide and soluble sulfate anion. The time required for this stage is 30 min, (2) after the rapid hydration process stage, the cation exchange and flocculation–agglomeration processes begin. These processes resulted in reducing the repulsion forces and thickness of the double-diffused water layers in clay particles which promotes rapid aggregation and flocculation of the clay particles into silt size with inter-aggregation voids. The required time for these stages extended into few hours and may extend into seven days, (3) with and/or after cation exchange and flocculation–agglomeration processes, the pozzolanic reactions between soluble silica, alumina, sulfate, and calcium on the active clay faces and edges are carried out. With increasing of curing time, the essential pozzolanic products "tobermorite and ettringite minerals" growth on the faces and edges of clay particles, in addition to recrystallization of some weak crystallized portlandite and parawollastonite CKD minerals. The required time for this pozzolanic stage extended from 24 h until the pH of CKD-clay system created unfavorable conditions that was achieved after 56 curing days.

-

4.

According to the results of this study, the use of a considerable amount of CKD in the stabilization of problematic clays could potentially consume the bulk of the hazardous CKD materials that generate every year. As well as is considered as the most economical and environmental alternative to the other chemical soil stabilizer agents.

References

Abd El-Aziz MA, Abo-Hashema MA (2018) Enhancing stability of clayey subgrade materials with cement kiln dust stabilization. Int J Pavement Eng Tech (PEAT) 19(2):1–19. https://doi.org/10.1515/ijpeat-2016-0022

Abdel-Ghani NT, El-Sayed HA, El-Habak AA (2018) Utilization of by-pass cement kiln dust and air-cooled blast-furnace steel slag in the production of some ‘‘green” cement products. J HBRC 14(3):408–414. https://doi.org/10.1016/j.hbrcj.2017.11.001

Adeyanju EA, Okeke CA (2019) Clay soil stabilization using cement kiln dust. In: 1st inter. conf. on sustainable infrastructural development, IOP conf. series: mater. sci. and eng., vol 640, p 012080. https://doi.org/10.1088/1757-899X/640/1/012080

Al-Aghbari MY, Mohamedzein YEA, Taha R (2009) Stabilisation of desert sands using cement and cement dust. Proc Inst Civ Eng Ground Improv 162(3):145–151. https://doi.org/10.1680/grim.2009.162.3.145

Ali AAM, Negm AM, Bady MF, Ibrahim MGE, Suzuki M (2016) Environmental impact assessment of the Egyptian cement industry based on a life-cycle assessment approach: a comparative study between Egyptian and Swiss plants. Clean Technol Environ Policy 18:1053–1068. https://doi.org/10.1007/s10098-016-1096-0

ASTM (C 25-99) (1999) Standard test method for chemical analysis of limestone, quicklime, and hydrated lime. ASTM International, West Conshohocken

ASTM (D 2166-00) (2000) Standard test method for unconfined compressive strength of cohesive soil. ASTM International, West Conshohocken

ASTM (D 4318-00) (2000) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. ASTM International, West Conshohocken

ASTM (D 2487-00) (2000) Standard practice for classification of soils for engineering purposes (unified soil classification system). ASTM International, West Conshohocken

ASTM (D4609-02) (2002) Standard guide for evaluating effectiveness of admixtures for soil stabilization. ASTM International, West Conshohocken

ASTM (D 422-63) (2003) Standard test method for particle-size analysis of soils. ASTM International, West Conshohocken, PA

ASTM (C114-04) (2004) Standard test methods for chemical analysis of hydraulic cement. ASTM International, West Conshohocken

ASTM (D4972-01) (2007) Annual book of ASTM standard. Standard test method for pH of soils. ASTM International, West Conshohocken

ASTM (D7348-08) (2008) Standard test methods for loss on ignition (LOI) of solid combustion residues. Ignition (LOI) of solid combustion residues. ASTM International, West Conshohocken

Attoh-Okine NO (1995) Lime treatment of laterite soils and gravels—revisited. J Constr Build Mater 9(5):283–287. https://doi.org/10.1016/0950-0618(95)00030-J

Azadegan O, Jafari SH, Li J (2012) Compaction characteristics and mechanical properties of lime/cement treated granular soils. Electron J Geotech Eng 17:2275–2284

Baghdadi ZA (1990) Utilization of kiln dust in clay stabilization. J King Abdul-Aziz Univ J Eng Sci 2:153–163

Baghdadi ZA, Fatani MN, Sabban NA (1995) Soil modification by cement kiln dust. ASCE J Mater Civ Eng 7(4):218–222. https://doi.org/10.1061/(ASCE)0899-1561

Baghdadi ZA, Rahman MA (1990) The potential of cement kiln dust for the stabilization of dune sand in highway construction. J Build Environ 25(4):285–289. https://doi.org/10.1016/0360-1323(90)90001-8

Barker JE, Rogers CDF, Boardman DI (2007) Ion migration associated with lime piles: a review. Proc Inst Civ Eng Ground Improv 11(2):87–98. https://doi.org/10.1680/grim.2007.11.2.87

Beetham P, Dijkstra T, Dixon N, Fleming P, Hutchison R, Bateman J (2015) Lime stabilisation for earthworks: a UK perspective. Proc Inst Civ Eng Ground Improv 168(2):81–95. https://doi.org/10.1680/grim.13.00030

Bell FG (1988) Stabilisation and treatment of clay soils with lime: part (1)-basic principles. Ground Engi 21(1):10–15. http://worldcat.org/issn/00174653

Bell FG (1996) Lime stabilization of clay minerals and soils. J Eng Geol 42(4):223–237. https://doi.org/10.1016/0013-7952(96)00028-2

Bell FG (2007) Engineering geology, 2nd edn. Elsevier (Pub.), Butterworth–Heinemann, p 592 (eBook ISBN: 9780080469522)