Abstract

Metal additive manufacturing (AM) processes produce heterogeneous microstructures, leading to significant uncertainty in mechanical behavior. Process-induced defects cause additional uncertainty and can degrade performance, particularly for local processes like fatigue. However, time and monetary costs impose constraints on using repeated experiments to quantify this uncertainty across the process parameter space. Applying uncertainty quantification methods with computational materials simulations can help to alleviate these costs. In this paper, a physics-based process-structure–property (PSP) simulation framework is developed and applied to laser powder bed fusion AM of Ti-6Al-4V. Microstructures are generated from process-structure simulations that combine an analytical temperature field solution with a kinetic Monte Carlo-based model incorporating crystallographic texture and porosity development. The microstructures are passed to structure-property simulations comprising a fast Fourier transform-based crystal plasticity solver to predict a fatigue indicator parameter. Two uncertainty quantification problems are addressed: (1) probabilistic parameter calibration for the thermal model and (2) prediction of extreme values and the associated uncertainty of the fatigue indicator parameter using the full PSP framework. The simulations demonstrate the detrimental influence of keyhole porosity on fatigue, while also showing that pore-microstructure interaction increases uncertainty in the fatigue indicator parameter extreme values. The uncertainty quantification capabilities of the PSP framework provide a path toward using computational materials simulations to support qualification and certification of AM parts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In metal additive manufacturing (AM) processes, components are built by adding material in a layer-by-layer fashion. Parts with complex geometries can be produced more quickly and with less material waste than in traditional manufacturing processes. Despite the potential advantages of AM, qualification and certification of AM components for structural applications remain a significant challenge [1]. Heterogeneous microstructures typical of AM parts can produce significant uncertainty in mechanical behavior, while process-induced defects like porosity often degrade structural properties [2, 3]. Fatigue behavior, a critical concern for aerospace components, is particularly sensitive to defects and microstructural features [2, 4].

While standards for AM process qualification like NASA Technical Standard 6030 [5] have been successfully developed, the qualification procedure relies fully on experiments. Even for a single AM process parameter set, many experiments are needed to characterize fatigue behavior and its associated uncertainty [6]. Variability during and between builds can produce process-escape flaws that in turn serve as crack initiation sites, increasing scatter in fatigue properties and degrading the fatigue life of a part [3, 7]. As a result, the required experiments become increasingly time-consuming and costly constraining the ability to incorporate new materials and realize new designs in AM. In addition, using trial-and-error experiments to search for optimal AM process parameter sets can further increase costs [8].

Process-structure-property (PSP) simulations enable exploration of the design space for AM materials while reducing the number of costly experiments required. PSP simulations can also incorporate stochasticity in the AM process, enabling a quantitative description of microstructural and property variability. Since qualification and certification require characterizing the tails of the distribution of a quantity of interest, uncertainty quantification (UQ) is a useful component in PSP simulations [1, 9]. Linking UQ with PSP simulations can also accelerate material development and design in an integrated computational materials engineering (ICME) context [8,9,10].

Several studies have investigated PSP simulations with various output quantities of interest, simplifying assumptions, and consideration of uncertainty. For example, Agius et al. [11] linked two-dimensional phase field and crystal plasticity simulations to predict macroscale stress–strain curves and mesoscale deformation in a titanium alloy produced by laser powder bed fusion (LPBF). The microscale plastic strain fields were found to vary across five simulated microstructures, while macroscale stress–strain curves remained very similar. Herriott et al. [12] used a finite-volume thermal model, a cellular automata process model, and a Fourier transform-based crystal plasticity model to study variation in stress–strain behavior for subvolumes with different microstructural features within a build. The results demonstrated the influence of grain size, morphology, and anisotropy on the effective yield strength. Similarly, Liu et al. [13] studied differences in predicted stress–strain curves and micromechanical fields for process parameter sets that produced either equiaxed or columnar microstructures.

Incorporating defects into PSP simulations adds additional complexity. Yan et al. [14] studied the influence of lack-of-fusion pores by simulating builds with two different hatch spacing values. The PSP simulations in [14] included a computational fluid dynamics melt pool model and a reduced-order crystal plasticity model that predicted the Fatemi-Socie fatigue indicator parameter. The results demonstrated the detrimental influence of a lack-of-fusion pore on fatigue behavior for a single-crystal and a polycrystal simulation. The influence of porosity has also been studied by incorporating experimentally imaged microstructures and pore features in a crystal plasticity simulation [15]. The size, morphology, and microstructural neighborhood of a pore have all been shown to influence strain localization near the pore [16,17,18].

Computational expense often prohibits generating statistical distributions of output quantities of interest using repeated simulations of high-fidelity models [8]. One approach to mitigate this problem is through data-driven models, which use machine learning methods to predict a quantity of interest and its associated uncertainty. A variety of data-driven models have been applied to predict material behavior and property variations in AM parts in a PSP context [19,20,21,22,23]. While data-driven models can provide rapid property predictions and enable UQ, substantial experimental data and/or predictions from higher-fidelity physics-based models are still required for training. Furthermore, interpretability of the results is often limited, and data-driven models are typically unreliable outside of the parameter space used for training.

A second approach to incorporate UQ into PSP simulations is to seek a balance between fidelity and computational expense in physics-based models to predict distributions and extreme values of parameters relevant to fatigue without the limitations of data-driven models. Incorporating probabilistic calibration methods, together with experimental data, can help to quantify epistemic uncertainty in important input parameters for the model [1]. The present study describes progress in both the general area of uncertainty-quantified physics-based PSP simulations and the specific goal of quantifying fatigue variability and the influence of defects in LPBF Ti-6Al-4V.

Build conditions that may induce keyhole porosity are considered to study the influence of defects. The keyhole mode is associated with high input energy densities that produce deep melt pools [24]. Deep melt pools can ensure that sufficient remelting occurs between layers to avoid widespread porosity, as long as the energy density is not so high that keyhole instabilities occur [25, 26]. However, complex fluctuations within the melt pool may cause the keyhole to randomly collapse and leave behind small spherical pores, even at less extreme energy densities [27]. These small keyhole pores, which are a form of process escape flaws, are of interest in the present study.

Three specific objectives are addressed:

-

1.

Develop an integrated PSP simulation framework capable of simulating many AM-generated microstructures.

-

2.

Use a probabilistic calibration approach to estimate effective values of key thermophysical properties based on melt pool dimensions.

-

3.

Predict spatial and statistical distributions of a fatigue indicator parameter (FIP); quantify uncertainty about extreme values of the FIP; and quantify the influence of keyhole porosity on the FIP.

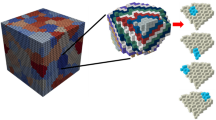

To address the first objective, the models within the PSP framework are selected to balance computational cost and physical fidelity. The process-structure model is based on a kinetic Monte Carlo formulation [28], modified to incorporate the temperature field, crystallographic texture, and stochastic development of keyhole porosity. The structure-property model uses an elasto-viscoplastic fast Fourier transform (EVP-FFT) crystal plasticity formulation [29], which shares a voxel-based microstructure representation with the process-structure simulations. Spectral solution methods like EVP-FFT are also more computationally efficient than typical crystal plasticity finite element simulations [29].

The second objective is addressed using estimates of the melt pool width derived from the temperature field in the process-structure simulations. Experimental measurements of the melt pool width at various process parameter combinations are taken from [30]. Probabilistic calibration of the effective thermophysical parameters is then completed using a sequential Monte Carlo algorithm.

The third objective is addressed using the full PSP framework. A subgrain-averaged value of the accumulated plastic strain, calculated for each grain in the EVP-FFT simulations, is chosen as the FIP. Statistical distributions for cases with and without keyhole porosity are generated by collecting the FIP values for all grains across a total of 400 PSP simulations. The influence of keyhole pores is assessed by computing sample-based estimates of the extreme values of the FIP distributions, which also reveal the uncertainty associated with microstructural variations.

Methods

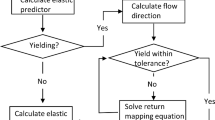

Schematic of the PSP framework, with UQ tasks in red boxes. The micrograph of a scan track in the “Sequential Monte Carlo calibration” box is from Fig. 4 in [31], used under Creative Commons Attribution (CC BY) 4.0 (https://creativecommons.org/licenses/by/4.0/), cropped from original

The PSP framework and the UQ tasks addressed in the present work are shown schematically in Fig. 1. The temperature field calculated from the thermal model is imposed on the process-structure model to generate microstructures as a function of process parameters and the material thermophysical properties. The microstructural information is passed to the structure-property model, which predicts the micromechanical stress and strain fields that develop when the material is subjected to mechanical loads. The thermal, process-structure, and structure-property models are presented in the remainder of this section, together with preprocessing steps required to transfer information between each model. While LPBF Ti-6Al-4V is the focus of the current study, the framework and the underlying models are extensible to other processes and material systems.

Thermal Model

The thermal model is based on the analytical Rosenthal solution, which was derived by solving the heat equation for a point source moving at a constant velocity in a semi-infinite domain [32]. The temperature field, T, is given by

where \(T_0\) is the preheat temperature; P is the input laser power; v is the laser speed; R is the distance of a point from the heat source; and \(\xi \), \(y^\prime \), and \(z^\prime \) are local coordinates in the reference frame of the moving heat source; \(\lambda \) is the absorptivity; k is the thermal conductivity; \(\alpha = k /(\rho c_p)\) is the thermal diffusivity; \(\rho \) is the mass density; and \(c_p\) is the specific heat capacity. With \(R = \sqrt{ \xi ^2 + {y^\prime }^2 + {z^\prime }^2}\), the Rosenthal solution predicts transverse isotherms that are perfectly semicircular. As a result, the melt pool depth is identically equal to half the melt pool width. Following the approach outlined by Pauza et al. [33] to account for different melt pool shapes, the equation for R is modified to

where \(\eta _z\) is a scaling factor. Using \(\eta _z < 1\) results in the melt pool depth being greater than half the width, which will occur in the transition and keyhole melt pool regimes of interest in the present study [34].

Process-Structure Model

The process-structure model is built on the open-source Stochastic Parallel PARticle Kinetic Simulator (SPPARKS) [28]. The temperature field is incorporated by specifying the laser power, scan velocity, and heat source location at a sequence of time steps. Each layer is simulated by rastering the heat source across the domain in a specified pattern and at a specified height. A full AM build consists of a sequence of layers separated by a specified layer thickness.

The simulation domain is discretized using a regular three-dimensional grid of cubic voxels or lattice sites that represent a polycrystalline microstructure [35]. Lattice sites are activated once they are at or below the height of the heat source. All sites are initially assigned a randomized grain identification (ID) value. Connected sites that share the same grain ID represent a grain. Microstructural evolution is captured through three model components: coupled solidification and texture development, grain coarsening, and keyhole porosity formation.

Solidification and Texture Development

Solidification and texture development are captured through a homogenized mesoscale description of epitaxial grain growth. The large thermal gradients characteristic of LPBF and the limited constitutional undercooling in Ti-6Al-4V indicate that neglecting grain nucleation is a reasonable simplification [36]. Grain growth thereby occurs through the advancement of the solidification front into the melt pool. A site is considered to be molten when its temperature reaches the liquidus temperature, \(T_L\).

The solidification model closely follows Rodgers et al. [37]. A molten site is eligible for solidification when its temperature falls below \(T_L\). For each eligible site, a capture distance, \(d_c\), is calculated, given by

where \(t_0\) is the time step when the temperature of the molten site first falls below \(T_L\), \(t_j\) is the current time step, \(v_g \left( \Delta T_t \right) \) is the grain growth velocity as a function of the undercooling \(\Delta T\) at time step t, and \(\Delta t\) is the time step size. The molten site solidifies during the first time step when at least one solid site falls within the capture distance. If multiple solid sites are within the capture distance, one of the sites is randomly selected, and the molten site joins the corresponding grain. For solidification of Ti-6Al-4V, the function \(v_g \left( \Delta T \right) \) is taken from [38]:

with \(\Delta T\) in K or \(^o\)C.

Each grain ID value is assigned Euler angles drawn from an orientation distribution function representing a random crystallographic texture. The crystallographic \(\left<001\right>\) directions are preferred grain growth directions for cubic crystals like the \(\beta \) phase of Ti-6Al-4V. Therefore, to describe texture development, the capture distance in Eq. (3) is modified to

where \(\theta _i\) is the angle between the thermal gradient and the nearest \(\left<001\right>\) direction of neighboring grain i. At each molten site, a separate capture distance is calculated for each neighboring solid grain. The \({\text {cos}} \theta _i\) term ensures that the capture distance is larger for grains with a preferred growth direction closely aligned with the temperature gradient at the molten site. This approach mimics texture development in cellular automata models, where the preferred-growth directions correspond to the diagonals of expanding decentered octahedra [36]. A similar concept has also been used to describe texture development in a standard Potts Monte Carlo scheme adapted to simulate LPBF builds [33].

Coarsening

Solid-state grain coarsening is simulated using the standard Potts kinetic Monte Carlo framework in SPPARKS [28, 39]. Grain coarsening is driven by minimization of the total grain boundary energy E, given by

where N is the total number of active lattice sites in the domain; \(n_i\) is the number of sites neighboring site i; \(S_i\) and \(S_j\) are grain IDs of sites i and j, respectively; and \(\delta_{{S_i}{S_j}}\) is the Kronecker delta. Coarsening proceeds by “flipping” the grain ID of a randomly selected lattice site to the grain ID of a neighboring site. The flip attempt is accepted with a probability given by the Metropolis [40] transition function

where \(\Delta E\) is the energy change caused by the grain ID reassignment and \(M_i\) is the normalized mobility of the site under consideration. The normalized mobility is calculated from the ratio of the temperature-dependent mobility of the site to the maximum mobility in the simulation, corresponding to \(T = T_L\):

where \(T_i\) is the temperature at site i, \({\bar{R}}\) is the gas constant, and Q is a grain growth activation energy. The time step associated with the Monte Carlo flips is linked to a physical time step following the procedure in [37, 41], which is based on grain growth kinetics. As noted in [33], the large thermal gradients in the heat-affected zone surrounding the melt pool in LPBF cause the mobility to rapidly drop off to near-negligible values. As a result, only a limited amount of coarsening occurs in the simulations. Following [37], three Potts “smoothing” steps are also performed on each newly solidified site to alleviate cases where highly disordered small grains result from the stochastic grain selection during solidification.

Keyhole Porosity

With increasing input energy density, LPBF processes typically transition from a conduction mode to a keyhole mode [26]. As noted in "Introduction", keyhole pores may be left behind due to collapse of the keyhole. The complex physical phenomena associated with fluid flow in a keyhole make it difficult to predict keyhole porosity from physics-based models alone [26, 42]. Therefore, in the present study, keyhole porosity is stochastically incorporated into the process-structure simulations. Before each simulation, the number of pores and the pore diameter are specified. Each pore is seeded below the heat source at a randomly selected time step. The simulation then continues, with grain growth occurring around the pore. Remelting or closure of the pore is not considered.

Process-Structure to Structure-Property Linkage

The process-structure model and the structure-property model share the same voxel-based discretization of the microstructure. However, the prior \(\beta \) grain structure present during the build typically transforms fully or nearly fully to \(\alpha \) phase during cooling in LPBF Ti-6Al-4V [43]. This phase transformation is not incorporated into the process-structure simulations and therefore must be addressed in a preprocessing step prior to the structure-property simulations.

The phase transformation follows the Burgers orientation relationship (BOR) [44], in which crystallographic planes and directions in the body-centered cubic (BCC) \(\beta \) phase and hexagonal close-packed (HCP) \(\alpha \) phase are related by

From Eq. (9), there are twelve distinct \(\alpha \) variants that can form from one prior \(\beta \) orientation. Each variant relationship can be expressed in terms of rotation matrices:

where \(\varvec{\textrm{A}_k}\) is the orientation matrix for the \(\alpha \) phase, \(\varvec{\textrm{B}}\) is the orientation matrix for the \(\beta \) phase, \(\varvec{\textrm{S}_k^\beta }\) is a matrix from a set of 12 cubic symmetry operators, and \(\varvec{\textrm{D}}\) is a rotation matrix characterized by the Bunge Euler angles \(\left( \phi _1, \Phi , \phi _2 \right) = \left( 135^\textrm{o}, 90^\textrm{o}, 324.74^\textrm{o} \right) \) that encodes the BOR [45]. The Euler angles for \(\varvec{\textrm{D}}\) are chosen such that the local x direction in the HCP phase corresponds with a \(\left[ 2{\bar{1}}{\bar{1}}0\right] _\alpha \) direction [46]. Selecting an \(\alpha \) variant corresponds to selecting one of the 12 possible cubic symmetry operators for \(\varvec{\textrm{S}_k^\beta }\). In the present work, one possible variant is selected at random for each prior \(\beta \) grain (i.e., each variant is considered to be equally likely to form). Once the components of the \(\alpha \) orientation matrix \(\varvec{\textrm{A}_k}\) are determined for the selected variant, the Euler angles for each \(\alpha \) grain are extracted and used as inputs for the grain orientations in the structure-property model.

Three further preprocessing steps are also required. First, some unmelted regions and disordered regions with small grains remain near the bottom of the domain after a SPPARKS simulation. Therefore, all voxels below the height of the first build layer are removed from the domain. Second, it is possible for two disconnected regions in the output from SPPARKS to share the same grain ID value. To ensure that all disconnected regions have unique grain IDs and thereby avoid errors in calculating microstructural quantities of interest, grains are re-indexed using a connected components algorithm [47]. Finally, all voxels within a pore are assigned to be part of a zero-stiffness gas phase.

Structure-Property Model

Crystal Plasticity Constitutive Equations

Key aspects of the EVP-FFT crystal plasticity formulation are presented in this section. Further details can be found in [29]. The EVP-FFT formulation assumes small strains. The plastic strain rate tensor \(\varvec{{\dot{\varepsilon }}^p}\) is determined at each material point \(\varvec{\textrm{x}}\) using a viscoplastic flow rule given by

where \(N_s\) is the total number of slip systems, \({\dot{\gamma }}_0\) is a reference strain rate, n is the inverse rate sensitivity, \(\varvec{\textrm{m}^s}\) is the Schmid tensor for slip system s, \(\varvec{\sigma }\) is the Cauchy stress tensor, and \(\tau ^s\) is the critical resolved shear stress (CRSS) for slip system s.

The CRSS on each slip system is updated using a Voce hardening law, given by

where \(\tau _0^s\) is the initial CRSS, \(\theta _0^s\) is the initial hardening slope, \(\theta _1^s\) is the asymptotic hardening slope, and \(\tau _0^s + \tau _1^s\) is the intercept of the asymptote of the hardening curve for slip system s. The basal, prismatic, and <c+a> pyramidal slip systems for the HCP \(\alpha \) phase of Ti-6Al-4V are considered in the model. Each slip system has a unique initial CRSS (\(\tau _0^\text {basal}\), \(\tau _0^\text {prism}\), and \(\tau _0^\text {pyr}\), respectively), while differences in the remaining hardening parameters are neglected. The total accumulated slip, \(\Gamma \), is given by

where \({\dot{\gamma }}^s\) is the slip rate on slip system s, and t is the elapsed time in the simulation. The latent and self-hardening coefficients are assumed to be unity for all slip systems.

Fatigue Indicator Parameter Calculation

To demonstrate the applicability of the PSP framework to fatigue, the accumulated plastic strain, \(\varepsilon ^p\), is chosen as the FIP and is calculated at each voxel as

where \({\dot{\varepsilon }}^p\) is the equivalent plastic strain rate. The local plastic strain is highly sensitive to the voxel size, particularly near discontinuities like grain boundaries and pores. The plastic strain is therefore regularized through nonlocal averaging of voxel groups within a grain [48]. The averaging volume consists of a voxel and all of its immediate neighbors (i.e., faces, edges, and corners) that belong to the same grain, resulting in a maximum volume of 27 voxels. The averaging volume for voxels adjacent to a grain boundary or pore will be smaller since one or more neighbors do not belong to the same grain. A minimum averaging size is set as 15 voxels to avoid cases where the averaging volume becomes excessively small and thereby more sensitive to numerical fluctuations. The highest FIP value across all eligible voxel groups within a grain, denoted as \({\bar{\varepsilon }}^p\) and referred to as the subgrain-averaged accumulated plastic strain, is then assigned to the grain. This process is repeated for all grains in a simulation, resulting in one FIP value for each eligible grain. The averaging scheme is similar to the approach of Brockman et al. [49], who defined an averaging distance for FIPs calculated at the centroid of each element in a set of finite element computations.

Due to the nature of spectral solution methods, the EVP-FFT model imposes microstructural periodicity on all surfaces. However, the SPPARKS simulations do not produce periodic microstructures. As a result, nonphysical FIP hot spots can appear near the outer surfaces of the domain, where the EVP-FFT simulations essentially connect dissimilar grain topologies. To mitigate this problem, the three outer layers of voxels on all sides of the domain are excluded from all averaging volumes.

Model Parameters

The domain used for the process-structure simulations consists of \(128 \times 128 \times 163\) voxels. The last dimension coincides with the build direction. A voxel size of \(\Delta x = 5\) μm in each direction and a time step of \(\Delta t = 3.2\) μs were chosen to balance numerical accuracy with computational efficiency for microstructures having on the order of hundreds of grains. After removing voxels below the first layer height, the domain for the structure-property simulations consists of \(128 \times 128 \times 128\) voxels. To optimize FFT calculations, the EVP-FFT solver requires the number of voxels in each dimension to be a power of 2 [29].

The LPBF process parameters given in Table 1 are chosen to investigate build conditions near the keyhole porosity boundary observed in experiments by Gordon et al. [25]. Under these conditions, keyhole pores may be present in a build. To study the influence of keyhole pores, simulations with a fully dense microstructure are compared with simulations containing a single pore with a 30-μm diameter (\(\sim 0.005\%\) porosity for an overall simulation volume of 0.26 mm\(^3\)). The pore is inserted during the process-structure simulations as described in "Keyhole Porosity". Eligible time steps for pore insertion are constrained so that the pore surface is at least six voxels away from the boundaries of the domain to avoid edge effects in the structure-property simulations. Rotation of the scan path by \(67^\textrm{o}\) between each layer is standard in many LPBF machines [50]. Twenty-eight layers are included in each process-structure simulation.

Effective values of the thermal conductivity, k, and the volumetric heat capacity, \(\rho c_p\), are determined using the calibration procedure described in "Thermophysical Property Calibration". The remaining parameters in the thermal and process-structure models are given in Table 2. The reference temperature, \(T_0\), and liquidus temperature, \(T_L\), are taken from [36]. The absorptivity, \(\lambda \), is taken from [51]. The scaling factor, \(\eta _z\), is chosen such that the melt pool width and depth are equal to approximate conditions near the keyhole boundary. The pre-exponential factor, \(K_0\), and activation energy, Q, for grain coarsening are fitted from grain growth experiments [52]. The grain growth parameters enable linking the grain coarsening model with the temperature evolution and solidification as described in [37, 41].

The elasto-viscoplastic parameters in Table 3 are based on the range of values in the literature for the \(\alpha \) phase of titanium alloys, in which the CRSS values for the basal and prismatic slip systems are typically much lower than for the pyramidal slip systems [53,54,55,56,57,58]. The applied strain in the build direction, \(\varepsilon _\text {app} = 0.6\%\), with a step size of \(\Delta \varepsilon = 0.02\%\), is chosen to induce heterogeneous micromechanical plastic strain fields without exceeding the macroscopic yield point. This behavior is characteristic of the high-cycle fatigue regime. The applied strain rate is equal to the reference strain rate, \({\dot{\gamma }}_0\), with \({\dot{\gamma }}_0\) and the stress exponent, n, chosen for numerical convenience as in [59]. These parameters could be further investigated in conjunction with experiments designed to measure rate-sensitive behavior.

For voxel size \(\Delta x = 5\) μm, the choice of averaging over the 26 immediate neighbors of each voxel for the FIP regularization implicitly introduces an averaging volume radius of approximately 8.7 μm (i.e., \(\Delta x \sqrt{3}\)). This value is within the range of averaging volume sizes considered in [49]. Neglecting the outer three layers of voxels reduces the effective domain size by 30 μm in each direction. On average, about 170 grains per simulation are eligible for FIP determination.

Results

Results are first presented for the probabilistic calibration of the thermophysical properties k and \(\rho c_p\) in "Thermophysical Property Calibration". The outcome of the calibration is the posterior distribution for each parameter. Then, microstructures and FIP distributions predicted by the PSP simulations are analyzed in "Simulated Microstructures and Micromechanical Fields" and "Fatigue Indicator Parameter Distributions and Extreme Values". A total of 400 simulations are completed using the full PSP framework, with the thermophysical properties k and \(\rho c_p\) fixed at their most probable values (i.e., the maximum a posteriori (MAP) estimates) inferred from the posterior distributions in "Thermophysical Property Calibration". Each process-structure simulation takes approximately 2.5 hours, while each structure-property simulation takes approximately 2 hours on a single core of an Intel Xeon Gold 6148 processor in the NASA Langley Research Center K-Cluster. The first 200 simulations consider a fully dense microstructure with no pores, while the second 200 each include one keyhole pore. The two groups of simulations are denoted as fully dense (FD) and keyhole (KH) simulations, respectively. Otherwise, all parameters are the same across all simulations. Stochasticity in the simulations thereby represents aleatoric uncertainty associated with microstructural variability and arises from four sources:

-

1.

The random initial assignment of grain ID values.

-

2.

The grain selection procedure during solidification.

-

3.

Random selection of an \(\alpha \) variant for each prior \(\beta \) grain in the microstructure.

-

4.

Pore location and microstructural neighborhood in KH simulations.

Of specific interest are the extreme values of the FIP, the associated uncertainty, and how the values shift for the KH simulations.

Thermophysical Property Calibration

In the LPBF process, thermophysical properties are spatially heterogeneous due to both their inherent temperature dependence and the presence of powder, liquid, and solid material. However, the Rosenthal solution assumes constant thermophysical properties and neglects heat transfer associated with melting and solidification. To address these limitations, it is hypothesized that effective values of the thermophysical properties can be determined by calibrating the thermal model using melt pool width measurements at various laser power and velocity values.

To set up the calibration problem, the \(i^\text {th}\) measured melt pool width, \(W_i\), is assumed to be given by

where \({\mathcal {M}} \left( k, \rho c_p; \varvec{\theta _i}\right) \) is the predicted melt pool width from the Rosenthal solution as a function of the thermophysical properties and laser power and velocity condition, \(\varvec{\theta _i}=[P_i, v_i]\). The term \(\epsilon _i\) represents measurement error or noise. For each observation, the error is assumed to be independent and identically distributed according to a zero-mean Gaussian distribution; i.e., \(\epsilon _i \sim {\mathcal {N}} \left( 0, \sigma ^2 \right) \) where \(\sigma ^2\) is the noise variance. Melt pool width measurements at 16 laser power-velocity combinations are taken from [30]. Measured melt pool widths represent the size of the melt pool perpendicular to the direction of laser travel along a scan track.

Calculating the predicted melt pool width requires inverting the Rosenthal solution to obtain an equation for the isotherm \(T = T_L\). Relevant dimensions are shown in Fig. 2. Point w represents the maximum extent of the melt pool perpendicular to the direction of laser travel. Since isotherms are symmetric about the \(\xi \) axis in the Rosenthal solution, the predicted melt pool width is given by

where \(y_w\) is the \(y^\prime \) coordinate at point w, \(R_{w}\) is the distance from the heat source at the origin to point w, and \(\phi _w\) is the corresponding polar angle. The distance \(R_{w}\) is found using a root-finding algorithm (Brent’s method [60]) with the equation

where M and N are inverse length scales given by

The angle \(\phi _w\) is found from

Derivations of Eq. (17) and Eq. (19) are given in Appendix A. This approach closely follows [51], where Eq. (17) was further simplified using a small-angle approximation for \(\phi _w\) and the assumption that \({\text {log}} \left( N R_{w}\right) / \left( M R_{w}\right) \approx 0\). Although the resulting closed-form approximation for \(y_w\) obtained in [51] avoids the root-finding step, the model retains more flexibility by using Eq. (17) directly.

Calibration is carried out using the sequential Monte Carlo (SMC) procedure described in Appendix B.1. SMC is a Bayesian inference technique that generates samples from the posterior distribution for the calibration parameters (k, \(\rho c_p\), and \(\sigma \)) given a model, measured data, and prior distributions on the parameters. Uniform priors are used for each calibration parameter and are given in Table 4. Note that \({\text {log}} \rho c_p\) is used in the SMC procedure as it alleviates numerical difficulties observed when \(\rho c_p\) was used directly. The prior on \({\text {log}} \rho c_p\) implies lower and upper bounds for \(\rho c_p\) of approximately \(10^4\) \( \text {J} / \left( \text {m}^3 \cdot \text {K} \right) \) and \(10^9\) \( \text {J} / \left( \text {m}^3 \cdot \text {K} \right) \), respectively.

Pairwise plots of the posterior distributions of the thermophysical properties (\({\text {log}} \rho c_p\) and k) and the standard deviation of the noise term (\(\sigma \)). Plots along the diagonal represent the marginal distribution of each parameter. Off-diagonal plots represent the joint distributions of pairs of parameters indicated by the axis labels

Pairwise plots of kernel density estimates (KDE) of the posterior distributions of each calibration parameter are shown in Fig. 3. MAP estimates and \(95\%\) credible intervals inferred from the posterior samples for each parameter are given in Table 4. The value of each calibration parameter falls within the \(95\%\) credible interval with \(95\%\) probability. The posterior distribution for \({\text {log}} \rho c_p\) is much sharper than for k, suggesting that there is significantly more uncertainty in the thermal conductivity. The range of the \(95\%\) credible interval for k is on the same order of magnitude as the MAP estimate, while the range of the \(95\%\) credible interval for \({\text {log}} \rho c_p\) is approximately \(1.5\%\) of the MAP estimate. Note that none of the posterior samples have \(k < 0\); rather, the small probability assigned to negative values of k is an artifact of the KDE fitting process.

Posterior predictive checking, in which the posterior predictive distribution of the calibrated model is compared to the observed data, is a useful step for determining whether the model is a reasonable description of the data generating process. To this end, the measured melt pool widths and the predicted values from the calibrated model are shown in Fig. 4. The \(95\%\) credible interval contains \(95\%\) of the predicted melt pool widths from the model for a given power and velocity. The credible interval represents uncertainty in the predicted melt pool width associated with uncertainty in the thermophysical properties. Subsequent observations of the melt pool width at a given power and velocity have a \(95\%\) probability of being within the \(95\%\) predictive interval, which incorporates the noise term, \(\epsilon _i\).

The results in Fig. 4 suggest that the model captures the correct trends in the data, including the separation of melt pool widths by laser power and the decreasing trend with respect to increasing scan velocity. Further measurements would be useful to validate the model and determine the extent to which \(\sigma \) represents true experimental noise versus compensating for model inadequacy. The MAP value of \(\sigma \) does appear to be on the order of experimentally measured melt pool variations, albeit with a different material: Criales et al. [61] found a standard deviation of approximately 10 μm for measurements of the steady-state melt pool width across multiple laser scans in LPBF Inconel 625.

Simulated Microstructures and Micromechanical Fields

Example microstructures generated by the process-structure simulations. a Fully dense microstructure. b Microstructure with one internal keyhole pore (dark gray color). c Inverse pole figure map with respect to the build direction for the microstructure shown in a. The map is based on the prior \(\beta \) grain orientations

Example simulated microstructures from the process-structure model for the FD and KH simulations are shown in Fig. 5. For \(P = 370\) W and \(v = 1.2\) m/s, the melt pool depth is approximately 168 μm while the layer thickness is 30 μm, producing significant remelting of each layer. As a result, the simulated microstructures are dominated by columnar grains, elongated in the build direction. The inverse pole figure map in Fig. 5c demonstrates texture development in the prior \(\beta \) grains. Many of the large columnar grains have a \(\left<001\right>\) direction closely aligned with the build direction. Details of the grain morphology and texture vary across all microstructures due to the stochasticity in the process-structure simulations.

Pole figures for the microstructure shown in Fig. 5a. The build direction points out of the page. The pole figure is based on the prior \(\beta \) grain orientations

Pole figures generated using the open-source DREAM.3D code [62] for the microstructure in Fig. 5a are shown in Fig. 6. The pole figures suggest the development of a rotated cube texture in the prior \(\beta \) grains, with \(\left<001\right>\) poles clustered near the build direction as suggested by Fig. 5c. A similar texture has been observed in experiments using LPBF and other AM processes, particularly with process parameter sets that produce large columnar prior \(\beta \) grains in Ti-6Al-4V [63, 64].

a Microstructure of a simulation with a pore shown on planes that bisect the pore parallel to the build direction. b Spatial distribution of accumulated plastic strain on the planes shown in a. Note the asymmetric distribution of plastic strain surrounding the pore, with the worst-case hotspot on the bottom-right of the pore. Plastic strain hot spots far away from the pore are near grain boundaries

Example accumulated plastic strain contours at the end of a KH simulation are shown in Fig. 7, together with the corresponding microstructure for reference. The three outer layers of voxels on all sides of the domain are excluded from Fig. 7 since these voxels are excluded from FIP calculations (see "Fatigue Indicator Parameter Calculation"). The plastic strain distribution near the pore is asymmetric with respect to both the magnitude of the plastic strain and the shape of the contours surrounding the pore. The asymmetry is due to interactions between the strain concentration induced by the pore and the anisotropic material behavior of each grain. The asymmetry suggests that significant interactions between pores and the microstructure may determine the most critical plastic strain hot spots. Meanwhile, plastic strain concentrations far from the pore in Fig. 7 occur near grain boundaries.

Fatigue Indicator Parameter Distributions and Extreme Values

A histogram of the FIP values (i.e., the subgrain-averaged accumulated plastic strain \({\bar{\varepsilon }}^p\)) for all grains across all 200 FD simulations is shown in Fig. 8. Each microstructural realization can be interpreted as a statistical volume element (SVE) [65], which describes microstructure variations resulting from stochasticity in the LPBF process captured by the SPPARKS simulations. The microstructure in each SVE represents a sample from the possible combinations of microstructural features like texture, morphology, and misorientations between grains. The microstructural features in turn interact to determine the FIP value in each grain, leading to the statistical distribution observed in Fig. 8. Many SVE realizations are needed to characterize the upper tail of the distribution, which represents extreme microstructural configurations where cracks are most likely to initiate [65].

To study the influence of porosity on both the overall distribution and the extreme values, histograms of the FIP for all FD and KH simulations are compared in Fig. 9. The data from Fig. 8 are shown again in Fig. 9a but with the horizontal axis extended to enable comparisons. Due to the low volume fraction of porosity, most grains in KH simulations are not influenced by strain localization near the pore. As a result, below \({\bar{\varepsilon }}^p \approx 0.004\), the distributions in Fig. 9c and a are very similar to one another. However, the upper tail of the histogram for KH simulations reaches much higher values of \({\bar{\varepsilon }}^p\). Comparing the histograms on a logarithmic scale in Fig. 9b and d demonstrates that a bimodal distribution develops for KH simulations. The second mode at higher accumulated plastic strain is characteristic of grains influenced by strain localization associated with the pore. The spread of values around the second mode in Fig. 9d suggests that microstructural heterogeneity near the pore significantly influences the resulting plastic strain distribution. This provides further evidence for significant interactions between the pore and the surrounding microstructure, as observed for a single case in Fig. 7.

While the histograms in Fig. 9 aid in understanding the influence of porosity, it is useful to quantify both the porosity-induced shift in an extreme value measure and the uncertainty associated with this measure. A sample-based estimate of the 99th percentile is chosen to characterize the extreme values of the FIP distributions. A sample consists of the FIP values from all of the grains across a given number of simulations. Intervals at a desired confidence level can be calculated for the percentile based on the total number of samples, as described in Appendix B.2. The confidence interval represents uncertainty associated with using a finite number of samples to calculate the 99th percentile.

The evolution of the sample-based 99th percentile and the associated \(95\%\) confidence interval as more simulations are added to the sample is shown in Fig. 10 for both FD and KH simulations. Estimates are shown in increments of ten simulations (i.e., the sample sizes are \(\{10, 20, 30, \ldots , 200\}\) simulations). For FD simulations, the estimated 99th percentile and \(95\%\) confidence interval stabilize after roughly 50 simulations, Fig. 10b. Even for smaller sample sizes of FD simulations, the width of the \(95\%\) confidence interval is more than an order of magnitude smaller than the estimated 99th percentile value.

For KH simulations, the estimated 99th percentile is significantly higher, supporting the observations from the results in Fig. 9. In addition, the \(95\%\) confidence interval is much wider across all sample sizes compared to FD simulations. The wider confidence interval further demonstrates pore-microstructure interactions. Each microstructure instantiation or SVE with a keyhole pore samples from the same set of microstructural features as the FD simulations, but with the additional complexity of how these features interact with the pore. As a result, more simulations are needed to characterize the mode at higher values of \({\bar{\varepsilon }}^p\) in Fig. 9d, which in turn strongly influences the values of the 99th percentile.

Discussion

Analysis of Key Results

The results in "Thermophysical Property Calibration" demonstrate that measured melt pool widths can be used to obtain probabilistic estimates for the effective thermophysical properties. Based on the posterior predictive checks in Fig. 4, the calibrated model captures the correct trends in the melt pool widths, although further measurements are needed for validation. The MAP estimates also appear to be physically reasonable, based on the temperature dependence of the thermophysical properties reported in [36]. The MAP estimate for k falls roughly in the center of the range of thermal conductivity values between \(T_0\) and \(T_L\) in [36]. Taking values near the center of the range for the density and specific heat capacity (\(\rho \approx 4300\) \(\text {kg} / \text {m}^3\) and \(c_p \approx 690\) \(\text {J} / \left( \text {kg} \cdot \text {K} \right) \)) also approximately reproduces the MAP estimate for \(\rho c_p\).

Distributions of predicted melt pool dimensions using samples from the thermophysical property posterior distributions provide further insight into the calibration procedure. Pairwise plots of the posterior thermophysical property distributions and the predicted melt pool dimensions for \(P = 370\) W and \(v = 1.2\) m/s are shown in Fig. 11. The noise term, \(\epsilon \), is not considered here. The strong correlation between \({\text {log}} \rho c_p\) and the melt pool width is consistent with the sharper posterior distribution for \({\text {log}} \rho c_p\). Meanwhile, there is more uncertainty in the posterior distribution for k, consistent with a weaker correlation with the melt pool width. The closed-form estimate for the width in [51] indicates that the influence of the thermal conductivity approaches zero in the limit of long and thin melt pools. On the other hand, the length of the melt pool tail is proportional to 1/k, so the sharp increase in melt pool length for small k is due to an asymptote at \(k = 0\).Footnote 1. The stronger correlation between k and the melt pool length suggests that including length measurements in the calibration would help reduce uncertainty, although this would require in situ measurements during a build [66].

Pairwise plots of the posterior distributions of the thermophysical properties and the predicted melt pool width and length for \(P = 370\) W and \(v = 1.2\) m/s. Posterior samples of \(\rho c_p\) and k are propagated through the Rosenthal solution-based model for the melt pool dimensions (Eq. (17), Eq. (A9), and Eq. (A10)) to determine the melt pool width and length distributions

A key outcome of the simulations with the full PSP framework is the observed interaction between a pore and the surrounding microstructure. Variations in the plastic strain field surrounding the pore are clearly present in Fig. 7, while the statistical analyses in Figs. 9 and 10 enable quantitative comparisons. The results support previous experimental and computational observations of highly heterogeneous strain fields when the grain size is similar to or larger than pores or voids [18, 67].

Bivariate histogram of the subgrain-averaged accumulated plastic strain and the maximum Schmid factor across all six basal and prismatic slip systems for grains in the KH simulations. Grains are categorized based on whether or not they neighbor a pore. Shading represents the number of grains in each bin in the histogram

Some experimental evidence also points toward the importance of pore-microstructure interaction in high-cycle fatigue. In a study of four specimens subjected to high-cycle fatigue, Shamir et al. [68] observed that shorter fatigue life appeared to be correlated with higher basal or prismatic Schmid factors and lower pyramidal Schmid factors in the general vicinity of pores. To compare with these results, a bivariate histogram of the maximum Schmid factor across all six basal and prismatic slip systems for each grain in the KH simulations is shown in Fig. 12. The Schmid factor is calculated based on the macroscopic applied loading direction and the initial orientation of each grain. For grains both neighboring a pore and not neighboring a pore, the maximum attainable accumulated plastic strain appears to increase with increasing maximum Schmid factor. However, any correlation between the plastic strain and the Schmid factor is very weak. Together with the highly heterogeneous plastic strain fields observed in Fig. 7, this suggests that the complex stress states near pores and grain boundaries likely have a stronger influence than the macroscopic Schmid factors on plastic strain accumulation at this stage of loading.

Limitations and Extensions

The process-structure simulations are limited by the assumptions of a point heat source and a steady-state temperature distribution in the Rosenthal solution. Incorporating a finite-size heat source, such as the Goldak heat source [69], would aid transferability across AM systems. Computationally efficient methods that account for thermal transients (e.g., [70, 71]) would also enhance the process-structure model without excessive computational cost. Transient heat buildup has been observed to increase the melt pool size and produce larger fluctuations in the melt pool morphology [61], which can influence solidification, texture, and porosity. The relevance of keyhole porosity and crystallographic texture to the FIP in the present study motivates more detailed analysis of porosity formation and its interaction with solidification. For example, the probability of keyhole pore formation could be scaled based on the thermal history at each point. Alternatively, higher-fidelity methods like computational fluid dynamics (CFD) can account for the influence of process fluctuations, powder characteristics, and various complex physics on the melt pool and porosity development [42]. While the computational expense of CFD precludes direct integration into the current PSP framework, seeding keyhole porosity based on CFD predictions is a possible extension beyond the purely stochastic approach in the present study.

During preprocessing for the structure-property simulations, each prior \(\beta \) grain was transformed into a randomly selected \(\alpha \) variant. This approach contains three assumptions: each prior \(\beta \) grain transforms to a macrozone or microtextured region, the \(\alpha \) lath structure within each macrozone can be homogenized, and variant selection can be neglected. Prior work has shown that prior \(\beta \) grain boundaries and macrozones oriented for basal or prismatic slip play an important role in strain localization and fatigue failure [72,73,74]. However, strain accumulation, void formation, and crack initiation and growth have also been observed in well-oriented \(\alpha \) laths and at \(\alpha \) grain boundaries [75,76,77]. Longer fatigue lives have also been correlated with finer \(\alpha \) laths surrounding a pore [68, 78]. Crystal plasticity simulations at the \(\alpha \) lath scale may therefore provide further insight but would require mesh or voxel sizes on the order of 1 μm or smaller to sufficiently discretize the laths. Meanwhile, variant selection, which will influence crystallographic texture of the microstructures, could be incorporated into the process-structure model through an energy minimization mechanism [79,80,81]. A weighted averaging scheme for the \(\alpha \) variants in each prior \(\beta \) grain [82, 83] could then be used to set up the crystal plasticity simulations.

The present study did not attempt to distinguish between the \(\alpha \) phase and the martensitic \(\alpha ^\prime \) phase. High cooling rates in LPBF Ti-6Al-4V typically promote diffusionless transformation from the prior \(\beta \) phase to \(\alpha ^\prime \) [79]. However, the trends in CRSS values across basal, prismatic, and pyramidal slip systems are similar between \(\alpha \) and \(\alpha ^\prime \) [84], suggesting that the plastic strain localization trends observed in the present study would hold for either phase. This observation is reasonable since \(\alpha \) and \(\alpha ^\prime \) share the HCP crystal structure and both follow the BOR with the prior \(\beta \) phase. Post-build heat treatments can transform \(\alpha ^\prime \) to \(\alpha \) and coarsen the lath structure, while the larger-scale prior \(\beta \) morphology remains unchanged for temperatures below the \(\beta \) transus [43]. Simulations at the prior \(\beta \) scale are therefore relevant to heat treated material as well, although lower-length-scale changes in the \(\alpha \) lath structure would be an interesting area of further research.

The structure-property simulations considered only monotonic loading in order to demonstrate the PSP framework with reduced computational cost. Experiments have suggested that plastic strain localization during the first cycle or first few load cycles is correlated with fatigue strength or failure location [75, 85, 86]. Therefore, the plastic strain localization and the accumulated plastic strain FIP analyzed in the present work are expected to be relevant to the fatigue behavior. However, considering cyclic loading would enable calculation of FIPs based on the local cyclic plastic strain range, which may be more strongly correlated with the actual fatigue life. A further consideration related to FIPs is the regularization scheme. Other studies have considered averaging over an entire grain [65], slip band or sub-band averaging [16, 87], subgrain averaging as in the present study [49], and weighted subgrain averaging [88]. Methods for choosing an appropriate averaging scheme and length scale—which introduces a physical length scale to length-scale-invariant crystal plasticity models [88]—are a useful avenue for future study.

Additional enhancements to the structure-property simulations include considering larger pores and pore-to-pore-interactions. In cases where the pores are large enough that the stress concentraion interacts with the simulation boundaries, the domain size would need to be increased to fully resolve the stress and strain fields. Switching to a conventional plasticity model would also be appropriate for pores much larger than the grain size, while fracture mechanics methods can be used to study large sharp pores (e.g., due to lack of fusion) that behave similarly to stage II fatigue cracks. Finally, incorporating residual stress development and free surfaces into the simulations could also advance understanding of how these features interact with porosity to degrade the fatigue life [6].

Overall, the results in the present study increase understanding of the effect of porosity and pore-microstructure interaction on fatigue behavior. However, using computational materials simulations in qualification, certification, and ICME applications requires building trust in the quantitative predictions of a model [1]. An important step in this direction is rigorously calibrating the crystal plasticity parameters, although an inexpensive surrogate model would likely be needed to use probabilistic methods like SMC [89]. Building the surrogate using an interpretable data-driven method like symbolic regression [90] could also help select necessary plasticity model components (e.g., a backstress term with an appropriate hardening law). Data-driven methods have been successfully used to parametrize general physics-based equations for yield strength, hardening, and tensile strength that are valid across different processing routes of Ti-6Al-4V [91, 92]. Full posterior distributions on calibrated parameters could then serve as inputs to a sensitivity analysis on microstructural and mechanical quantities of interest. While MAP estimates of the thermophysical properties from "Thermophysical Property Calibration" were used here in order to focus on the effects of defects and aleatoric uncertainty in the microstructures, further simulations could also propagate uncertainty in the properties to the FIP distributions in "Fatigue Indicator Parameter Distributions and Extreme Values". Quantifying and incorporating epistemic uncertainty on the parameters due to limited data will help build further confidence in the model predictions. Challenge problems involving microstructure and micromechanical behavior predictions, such as the AM-Bench and Air Force Research Laboratory modeling challenges [93, 94], also provide an opportunity for validating models in the PSP framework at length scales relevant to fatigue.

Concluding Remarks

A physics-based PSP simulation framework was developed for quantifying uncertainty in metal AM. While the framework was applied to Ti-6Al-4V produced by laser powder bed fusion, it is extensible to other processes and material systems. UQ was achieved through a calibration procedure and repeated simulations of the full framework to characterize distributions and extreme values of output quantities of interest. UQ capabilities are crucial for advancing PSP simulations towards use in qualification and certification processes for aerospace and other industries.

A probabilistic calibration procedure was used to determine values for the effective thermophysical properties based on a thermal model and measured melt pool widths. The resulting calibrated parameters and predicted melt pool widths are physically reasonable. The posterior distribution for the volumetric heat capacity has less uncertainty due to a stronger correlation with melt pool width, while measurements of the melt pool length would enable better calibration of the effective thermal conductivity. Statistical distributions of a fatigue indicator parameter, the accumulated plastic strain, were built up using simulations with and without a keyhole pore. When keyhole porosity is present, the 99th percentile of the distribution increases, even with a low porosity volume fraction. The uncertainty bounds on the 99th percentile also become wider due to significant interactions between the pore and the surrounding heterogeneous microstructure. Identifying both process-induced defects and the complex stress and strain distributions controlled by the microstructure and crystallographic texture is thereby critical for assessing fatigue in AM parts.

Notes

Note that samples from the posterior distribution of k include values on the order of \(10^{-3}\) \( \text {W} / \left( \text {m} \cdot \text {K} \right) \) or smaller, resulting in melt pool lengths on the order of \(10^4\) μm or larger. Therefore, to aid visualization, samples with melt pool length greater than \(10^4\) μm (a total of 95 out of 5000 samples) are excluded from the KDE fits shown in Fig. 11

References

Mahadevan S, Nath P, Hu Z (2022) Uncertainty quantification for additive manufacturing process improvement: recent advances. ASCE-ASME J Risk and Uncert in Engrg Sys Part B Mech Eng 8(1):010801. https://doi.org/10.1115/1.4053184

Yadollahi A, Shamsaei N (2017) Additive manufacturing of fatigue resistant materials: challenges and opportunities. Int J Fatigue 98:14–31. https://doi.org/10.1016/j.ijfatigue.2017.01.001

Seifi M, Gorelik M, Waller J, Hrabe N, Shamsaei N, Daniewicz S et al (2017) Progress towards metal additive manufacturing standardization to support qualification and certification. JOM 69(3):439–455. https://doi.org/10.1007/s11837-017-2265-2

Li P, Warner DH, Fatemi A, Phan N (2016) Critical assessment of the fatigue performance of additively manufactured Ti–6Al–4V and perspective for future research. Int J Fatigue 85:130–143. https://doi.org/10.1016/j.ijfatigue.2015.12.003

Additive manufacturing requirements for spaceflight systems. In: National aeronautics and space administration (2021). NASA Technical Standard 6030

Molaei R, Fatemi A, Sanaei N, Pegues J, Shamsaei N, Shao S et al (2020) Fatigue of additive manufactured Ti-6Al-4V, part II: the relationship between microstructure, material cyclic properties, and component performance. Int J Fatigue 132:105363. https://doi.org/10.1016/j.ijfatigue.2019.105363

Sanaei N, Fatemi A, Phan N (2019) Defect characteristics and analysis of their variability in metal L-PBF additive manufacturing. Mater Des 182:108091. https://doi.org/10.1016/j.matdes.2019.108091

Kouraytem N, Li X, Tan W, Kappes B, Spear AD (2021) Modeling process-structure-property relationships in metal additive manufacturing: a review on physics-driven versus data-driven approaches. J Phys Mater 4(3):032002. https://doi.org/10.1088/2515-7639/abca7b

Peralta AD, Enright M, Megahed M, Gong J, Roybal M, Craig J (2016) Towards rapid qualification of powder-bed laser additively manufactured parts. Integr Mater Manuf Innov 5(1):154–176. https://doi.org/10.1186/s40192-016-0052-5

Whelan G, McDowell DL (2020) Machine learning-enabled uncertainty quantification for modeling structure-property linkages for fatigue critical engineering alloys using an ICME workflow. Integr Mater Manuf Innov 9(4):376–393. https://doi.org/10.1007/s40192-020-00192-2

Agius D, O’Toole P, Wallbrink C, Sterjovski Z, Wang CH, Schaffer GB (2021) Integrating phase field and crystal plasticity finite element models for simulations of titanium alloy Ti–5553. J Phys Mater 4(4):044014. https://doi.org/10.1088/2515-7639/ac194f

Herriott C, Li X, Kouraytem N, Tari V, Tan W, Anglin B et al (2019) A multi-scale, multi-physics modeling framework to predict spatial variation of properties in additive-manufactured metals. Model Simul Mater Sci Eng 27(2):025009. https://doi.org/10.1088/1361-651X/aaf753

Liu PW, Wang Z, Xiao YH, Lebensohn RA, Liu YC, Horstemeyer MF et al (2020) Integration of phase-field model and crystal plasticity for the prediction of process-structure-property relation of additively manufactured metallic materials. Int J Plast 128:102670. https://doi.org/10.1016/j.ijplas.2020.102670

Yan W, Lian Y, Yu C, Kafka OL, Liu Z, Liu WK et al (2018) An integrated process-structure-property modeling framework for additive manufacturing. Comput Methods Appl Mech Eng 339:184–204. https://doi.org/10.1016/j.cma.2018.05.004

Kafka OL, Jones KK, Yu C, Cheng P, Liu WK (2021) Image-based multiscale modeling with spatially varying microstructures from experiments: demonstration with additively manufactured metal in fatigue and fracture. J Mech Phys Solids 150:104350. https://doi.org/10.1016/j.jmps.2021.104350

Prithivirajan V, Sangid MD (2018) The role of defects and critical pore size analysis in the fatigue response of additively manufactured IN718 via crystal plasticity. Mater Des 150:139–153. https://doi.org/10.1016/j.matdes.2018.04.022

Cao M, Liu Y, Dunne FPE (2022) A crystal plasticity approach to understand fatigue response with respect to pores in additive manufactured aluminium alloys. Int J Fatigue 161:106917. https://doi.org/10.1016/j.ijfatigue.2022.106917

Yeratapally SR, Lang CG, Cerrone AR, Niebur GL, Cronberger K (2022) Effect of defects on the constant-amplitude fatigue behavior of as-built Ti-6Al-4V alloy produced by laser powder bed fusion process: assessing performance with metallographic analysis and micromechanical simulations. Addit Manuf 52:102639. https://doi.org/10.1016/j.addma.2022.102639

Wang Z, Liu P, Ji Y, Mahadevan S, Horstemeyer MF, Hu Z et al (2019) Uncertainty quantification in metallic additive manufacturing through physics-informed data-driven modeling. JOM 71(8):2625–2634. https://doi.org/10.1007/s11837-019-03555-z

Saunders R, Rawlings A, Birnbaum A, Iliopoulos A, Michopoulos J, Lagoudas D et al (2022) Additive manufacturing melt pool prediction and classification via multifidelity Gaussian process surrogates. Integr Mater Manuf Innov. https://doi.org/10.1007/s40192-022-00276-1

Liu S, Stebner AP, Kappes BB, Zhang X (2021) Machine learning for knowledge transfer across multiple metals additive manufacturing printers. Addit Manuf 39:101877. https://doi.org/10.1016/j.addma.2021.101877

Herriott C, Spear AD (2020) Predicting microstructure-dependent mechanical properties in additively manufactured metals with machine- and deep-learning methods. Comput Mater Sci 175:109599. https://doi.org/10.1016/j.commatsci.2020.109599

Collins PC, Haden CV, Ghamarian I, Hayes BJ, Ales T, Penso G et al (2014) Progress toward an integration of process-structure-property-performance models for three-dimensional (3-D) printing of titanium alloys. JOM 66(7):1299–1309. https://doi.org/10.1007/s11837-014-1007-y

Cunningham R, Zhao C, Parab N, Kantzos C, Pauza J, Fezzaa K et al (2019) Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science 363(6429):849–852. https://doi.org/10.1126/science.aav4687

Gordon JV, Narra SP, Cunningham RW, Liu H, Chen H, Suter RM et al (2020) Defect structure process maps for laser powder bed fusion additive manufacturing. Addit Manuf 36:101552. https://doi.org/10.1016/j.addma.2020.101552

Gan Z, Kafka OL, Parab N, Zhao C, Fang L, Heinonen O et al (2021) Universal scaling laws of keyhole stability and porosity in 3D printing of metals. Nat Commun 12(1):2379. https://doi.org/10.1038/s41467-021-22704-0

Huang Y, Fleming TG, Clark SJ, Marussi S, Fezzaa K, Thiyagalingam J et al (2022) Keyhole fluctuation and pore formation mechanisms during laser powder bed fusion additive manufacturing. Nat Commun 13(1):1170. https://doi.org/10.1038/s41467-022-28694-x

Webb III EB, Garcia Cardona C, Wagner G, Tikare V, Holm E, Plimpton S, et al (2009) Crossing the mesoscale no-mans land via parallel kinetic Monte Carlo. SAND2009-6226

Lebensohn RA, Kanjarla AK, Eisenlohr P (2012) An elasto-viscoplastic formulation based on fast Fourier transforms for the prediction of micromechanical fields in polycrystalline materials. Int J Plast 32–33:59–69. https://doi.org/10.1016/j.ijplas.2011.12.005

Kusuma C (2016) The effect of laser power and scan speed on melt pool characteristics of pure titanium and Ti-6Al-4V alloy for selective laser melting. Wright State University, Dayton, OH

Bidare P, Maier RRJ, Beck RJ, Shephard JD, Moore AJ (2017) An open-architecture metal powder bed fusion system for in-situ process measurements. Addit Manuf 16:177–185. https://doi.org/10.1016/j.addma.2017.06.007

Rosenthal D (1946) The theory of moving sources of heat and its application to metal treatments. Trans ASME 68(8):849–865. https://doi.org/10.1115/1.4018624

Pauza JG, Tayon WA, Rollett AD (2021) Computer simulation of microstructure development in powder-bed additive manufacturing with crystallographic texture. Model Simul Mater Sci Eng 29(5):055019. https://doi.org/10.1088/1361-651X/ac03a6

King WE, Barth HD, Castillo VM, Gallegos GF, Gibbs JW, Hahn DE et al (2014) Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J Mater Process Technol 214(12):2915–2925. https://doi.org/10.1016/j.jmatprotec.2014.06.005

Holm EA, Battaile CC (2001) The computer simulation of microstructural evolution. JOM 53(9):20–23. https://doi.org/10.1007/s11837-001-0063-2

Zinovieva O, Zinoviev A, Ploshikhin V (2018) Three-dimensional modeling of the microstructure evolution during metal additive manufacturing. Comput Mater Sci 141:207–220. https://doi.org/10.1016/j.commatsci.2017.09.018

Rodgers TM, Moser D, Abdeljawad F, Jackson ODU, Carroll JD, Jared BH et al (2021) Simulation of powder bed metal additive manufacturing microstructures with coupled finite difference-Monte Carlo method. Addit Manuf 41:101953. https://doi.org/10.1016/j.addma.2021.101953

Dezfoli ARA, Hwang WS, Huang WC, Tsai TW (2017) Determination and controlling of grain structure of metals after laser incidence: theoretical approach. Sci Rep 7(1):41527. https://doi.org/10.1038/srep41527

Rodgers TM, Madison JD, Tikare V (2017) Simulation of metal additive manufacturing microstructures using kinetic Monte Carlo. Comput Mater Sci 135:78–89. https://doi.org/10.1016/j.commatsci.2017.03.053

Metropolis N, Rosenbluth AW, Rosenbluth MN, Teller AH, Teller E (1953) Equation of state calculations by fast computing machines. J Chem Phys 21(6):1087–1092. https://doi.org/10.1063/1.1699114

Raabe D (2000) Scaling Monte Carlo kinetics of the Potts model using rate theory. Acta Mater 48(7):1617–1628. https://doi.org/10.1016/S1359-6454(99)00451-6

Khairallah SA, Anderson AT, Rubenchik A, King WE (2016) Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater 108:36–45. https://doi.org/10.1016/j.actamat.2016.02.014

Pegues JW, Shao S, Shamsaei N, Sanaei N, Fatemi A, Warner DH et al (2020) Fatigue of additive manufactured Ti-6Al-4V, part I: the effects of powder feedstock, manufacturing, and post-process conditions on the resulting microstructure and defects. Int J Fatigue 132:105358. https://doi.org/10.1016/j.ijfatigue.2019.105358

Burgers WG (1934) On the process of transition of the cubic-body-centered modification into the hexagonal-close-packed modification of zirconium. Physica 1(7–12):561–586. https://doi.org/10.1016/S0031-8914(34)80244-3

Glavicic MG, Goetz RL, Barker DR, Shen G, Furrer D, Woodfield A et al (2008) Modeling of texture evolution during hot forging of alpha/beta titanium alloys. Metall Mater Trans A 39(4):887–896. https://doi.org/10.1007/s11661-007-9376-2

Glavicic MG, Kobryn PA, Bieler TR, Semiatin SL (2003) A method to determine the orientation of the high-temperature beta phase from measured EBSD data for the low-temperature alpha phase in Ti-6Al-4V. Mater Sci Eng A 346(1–2):50–59. https://doi.org/10.1016/S0921-5093(02)00535-X

Silversmith W (2023) cc3d: connected components on multilabel 3D & 2D images. https://pypi.org/project/connected-components-3d/

McDowell DL, Dunne FPE (2010) Microstructure-sensitive computational modeling of fatigue crack formation. Int J Fatigue 32(9):1521–1542. https://doi.org/10.1016/j.ijfatigue.2010.01.003

Brockman RA, Hoffman RM, Golden PJ, Musinski WD, Jha SK, John R (2021) A computational framework for microstructural crack propagation. Int J Fatigue 152:106397. https://doi.org/10.1016/j.ijfatigue.2021.106397

Leicht A, Yu CH, Luzin V, Klement U, Hryha E (2020) Effect of scan rotation on the microstructure development and mechanical properties of 316L parts produced by laser powder bed fusion. Mater Charact 163:110309. https://doi.org/10.1016/j.matchar.2020.110309

Tang M, Pistorius PC, Beuth JL (2017) Prediction of lack-of-fusion porosity for powder bed fusion. Addit Manuf 14:39–48. https://doi.org/10.1016/j.addma.2016.12.001

Gil FJ, Planell JA (1991) Growth order and activation energies for grain growth of Ti–6Al–4V alloy in ß phase. Scr Metall Mater 25(12):2843–2848. https://doi.org/10.1016/0956-716X(91)90167-Y

Smithells CJ, Gale WF, Totemeier TC (2004) Smithells metals reference book, 8th edn. Elsevier Butterworth-Heinemann, Amsterdam

Mayeur JR, McDowell DL (2007) A three-dimensional crystal plasticity model for duplex Ti–6Al–4V. Int J Plast 23(9):1457–1485. https://doi.org/10.1016/j.ijplas.2006.11.006

Zhang M, Zhang J, McDowell DL (2007) Microstructure-based crystal plasticity modeling of cyclic deformation of Ti–6Al–4V. Int J Plast 23(8):1328–1348. https://doi.org/10.1016/j.ijplas.2006.11.009

Bridier F, McDowell DL, Villechaise P, Mendez J (2009) Crystal plasticity modeling of slip activity in Ti–6Al–4V under high cycle fatigue loading. Int J Plast 25(6):1066–1082. https://doi.org/10.1016/j.ijplas.2008.08.004

Ozturk T, Rollett AD (2018) Effect of microstructure on the elasto-viscoplastic deformation of dual phase titanium structures. Comput Mech 61(1–2):55–70. https://doi.org/10.1007/s00466-017-1467-3

Gu T, Stopka KS, Xu C, McDowell DL (2020) Prediction of maximum fatigue indicator parameters for duplex Ti–6Al–4V using extreme value theory. Acta Mater 188:504–516. https://doi.org/10.1016/j.actamat.2020.02.009

Cocke CK, Rollett AD, Lebensohn RA, Spear AD (2021) The AFRL additive manufacturing modeling challenge: predicting micromechanical fields in AM IN625 using an FFT-based method with direct input from a 3D microstructural image. Integr Mater Manuf Innov 10(2):157–176. https://doi.org/10.1007/s40192-021-00211-w

Brent RP (1973) Algorithms for minimization without derivatives. Prentice-Hall, Englewood Cliffs, NJ

Criales LE, Arısoy YM, Lane B, Moylan S, Donmez A, Özel T (2017) Laser powder bed fusion of nickel alloy 625: experimental investigations of effects of process parameters on melt pool size and shape with spatter analysis. Int J Mach Tools Manuf 121:22–36. https://doi.org/10.1016/j.ijmachtools.2017.03.004

Groeber MA, Jackson MA (2014) DREAM.3D: a digital representation environment for the analysis of microstructure in 3D. Integr Mater Manuf Innov 3(1):56–72. https://doi.org/10.1186/2193-9772-3-5

Pesach A, Tiferet E, Vogel SC, Chonin M, Diskin A, Zilberman L et al (2018) Texture analysis of additively manufactured Ti-6Al-4V using neutron diffraction. Addit Manuf 23:394–401. https://doi.org/10.1016/j.addma.2018.08.010

Saville AI, Vogel SC, Creuziger A, Benzing JT, Pilchak AL, Nandwana P et al (2021) Texture evolution as a function of scan strategy and build height in electron beam melted Ti-6Al-4V. Addit Manuf 46:102118. https://doi.org/10.1016/j.addma.2021.102118

Przybyla CP, McDowell DL (2010) Microstructure-sensitive extreme value probabilities for high cycle fatigue of Ni-base superalloy IN100. Int J Plast 26(3):372–394. https://doi.org/10.1016/j.ijplas.2009.08.001

Lane B, Heigel J, Ricker R, Zhirnov I, Khromschenko V, Weaver J et al (2020) Measurements of melt pool geometry and cooling rates of individual laser traces on IN625 bare plates. Integr Mater Manuf Innov 9(1):16–30. https://doi.org/10.1007/s40192-020-00169-1

Carroll JD, Brewer LN, Battaile CC, Boyce BL, Emery JM (2012) The effect of grain size on local deformation near a void-like stress concentration. Int J Plast 39:46–60. https://doi.org/10.1016/j.ijplas.2012.06.002

Shamir M, Syed AK, Janik V, Biswal R, Zhang X (2020) The role of microstructure and local crystallographic orientation near porosity defects on the high cycle fatigue life of an additive manufactured Ti-6Al-4V. Mater Charact 169:110576. https://doi.org/10.1016/j.matchar.2020.110576

Goldak J, Chakravarti A, Bibby M (1984) A new finite element model for welding heat sources. Metall Trans B 15(2):299–305. https://doi.org/10.1007/BF02667333

Schwalbach EJ, Donegan SP, Chapman MG, Chaput KJ, Groeber MA (2019) A discrete source model of powder bed fusion additive manufacturing thermal history. Addit Manuf 25:485–498. https://doi.org/10.1016/j.addma.2018.12.004

Wolfer AJ, Aires J, Wheeler K, Delplanque JP, Rubenchik A, Anderson A et al (2019) Fast solution strategy for transient heat conduction for arbitrary scan paths in additive manufacturing. Addit Manuf 30:100898. https://doi.org/10.1016/j.addma.2019.100898

Le Biavant K, Pommier S, Prioul C (2002) Local texture and fatigue crack initiation in a Ti-6Al-4V titanium alloy. Fatigue Fract Eng Mater Struct 25(6):527–545. https://doi.org/10.1046/j.1460-2695.2002.00480.x

Germain L, Gey N, Humbert M, Bocher P, Jahazi M (2005) Analysis of sharp microtexture heterogeneities in a bimodal IMI 834 billet. Acta Mater 53(13):3535–3543. https://doi.org/10.1016/j.actamat.2005.03.043

Kapoor K, Yoo YSJ, Book TA, Kacher JP, Sangid MD (2018) Incorporating grain-level residual stresses and validating a crystal plasticity model of a two-phase Ti–6Al–4 V alloy produced via additive manufacturing. J Mech Phys Solids 121:447–462. https://doi.org/10.1016/j.jmps.2018.07.025

Foehring D, Chew HB, Lambros J (2018) Characterizing the tensile behavior of additively manufactured Ti-6Al-4V using multiscale digital image correlation. Mater Sci Eng A 724:536–546. https://doi.org/10.1016/j.msea.2018.03.091

Moridi A, Demir AG, Caprio L, Hart AJ, Previtali B, Colosimo BM (2019) Deformation and failure mechanisms of Ti–6Al–4V as built by selective laser melting. Mater Sci Eng A 768:138456. https://doi.org/10.1016/j.msea.2019.138456

Geathers J, Torbet CJ, Jones JW, Daly S (2015) Investigating environmental effects on small fatigue crack growth in Ti-6242S using combined ultrasonic fatigue and scanning electron microscopy. Int J Fatigue 70:154–162. https://doi.org/10.1016/j.ijfatigue.2014.09.007

Li P, Warner DH, Pegues JW, Roach MD, Shamsaei N, Phan N (2019) Investigation of the mechanisms by which hot isostatic pressing improves the fatigue performance of powder bed fused Ti-6Al-4V. Int J Fatigue 120:342–352. https://doi.org/10.1016/j.ijfatigue.2018.10.015

Simonelli M, Tse YY, Tuck C (2014) On the texture formation of selective laser melted Ti-6Al-4V. Metall Mater Trans A 45(6):2863–2872. https://doi.org/10.1007/s11661-014-2218-0

Xiang H, Van Paepegem W, Kestens LAI (2022) Variant selection during BCC to HCP phase transformation in selective laser melted Ti-6Al-4V. Materialia 24:101470. https://doi.org/10.1016/j.mtla.2022.101470

DeMott R, Collins P, Kong C, Liao X, Ringer S, Primig S (2020) 3D electron backscatter diffraction study of \(\alpha \) lath morphology in additively manufactured Ti-6Al-4V. Ultramicroscopy 218:113073. https://doi.org/10.1016/j.ultramic.2020.113073

Pinz M, Benzing JT, Pilchak A, Ghosh S (2022) A microstructure-based porous crystal plasticity FE model for additively manufactured Ti-6Al-4V alloys. Int J Plast 153:103254. https://doi.org/10.1016/j.ijplas.2022.103254

Deka D, Joseph DS, Ghosh S, Mills MJ (2006) Crystal plasticity modeling of deformation and creep in polycrystalline Ti-6242. Metall Mater Trans A 37(5):1371–1388. https://doi.org/10.1007/s11661-006-0082-2