Abstract

The aim of this paper is to investigate peach pomace extract as a cheap, raw, green and non-toxic anti-corrosion material for mild steel corrosion in neutral media of 0.5 M NaCl solution. The chemical profile of the extract was analyzed using gas chromatography mass spectrometry (GC–MS) and high performance liquid chromatography analysis. Gravimetric, PR technique, scanning electron microscopy were used to study the corrosion inhibitive. The influence of immersion period on inhibition efficiency was evaluated. The mechanism of action of the inhibitor is also discussed. The gravimetric, polarization measurements and surface analysis evinced that the growth of inhibitory properties is prolonged and corrosion rate reduction after 40–50 h of exposure. The potentiodynamic polarization curves indicated that PPE acts as a mixed-type inhibitor. The phenomenon of prolonged action “40–50 h” and the influence of the time of film formation on its effectiveness were explained. The formation of polymerisation flavanol-aldehyde adduct, polymers of flavan-3-ols-anthocyanins and oxidation compounds of the p-quinones structure due to extract transformation in water causes main corrosion reduction in 40–50 h.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Corrosion protections of metals are part of the environment protection, which occupies nowadays a key place in the chemical engendering. various methods are known to improve the corrosion resistance of metals and alloys. The most effective is the modification of the surface of metals as well as the use of corrosion inhibitors [1,2,3,4,5,6]. If there is a need for anti-corrosion protection of metals operating in aqueous media containing chlorides, it is promising to use corrosion inhibitors. Most of the traditional organic and inorganic inhibitors are synthetic compounds, which are costly and often lead to serious environmental problems. Inhibitors based on "green" organic compounds have been used widely to prevent corrosion of mild steel in water systems that was induced chlorides.

Integrated valorisation of fruit waste is a progressive direction of resource conservation, owing to their environmental and economic values. A significant amount of waste is generated in the processing of fruit and berry crops. Peach pomace is a waste produced by the fruit processing industry in massive quantities each year (21.6 million tons in 2018) which may reach from 15 to 28% of transformed raw material, depending on the process conditions [7]. A numerous papers reported the application of fruits pomace extracts as a corrosion inhibitor of steel and its alloys in different electrolytes. Several studies already attested the good anticorrosive effectiveness of Prunusdulcis (almond) [8], grape [9], apricot [10], gooseberry [11], apple [12] pomace extracts on steel in various solutions. An important step in the use of “green” organic compounds from plant resources is the extraction process (polarity indices, temperature).The analysis of the scientific literature indicates that in the recent years it has become more and more urgent, not to use the traditional solvents, but a more scientifically sound selection of mixtures of extractants or extraction methods (phased use of solvents or in combination with microwave and ultrasound irradiations), which is subsequently accompanied by qualitative and quantitative methods analysis of component composition [13]. Thus, preliminary studies on the influence of extraction methods on the component composition of the obtained extract in modern scientific research on the development of “green” corrosion inhibitors should be the first step [2, 8, 14].

Moreover, the inhibitory efficiency and multifunctionality of the obtained extracts largely depends on the type of extractant/system of extractants chosen to extract organic compounds. Besides this, the solvent mixture provides a polarity variation capable of extracting compounds of different degrees of polarity. Also, the authors have found that the highest inhibitory properties for copper in 0.5 M NaCl solution has an extract from an olive leaf obtained with a water/methanol solvent mixture and an extract obtained using an acidified aqueous solution [15]. In a number of works it has been also indicated that a solvent is selected for the extraction of plant materials with a close pH value depending on the type of corrosive medium (alkaline, acidic). So, different authors have studied the inhibitory effectiveness of ginger extract in various corrosive environments [16]. In these investigations, the ginger corrosion inhibitors were generally prepared by the acid extraction and used for the acid-medium corrosion. It was reported that crude extract of Pterocarpus santalinoides (PSLE) had been studied as mild steel corrosion inhibitor in H2SO4 solution and the protection efficacy by the different extracts decreases in order ethanolic extract > methanolic extract > aqueous extract [1].

In the literature, one can also find no information about possible applications of the peach pomace and its extracted compounds for the development of corrosion inhibitor of mild steel in neutral media. The corrosion protection of mild steel in 1 M HCl solution by peach juice and corrosion protection of mild steel in 0.5 M H2SO4 peach leaves solution by were studied only in several papers [17].The prime target of the present work firstly is to determine the chemical composition of peach pomace extract (PPE) obtained with a mixture of solvents to extract volatile organic compounds (VOCs) and semi-volatile components. Secondly, is to evaluate the corrosion inhibition effect of PPE as “green” corrosion inhibitor of mild steel in neutral media of 0.5 M NaCl solution.

2 Experimental Details

2.1 Specimen and Extract Preparation

The peach extract obtained from the pomace remained after mechanical pressing of the fresh fruit to produce juices. The peach pomaces were purchased from the juice company «SANDORA» (Mykolaiv city, Ukraine), July/2019 harvest. The mild strips were purchased from Rocholl, Aglasterhausen, Germany.

The by-product pomace (2 g) was mixed with 25 mL of solution 2-propanol/ethanol/water (v:v:v = 50/20/30) in an extraction vessel. The mixture was placed in the ultrasound bath. Ultrasound-assisted extraction is a method to improve extraction since it can decrease the solvent consumption and extraction time [7]. The extraction parameters were: temperature 65 °C and time 50 min. The final extract was then filtered in Whatman filter paper No. 1.

The carbon steel strips with the chemical composition 0.20% C, 0.43% Mn, 0.55% Si, 0.016% S, 0.02% P and Fe balanced were used for the corrosion tests and electrochemical measurements. The carbon steel (DIN 17,100 R St 37-2) were purchased from Rocholl (Aglasterhausen, Germany).

2.2 Gas Chromatography–Mass Spectrometry Analysis (GC–MS)

The composition of substances of the extract was identified by gas chromatography coupled to mass spectrometry (GC–MS). A Shimadzu gas chromatograph (model GC 17A) equipped with a flame ionization detector (FID) was operated under the following conditions: capillary fused silica column (CBP-5) (length, 25 m; internal diameter, 0.25 mm; film thickness, 0.22 µm), ion source temperature of 280 °C. The volatile compounds present in the apricot pomace extract were identified using software database Libraries (NIST MS search version on Wiley library).

2.3 High Performance Liquid Chromatography Analysis (HPLC)

Identification and quantification of phenols were obtained by HPLC. The analysis was conducted in HPLC-Diode array detection (DAD) Agilent 2100 Series HPLC system (Agilent Technologies, Palo Alto, CA, USA) using a Sorbax Eclipse XDB-C18 column (Agilent technologies, 9.4 × 124 × 250 mm, 5.0 μm). The samples were eluted using a linear gradient of concentration from water containing 1% of acetic acid (Solvent A) to 100% of acetonitrile (solvent B). The elution conditions were as follows: 0–15 min, B from 8 to 30% (5 min); 22–35 min, B from 30 to 70% (10 min); and 35–40 min, B from 70 to 8%. A volume of 20 μL was injected and the samples were analyzed in triplicate.

2.4 Weight Loss Measurements

For weight loss estimations the mild steel specimens were set up as ASTM G 31-72. Mild steel coupons of dimensions 5.0 × 3.0 × 0.2 cm were used in the weight loss experiments. Before each experiment, the coupons were abraded and polished using emery papers (grades 220–1200), washed thoroughly with distilled water, degreased with acetone and finally dried. The initial weight of each coupon was taken (before immersion) using an analytical balance. Then, the specimens were immersed in 0.5 M NaCl solution without and with different concentrations of the peach pomace extract. After the immersion period, the specimens were taken out, washed, dried and weighed again. The difference in weight was calculated from the initial and final weight of the specimens. All the experiments were performed in triplicate and the average weight loss values were recorded. Three values were obtained by repeating experiments three times, and an average value was recorded. Average values of the weight loss data were used in corresponding calculations.

2.5 Electrochemical Measurements

Electrochemical experiments were carried out in the conventional three-electrode cell with a platinum counter electrode (CE), a saturated calomel electrode (SCE) coupled to a fine Luggin capillary as the reference electrode (RE) and a working electrode (WE). The carbon steel working electrode was designed with a fixed exposed surface area of 0.385 cm2. For the electrochemical experiments, the surface area of the platinum counter electrode is larger than that of WE, and the CE is countered to the total exposed surface of WE. Thus, the electrical field distribution could be uniform. All electrochemical measurements were carried out using a PARSTAT 2273 advanced electrochemical system (Princeton Applied Research).

The linear polarization technique (LPR) was applied to study time variation of the polarization resistance. Polarization resistance values Rp were measured during the immersion time of the samples in an aggressive solution without and with peach pomace extract [14, 15].

3 Results and Discussion

3.1 Composition of Peach Pomace Extract

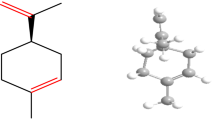

Mass spectrometry is utmost sensitive method for molecular analysis of volatile organic compounds (VOCs) and semi-volatile components. Combination of chromatography and mass spectrometry (GC–MS) provides the leverage required to separate as well as identify the components. The GC–MS analysis of PPE (Fig. 1a, b, Table 1) showed the presence of 21 VOCs compounds and Fig. 1 depicts the structures of the main compounds. Benzaldehyde (8.0%), (E,E)-2,4-Hexadienal(4.8%) in PPE were present as major identified phytoconstituents. Some other important compounds detected via GC–MS are linalool (5.8%) and thymol (12.2%). The other major compounds of PPE were Geraniol (4.7%), Cinnamaldehyde (58.5%), Octadecanal (4.3%) and Docosanal (6.8%).

According to the HPLC analysis, neochlorogenic and chlorogenic acids were the major phenolic compound found in peach pomace extract, which contained also other hydroxycinnamic acid derivatives, flavan-3-ols acids, hydroxybenzoic acids, flavonols and anthocyanins (Table 2). Three free cinnamic acids were identified: p-coumaric acid, ferulic acid and sinapic acid. More importantly, after using the solution 2-propanol/ethanol/water as solvents volatile, semi-volatile and high molecular weight chemical components were extracted from peach pomace and therefore is a potentially can be for use as a corrosion inhibitor of metals.

3.2 Extract Concentration and Immersion Time Effect

3.2.1 Mass Loss Measurements

The immersion time is an important parameter in assessing the stability of corrosion inhibitive properties of organic compounds. Figure 2 illustrates the effect of immersion time on the inhibitive performance of PPE.

The formation process of the protective layer can be classified into two steps, namely primary adsorption (1–30 h) as the first step and then a slow chemical transformation (polymerization) the molecules that were adsorbed on the steel surface (40–50 h). It is evident from Fig. 2 that inhibition efficiency in 0.5 M NaCl containing PPE slowly increased up to the moment when it reached 30 h of immersion, and then it rapidly increased between 40 and 48 h of immersion till reached its saturation. According to the results above, the maximum inhibition efficiency (about 98%) was obtained at 800 ppm PPE extract after 48–50 h immersion. This suggested that the corrosion protectiveness of PPE film-forming on the steel surface was enhanced by prolonging the PPE treatment. The effect of immersion time in a 0.5 M NaCl solution with PPE on the weight loss rate indicated that PPE not only keeps its inhibitive activity for steel but also improves its effectiveness over the long-term immersion due to the synergistic influence of the main compounds which offer an additional protection.

3.2.2 Electrochemical Characterization Studies

PR technique was used to investigate the time dependence of polarization resistance during immersion in inhibited and non-inhibited solutions [15]. Figure 3 depicts the polarization resistance (Om) for the electrode in 0.5 M NaCl saturated with inhibitor.

The results illustrate that the steel can be corroded severely without a protective film. Figure 3 shows that the values of polarization resistance are higher with the addition of PPE. The polarization resistance values increased from 3.1to 5.1 × 10–3 Om after only 12 h of immersion time and decreased afterward reaching the minimum of Rp value (2.15 × 10−3Om) after 24 h of immersion period in the corrosive solution. The same behavior was shown in the case of the evolution of inhibition efficiency (%) in function of immersion time (Fig. 3). Such time dependence means that the formation of a barrier layer on the surface is a continuous process which requires at least 45–48 h. The relatively poor protection afforded by peach pomace extract on steel at the initial immersion compared to the results obtained at long exposure suggests that the formation of a highly protective and stable inhibitor layer on steel surface might need more time than 1–30 h to evolve completely. The authors obtained similar results related to the effect of immersion time on the inhibition performance of the grape pomace [9], rape cake and raphanus cake [14, 18], Centaureacyanus [19, 20] and apricot pomace extracts [20,21,22,23].

The polarization plots for the steel samples exposed to the solution including PPE is illustrated in Fig. 4. It is seen from Fig. 4 that the current strength of both anodic and cathodic branches considerably reduced in the presence of PPE.

3.2.3 Effect Immersion Time on the Component Composition and Properties Peach Pomace Extract in 0.5 M NaCl Solution

The identified compounds the various classes of compounds possess satisfactory corrosion mitigation properties and high electrochemical activity. Understanding the electrochemical reaction mechanisms of the mixture electro-active compounds derived from the plant extracts is important. In order to better understand the difference of electrochemical reactions on the electrode depending on the type of extract, the electrode used in this work was glassy carbon electrode. In order to investigate the mechanism of the corrosion resistance of PPE in the process of protective film formation in a corrosive medium, cyclic voltammogram (CVA) on a glassy electrode were taken (Fig. 5).

It should be noted that the highest current value (0.61 mA) is observed on the electrode, which was previously exposed to PPE for 48 and 120 h. By increasing the exposure time of the electrode to 120 h, the current value decreases and is lower than the value recorded for the sample exposed for 5 min. The results obtained confirm that it is after 48 h in the solution of the plant extract that a modification of the component composition of the PPE occurs, which is explained by the possible oxidative and isomeric transformations of organic compounds.

For a more complete study of the protective film formation mechanism, the component composition of the solution containing 800 ppm of PPE 120 h of formation of the protective film was studied by means of GC–MS (Fig. 6).

The results obtained indicate that along with the main components of the extract, the presence of the p-quinones structure (RT 2.53) and the oxidized structures of the phenolic compounds were identified in the composition. The transformation (polymerisation) products of the phenolic flavanol and aldehydes namely flavanol-aldehyde adducts (RT 4.34; RT 6.78; RT 7.65), polymers of flavan-3-ols-anthocyanins have also been identified. The inhibitor shows enhanced inhibition performance might because a protective layer composes mixes adducts of polymerisation and oxidation components of extract. A similar mechanism of action has also been recorded by other authors [24].

3.3 Surface Characterization

SEM micrographs (Fig. 7b) of the steel surface in 0.5 M NaCl solution exhibit the changes occurred during the corrosion process in presence of the inhibitor.

Figure 7b shows the surface morphology of specimens after 48 h immersion in the solutions with peach pomace extract (800 ppm).The steel immersed for 48 h in NaCl (Fig. 7a) shows basically flower-like flakes with finger-like structures protruding in a random manner and bumpy surface.

The close examination of the SEM images reveals that the specimens immersed in the inhibitor-containing solutions possess smoother surfaces compared to those immersed in a blank 0.5 M NaCl solution, which are rough and coarse. This improvement of the surface morphology indicates the formation of a good protective film of PPE which is responsible for the inhibition observed.

3.4 Mechanism of Corrosion and Inhibitor Performance

To understand the mechanism of action of PPE, it is good to highlight the corrosion mechanism of.

carbon steel in nearly neutral aerated aqueous medium such as NaCl solution. The corrosion mechanism of carbon steel in neutral NaCl aqueous medium had been well built [25], which is shown in Fig. 8 and can be expressed as the following typical reactions:

Reaction (1) as an anodic reaction represents the dissolution of steel, the generated Fe2+partially became Fe3+ by the oxidation of dissolved oxygen. In the cathode sites, the oxygen reduction reaction presented at reaction (2) occurred and produced OH−. Then, corrosion products including FeOOH, Fe2O3 and Fe3O4 would generate at the interface between steel and NaCl solution [25, 26].

The inhibitory action of PPE could be attributed to the adsorption and interactions of its components between themselves as on the steel surface so in solution. This layer acts a self-protective barrier, characterized high degree of the protective. The data obtained indicate that the process of film formation can potentially be divided into the two stages. The first stage (1–20 h) corresponds to the adsorption of more reactive compounds along with the formation of an insufficiently solid protective film due to the attraction effect. On the one hand this can be the charged molecules interaction to the steel surface by electrostatic interaction or interaction of unshared electron pairs in the molecule with the metal. The adsorption of the compounds of extract can occur on the metal surface via interaction of π-electrons of the molecules with the metal or a combination of the above types of interaction.

However, the increase of the immersion time to 30–120 h promotes transformation of the primary protective layer both on the metal surface and in solution connected with the appearance of higher molecular weight compounds exhibiting a protective effect (Fig. 9). It is suggested that there are two main causes for transformation of extract during the holding time. One is that the formation of polymerisation flavanol-aldehyde adducts and polymers of flavan-3-ols-anthocyanins. The other is that the oxidation components of the extract and the formation of compounds of a more stable shape (oxidation of flavonoids to quinones).

The formation of polymerisation flavanol-aldehyde adduct (Condensation Products of Cinnamal aldehyde with Catechin) [26,27,28], polymers of flavan-3-ols-anthocyanins and oxidation compounds of the p-quinones structure due to extract transformation in water causes main corrosion reduction in 40–50 h. The new self-transformed protective layer provides better protective properties. Thus, the high inhibiting efficiency of PPE in respect to steel corrosion in a neutral solution is a consequence of the formation of a protective film with the participation of the main components of the extract and the products of their chemical transformations on the corroding steel. Therefore, the inhibitor built the stable isolation film on the steel surface, suppressing the corrosion process.

4 Conclusions and Future Perspective

Our current study has described an experimental investigation of corrosion inhibition by PPE as corrosion inhibitors in neutral medium. The extraction from waste was a conventional extraction process using of solution 2-propanol/ethanol/water (v:v:v = 50/20/30) as the solvent. After all the investigations the following conclusions are obtained:

-

Four dominant volatile compounds were identified, which are thymol (12.2%), hexanal (10.8%), cinnamaldehyde (8.5%) and α-Terpineol (8.8%). According to HPLC analyze the main semi-volatile and high molecular components of the extract are as follows: hydroxybenzoic acids, flavonols and anthocyanins.

-

The inhibition efficiency values increased with increasing PPE concentration and time of immersion. The addition of 800 ppm PPE to 3.5% NaCl led to a higher corrosion inhibition performance. The inhibitor gives maximum efficiency at 72 h of immersion time.

-

The results obtained from the potentiodynamic polarization indicate that PPE has affected anodic and cathodic reactions, allowing a mixed-type inhibition by a simple blockage of the active sites on the metal.

-

Formation of smooth and homogenous film can be observed in the SEM images of the sample after immersion in 0,5 M NaCl solution containing 800 ppm PPE.

-

The main corrosion rate reduction appeared after 40–50 h of exposure—time required for the formation of new compounds in the solution. The flavanol-aldehyde adducts and oxidation compounds of the p-quinones were identified in water solution after 120 h.

Further research will be aimed at studying the mechanisms of transformation of a peach pomace extract in solution of 0.5 M NaCl using individual organic substances. The chemical transformations that require several hours or days can be completed in few minutes by oxygen purge. In this regard, the next stage of research will be the search for methods for intensifying the chemical transformation of the extract and studying the reaction mechanisms.

References

Ahanotu CC, Onyeachu IB, Solomon MM, Chikwe IS, Chikwe OB, Eziukwu CA (2020) Pterocarpus santalinoides leaves extract as a sustainable and potent inhibitor for low carbon steel in a simulated pickling medium. Sustain Chem Pharm 15:100196

Alibakhshi E, Ramezanzadeh M, Haddadi SA, Bahlakeh G, Ramezanzadeh B, Mahdavian M (2018) Persian Liquorice extract as a highly efficient sustainable corrosion inhibitor for mild steel in sodium chloride solution. J Clean Product 210:660–672

Khajuria A, Kumar R, Bedi R (2019) Effect of boron addition on creep strain during impression creep of P91 steel. J Mater Eng Perform 28:4128–4142

Khajuria A, Akhtar M, Bedi R, Kumar R, Ghosh M, Das CR, Albert SK (2020) Microstructural investigations on simulated intercritical heat-affected zone of boron modified P91-steel. Mater SciTechnol 36:1–12

Khajuria A, Kumar R, Bedi R (2018) Characterizing creep behaviour of modified 9Cr1Mo steel by using small punch impression technique for thermal powerplants. J MechMechEng 4:47–61

Khajuria A, Akhtar M, Pandey MK, Singh MP, Raina A, Bedi R, Singh B (2019) Influence of ceramic Al2O3 particulates on performance measures and surface characteristics during sinker EDM of stir cast AMMCs. World J Eng 16(4):526–538

Plazzotta S, Ibarz R, Manzocco L, Martín-Bellos O (2020) Optimizing the antioxidant biocompound recovery from peach waste extraction assisted by ultrasounds or microwaves. Ultrason Sonochem 63:276104954

Pal S, Lgaz H, Tiwari P, Chung IM, Ji G, Prakash R (2019) Experimental and theoretical investigation of aqueous and methanolic extracts of Prunusdulcis peels as green corrosion inhibitors of mild steel in aggressive chloride media. J Mol Liq 276:347–361

Vorobyova V, Chygyrynets´ O, Skiba M, Zhuk T, Kurmakova I, Bondar OA, (2018) A comprehensive study of grape pomace extract and its active components as effective vapour phase corrosion inhibitor of mild steel. Int J Corros Scale Inhibit 7(2):185–202

Vorobyova V, Skiba M, Chygyrynets O (2018) A novel eco-friendly vapor phase corrosion inhibitor of mild steel. Pigm Resin Technol 48(2):137–147

Dehghani A, Bahlakeh G, Ramezanzadeh B (2019) A detailed electrochemical/theoretical exploration of the aqueous Chinese gooseberry fruit shell extract as a green and cheap corrosion inhibitor for mild steel in acidic solution. J Mol Liq 282:366–384

Umoren S, Obot IB, Gasem Z, Odewunmi NA (2015) Experimental and theoretical studies of red apple fruit extract as green corrosion inhibitor for mild steel in HCl solution. J DispersSciTechnol 36(6):789–802

Nasr K, Fedel M, Essalah K, Deflorian F, Souissi N (2018) Experimental and theoretical study of Matricariarecutita chamomile extract as corrosion inhibitor for steel in neutral chloride media. Anti-Corrosion Methods Mater 65(3):92–309

Vasyliev G, Vorobiova V (2019) Rape grist extract (Brassic anapus) as a green corrosion inhibitor for water systems. Mater Today 6:178–186

Vasyl’Ev HS (2013) Measurement of polarization resistance with computer logging of results. Mater Sci 48(5):694–696

Refait P, Rahal C, Masmoudi M (2020) Corrosion inhibition of copper in 05 M NaCl solutions by aqueous and hydrolysis acid extracts of olive leaf. J ElectroanalChem 859:113834

Liu Y, Song Z, Wang W, Jiang L, Zhang Y, Guo M, Xu N (2019) Effect of ginger extract as green inhibitor on chloride-induced corrosion of carbon steel in simulated concrete pore solutions. J Clean Product 214:298–307

Vasyliev G, Vorobyova V, Zhuk T (2020) Raphanus sativus L. extract as a scale and corrosion inhibitor for mild steel in tap water. J Chem 2020:1–9

Yaro SA, Ibraheem FH (2010) The inhibition effect of peach juice on corrosion of low carbon steel in hydrochloric acid at different temperatures. Iraqi J Chem Petrol Eng 11(1):65–76

Vorobyova V, Skiba M (2019) Apricot cake extract as corrosion inhibitor of steel: chemical composition and anti-corrosion properties. Chem J Moldova 1(14):77–87

Vorobyova V, Chygyrynets O, Skiba M (2018) 4-Hydroxy-3-methoxybenzaldehyde as a volatile inhibitor on the atmospheric corrosion of carbon steel. J ChemTechnolMetall 53(2):336–345

Vorobyova VI, Skiba MI, Shakun AS, Nahirniak SV (2019) Relationship between the inhibition and antioxidant properties of the plant and biomass wastes extracts: a review international. J Corrosion Scale Inhib 8(2):150–178

Vorobyova V, Chygyrynets O, Skiba M, Trus I, Frolenkova S (2018) Grape pomace extract as green vapor phase corrosion inhibitor. ChemChemTechnol 12(3):410–418

Keramatinia M, Ramezanzadeh B, Mahdavian M (2019) Green production of bioactive components from herbal origins through one-pot oxidation/polymerization reactions and application as a corrosion inhibitor for mild steel in HCl solution. J Taiwan InstChemEng 105:134–149

Saker S, Aliouane N, Hammache H, Chafaa S, Bouet G (2015) Tetraphosphonic acid as eco-friendly corrosion inhibitor on carbon steel in 3 % NaCl aqueous solution. Ionics 21(7):2079–2090

Duenas M, Fulcrand H, Cheynier V (2005) Formation of anthocyanin–flavanol adducts in model solutions. Anal Chim Acta 563(1–2):15–25

Tanaka T, Matsuo Y, Yamada Y, Kouno I (2008) Structure of polymeric polyphenols of cinnamon bark deduced from condensation products of cinnamaldehyde with catechin and procyanidins. J Agric Food Chem 56(14):5864–5870

Salas E, Atanasova V, Poncet-Legrand C, Meudec E, Mazauric JP, Cheynier V (2004) Demonstration of the occurrence of flavanol–anthocyanin adducts in wine and in model solutions. Anal Chim Acta 513(1):325–332

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vorobyova, V., Skiba, M. Peach Pomace Extract as Efficient Sustainable Inhibitor for Carbon Steel Against Chloride-Induced Corrosion. J Bio Tribo Corros 7, 11 (2021). https://doi.org/10.1007/s40735-020-00450-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-020-00450-y