Abstract

In this work, in the first step, the 1-methyl-3-(3-trimethoxysilylpropyl) imidazolium chloride ([MTMSPIm]Cl) is immobilized on HY and NaY zeolites as an acidic catalyst. The synthesized catalysts were well characterized by different methods such as FTIR, TGA, XRD, BET, SEM, EDX and ICP. The characterizations of catalysts indeed show the ionic liquid supported on amine-functionalized zeolites. Also, the result shows the micro-/mesoporous structure for catalysts which have been emerged as an important class of catalytic materials. The micro-/mesocatalyst ([MTMSPIm]Cl@zeolite) was used as an acidic catalyst to synthesize coumarins via Pechmann reaction in solvent-free condition. The effect of different factors such as catalyst amount, solvent and time was investigated. Finally, catalyst can be easily separated and reused for the next reactions at least for five runs without any significant changes in yield and structure of the catalyst. Comparison of modified zeolite with [MTMSPIm]Cl shows higher yield and selectivity and mild condition related to other works.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the past decades, interest in ionic liquids (ILs) has been increased for organic reactions due to their unique properties such as solubility, very low vapor pressure, low toxicity, high chemical and thermal stabilities, which are often named as green solvents [1]. Also, ILs show good catalytic activity and high selectivity as a homogeneous catalyst for organic reaction. But ionic liquids are very expensive, and many efforts are made on the basis of economic criteria to minimize the amount of ILs in the reactions [2]. We know homogenous catalysts have some limited use, because usually separating them from the reaction products is difficult, which may lead to environmental and economic problems, especially in the case of expensive and toxic catalyst. Recently, to overcome these limitations, the immobilization of ionic liquid onto some solid supports such as polymer, complex, magnetite nanoparticles, graphene and mesoporous materials has been developed [3,4,5]. Zeolites are crystalline microporous aluminosilicate which have Brøonsted and Lewis sites, act as solid acid catalysts and are used as a support for heterogeneous catalyst [6,7,8,9]. Although zeolites have many advantages, diffusion limitations not only lead to a negative influence on catalytic activity but can also cause a loss in selectivity and a reduction in the lifetime of the catalyst. Then, recently, significant efforts have been made to prepare micro-/mesoporous zeolite materials [10]. Literature review shows that in some work, composites of zeolite and ILs were prepared [11,12,13], but a micro-/mesostructure of zeolite by immobilization of ILs on it has not been reported yet.

Coumarins and their derivatives are widely applied in many areas, for example as drug in present-day and modern medicine, biology, polymer sciences [14], also as inhibitor of platelet aggregation, antibacterial, anticancer, inhibitor of steroid \(\alpha\) reductase and inhibitor of HIV-1 protease [15, 16]. Also coumarins have been used as optical brightening agents, laser dyes and fluorescent markers [17].

There are some classical methods which are used for the synthesis of coumarin such as Pechmann reaction [18], Knoevenagel condensation [19], Wittig reactions [20], Perkin [21], Reformatsky [22], Wittig [19, 23], Claisen rearrangement [24] and flash vacuum pyrolysis [25].

The Pechmann reaction with very simple starting materials (phenols, β-ketoesters and acid catalysts) is one of the simplest and direct methods for the synthesis of coumarins [26]. Literature review showed that the synthesis of coumarin via Pechmann reaction has been done in the presence of some solid acid catalysts such as nafion, natural zeolite, amberlyst 15, ionic liquid, cation-exchanged resin, and Graphite/montmorillonite K10 [27, 28].

Along this work, we grafted an imidazolium-type ionic liquid 1-methyl-3-(3-trimethoxysilylpropyl) imidazolium chloride [MTMSPIm]Cl, which is pre-functionalized with a trimethoxysilylpropyl group on the surface of HY and NaY zeolite and characterized by XRD, FTIR, SEM, EDAX, BET and TGA methods. Then, inorganic/organic hybrid catalyst was used for the preparation of coumarins under different conditions via Pechmann reaction. Our study showed that the [MPIm]Cl@HY zeolite was very effective and could be recovered and reused several times without significant decrease in its efficiency (Scheme 1).

Experimental

All materials and solvents were purchased from Aldrich or Merck, while NaY Zeolite was purchased from Iran zeolite Company (Tehran, Iran). X-ray powder diffraction patterns were recorded on an X-ray diffractometer (Philips 1840) with radiation of Cu-Kα at room temperature. Energy-dispersive X-ray spectroscopy (Oxford X-max) and Fourier transform infrared (FTIR) spectroscopy were performed with a Galaxy series FTIR 5000 spectrometer. Thermogravimetric analyses (TGA and DTA) were performed using a Diamond Pyris TM, TG/DT 6300 instrument, from 30 to 600 °C at a heating rate of 10 °C/min under Ar flow. The field emission scanning electron microscope (FESEM) photographs of the samples were obtained using a Zeiss Sigma-VP FESEM instrument. BET apparatus (ASAP 2020 V3.04 E with adsorption of nitrogen at 76.34 °K) was used. 1HNMR spectra were obtained on a Bruker Avance 300 MHz spectrometer.

Preparation of 1-methyl-3-(3-trimethoxysilylpropyl) imidazolium chloride grafted on zeolite ([MTMSPIm]Cl@HY and NaY zeolite)

The synthesis of methyl propylimidazolium chloride immobilized to zeolite ([MPIm]Cl@HY) has been done in three main steps (Scheme 2).

In the first step, for the preparation of HY, 2 g of NaY zeolite was added to 200 mL of NH4Cl solution (0.002 M) and stirred for 24 h. Then, solid was filtered, washed with water and calcined at 300 °C for 5 h to remove NH3.

In the second step, 3-chloropropyltrimethoxysilane (CPTS, 1 mmol) was added to 1-methylimidazole (1.2 mmol) at 88 °C in dry toluene and refluxed for 30 h under nitrogen atmosphere. Then, the brown-colored paste was added to 0.4 g of HY zeolite in 50 mL dry toluene and refluxed for 24 h under nitrogen atmosphere. Finally, the solid powder was filtered and then dried and characterized by FTIR, XRD, BET, SEM and EDX, and TGA methods.

Synthesis of coumarin

In a typical reaction method, different amounts of prepared catalyst were added to a mixture of resorcinol derivative (1 mmol) and ethyl acetoacetate (1 mmol) in a round flask (250 mL) and stirred at 130 °C without the presence any solvent. The advancement of the reaction was considered by TLC. After completion of the reaction, the mixture of reaction was dissolved in hot toluene (3 × 5 mL) and then the catalyst was separated. Finally, the solvent was evaporated and then product was re-crystallized from a mixture of EtOH/H2O. In order to reuse the catalyst, it was washed with hot toluene and diethyl ether. All samples were evaluated via FTIR and NMR.

7-Hydroxy-4-methylcoumarin: 1H-NMR ± (DMSO d6): 2.65 (s, 3H, Me), 6.4 (s, 1H, olefinic CH), 6.9–7.7 (m, 3H, aromatic protons), OH is unobserved. 1530; 1H NMR (CDCl3) d 2.39 (3H, s), 3.28 (br s, 1H), 6.06 (s, 1H), 6.8 (s, 1H), 6.82 (d, 1H), 7.44 (d, 1H). 13C NMR (CDCl3): d¼161.7, 159.6, 152.6, 151.80, 128.9, 113.9, 112.5, 111.5, 109.7, 22.0. IR, ʋ (KBr disc): up to 3000 (OH broad), 1690 cm−1. Mp 183–185 °C.

Results and discussion

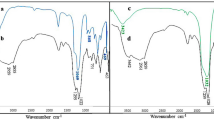

The FTIR spectra for pure and functionalized HY and NaY zeolite by [MPIm]Cl are shown in Fig. 1a–d, which exhibit characteristic bonds related to the asymmetric stretching of Al–O–Si at about 1018–1030 cm−1 and the symmetric stretching and bending frequency bands of Al–O–Si framework of zeolite at ca.747 and 439 cm−1, respectively [29]. The FTIR spectroscopy of [MPIm]Cl@HY and NaY (Fig. 1c, d) show the new broad absorption bands at 1573 cm−1 and 1458 cm−1 (C=N and C=C stretching) and the bands at 1956, 2955 cm−1 (aliphatic C–H stretching) and 3151 cm−1 (unsaturated C–H stretching), respectively which confirmed the presence of [MPIm]Cl in the surface of zeolite [24], which confirmed the presence of [MPIm]Cl in the surface of zeolite [30].

Scanning electron microscopy images of [MPIm]Cl@NaY and [MPIm]Cl@HY are shown in Fig. 2a–d. They indicate that the morphology of zeolite HY crystals without formation of separate amorphous phase is obtained by average size of about 400 nm (Fig. 2a, b). The functionalized zeolite morphology shows that some grooves and voids took place on the surface of zeolite, which may be the evidence for the overgrowth of the mesoporous phase in the sample (Fig. 2c, d). These results are the same as other results in the literature [31].

The EDX (Fig. 2e, f) and elemental analysis results in Table 1 for [MPIm]Cl@NaY and [MPIm]Cl@HY indicate that a Si/Al and C/N molar ratios are about 2.8 and 3, respectively. These results establish the presence of aluminosilicate and imidazolium agents in the samples [32].

N2 adsorption–desorption curves of NaY and HY zeolites functionalized by [MPIm]Cl are shown in Fig. 3a, b. The behavior of NaY and HY zeolite after introducing ionic liquid were typical for a microporous solid (type I) but in the two cases small hysteresis loop between (0.4 and 0.9) for P/P0. Brunauer–Emmett–Teller (BET) surface area and among the volume of samples summarize in Table 2. The reduction in surface area and pore volume related to pure NaY zeolite (SBET = 530.30 m2/g) confirms the presence of ionic liquid on the surface of zeolite. Also, the decreasing of surface area may be due to blocking of the zeolite pores and accessible cages functional groups and which mesophase after functional by [MPIm]Cl [27, 33]. The BJH shows the distribution of pore size of the related materials to be about 1–100 nm and confirms the presence of catalyst with broad size and two ranges.

Figure 4a–d shows the powder X-ray diffraction (XRD) patterns of pure NaY and HY zeolites after functionalized by [MPIm]Cl group. In the wide angle range, all samples show characteristic reflection related to Y zeolite, and after functionalized with [MPIm]Cl group, the intensity of reflection due to decreasing crystallinity of microporous phase was reduced. Also, low-angle range XRD patterns containing (100), (110) and (200) peaks with low intensity corresponding to hexagonal pore symmetry of MCM-41 (Fig. 5a, b) confirm the presence of mesoporous phase with small order which is also observed in the SEM and BET results [31].

Thermogravimetric analysis of [MPIm]Cl@NaY and [MPIm]Cl@HY is shown in Fig. 6a, b. Four weight loss steps took place in the TGA/DTA diagrams. In the first step, from 25 to 150 °C, 7.60% and 7.15% weight loss can be seen related to the physical desorption of the water molecules in the [MPIm]Cl@NaY and [MPIm]Cl@HY, respectively. The second step of about 220 °C in two cases is associated with the loss of free water molecules that are inside the pores or water molecules which by hydrogen bonding are linked with Si–O and Al–O groups and established. In the third step after 220 °C with 16.27% and 17.05% weight loss, the mass decline around 400 °C can be attributed to the decomposition of [MPIm]Cl agent. Also, the small endothermic peaks of about 330–370 °C in DTG can correspond to the dehydration of the hydroxyl groups inside the micro- and meso-phases [34].

Catalyst activity

In this section, we examined the acidic rule of catalyst for the preparation of coumarin compounds via Pechmann reaction. For optimization reaction conditions, firstly we considered the reaction of resorcinol (1 mmol) with ethyl acetoacetate (EAA, 1 mmol) in the presence of different amounts of synthesized catalyst (0.02–0.2 g) at 130 °C. The progress of the treatment was monitored by TLC (n-hexane/EAc) method. The results are demonstrated in Table 3, which show that the yield of reaction is trace without using catalyst and then catalyst plays a special role in the preparation of comarin. Entries 1–8 illustrate that with the increase in catalyst amount due to increasing acidic sites, the yield of reaction increased, but after 0.18 g (entry 8), no significant change can be observed. To consider the effect of catalyst nature, the before study shows the activities of some zeolites such as H-Y(US), H-ZSM-5 due to diffusion limitations in porous zeolite which are very low for preparation of coumarin from resorcinol; entries 15 and 16 confirmed this subject [35]. But result of catalyst shows with functionalized zeolite, a micro-/mesostructure was created based on other works; these kinds of catalysts with bigger porous size and higher stability are suitable for entering bulk molecule and increasing the yield and lifetime of the catalyst [36].

The entries 8 and 18 show that functionalized acidic form of zeolite (HY) is the better catalyst related to NaY zeolite; it seems combination of Brøonsted acid sites because introducing hydrogen group to zeolite and nucleophilic group to ILs increased catalyst activity.

In the next step, to consider the effect of solvents on the preparation of cumarin with functionalized zeolite by ionic liquid and yield in the optimum conditions, some polar solvents were used (entries 10–13). The result shows that with the use of polar solvent, the yield of reaction decreased compared to the solvent-free condition; it seems the interaction between solvents and ionic liquid deactivated ILs sites to formation of coumarin; in the case of water, this effect is very high. As described in the literature, in the wet media ionic liquids, hydrolytically unstable reagents are stabilized due to the fact that the water is in the form of isolated molecules rather than aggregates as found in the molecule of solvents [37,38,39]. To consider the importance of problems for green chemistry, the creation of solvent-free conditions for reaction is advantageous, which avoids the use of environmental hazardous and toxic solvents in this work.

Furthermore, in order to show the excellent catalytic activity, we studied the reaction of different activated phenols with [MTMSPIm]Cl@HY-Z catalyst EAA, which shows clean and afforded exclusive coumarins in high yields in relatively short times (Table 4).

Although the careful mechanism is not recognized, based on other work [26] a plausible mechanism to the formation of coumarin catalyzed by [MTMSPIm]Cl@zeolite is shown in Scheme 3. In the first step, [MTMSPIm]Cl@zeolite activated the hydroxyl of phenolic groups and protonated EAA and phenolic groups and then resorcinol made nucleophilic attack to the carbonyl group. The transesterification occurred between reactants at two sites, and [MTMSPIm]Cl@zeolite absorbed proton again. In the next steps, EtOH and H2O removing and coumarin derivatives were synthesized. The catalytic activity of micro/mesostructure [MTMSPIm]Cl@zeolite comprised with other reported heterogeneous catalysts for combination of resorcinol and ethyl acetoacetate which prepared coumarin that shows in this work the condition of reaction (amount of catalyst, yields, time and temperature of reaction) are very mild and eco-friendly due to solvent free condition (Table 5).

As expected, the Pechmann reaction strongly depends on the temperature. If the reaction temperature was reduced from 130 to 100 and 80 °C, the yield of cumarin decreased even after 5 h of reaction time to over 0.18 g of [MTMSPIm]Cl@HY-Z from 96.5 to 53 to 33.5%, respectively.

One of the great advantages of this catalyst is simple separation by using filtration, which can easily lead to the facile reusability of the catalyst. To study the reusability of the [MPIm]Cl@HY, the filtered catalyst was washed with hot toluene and diethyl ether and then reused on the optimum condition (resorcinol (1 mmol), catalyst (0.18 g), time 150 min and temperature 130 °C) without obvious loss of catalytic activity. The results are presented in Fig. 7, and also the XRD and FTIR show no change (Fig. 8a, b) in the crystallinity of [MPIm]Cl@HY zeolite, which confirm the high stability for micro-/mesoporous structure catalyst.

Conclusion

In conclusion, an extremely efficient method has been developed for the preparation of immobilized [MPIm]Cl in NaY and HY zeolite, which is characterized by different methods for confirmation of a micro-/mesoporous structure. The micro-/mesoporous structure of zeolite has a number of advantages with respect to both zeolites and mesoporous materials. This kind of catalyst improves the reactant molecules diffusion inside the crystal, increases availability of active sites, reduces diffusion path of the reactant and coke precursor molecules and mesoporous materials with higher hydrothermal stability and acidity. The micro-/meso[MPIm]Cl@zeolite as a recyclable catalyst under solvent-free conditions with an environmentally benign nature was used for the synthesis of coumarins via Pechmann reaction. The high yield and simple and clean experimental way confirmed that the combination of tunable pore and acid sites in zeolite and nucleophilic group of ILs is useful for organic reaction. Also, the result show that hierarchical catalyst can be used sometimes without significant change in yield and structure of the catalyst.

References

H. Olivier-Bourbigou, L. Magna, D. Morvan, Appl. Catal. A Gen. 373(1–2), 1–56 (2010)

B. Karimi, D. Enders, Org. Lett. 8(6), 1237–1240 (2006)

J. Davarpanah, A.R. Kiasat, J. Nanoanalysis. 4(4), 299–306 (2017)

S. Sadjadi, M.M. Heravi, RSC Adv. 7(49), 30815–30838 (2017)

D.W. Kim, D.Y. Chi, Angew. Chem. Int. Ed. 43(4), 483–485 (2004)

M. Zendehdel, F. Zamani, H. Khanmohammadi, Micropor. Mesopor. Mater. 225, 552–563 (2016)

M. Zendehdel, M.A. Bodaghifard, H. Behyar, Z. Mortezaei, Micropor. Mesopor. Mater. 266, 83–89 (2018)

J. Jin, C. Peng, J. Wang, H. Liu, X. Gao, C. Xu, Ind. Eng. Chem. Res. 53(8), 3406–3411 (2014)

Z.M. Li, Y. Zhou, D.J. Tao, W. Huang, X.S. Chen, Z. Yang, RSC Adv. 4(24), 12160–12167 (2014)

F. Hoffmann, M. Cornelius, J. Morell, M. Froba, Angew. Chem. Int. Ed. 45(20), 3216–3251 (2006)

B. Kaur, R. Srivastava, Electrochim. Acta. 133, 428–439 (2014)

N. Ndiege, R. Raidoo, M.K. Schultz, S. Larsen, Langmuir 27, 2904–2909 (2011)

D. Yuan, D. He, S. Xu, Z. Song, M. Zhang, Y. Wei, Y. He, Sh Xu, Z. Liu, Y. Xu, Micropor. Mesopor. Mater. 204, 1–7 (2015)

M. Loncaric, D. Gaso-Sokac, S. Jokic, M. Molnar, Biomolecules 10(1), 151 (2020)

G.J. Fan, W. Mar, M.K. Park, E.W. Choi, K. Kim, S. Kim, Bioorg. Med. Chem. Lett. 11(17), 2361–2363 (2001)

G.P. Romanelli, D. Bennardi, D.M. Ruiz, G. Baronetti, H.J. Thomas, G.C. Autino, Tetrahedron Lett. 45(48), 8935–8939 (2004)

S. Sethna, R. Phadke, Org. React. 7, 1–58 (2004)

G. Jones, Org. React. 15, 204–599 (2004)

R.H. Vekariya, H.D. Patel, Synth. Commun. 44(19), 2756–2788 (2014)

R.L. Shriner, Org. React. 1, 1–37 (2004)

J.K. Augustine, A. Bombrun, B. Ramappa, C. Boodappa, Tetrahedron Lett. 53(33), 4422–4425 (2012)

A. Maercker, Org. Synth. 14, 270–291 (1934)

Y.J. Jang, S.E. Syu, Y.J. Chen, M.C. Yang, W. Lin, Org. Biol. Chem. 10(4), 843–847 (2012)

K.C. Majumdar, P. Debnath, P.K. Maji, Tetrahedron Lett. 48(30), 5265–5268 (2007)

M.C. Laufer, H. Hausmann, W.F. Holderich, J. Catal. 218, 315–320 (2003)

M. Opanasenko, M. Shamzhy, J. Cejka, ChemCatChem. 5(4), 1024–1031 (2013)

W. Li, F. Li, H. Wang, M. Liao, P. Li, J. Zheng, C. Tu, R. Li, Mol. Catal. 480, 110642 (2020)

B.M. Reddy, M.K. Patil, P. Lakshmimana, J. Mol. Catal. A Chem. 256(1–2), 290–294 (2006)

I.I. Ivanova, E.E. Knyazeva, Chem. Soc. Rev. 42(9), 3671–3688 (2013)

J. Perez-Ramírez, D. Verboekend, A. Bonilla, S. Abello, Adv. Funct. Mater. 19(24), 3972–3979 (2009)

M. Zendehdel, A. Mobinikhaledi, Z. Mortezaei, J. Iran Chem. Soc. 12, 283–292 (2015)

C.K. Modi, P.M. Trivedi, J. Chem. Micropor. Mesopor. Mater. 155, 227–232 (2012)

S. Wang, B. He, R. Tian, C. Sun, R. Dai, X. Li, X. Wu, X. An, X. Xie, J. Colloid Interface Sci. 527, 339–345 (2018)

L.H. Chen, X.Y. Li, J.C. Rooke, Y.H. Zhang, X.Y. Yang, Y. Tang, F.S. Xiao, B.L. Su, J. Mater. Chem. 22(34), 17381–17403 (2012)

E. Amigues, C. Hardacre, G. Keane, M. Migaud, M.O. Neill, Chem. Commun. 1, 72–74 (2005)

S. Doherty, P. Goodrich, C. Hardacre, V. Parvulescu, C. Paun, Adv. Synth. Catal. 350(2), 295–302 (2008)

S. Rostamnia, H. Xin, J. Mol. Liq. 195, 30–34 (2014)

S.P. Chavan, K. Shivasankar, R. Sivappa, R. Kale, Tetrahedron Lett. 43(47), 8583–8586 (2002)

S. Frère, V. Thiéry, T. Besson, Tetrahedron Lett. 42(15), 2791–2794 (2001)

V. Singh, J. Singh, P. Kaur, G.L. Kad, J. Chem. Res. 2, 58 (1997)

S.S. Bahekar, D.B. Shinde, Tetrahedron Lett. 45, 7999–8001 (2004)

R.A. Gibbs, S.K. De, Synthesis 36, 1231–1233 (2005)

R.S. Keri, K.M. Hosamani, H.R.S. Reddy, Catal. Lett. 131(1–2), 321–327 (2009)

B. Rajitha, V.N. Kumar, J. Venu Madhav, P. Someshwar, Arkivoc 12, 23–27 (2006)

J. Martínez, L. Sanchez, F.J. Perez, V. Carranza, F. Delgado, L. Reyes, R. Miranda, J. Chem. (2016) . https://doi.org/10.1155/2016/4678107

S. Sudha, J. Mol. Catal. A Chem. 291, 22–29 (2008)

K. Shanmugapriya, M. Palanichamy, V.V. Balasubramanian, V. Murugesan, Micropor. Mesopor. Mater. 95(1–3), 272–278 (2006)

N.R. Radwan, M. Hagar, T.H. Afifi, F. Al-wadaani, R.M. Okasha, Catalysts 8(1), 36 (2018)

S. Das, A. Majee, A. Hajra, Green Chem. Lett. Rev. 4(4), 349–353 (2011)

V. Singh, S. Kaur, V. Sapehiyia, J. Singh, G.L. Kad, Catal. Commun. 6, 57–60 (2005)

V. Soares, M. Alves, E. Souza, I. Pinto, J. Rubim, Int. J. Mol. Sci. 8, 392–398 (2007)

Acknowledgements

Thanks to the Iranian Nanotechnology Innovation Council and the Research Council of Arak University and Center of Excellence in the Chemistry Department of Arak University and zeolite and porous materials committee of Iranian Chemical Society for supporting of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zendehdel, M., Khaghaninejad, S., Tavakoli, F. et al. Immobilized ionic liquid on the zeolite: its characterization and catalytic activity in the synthesis of coumarins via Pechmann reaction. J IRAN CHEM SOC 17, 2555–2565 (2020). https://doi.org/10.1007/s13738-020-01950-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-020-01950-x