Abstract

An Ag2O/Ag electrode was prepared through the electrochemical oxidation of sterling silver. This electrode was used as a cathodic electron acceptor in a microbial fuel cell (MFC). The Ag2O/Ag electrode was characterized by scanning electron microscopy, X-ray powder diffraction and linear sweep voltammetry. The maximum voltage output of the MFC with the Ag2O/Ag cathode was maintained at between 0.47 and 0.5 V in 100 cycles, indicating the good regenerative capacity of the Ag2O/Ag electrode. The overpotential loss for silver oxide was 0.021–0.006 V, and the maximum power output, open circuit potential and short circuit current of the MFC were 1.796 W m−3, 0.559 V and 9.3375 A m−3, respectively. The energy required for electrochemical reoxidation ranged from 40% to 55% of the energy produced by the MFC. Results indicated that the Ag2O/Ag electrode could be used as a cathodic electron acceptor in MFCs with excellent stability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

According to the World Energy Statistics (2012) of the International Energy Agency, the current global energy demand is ~5.3 × 1020 J/year. More than 80% of this energy demand is met by burning fossil fuels, but this process is unsustainable [1]. Furthermore, the consumption of fossil fuels generates serious environmental pollution and greenhouse gas effect. Thus, new methods of renewable energy production are required [2]. In recent years, microbial fuel cells (MFCs) have attracted increasing attention as innovative devices that produce electricity from wastewater, providing a new way to treat wastewater while obtaining a source of clean and renewable energy [3,4,5]. As an important component of MFCs, the cathode affects the electricity generation characteristics of these devices. Many studies have focused on the nature and type of the electrode, the catalyst on the electrode, the inoculum species and the cathodic electron acceptor [6,7,8]. In a single-chamber MFC, oxygen is the most sustainable cathodic electron acceptor because of its high redox potential and unlimited availability [9]. However, the poor oxygen reduction kinetics of oxygen restricts the performance of an oxygen cathode, and expensive catalysts are conventionally required (e.g., platinum-based catalysts). Furthermore, energy recovery is limited by a voltage loss when O2 is reduced at the cathode. Another problem is the limited activity of anaerobic microorganisms due to the diffusion of dissolved O2 into the anode, leading to low or no energy production.

The standard potential needed by an electron acceptor to generate a positive electromotive force should be higher than −320 mV (the redox potential of organic matter oxidized by microorganisms in the anode) [10]. Some solid metal oxides (e.g., silver oxide, lead dioxide and manganese dioxide) possess high redox potentials. Manganese dioxide and lead dioxide are usually not employed as electron acceptors but as catalysts for oxygen reduction [11,12,13,14,15]. Silver oxide/silver (Ag2O/Ag) couple has been used for decades in alkaline batteries. The standard reduction potential of Ag2O/Ag is 0.342 V vs the standard hydrogen electrode (SHE) (Eq. (1)), which is higher than that of other electron acceptors commonly present in anaerobic environments (such as CO2 and SO4 2−), but lower than oxygen evolution (0.82 V vs SHE at pH 7). When the couple is used as a cathodic electron acceptor in MFC, the potential difference between the anode and the silver oxide electrode is sufficiently large to support the energy extraction for human needs and to also sustain exoelectrogen growth and competition for electron donors. As the silver oxide is reduced to silver, hydroxyl is generated (Eq. (1)), which can neutralize the hydrogen ions produced at the anode. Thus, the solution can remain neutral. Both silver oxide and silver remain in the solid state in water and are not harmful to microbial growth because of their noncontact. Therefore, the conditions are suitable for microbial growth. Meanwhile, the antimicrobial effect of the Ag2O/Ag electrode prevents microorganism growth on its surface. Thus, the Ag2O/Ag electrode can be used in a single-chamber MFC.

In the present study, an Ag2O/Ag electrode was prepared through the electrochemical oxidation of sterling silver. The electrode was characterized by scanning electron microscopy (SEM), X-ray diffraction (XRD) and linear sweep voltammetry (LSV). Then, the Ag2O/Ag electrode was used as a cathodic electron acceptor in a single-chamber MFC. The performance of the MFC with the Ag2O/Ag cathode was investigated by measuring its power output and open circuit potential (OCP). Furthermore, the energy recovery of the MFC with the Ag2O/Ag cathode was analyzed.

2 Materials and Methods

2.1 Preparation and Characterization of the Ag2O/Ag Electrode

The Ag2O/Ag electrode was prepared through the electrochemical oxidation of sterling silver (1.5 cm × 3 cm × 0.1 cm). Pieces of sterling silver were sanded smooth with a fine silicon carbide sand paper. Then, the sterling silver was oxidized electrochemically in a sodium hydroxide solution (NaOH, 1 mol L−1, pH 14) at a current density of 1 mA cm−2. To avoid formatting silver peroxide (AgO), the process was stopped after the power voltage increased to 0.6 V. The surface morphology of the Ag2O/Ag electrode was examined SEM (JSM-7001F) at 10 kV. The XRD patterns of silver oxide and sterling silver were recorded on a power diffractometer (XRD-6000, Shimadzu LabX, Japan) operated at 40 keV and 100 mA using CuK α source (0.154178 nm). The diffraction data were recorded with 2θ ranging from 10° to 60° and at a scanning step of 6°/min.

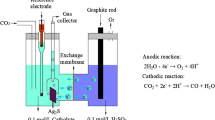

2.2 MFC Construction and Operation

Experiments were conducted using a single-chamber MFC made of a glass bottle with an operating volume of 90 mL and an inlet and outlet on its sides. The precolonized microbial anode (carbon felt, 2 cm × 4 cm × 1 cm) and Ag2O/Ag cathode were placed in the bottle at a separation distance of approximately 1.5 cm and connected externally with concealed copper wire through a 1000-Ω loading. The precolonized microbial anode was removed from a double-chamber MFC that had been running for more than 3 months. The MFC was filled with 80 mL of nutrient solution containing 1000 mg L−1 NaAc·3H2O as the carbon source, 100 mM phosphate buffer and 20 mL L−1 trace mineral element solution. The MFC was conducted in a continuous flow mode at 35 °C. The nutrient solution was continuously pumped into the MFC with a peristaltic pump, and hormone replacement therapy lasted for 10 h. When silver oxide was completely reduced to elemental silver, the cathode was removed, reoxidized and then reinstalled in the MFC. The entire process was repeated in accordance with the above-mentioned method. Three groups of parallel experiments were carried out simultaneously, and the results were the average values of the parallel experiments.

2.3 Measurements and Calculations

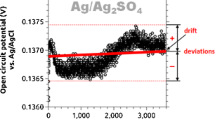

The voltage (E) and the OCP were measured by a multimeter (UNI-T 803; Uni-Trend Electronics Co., Ltd., Shanghai, China). Voltage values were recorded every 5 min. Current density (I) and power density (P) were obtained according to I = E/RV and P = EI/V, where E is the voltage, R is the electrical resistance, I is the current, and V is the working volume of the MFC. The polarization curve was obtained by changing the external circuit resistances from 10, 000 to 0 Ω. The anode and cathode potentials were measured using a Ag/AgCl electrode (+0.197 V vs SHE) for reference.

The electrochemical capability of the MFC was characterized by LSV on an electrochemical workstation (Princeton Applied Research, America). The LSV tests were conducted in the same reactor filled with the same media solution but without carbon source and bacterial inoculum [16]. The Ag2O/Ag electrode or sterling silver was the working electrode, and the platinum mesh (2 cm × 2 cm) and Ag/AgCl electrodes were the counter and reference electrodes, respectively. The potential was scanned from −0.4 to 0.6 V at a rate of 1.0 mV s−1.

3 Results and Discussion

3.1 Characterization of the Ag2O/Ag Electrode

SEM images of sterling silver and silver oxide crystal after electrochemical oxidation are shown in Fig. 1. The figure shows that several small crystal particles appeared on the surface of sterling silver after electrochemical oxidation. The particle size of these crystals was approximately 0.6–1.5 μm. Figure 2 presents the XRD patterns of silver oxide, showing three peaks. The diffraction peaks at 2θ = 38.74° and 44.8° were ascribed to the reflections of sterling silver. The diffraction peak at 2θ = 33.49° was ascribed to the reflections of Ag2O (111). The data in Figs. 1 and 2 indicate that Ag2O formed on the surface of sterling silver.

3.2 Electrochemical Activity of Silver Oxide

The electrochemical performance of the Ag2O/Ag electrode with respect to current density was evaluated using LSV tests in the absence of bacteria (Fig. 3). As shown in Fig. 3, the Ag2O/Ag electrode showed much larger current response than the sterling silver across the potential scan range, and a significant reduction peak at −0.308 V (vs Ag/AgCl) was observed for the Ag2O/Ag electrode. Meanwhile, the voltammetric response of the sterling silver was almost flat. The large current response from the Ag2O/Ag electrode indicated a high limiting current density and good electrochemical performance. This result may be attributed to the excellent electrochemical performance of Ag2O, which is often used as a positive electrode in silver–zinc batteries [17]. Thus, the Ag2O/Ag electrode could be a suitable electron acceptor for MFCs. In the following experiments, the Ag2O/Ag electrode was installed in the MFC and used as cathode. The performance of the MFC was tested.

3.3 MFC Performance

The performance of the MFC with the Ag2O/Ag cathode was evaluated by monitoring the voltage output, anode and cathode potentials, and power density of the cell. Figure 4a shows the voltage output of the MFC in three consecutive cycles with a 1000-Ω loading. The performance of the three cycles was similar. The maximum voltage outputs of the three cycles were 0.477, 0.481 and 0.491 V. Those subtle differences were probably due to the instability of the measuring instrument and operation. To verify the effect of the repeated regeneration of the Ag2O/Ag electrode, the MFC was operated for 100 cycles in this study (Fig. 4b). As shown in Fig. 4b, the performance of the MFC was stable even after 100 cycles, and the maximum voltage output of every cycle was maintained between 0.47 and 0.5 V. The charge–discharge of the Ag2O/Ag electrode in a NaOH electrolyte had not diminished in 100 cycles because of the reversibility of the Ag2O/Ag redox couple. In addition, the Ag2O/Ag electrode could also be reused many times without any performance loss. The XRD patterns of the Ag2O/Ag electrode were recorded before and after regeneration (Fig. 2). Ag was partially oxidized to Ag2O after electrochemical oxidation (Fig. 2a). When used as a cathodic electron acceptor, Ag2O accepted the electrons and was reduced to Ag. Ag2O was almost completely reduced at the end of the cycle (Fig. 2b).

The anode and cathode potentials were measured during the polarization (Fig. 4c). The anode potential slowly increased from −0.438 V (vs Ag/AgCl) to −0.363 V (vs Ag/AgCl) with increasing current density, which is consistent with previous observations [9, 18, 19]. Meanwhile, the cathode potential slowly decreased from 0.141 V (vs Ag/AgCl) to 0.126 V (vs Ag/AgCl). Compared with the cathode potentials of the MFC with persulfate [20] as the electron acceptor, the potential of the Ag2O/Ag electrode was lower. However, it was stable within the range of current density (0.05–1.5 A m−3). The overpotential loss for Ag2O (0.021–0.006 V) was much lower than that for oxygen (0.38–0.89 V), and the Ag2O/Ag couple exhibited superior electrochemical properties. Therefore, the voltage and power output could be significantly increased.

The voltage–current density (V–I) and power–current density (P–I) polarization curves of the MFC with the Ag2O/Ag cathode are shown in Fig. 4d. The figure shows that the maximum power output of the MFC was 1.796 W m−3 at a current density of 6.675 A m−3 normalized to the working volume of the MFC (0.319 W m−2 of the cathode geometric surface area). According to Ohm’s law, the maximum power occurred at the point where the internal resistance equaled the external resistance [21]. The internal resistance calculated from the polarization curve was 500 Ω. The OCP and short circuit current of the MFC were 0.559 V and 9.3375 A m−3, respectively. This power output level was comparable with those reported for other MFC setups in the literature that used oxygen as a cathodic electron acceptor, i.e., 0.26 W m−2 for a cathodic area with Pt-doped carbon cloth (0.5 mg cm−2 Pt catalyst on the water side and a carbon/polytetrafluoroethylene diffusion layer on the air side) [20] and 1.1 ± 0.21 W m−3 for the working volume of the MFC with Pt-doped carbon cloth (0.5 mg cm−2) [22]. The polarization curve displayed power overshoot at a low resistance. When the current density exceeded 9.2 A m−3, the voltage and power density decreased rapidly. This phenomenon might be attributed to the effect of external circuit load on the performance of the MFC. When the external circuit load of the MFC was high, the current was low, and the electrons produced by microbial decomposing organic matter were sufficient for external circuit transmission. Thus, the current was relatively stable, and the output voltage was high. However, when the external circuit load of the MFC was low, the current was high, and the electrons were inadequate for external circuit transmission. Thus, the current increased slowly and the voltage and power density decreased rapidly when the external circuit load was reduced from 100 to 0 Ω (short circuit condition).

3.4 Regeneration of the Ag2O/Ag Electrode

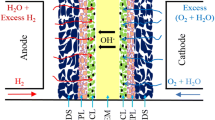

The MFC in this study used the Ag2O/Ag cathode to replace the oxygen gas cathode, which was the key difference with other MFCs. In the MFC, Ag2O accepted electrons and was reduced to Ag. Then, the Ag2O/Ag electrode required removal and regeneration. Ag2O regeneration can be realized through several methods, such as direct exposure to air at room temperature (~20 °C) [1], exposure to oxygen at 300 °C and 2 MPa O2 [23] and electrochemical reoxidation. The first method is time-consuming and generates a weak regeneration effect. The second method produces a strong regeneration effect but requires high temperature and pressure. The last method can be performed at ambient temperature and pressure and requires only several minutes for Ag2O regeneration. Importantly, this method generates a strong regeneration effect. In the present study, electrochemical reoxidation was used for Ag2O/Ag regeneration. During regeneration, the Ag2O/Ag electrode and the platinum mesh electrode were connected to the negative and positive electrodes of the power source, respectively. The electrolyte was NaOH solution (1 M, pH 14). The power voltage was adjusted, and the current density was maintained at 0.5–1 mA cm−2. On the basis of the cyclic voltammogram of silver (figure was not listed), Ag was oxidized into Ag2O at 0.51 V and AgO at 0.77 V (vs normal hydrogen electrode). Thus, the power voltage was controlled below 0.6 V to avoid formatting of AgO. Up to 10–20 min was needed to regenerate Ag2O/Ag. The energy produced by the MFC per cycle was approximately 2.6–3.0C, and 40%–55% was required for electrochemical reoxidation, depending upon the current density (0.5–1 mA cm−2) applied. Less energy and long time were required for electrochemical reoxidation at low current densities and vice versa.

4 Conclusion

In this study, an Ag2O/Ag solid-state electrode was prepared through the electrochemical oxidation of sterling silver and finally installed in a single-chamber MFC as a cathode and electron acceptor. The maximum output voltages of the MFC were maintained between 0.47 and 0.5 V in 100 cycles, and the overpotential loss for silver oxide ranged from 0.021 to 0.006 V. The maximum output power, OCP and short circuit current of the MFC were 1.796 W m−3, 0.559 V and 9.3375 A m−3, respectively. The energy required for electrochemical reoxidation ranged from 40 to 55% of the energy produced by the MFC. The results demonstrated that the Ag2O/Ag electrode could be used as a highly stable electron acceptor in a single-chamber MFC.

References

X. Xie, M. Ye, P.C. Hsu, N. Liu, C.S. Criddle, Y. Cui, Proc. Natl. Acad. Sci. USA 110, 15925 (2013)

R. Haase, R. Müller, D. Landgrebe, P. Scholz, M. Riemer, Acta Metall. Sin. (Engl. Lett.) 28, 1518 (2015)

Z.S. Lv, D.H. Xie, F.S. Li, Y. Hu, C.H. Wei, C.H. Feng, J. Power Sources 246, 642 (2014)

R.D. Cusick, P.D. Kiely, B.E. Logan, Int. J. Hydrog. Energy 35, 8855 (2010)

C.T. Wang, W.J. Chen, R.Y. Huang, Int. J. Hydrog. Energy 35, 7217 (2010)

L. Birry, P. Mehta, F. Jaouen, J.P. Dodelet, S.R. Guiot, B. Tartakovsky, Electrochem. Acta 56, 1505 (2011)

H.Y. Dai, H.M. Yang, X. Liu, X. Jian, Z.H. Liang, Acta Metall. Sin. (Engl. Lett.) 29, 483 (2016)

H.Y. Dai, H.M. Yang, X. Liu, Y. Zhao, Z.H. Liang, Bioresour. Technol. 202, 220 (2016)

Y. Wang, C.G. Niu, G.M. Zeng, W.J. Hu, D.W. Huang, M. Ruan, Int. J. Hydrog. Energy 36, 15344 (2011)

Z.J. Wang, B.S. Lim, C.S. Choi, Bioresour. Technol. 102, 6304 (2011)

X. Li, B.X. Hu, S. Suib, Y. Lei, B.K. Li, J. Power Sources 195, 2586 (2010)

L.X. Zhang, C.S. Liu, L. Zhuang, W.S. Li, S.G. Zhou, J.T. Zhang, Biosens. Bioelectron. 24, 2825 (2009)

Q. Wen, S.Y. Wang, J. Yan, L.J. Cong, Z.C. Pan, Y.M. Ren, Z.J. Fan, J. Power Sources 216, 187 (2012)

Y.F. Chen, Z.S. Lv, J.M. Xu, D.Q. Peng, Y.X. Liu, J.X. Chen, X.B. Sun, C.H. Feng, C.H. Wei, J. Power Sources 201, 136 (2012)

J.M. Morris, S. Jin, J.Q. Wang, C.Z. Zhu, M.A. Urynowicz, Electrochem. Commun. 9, 1730 (2007)

H.M. Wang, Z.C. Wu, A. Plaseied, P. Jenkins, L. Simpson, C. Engtrakul, Z.Y. Ren, J. Power Sources 196, 7465 (2011)

D.F. Smith, C. Brown, J. Power Sources 96, 121 (2001)

L. Zhang, S.G. Zhou, Y.T. Li, Y. Yuan, Bioresour. Technol. 101, 3514 (2010)

J. Li, Q. Fu, Q. Liao, X. Zhu, D.D. Ye, X. Tian, J. Power Sources 194, 269 (2009)

L.H. Liu, O. Tsyganova, D.J. Lee, A. Su, J.S. Chang, A.J. Wang, N.Q. Ren, Int. J. Hydrog. Energy 37, 15792 (2012)

Y.P. Mao, L.H. Zhang, D.M. Li, H.F. Shi, Y.D. Liu, L.K. Cai, Electrochim. Acta 55, 7804 (2010)

U. Karra, S.S. Manickam, J.R. McCutcheon, N. Patel, B.K. Li, Int. J. Hydrog. Energy 38, 1588 (2013)

V.A. Lavrenko, A.I. Malyshevskaya, L.I. Kuznetsova, V.F. Litvinenko, V.N. Pavlikov, Powder Metall. Met. Ceram. 45, 476 (2006)

Acknowledgements

This work was jointly funded by the National Natural Science Foundation of China and Shenhua Group Corp. (Grant No. U1261103), the Natural Science Foundation of Shanxi Province of China (Grant No. 201601D011023).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://springerlink.bibliotecabuap.elogim.com/journal/40195

Rights and permissions

About this article

Cite this article

Dai, HY., Yang, HM., Jian, X. et al. Performance of Ag2O/Ag Electrode as Cathodic Electron Acceptor in Microbial Fuel Cell. Acta Metall. Sin. (Engl. Lett.) 30, 1243–1248 (2017). https://doi.org/10.1007/s40195-017-0616-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0616-1