Abstract

Modern heat resistant 9–12% Cr steels require optimised heat treatments and welding strategies to receive the best mechanical and long-term creep properties during the fabrication of power plant components. Therefore, the phase transformation temperatures—especially the austenite and martensite transformation temperatures—have to be well known to define optimised heat treatment and interpass temperatures as well as heating and cooling rates. Since phase transformations are influenced by the chemical composition of the materials and other numerous factors, it is important to pay attention to the circumstances surrounding the determination of these temperatures. To determine specific phase transformation temperatures various methods and procedures like dilatometry, single-sensor differential thermal analysis (SS DTA) or differential scanning calorimetry (DSC) were established. The presented comparative study was initiated to investigate and quantify possible scattering within the measured values of participating institutions. Therefore, the commercially available martensitic heat resistant steel P91 was used to compare specific phase transformation temperatures determined by several participating institutes and laboratories. Two different simplified temperature cycles were defined to identify possible scattering and differences within the determined phase transformation temperatures. Furthermore, possible differing results regarding the evaluation of a given dilatometry data set by various institutes and laboratories were discussed. The presented round robin test shows that institutes and laboratories although using standard methods of analysis—which are said to be state of the art—are reporting variable values for the critical phase transformation temperatures in the steel of interest. It is also shown that the amount of scattering can vary widely depending strongly on the specific phase transformation temperature which has to be determined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

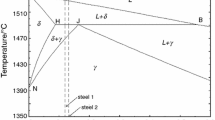

Advanced creep resistant 9–12% Cr steels show very critical characteristics related to their heat treatment, i.e. normalizing, tempering as well as after welding and post-weld heat treatment (PWHT). In order to determine the optimum heat treatment parameters, exact knowledge of phase transformation temperatures is mandatory. In case of welding 9–12% Cr steels followed by an optimal PWHT, the start of austenite formation (Ac 1-temperature), its completion (Ac 3-temperature) during heating as well as the beginning (M s -temperature) and completion of martensite formation (M f -temperature) during cooling are of great interest regarding the mechanical and long-term creep properties of welded joints.

With respect to phase transformations during welding and heat treatments, the heating and cooling rates have to be considered as transformation temperatures are strongly influenced by these. Significant superheating or undercooling may occur compared to the predicted equilibrium phase transformation temperatures.

There exist several different methods of measuring phase transformation temperatures like dilatometry, single-sensor DTA or differential scanning calorimetry. Each method has its own characteristics, advantages and disadvantages. Due to the physical background of the different methods, differences between determined points of phase formation as well as in scattering within the measured values can occur.

Parallel to the various devices and methods of measuring, different methods and algorithms are used to evaluate measured data sets. The variety of these methods exhibits advantages and disadvantages with respect to the exactness of the results. One of the most commonly used algorithms regarding determination of phase transformation temperatures on dilatometric data is the so-called tangent method. Next to manually procedures, various methods of evaluation based on mathematical calculations exist and are still part of development and investigations. Yang and Bhadeshia proposed a method in which dilatometric data are interpreted by defining the first onset of transformation to be that at which a critical strain is achieved relative to the thermal contraction of the parent phase. The critical strain is calculated for 1 vol% martensitic transformation assuming that the latter occurs at room temperature, by using equations for the lattice parameters of austenite and martensite [1]. Like the different methods of measuring, the methods of evaluation can strongly affect the determination of phase transformation temperatures.

It has to be mentioned, that only a few standards and guidelines exist in the field of measurement and determination of phase transformation temperatures. Examples are the American ASTM A1033-10 [2] as well as the German SEP guidelines [3] and [4]. Especially, the latter are giving instructions regarding the preparation of time-temperature transformation (TTT-) diagrams. Other standards like [5], [6] and [7], which describe methods to evaluate linear thermal expansion of solid materials by thermomechanical analysis or dilatometry, can give practical hints regarding the experimental setup, sample preparation and implementation of experiments.

It is known that phase transformation temperatures in ferritic/martensitic steels are influenced by various factors. Ac 1-, Ac 3-, M s - and M f -temperatures are strongly dependent on the chemical composition of the material. Depending on the alloying content elements like C, Mn, Cr, Mo and Si lead to an increase or decrease, respectively of the individual transformation temperatures [8, 9]. The influence degree of C depends on C-X interactions and interactions between substitutional alloying elements can play an important role in changing the M s -temperature [8, 10]. Furthermore, it is important to note that the prior austenite grain size as well as austenitisation temperature exert significant influence on the different phase transformation temperatures [11, 12]. The available time given to phase transformations to occur, which is directly connected to heating and cooling rates, influences the values of phase transformation temperatures as can be seen from continuous heating transformation (CHT-) and continuous cooling transformation (CCT-) diagrams [12]. This short and incomplete numeration of factors affecting the phase transformations exhibits the importance of paying attention to the circumstances surrounding the determination of Ac 1-, Ac 3-, M s - and M f -temperatures.

The aim of the presented study was to take advantage of the expertise of various institutes and laboratories and to evaluate different methods of phase transformation measurements. Further, the comparative study was initiated to investigate and quantify possible scattering within the measured values of participating institutions. Thereby, possible influences within experimental work as well as differences within the results induced by the methods of evaluation should be investigated.

2 Objectives and test conditions

The presented round robin test is divided into three parts. In the first two parts—Task 1 and Task 2—the participants were asked to carry out practical experiments using their standard methods to measure and analyse the phase transformation temperatures Ac1 (beginning of austenite transformation), Ac 3 (completion of austenite transformation), M s (beginning of martensite transformation) and M f (completion of martensite transformation). The temperature cycles within Task 1 and Task 2 were kept simple to keep the focus of the investigation on possible influences and scattering regarding the transformation temperatures. Further, this elementary temperature cycles—only consisting of simple linear heating, holding and cooling segments—should also allow the use of different devices and methods of analysis. In general, determination of phase transformation temperatures seems to be a simple task within materials science. The main aim of Task 1 and Task 2 was to check how close to each other the results of different laboratories are, if the same material as well as the same temperature cycles is used. Therefore, each laboratory was requested to perform the given experiments and an own analysis.

In the third part of the presented study (Task 3), the participants were asked to determine the four phase transformation temperatures Ac 1, Ac 3, M s and M f on a given data set. That means each laboratory should use its standard method or algorithm. The evaluation of one single data set by every participant should show possible differences in the results caused by evaluation methods.

2.1 Materials

For experimental work within Task 1 and Task 2, commercially available martensitic heat resistant steel P91 according to ASTM A335 M—also designated as X10CrMoVNb9-1 according to VdTÜV 511/2-06.2001 and VdTÜV 511/2 sheet 12.2003—was used. Table 1 shows the chemical composition of the delivered material as well as corresponding cut-off grades for the alloying elements given by the standards mentioned above. Sufficient material, depending on the applied experimental methods, was distributed to each participant. Due to the variety of sample shapes and sizes, the preparation of specimens was done by each laboratory itself.

The material was delivered as hot finished seamless steel tube with an outer diameter (OD) of 48.3 and 7.14 mm wall thickness (WT). As common in trade, the tube material was present in normalized (1060 °C for 20 min followed by air cooling) and tempered (780 °C for 60 min followed by air cooling) condition.

The dilatometry experiments to measure and create a data set for Task 3 were carried out on a new generation experimental 9Cr steel, which is a possible candidate material for high temperature applications in future ultra-supercritical power plants. The 9Cr3W3CoVNbBN alloy used is generally known and designated as martensitic boron and nitrogen strengthened 9Cr steel (MARBN). The chemical composition of the MARBN alloy is also given in Table 1. MARBN material was present in normalized (1150 °C/1 h) and tempered (770 °C/4 h) condition. Further information regarding this alloy can be found in literature, for example [13–15].

The MARBN alloy was selected to include a material that is currently part of material research in many countries. Further, the use of MARBN material should clearly separate Task 1 and Task 2 from Task 3.

Task 1: Measurement of phase transformation temperatures according to ASTM A1033-10

In the first part of the presented round robin test, the participants were asked to carry out slow heating experiments to determine close to equilibrium values of Ac 1 and Ac3 referring to ASTM A1033-10 standard. Further, the determination of M s and M f should allow a comparison of the several methods of analysis and show possible scattering of identified transformation temperatures.

The temperature cycle defined for Task 1 is shown in Fig. 1. After heating up a sample from room temperature (RT) to 700 °C using a moderate heating rate of 10 K/s, the heating rate was reduced to 28 K/h [2]. Due to the slow heating rate within the temperature range between 700 and 1000 °C, the austenite formation between Ac 1 and Ac 3 occurs close to the thermodynamic equilibrium condition. In case of the use of slow heating devices, the implementation of slower heating rates for the first part of the temperature cycle was possible. After reaching 1000 °C, the sample had to be cooled down to room temperature using a cooling rate of 10 K/s. The defined cooling rate as well as the scheduled determination of M s and M f are not of technical relevance but useful to determine a possible scattering between the results of the several participants and experimental methods, respectively.

Within Task 1, the defined temperature cycle was repeated three times to get an average value of three experiments. For every experiment, a new specimen was used to exclude possible influences of thermally induced microstructure changes.

Task 2: Measurement of phase transformation temperatures referring to a welding process

In the second task, a faster thermal cycle was investigated with regard to the thermo-physical simulation of a welding process. The applied temperature cycle shown in Fig. 2 is defined by a peak temperature of 1300 °C as well as higher heating and cooling rates.

Within the second temperature cycle, a heating rate of 100 K/s was defined to heat up the sample from room temperature to 1300 °C to determine Ac 1 and Ac 3 under conditions close to a welding process. The holding time of 10 s at 1300 °C was defined to exclude problems regarding the control and measuring systems of the several devices as well as to enable a complete through heating of the sample. Subsequently, the sample had to be cooled down to room temperature at a cooling rate of 20 K/s—which corresponds to a t 8/5-time of 15 s—to determine M s and M f .

Main objective of Task 2 was to identify possible difficulties and effects on the scattering of the measured phase transformation temperatures caused by higher heating and cooling rates. As described above, measurements applying temperature cycle 2 also were repeated three times.

Task 3: Evaluation of a given data set

In the third part of the presented study, the evaluation of a given data set by every participant should show possible differences between evaluation methods as well as possible subjective influences.

As shown in Fig. 3, crude data consisting of time (t), temperature (T) and change in length (∆l) was provided by the coordinators. The data was measured on boron and nitrogen containing new generation 9Cr martensitic heat resistant steel using a push rod dilatometer. Using this data set, every contributor was asked to determine the transformation temperatures Ac 1, Ac 3, M s and M f . Each laboratory used its standard method for analysing the given data set. Regarding the definition of transition points, no restrictions in methods or algorithms were made by the coordinators.

The experimental temperature cycle for Task 3 was defined as follows: the sample was heated up in vacuum atmosphere to 1300 °C applying a linear heating rate of 10 K/s. After 10-s holding time, the specimen was cooled down at a linear cooling rate of 20 K/s which was realised with Argon gas.

3 Methods

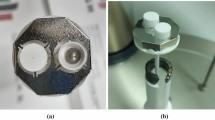

The coordinators did not make restrictions regarding experimental details like heating system (i.e. induction or furnace heating), shielding and cooling gases, types of thermocouples, sample holder materials, etc. The methods of evaluation used to analyse the measured data was not specified. For example, manually drawn tangents or mathematical software—partly included within the measurement systems as well as self-made and programmed by the institutions—were used to evaluate the measured crude data.

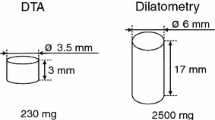

Most of the participants used dilatometry devices and measured the change in length of the samples. Only one participant determined the phase transformation temperatures by measuring the change in diameter. The used devices were from different fabricators and of different age. Two institutes used the differential thermal analysis (DTA) and single sensor differential thermal analysis (SSDTA) to determine the phase transformation temperatures.

4 Results

It has to be mentioned that the following diagrams and results were anonymised. That means the presented measured values cannot be traced back to a specific institution. The participant numbers given in the diagrams are not correlating with the order of the participants named in the acknowledgement.

Task 1

The Figs. 4 and 5 illustrate the average values of phase transformation temperatures Ac 1, Ac 3, M s and M f which were measured and determined by the participants within Task 1. Regarding the austenite transformation temperatures the values for Ac 1 —apart from the institutes 11 and 12—show a much lower deviation than the Ac 3-temperatures. This is also visible in Table 2, which provides a comparison of Task 1 and Task 2 regarding minimum, maximum and average values as well as the calculated standard deviations of phase transformation temperatures. The significant scatter is particularly visible in the standard deviations of Ac 1 (18.1 °C) and Ac 3 (28.3 °C). The span between the minimum and maximum value for the completion of austenite formation (96 °C) is much wider compared with Ac 1 (57 °C), Table 2.

The values of M s and M f determined within Task 1 show similar trends. As in the case of austenite phase transformation temperatures, the values for the initial and completion of the martensite phase formation show statistically significant variations within each dataset. This is reflected in the standard deviation of the M f -temperature (30.6 °C). This value is twice as high compared to the standard deviation of the M s -temperature (16.1 °C). Additionally, the difference between the minimum and maximum measured values within each of the M s and M f datasets shows a large deviation of 107 and 65 °C, respectively and as reflected in Table 2.

The results of Task 1 indicate that determination of the completion of a phase transformation is more complex and critical than its start.

Task 2

As already mentioned, the second temperature cycle was defined to identify a possible increase in scattering caused by fast heating and cooling rates. The results of Task 2 are shown in Figs. 6 and 7. Within both diagrams an increased scattering of Ac 1, Ac 3 and M f is observed. Only the scattering of the M s -temperature is not significantly affected by the increased heating and cooling rates.

In general, the austenite transformation temperatures Ac 1 and Ac 3 are showing the same trends as described within Task 1. However, the faster temperature cycle increases the standard deviation of both transformation temperatures. The comparative values within Table 2 make clear that the temperature cycle affects the determination of austenite start temperature Ac 1 (increases from 18.1 to 26.1 °C) less than the determination of austenite finish temperature Ac 3 (increases from 28.3 to 43.0 °C). Compared to Task 1, the span between the maximum and minimum values is increased with increased heating rate for the Ac 1 (increases from 57 to 88 °C) and Ac 3 (increases from 96 to 160 °C). In this case, the Ac 3-temperature is significantly more affected in comparison to Ac 1.

As already indicated, scattering within the determined values of the M s -temperature remains nearly constant. The standard deviation remains slightly above the calculated value from Task 1 (16.3 °C versus 16.1 °C). Besides that the gap between highest and lowest measured value decreased slightly from 65 to 57 °C, see also Table 2. Contrary to the M s -temperature, the measured values regarding the completion of martensite transformation exhibit an increased scattering compared to Task 1. The standard deviation changes from 30.6 to 40.0 °C. Similarly, the span between minimum and maximum measured values increases from 107 to 139 °C.

The values of Task 1 and Task 2, showing the differences in scattering and calculated standard deviations of the phase transformation temperatures, are summarised in Table 2.

Task 3

Figure 8 shows the phase transformation temperatures evaluated by the participants for the given data set (see Fig. 3) using their standard method of analysis. Table 3 summarizes the collected phase transformation temperatures and shows the calculated average values as well as the standard deviations. It becomes apparent again—as already shown for the results of the first two tasks—the onset of the phase transformations seems to be easier to determine than its completion.

The calculated standard deviations, especially for the Ac 1- and M s -temperature, are indicating a lower scattering of the evaluated temperatures in comparison to Task 1 and Task 2, see Tables 2 and 3. However, the difference of the standard deviations between the completion and beginning is significant. As an indicator for the scattering of the evaluated values, the standard deviation for Ac 3 (20.7 °C) is about three times higher than in case of Ac 1 (6.2 °C).

Regarding the martensite transformation temperatures, this ratio is even increased. The calculated standard deviation for M f (29.0 °C) is about six times higher than the value calculated for the M s -temperatures (4.6 °C). Analogous to these ratios, the ranges between the highest and lowest values also deviate significantly. The span between these values amounts to 60 °C for the Ac 3- as well as 75 °C regarding the M f -temperatures. Whereas the differences between the minimum and maximum values evaluated for the Ac 1- and M s -temperatures are only 19 and 15 °,C respectively.

5 Discussion

The results of the presented study show that great discrepancies can occur within the determination of phase transformation temperatures by different laboratories. Although each participant used the same material as well as the same temperature cycles, the determined temperatures differ partly widely from each other. The reasons for these deviations are difficult to find. Therefore, the following remarks can only discuss approaches and ideas for possible causes. In order to determine the influence of individual parameters or evaluation methods on the determination of phase transformation temperatures further detailed investigations are necessary.

First, it can be noted that differences in the exact determinability between the various phase transformations appear to exist. The results show that the beginning of a phase transformation seems to be more clearly determinable than its end. In all three tasks, the quality of the determined Ac 1- and M s -temperatures seems to be much higher in comparison to the phase completion temperatures Ac 3 and M f . This can be attributed to the respective standard deviations, see Tables 1 and 2. In all tasks, the deviations for Ac 1 and M s are much lower than for Ac 3 and M f . Therefore, the definition of an exact point were the phase transformation is completed seems to be difficult and varies from laboratory to laboratory. One possible reason could be the linearity of the measured change in length. For example, if the measured curve tends to a curvature at higher temperatures, the creation of tangents to analyse the curve can be more difficult and inaccurate. Especially, Task 3 shows that the definition of phase completion is a problem. Although in this case, influences by experimental parameters were excluded and each participant evaluated the same data set, Ac 3 and M f show significant deviations.

A further result of the study is that heating and cooling rates influence the deviations between the determined phase transformations. The participants carried out experiments using low (Task 1) and high (Task 2) heating and cooling rates. The minimum, maximum and deviation values in Table 2 show clearly that higher heating and cooling rates increase the deviation of the determined phase transformation temperatures. The standard deviation of Ac 1, Ac 3, M s and M f within Task 1 is always lower than in Task 2. It is possible that faster temperature cycles influence the linearity of the measured curves. For example, that means the higher the heating rate the greater the curvature of the measured change in length curve. This could possibly affect the accuracy of the evaluation.

In contrast to the first two tasks, the participants did not carry out practical experiments within Task 3. The purpose of this task was to examine possible influences of the evaluation methods on the deviation of Ac 1, Ac 3, M s and M f . This showed that the use of a given data set to determine the phase transformation temperatures lowers the deviation within the results of the participants. In comparison to Task 1 and Task 2, all standard deviations in Task 3 are lower. Especially the determined values for Ac 1 and M s (apart from participants 5 and 11) are very close each other. This indicates that the evaluation of measured data contains less error sources than the execution of the experiments with subsequent evaluation. Therefore, possible reasons for the significant deviations in Task 1 and Task 2 seem to be more related to how experiments are performed and how the data are measured.

Looking on the parameters which have to be defined before the execution of the measurements, there are a number of variables that may impact deviations within the measured values. An attempt to identify potential sources of deviation in the experimental data is discussed in this section. The evaluation of participant’s comments and information on experimental details showed, that the parameter settings of the individual laboratories, used for the experiments in Task 1 and Task 2, were partly different from each other. Sample holder materials varied between fused silica, aluminium oxide (Al2O3), silica (SiO2) as well as silicon nitride in combination with mica plates. The different physical properties of these materials, such as thermal conductivity and thermal expansion coefficient, in conjunction with the respective measuring system, could influence the measurement of the change in length or diameter. Further, thermocouples of type K, S and R were used to measure and control the temperatures as well as the heating and cooling rates, respectively. The use of different thermocouples could be another reason for the significant deviations in the first two tasks since every type is suitable for a certain temperature range (type K: up to 1200 °C, types R and S: 1600 °C). Since the accuracy of type K (±4 °C at 1000 °C) and type R/S (±1 °C at 1000 °C) is different and decreases with increasing temperature, this may also affect the accuracy of the measurements as well as the temperature control during the experiments. The atmosphere inside the test chambers was predominantly adjusted as vacuum, whereby the individual pressures differed from each other. Only two participants measured the phase transformation temperatures under an inert atmosphere using pure argon and helium gas. Further, differing gases were used to control the required cooling rates. Reported gases utilized to control the cooling rates included argon, helium, nitrogen and hydrogen. The different types of cooling gases influence the cooling cycles due to the thermal conductivity and heat capacity of the utilized gas. Comparing the results and values, no correlation between the mentioned parameters and the scattering within the determined temperatures could be observed. That means, strongly differing values of Ac 1, Ac 3, M s and M f were not clearly dependent on one of the experimental parameters mentioned above. In the presented study, it cannot be stated that, for example, the use of thermocouples of type K results in higher values or that specimen holders made of fused silica allow a more precise determination. The interaction and the influence of the individual parameters are very complex. Therefore, studies on the influence of individual parameters are necessary in order to determine the experiment variables with the greatest influence in the measurement of phase transformation temperatures.

In the previous paragraph, statements were made regarding the various types of thermocouples that can be used to determine phase transformation temperatures. Thinking about temperature measuring not only the type of the thermocouples has to be suitable for the temperature cycle to be examined—especially regarding the peak temperature—but also the method of attaching the thermocouple on a sample may affect the measured values. For example, the thin wires of a thermocouple could be placed separately with a certain distance—e.g., 0.5 or 1 mm—between each other. The closer or wider the wires are placed to each other, the more accurate or defective the measurements are. As another possibility, the wires could be placed and welded together at one point on the sample. Also such configurations may affect the final results compared to each other. Further, the quality of the attachment or spot weld respectively may influence the temperature measuring. That means an optimal electrical contact is also essential for the accuracy of the measured temperatures. The coordinators did not set limitations regarding the thermocouples and measurement systems. This short explanation only tries to show, how measuring the temperature can affect the determined transformation temperatures.

In addition to the experimental parameters, the evaluation methods used can also contain causes for the deviations of the phase transformation temperatures determined in this study. The participants used different methods to evaluate the measured (Task 1 and Task 2) and given data (Task 3). The values numbered as 2, 6, 7, 10 and 11 were determined by tangents manually drawn to the measured data curve which indicate the beginning or completion of a phase formation as a slope change within the curve. The differences between these results may arise due to varying subjective assessments when drawing the required tangents. Further settings, such as the considered area of the data curve or the resolution of the axes, can influence the evaluation result. The view on a measured data curve varies from person to person. Therefore, it is conceivable that the deviation between the temperatures to be determined increases, the greater the subjective influence on the evaluation process. The temperatures numbered as 1, 3, 5 and 8 were determined using mathematical calculation software. Several participants used self-written algorithms based on commercially available mathematical software. Others evaluated the measured data using software tools integrated within the used devices. Three institutions made no comments on evaluation of the measured data. Comparing manually and mathematical determined values no correlation regarding narrower scattering bands or smaller distances between the several values of a specific transformation temperature could be found. Just determined start and completion temperatures numbered as 5 are showing closest distance (between Ac 1 and Ac 3 as well as M s and M f ) to each other in all tasks, which may be attributable to the specific software algorithm used for the evaluation. Apart from participants 5 and 11, the values for Ac 1, Ac 3, M s and M f in Task 3 are approximately in good agreement. Therefore, the specific experimental procedure seems to have a greater influence on the final results than the evaluation process or method, respectively.

The definition of beginning and completion of a phase formation differed between the institutions. Percentages defining the beginning and completion reached from 0.1 to 3% and 95 to 99.9%, respectively. In general, the defined percentage affects directly the determined values. Looking on the results numbered as 1, 2 and 3 exhibits a significant discrepancy between the determined values within Task 1 and Task 2, even though beginning and completion of phase formations was defined equally at 1 and 99%, see Figs. 4 to 7. In Task 3, the mentioned results are much closer together, see Fig. 8. These two facts indicate that the main influences regarding scattering within the determined phase transformation temperatures are generated due to the implementation and execution of the specific experiments.

Although the presented results partly show great discrepancies, it has to be mentioned that the determination of Ac 1-temperature close to the thermodynamic equilibrium—which is essential to define optimized PWHT temperatures—seems to be sufficiently accurate. Apart from the participants 11 and 12, the values for Ac 1 in Task 1 are in good agreement. The values of M s -temperature—of great importance for setting interpass temperatures within optimized welding procedures required for high quality weldments in 9–12% Cr steels—were determined in narrow scatter bands. The determined austenite (Ac 1) and martensite start (M s ) transformation temperatures within the presented study are generally adequate and suitable.

The level of normalizing temperature strongly depends on the austenite finish temperature Ac 3. Therefore, an exact knowledge of Ac 3 helps to set a minimum value for conventional normalisation practises, which aims to sufficiently resolutionise a given material. Based on a well-established martensite finish temperature M f , the interpass temperatures could be defined more precisely to affect the toughness and ductility properties of weldments. The presented results show that an exact determination of phase completion seems to be unclear and more complex to define, although the given temperature cycles of Task 1 and Task 2 were kept relatively simple. Further, within Task 1, a slow temperature cycle according to ASTM A1033-10 was chosen, which is generally used to obtain phase transformations close to the thermodynamic equilibrium. That means, a complete heating of the sample through the whole cross-section is guaranteed and effects like skin effect under induction heating or delayed thermal expansion occurring under faster heating and cooling rates are minimized and out of the question respectively.

Although the defined temperature cycle in Task 2 was not appropriate to simulate the heat flow during a welding process in a realistic manner, it shows clearly that faster heating and cooling rates cause an increased scattering and differences within the determined phase transformation temperatures. Faster heating and cooling rates demand higher standards regarding the measuring and control systems. Further, the measured data curves could be affected due to the physical effects mentioned at the end of the last section. The samples were heated linearly. However, due to these physical effects, the measured data curves, for example the change in length, are partly curved and non-linear. This makes the use of evaluation algorithms such as the tangent method more difficult and inaccurate. Therefore, as observed within Task 2 the determined phase transformation temperatures—especially Ac 3 and M f —exhibit a wider scattering compared to the results within Task 1. The results show that in the case of high heating and cooling rates mathematical evaluation methods should be used. For example, the derivation of the measured data curve could be used to interpret phase transformations as a dramatic change in the slope. Particularly when creating diagrams which are strongly influenced by the thermal cycle used (for example, CCT diagrams), the use of mathematical methods could increase the accuracy.

6 Conclusions

The purpose of this study was to evaluate and identify potential sources of error in common procedures used to obtain data and analyse the data with regard to phase transformations in steels. Future studies will use this developed dataset to provide clear recommendations to standards and procedures to reduce the uncertainty and inconsistencies in the balance of the measured temperatures as shown in this study. With regard to the provided data in this manuscript, the following conclusions can be made:

-

Determination of the relevant phase transformations in 9Cr steels can exhibit statistically significant deviations. It can be stated that the beginning of a phase transformation seems to be more clearly determinable than its end.

-

The heating and cooling rates strongly affect the precision of determined values. Increased heating and cooling rates lead to an increased scattering. Due to physical effects, i.e. delayed thermal expansion, evaluation of measured data curves becomes more complex and complicated.

-

A number of variables was the execution of the measurements. Therefore, detailed equal experimental standards should be defined, which requires a systematic investigation of the parameters like type of thermocouples, sample holder materials, atmosphere, shielding gases etc.

-

The participants used specific definitions of beginning and completion of phase transformations. Further, various evaluation methods were used. More detailed specifications in the standards might help to reduce the depicted deviations.

-

The evaluation of a given data set by all participants showed comparatively small deviations. Especially, Ac 1 and M s were determined in good agreement between all participants. This shows that possible sources of error seem to be related to the execution of the experiments rather than to the evaluation of the measured data.

-

The results show that uniform mathematical evaluation methods, which reduce the subjective influence, should be used to evaluate measured data. Therefore, mathematical methods and algorithms should be developed and introduced into standards that increase the quality and safety in the determination of phase transformation temperatures.

References

Yang H-S, Bhadeshia HKDH (2007) Uncertainties in dilatometric determination of martensite start temperature. Materials Science and Technology 23(5)

ASTM A1033-10: Standard Practice for Quantitative Measurement and Reporting of Hypoeutectoid Carbon and Low-Alloy Steel Phase Transformations

SEP 1680: Aufstellung von Zeit-Temperatur-Umwandlungsschaubildern für Eisenlegierungen, 3rd Edition, (1990)

SEP 1681; Guidelines for preparation, execution and evaluation of dilatometric transformation tests on iron alloys, 2nd Edition, (1998)

ASTM E228-11: Standard Test Method for Linear Thermal Expansion of Solid Materials with a Push-Rod Dilatometer.

ASTM E831-12 Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis.

DIN 51045-1 Determination of the thermal expansion of solids—part 1: basic rules, (2005)

Wang, J. et al.: Determination of Martensite Start Temperature in Engineering Steels, Part I. Empirical Relations Describing the Effect of Steel Chemistry, Materials Transactions, JIM, Vol. 41, No. 7 pp. 761 to 768 (2000)

Ganesh, B.J. et al.: Differential scanning calorimetry study of diffusional and martensitic phase transformations in some 9 wt-%Cr low carbon ferritic steels, Materials Science and Technology, Vol. 27 No. 2 (2000)

Capdevila C et al (2002) Determination of M s temperature in steels: a Bayesian neural network model. ISIJ International 42(8):894–902

Yang H-S, Bhadeshia HKDH (2009) Austenite grain size and the martensite-start temperature. Scr Mater 60:493–495

García de Andrés C et al (2002) Application of dilatometric analysis to the study of solid–solid phase transformations in steels. Mater Charact 48:101–111

Abe F (2006) Metallurgy for long-term stabilization of ferritic steels for thick section boiler components in USC power plant at 650 °C, proceedings of the 8th Liège Conference Materials for Advanced Power Engineering 2006. Forschungszentrum Jülich, Liege

Abe F (2008) Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants. Sci Technol Adv Mater 9:013002 (15pp)

Mayr, P. Evolution of microstructure and mechanical properties of the heat affected zone in B-containing 9% chromium steels, Doctoral dissertation, Graz University of Technology, (2007)

Acknowledgements

The authors would like to thank the following participants for their cooperation within the presented collaborative study: Benteler Steel/Tube GmbH, Paderborn, Germany: Canadian Centre for Welding and Joining, University of Alberta, Canada; Department of Materials Science and Engineering, Ohio State University, Columbus, USA; Deutsche Edelstahlwerke GmbH, Krefeld, Germany; Indira Gandhi Centre for Atomic Research, Kalpakkam, India: Institute for Materials Applications in Mechanical Engineering, RWTH Aachen, Germany; Institute of Materials Science and Engineering, Technische Universität Chemnitz, Germany; Institute of Materials Science and Welding, Graz University of Technology, AustriaKobe Steel, Ltd., Japan; and ThyssenKrupp Steel Europe AG, Duisburg, Germany.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Nitsche, A., Mayr, P. Round Robin test on measurement of phase transformation temperatures in 9Cr1Mo steel. Weld World 61, 81–90 (2017). https://doi.org/10.1007/s40194-016-0405-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0405-x