Abstract

Carrier gas hot extraction (CGHE) technique was used for measurement of hydrogen in press-hardened (and as delivered) condition of 22MnB5 steel primarily coated with a thin layer of Al–Si. The CGHE technique was applied using different temperature programs: isothermal heating, temperature step, and linear heating in solid state. The effusing hydrogen was measured using thermal conductivity device (TCD) and high resolution mass spectroscopy (MS). Single isothermal heating at 400 and 900 °C allowed determining absolute value of effusing hydrogen. The linear heating, also known as thermal desorption analysis (TDA), revealed temperature dependent hydrogen effusion peaks. The deconvolution of the TDA spectra by peak fitting allowed the calculation of hydrogen desorption energies for each peak. The results showed good agreement between hydrogen concentrations measured with MS and TCD. In addition, the as-received ferrite-perlite microstructure showed only hydrogen effusion above 400 °C. The subsequent press hardening process leads to hydrogen uptake in the microstructure. In general, the press-hardened 22MnB5 revealed a hydrogen concentration of 0.4 to 0.5 ppm. The biggest concentration was released at isothermal holding at 400 °C indicating reversibly trapped hydrogen. TDA results with different heating rates confirmed mostly diffusible and reversible trapped hydrogen due to calculated activation energies in the range from 4 to 20 kJ mol−1; it was ascertained that nearly 90 % of the hydrogen left the specimens below 400 °C. Melt extraction (ME) was performed to measure the total hydrogen amount (including the diffusible and trapped hydrogen) and showed that above 900 °C up to 1 ppm hydrogen is trapped.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

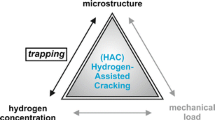

Absorption of hydrogen in steels can occur during steel manufacturing or later service conditions, e.g., hydrogen uptake due to pickling or heat treatment procedures like hot rolling. This may cause degradation of the mechanical properties under specified load condition, known as hydrogen-assisted cracking (HAC) [1]. In general, hydrogen can be absorbed into the metal lattice from acidic/alkaline media as well as from gaseous environment. Hydrogen evolution reactions in an acidic or alkaline media proceed in three steps known as the Volmer, Heyrovsky, and Tafel steps as follows [2]:

-

Volmer (discharge)

$$ {\mathrm{H}}_2\mathrm{O}+1{\mathrm{e}}^{-}\to {\mathrm{H}}_{\mathrm{ads}}+{\mathrm{OH}}^{-} $$(1) -

Heyrovsky (electrochemical desorption)

$$ {\mathrm{H}}_{\mathrm{ads}}+{\mathrm{H}}_2\mathrm{O}+{\mathrm{e}}^{-}\to {\mathrm{H}}_2+{\mathrm{OH}}^{-} $$(2) -

Tafel (chemical desorption)

$$ {\mathrm{H}}_{\mathrm{ads}}+{\mathrm{H}}_{\mathrm{ads}}\to {\mathrm{H}}_2 $$(3)

In addition to the desorption steps (Eqs. 2 and 3), some of adsorbed hydrogen can be absorbed into the metal lattice. From the gas phase, e.g., the molecular hydrogen dissociates into atoms followed by adsorption and absorption into the metal lattice. The absorbed hydrogen diffuses through the interstitial sites within the lattice or maybe trapped reversibly or irreversibly at different lattice defects [3]. It has been proved that the susceptibility of steels to HAC generally increases with increasing tensile strength [4, 5]. There are several methods to reduce the risk of HAC by limiting the hydrogen uptake: e.g., by decreasing the hydrogen uptake from electrolytic reactions by the addition of corrosion inhibitors or application of surface coating acting as hydrogen permeation barrier. Thermal degassing procedures can be performed like so-called dehydrogenation heat treatment (DHT). Additionally, different alloying elements such as V, Ti, or B can be used in order to influence the hydrogen solubility of the material [6]. Besides the different mentioned method of limiting the hydrogen concentration in the material, it is of high interest performing accurate measurements of hydrogen content in metals, e.g., for evaluation of hydrogen uptake reactions or practicability of heat treatment methods.

2 Determination of hydrogen content in metals

Hydrogen measurements can be made before, after, or during the manufacturing process or under later service conditions. Small absolute hydrogen amount can cause degradation of mechanical properties accompanied by HAC. Therefore, it is necessary to use very analytical methods like carrier gas hot extraction (CGHE) technique. This method is common for accelerated hydrogen measuring and for quantification of diffusible and trapped hydrogen concentration in metals [7]. This technique is based on solid (or melt) extraction method. Different detection systems such as thermal conductivity device (TCD) and mass spectrometer (MS) have been developed for high resolution measurement of hydrogen in combination with CGHE technique.

The CGHE method can be applied for both, solid and melt extraction. Heating below the melting point (e.g., 900 °C) is applied for solid sample hydrogen extraction. In this case, the CGHE method allows measurement of diffusible and (temperature dependent) trapped hydrogen below the melting point. As a second option, the melt extraction technique with CGHE is applied and provides measurement of the total hydrogen amount up to the melting point of the sample (including trapped hydrogen above 900 °C).

Nitrogen with a purity of 99.999 % (N2 5.0) is used as the carrier gas because of the quite large difference in thermal conductivity compared to hydrogen. The effusing hydrogen is directed to the detection system via the carrier gas. As example, thermal conductivity detector (TCD) or mass spectrometer (MS), as shown in Fig. 1, are available to detect hydrogen with a resolution of 0.01 μg/g. In the following, the parts per million values of the obtained hydrogen concentrations equal to weight − parts per million.

Schematic illustration in accordance to [6] of a thermal conductivity detector (TCD) and b quadrupole mass spectrometer (MS)

The TCD is based on the measurement of the change in thermal conductivity by insertion of hydrogen in the carrier gas compared to the hydrogen-free carrier gas flow (Fig. 1a). In addition to the TCD, mass spectrometry can be applied for high resolution determination of hydrogen. MS principle is based on ionizing chemical compounds to generate charged molecules or molecule fragments. The ionized particles are accelerated through the centre axis between the quadrupole rods (Fig. 1b) which isolate the targeted ions by mass over charge (m/z) ratio [6].

The calibration for both detector units can be performed with gas calibration or certified reference materials. Due to the high mobility of hydrogen even at room temperature, there is actual no certified reference material available for diffusible hydrogen. In addition, due to the effect of duration and condition of storage of reference materials, applying gas calibration with a fixed volume of the hydrogen is recommended. Using a controlled furnace to heat the sample, the carrier gas hot extraction method can be performed isothermally and thermally. The isothermal technique involves heating the samples at a constant temperature and gives an absolute value for hydrogen content in the metal. However, the damages caused by hydrogen are not only depending on the amount of absorbed hydrogen in the steel, but also on its diffusivity in the material. To characterize the diffusivity of hydrogen at various temperatures and in contrast to the various analyses being used to quantify the amount of hydrogen in metals, thermal desorption analysis (TDA) can be performed. TDA refers to the measurement of hydrogen by linear sample heating. In addition, this technique can be used to study hydrogen trapping and classifying into strong and weak hydrogen traps [8, 9]. According to Pressouyre [10], traps can be classified into attractive, physical, and mixed ones. Attractive traps such as grain boundaries, dislocations, crack tips, and impurities tend to be more reversible; whereas, physical traps such as high angle grain boundaries, incoherent particle-matrix interfaces, and voids need a higher desorption energy for releasing hydrogen. This means this type of hydrogen trap has a higher binding energy. The necessary desorption energy can be provided, e.g., by mechanical load or increased temperature.

3 Experimental

3.1 Material and processing

Boron manganese steel, known as 22MnB5, previously coated with a layer of Al–Si was used for the experiments. 22MnB5 steels are high strength structural steels (HSS) widely used in the automobile industry with a tensile strength of 1,000 to 1,200 MPa. Initially, the microstructure of 22MnB5 steel consists of ferrite-perlite microstructure (show in Fig. 2a) which transforms to a martensitic microstructure by press hardening process (shown in Fig. 2b). Hydrogen can be already trapped in the initial “as-received” ferrite-perlite microstructure or can enter in the material during press hardening process. As example, the hydrogen can evolve from carbon hydrides contained in drawing greases which may contaminate the surface of the press hardening tools. Another hydrogen source is moisture from air in case of insufficient shielding gas atmosphere during furnace heating of the steel samples. In case of Al-based coating (90 % Al–10 % Si), the alloy has a melting point of about 600 °C. In case of the molten coating, the hydrogen solubility of the Al–Si coating is increased and hydrogen can be trapped permanently in the coating or diffuses to the bulk material very fast (due to the increased temperatures).

The applied press hardening process (conducted in laboratory environment) includes austenitization of the steel sheets in a furnace at 930 °C for 5 min followed by quenching between water the cooled press tools. To prevent oxidation during heat treatment, the sheet material of 1.5 mm is previously coated with a layer of 150 g/m2 of Al–Si. After the press hardening process, the samples were maintained in liquid nitrogen to prevent the effusion of hydrogen. Steels sheets were cut to 30 × 20 × 1.5 and 5 × 5 × 1.5 mm3 for solid and melt extraction measurements, respectively. Prior to the analysis, the samples were cleaned in acetone properly according to the ISO 3690 [11]. The used boron manganese steel grade has a specified chemical composition with C and Mn as main alloying elements as shown in the Table 1.

3.2 Analytical method

The specific hydrogen concentration in the press-hardened specimens was determined by the CGHE hydrogen gas analyzer G8 Galileo from Bruker Elementals coupled with an external quadrupole mass spectrometer from In Process Instruments (IPI). The released hydrogen gas flows through reagent columns and molecular sieves for avoiding impurities and contaminants in the analyzing gas flow prior reaching the detector unit (coupled with TCD or MS). In general, the specimens are heated to the desired analyzing temperature via infrared furnace (solid extraction) or pulse furnace (melt extraction). The hydrogen analyzing unit is shown in the Fig. 3.

3.2.1 Melt extraction

The melt extraction technique was applied to measure the total amount of hydrogen in the samples corresponding to a specific hydrogen concentration. To this, press-hardened condition samples were melted in a graphite crucible using a pulse (IP) furnace with joule heating.

3.2.2 Solid extraction

In addition to the pulse furnace, an external infrared (IR) furnace was coupled to TCD or MS sensor unit for hydrogen measuring. The maximum temperature of the infrared furnace is limited to 950 °C due to the glass plunger acting as specimen chamber inside the furnace. The solid extraction method was conducted with three different temperature programs: isothermal heating (program 1), temperature steps (program 2), and linear heating rate (program 3).

The three heating programs were used to identify hydrogen releasing temperatures (programs 1 and 2) and for calculation of activation energy for hydrogen release from the traps (program 3). The analysis conditions which were applied for the solid extraction procedures are summarized in Table 2. Additionally, the melt extraction temperature is given.

3.2.3 Hydrogen detection

The hydrogen concentration in press hardened 22MnB5 steels was determined using both detector units: TCD and MS. For comparison, the initial “as-received” condition and the press hardened condition were examined with isothermal holding each at 400 and 900 °C (heating program 1, see Table 2). The press-hardened condition was examined with the heating program 2 (400 and 900 °C steps, see Table 2) and with linear heating (heating program 3, see Table 2). The specific amount of hydrogen obtained with the TCD is calculated via prior determined calibration factor for the TCD values in millivolt. The corresponding hydrogen concentration obtained with the MS is calculated for each sample via analysis software according to the Eq. 4.

where I is the integrated recorded ion current vs. time in A, F is the previous determined calibration factor in ampere per microgram, and M is the sample weight in grams.

4 Results and discussion

In Fig. 4, the obtained results for the heating program 1 (isothermal holding at 400 and 900 °C) for as-received and press-hardened condition are shown. The heating program 2 (isothermal holding at 400 °C with subsequent heating and holding at 900 °C) and the heating program 3 (linear heating with constant heating rate) is shown for the press-hardened condition. Additionally, melt extraction was conducted for the press-hardened condition avoiding prior heating of these examined specimens.

According to the results indicated in Fig. 4, hydrogen measurements with CGHE technique showed a very good reproducibility between TCD and MS signal. It has to be noticed that the TCD signal is generally slightly higher which is due to the lower resolution of the TCD. But it has to announce that this behavior is not considerable for measurements in the solid state. For the heating program 1, it is worth to see that the “as-received condition” showed only hydrogen evolution above 900 °C (~0.2 ppm) which indicates strong trapping sites. In contrast, the press-hardened condition showed over 0.3 ppm at 400 °C and nearly 0.5 ppm at 900 °C (measured with TCD). The results suggest that an average hydrogen amount of 0.1 to 0.2 ppm is absorbed due to the press hardening. These results were confirmed for the heating programs 2 and 3 (both with 0.45 ppm measured with MS). They indicate that most of hydrogen is released below 400 °C and a smaller part from 400 to 900 °C. Additionally, melt extraction of nonheat-treated specimens in press-hardened condition showed average hydrogen concentration above 1.5 ppm which indicates that the biggest portion of the hydrogen is trapped irreversibly. It is assumed that this hydrogen portion is trapped during the press hardening process. The reason is assumed to be the changed microstructure of the Al-Si-layer which undergoes (partly oxidization or) melting because of the necessary austenitization of the steel samples for press hardening above A c3 temperature. As for example, the phase boundary between the bulk material and the coating perhaps act as irreversible trapping site.

In addition to the obtained hydrogen concentrations, the obtained time and temperature dependent TCD or MS signal was interpreted. Figure 5 shows the summarized results for the heating programs 1 to 3 for the press hardened condition. Each part of Fig. 5 shows on the left y-axis the obtained ion current from the MS, and on the secondary y-axis, the obtained TCD signal in millivolt for qualitative comparison. The temperature program is shown in each part of Fig. 5a–d by a red straight line according to Table 2 with:

-

Figure 5a. Heating program 1—isothermal holding at 400 °C

-

Figure 5b. Heating program 1—isothermal holding at 900 °C

-

Figure 5c. Heating program 2—isothermal holding at 400 °C and subsequently at 900 °C

-

Figure 5d. Heating program 3—constant heating rate of linear heating 0.25 K s−1 from 50 to 900 °C

The following results were obtained for the described heating programs 1 to 3 (see Table 2).

During the analysis at a constant degassing temperature using heating program 1 (Fig. 5a with 400 °C and 5b with 900 °C), the obtained signal curve include two or more hydrogen effusion peaks. Two maximum peaks were observed for both temperatures. Due to the primarily coating with the Al–Si layer of the press-hardened 22MnB5, the first effusion peak is assumed to be related to the desorbed hydrogen from the coating, whereas, the second peak, with a small delay, is assumed to be related to the desorbing hydrogen from the bulk material. It has to be mentioned that the effect of the Al–Si coating has to be investigated further (with hydrogen charged uncoated and coated specimens).

The heating program 2 combined a two-temperature step program, as shown in Fig. 5c. This method was used for separation of desorbing hydrogen below 400 °C and above this temperature up to 900 °C. Hydrogen below 400 °C is assumed diffusible or (weak) reversibly trapped. The analysis duration for each isothermal holding step was optimized with special respect for distinct peak separation. However, this method is less suitable for appropriate information about the hydrogen distribution at possible traps, but it enables separating the low temperature peaks from high temperature peaks and further integration of the peaks. As shown in Fig. 4, the main portion of hydrogen effuses at isothermal holding temperature of 400 °C. Only a small amount of hydrogen effuses when subsequent heating to 900 °C. This indicates that the hydrogen is mostly diffusible or reversibly trapped due to the extraction temperature of 400 °C [11].

For more precise evaluation of hydrogen mobility and desorption kinetics, the TDA method was carried out using three different heating rates (heating program 3 according to Table 2). An example for the obtained signal evolution using a heating rate of 0.25 K s−1 is given in Fig. 5d. This technique involves linear heating of the specimen resulting in the release of hydrogen from the sample at different temperatures. According to the higher sensitivity of MS, it is more favorable to perform the thermal desorption analysis by MS. Additionally to the mentioned 0.25 K s−1, the heating rates of 0.33 and 0.50 K s−1 were examined.

After performing the measurements by TDA, desorption rate in parts per million per minute is calculated and plotted versus the temperature. Due to the overlapping of the recorded peaks, deconvolution of the TDA spectra is necessary. It is assumed that hydrogen desorption peak follows the Gaussian equation, which assumes a symmetric peak shape [8]. It has to be noticed that the TDA leads to measurement of a specific desorption energy of hydrogen from the traps. In the following, this desorption energy is called activation energy. In other words, the binding energy is calculated which is needed to release (to activate) the hydrogen from the specific traps. Equation 5 (which is obtained by simplification of the Polanyi-Wigner equation in accordance to [6]) was used to determine the activation energy for hydrogen desorption related to each peak observed in the TDA spectra.

where Ф is the heating rate in Kelvin per second, T p is the maximum peak temperature corresponding to each peak in Kelvin, R is the universal gas constant (8.31 J K−1 mol−1) and E a is the activation energy for hydrogen diffusion in joule per mole. For all TDA experiments the initial temperature was 50 °C and the final temperature was approximately 900 °C. Each heating rate was examined with minimum three specimens to ensure reliable measurements. As example for the obtained temperature dependent hydrogen effusion spectra, the following Fig. 6 shows the measured desorption rate in parts per million per minute versus temperature in degrees Celsius for a specific heating rate Ф of 0.25 K s−1.

From Fig. 6, it can be derived that the peak deconvolution showed three separated peaks. It is obvious to see that the biggest part of the initial hydrogen amount is diffusible or reversibly trapped. This can be proven by the relatively low peak temperatures of approximately 140 °C for the first peak (left side) and 340 °C for the second peak (central region). Such similar (relatively) low extraction temperature peaks have been reported by Perez Escobar et al. [12] and were suggested to be related to microstructural defects in martensitic steel grades. Only the third peak in Fig. 6 (right side) can be considered to be more irreversible than reversible by assessing the high peak temperature of approximately 514 °C.

By plotting the heating rate Ф and the square peak temperature T 2 p on logarithmic scale as a function of the inverse peak temperature T − 1 p for each peak, it is possible to derive the activation energy E a for hydrogen release as described in Fig. 7 according to Eq. 5. Linear regression analysis of the data plots (for the corresponding peaks for each heating rate) gives the slope of the regression function. This allows the calculation of the needed activation energy.

From Fig. 7, it can be derived that the first and second peaks for the different heating rates showed a very good reproducibility due to the very good stability index of the regression lines. Only the third peak regression line showed a decreased quality which is due to the relatively small effusing rate of hydrogen compared to the signal noise ratio of the MS signal. In addition, increasing the heating rate decreases the analyzing time which in turn increases the overlapping of the peaks and influences the amount of effusing hydrogen measured for each peak. The heating rate Ф of 0.25 K/s with heating times of about 3,400 s shows a better agreement with the results of isotherm heating and the temperature step program. Nevertheless, the linear regression analysis allowed calculating the specific activation energies for each peak. The following Table 3 presents the obtained heating rate dependent peak temperatures and the calculated activation energy E a according to Fig. 7.

From Table 3, it can be derived that single hydrogen peak temperatures showed very low deviation. Using the three different linear heating rates, it was obtained that the first peak showed relatively low activation energy for hydrogen desorption of 4.7 kJ mol−1. The second and the third hydrogen peak were calculated with higher activation energy of 17.4 and 20.3 kJ mol−1. The results indicate that the first hydrogen peak indicates hydrogen in the metal lattice due to the low activation energy. The second and third peak indicates a higher trap binding energy. According to Pressouyre and Bernstein [13], the calculated activation energies indicate reversible character of the hydrogen traps (like vacancies, dislocations, or interstitial atoms). Additionally, the calculated activation energies are in good agreement to the values reported by Perez Escobar et al. [12].

Besides the calculation of the activation (desorption) energy E a , the corresponding hydrogen concentration for each peak according to the area fraction A f was calculated. The following Table 4 shows the calculated area fraction of the peak and the corresponding hydrogen concentration for the examined heating rates. Additionally, the total recorded amount of hydrogen up to 900 °C is given.

From Table 4, it can be seen that the biggest part of hydrogen is released below 400 °C (see Table 3) independent of the used heating rate. In general, the total hydrogen amount of the specimens (heating up to 900 °C) was about 0.42 to 0.45 ppm. It can be derived that the mass spectrometry (MS) is sufficient for determining especially very low hydrogen concentrations. In contrast to the lower heating rates, the highest heating rate of 0.50 K s s−1 showed the biggest hydrogen portion for the third peak. As mentioned, this is assumed to be influenced by the relatively fast heating condition of the specimens which leads to a coverage of the second peak due to the rapidly increasing hydrogen flux with increasing temperature. From this point of view, it is recommended to use relatively low heating rates in order for improved separation of the obtained peaks.

5 Summary

The experiments in this study applied the carrier gas hot extraction technique for determination of hydrogen both in solid and melt status. The hydrogen mobility and possible trapping was determined for the press hardened 22MnB5. Different analyze methods including isotherm, a two-temperature step program and thermal desorption spectroscopy were performed using TCD and MS analysis. The following results can be concluded from this work:

-

The results obtained with each detector (TCD and MS) were in acceptable range with a low deviation, in which the MS should be preferred due to the higher resolution compared to the TCD. Especially for low effusion rates e.g. when conducting TDA with low heating rate, the MS allows much improved accuracy.

-

Three different peaks obtained by TDA and the amount of desorption energy needed for release of hydrogen from each peak was calculated with 4.7 kJ mol−1 for the first peak, 17.4 kJ mol−1 for the second peak, and 20.3 kJ mol−1 for the third peak. These desorption energies show that the hydrogen is mostly diffusible or reversibly trapped.

-

The effusing hydrogen determined with TDA using the MS (for a heating rate of 0.25 K s−1) was in a better agreement with the hydrogen concentration obtained by isothermal program and temperature-step program.

-

In case of TDA using high heating rates, the overlapping effect could cover the single peaks. In other words, high heating rates are not appropriate for TDA of high strength martensitic steels due to the low diffusion (equals very low temperature dependent effusion rates) of hydrogen through the microstructure.

-

To understand more about the barrier effect of Al–Si coatings on absorption and especially on desorption of previously absorbed hydrogen, further investigations should be conducted (e.g., permeation experiments).

References

Kasuya T (2001) Modelling of trap-controlled hydrogen diffusion in steel. Defect Diff Forum 188–190:115–124

Flis-Kabulska I, Zakroczymski T, Flis J (2007) Accelerated entry of hydrogen into iron from NaOH solutions at low cathodic and low anodic polarisations. Electrochim Acta 52(9):2966–2977

Choo W, Lee J (1982) Thermal analysis of trapped hydrogen in pure iron. Metall Trans A 13:135–140

Swieczko-Zurek B, Sobieszczyk S, Cwiek J, Zielinski A (2006) Evaluation of susceptibility of high strength steels to hydrogen delayed cracking. J Achiev Mater Manuf Eng 18(1–2):243–246

Eliaz N, Shachar A, Tal B, Eliezer D (2002) Characteristics of hydrogen embrittlement, stress corrosion cracking and tempered martensite embrittlement in high-strength steels. Eng Fail Anal 9:167–184

http://www.chemguide.co.uk/analysis/masspec/howitworks.html. 30 Apr 2014

Sastri V (1987) Methods for determining hydrogen in steels. Talanta 34(5):489–493

Bergers K, Camisao-Souza E, Thomas I, Mabho N, Flock J (2010) Determination of hydrogen in steel by thermal desorption mass spectrometry. Steel Res Int 81(7):499–507

Perez-Escobar D, Verbeken K, Duprez L, Verhaege M (2012) Evaluation of hydrogen trapping in high strength steels by thermal desorption spectroscopy. Mater Sci Eng A Struct 551:50–58

Pressouyre GM (1979) A classification of hydrogen traps in steel. Metall Trans A 10:1571–1573

ISO 3690:2012 - Welding and allied processes. Determination of hydrogen content in arc weld metal

Perez-Escobar D, Depover T, Duprez L, Verbeken K, Verhaege M (2012) Combined thermal desorption spectroscopy, differential scanning calorimetry, scanning electron microscopy and X-ray diffraction study of hydrogen trapping in cold deformed TRIP Steel. Acta Mater 60(6–7):2593–2605

Pressouyre GM, Bernstein IM (1978) A quantitative analysis of hydrogen trapping. Metall Trans A 9:1571–1580

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2501, recommended for publication by Commission II “Arc Welding and Filler Metals.”

Rights and permissions

About this article

Cite this article

Salmi, S., Rhode, M., Jüttner, S. et al. Hydrogen determination in 22MnB5 steel grade by use of carrier gas hot extraction technique. Weld World 59, 137–144 (2015). https://doi.org/10.1007/s40194-014-0186-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0186-z