Abstract

In the present work, the heterogenization of MoO2(acac)2 onto imine functionalized zeolite beta is reported. The catalyst was characterized by Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), scanning electron microscopy-energy dispersive X-ray analysis (SEM–EDX), BET surface area measurements, CHN microanalysis and inductively coupled plasma (ICP). The activity of the catalyst was assessed in the synthesis of octahydroquinazolinone derivatives under reflux condition and microwave irradiation. The catalyst can be recycled and reused five times without significant loss of activity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Multi-component reactions (MCRs), due to their productivity, simple procedures, atom economy, high selectivity and facile execution, are one of the best tools in combinatorial chemistry [1, 2]. The synthesis of dihydropyrimidinones (DHPMs), has attracted keen interest from many researchers for their widespread biological and therapeutic properties such as antibacterial, antiviral, antihypertensive, antitumor effects, anti-inflammatory and calcium channel blockers [3,4,5]. Octahydroquinazolinone is one of the fused derivatives of DHPMs which exhibit potential antibacterial activity against many kinds of bacteria including Staphylococcus aureus, Escherichia coli and Pseudomonas aeruginosa [6]. Moreover, calcium antagonist and antimicrobial activity of these heterocyclic compounds is reported [7, 8]. The conventional synthesis of octahydroquinazolinones involves the one pot three-component Biginelli condensation of cyclic β-diketones with aromatic aldehydes and urea. Some catalysts have been used to perform this transformation, including concentrated HCl [7, 8], concentrated H2SO4 [9], trimethylsilyl chloride [10], Nafion-H [11], ionic liquid [12], silica sulfuric acid [13], SiO2-NaHSO4 [14] and Cu/SiO2 [15]. However, despite the potential utility of aforementioned methods, some of them are associated with several disadvantages such as long reaction time, drastic reaction condition, difficult catalyst recovery, low yields of products and tedious workup. These drawbacks can be overcome by using microwave irradiation instead of traditional heating. Microwave-assisted organic synthesis (MAOS) is a powerful technique to accelerate organic chemical transformations [16,17,18]. The remarkable features of this approach are enhanced reaction rates, formation of purer products in high yields and easier work-up procedures than traditional methods. Furthermore, the conjunction of this non-classical activation with solvent-free condition makes it as an eco-friendly green approach [19, 20]. A literature survey revealed that few methods have been reported for the synthesis of octahydroquinazolinone derivatives under microwave condition [21,22,23,24,25]. Molybdenum-based heterogeneous catalysts have been effectively used in oxidative transformations [26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42]. Recently, Mishra et al. reported the synthesis of octahydroquinazolinone derivatives using MoO3–ZrO2 nanocomposite as an effective heterogeneous catalyst [23]. In this context, zeolite beta with superior physicochemical properties such as large pore size, high silicon to aluminum ratio, high acid strength and thermal stability could be a good support for the immobilization of molybdenum species. In continuation of our recent work [43], herein anchoring of MoO2(acac)2 onto zeolite beta through Schiff base condensation reaction between 3-aminopropyltrethoxysilane (APTES) functionalized zeolite beta and 2-pyridine carbaldehyde is reported (Scheme 1). The resultant material has been examined as a catalyst for the synthesis of octahydroquinazolinones (4a–4r) (Scheme 2).

Immobilization of molybdenum onto zeolite beta through a functionalization of zeolite beta with 3-aminopropyltrethoxysilane (APTES), b schiff base condensation between APTES functionalized zeolite beta and 2-pyridine carbaldehyde, c attachment of molybdenum complex onto imine-functionalized zeolite beta

Experimental

Materials and apparatus

All solvents and organic reagents were purchased from Merck and used without further purification. MoO2(acac)2 was purchased from Aldrich. The powder X-ray diffraction (XRD) patterns of the samples were recorded on a Philips PW1840 diffractometer with Cu-Kα radiation (1.5418 Å), in the range of 4–70° at a scan rate of 0.1° 2θ/s. SEM–EDX analyses were done on a LEO 1430 VP instrument. The molybdenum content was measured by inductively coupled plasma (ICP; Labtam 8440 plasma lab). The specific surface area based on nitrogen physisorption was determined by Sibata surface area apparatus 1100. Microwave irradiation was performed in a LBP125 microwave oven. FT-IR spectra were recorded on a Perkin-Elmer model spectrum one using KBr plates in the range of 400–4000 cm−1. 1H NMR spectra were recorded on Bruker Advance spectrometer at 500 MHz, by using CDCl3 or DMSO-d6 as solvent and TMS as internal reference. Melting points were measured on a BUCHI Melting point B-540 apparatus and are uncorrected. Elemental analysis (CHN) was performed on Carlo-Erba EA1110 CNNO-S instrument.

Catalyst preparation

The heterogeneous molybdenum catalyst (Mo@imine-Z) was prepared according to the following five-step procedure (Scheme 1).

Synthesis of zeolite beta: Z

Zeolite beta was prepared according to the reported method [44].

Preparation of zeolite H-beta: Z-H

Activation of zeolite was carried out according to the literature procedure [45].

Preparation of APTES functionalized zeolite H-beta: APTES@Z

A post-synthetic modification method was used to prepare aminopropylated zeolite beta (APTES@Z) as per reported procedure [46]. The result of CHN elemental analysis indicated that there is 0.34 mmol/g of nitrogen, which imply that organoamine was successfully incorporated onto the zeolite [43].

Grafting of 2-pyridine carbaldehyde on aminopropylatedzeolite H-beta: imine@Z

Imine-functionalized zeolite H-beta (imine@Z) was prepared according to the reported method [47]. The loading of pyridine moiety onto the zeolite is 0.14 mmol/g, based on CHN analysis [43].

Immobilizing of MoO2(acac)2 onto imine-functionalized zeolite H-beta: Mo@imine-Z

A mixture of imine-functionalized zeolite H-beta (2.0 g) and MoO2(acac)2 (0.113 g, 0.5 mmol) in methanol (20 mL) was stirred under reflux conditions for 24 h. Then, the solid was centrifuged and Soxhlet extracted with ethanol and acetone to remove the remaining non-supported complex and dried at 60 °C overnight, leading to molybdenum anchored zeolite H-beta (2.04 g) as a pale yellow powder. The metal loading in the catalyst was found to be 1.70 wt% based on ICP analysis.

Typical procedure for the synthesis of octahydroquinazolinones

Method A: reflux conditions

To a mixture of dimedone (1 mmol), aldehyde (1 mmol) and urea (1.5 mmol), catalyst (10 wt% based on all substrates) was added. The mixture was stirred for appropriate time in ethanol (5 mL) under reflux condition. After the completion of the reaction (as evidenced by TLC) and evaporation of ethanol, ethyl acetate (20 mL) was added and the mixture was centrifuged to separate the catalyst. The filtrate was concentrated and the crude solid product was recrystallized from ethanol to afford pure product. The recycled catalyst was washed with ethyl acetate and acetone. After being dried at 60 °C, it can be reused without further purification. All of the products were known and identified by comparison of their melting points and spectral data with those reported in the literature.

Method B: microwave irradiation

In an Erlenmeyer flask, a mixture of dimedone (1 mmol), aldehyde (1 mmol) and urea (1.5 mmol), were mixed with catalyst (10 wt% based on all substrates). The reaction mixture was irradiated by microwave at 360 W for appropriate time. After the completion of the reaction (as was monitored by TLC), the reaction mixture was cooled and diluted with ethyl acetate (20 mL) and the same workup as method A gave pure product and the catalyst was recovered and reused for successive reactions.

Selected characterization data

7,7-Dimethyl-4-phenyl-4,6,7,8-tetrahydro-1H,3H-quinazoline-2,5-dione (4a)

mp = 290–292 °C; IR (KBr): υmax = 3385 and 3255 (NH), 3126 (CH), 2939 (CH), 1697 (C=O, ring), 1616 (C=O, urea), 1454 (C=C) cm−1; 1H NMR (DMSO-d6, 500 MHz): δ = 0.84 (s, 3H, CH3), 0.97 (s, 3H, CH3), 1.98 (d, 1H, J = 16.1 Hz, CH2), 2.14 (d, 1H, J = 16.1 Hz, CH2), 2.22 (d, 1H, J = 17.3 Hz, CH2), 2.36 (d, 1H, J = 17.3 Hz, CH2), 5.10 (d, 1H, J = 2.48 Hz, CH), 7.15–7.19 (m, 3H, Ar–H), 7.25 (t, 2H, J = 7.6 Hz, Ar–H), 7.69 (s, 1H, NH), 9.39 (s, 1H, NH) ppm.

Results and discussion

Characterization of the heterogeneous catalyst

FT-IR spectroscopy was employed to examine the covalent grafting steps (Fig. 1). All spectra showed a broad band around 3430 cm−1 due to the O–H stretching vibrations of surface silanol groups and remaining physisorbed water, a peak about 1630 cm−1 corresponding to the bending vibrations of adsorbed water, a strong band about 1080 cm−1 with a shoulder at 1220 cm−1 arising from asymmetric Si–O–Si stretching vibrations, a band around 790 cm−1 assigned to symmetric Si–O–Si stretching and a band around 560 cm−1 assigned to Si–O–Si bending modes. Fig. 1b shows the Z-H spectrum. The band at 953 cm−1 corresponding to the bending vibrations of non-condensed silanol groups (Si–O–H) was observed after activation followed by calcination of zeolite, implying that the activation step is successful. The APTES post-grafting is confirmed by the appearance of new peaks at about 2930 and 1384 cm−1 which are assigned to the stretching and bending vibrations of CH2 groups respectively and a weak broad band around 1580 cm−1 due to N–H bending vibrations of amine functional group (Fig. 1c). Meanwhile, the peak at 953 cm−1 related to the bending vibration of Si–OH was disappeared in the FT-IR spectrum of APTES@Z, indicating that almost all hydroxyl groups were reacted with amino groups of APTES. Interestingly, after treatment with 2-pyridinecarbaldehyde, one change in the spectra was observed, the O–H band at 1630 cm−1 merged with a new broad band centered at 1650 cm−1 attributable to the C=N stretching of imine generated through Schiff base condensation between amine group of APTES and carbonyl group of 2-pyridinecarbaldehyde. Thus, it is evident that 2-pyridinecarbaldehyde functional group is chemically bonded to the surface of functionalized zeolite (Fig. 1d). In the IR spectra of the MoO2(acac)2, there are two mid-intensity bands at 1585 and 1501 cm−1, which are assigned to stretching vibration of C=O and C=C bonds, respectively and two bands at 904 and 933 cm−1 attributed to the stretching modes of terminal Mo=O bonds (Fig. 1e). Upon immobilization of molybdenum onto imine@Z, the C = N band shifted to lower wave number (1627 cm−1) indicating successful coordination of the imine nitrogen to the metal center (Fig. 1f) (Scheme 1) [32, 41, 47]. In addition, the appearance of two bands at 911 and 933 cm−1 could be ascribed to the stretching vibrations of molybdenum oxide (Mo=O). This could be related to replacement of one of the acac ligands of this complex with supported bidentate ligands. The weakness of the bands at 911 and 933 cm−1 corresponding to the Mo=O terminal bonds, is due to the relatively low Mo loading. (Scheme 1) [37,38,39,40,41].

FT-IR spectra of a zeolite beta (Z), b Activated zeolite beta (zeolite H-beta, Z-H), c APTES functionalized zeolite beta (APTES@Z), d imine-functionalized zeolite beta (imine@Z), e molybdenum complex (MoO2(acac)2), f Molybdenum complex anchored onto imine-functionalized zeolite beta (Mo@imine-Z). The FT-IR spectra of the samples were recorded in transmission mode with a Perkin-Elmer model spectrum one spectrophotometer using KBr plates. The samples were ground with KBr and compressed into a pellet and placed into an IR cell. The spectra were recorded at room temperature after strip of background in the region of 400–4000 cm−1 with a resolution of 4 cm−1 and instrument acquiring 16 scans per sample

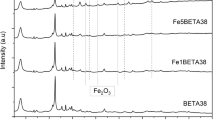

The structural features of zeolite beta before and after functionalization were checked by XRD measurements (Fig. 2). The characteristic peaks of zeolite beta at 2θ values of 7.8°, 21.5°, 22.5°, 25.5°, 26.8°, 29.5°, 30.6°, 34.6° and 43.8° were observed in the XRD patterns. These peaks are in good agreement with the zeolite beta data [44]. The XRD patterns clearly show that the crystallinity of zeolite matrix retained after calcination and grafting treatment. Upon the treatment for anchorage of molybdenum, the intensity of main reflection was somehow decreased and the diffraction lines were broadened. No distinct XRD diffraction peak for molybdenum can be detected, implying that the metal has been homogeneously dispersed over the zeolite surfaces.

X-ray diffraction patterns of a zeolite beta (Z), b activated zeolite beta (zeolite H-beta, Z-H), c APTES functionalized zeolite beta (APTES@Z), d imine-functionalized zeolite beta (imine@Z), e molybdenum complex anchored onto imine-functionalized zeolite beta (Mo@imine-Z); Powder XRD analysis was conducted on a Philips PW1840 diffractometer operated at 40 kV and 40 mA using Cu-Kα radiation (λ = 1.5418 Å), over 2θ range 4–70° at a scan rate of 0.1° 2θ/s. The scan was performed at room temperature

The surface-morphology of the synthesized zeolite and the prepared catalyst were investigated by using a scanning electron microscope and the corresponding images are presented in Fig. 3. The crystallites of the unloaded zeolite, have a very well defined spherical grain with a crystal size of about 0.5 μm (Fig. 3a). After supporting the molybdenum complex on zeolite, the particle size however, reduced and smaller particles were obtained (Fig. 3b). The particle size was evaluated around 30.75 nm from the XRD pattern according to Scherrer equation. The particle size obtained by SEM is higher than the corresponding crystallite size. This difference can be attributed to the aggregation of the particles.

The specific surface area of un-functionalized zeolite beta was 550 m2 g−1 which upon functionalization with APTES reduced to 410 m2 g−1. This reduction in surface area confirmed the successful grafting of organics into the void space of zeolite [43]. In the EDX spectra of catalyst (Mo@imine-Z), the small peak for molybdenum clearly indicates that molybdenum is attached onto the surface of zeolite beta (Fig. 4).

Catalytic activity

To find out the optimum reaction condition, the condensation reaction between benzaldehyde (1 mmol), dimedone (1 mmol) and urea (1.5 mmol) in the presence of Mo@imine-Z under reflux condition was chosen as a model reaction (Scheme 2). The obtained results are presented in Table 1. Initially, to determine the amount of catalyst, this model reaction was carried out in the presence of 5, 10, 15 and 20 wt% of catalyst. The best results were obtained by using 10 wt% of the catalyst (Table 1, entry 2). In the absence of the catalyst very low yield was obtained (Table 1, entry 5). To examine the effect of unsupported catalyst, the same model reaction was performed in the presence of molybdenum complex (10 wt%) in ethanol, and high yield of product was obtained (Table 1, entry 6). In order to evaluate the role of zeolite support in the reaction, we carried out the model reaction by using 10 wt% of zeolite as catalyst. The reaction was not completed even after 6 h (Table 1, entry 7). The same model reaction in the presence of 10wt% of the catalyst was performed in different solvents to assess the effect of solvent on the reaction. From the economical and environmental point of view, ethanol was chosen as the best solvent for all further reactions. To improve efficiency, we carried out this reaction under microwave irradiation and solvent free condition. In this context, the effect of different microwave power settings such as 180, 360, 540 and 720 W was also investigated. The best results were obtained by using microwave power of 360 W and 10 wt% of catalyst (Table 1, entry 13).

The generality of this process was demonstrated by the wide range of substituted aryl aldehydes to synthesize the corresponding products in good yields (Table 2). Aromatic aldehydes carrying different functional groups were subjected to the reaction and in all cases the desired product was obtained in good yields (4a–4k). These results are summarized in Table 2 (entries 1–11). It was shown that the aromatic aldehydes bearing electron-withdrawing groups reacted faster than those bearing electron-donating groups as would be expected. Encouraged by these results, we expanded the scope of the present method by replacement of urea with thiourea to obtain the corresponding octahydroquinazolinone derivatives (4l–4r). It was observed that the reaction of aromatic aldehydes with thiourea proceeded at a lower rate (Table 2, entries 12-18). As shown in Table 2, microwave affords the desired products in excellent yields in rather short times.

A plausible mechanism for the heterogenized molybdenum catalyzed synthesis of octahydroquinazolinone is presented in Scheme 3. As shown, prior activation of the carbonyl group of aldehyde by molybdenum to give intermediate I, followed by condensation with urea and dehydration provides iminium intermediate III. The Michael reaction between the enolate form of dimedone and intermediate III gives intermediate IV which subsequently cyclizes to octahydroquinazolinone with expulsion of water (Scheme 3).

In order to show the merits of the present work, we have tabulated some of the literature results for the synthesis of 7,7-dimethyl-4-phenyl-4,6,7,8-tetrahydro-1H,3H-quinazoline-2,5-dione (4a) in Table 3, which shows that our method is superior to the previously reported methods in term of yields and reaction times.

Catalyst reusability

The reusability of a catalyst is an important factor for its upgrade use. Reusability of our catalyst was investigated in the synthesis of octahydroquinazolinone by choosing the reaction between dimedone, benzaldehyde and urea under solvent free condition as model reaction. The catalyst was separated after each run, washed with ethyl acetate and acetone, dried in an oven at 60 °C and reused in subsequent runs. The results show that the catalyst can be reused in subsequent reactions without significant decrease in activity even after five runs (Fig. 5). ICP analysis showed 10% decrease in the Mo content on the catalyst before and after five run use. The decrease in activity can be attributed to the metal leaching.

Reusability of the catalyst was investigated in the synthesis of 7,7-dimethyl-4-phenyl-4,6,7,8-tetrahydro-1H,3H-quinazoline-2,5-dione (4a). A mixture of dimedone (1 mmol), benzaldehyde (1 mmol) and urea (1.5 mmol), were mixed with catalyst (33.6 mg). The reaction mixture was irradiated by microwave at 360 W for 3 min under solvent free condition. After completion of the reaction (as was indicated by TLC), the reaction mixture was cooled and diluted with ethyl acetate (20 mL). The mixture was centrifuged to separate the catalyst. The filtrate was concentrated and the crude solid product was recrystallized from ethanol to afford pure product. The separated catalyst was washed thoroughly with ethyl acetate and acetone, dried in an oven at 60 °C and reused in subsequent runs without further purification. The catalyst can be reused in subsequent reactions without significant loss in activity even after five runs

Conclusion

A simple, efficient and green procedure for the synthesis of octahydroquinazolinones using molybdenum heterogeneous catalyst under solvent-free condition has been developed. Within the framework of green chemistry this method offers several significant advantages such as non-hazardous experimental condition, short reaction times, atom economy, easy work-up, mild reaction condition, use of stoichiometric amount of catalyst and reusability of catalyst.

References

Domling A (2006) Recent developments in isocyanide based multicomponent reactions in applied chemistry. Chem Rev 106:17–89

Arndtsen BA (2009) Metal-catalyzed one-step synthesis: towards direct alternatives to multistep heterocycle and amino acid derivative formation. Chem Eur J 15:302–313

Kappe CO (2000) Biologically active dihydropyrimidones of the Biginelli-type: a literature survey. Eur J Med Chem 35:1043–1052

Ashok M, Holla BS, Kumari NS (2007) Convenient one pot synthesis of some novel derivatives of thiazolo[2,3-b]dihydropyrimidinone possessing 4-methylthiophenyl moiety and evaluation of their antibacterial and antifungal activities. Eur J Med Chem 42:380–385

Kwon OW, Moon E, Chari MA, Kim TW, Kim AJ, Lee P, Ahn KH, Kim SY (2012) A substituted 3,4-dihydropyrimidinone derivative (compound D22) prevents inflammation mediated neurotoxicity; role in microglial activation in BV-2 cells. Bioorg Med Chem Lett 22:5199–5203

Kidwai M, Saxena S, Khan MKR, Thukral SS (2005) Synthesis of 4-aryl-7,7-dimethyl-1,2,3,4,5,6,7,8 octahydroquinazoline-2-one/thione-5-one derivatives and evaluation as antibacterials. Eur J Med Chem 40:816–819

Yarim M, Sarac S, Kilic FS, Erol K (2003) Synthesis and in vitro calcium antagonist activity of 4-aryl-7,7-dimethyl/1,7,7-trimethyl-1,2,3,4,5,6,7,8-octahydroquinazoline-2,5-dione derivatives. IlFarmaco 58:17–24

Ladani NK, Patel MP, Patel RG (2009) An efficient three component one-pot synthesis of some new octahydroquinazolinone derivatives and investigation of their antimicrobial activities. ARKIVOC 7:292–302

Hassani Z, Islami MR, Kalantari M (2006) An efficient one-pot synthesis of octahydroquinazolinone derivatives using catalytic amount of H2SO4 in water. Bioorg Med Chem Lett 16:4479–4482

Kantevari S, Bantu R, Nagarapu L (2006) TMSCl mediated highly efficient one-pot synthesis of octahydroquinazolinone and 1,8-dioxo-octahydroxanthene derivatives. ARKIVOC 16:136–148

Lin H, Zhao Q, Xu B, Wang X (2007) Nafion-H catalyzed cyclocondensation reaction for the synthesis of octahydroquinazolinone derivatives. J Mol Catal A 268:221–226

Khurana JM, Kumar S (2010) Ionic liquid: an efficient and recyclable medium for the synthesis of octahydroquinazolinone and biscoumarin derivatives. Monatsh Chem 141:561–564

Mobinikhaledi A, Foroughifar N, Khodaei H (2010) Synthesis of octahydroquinazolinone derivatives using silica sulfuric acid as an efficient catalyst. Eur J Chem 1:291–293

Azzam SHS, Siddekha A, Nizam A, Pasha MA (2012) SiO2-NaHSO4 as an efficient reusable heterogeneous catalyst for the one-pot three-component synthesis of octahydro-quinazolin-2,5-diones in water. Chin J Catal 33:677–680

Heravi MM, Karimi N, Hamidi H, Oskooie HA (2013) Cu/SiO2:a recyclable catalyst for the synthesis of octahydroquinazolinone. Chin Chem Lett 24:143–144

Lidstrom P, Tierney J, Wathey B, Westman J (2001) Microwave assisted organic synthesis: a review. Tetrahedron 57:9225–9283

Kappe CO, Stadler A (2005) Microwaves in organic and medicinal chemistry. Wiley, Weinheim

Loupy A (2002) Microwaves in organic synthesis. Wiley, Weinheim

Ranu BC, Hajra A, Jana U (2000) Microwave assisted simple synthesis of quinolones from anilines and alkyl vinyl ketones on the surface of silica gel in the presence of indium(III)chloride. Tetrahedron Lett 41:531–533

Quiroga J, Cisneros C, Insuasty B, Abonia R, Nogueras M, Sanchez A (2001) A regiospecific three-component one-step cyclocondensation to 6-cyano-5,8-dihydropyrido[2,3-d]pyrimidin-4(3H)-ones using microwaves under solvent-free conditions. Tetrahedron Lett 42:5625–5627

Niralwad KS, Shingate BB, Shingare MS (2010) Microwave-assisted one-pot synthesis of octahydroquinazolinone derivatives using ammonium metavanadate under solvent-free condition. Tetrahedron Lett 51:3616–3618

Badadhe PV, Chate AV, Hingane DG, Mahajan PS, Chavhan NM, Gill CH (2011) Microwave-assisted one-pot synthesis of octahydroquinazolinone derivatives catalyzed by thiamine hydrochloride under solvent-free condition. J Korean Chem Soc 55:936–939

Samantaray S, Mishra BG (2011) Combustion synthesis, characterization and catalytic application of MoO3–ZrO2 nanocomposite oxide towards one pot synthesis of octahydroquinazolinonesJ. Mol Catal A Chem 339:92–98

Jadhav S, Anandgaonker PL, Kulkarni G, Gaikwad ST, Rajbhoj AS (2014) Microwave-assisted one-pot synthesis of octahydroquinazolinone derivatives using molybdenum oxide nanoparticles in solvent-free condition. J Clust Sci 25:1389–1399

Kuraitheerthakumaran A, Pazhamalai S, Manikandan H, Gopalakrishnan M (2014) J Saudi Chem Soc 18:920–924

Arnold U, Cruz RSD, Mandelli D, Schuchardt U (2001) Activity, selectivity and stability of metallosilicates containing molybdenum for the epoxidation of alkenes. J Mol Catal A 165:149–158

Fuerte A, Iglesias M, Sanchez F, Corma A (2004) Chiral dioxomolybdenum(VI) and oxovanadium(V) complexes anchored on modified USY-zeolite and mesoporous MCM-41 as solid selective catalysts for oxidation of sulfides to sulfoxides or sulfones. J Mol Catal A 211:227–235

Reyes P, Borda G, Gnecco J, Rivas BL (2004) MoO2(acac)2 immobilized on polymers as catalysts for cyclohexene epoxidation: effect of the degree of crosslinking. J Appl Polym Sci 93:1602–1608

Wang G, Feng L, Luck RL, Evans DG, Wang Z, Duan X (2005) Sol-gel synthesis, characterization and catalytic property of silicas modified with oxomolybdenum complexes. J Mol Catal A 241:8–14

Sakthivel A, Zhao J, Raudaschl-Sieber G, Hanzlik M, Chiang AST, Kuhn FE (2005) Heterogenization of chiral molybdenum(VI)dioxo complexes on mesoporous materials and their application in catalysis. Appl Catal A 281:267–273

Bruno SM, Fernandes JA, Martins LS, Goncalves IS, Pillinger M, Ribeiro-Claro P, Rocha J, Valente AA (2006) Dioxomolybdenum(VI) modified mesoporous materials for the catalytic epoxidation of olefins. Catal Today 114:263–271

Masteri-Farahani M, Farzaneh F, Ghandi M (2006) Synthesis and characterization of molybdenum complexes with bidentate Schiff base ligands within nanoreactors of MCM-41 as epoxidation catalysts. J Mol Catal A 248:53–60

Bakala PC, Briot E, Salles L, Bregeault JM (2006) Comparison of liquid-phase olefin epoxidation over MoOx inserted within mesoporous silica (MCM-41, SBA-15) and grafted onto silica. Appl Catal A 300:91–99

Tangestaninejad S, Moghadam M, Mirkhani V, Mohammadpoor-Baltork I, Ghani K (2008) MoO2(acac)2 supported on silica functionalized imidazole as a highly efficient and reusable catalyst for alkene epoxidation with tert-BuOOH. Inorg Chem Commun 11:270–274

Gomes AC, Bruno SM, Gago S, Lopes RP, Machado DA, Carminatti AP, Valente AA, Pillinger M, Goncalves IS (2011) Epoxidation of cyclooctene using soluble or MCM-41-supported molybdenum tetracarbonylepyridylimine complexes as catalyst precursors. J Organomet Chem 696:3543–3550

Farias M, Martinelli M, Rolim GK (2011) Immobilized molybdenum acetylacetonate complex on montmorillonite K-10 as catalyst for epoxidation of vegetable oils. Appl Catal A 403:119–127

Sharma RK, Pandey A, Gulati S (2012) Silica-supported molybdenum complex: a novel, selective and reusable organic–inorganic hybrid catalyst for eco-friendly oxidation of sulfides and olefins. Polyhedron 45:86–93

Esnaashari F, Moghadam M, Mirkhani V, Tangestaninejad S, MohammadpoorBaltork I, Khosoropour AR, Zakeri M, Hushmandrad S (2012) MoO2(acac)2 supported on multi-wall carbon nanotubes: highly efficient and reusable catalysts for alkene epoxidation with tert-BuOOH. Polyhedron 48:212–220

Gao B, Wan M, Men J, Zhang Y (2012) Aerobic selective oxidation of benzyl alcohols to benzaldehyde catalyzed by bidentate Schiff base dioxomolybdenum(VI) complex immobilized on CPS microspheres. Appl Catal A 439–440:156–162

Esnaashari F, Moghadam M, Mirkhani V, Tangestaninejad S, Mohammadpoor-Baltork I, Khosoropour AR, Zakeri M (2012) Multi-wall carbon nanotubes supported molybdenyl acetylacetonate: efficient and highly reusable catalysts for epoxidation of alkenes with tert-butyl hydroperoxide. Mater Chem Phys 137:69–75

Rayati S, Abdolalian P (2013) Heterogenization of a molybdenum Schiff base complex as a magnetic nanocatalyst: an eco-friendly, efficient, selective and recyclable nanocatalyst for the oxidation of alkenes. C R Chim 16:814–820

Zhang J, Jiang P, Shen Y, Zhang W, Li X (2015) Molybdenum(VI) complex with a tridentate Schiff base ligand immobilized on SBA-15 as effective catalysts in epoxidation of alkenes. Microporous Mesoporous Mater 206:161–169

Tabatabaeian K, Zanjanchi MA, Mamaghani M, Dadashi A (2014) Anchoring of ruthenium onto imine functionalized zeolitebeta: an efficient route for the synthesis of 4H-benzo[b]pyrans and pyrano[c]chromenes. Can J Chem 92:1086–1091

Robson H (2001) Verified synthesis of zeolitic materials, 2nd edn. Elsevier, Amesterdam

Ortiz-Iniesta MJ, Heeres HJ, Melian-Cabrera I (2013) Direct activation of microcrystalline zeolites. Microporous Mesoporous Mater 171:208–214

Liu H, Wang L, Li P (2008) Highly efficient and recyclable palladium catalyst anchored on organic-inorganic hybrid material: application in the heck reaction. Synthesis 38:2405–2411

Sharma RK, Rawat D (2012) Silica immobilized nickel complex: an efficient and reusable catalyst for microwave-assisted one-pot synthesis of dihydropyrimidinones. Inorg Chem Commun 17:58–63

Acknowledgement

We are grateful to the Research Council of University of Guilan for their partial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hadigavabar, A.D., Tabatabaeian, K., Zanjanchi, M.A. et al. Molybdenum anchored onto zeolite beta: an efficient catalyst for the one-pot synthesis of octahydroquinazolinone derivatives under solvent-free conditions. Reac Kinet Mech Cat 124, 857–871 (2018). https://doi.org/10.1007/s11144-018-1370-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-018-1370-8