Abstract

Biochar has been recently considered as a potential soil additive to mitigate the landfill gas emissions in the soil cover. Some physical and chemical properties of biochar, like high phosphorus and organic matter contents, porous structures, and high specific surface area, are prone it a good soil amendment material to enhance the microbial methane oxidation and gas adsorption capacities of the soils. Three different types of biochar: wood chip, two herbaceous biomasses (corn straw and rice straw), were used to modify a silty soil in this study. Microbial CH4 oxidation and CH4 and CO2 adsorption capacities of the modified soils were investigated by the batch tests. The test results showed that the maximum methane oxidation rate (MOmax) of the soil modified by 30% biochar content (Bc) was 3–4 times that of the host soil. An optimum Bc corresponding to the peak value of MOmax was identified. For the three biochars tested, the optimum Bc ranged between 20 and 30% and soil modified by wood-derived biochar exhibits the highest MOmax, because woody biochar has the highest specific surface area and lower pH. Moreover, MOmax also increased with the preincubation time. It is suggested that preincubated sample has the advantage over the fresh sample for building up the content of methanotrophs in the soil before constructing the cover system. The adsorption kinetics and isotherms of CH4 and CO2 in the modified soils followed the pseudo-second-order equation and Langmuir model, respectively. By adding 20% Bc, the maximum adsorption capacity of CH4 and CO2 in the modified soil was about 54 times and 80 times that of the host soil, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

About 2 billion tonnes of municipal solid waste (MSW) was generated annually and it is expected to increase to 3.4 billion by 2050 [1]. Landfill is one of the key components in the MSW management. Degradation of wastes in the landfills can produce leachate and landfill gases, which are the potential threats to the environment. Landfill gases consist mainly of 55–60% methane (CH4) and 40–45% carbon dioxide (CO2). Regarding the anthropogenic CH4 emissions, landfills are the third largest source in the world. Soil cover is one of the common barriers adopted in the landfills to mitigate the emissions of landfill gases, which replies on the low gas conductivity of cover material to maintain the low gas fluxes through the soil cover [2].

A bio-cover is a novel soil cover system that mitigates CH4 emission of MSW landfills using the methanotrophic bacteria to oxidise CH4 [3,4,5,6]. Methanotrophs use methane as a metabolic substrate. The methane oxidation process of methanotrophs is a microbial activity in the natural environment [7]. Microbial oxidation of methane has been observed in the landfills. With the help of this natural process, the bio-cover layer could mitigate the methane emissions from landfills [8, 9]. In general, the bio-cover consists of an upper oxidation enhancing layer overlying a gas distribution layer. Past studies have shown that organic-rich materials such as compost and sewage sludge are commonly used in the bio-cover to optimise the environmental conditions for the activity of methanotrophic bacteria, thus enhance CH4 oxidation [10, 11]. However, Humer and Lechner [12] found that the maturity of the compost could greatly affect the CH4 oxidation ability of the soil cover. Besides, immature compost did not improve the CH4 oxidation capacity, but rather producing CH4 [13].

Biochar is an organic material produced from biomass through pyrolysis. Its highly porous structure and high organic matter content can favour the microbial activities, which have been recently considered as a potential soil amendment material to enhance CH4 oxidation in the bio-cover [14,15,16]. However, most of past studies on the microbial methane oxidation using biochar-modified soils were based on the laboratory column tests. The column tests are appropriate to model the performance of soil cover subjected to the boundary conditions specified for the operating scenarios found in the landfills. On the other hand, the batch test is better than the column test to investigate the effects of different controlling factors. Based on the batch test results, Chiu and Lei [17] reported that biochar-modified soils exhibited the optimum biochar and water contents, which gave the maximum methane oxidation rate.

The porous structure, relatively high specific surface area, and abundant surface functional groups on the surface of biochar make it a low-cost effective adsorbent for heavy metal [18, 19]. Hence, using biochar in the bio-cover to mitigate the CH4 emissions would involve the microbial oxidation and adsorption mechanisms. Based on the batch tests, Sadasivam and Reddy [20] showed that several pure biochars had very good adsorption capacity for CH4, which also depended on the water content and temperature. However, the adsorption tests for biochar-modified soils have been rarely reported in the literature. Yargicoglu et al. [21] showed that a high variability in the physical and chemical properties of different biochars was observed due to different feedstocks and production processes. To understand the performance of biochars produced from different sources, three different types of biochar (wood chip, corn stalk, and rice stalk) were tested in this study. The CH4 oxidation and gas adsorption capacities of the biochar-modified soils were determined from the batch tests. Then, the test results were compared with the physical and chemical properties to identify the controlling factors for the removal of CH4.

Materials and Methodology

Materials

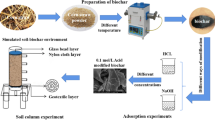

A low plasticity silt was tested in this study. The basic physical properties were determined in accordance with the procedures given in GB/T 50123-1999 [22]. Figure 1 shows the grain size distribution. Most of the particles are smaller than 75 µm. The liquid limit and plasticity index of the tested soil are 27% and 8, respectively. The maximum dry density and optimum water content obtained from the standard compaction test are 1760 kg/m3 and 16%, respectively. Three different biochars were tested in this study. They were derived from wood chip (W), corn straw (C), and rice straw (R). C and R are herbaceous biomasses. All of them were pyrolysed in a low oxygen environment at a temperature of 500 °C. To prepare a more homogeneous sample, the biochar samples were grounded and sieved through a sieve with 2 mm openings. The specific surface area was determined by the BET method. The hydraulic conductivity (k) was determined by a flexible wall permeameter conducted at an effective confining pressure of 50 kPa. Back pressure saturation was conducted to remove any trapped air bubbles in the soil specimens. The pore pressure parameter B was measured after back pressure saturation. A B value of at least 0.95 was achieved for each specimen. Organic matter (OM) and ash were determined by loss of ignition at a temperature of 550 °C according to the procedures given in NY/T 85-1988 [23]. The substance remaining after ignition is considered as ash. Phosphorus (P) and pH were determined in accordance with the procedures given in LY/T 1232-1999 [24] and LY/T 1239-1999 [25], respectively. The grain size distribution curves of three biochars are depicted in Fig. 1. It is apparent that the biochars are coarse materials, which consist of 52%, 50%, and 30% of particle sizes larger than 75 µm for W, C, and R, respectively. Table 1 summarises the basic physical and chemical properties of the tested biochars. R has more ash than W. This is consistent with the results of past studies which show that biochar derived from woody biomass contains less amount of ash than that from herbaceous biomass [26]. In this study, all three tested biochars were pyrolysed at the same temperature of 500 °C. Uchimiya et al. [27] showed that a pyrolysis temperature higher than 400 °°C can produce biochar of high specific surface area and substantial amount of internal porosity. Table 1 depicts that the range of BET-specific surface area is between 82 and 196 m2/g which is one order of magnitude higher than that of kaolinite. Besides, W has a higher specific surface area than C and R. Wang et al. [28] proposed that the lower specific surface area observed in the herbaceous biochar may be attributed to its higher non-combustible component content compared to the woody biochar.

Methane Oxidation Test

Two series of laboratory batch tests were conducted to study the effects of biochar contents (Bc) and preincubation time on CH4 oxidation of biochar-modified soils. Air-dried samples of biochar and soil were mixed thoroughly according to the target Bc. Bc is defined as the ratio of the dry mass of biochar to the dry mass of host soil. Bc tested in the study ranged from 10 to 50%. Then, water was added to the samples to achieve a water content of 20%. To prepare preincubated samples, fresh samples were stored in the airtight containers in the laboratory under an ambient temperature of 25 °C. 100 g of biochar-modified soil with a water content of 30% was put inside a 1 L container, where a headspace concentration of 5% CH4 (v/v) and 95% air (v/v) was maintained. Each week, the containers were re-opened and were flushed by fresh air for at least an hour to ensure sufficient supply of oxygen for the aerobic microbial activities. Then, the containers were resealed after injecting 5% concentration of CH4 by volume. The above procedures were repeated until reaching the target preincubation time of 14 days and 28 days. It is assumed that the methanotrophic bacteria can grow in the soil samples inside the containers during the preincubation [29].

12 g of soil mixture (fresh or preincubated) was placed inside each 135 ml gas container. An isobutyl stopper was used to close the opening of the container. Tape was used to wrap around the stopper and the opening of the container to minimise gas leakage. The test procedures followed those recommended by Albanna and Fernandes [30]. First, 10 ml of air inside the container was replaced by 10 ml of mixture of CH4 and CO2 (volumetric ratio of 1:1) using a syringe through the stopper at the top of the container. Silicone rubber was used to seal the pinhole on the stopper. Thereafter, the container was placed inside an environmental chamber under a constant temperature of 25 °C for 24 h. Then, 10 ml of gas sample was extracted from each container and the volume fraction of CH4 was measured by gas chromatography. After extracting gas sample, the container was flushed by fresh air for at least an hour. Then, 10 ml of mixture of CH4 and CO2 was injected to replace 10 ml of air inside the container. As a result, the same initial volume fractions of gases were maintained. The above procedures were repeated and the gas sample was extracted for each subsequent 24 h. The batch tests lasted for a total of 30 days. It should be noted that the initial volume fraction of CH4 is assumed as that measured from the gas sample taken from the container 2 h after the first gas injection. The methane oxidation rate per unit dry mass per unit of time (µg CH4 g−1 day−1) is calculated as the difference of volume of methane at a given time of incubation and its initial volume.

Gas Adsorption Test

The adsorption test method suggested by Do [31] was used to determine the gas adsorption properties of biochar-modified soils. The tests consisted of five series: host soil, biochar R, and biochar-modified soils with a Bc of 5%, 10%, and 20%. For each test series, three initial gas concentrations were tested. The soil samples were first sterilised in an autoclave for at least 1 h to minimise the effects of micro-organisms on the consumption of CH4. Then, the sterilised samples were mixed with water to achieve a water content of 20%. 6 g of dry soil mixture was placed inside each 320 ml gas container. An isobutyl stopper was used to close the opening of the container. Tape was used to wrap around the stopper and the opening of container to minimise gas leakage. The test procedures followed those recommended by Sadasivam and Reddy [20]. First, 20, 40, and 60 ml of air inside the container were replaced by 20, 40, and 60 ml of mixture of CH4 and CO2 (volumetric ratio of 1:1) using a syringe through the stopper at the top of container, respectively. Silicone rubber was used to seal the pinhole on the stopper. The initial concentrations of CH4 and CO2 were 3.1%, 6.2%, and 9.4% (v/v). Thereafter, the containers were placed inside an environmental chamber under a constant temperature of 25 °C. For each test series and initial gas concentration, eight test specimens (gas containers) were prepared to collect gas samples at eight different time intervals (2, 4, 6, 10, 20, 30, 60, and 120 min). 10 ml of gas sample was extracted from each container. Then, the volume fraction of CH4 and CO2 was measured by gas chromatography. It should be noted that the initial gas concentration was determined from a control gas container without soil specimen and three replicas were tested to determine the average gas adsorption rate of a specimen.

Adsorption Models

In the literature, the adsorption kinetics measured by the batch tests is normally modelled by either the pseudo-first-order or pseudo-second-order equations [32]. The pseudo-first-order equation was proposed by Largergren [33], assuming that the uptake rate is first order with respect to the available surface sites. It has the following form:

where q is the adsorption capacity (mol/kg), qe is the equilibrium adsorption capacity (mol/kg), t is time (min.), and k1 is the rate constant for the first-order equation (min−1). On the other hand, the pseudo-second-order model assumes that the uptake rate is second order with respect to the available surface sites. It has the following form:

where k2 is the rate constant (kg/mol/min) for the second-order equation. After determining qe for a particular species concentration (or partial pressure of species), adsorption is usually described as isotherms. Langmuir and Freundlich models are two common isotherm models [34]. The following equation represents Langmuir model:

where q0 is the maximum adsorption capacity (mol/kg), Pe is the partial pressure of species (kPa), and b (kPa−1) is the model parameter related to energy of adsorption.

Test Results and Discussion

Physical and Chemical Properties

Table 2 summarises some basic physical and chemical properties of the host soil and the biochar-modified soils. The specific gravities (Gs) of biochars W, C, and R used in this study are 0.71, 0.68, and 0.69, respectively (see Table 1). Ameloot et al. [35] suggested that the high hydrogen-to-carbon (H:C) ratio may be the reason for the low specific gravity of biochar, because H:C can be related to the charring intensity. As expected, Gs of biochar-modified soils are smaller than that of the host soil, which decreases with increasing Bc. Hence, a smaller bulk density is expected for the modified soil than that of the host soil. It is apparent from Fig. 1 that adding biochar can shift the grain size distribution curve of the modified soil to the left-hand side as illustrated by the soil modified by 20% Bc biochar R (20% R). In other words, biochar-modified soils have more coarse particles than the host soil. Figure 2 shows the plasticity of soils modified with 10% and 20% Bc. It is evident that the plasticity of modified soils moves towards the right-hand side on the plasticity chart with increasing Bc, i.e., increasing the plasticity. It should be noted the change in the liquid limit is more significant than the change in the plasticity index. Coarser particle sizes, but higher plasticity observed in the biochar-modified soils are different from the conventional coarse-grained soils which normally exhibit negligible plasticity. The BET-specific surface areas of biochars W, C, and R are 196, 82, and 118 m2/g, respectively. These values are about one order of magnitude higher than that of kaolinite, resulting in the high affinity to water [36]. Hence, more water is required for the biochar-modified soil to behave in a plastic or liquid manner than the host soil. Besides, soils modified by C and R exhibit higher plasticity than those modified by W. This observed difference may be attributed to the high ash content in herbaceous biomass-derived biochar resulting in a higher cation-exchange capacity (CEC) [37].

Figure 3 depicts the standard compaction curves of the biochar-modified soils. It is shown that the maximum dry density decreases, but the optimum water content increases with increasing Bc for all three biochars tested. The compaction test results are consistent with the consistency presented in Fig. 2. For a soil with higher plasticity, it is less prone to compactibility, i.e., lower maximum dry density and higher optimum water content. The measured hydraulic conductivity (k) and the corresponding void ratio (e) are summarised in the sixth and seventh columns of Table 2. The reported k of each test is the average value of three replicas. The maximum error bound is around ± 45% of the average value. It is found that the values of k of modified soils are at least one order of magnitude higher than that of the host soil. The effects of the test results are opposite to those reported in Chiu et al. [38]. It should be noted e of the host soil is 0.348, the lowest compared to the values of the modified soils. Hence, it is unclear either a high e or an addition of biochar, which contributes to the high hydraulic conductivity of the modified soils.

Table 2 also summarises some basic chemical properties like pH, phosphorus (P), and organic matter (OM) of the biochar-modified soils. The host soil is slightly acidic with a pH value of 5.8 and all three biochars are alkaline. Among the three biochars, the soil modified by the biochar R is the most alkaline, e.g., soil modified by 20% Bc; biochars R and W have a pH value of 10.4 and 8.6, respectively. As shown in Table 1R has more ash content than W, because rice straw is the herbaceous plant. The ash of biochar is usually rich in soluble trace elements such as potassium, sodium, and magnesium. When it is applied to the soil, it becomes a base ion, which can improve the base saturation of acidified soil, reduce the hydrogen ion of soil through adsorption and exchange, and reduce the content of exchangeable acid [39]. It should be noted that pH is a crucial factor influencing the microbial oxidation of methane. Past studies have shown that slightly acidic-to-neutral is the favourable condition for microbial oxidation of methane.

The contents of P and OM follow similar trend. Both properties increase with increasing Bc. By adding 20% Bc, the contents of P and OM can increase to a value around 7 g/kg and 14%, respectively. As P and OM are the basic nutrients for the growth of microbial activities, these enhanced contents can promote the metabolism of methanotrophic bacteria in the biochar-modified soils [40]. Besides, the soil porosity and water retention capacity are also related to the OM content. Chiu et al. [38] found that the biochar-modified soil can hold more water than the host soil for a given suction. The increase of OM content can increase the aggregate structure of the soil resulting in more intra-aggregate pores. It is postulated the high internal micro-porosities of biochar itself and substantial intra-aggregate pores in the modified soil matrix contribute to its higher water retention capacity.

Methane Oxidation Capacity

The batch test results of methane oxidation for the soils modified by three different biochars are very similar. For illustration, the relationship between methane oxidation rate and incubation time of biochar R modified soils is shown in Fig. 4. The test results of the host soil and pure biochar are also shown in the figure for comparison. It is apparent that biochar R alone exhibits negligible methane oxidation throughout the 30-day incubation period. As the pH of biochar R is over 10, its high alkalinity may inhibit the microbial activities leading to negligible methane oxidation. This result is consistent with the past findings. Reddy et al. [29] recently conducted a study on the effects of pH on methane oxidation in a landfill cover soil. They concluded that there is an optimum range of pH (between 7 and 7.6) which exhibits the maximum methane oxidation rate. As the pH decreases to strongly acidic (a pH of 2) and increases to strongly alkaline (a pH of 12) conditions, negligible oxidation and no oxidation are observed, respectively. On the other hand, the other six test specimens exhibit a similar trend where the methane oxidation rate increases with time and reaches a maximum value (MOmax), beyond which it reduces to a negligible value at the end of the 30-day incubation period. It is evident from the test results that MOmax is influenced significantly by Bc. By adding a 30% Bc, MOmax increases from 60 to 210 µg CH4 g−1 day−1.

Figure 4 also indicates that after reaching MOmax, methane oxidation rate decreases with time. Similar trend was observed in the past studies on other soils [41,42,43] and composts [44, 45]. The reason for this phenomenon may be due to the exopolymeric substances (EPS), products of methane oxidation activities. It is postulated that the amount of methane oxidising bacteria reduces with the accumulation of EPS and depletion of soil nutrients leading to a lower methane oxidation rate. As the impact of EPS on methane oxidation activity is a very complex process, further study is required.

Effects of preincubation time on the relationships between methane oxidation rate and incubation time are depicted in Fig. 5. All three soil specimens were modified by the same Bc of 20%, but two of them were preincubated for 14 days and 28 days before conducting the batch tests for methane oxidation. It is apparent that there is a shift of time for reaching MOmax. The 28-day preincubated specimen has the shortest time (3 days), while the fresh (0-day preincubated) specimen has the longest time (12 days) as expected. It is because the preincubation period can enhance the microbial activities and substantial amount of bacteria was already available in the beginning of the batch tests. Hence, a high methane oxidation rate was observed at the first day of batch test for the 28-day preincubated specimen. It takes the shortest time to reach MOmax for this specimen. Furthermore, the values of MOmax are also different for the three specimens, which are 142, 218, and 233 µg/g/day for 0-day, 14-day, and 28-day preincubated specimens, respectively. There is a sharp rise in the MOmax between 0- and 14-day preincubated specimens. The rising rate becomes mild after 14 days. The difference in MOmax between 14 and 28 days preincubated specimens decreases to about 7%. It seems that the magnitude of MOmax would be influenced significantly by the preincubation period. Thus, it should be careful to apply the measured methane oxidation rate directly in the quantitative design of the bio-cover. To better understand the long-term field performance of bio-cover, further study should be conducted to investigate the effects of a longer preincubation period.

Figure 6 depicts the effects of Bc on MOmax of soils modified by three different biochars. All three biochars exhibit a similar trend. It can be seen from the test results that there is an optimum Bc which corresponds to a peak value of MOmax. The optimum Bc is between 20 and 30%. There are many factors that influence the methane oxidation process in soils; for example, soil texture, organic matter content, water content, pH, nutrients, temperature, and CH4 and O2 concentrations [44, 46]. Soils with coarser grains and higher organic matter contents exhibit higher oxidation efficiency [12]. However, the oxidation process is also affected by the pH of soil, because methanotrophic bacteria are sensitive to the pH. Past studies have shown that all types of methanotrophic bacteria can grow in pH values ranging from 5.8 to 7.4 and they cannot grow at pH values below 5 [7, 47]. As shown in Fig. 1 and Table 2, addition of biochar can increase the amount of coarser grains, P content and OM content of the modified soils, from which the oxidation capacity may be enhanced. On the other hand, the pH values of biochar-modified soils are higher than the reported optimal range for the growth of methanotrophic bacteria. It is postulated that the strong alkalinity at high Bc may reduce the activity of methanotrophic bacteria leading to a reduction in the oxidation rate. Among the three tested biochars, soils modified by biochar W exhibit the lowest pH. Besides, W has the highest specific surface area. Thus, soils modified by biochar W show the highest methane oxidation capacity, as depicted in Fig. 6. It should be noted that a wide range of Bc was tested in the batch tests, such that the optimum range of Bc can be identified. The observed optimum Bc between 20 and 30% was only valid for disturbed soil samples under certain test conditions, such as a water content of 30% and a pH between 8.3 and 10.4. Thus, the influencing factors such as pH and soil density have not been considered. For the similar oxidation rate, a much lower value of Bc should be expected under slightly acidic condition. In the design of bio-cover, the design methane load is another factor governing the methane removal efficiency of soil cover. Furthermore, the transport properties of gas and water, and water retention properties of biochar-modified soil are also important properties in the design of soil cover. These properties are also influenced by the Bc. Using much larger physical models, Yargicoglu et al. [16] adopted a biochar dosage by weight between 2 and 10% to study long-term methane removal capacity of biochar amended soil cover.

Gas Adsorption Capacity

For the host soil, pure biochar, and modified soil with different Bc tested, adsorption kinetic isotherm follows similar trend for both CH4 and CO2. For illustration the batch test results of the adsorption capacity (q) of CH4 vs time for the biochar R modified soil with 20% Bc are depicted in Fig. 7a–c. Each data point represents the average value of three replicas. It is shown that the adsorption capacity of CH4 reaches or close to an equilibrium value within 60 min. from the start of the tests for all three gas concentrations. The pseudo-first-order and pseudo-second-order models were used to best fit the test data. Table 3 summarises the fitting parameters of the two models. Based on the correlation of determination (R2) value, the pseudo-second-order model fits the test data better than the pseudo-first-order model. The test results are consistent with those of adsorption process of pure biochar on heavy metals and gas [20]. It should be noted that the pseudo-second-order model is superior in terms of fit to the pseudo-first-order model, because the equilibrium adsorption capacity (qe) predicted by the first-order model is often further away from the experimental data. Thus, the superiority of the pseudo-second-order model over the pseudo-first-order model does not necessarily due to the physical basis, but rather than the mathematical basis. Allen et al. [48] showed that it is merely a general equation with a k2 value representing a lump value of different controlling mechanisms. No meaningful mechanism can be confidently postulated from the model. However, for either batch or continuous system design, a lumped analysis is sufficient [49, 50].

Using the pseudo-second-order model, qe of CH4 and CO2 for each testing condition is evaluated and presented in Fig. 8a, b. It is apparent that qe of CH4 and CO2 increases with increasing gas concentration and Bc. For an initial gas concentration of 9.4%, qe of CH4 for soils modified with Bc of 5%, 10%, and 20% is 1.8, 4, and 6 times of that of the host soil. For an initial gas concentration of 9.4%, qe of CO2 for soils modified with Bc of 5%, 10%, and 20% is 2.5, 4.3, and 9.3 times higher than that of the host soil. The biochar is a porous material, which has a relatively high specific surface area. The biochar R used in the study has a specific surface area of 118 m2/g, which is around one order of magnitude higher than that of kaolinite. This high specific area enhances the gas adsorption of the modified soil.

Figure 9a, b shows the best-fit pseudo-second-order rate constant (k2) of CH4 and CO2 for different test conditions. It can be seen that k2 of CH4 and CO2 decreases with increasing Bc for a given initial gas concentration. The specific surface area of biochar R is higher than the host soil. In other words, more adsorption sites are available for modified soils with higher Bc, and hence, the adsorption equilibrium time is longer and a lower value of k2 is expected. For the host soil, no specific trend between k2 and the initial gas concentration is observed. For the biochar-modified soils and pure biochar R, k2 of CH4 and CO2 decreases with increasing initial gas concentration. The Langmuir isotherm adsorption model was used to best fit the relationship between qe and partial pressure of gas species, as shown in Fig. 10a, b. Two best-fit model parameters q0 and b are obtained. q0 is the maximum adsorption capacity and b is the parameter related to the energy of adsorption. The best-fit values for different test samples are summarised in Table 4. The magnitude of q0 for the pure biochar R is in the same order of magnitude to that of 7 biochars reported in Sadasivam and Reddy [20]. Besides, it is also revealed that q0 for CO2 is higher than that for CH4 which may due to the fact that higher interaction and stronger attractive forces of CO2 molecules with the surfaces of biochar. Similar results have been reported for the activated carbon [51, 52]. It should be noted that CO2 has a certain polarity. The surface polarity of activated carbon has a significant role in promoting the adsorption of CO2, while CH4 has no polarity. The results show that the increase of polar surface functional groups of activated carbon is beneficial to the increase of CO2 adsorption on activated carbon [20]. Manna et al. [53] studied the surface functional groups of rice straw and wheat straw-derived biochars obtained at different pyrolysis temperatures using FTIR. It was found that all biochars had polar surface functional groups such as phenolic hydroxyl groups, which may be beneficial to CO2 adsorption but not to non-polar CH4 adsorption.

Conclusions

In this study, batch tests were presented to determine the microbial CH4 oxidation and gas adsorption capacities of biochar-modified soils. Three different biochars were tested. The batch test results were interpreted with the help of the physical and chemical properties of the biochars. The main conclusions are summarised as follows:

-

(i)

Wood-derived biochar (W) exhibits a higher BET-specific surface area, but a lower ash content than the two herbaceous biomass-derived biochar (corn straw, C and rice straw, R). With such properties, soil modified by W has the lowest pH (still alkaline), lower plasticity, and better compactibility than soil modified by herbaceous biomass-derived biochar.

-

(ii)

Biochar could enhance effectively the microbial methane oxidation capacity of soil. By adding a 30% biochar content (Bc), the maximum methane oxidation rate (MOmax) of the freshly prepared biochar-modified soil increased from 60 to 210 µg CH4 g−1 day−1, i.e., 3–4 times of the host soil. An optimum Bc corresponding to the peak value of MOmax was identified. For the three biochars tested, the optimum Bc ranged between 20 and 30% under a water content of 30%. Among the three biochar tested, soil modified by W exhibits the highest MOmax, because W has the highest specific surface area and lowest pH. Besides, MOmax was influenced by the preincubation time, implying that the soil could be preincubated to build up the content of methanotrophs first before constructing the cover system.

-

(iii)

The batch test results revealed that the pseudo-second-order equation and Langmuir model were suitable to model the adsorption kinetics and isotherms of CH4 and CO2, respectively, in the biochar-modified soils. Biochar is a good adsorbent because of its high specific surface area. By adding 20% Bc, the maximum adsorption capacity of CH4 and CO2 in the modified soils could reach 0.012 mol/kg and 0.043 mol/kg, respectively, which were about 54 times and 80 times of that of the host soil. CO2 adsorption was higher than that of CH4, because the rice straw biochar contained the hydroxyl surface function group which could be beneficial to the polar CO2 adsorption.

References

World Bank (2018) What a waste 2.0, A global snapshot of solid waste management to 2050. Urban Development Series, World Bank

EPA (2004) Technical guidance for RCRA/CERCLA final covers. EPA540-R-04-007, OSWER 9283.1-26, U.S. Environmental Protection Agency

Humer M, Lechner P (1999) Alternative approach to the elimination of greenhouse gases from old landfills. Waste Manag Res 17:443–452

Stern JC, Chanton J, Abichou T, Powelson D, Yuan L, Escoriza S, Bogner J (2007) Use of biologically active cover to reduce landfill methane emissions and enhance methane oxidation. Waste Manag 27:1248–1258

Huber-Humer M, Roder S, Lechner P (2009) Approaches to assess biocover performance on landfills. Waste Manag 29:2092–2104

Safari E, Al-Suwaidi G, Rayhani MT (2017) Performance of biocover in mitigating fugitive methane emissions from municipal solid waste landfills in cold climates. J Environ Eng 143(5):06017003

Hanson RS, Hanson TE (1996) Methanotrophic bacteria. Microbiol Rev 60:439–471

Mancinelli R, McKay C (1985) Methane oxidizing bacteria in sanitary landfills. Argonne National Laboratory Report ANL/CNSV-TM-167, 437-450

Czepiel PM, Mosher B, Crill PM, Harriss RC (1996) Quantifying the effect of oxidation on landfill methane emissions. J Geophys Res Atmos 101(D11):16721–16729

Bohn S, Brunke P, Gebert J, Jager J (2011) Improving the aeration of critical fine-grained landfill top cover material by vegetation to increase the microbial methane oxidation efficiency. Waste Manag 31(5):854–863

Huber-Humer M, Tintner J, Böhm K, Lechner P (2011) Scrutinizing compost properties and their impact on methane oxidation efficiency. Waste Manag 31(5):871–883

Humer M, Lechner P (2001) Design of a landfill cover layer to enhance methane oxidation results of a two year field investigation. In: Proceedings of the 8th International Waste Management and Landfill Symposium 2, 541–550

Barlaz MA, Green RB, Chanton JP, Goldsmith CD, Hater GR (2004) Evaluation of a biologically active cover for mitigation of landfill gas emissions. Environ Sci Technol 38(18):4891–4899

Reddy KK, Yargicoglu EN, Yue D, Yaghoubi P (2014) Enhance microbial methane oxidation in landfill cover soil amended with biochar. J Geotech Geoenviron Eng 140(9):04014047

Chiu ACF, Xiao Y (2018) Physical modelling of mitigating methane emission from biochar modified MSW landfill cover. In: Proc. 8th Int. Congress on Environ. Geotechnics, Zhan, Chen and Bouazza ed., Hangzhou, 429–434

Yargicoglu EN, Reddy KR (2018) Methane oxidation: effect of biochar amendment ratio and cover profile. J Geotech Geoenviron Eng 144(3):04017123

Chiu CF, Lei GH (2017) Use of biochar to enhance methane oxidation for MSW landfill bio-cover. In: Proc. 19th Int. Conf. Soil Mechanics & Geotechnical Engineering, Seoul, 3111–3114

Komkiene J, Baltrėnaitė E (2016) Biochar as adsorbent for removal of heavy metal ions Cadmium(II), Copper(II), Lead(II), Zinc(II) from aqueous phase. Int J Environ Sci Technol 13:471–482

Wang XH, Li X, Liu GQ, He YF, Chen C, Liu XY, Li G, Gua YQ, Zhao YQ (2019) Mixed heavy metal removal from wastewater by using discarded mushroom-stick biochar: adsorption properties and mechanisms. Environ Sci Process Impacts 21:584–592

Sadasivam BY, Reddy KR (2015) Adsorption and transport of methane in biochars derived from waste wood. Waste Manag 43:218–229

Yargicoglu EN, Sadasivam BY, Reddy KR, Spokas K (2015) Physical and chemical characterization of waste wood derived biochars. Waste Manag 36:256–268

GB/T 50123-1999 (1999) Standard for soil test method. Ministry of Construction, P.R. China (in Chinese)

NY/T 85-1988 (1988) Method for determination of soil organic matter. Ministry of Agriculture, P.R. China (in Chinese)

LY/T 1232-1999 (1999) Determination of total phosphorus in forest soil. Forestry Standards, P.R. China (in Chinese)

LY/T 1239-1999 (1999) Determination of pH value in forest soil. Forestry Standards, P.R. China (in Chinese)

Mukome FND, Zhang X, Lucas CRS, Six J, Parikh SJ (2013) Use of chemical and physical characteristics to investigate trends in biochar feedstocks. J Agric Food Chem 61:2196–2204

Uchimiya M, Wartelle LH, Klasson KT, Fortier CA, Lima IM (2011) Influence of pyrolysis temperature on biochar property and function as a heavy metal sorbent in soil. J Agric Food Chem 59:2501–2510

Wang S, Gao B, Zimmerman AR, Li Y, Ma L, Harris WG, Migliaccio KW (2015) Physicochemical and sorptive properties of biochars derived from woody and herbaceous biomass. Chemosphere 134:257–262

Reddy KR, Rai RK, Green SJ, Chetri JK (2020) Effect of pH on methane oxidation and community composition in landfill cover soil. J Environ Eng 146(6):04020037

Albanna M, Fernandes L (2009) Effects of Temperature, moisture content, and fertilizer addition on biological methane oxidation in landfill cover soils. Pract Period Hazard Toxic Radioact Waste Manag 13(3):187–195

Do DD (1998) Adsorption Analysis: Equilibria and Kinetics. Imperial College Press, London

Simonin JP (2016) On the comparison of pseudo-first order and pseudo-second order rate laws in the modeling of adsorption kinetics. J Chem Eng 300:254–263

Lagergren S (1898) Zur theorie der sogenannten adsorption geloester stoffe. Veternskapsakad Handl 24:1–39

Reed BE, Matsumoto MR (1993) Modeling Cadmium adsorption by activated carbon using the Langmuir and Freundlich isotherm expressions. Sep Sci Technol 28(13–140):2179–2195

Ameloot N, Graber ER, Verheijen FGA, De Neve S (2013) Interactions between biochar stability and soil organisms: review and research needs. Eur J Soil Sci 64(4):379–390

Guo Y, Tang H, Li G, Xie D (2014) Effects of cow dung biochar amendment on adsorption and leaching of nutrient from an acid yellow soil irrigated with biogas slurry. Water Air Soil Pollut 225(1):1–13

Yang F, Lee X, Wang B (2015) Characterization of biochars produced from seven biomasses grown in three different climate zones. Chin J Geochem 34:592–600

Chiu ACF, Xiao Y, Qiao B (2019) Water retention and unsaturated hydraulic behaviors of a biochar-modified silt. Geotech Eng 50(1):10–15

Fidel RB, Laird DA, Thompson ML, Lawrinenko M (2017) Characterization and quantification of biochar alkalinity. Chemosphere 167:367–373

Scheutz C, Kjeldsen P (2004) Environmental factors influencing attenuation of methane and hydrochlorofluorocarbons in landfill cover soils. J Environ Qual 33(1):72–79

Kightley D, Nedwell DB, Cooper M (1995) Capacity for methane oxidation in landfill cover soils measured in laboratory-scale soil microcosms. Appl Environ Microbiol 61:592–610

Hilger HA, Cranford DF, Barlaz MA (2000) Methane oxidation and microbial exopolymer production in landfill cover soil. Soil Biol Biochem 32(4):457–467

De Visscher A, Van Cleemput O (2003) Induction of enhanced CH4 oxidation in soils: NH4+ inhibition patterns. Soil Biol Biochem 35:907–913

Wilshusen JH, Hettiaratchi JPA, Stein VB (2004) Long-term behaviour of passively aerated compost methanotrophic biofilter columns. Waste Manag 24:643–653

Mor S, De Visscher A, Ravindra K, Dahiya RP, Chandra A, Van Cleemput O (2006) Induction of enhanced methane oxidation in compost: temperature and moisture response. Waste Manag 26(4):381–388

Börjesson G, Chanton J, Svensson BH (2001) Methane oxidation in two Swedish landfill covers measured with carbon-13 to carbon-12 isotope ratios. J Environ Qual 30:369–376

Whittenbury R, Phillips KC, Wilkinson JF (1970) Enrichment, isolation and some properties of methane utilizing bacteria. J Gen Microbiol 61:205–218

Allen SJ, Gan Q, Matthews R, Johnson PA (2005) Kinetic modeling of the adsorption of basic dyes by kudzu. J Colloid Interface Sci 286:101–109

Kumar U, Bandyopadhyay M (2006) Fixed bed column study for Cd(II) removal from wastewater using treated rice husk. J Hazard Mater 129:253–259

Song ST, Hau YF, Saman N, Johari K, Cheu SC, Kong H, Mat H (2016) Process analysis of mercury adsorption onto chemically modified rice straw in a fixed-bed adsorber. J Environ Chem Eng 4:1685–1697

Dreisbach F, Staudt R, Keller JU (1999) High pressure adsorption data of methane, nitrogen, carbon dioxide and their binary and ternary mixtures on activated carbon. Adsorpt J Int Adsorpt Soc 5(3):215–227

Ho YS (2006) Review of second-order models for adsorption systems. J Hazard Mater 136(3):681–689

Manna S, Singh N, Purakayastha TJ, Berns AE (2000) Effect of deashing on physico-chemical properties of wheat and rice straw biochars and potential sorption of pyrazosulfuron-ethyl. Arab J Chem 13(1):1247–1258

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chiu, C.F., Huang, Z.D. Microbial Methane Oxidation and Gas Adsorption Capacities of Biochar-Modified Soils. Int. J. of Geosynth. and Ground Eng. 6, 24 (2020). https://doi.org/10.1007/s40891-020-00202-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-020-00202-5