Abstract

Over the last years, additive manufacturing (AM) has been gathering momentum both in the academic and in the industrial world. Besides the obvious benefits in terms of flexibility and process capabilities, the environmental performance of such processes has still to be properly analyzed. Actually, the advantages of additive manufacturing over conventional processes are not obvious. Indeed, different manufacturing approaches result in different amounts of involved material and in different processing energy demands. Environmental comparative analyses are hence crucial to properly characterize AM processes. In this paper, an energetic comparison between the emerging wire arc additive manufacturing (WAAM) process and a traditional machining-from-bulk solution to produce a steel blade is presented. A methodology accounting for all the material and energy flows of the whole component life cycle is proposed. Experimental measurements and environmental databases are used to quantify the primary energy demand at each stage of the life cycle. The results reveal that, for the analyzed case study, an integrated additive (WAAM)-subtractive manufacturing route enables significant material and primary energy savings with respect to traditionally applied approaches.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Additive manufacturing (AM) for metal part fabrication has been gaining an increasing market share due to its flexibility and process capabilities. AM appears to be particularly suitable for small batches, like highly customized parts (e.g., prostheses used in surgical implants) or prototypes. In this context, wire arc additive manufacturing (WAAM) is a process enabling the production of three-dimensional components in a layer-wise way. WAAM belongs to the class of direct energy deposition technologies [1]. The layers are created by selectively deposing the molten metal through a dedicated head. The raw material is fed in the form of a metal wire and it is molten by means of the heating action of an electric arc [2]. The advantages of WAAM are related to both (i) the achievable build rate, significantly higher than the one of laser-based additive processes (50–130 g/min versus 2–10 g/min) [3], and (ii) the chance of producing larger components (1000–2000 mm versus 300–600 mm) [4]. The main drawbacks of WAAM are the reduced dimensional accuracy and the feature resolution when compared with other powder-based AM processes [5]. Therefore, WAAM is economically convenient for the manufacturing of large parts with reduced complexity, as large aircraft components [6]. A post-WAAM finishing operation is usually necessary to achieve the functional requirements of the part [7, 8], and milling (being suitable to obtain high accuracy and surface finish on complex surfaces with a high productivity) is one of the commonly investigated processes [9].

Some studies in literature focused on the economic sustainability of additive manufacturing, while the environmental performance of AM processes has been assessed mainly for the powder-based ones [10, 11]. It is worth remarking that AM requires a different amount and kind of material with respect to pure machining. Moreover, these approaches are characterized by different processing energies (e.g., in terms of electrical energy demand for adding or removing the material). Several researches matching the different approaches from the environmental perspective have been presented over the last few years. Some of the authors of this paper carried out an environmental comparison between electron beam melting (EBM) and turning of Ti-6Al-4V parts [12]. Paris et al. evaluated the cumulative energy demand of conventional machining and EBM to manufacture an airplane turbine made of a titanium alloy [13]. Tang et al. proposed a comparison between a binder jetting process and conventional CNC machining [14]. Peng et al. analyzed three different manufacturing routes to produce an impeller. Specifically, they compared an additive-based approach to both conventional- and remanufacturing-based routes by applying a life cycle assessment (LCA) [15]. A couple of studies have been introduced to identify decision-support tools for selecting additive over conventional machining processes (and vice versa) when metals parts are to be manufactured [16, 17]. As far as polymer components manufacturing is concerned, Faludi et al. applied a full LCA to compare two AM processes (fused deposition modelling and 3D printing) with conventional machining [18]. Yoon et al. published an analysis focused on the specific energy consumption (SEC) of injection molding, fused deposition modelling (FDM), and milling for components made of ABS P400 [19]. As for the powder-based direct energy deposition (DED) processes, Morrow et al. presented the first comparative analysis quantifying the energy consumption and CO2 emissions associated with laser-based direct metal deposition (DMD) and CNC milling for the production of molds and dies [20]. A LCA of Ti-6Al-4V parts was carried out by Serres et al. to compare a direct additive laser manufacturing approach (CLAD) and machining [21]. Recently, Liu et al. compared, under cradle-to-gate system boundaries, a DED process and a milling one when producing a steel-based high-speed gear to be used in a wind turbine [22]. To the authors’ knowledge, only two papers dealing with the environmental characterization of WAAM have been published so far. Jackson et al. dealt with the comparison between WAAM and powder-based processes [23], while Bekker and Verlinden have recently presented a comparative LCA analysis between WAAM, green sand casting, and milling [24]. To further characterize such a process category from the environmental point of view, this paper assesses the energy efficiency of WAAM with respect to a machining-from-bulk solution to produce a NACA airfoil. All the main required resources (e.g., energy and materials) have been accounted for, together with the benefits arising from material recycling.

2 Case Study and Manufacturing Approaches

The assumed test case is a blade designed according to the NACA 9403 standard, having a 100 mm chordal length and made of EN S235JR structural steel. Among others, this component has been identified to be a suitable candidate for a WAAM-based process. A 3D sketch of the blade with its main dimensions is shown in Fig. 1. The values of mass and volume of each feature of the product are listed in Table 1. Two alternative production approaches based either (i) on an integrated additive-subtractive route or (ii) on pure subtractive manufacturing have been compared by applying a cradle-to-gate plus end-of-life system boundary. A single produced part has been assumed as functional unit. The material production (including the pre-manufacturing) and the part manufacturing phases have been considered, together with the impact of transportation. The primary energy demand per produced part has been adopted as metric for the process comparison. The manufacturing cycles for the test case have been developed and experimentally characterized for each production approach.

2.1 Integrated Additive–Subtractive Approach

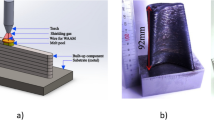

WAAM is a welding-based direct energy deposition technique using metal wire as feedstock. A substrate to build the part on is needed. Therefore, it is convenient to arrange the deposition in a way that such substrate is a functional part of the final component. This is a good practice to speed up the whole manufacturing process, since the additively manufactured part has not to be cut away from the base plate. Moreover, simple-shaped segments of the final component can be obtained by using fast traditional technologies (such as milling or forging). For the above mentioned reasons, the integrated manufacturing route graphically described in Fig. 2a has been envisaged for the present case study. The blade root (in red color) has been obtained by means of a milling process, and it has been used as the substrate on which the thin airfoil (in blue color) has been deposited by means of WAAM. Then, a post-AM machining (milling) operation has been performed to achieve the desired surface finish on the airfoil’s aerodynamic surfaces.

The raw material is produced by means of primary (i.e., from virgin sources) and/or secondary routes (i.e., from recycling). Then, specific material inputs are needed for manufacturing: a bulk workpiece for machining and a steel wire for WAAM. Additional pre-manufacturing processes (namely, hot rolling and wire drawing) have to be accounted for with their material wastes (mHRs and mWDs, respectively). According to Fig. 2a, the mass of the workpiece required to produce the root (weighing mrootwp, in kg) includes the mass of the root (mroot) and the mass of the chips obtained as a by-product of the milling process (mrootc). The mass of the wire (mairfoilwire) for the AM process must compensate for the mass of the airfoil (mairfoil), the mass of WAAM process scraps (mWAAMs), and the mass of the machining allowance to be removed during the finish operations (mairfoilc).

The mass of the material involved for the additive-subtractive approach can be computed according to Eq. 1. yHR and yWD are the input/output ratios quantifying the input material mass necessary for obtaining 1 kg of output material in hot rolling and wire drawing, respectively. yHR and yWD account for the material losses in the pre-manufacturing stage.

Moreover, each manufacturing step requires an amount of energy (as highlighted by the arrows in Fig. 2), which must be quantified together with the material flows.

2.2 Subtractive Approach

A conventional milling process has been assumed as benchmark for the comparison. As shown in Fig. 2b, the blade (the weight of which is labelled as mblade) is produced in its final geometry by removing the exceeding material in the form of chips (weighing mbladec) from a parallelepiped-shaped workpiece (weighing mbladewp). The mass of the material required for the pure subtractive approach can be modelled according to Eq. 2.

The energy demands of material production, pre-manufacturing, and machining have been assessed as detailed in the following section.

3 Data Inventory

Experimental tests have been carried out to set a base to quantify the energy requirements of the alternative manufacturing processes. For machining and WAAM these tests have been carried out by equipping the production machines with sensors able to directly measure the energy consumption and the use of consumable materials (e.g., the gas flux for WAAM). Data concerning the material production and the pre-manufacturing phases have been collected from environmental databases and scientific literature.

3.1 Material Production and Pre-manufacturing

The eco-properties of a structural steel with a nominal chemical composition of Fe 97.0–99.5%, C < 0.18%, Mn 0.5–1.4%+ impurities have been acquired from the CES Selector 2017 software [25]. The average values applied to assess the energy demand for the material production and the pre-manufacturing phases are listed in Table 2. The embodied energies for primary or secondary production refer to the energy required to make 1 kg of in-stock material (in the form of ingots) from its ores/feedstock or from recycling routes, respectively. The ‘recycled content approach’ and the ‘substitution method’ have been then applied, as proposed by Hammond and Jones, to compute the benefits deriving from material recycling [26]. The full benefits are ascribed to the input side by the first criterion, and to the end of life (EoL) by the second one. The EoL recyclability has been here supposed to be equal for both process scraps and bulk material [27], even if more complex scenarios could be outlined [28].

3.2 Product Manufacturing

The data inventory for product manufacturing by means of either the additive-subtractive approach or the pure subtractive approach is detailed in the following sub-Sects. 3.2.1 and 3.2.2.

3.2.1 Additive–Subtractive Approach

As earlier mentioned, the blade has been produced according to the manufacturing route presented in Fig. 2a. The root of the blade (weighing mroot) has been obtained by machining a 40 × 110 × 25 mm workpiece, which volume and mass (mrootwp) are respectively equal to 110 × 103 mm3 and 0.847 kg. A Mori Seiki NMV 1500 DCG 5-axis milling center was used for this task. The Specific (electric) Energy Consumption (SEC, in J/mm3) of the machine tool has been measured and correlated with the Material Removal Rate (MRR, in mm3/s), by applying the empirical method proposed by Kara and Li [29] and recalled in Eq. 3. The machine tool is considered as a single holistic system, and C0 and C1 are the machine-specific coefficients [30].

A study concerning the energy consumption of this Mori Seiki machine tool when milling a carbon steel has been already carried out by the authors [31]. The details of the experiments performed to determine the power consumption of the machine tool are presented in a previous work [32]. The main results of the former research are summarized in Fig. 3 under the label ‘Test 1’.

To collect further data at lower MRRs, an additional experimental campaign has been carried out. The tests have been performed under the same setup, in dry cutting conditions, and planned according to the Design of Experiments (DoE) procedures. Four process parameters (cutting speed, axial depth of cut, radial tool engagement, and feed per tooth) with three levels of variation for each factor have been considered in the present research. The test conditions are presented in Table 3. The energy consumption results are plotted in Fig. 3 under the label ‘Test 2’. The coefficients C0 and C1 of Eq. 3 have been obtained by means of a regression analysis. Comparable results have been obtained by Kara and Li [29] when assessing the energy requirements of similar machine tools.

The total amount of material to be removed (mrootc = 0.348 kg) has been assumed to be machined in two subsequent operations of roughing and finishing, both programmed by using the ESPRIT CAM software. Four fluted 8-mm diameter end-mills have been used. The process parameters, hence the MRR values, have been specifically chosen per each operation. Further details are provided in Table 4, together with the calculation of the SEC values. The resulting electric energy consumption due to the cutting process is equal to 1.76 MJ. An extra-amount of 0.66 MJ is added to account for the energy consumption during non-productive times (i.e., machine tool setup, lasting 5 min in idle operational mode). The energy for tooling has been neglected in the present research since, according to Dahmus and Gutowski [33], even if energy-intensive materials and processes are required for the production of cutting tools, their environmental impact is limited as amortized over numerous products. It can be hence assumed to be negligible on a per-part basis. Moreover, the contribution of tooling on the specific energy requirements of cutting processes (i.e., per unit of removed material) has been proven to be small in comparison to that of the machine tool usage, particularly for low MRRs [34].

The airfoil has been deposited, layer by layer, by using the root as substrate. Manufacturing a part by WAAM requires to determine the deposition toolpath as well as the idle times to avoid collapse and re-melting due to the high energy input of the arc-based processes. Moreover, the geometry of the weld bead must be taken into account in order to assess the final number of layers and the thickness of the deposited geometry. This is determined by the welding parameters: welding speed, wire feed speed, and voltage. The power source used to additively manufacture the airfoil is an Awelco Pulsemig 250 constant DC voltage source. The shielding gas was an 82% Ar—18% CO2 mixture. The adopted welding parameters are listed in Table 5. A 0.8-mm diameter wire was used as feedstock. The deposition toolpath was generated by means of a CAM software developed by the authors [4]. The input of the software is the skeleton surface of the blade, generated as an extrusion of the camber line. Based on this input, the software computes the toolpath that has a Z-level pattern with alternate deposition directions for every layer. The selected welding parameters produced a weld bead 6.8 mm wide and 1.8 mm high. The width was sufficiently large to accommodate the final airfoil geometry with enough machining allowance, since the maximum thickness of the airfoil profile is equal to 3.0 mm. The duration of the idle times was determined by a thermal finite element simulation [35]. No remelting-related issues affected the as-deposited airfoil (shown in Fig. 4a), and a satisfactory dimensional accuracy was achieved.

Experimental data have been collected to assess the demanded energy and the amount of used material for the WAAM process. The main source of energy consumption is the arc welding process itself. The current, the voltage, and the power have been monitored during the deposition process. The welding current has been measured by a (LEM HTFS 200-P) hall effect gauge which returns a voltage signal proportional to the sensed current. This sensor has been installed on the ground cable of the welding machine. The voltage has been directly measured by connecting two leads to the end tip of the welding torch and to the ground connection of the workpiece holding table. Both signals have been sampled at a rate of 1 kHz using a National Instrument (NI DAQ 9215) data acquisition card interfaced to a PC by means of the LabVIEW Signal Express software. The total electric energy consumption of the process, which lasted for 1 h and 35 min, has been measured to be 6.64 MJ, including both productive and non-productive production modes. The deposition rate for productive time has been quantified in 1.06 kg/h. The surface of the airfoil has been acquired by using a Mitutoyo Euro Apex CMM machine to check the dimensional accuracy and to measure the effective deposited volume. From the resultant point cloud, the deposited volume has been calculated and compared with the theoretical one. The mass of the consumed wire (mairfoilwire) has been assessed to be 0.340 kg, with a material-use efficiency of 98.7%. The total consumption of shielding gas has been 271 L. The energy demand for the shielding gas production has been left out of the boundaries of this study since it could be considered negligible [12]. The highest estimation of energy consumption for Argon production by separation of inert gases from air is considered lower than 1 kJ/L [36].

The as-deposited airfoil has been machined, by means of the Mori Seiki NMV 1500 DCG milling center, to achieve a surface finish compatible with the aerodynamic requirements. A 10-mm diameter Garant 207280 ball-end mill has been chosen for this task. The use of a 5-axis machine tool allows reducing the tool overhang and, consequently, the induced vibrations, which represent a detrimental phenomenon for the milled surface finish. However, due to the aspect ratio of the thin airfoil to be produced, the process parameters (i.e., cutting speed, feed, and tool-workpiece engagement) have been kept quite conservative. The total amount of material to be removed (mairfoilc) is equal to 0.241 kg. The data inventory for both the semi-finishing and the finishing operations are listed in Table 6, and a detail of the finished blade is given in Fig. 4b. The total electric energy consumption for the airfoil machining is equal to 19.64 MJ (including 0.66 MJ added to account for the energy consumption during non-productive times).

3.2.2 Pure Subtractive Approach

The pure subtractive approach is a traditionally-applied route to produce the blade subject of the present case study. The complete blade (weighing mblade), according to Fig. 2b, could be obtained by removing 2.454 kg of chips (mbladec) from a 40 × 110 × 90 mm workpiece that weights 3.049 kg (mbladewp). To enable a proper process comparison, the cutting conditions to machine the blade root (in Table 4) and the airfoil (in Table 6) have been kept unvaried with respect to the additive-subtractive approach. As a result, the removal of 0.589 kg of workpiece material requires 20.74 MJ of electric energy. The remaining 1.865 kg of chips (equal to approximately 76% of the total chip mass) is removed by means of a roughing operation. If a MRR of 143.2 mm3/s is adopted, the resulting electric energy consumption is equal to 4.36 MJ. A further increase in MRR would not allow achieving a substantial reduction in the SEC value, as shown in Fig. 3. The total electric energy consumption for the entire blade machining is equal to 25.76 MJ (including 0.66 MJ added to account for the energy consumption during the non-productive times).

3.3 Transportation

The two manufacturing approaches involve different amounts of material to be shipped. The transportation of the material (mrootwp and mairfoilwire—or mbladewp) from the production site to the manufacturing plant (on a presumed distance of 500 km), and of the material scraps (mrootc, mWAAMs, and mairfoilc—or mbladec) from the manufacturing plant to the recycling plant (on a distance of 500 km) has been encompassed in the analysis. Other transportation impacts, including those identical for both the approaches, were neglected. An energy penalty per unit weight and distance of 0.94 × 10−3 MJ/kg km concerning a 32-t truck has been assumed [37].

4 Results and Discussion

The results collected in Sect. 3 are summarized and discussed in the following. The graph in Fig. 5 plots the values of the masses involved in each approach, labelled according to Fig. 2. As it can be noticed, the pure subtractive approach results in a significantly higher amount of involved material. To be more specific, a material saving as high as 60% is obtained when choosing the integrated additive-subtractive approach here presented. This is mainly due to the subtractive nature of the machining-based approach, which causes a noteworthy amount of chips (mbladec) as by-product of the process. Such differences in material usage result in different energy demands for the raw material production.

The results in terms of energy demand for both the manufacturing approaches are plotted in Fig. 6. The impact of raw material production has been computed, with reference to Table 2, by considering three different scenarios: (i) primary production from virgin sources, (ii) recycling benefits awarded by means of the ‘recycled content approach’, and (iii) recycling benefits awarded by means of the ‘substitution method’. In all the analyzed scenarios, the material-related energy demand of the pure subtractive approach is significantly higher, and such a difference could be up to 50 MJ (for the primary material production from virgin sources scenario). For what concerns the energy for manufacturing, it has been experimentally measured, as detailed in Sect. 3. The total electric energy demand for the additive-subtractive approach and the pure subtractive approach is equal to 28.7 MJ and 25.8 MJ, respectively. To make these results comparable with the embodied energies of the material and the pre-manufacturing data, the electrical energy has been converted (in Fig. 6) into to the primary energy value, by assuming a conversion factor of 0.34. It is appropriate to remark that the corresponding consumption of fossil fuel and the emissions of carbon dioxide depend on the energy mix of each specific country [37].

The additive-subtractive approach is the most energy efficient, regardless of the considered scenario. Besides the already commented difference about the raw material production, significant differences occur in the processing energy related to pre-manufacturing (66.3 MJ versus 32.6 MJ). In fact, even though the integrated approach requires two pre-manufacturing processes (hot rolling and wire drawing) instead of one (as shown in Fig. 2), the higher amount of material to be processed badly affects the overall energetic performance of the pre-manufacturing step of the pure subtractive approach. The impact of each manufacturing step towards the total energy demand is quantified in the primary energy breakdown reported in Fig. 7 (for the primary material production scenario).

The pre-manufacturing step accounts for a notable portion of the total primary energy demand: 21% for the integrated additive-subtractive approach, and 29% for the pure subtractive one. Within the pre-manufacturing step, the main contribution is given by the processing energies (32.6 MJ and 66.3 MJ), while the energy demands due to the process material losses are one order of magnitude smaller (2.7 MJ and 4.0 MJ). As far as the manufacturing step is concerned, an opposite trend can be observed. The processing energies are quite similar in the two approaches, while the energies related to the material scraps are significantly different (65.0 MJ versus 15.7 MJ). This result is due to the higher amount of chips produced in the pure subtractive approach. Transportation impacts appear to be negligible, and this evidence confirms previously achieved results [12]. Moreover, the choice of recycling chips and bulk material as EoL strategy provides benefits in both the approaches, as expected. It is worth to highlight that a variability of ± 15% in input data would not change the achieved conclusions.

4.1 Comments on the Process Effectiveness

The above presented results highlight that, for the specific test case, the WAAM–milling process enabled a reduction of total primary energy demand with respect to the traditional pure subtractive process. The efficiency of the integrated approach is due to the relatively low energy requirement and cycle time of WAAM (particularly if compared to the powder-bed based AM processes). Moreover, the process comparison is heavily affected by the amount of involved materials, and by the mass of chips obtained as by-product of the material removal process. The solid-to-cavity ratio in machining (i.e., the mass of the final part divided by the mass that would be contained within the bounding volumetric envelope of the part itself) becomes therefore a variable of utmost importance in such a kind of analysis [17].

Also, it is worth to broaden the domain of the discussion by considering two additional aspects: (i) the mechanical properties of the WAAM processed material, and (ii) the productivity of the two technologies. As far as the first issue is concerned, the here presented process comparison is meaningful only if the additive-based process can produce a material with adequate mechanical properties. A mild steel has been used in this research. Previous works proved that WAAM can effectively deal with such material. Haden et al. [38] executed wear and tensile tests on a WAAM-processed ER70S-6, highlighting that both yield strength and UTS were within the range of expected values for the material. Similar tests performed by Suryakumar et al. [39] also provided comparable results. Some of the authors of this paper analyzed both hardness and microstructure of ER70S-6 samples at different distances from the substrate [3], finding an almost uniform pattern which suggests that a homogenous material can be fabricated by using WAAM. The here presented energy model does not account for thermal treatments, which are likely unnecessary for the mild steel, according to the above mentioned references. However, further post-process treatments could be required for other materials, as Ti-6Al-4V [40, 41] or ER2319 aluminum alloy [42]. In such a case, the model for the energy efficiency comparison should be extended downstream to include the energy required by the post-process treatments.

The second concern is related to the processing time, since the possible loss of productivity to achieve such a reduction in energy demand has to be questioned. For the selected test case, total processing times of 4.6 and 3.6 h were estimated for the WAAM-subtractive approach and for the machining process, respectively. Therefore, the integrated approach results in a higher energy efficiency, but it increases the processing time of about 26%. In this research, three quarters of the WAAM processing time were due to the interlayer cooling, which (i) strictly depends on the given set of material, workpiece geometry, and process parameters, and (ii) could be reduced by using external cooling systems (as impinging air jets [43] or a water cooled workpiece tank [44]). In this respect, further analyses have to be developed to find the best compromise between the reduction of total cycle time and the extra-consumption of energy due to the cooling systems.

5 Conclusions and Outlooks

An energy-based comparative analysis between an integrated additive (WAAM)-subtractive approach and a pure milling process has been presented in this paper. A steel blade, designed according to the NACA 9403 standard, has been considered as case study. Energy, material and resource flows along the entire life cycle of the component have been quantified by means of experimental tests and environmental databases. A methodology suitable to account for all the main factors of influence has been presented. Particular attention has been paid to the modelling of the pre-manufacturing steps. Also, three different end-of-life scenarios have been assumed. Such choice was driven by the will to outline the role of recycling on the environmental performance of different manufacturing routes. Results revealed that a significant share of the total energy demand is related to the pre-manufacturing steps, as they account for more than 20% of the total energy demand. The WAAM-based integrated approach, for the considered case study, guarantees a significant energy saving with respect to conventional machining. Actually, an energy saving as high as 34% has been recorded for the scenario not including recycling. This result is mainly due to the efficiency in material use characterizing this additive manufacturing process. Unlike powder-based AM processes, WAAM enables material saving and keeps the processing energy demand quite low. A thin-walled geometry, which has proved to be particularly advantageous for additive manufacturing, has been considered in this research. Overall, to fully characterize the environmental performance of WAAM processes, further comparative analyses with varying the main factors of influence (such as the product geometry and the ecological properties of the materials) should be performed to identify the sustainable domain of application of integrated additive-subtractive approaches.

References

Lorenz, K.A., Jones, J.B., Wimpenny, D.I., & Jackson, M.R. (2015). A review of hybrid manufacturing. Solid Free. Fabr. Conf. Proceedings.

Ding, D., Pan, Z., Cuiuri, D., & Li, H. (2015). A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robotics and Computer-Integrated Manufacturing,31, 101–110.

Liberini, M., Astarita, A., Campatelli, G., Scippa, A., Montevecchi, F., Venturini, G., et al. (2017). Selection of optimal process parameters for wire arc additive manufacturing. Procedia CIRP,62, 470–474.

Venturini, G., Montevecchi, F., Scippa, A., & Campatelli, G. (2016). Optimization of WAAM deposition patterns for T-crossing features. Procedia CIRP,55, 95–100.

Ding, D., Pan, Z., Cuiuri, D., & Li, H. (2015). Wire-feed additive manufacturing of metal components: technologies, developments and future interests. International Journal of Advanced Manufacturing Technology,81, 465–481.

Addison, A., Ding, J., Martina, F., Lockett, H., & Williams, S. (2015). Manufacture of complex titanium parts using wire + arc additive manufacture. Titan. Eur.

Flynn, J. M., Shokrani, A., Newman, S. T., & Dhokia, V. (2016). Hybrid additive and subtractive machine tools—research and industrial developments. International Journal of Machine Tools and Manufacture,101, 79–101.

Karunakaran, K. P., Suryakumar, S., Pushpa, V., & Akula, S. (2010). Low cost integration of additive and subtractive processes for hybrid layered manufacturing. Robotics and Computer-Integrated Manufacturing,26, 490–499.

Montevecchi, F., Grossi, N., Takagi, H., Scippa, A., Sasahara, H., & Campatelli, G. (2016). Cutting forces analysis in additive manufactured AISI H13 alloy. Procedia CIRP,46, 476–479.

Peng, T., & Chen, C. (2018). Influence of energy density on energy demand and porosity of 316L stainless steel fabricated by selective laser melting. International Journal of Precision Engineering and Manufacturing-Green Technology,5(1), 55–62.

Lee, H., Lim, C. H. J., Low, M. J., Tham, N., Murukeshan, V. M., & Kim, Y.-J. (2017). Lasers in additive manufacturing: A review. International Journal of Precision Engineering and Manufacturing-Green Technology,4(3), 307–322.

Priarone, P. C., Ingarao, G., Di Lorenzo, R., & Settineri, L. (2017). Influence of material-related aspects of additive and subtractive Ti-6Al-4V manufacturing on energy demand and carbon dioxide emissions. Journal of Industrial Ecology,21(S1), S191–S202.

Paris, H., Mokhtarian, H., Coatanea, E., Museau, M., & Ituarte, I. F. (2016). Comparative environmental impacts of additive and subtractive manufacturing technologies. CIRP Annals,65(1), 29–32.

Tang, Y., Mak, K., & Zhao, Y. F. (2016). A framework to reduce product environmental impact through design optimization for additive manufacturing. Journal of Cleaner Production,137, 1560–1572.

Peng, S., Li, T., Wang, X., Dong, M., Liu, Z., Shi, J., et al. (2017). Toward a sustainable impeller production—environmental impact comparison of different impeller manufacturing methods. Journal of Industrial Ecology,21(S1), S216–S229.

Watson, J. K., & Taminger, K. M. B. (2018). A decision-support model for selecting additive manufacturing versus subtractive manufacturing based on energy consumption. Journal of Cleaner Production,176, 1316–1322.

Priarone, P. C., & Ingarao, G. (2017). Towards criteria for sustainable process selection: On the modelling of pure subtractive versus additive/subtractive integrated manufacturing approaches. Journal of Cleaner Production,144, 57–68.

Faludi, J., Bayley, C., Bhogal, S., & Iribarne, M. (2015). Comparing environmental impacts of additive manufacturing vs traditional machining via life-cycle assessment. Rapid Prototyping Journal,21, 14–33.

Yoon, H.-S., Lee, J.-Y., Kim, H.-S., Kim, M.-S., Kim, E.-S., Shin, Y.-J., et al. (2014). A comparison of energy consumption in bulk forming, subtractive, and additive processes: Review and case study. International Journal of Precision Engineering and Manufacturing-Green Technology,1(3), 261–279.

Morrow, W. R., Qi, H., Kim, I., Mazumder, J., & Skerlos, S. J. (2007). Environmental aspects of laser-based and conventional tool and die manufacturing. Journal of Cleaner Production,15, 932–943.

Serres, N., Tidu, D., Sankare, S., & Hlawka, F. (2011). Environmental comparison of MESO-CLAD process and conventional machining implementing life cycle assessment. Journal of Cleaner Production,19, 1117–1124.

Liu, Z., Jiang, Q., Cong, W., Li, T., & Zhang, H.-C. (2017). Comparative study for environmental performances of traditional manufacturing and directed energy deposition processes. International Journal of Environmental Science and Technology.. https://doi.org/10.1007/s13762-017-1622-6.

Jackson, M. A., Van Asten, A., Morrow, J. D., Min, S., & Pfefferkorn, F. E. (2018). Energy consumption model for additive–subtractive manufacturing processes with case study. International Journal of Precision Engineering and Manufacturing-Green Technology,5(4), 459–466.

Bekker, A. C. M., & Verlinden, J. C. (2018). Life cycle assessment of wire arc additive manufacturing compared to green sand casting and CNC milling in stainless steel. Journal of Cleaner Production,177, 438–447.

CES Selector 2017 (v. 17.2.0), Granta Design Limited.

Hammond, G., & Jones, C. (2010). Inventory of carbon and energy (ICE), annex B: How to account for recycling; a methodology for recycling. Bath: The University of Bath.

Priarone, P. C., Ingarao, G., Lunetto, V., Di Lorenzo, R., & Settineri, L. (2018). The role of re-design for additive manufacturing on the process environmental performance. Procedia CIRP,69, 124–129.

Ingarao, G., Priarone, P. C., Deng, Y., & Paraskevas, D. (2018). Environmental modelling of aluminium based components manufacturing routes: Additive manufacturing versus machining versus forming. Journal of Cleaner Production,176, 261–275.

Kara, S., & Li, W. (2011). Unit process energy consumption models for material removal processes. CIRP Annals,60(1), 37–40.

Li, W., & Kara, S. (2011). An empirical model for predicting energy consumption of manufacturing processes: A case of turning process. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture.,225, 1636–1646.

Campatelli, G., Lorenzini, L., & Scippa, A. (2014). Optimization of process parameters using a Response Surface Method for minimizing power consumption in the milling of carbon steel. Journal of Cleaner Production,66, 309–316.

Campatelli, G., Scippa, A., Lorenzini, L., & Sato, R. (2015). Optimal workpiece orientation to reduce the energy consumption of a milling process. International Journal of Precision Engineering and Manufacturing-Green Technology,2, 5–13.

Dahmus, J., & Gutowski, T. (2004). An environmental analysis of machining. In Proceedings of the 2004 ASME International Mechanical Engineering Congress and RD&D Exposition, Anaheim, California, USA.

Priarone, P. C., Robiglio, M., Settineri, L., & Tebaldo, V. (2016). Modelling of specific energy requirements in machining as a function of tool and lubricoolant usage. CIRP Annals,65(1), 25–28.

Montevecchi, F., Venturini, G., Grossi, N., Scippa, A., & Campatelli, G. (2018). Idle time selection for Wire-Arc Additive Manufacturing: A finite element-based technique. Additive Manufacturing,21, 479–486.

Weir, G., & Muneer, T. (1998). Energy and environmental impact analysis of double-glazed windows. Energy Conversion and Management,39, 243–256.

Ashby, M. F. (2013). Materials and the environment: Eco-informed material choice (2nd ed.). Waltham and Kidlington: Butterworth Heinemann/Elsevier. ISBN: 978-0-12-385971-6.

Haden, C. V., Zeng, G., Carter, F. M., Ruhl, C., Krick, B. A., & Harlow, D. G. (2017). Wire and arc additive manufactured steel: Tensile and wear properties. Additive Manufacturing,16, 115–123.

Suryakumar, S., Karunakaran, K. P., Chandrasekhar, U., & Somashekara, M. A. (2013). A study of the mechanical properties of objects built through weld-deposition. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture.,227, 1138–1147.

Brandl, E., Baufeld, B., Leyens, C., & Gault, R. (2010). Additive manufactured Ti-6A1-4V using welding wire: Comparison of laser and arc beam deposition and evaluation with respect to aerospace material specifications. Physics Procedia.,5, 595–606.

McAndrew, A. R., Alvarez Rosales, M., Colegrove, P. A., Hönnige, J. R., Ho, A., Fayolle, R., et al. (2018). Interpass rolling of Ti-6Al-4V wire + arc additively manufactured features for microstructural refinement. Additive Manufacturing,21, 340–349.

Hönnige, J. R., Colegrove, P. A., Ganguly, S., Eimer, E., Kabra, S., & Williams, S. (2018). Control of residual stress and distortion in aluminium wire + arc additive manufacture with rolling. Additive Manufacturing.. https://doi.org/10.1016/j.addma.2018.06.015.

Montevecchi, F., Venturini, G., Grossi, N., Scippa, A., & Campatelli, G. (2018). Heat accumulation prevention in Wire-Arc-Additive-Manufacturing using air jet impingement. Manufacturing Letters,17, 14–18.

Abe, T., Katagiri, M., & Sasahara, H. (2012). Accurate fabrication by improvement of lamination path on direct metal lamination using arc discharge. In Proc. ASPE 2012 Annu. Meet. Vol. 54, pp. 269–299.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Campatelli, G., Montevecchi, F., Venturini, G. et al. Integrated WAAM-Subtractive Versus Pure Subtractive Manufacturing Approaches: An Energy Efficiency Comparison. Int. J. of Precis. Eng. and Manuf.-Green Tech. 7, 1–11 (2020). https://doi.org/10.1007/s40684-019-00071-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-019-00071-y