Abstract

Sewage treatment station in oilfield needs a new process to meet the desired requirements. A new process was proposed to meet the discharge standards, which consisted of the following sub-processes: electrochemical treatment → coagulation treatment → integrated biochemical treatment of moving bed biofilm reactor and membrane bio-reactor → combined treatment process of macroporous adsorption resin. Electrochemical treatment included 5 electrolytic cells, total volume of which was 10 L. The PFS was chosen as the coagulants in the coagulation treatment, and the removal rate of COD could reach 66% when the dosage of PFS was 500 mg/L. The biochemical treatment consisted of anoxic tank, aerobic tank and membrane zone, and the removal rate of COD was about 55–70% when HRT was 12 h. SD300 resin was chosen as the best adsorbent in the treatment using macroporous adsorption resin. In addition, the effluent COD after coagulation treatment process becomes about 180 mg/L, the effluent COD after biological treatment becomes about 50 mg/L, and the last effluent COD with the macroporous adsorption resin becomes about 20 mg/L. The three-dimensional fluorescence spectrum was used to analyze the differences in types of organic matters in water samples between the raw water and the treated one. The results demonstrated that the new process meets the needs of wastewater treatment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the production of crude oil and natural gas, a large amount of oil wastewater is usually produced in the process of oil and gas exploration and development (Guo 2015). According to the different oils, oil sewage can be divided into heavy oil sewage, dilute oil sewage and high condensate oil sewage, etc. (Wang et al. 2005). Heavy oil, as an important part of the energy supply, is being increasingly exploited. Accordingly, a large amount of heavy oil wastewater is produced from heavy oil process. Compared with light oil wastewater, crude oil wastewater contains more polar organics and complicated dissolved recalcitrant compounds, such as naphthenic acid, heterocyclic compounds, surfactants and heavy mineral oil (Tong et al. 2013). Most of those contaminants are poisonous and macromolecular (Chen et al. 2014). How to economically and effectively deal with the large amounts of oil wastewater to reach the reinjection or back and efflux required? The problem has important significance to the economic development of the oil field.

The sewage wastewater in this paper which was from the Liaoning sewage treatment plant was heavy oil wastewater. The wastewater was weakly alkaline, with large amount of colloid and asphaltene, high hardness and great content of SiO2. The main pollutants in the wastewater were the oil and the organic polymer, such as emulsifier and emulsion breaker. The inlet was the wastewater from the processes of deoiling, flotation, desilication, backwashing filter and resin bed regeneration, which contained reverse demulsifier, purifying agent, flocculant aid, acid pickle, waste lye and other chemical agents. The drainage of each kind of the wastewater was random. The displacement and the time of drainage could not be sure, with the deoiling sewage and the production sewage deoiling generating almost every moment. The temperature of mixed inflow was unstable, and oil content and COD vary greatly. All above showed that the complexity of the inflow made the water treatment more difficult in the station.

In recent years, the industrial wastewater treatment methods include physical and chemical methods and biochemical methods (Shanfa et al. 2003). Physical and chemical methods include electrolysis, membrane separation, adsorption, coagulation treatment and chemical oxidation. The coagulation method can be used to reduce the turbidity and chroma of the wastewater, and remove the high molecular substances, colloidal organic pollutants and certain heavy metals (mercury, cadmium), which is widely used in the treatment of oilfield wastewater. Biochemical treatment methods mainly include activated sludge method, biofilm method and the integrated biochemical treatment methods. But this method requires that the sewage has good biodegradability, the water quality and color are stable, and water temperature change is small (about 35 °C). However, the quality of heavy oil wastewater in this paper is not biodegradable because of its poor biodegradability. Therefore, the integrated processing system was applied in the whole treatment.

The electrochemical treatment and flocculation treatment can be used to reduce the turbidity and chroma of the wastewater, and also remove the macromolecule substances. The moving bed biofilm reactor and membrane bio-reactor were combined to treat the heavy oil wastewater. Its advantages are high separation efficiency and low energy consumption. The effluent quality was good. Finally, macroporous adsorption resin was used for comprehensive treatment. Adsorption is a surface phenomenon in which the pollutants accumulate on any solid surface, the compound (pollutant) that sticks or adheres to the solid surface is called as adsorbate, and the solid surface is known as adsorbent. The adsorption is affected by temperature, nature of adsorbates and adsorbents, presence of other pollutants, and other atmospheric and experimental conditions. Adsorption is also considered as one of the best wastewater treatment methods due to its wide range of applications and ease of operation (Ali and Gupta 2006; Ali et al. 2012; Ali 2014). The method is simple, and the COD was removed easily to meet the requirements of standard.

While the initial station could meet the national comprehensive discharge standard of sewage, with the increasing of water and the aging of equipment, the current treatment process was not suitable for the requirements of the current environmental protection and the production of oilfield. So the existing treatment process needed to be improved as required. As an advanced treatment technology, the effluent could meet the standards of discharge.

The study was conducted in the Liaoning Huansilian Heavy Oil Wastewater Treatment Plant, China, from May 2, 2014, to October 6, 2014.

Materials and methods

Experimental wastewater

The experimental water was from the Huansilian sewage treatment plant in Liaohe oilfield (hereinafter referred to as raw water); its basic indicators are illustrated in Table 1.

Instrumentation

Three-dimensional fluorescence spectrometer

The datasets which indicated the components of wastewater were obtained with a HORIBA MAX three-dimensional fluorescence spectrometer.

Electrochemical treatment unit

The parameters of electrochemical device are set as follows: One group of electrode plate distance was 1 cm, the first group of the electrode anode used iron mesh electrode (12 cm × 6 cm), and the cathode used pure titanium electrode (6 cm × 12 cm); the next two groups of electrode anodes used titanium-coated PbO2 electrode (6 cm × 12 cm), and the cathodes were made of pure titanium electrode (6 cm × 12 cm); the final two groups of anode and cathode both used graphite electrode (6 cm × 12 cm); each group of plates was separately controlled by a DC power. The first group of electrodes was mainly used as an electric flocculation unit, the next two groups of electrodes were used as the electric catalytic oxidation unit, and the last two sets of electrodes were used as electrical floating units.

The total volume of the electrolytic cell was 10 L, the volume of the first to the third group of electrolytic cell was 1.5 L (12 cm × 5.5 cm × 23 cm), the volume of the fourth and the fifth groups electrolytic cell was 1.4 L (12 cm × 6 cm × 12 cm), the volume of the next settling basin was about 2.7 L, and the spacing of each group of plates was 5 mm. The first, the third, the fifth sets of electrolyzer used triangular weir overflow independently, and the height of overflow weir was 1 cm.

Coagulation treatment unit

Taiwan scholar Cheng (Cheng and Chi 2002) and other scholars found that PFS will form Fe(OH)3 colloid particles which were large and dense in the process of coagulation. So PFS is better than other coagulants, the removal rate of turbidity, color and organic matter is higher, and the residual fraction in the supernatant is lower. So PFS was chosen for the experiment.

Biochemical treatment unit

The experimental equipment was made of methyl methacrylate, the treatment ability was 120 L/days, the residence time was 12 h, the water inlet was directly extracted by the peristaltic pump, and the water flow control was carried out by the rotameter. The reaction tank was divided into anoxic tank, aerobic tank and membrane zone (anoxic tank was put before aerobic tank; the volume ratio was 1:1). The anoxic zone was 1.2 dm × 2.3 dm × 4.3 dm; aerobic zone was 1.8 dm × 2.3 dm × 3.9 dm, and perforated aeration pipes were set up at the bottom of the aerobic zone. The membrane zone was 1.0 dm × 2.3 dm × 4.3 dm. The ratio of the filtration time to the ceasing time of the flat membrane was 8:2, the filtration time was 8 min, and the ceasing time was 2 min.

The domestication of method was adopted that gradually increased the proportion of the effluent from the air flotation workshop in the domestication stage of biochemical treatment, and mixed culture with pure culture medium, the pure culture medium contained 245.25 mg/L sucrose, 285.6 mg/L CH3COONa, 229.24 mg/L NH4Cl, 40 mg/L KH2PO4, 354 mg/L NaHCO3, 20 mg/L CaCl2, 20 mg/L MgCl2 and 20 mg/L AlCl3. The inoculated sludge comes from a sewage treatment plant in Panshan County of Panjin. Domestication period included four stages. Pure culture medium was put into the inlet in Stage I, which culture 1–7 days; 2/3 pure culture medium and 1/3 air flotation effluent mixture were put into the inlet in Stage II, which culture 8–14 days; 1/2 pure culture medium and 1/2 air flotation effluent mixture were addition in Stage III, which culture 14–20 days; 1/3 pure culture medium and 2/3 air flotation effluent mixture were addition in Stage IV, which culture 20–24 days.

Treatment of macroporous adsorption resin unit

Three resins were selected for the experiment, which are SD300, SD500 and SD730. The polarities of the resins are nonpolar, weak polarity and polar, respectively. SD300 is made of polystyrene. SD500 and SD730 are both made of polyacrylic acid. The method of resin pretreatment from Dong et al. (2015) was referenced: All the resins were first treated in absolute ethanol for 24 h and then washed with deionized water (to complete removal of ethanol), soaked in 5% (m/m) NaOH for 6 h, washed with deionized water (until the pH of filtrate was 7), soaked in 5% (v/v) HCl for 6 h, and washed with deionized water (until the pH of filtrate was 7) in sequence.

Each resin was accurately weighed (0.5 g) and carefully transferred into a 250-mL flask, and filtered wastewater samples (100 mL) were transferred into the three flasks, respectively. Besides, filtered wastewater sample (100 mL) was transferred into the other flask at the same time (without resin). All these flasks were shaken in the thermostatic oscillator at 25 °C with a shaking speed of 150 rpm for 12 h and let stand for 12 h. After resin adsorption reached saturation, values of CODCr before and after adsorption were determined and then calculated equilibrium adsorption capacity q e.

The equilibrium adsorption capacity:

In the equation, q e stood for the equilibrium adsorption capacity (mg/g). C 0, C e stood for the initial concentration and the equilibrium concentration (mg/L). V stood for the volume of waste water (L). W stood for the dry weight (g) of the resin used.

Then, biochemical treatment of effluent was treated by SD300 resin, which was accurately weighed (0.2 g) and carefully transferred into a 250-mL flask and the effluent treated by biochemical process was transferred into the flask.

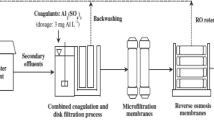

Experimental procedures

Experiments were carried out in the sewage treatment plant. The defects of the original treatment from the characteristics and the changes of macroscopic and microscopic indexes of dissolved organic matters were analyzed which can guide the transformation (Yin and Liu 2015). The experimental process flow chart is shown in Fig. 1.

Results and discussion

The three-dimensional fluorescence spectra of the raw water

Three-dimensional fluorescence spectra were divided into five regions with horizontal and vertical lines by using the same wavelength boundaries of excitation and emission in each spectrum. Based on a number of references, the excitation and emission boundaries were divided into five regions in this paper. The peaks of the spectrums were related to the humus, tyrosine or phenolic organics (Coble 1996). In general, the fluorescence peaks of the materials which were in the short excitation wavelength (<250 nm) and the short wavelength (<350 nm) were related to simple aromatic proteins, such as tyrosine (region I, II) (Ahmad and Reynolds 1999). Fluorescence peaks of the materials which were in the medium excitation wavelength (250–280 nm) and the short wavelength (<380 nm) were related to the soluble microbial metabolites (region IV) (Ismaili et al. 1998). Fluorescence peaks of the materials which were in the long excitation wavelength (>280 nm) and the long emission wavelength (>380 nm) were related to the substance and humic substances (region V) (Artinger et al. 2000). The data of three-dimensional fluorescence spectra with the excitation wavelength which were less than 250 nm have not been widely reported, but the reliable result could be provided by the latest technology measurement in this wavelength range. The shortest excitation wavelength of the three-dimensional fluorescence of the fulvic acid was 250 nm (Coble et al. 1990, 1993; McKnight et al. 2001; Sun et al. 2016; Zhou and Meng 2015).

The spectrum indicated that the center of the three-dimensional fluorescence spectrum peaks was located in the short excitation wavelength. Fluorescence peaks of the materials which were in the short excitation wavelength (<250 nm) and the long emission wavelength (>380 nm) were related to the fulvic acid (regional III).

The three-dimensional fluorescence spectrum of the raw water is shown in Fig. 2. There is only one fluorescence peak in the raw water, and its position is in the 255/375 nm, which belongs to the region of the fluorescence peak of microbial metabolites. Besides, there are some organic compounds which mostly appear are tyrosine and tryptophan in the region. These two compounds are aromatic amino acids, so it could be concluded that the organic matters in raw water include structures of benzene ring, amino and carboxyl group.

Electrochemical treatment unit

Effect of residence time on COD removal

In order to study the influence of residence time on the effect of electrochemical treatment, the effluent could be filled by large plastic barrel which is 250 L before the experiment, and a peristaltic pump was used to supply water continuously from the barrel to the electrochemical device in the experiment, which could maintain the stability of the influent quality. The hydraulic retention time (HRT) was controlled to 60, 50, 40, 30, 20 min, respectively, which was adjusted by the flow rate of inflow. And then the water was got after powering each stage of current value and voltage value 1 h and measured its COD, and the result is shown in Fig. 3.

As shown in Fig. 3, the residence time had a great influence on the effect of effluent. With the prolongation of residence time, the COD removal rate increased first and then decreased. When the residence time was 40 min, the COD removal rate was the best, which was 27.58%. Because the reaction which could reach a certain extent would stop, prolonging the residence time could increase the speed of the electrode material consumption, so the cost would increase.

The contribution of different electrodes on the removal of organics

In order to study the effect of different electrodes on the removal of organics, the effluent could be filled by large plastic barrel which is 250 L before the experiment, and kept stirring to maintain the stability of the influent quality. Dynamic inflow was used in the experiment. A peristaltic pump was used to supply water continuously from the barrel to the electrochemical device, influent flow rate was 15 L/h, and HRT was 40 min. At the same time, the current and voltage values of each group were kept constantly during the experiment, took each unit of water (the first unit of water is the next unit of water) and measured these CODs. The trend of COD and the removal rate of each unit are shown in Fig. 5.

As shown in Fig. 4, the COD removal rate of the precipitation area was very small, which means that the suspended matter was little. To a certain extent, COD in the electrocatalytic oxidation zone could be removed. This is due to the concentration of Cl− from the effluent reaching 1736 mg/L. The oxidation would occur to form Cl2, HOCl, hypochlorite in the titanium-coated PbO2 electrode [Formulas (2)–(4)], and then the electrode surface and the surrounding solution of organic matter were oxidized (Formula 5) (Scialdone et al. 2009).

Besides, the removal rate of COD was not high in the electrocatalytic oxidation zone, because the titanium-coated PbO2 electrode could produce hydroxyl radical (·OH), and Cl− would react with ·OH to generate chlorine radical which had lower activity (Formula 6). It would reduce the hydroxyl radical of oxidation of organic matters that had the highest activity, which reduced the removal rate of COD (Grebel et al. 2010; Polcaro et al. 2009).

As shown in Fig. 5, the removal rate of organic matters was low in the electro-flotation unit. That is because the electrocatalytic oxidation unit used a lot of Cl− which was highly conductive. The solution conductivity in the electro-flotation unit was poor (the TDS of electrocatalytic oxidation unit was 4056 mg/L; the TDS of electro-flotation unit was 2348 mg/L). So that fewer bubbles were generated at both ends of the graphite electrode, suspended matters could not be effectively carried to the liquid surface.

Coagulation treatment unit

The effect of the dosage of PFS

The coagulation effect of different dosage of PFS was investigated. Results showed that the removal rate of COD was on the increase when the dosage of PFS was lower than 200 mg/L. The removal rate of COD reached the highest level when the dosage reached 200 mg/L. With the increase in the dosage, the removal rate of COD was decreased when the dosage of PFS was more than 200 mg/L. This is due to the phenomenon of the stability of the colloid in the sewage after the dosage was excess. The Zeta potential of the supernatant was changed from positive to negative with the increase in dosage of PFS from Fig. 5. The reason is as follows: PFS produced electrical neutralization on the DOM of the effluent. When the dosage was more than 200 mg/L, the absolute value of the Zeta potential was increased, which increased the repulsion between one charged colloidal particle and other. The dosage of PFS reached 500 mg/L, which would make the colloidal particles in unstable state. The varying tendency of COD was consistent with the change trend of the Zeta potential.

Effect of pH on the coagulation properties of PFS

The result shows the effect of different pH on the coagulation performance of PFS. When pH was 6.00, CODCr was 80.2 mg/L; when pH was 7.00, CODCr was 96.4 mg/L; when pH was 8.00, CODCr was 88.6 mg/L.

According to Cheng et al., their findings about the coagulation of PFS being used to remove dissolved organic matter (DOM) show that the hydrolysis of the component of PFS and the complexation reaction between the component of PFS and the DOM with negative charge would occur simultaneously, and two kinds of reactions would compete with the component of PFS in the solution. The specific reaction is as follows:

Hydrolysis reaction:

Complexation reaction:

By combining with the changes of the Zeta potential of flocs and the Formulas (7) and (8), it can be inferred that the organic matters from the water were treated by coagulation when pH of water was 6, the coagulation mechanism is electric neutralization; PFS was hydrolyzed rapidly in the neutral or alkaline conditions, and then, it formed colloidal particles precipitated, and the electrical neutralization ability of PFS decreased. But adsorption complexation and sweeping became the main coagulation mechanism, which ensured the effect of removal of DOM in the neutral or alkaline conditions.

Analysis of three-dimensional fluorescence spectra of the supernatant of coagulation treatment

By comparison, it is found that the fluorescence peak positions of the coagulation supernatant were basically consistent at the three pH conditions. The organics in the water sample were mainly fulvic-like substance which was in the UV range and a little protein (Rodriguez et al. 2014). The fluorescence spectrum of supernatant at pH 6.00 was weaker than that at pH 8.00. That is because the humus is a kind of porous polymer with flexible structure that contains carboxy group, phenolic group and other acidic groups. In general, with the changes of the pH value, the acidic groups of organic macromolecular structure and the structure of the molecule itself would be changed. The study shows that the humus molecules have a linear stretch structure in neutral or alkaline conditions, while the humus molecules are in a state of curl in acidic conditions. The humus would make more fluorescent groups to be exposed in the solution when they have a linear stretch structure, so that the fluorescence intensity is enhanced (Royer et al. 2002). While the humus is in a state of curl, the fluorescence intensity is weakened.

Biochemical treatment unit

Domestication of biochemical treatment

The changes of concentration of COD and the removal rates of the inlet and outlet water in each stage are shown in Fig. 6. Because the materials of the pure culture medium are biodegradable, after the microorganism added to the system gradually adapted the environment, the removal rate of COD gradually increased in the Stage I. In the Stage II, the removal rate of COD is also gradually increased. In the Stage III and the Stage IV, the removal rate of COD gradually reduced after gradually increasing the proportion of air flotation effluent. On the one hand, this is because the proportion of air flotation effluent no less than 1/2 may suppress the microbial activity. On the other hand, it may be that the biochemical degradability of air flotation effluent was poor, the proportion of non-biodegradable organic matter increased after gradually increasing the proportion of air flotation effluent, and then the COD of effluent increased.

The removal of COD in the biochemical treatment

Biochemical treatment system began to enter the operational phase after domesticating for 24 days, the inlet is 100% of air flotation effluent, and run for 58 days. The changes of concentration of COD and the removal rate of the inlet and outlet water are shown in Fig. 7.

The CODCr of inlet fluctuated between 250 and 450 mg/L (average value was 353.6 mg/L); the quality of inlet was unstable. The CODCr of effluent was relatively stable, which fluctuated between 100 and 150 mg/L (the average value was 135.5 mg/L), and the removal rate of CODCr fluctuated between 55 and 70%. The results showed that the instability of influent directly affected the removal efficiency of the organic matter in the biochemical treatment system.

Analysis of the three-dimensional fluorescence spectrum

In order to study the changes of dissolved organic compounds in each unit of biochemical reactor, inlet, effluent of the anoxic zone, effluent of the aerobic zone and effluent of the MBR zone from biochemical reaction equipment were taken to flow through 0.45-m membranes, respectively, and the three-dimensional fluorescence spectra were created.

The three-dimensional fluorescence spectra of DOM in different units contained two major fluorescence peaks A and fluorescence peaks B. The excitation/emission wavelength of the fluorescence peak A was 250–255/375. The excitation/emission wavelength of the fluorescence peak B was 290/350–390. They belong to the fluorescence peak of plastein, the fluorescence peak A had relations with tyrosine, and the fluorescence peak B was related to tryptophan. There was a fluorescent peak C which was related to humic acid in the samples, and its peak (excitation/emission wavelength) is 260/420–440.

The contour lines of the three-dimensional fluorescence spectra showed the fluorescence intensity, and the thicker contour lines showed the higher fluorescence intensity. Compared to the inlet, the fluorescence intensity of fluorescent peaks (A and B) of DOM declined in the anoxic zone. But the fluorescence intensity of the fluorescence peak C changed little, because the fluorescence peak C was related to humic acid, the biochemical degradation ability is poor, and the kind of material was more stable in the biochemical treatment process. The position of the peak was another parameter which indicates the characteristics of DOM. Compared to the influent, the position of the fluorescence peak A of DOM in the anoxic tank was found that red-shifted by 5 nm along the excitation axis and the fluorescence peak B red-shifted by 20 nm along the emission axis. The position of fluorescence peak C was invariable. The positions of fluorescence peak A and B of DOM had no change in the aerobic pool. The fluorescence peak C blue-shifted by 15 nm along the emission axis. The positions of fluorescence peaks of DOM were no change in the MBR process. The positions of fluorescence peaks (A and B) of DOM from the final effluent unchanged. The fluorescence peak C blue-shifted by 5 nm along the emission axis. The redshift indicated that DOM contained carboxyl substituent group, hydroxyl group, alkyl group, amino group and carboxyl group (Swietlik et al. 2004). The blueshift which was observed showed that polycyclic aromatic hydrocarbon was decomposed and macromolecules were broken into simple molecules (Swietlik and Sikorska 2004). The changes of the positions of fluorescence peaks (A, B and C) showed that not only the concentration changed, but also the structure of DOM changed in the biochemical treatment system.

Treatment of macroporous adsorption resin unit

The selection of macroporous adsorption resin

After static adsorption of three kinds of resins, the equilibrium adsorption capacity was calculated. The equilibrium adsorption capacity of SD300, SD500 and SD730 was 21.96, 14.12 and 14.90 mg/g, respectively.

The order of equilibrium adsorption capacity of these macroporous adsorption resins is as follows: SD300 > SD500 > D730. Therefore, SD300 resin with the best adsorption capacity was chosen as the best adsorbent.

Biochemical treatment of effluent by macroporous adsorption resin

The experiment was carried out for two periods, and the changes of COD are observed in the periods (see Fig. 8).

From Fig. 8, the resin absorption capacity of organic matter in the two periods was not high when the water just entered the resin. The reason may be that the operation of the resin was not stable. After running the system for some time, the COD of effluent by treatment of resin in the two periods was about 20 mg/L, which has met the requirements of the National Planning of Water Pollution Control in Major River Valleys (2011–2015), Integrated Wastewater Discharge Standard (GB 8978-1996) and Synthetical Sewage Discharge Standard (DB21/ 1627-2008) in Liaoning Province. The COD meets the standard of no more than 50 mg/L that needs to be controlled within 50 mg/L.

Analysis of three-dimensional fluorescence spectrum

The main fluorescence peak (245/370 nm) (belongs to fluorescence peak of plastein) disappeared after the raw water through SD300 resin. The effluent showed a weak fluorescence peak (305/395 nm), which belongs to fluorescence peak of humic-like. It indicated that the inlet mainly contained plastein, which were adsorbed after flowing through macroporous adsorption resin, a part of humic substances retained in the solution and were not adsorbed.

The fluorescence intensity of each area was calculated by the FRI algorithm and determined the proportion of the volume of each area accounted for the total volume of five areas. The results are shown in Table 2.

After the inlet was adsorbed by the SD300 resin, the relative percentage content of aromatic protein (PI,n, PII,n) decreased from 44.52 to 31.92%, which showed that the aromatic protein substances were adsorbed by macroporous adsorption resin. The relative percentage content of humic substances increased, which indicated that the humic substances were not adsorbed by macroporous adsorption resin.

Conclusion

According to the water quality and the original treatment process, the existing treatment process was improved as required to solve the major problem that the effluent from the sewage treatment could not meet the discharge standard under current conditions. The proposed process would treat raw sewage by the flocculation firstly and then by the MBBR + MBR integrated biochemical treatment, and the macroporous adsorption resin and the final effluent meet the standard.

In the treatment of flocculation and electrochemical, PFS was chosen as the best flocculant because of the best effect of treatment. And the removal rate of COD could reach 66% when the dosage of PFS is 500 mg/L, which can be prepared for the subsequent treatment process. For the integrated biochemical treatment process of MBBR + MBR, when HRT was 12 h, the removal rate of COD was about 55–70%. The biochemical treatment system was prepared for the final resin treatment. Adsorption of macroporous adsorption resin would further improve the quality of effluent, and COD of final effluent was about 20 mg/L, which improve and meet the standard of discharge.

References

Ahmad SR, Reynolds DM (1999) Monitoring of water quality using fluorescence technique: prospect of on-line process control. Water Res 33(9):2069–2074. doi:10.1016/S0043-1354(98)00435-7

Ali Imran (2014) Water treatment by adsorption columns: evaluation at ground level. Sep Purif Rev 43(3):175–205. doi:10.1080/15422119.2012.748671

Ali Imran, Gupta VK (2006) Advances in water treatment by adsorption technology. Nat Protoc 1(6):2661–2667. doi:10.1038/nprot.2006.370

Ali Imran, Asim Mohd, Khan Tabrez A (2012) Low cost adsorbents for the removal of organic pollutants from wastewater. J Environ Manag 113(1):170–183. doi:10.1016/j.jenvman.2012.08.028

Artinger R, Buckau G, Geyer S et al (2000) Characterization of groundwater humic substances: influence of sedimentary organic carbon. Appl Geochem 15(1):97–116. doi:10.1016/S0883-2927(99)00021-9

Chen C, Wei L, Guo X, Guo S, Yan G (2014) Investigation of heavy oil refinery wastewater treatment by integrated ozone and activated carbon supported manganese oxides. Fuel Process Technol 124(4):165–173. doi:10.1016/j.fuproc.2014.02.024

Cheng WP, Chi FH (2002) A study of coagulation mechanisms of polyferric sulfate reacting with humic acid using a fluorescence-quenching method. Water Res 36(18):4583–4591. doi:10.1016/S0043-1354(02)00189-6

Coble PG (1996) Characterization of marine and terrestrial DOM in seawater using excitation emission matrix spectroscopy. Mar Chem 51(4):325–336. doi:10.1016/0304-4203(95)00062-3

Coble PG, Green SA, Blough NV, Gagosian RB (1990) Characterization of dissolved organic matter in the Black Sea by fluorescence spectroscopy. Nature 348(6300):432–435. doi:10.1038/348432a0

Coble PG, Schultz CA, Mopper K (1993) Fluorescence contouring analysis of DOC intercalibration experiment samples: a comparison of techniques. Mar Chem 41(1–3):173–178. doi:10.1016/0304-4203(93)90116-6

Dong Y, Zhao M, Sun-Waterhouse D (2015) Absorption and desorption behaviour of the flavonoids from Glycyrrhiza glabra L. leaf on macroporous adsorption resins. Food Chem 168:538–545. doi:10.1016/j.foodchem.2014.07.109

Grebel JE, Pignatello JJ, Mitch WA (2010) Effect of halide ions and carbonates on organic contaminant degradation by hydroxyl radical-based advanced oxidation processes in saline waters. Environ Sci Technol 44(17):6822–6828. doi:10.1021/es1010225

Guo P (2015) Application of near-surface absorption and compensation in seismic data in Liaohe oilfield. Spec Oil Gas Reserv 22(2):4–31. doi:10.3969/j.issn.1006-6535.2015.02.007

Ismaili MM, Belin C, Lamotte M et al (1998) Distribution et caractérisation par fluorescence de la matiére organique dissoute dans les eaux de la Manche centrale. Oceanol Acta 21(5):645–654. doi:10.1016/S0399-1784(99)80023-1

Linhong Wang, Zhenxing Zhao, Guihua Han, Ruili Li (2005) Treatment technology and research on oil-bearing sewage. Ind Water Treat 25(2):5–8. doi:10.3969/j.issn.1005-829X.2005.02.002

McKnight DM, Boyer EW, Westerhoff PK, Doran PT, Kulbe T, Andersen DT (2001) Spectrofluorometric characterization of dissolved organic matter for indication of precursor organic material and aromaticity. Limnol Oceanogr 46(1):38–48. doi:10.4319/lo.2001.46.1.0038

Polcaro AM, Vacca A, Mascia M (2009) Electrochemical treatment of waters with BDD anodes: kinetics of the reactions involving chlorides. J Appl Electrochem 39(11):2083–2092. doi:10.1007/s10800-009-9870-x

Rodriguez FJ, Schlenger P, Valverde MG (2014) A comprehensive structural evaluation of humic substances using several fluorescence techniques before and after ozonation. Part I: structural characterization of humic substances. Sci Total Environ 476–477:718–730. doi:10.1016/j.scitotenv.2013.11.150

Royer RA, Burgos WD, Fisher AS et al (2002) Enhancement of biological reduction of hematite by electron shuttling and Fe(II) complexation. Environ Sci Technol 36(9):1939–1946. doi:10.1021/es011139s

Scialdone O, Randazzo S, Galia A et al (2009) Electrochemical oxidation of organics in water: role of operative parameters in the absence and in the presence of NaCl. Water Res 43(8):2260–2272. doi:10.1016/j.watres.2009.02.014

Shanfa Tang, Zhang Ruicheng, Tian Chunxiang, Jiang Guang, Zeng Yubin (2003) Study on the treatment technologies of meeting standard discharge of thick oil produced water at Huansilian. Chem Eng Oil Gas 32(2):115–117. doi:10.3969/j.issn.1007-3426.2003.02.018

Sun K, Liang ST, Kang FX (2016) Transformation of 17 β-estradiol in humic acid solution by ε-MnO2 nanorods as probed by high-resolution mass spectrometry combined with 13C labeling. Environ Pollut 214:211–218. doi:10.1016/j.envpol.2016.04.021

Świetlik J, Sikorska E (2004) Application of fluorescence spectroscopy in the studies of natural organic matter fractions reactivity with chlorine dioxide and ozone. Water Res 38(17):3791–3799. doi:10.1016/j.watres.2004.06.010

Świetlik J, Dąbrowska A, Raczyk-Stanisławiak U et al (2004) Reactivity of natural organic matter fractions with chlorine dioxide and ozone. Water Res 38(3):547–558. doi:10.1016/j.watres.2003.10.034

Tong K, Zhang Y, Chu PK (2013) Evaluation of calcium chloride for synergistic demulsification of super heavy oil wastewater. Colloids Surf A 419:46–52. doi:10.1016/j.colsurfa.2012.11.047

Yin Y, Liu Y (2015) Analysis of fluid-structure interaction in thermal heavy oil recovery operations. Sustainability 7(4):4035–4048. doi:10.3390/su7044035

Zhou MH, Meng FG (2015) Aluminum-induced changes in properties and fouling propensity of DOM solutions revealed by UV–vis absorbance spectral parameters. Water Res 93(15):153–162. doi:10.1016/j.watres.2015.11.051

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (NSFC) (Grant No. 51279108), the Major Project of Shanghai Municipal Science and Technology Commission (13DJ1400105) and the Major State Research Development Program of China (2016YFC0402504).

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: J. Aravind.

Rights and permissions

About this article

Cite this article

Zhan, Y., Wei, R. & Zhou, H. Improvement on the treatment of thick oil sewage by using integrated biochemical treatment technology. Int. J. Environ. Sci. Technol. 15, 81–92 (2018). https://doi.org/10.1007/s13762-017-1366-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-017-1366-3