Abstract

In the present study the removal of nitrates from wastewater using Pseudomonas stutzeri microorganism in a Gas–Liquid–Solid bioreactor at the concentration of 200 ppm was studied for a period of 12 h. The response surface methodology with the help of central composite design and genetic algorithm were employed to optimize the process parameters such as airflow rate, biofilm carrier, carbon source, temperature and pH which are responsible for the removal of nitrates. The optimized values of parameters found from RSM are airflow rate 2.41 lpm, biofilm carrier 15.15 g/L, carbon source 85.0 mg/L, temperature 29.74 °C, pH 7.47 and nitrate removal 193.16. The optimized parameters obtained from genetic algorithm are airflow rate 2.42 lpm, biofilm carrier 15.25 g/L, carbon source 84.98 mg/L, temperature 29.61 °C, pH 7.51 and nitrate removal is 194.14. The value of R2 > 0.9831 obtained for the present mathematical model indicates the high correlation between observed and predicted values. The optimal values for nitrate removal at 200 ppm are suggested according to genetic algorithm and at these optimized parameters more than 96 % of nitrate removal was estimated, which meets the standards for drinking water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Direct discharge of wastewater containing nitrogen can cause environmental problem such as eutrophication of rivers and serious health problems in humans such as the blue baby syndrome in infants, liver damage and cancer (Gupta et al. 2003; Shrimali and Singh 2001). Extractive methods like reverse osmosis, electro-dialysis and ion exchange resins (Choi and Batchelor 2008; Schoeman and Steyn 2001; Park et al. 2008) produce a large amount of effluent containing high concentration of nitrate, which results in the second pollution, which must be treated later and thus increasing the overall cost of the process.

Biological denitrification has been focused by a large number of researchers recently (Rezaee et al. 2008; Kim et al. 2005; Foglar et al. 2005; Roaders and Xin-Min 2004; Wen et al. 2003; Hirata et al. 2001; Soares 2000), and work reported on biological denitrification of wastewater using a fluidized bed bioreactor is very little using Pseudomonas stutzeri. Biological treatment has high treatment efficiency, no sludge production, small area occupied and relatively low investment costs.

Biological denitrification occurs naturally when certain bacteria use nitrate as terminal electron acceptor in their respiratory process, in the absence of oxygen. Denitrification consists of a sequence of enzymatic reactions leading to the evolution of nitrogen gas. The process involves the formation of a number of nitrogen intermediates and in these processes microorganisms first reduce nitrates to nitrites and then produce nitric oxide, nitrous oxide and nitrogen gas. The pathway for nitrate reduction is:

Biological denitrification treatment consists of the provision of suitable carbon sources, which may be organic or inorganic compounds. Several sources of carbon with different combinations have been used for denitrification including succinic acid, ethanol and acetic acid (Kesseru et al. 2002), acetate, ethanol and hydrolysed rice (Khanitchaidecha et al. 2010), methanol (Ginige et al. 2009), news paper, cotton (Volokita et al. 1996a, b), acetate, ethanol and methanol (Adav et al. 2010), rice husk (Shao et al. 2008) and molasses (Ueda et al. 2006). Based on its price and availability, methanol is most commonly used as additional carbon source for bacterial denitrification. The combinations of parameters like airflow rate, biofilm carrier, carbon source, temperature and pH have not been studied by earlier investigators; these combinations are employed in the present experiments varying at different levels.

The response surface methodology (RSM), which is an efficient statistical technique for optimization of multiple parameters with minimum number of experiments, is to use a set of designed experiments to obtain an optimal response (Li et al. 2010; Vohra and Satyanarayana 2002; Francis et al. 2003). This technique has been applied in a wide range of fields such as drug and food industry, chemical and biological processes (Meilgaard et al. 1991; Otto 1999). RSM has been successfully applied to different processes for optimization of the experimental design. However, to our best knowledge, the application in biological reduction of nitrate removal (NR) with above said parameters is not yet reported.

The objective of the current study is to optimize the parameters like airflow rate, biofilm carrier, carbon sours, temperature and pH at different levels using RSM and genetic algorithm (GA) for a initial nitrate concentration of 200 ppm using P. stutzeri microorganism in Gas–Liquid–Solid bioreactor (GLS).

Research work was carryout out during January to April 2012 at Department of Chemical Engineering, National Institute of Technology, Warangal, Andhra Pradesh, India.

Materials and methods

Cell immobilization and inoculation of denitrifying bacteria

The experimental work was carried out in a GLS with attached growth process to investigate the removal of nitrate from the synthetic wastewater and P. stutzeri with low density polymer (polypropylene) used as the supporting media. The bacterium from the slants was inoculated into liquid broth containing nitrate concentration of 200 mg/L and was prepared by mixing: 48.9 mg of KNO3, 6 mg of MgSO4·7H2O, 0.2 mg of FeCl3·7H2O, 430 mg of Na2HPO4 and 320 mg of Na2H2PO4 (Lakshmi and Pydi 2008). The composition gives the initial nitrate concentration of 30 mg/L, to increase or decrease the nitrate composition we can vary the amount of potassium nitrate proportionately.

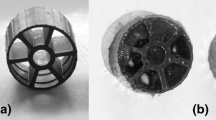

Experimental set-up

The GLS consists of a glass column of 0.5 m height, 93 mm of internal diameter (ID) and 100 mm of outer diameter (OD) with a capacity of 3.4 L. The setup was provided with a glass jacket of 118 mm ID and 122 mm OD, to maintain the temperature of the reactor and also provision was made for the supply of air/N2/O2 based on the requirement. A gas sparger was located at the base of column for uniform distribution of gas as shown in Fig. 1.

Analytical methods

All the analysis was done according to standard methods (APHA 2005). Runs were conducted according the central composite design (CCD) combinations and samples was collected for every 1 h, filtered and were used for the analysis of final nitrate concentration using Orion ion potentiometer.

Response surface methodology

Response surface methodology is a collection of mathematical and statistical techniques that are useful for modeling and analysis of problems in which output or response influenced by several factors and the goal is to find the correlation between the response and the factors (Parimala et al. 2011). It is also used for optimizing the response at different levels (Montgomery 1990; Raissi and Eslami 2009). The CCD is used since it gives a comparatively accurate prediction of all response variable averages related to quantities measured during experimentation (Theodore 2006). In this method, there is a possibility that the experiments will stop with fairly few runs and decide that the prediction model is satisfactory. In this study, we selected five experimental factors capable of influencing the NR efficiency at 200 ppm and those are shown in Table 1.

The optimization of parameters was conducted using CCD. The response function of interest is NR. These functions were approximated by a second degree polynomial of cubic, quadratic and interaction effects using the method of least squares. There was a set of total 50 experiments generated using CCD design with 43 being the combinations of the actual level of the experimental variables while the remaining 7 were replications at the central points, the experiments were conducted according to CCD and presented in Table 2.

Genetic algorithm

Genetic algorithm is a stochastic global search and optimization method that mimic the metaphor of natural biological evolution. GA operates on a population of potential solutions, applying the principle of survival of the fittest to produce successively better approximations to a solution. At each generation of a GA, a new set of approximations is created by the process of selecting individuals according to their level of fitness in the problem domain and reproducing them using operators borrowed from natural genetics. This process leads to the evolution of populations of individuals that are better suited to their environment than the individuals from which they were created, just as in natural adaptation.

Results and discussion

The CCD was used to find the optimal parameter for the NR from wastewater using P. stutzeri microorganism. The results of CCD experiments consisted of predicted and experimental data for studying the effects of five independent variables; viz., airflow rate, biofilm carrier, carbon source, temperature and pH for denitrification are presented in Table 2.

The regression equation obtained from analysis of variance (ANOVA) indicated that the multiple correlation co-efficient of R 2 is 0.9831, i.e. the model can explain 98.31 % variation in the response. It should be noted that a R 2 value greater that 0.75 indicates the aptness of the model. The adjusted R 2 and predicted R 2 values are 0.9409 and 0.9494, respectively. ANOVA results confirmed a satisfactory adjustment of the simplified quadratic model to the experimental data. It should be considered that the polynomial model is a reasonable approximation of the true functional relationship on a relative small region of the entire space of the independent values. The data were fitted with a second-order polynomial function. The ANOVA is shown in Table 3. The simplified second-order polynomial equation for NR in terms of actual factors is expressed as follows: NR = −39.45283 + 39.96121 × AF + 7.71900 × BC − 2.74660 × CS + 5.19204 × Temp + 36.08314 × pH − 0.23750 × AF × BC − 0.062500 × AF × CS + 0.062500 × AF × Temp + 0.18750 × AF × pH + 0.013750 × BC × CS − 0.018750 × BC × Temp − 0.18125 × BC × pH + 0.018750 × CS × Temp + 0.18125 × CS × pH − 6.25000E − 003 × Temp × pH − 7.11724 × AF2 − 0.21117 × BC2 + 8.82759E − 003 × CS2 − 0.11117 × Temp2 − 3.27931 × pH2.

Mutual effects of parameters on NR

Figure 2 represents the mutual effect on NR. The highest denitrification efficiency was obtained at airflow rate ranging from 2 to 3 lpm, biofilm carrier ranging from 10 to 20 g/L, carbon source ranting from 75 to 85 mg/L, temperature ranging from 25 to 35 °C and pH ranging from 6 to 8. The response surface plots of mutual effects of airflow rate, biofilm carriers, carbon source, temperature and pH on NR are shown in Fig. 1(a–j).

Response surfaces plots showing the mutual effect of biofilm carriers and airflow rate (a), carbon source and airflow rate (b), temperature and airflow rate (c), pH and airflow rate (d), carbon source and biofilm carriers (e), temperature and biofilm carriers (f), pH and biofilm carriers (g), temperature and carbon source (h), pH and carbon source (i), pH and temperature (j), for nitrate removal

The results indicate that highest NR was obtained when airflow rate is at 2.4 lpm, biofilm carrier is 15 g/L, carbon source maintained at 85 mg/L, temperature 30 °C and pH at 7. From the experiments, it is confirmed that the NR efficiency for the said parameters levels could be achieved more than 96 %.

The maximum NR can also be obtained from the following multi interaction combinations by keeping other parameters constant at optimum levels.

-

1.

Interaction between biofilm carriers and airflow rate (Fig. 1a): 15 g/L and 2.75 lpm.

-

2.

Interaction between carbon source and airflow rate (Fig. 1b): 85 mg/L and 2 lpm.

-

3.

Interaction between temperature and airflow rate (Fig. 1c): 27 °C and 2.5 lpm.

-

4.

Interaction between pH and airflow rate (Fig. 1d): 7 and 2.75 lpm.

-

5.

Interaction between carbon source and biofilm carriers (Fig. 1e): 85 mg/L and 15 g/L.

-

6.

Interaction between temperature and biofilm carriers (Fig. 1f): 30 °C and 17.50 g/L.

-

7.

Interaction between pH and biofilm carriers (Fig. 1g): 7 and 17.50 g/L.

-

8.

Interaction between temperature and carbon source (Fig. 1h): 30 °C and 85 mg/L.

-

9.

Interaction between pH and carbon source (Fig. 1i): 7 and 86 mg/L.

-

10.

Interaction between pH and temperature (Fig. 1j): 7.50 and 32.50 °C.

Figures 3 and 4 represents the optimal parameters for biological denitrification wastewater at the initial nitrate concentration of 200 ppm and operated for a period of 12 h. And it was observed that more than 193.1643 ppm of nitrates were removed with the optimized combination of parameters using RSM and 194.149 ppm removed with the combination of GAs. Optimal parameters and NR for both methods were shown in Table 4. Figure 5 shows the comparison between predicted and actual values.

Conclusion

Biological denitrification of wastewater was studied in a GLS using P. stutzeri microorganism at 200 ppm for a period of 12 h. The optimization of process parameters for denitrification was studied with RSM and GA. The parameters were studied at low and high range of airflow rate: 2–3 lpm, biofilm carrier: 10–20 g/L, carbon source: 75–85 mg/L, temperature: 25–35 °C and pH 6–8. The optimized values of parameters found using RSM is airflow rate 2.41 lpm, biofilm carrier 15.15 g/L, carbon source 85.0 mg/L, temperature 29.74 °C, pH 7.47 and NR is 193.16. The optimized parameters according to GA are airflow rate 2.42 lpm, biofilm carrier 15.25 g/L, carbon source 84.98 mg/L, temperature 29.61 °C, pH 7.51 and NR is 194.14.

References

Adav SS, Sunil S, Lee Duu-Jong, Lai JY (2010) Enhanced biological denitrification of high concentration of nitrite with supplementary carbon source. Appl Microbiol Biotechnol 85:773–778

APHA, AWW, WPCF (2005) Standard methods for the examination of water and wastewater, 21st edn. American Public Health Association, Washington

Choi J, Batchelor B (2008) Nitrate reduction by fluoride green rust modified with copper. Chemosphere 70:1108–1116

Foglar ML, Briski F, Sipos L, Vukovia M (2005) High nitrate removal from synthetic waste water with the mixed bacterial culture. Bioresour Technol 96:879–888

Francis F, Sabu A, Nampoothiri KM, Ramachandran S, Ghosh S, Szakasc A, Pandey A (2003) Use of response surface methodology for optimizing process parameters for the production of an amylase by Aspergillus orzae. Biochem Eng J 15:107–115

Ginige MP, Bowyer JC, Foley L, Keller J, Yuan Z (2009) A comparative study of methanol as a supplementary carbon source for enhancing denitrification in primary and secondary anoxic zones. Biodegradation 20:221–234

Gupta SK, Gupta AB, Gupta RC, Seth AK, Bassain JK, Gupta A (2003) Recurrent acute respiratory tract infections in areas with high nitrate concentrations in drinking water. Environ Health Perspect 108:363–365

Hirata A, Nakamura Y, Suneda T (2001) Biological nitrogen removal from industrial wastewater discharged from metal recovery process. Water Sci Technol 44:171–179

Kesseru Pete, Kiss Istvan, Bihari Zoltan, Polyak Bela (2002) Investigation of the denitrification activity of immobilized Pseudomonas butanovora cell in the presence of different organic substrates. Water Res 36(6):1565–1571

Khanitchaidecha Wilawan, Sumino Tatsuo, Kazama Futaba (2010) Influence of carbon source on biological nitrogen removal by immobilized bacteria. J Water Res Protect 2:527–531

Kim MJK, Park KS, Cho KS, Soo-Wan N, Park TJ, Bajpai R (2005) Aerobic nitrification—denitrification by heterotrophic Bacillus strains. Water Sci Technol 96:1897–1906

Lakshmi LP, Pydi Setty Y (2008) Liquid–Solid mass transfer in a two phase fluidized bed bioreactor. Chem Eng J 135:135–140

Li M, Feng C, Zhang Z, Chen R, Xue Q, Gao C, Sugiura N (2010) Optimization of process parameters for electrochemical nitrate removal using Box-Behnken design. Electrochim Acta 56:265–270

Meilgaard M, Civille GV, Carr BT (1991) Advanced statistical methods, sensory evaluation techniques, 2nd edn. CRC Press, Boca Raton, p 275

Montgomery DC (1990) Design and analysis of experiments, 2nd edn. Wiley, New York

Otto M (1999) Chemometrics: statistics and computer applications in analytical chemistry. Wiley-VCH, Chichester

Parimala T, Sneha PM, Ramachandra Rao SV, Satish Babu R (2011) Response surface optimization of process variables for alkaline protease production by Bacillus subtilis. J Chem Biol Phys Sci 1:228–236

Park J, Byun H, Choi W, Kang W (2008) Cement paste column for simultaneous removal of fluoride, phosphate and nitrate in acidic wastewater. Chemosphere 70:1429–1437

Raissi S, Eslami Farsani R (2009) Statistical process optimization through multi-response surface methodology. World Acad Sci Eng Technol 51:267–271

Rezaee A, Godini H, Dehestani S (2008) Biological denitrification by Pseudomonas stutzeri immobilized on microbial cellulose. World J Microbiol Biotechnol 24:2397–2402

Roaders M, Xin-Min Z (2004) Biological nitrogen removal using a vertically moving biofilm system. Bioresour Technol 93:313–319

Schoeman JJ, Steyn A (2001) Nitrate removal with reverse osmosis in a rural area in South Africa. Desalination 155:15–26

Shao L, Xu ZX, Yin HL, Chu HA (2008) Rice husk as carbon source and biofilm carrier for water denitrification. J Biotechnol 1363:647–677

Shrimali M, Singh KP (2001) New methods of nitrate removal from water. Environ Pollut 112:351–359

Soares MIM (2000) Biological denitrification of ground water. Air Soil Pollut 123:183–193

Theodore T (2006) Introduction to engineering statistics and six sigma. Springer-Verlag, London

Ueda T, Shinogi Y, Yamaoka M (2006) Biological nitrate removal using sugar-industry wastes. Paddy Water Environ 4:139–144

Vohra A, Satyanarayana T (2002) Statistical optimization of medium components by response surface methodology to enhance phytase production by Pichia anomla. Process Biochem 7:999–1004

Volokita M, Abeliovich A, Ines M, Soares M (1996a) Denitrification of groundwater using cotton as energy source. Water Sci Technol 34(1–2):379–385

Volokita M, Belkin S, Abeliovich A, Ines M, Soares M (1996b) Biological denitrification of drinking water using newspaper. Water Res 30:965–971

Wen J, Liping D, Ghozhu M (2003) The denitrification of nitrate contained waste water in a gas–liquid–solid three phase flow air lift loop bioreactor. Biochem Eng J 15:153–157

Acknowledgments

The authors would like to thank the Institute (National Institute of Technology, Warangal) for the facilities provided to carry out the experiments and computational work. The authors also thank the staff for the support given during the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srinu Naik, S., Pydi Setty, Y. Optimization of parameters using response surface methodology and genetic algorithm for biological denitrification of wastewater. Int. J. Environ. Sci. Technol. 11, 823–830 (2014). https://doi.org/10.1007/s13762-013-0266-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-013-0266-4