Abstract

A magnetic molecularly imprinted polymer (MMIP) was fabricated and used as the sorbent for the MMIP-dispersive solid-phase microextraction of fenitrothion prior its determination by high-performance liquid chromatography equipped with an ultraviolet detector. The MMIP was prepared using functionalized Fe3O4 nanoparticles as the magnetic supporter. Methacrylic acid, ethylene glycol dimethacrylate and fenitrothion were used as the functional monomer, the cross-linker and the template, respectively. The properties of the resultant MMIP were evaluated using X-ray diffraction spectroscopy, Fourier transform infrared spectroscopy and scanning electron microscopy. The sorbent exhibited high selectivity and affinity toward fenitrothion compared to other organophosphate pesticides with the maximum adsorption capacity of 31.5 mg g−1. The effective variables on the extraction were optimized by univariable and MultiSimplex methods. The calibration curve exhibited linearity over the concentration range of 0.3–50.0 μg L−1 with the limit of detection of 0.1 μg L−1. The relative standard deviations at 10.0 μg L−1 level of FNT (n = 5) for intra- and inter-day assays were 1.6 and 3.1%, respectively. The proposed method was successfully used for the determination of trace amounts of FNT in food and water samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pesticides are organic or inorganic chemical compounds widely used all over the world in the agriculture and household to eliminate or control pests. These compounds improve quantity and quality of farm crops and protect the human against the disease transferred by pests [1]. The important groups of organic pesticides are organophosphorus pesticides (OPPs), organochlorine pesticides (OCPs), pyrethroids and carbamate pesticides [2]. Among them, OPPs are the most commonly employed pesticides because of accessibility to their different types as well as their good insecticides performance [3]. In comparison with organochlorine pesticides, OPPs have higher toxicity but lower durability in the environment. OPPs are inhibitors of enzyme acetyl-cholinesterase and are suspected of being carcinogens and mutagens [4, 5]. Fenitrothion (FNT) is one of the most common organophosphorus insecticides frequently used to control insects in crops, such as vegetables, rice, fruits, coffee, soybeans and cereals. It is also employed to rein the mosquito vector carrying malaria. FNT is partially water-soluble and so can enter the ground and profound water [6]. Thus, development of a selective, simple and sensitive analytical technique for the determination of its residues in foods, environmental and biological matrices is of great importance. Gas chromatography (GC) and high-performance liquid chromatography (HPLC) are the main instruments used for quantification of FNT. However, due to its low concentration and matrix interferences, a sample preparation step is often necessary before instrumental analysis. Various pretreatment techniques including ion-pair assisted liquid–liquid extraction [7], solid-phase extraction [8], solid-phase microextraction (SPME) [9], stir bar sorptive extraction [10] and dispersive liquid–liquid microextraction [11] have been employed for the separation, clean-up and preconcentration of FNT from different samples. Among them, SPE and SPME have received growing interest for sample preparation because of their simplicity, short extraction times, high enrichment factor, low consumption of organic solvent, safety and ease of automation [12, 13]. However, the choice of the sorbent is the major goal in SPE and SPME methods. A proper sorbent must have high capacity and selectivity for the analyte, good chemical and mechanical stability and simplicity of operation. Among various sorbents applied in SPE and SPME, molecularly imprinted polymers (MIPs) have attracted great attention owing to their high selectivity, possibility of specific tailoring for target analyte, high stability, capacity, mechanical strength, durability to heat and pressure, ease of synthesis, as well as excellent reusability in complex matrix [14]. MIPs are synthetic polymers that are obtained by copolymerization of the functional monomer and cross-linker around the target or template molecule. The subsequent elimination of the template molecule leaves the recognition cavities which are complementary in size, shape and functionality to the analyte. These recognition holes are capable of selective sorption of the template molecules in preference to other structural analogs from the complex matrices [15]. However, the conventional MIPs synthetic methods including precipitation and bulk polymerization suffer from some drawbacks as the recognition sites are deeply embedded in the polymer and are not readily accessible, have high diffusion barrier and low-affinity binding [16]. To resolve these drawbacks, recently surface molecular imprinting method has been developed in which the recognition cavities of the molecule are built on the surface of the supporting matters such as silica particles [17] and magnetic nanoparticles (MNPs) [18]. The magnetic molecularly imprinted polymers (MMIPs) have lately received plentiful attention due to their selective recognition toward the target molecule as well as ease of separation with a magnet. In addition, because of the high surface-to-volume ratio of MNPs, the number of imprinting sites of the polymer is increased when they are used as the base for surface polymerization [19]. In recent years, MMIPs have been prepared and applied for the extraction, preconcentration and determination of some compounds involving pesticides [20, 21], but there is no report on the synthesis and its application for extraction of fenitrothion. In most work, the optimization of variable in solid-phase microextraction process is performed with one-factor-at-a-time. However, optimization methods that change all variables at the same time are more useful because interaction between them is considered. In this regard, the MultiSimplex program based on the simplex algorithm is an advantageous procedure for the optimization of variable. The MultiSimplex program is a user-friendly optimization method, designed as a multi-element, nonlinear optimization tool that combines the modified simplex method [22] with fuzzy set theory [23] and has been employed in some analytical applications [24]. The most advantage of MultiSimplex is that it allows simultaneous optimization of several response signals and evaluates the interaction between control variables. In MultiSimplex optimization, the control variables, step size value for each control variable as well as the expected responses are defined. The MultiSimplex then suggests k + 1 number of trials to be performed (where k is the number of control variables to be optimized). After performing the trials, the responses of the experiments are given to the software and the MultiSimplex suggests a new trial, the process is continued until the optimal conditions are reached. The closeness to the optimal conditions is evaluated by MultiSimplex program through the membership value which ranges from 0 to 1. When the membership value is close to 1, the optimal conditions are obtained [25].

In this work, a new MMIP for FNT was synthesized via surface molecularly imprinted polymerization using vinyl-modified Fe3O4@SiO2 nanoparticles as the magnetic supporter. The synthesized MMIP was evaluated using Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD) spectroscopy and scanning electron microscopy (SEM). The fabricated MMIP was applied as the sorbent for development of a selective, simple and relatively fast magnetic molecularly imprinted polymer-dispersive solid-phase microextraction (MMIP-DSPME). The factors affecting the extraction and preconcentration of FNT were optimized using MultiSimplex program and univariable method. The method was used for the extraction, clean-up and preconcentration of FNT from various matrices prior to its determination by HPLC–UV.

Experimental

Reagents and chemicals

Organophosphorus pesticides (OPPs), fenitrothion, diazinon and chlorpyrifos were supplied from Sigma-Aldrich Company (St. Louis, MO, USA). Standard stock solution of each OPP was prepared at the concentration level of 1000 mg L−1 in HPLC-grade methanol and stored in a refrigerator. Working solutions were prepared freshly by several dilutions of the stock standard solutions with methanol. 2,2-Azobisisobutyronitrile (AIBN), tetraethyl orthosilicate (TEOS) and ethylene glycol dimethacrylate (EGDMA) were acquired from Alfa Aesar (Tianjin, China). Acetonitrile (HPLC grade), methanol (HPLC grade) and vinyltriethoxysilane (VTES) were obtained from Merck Company (Darmstadt, Germany). All other chemicals employed were analytical grade provided by Merck Company (Darmstadt, Germany). High-purity water (18.2 MΩ cm) was provided by a Milli-Q water purification system (Millipore, Bedford, MA, USA). The Britton–Robinson (BR) buffer solution (0.2 mol L−1) was prepared by dissolving appropriate amounts of boric, acetic and phosphoric acids in 100 mL of deionized water, and the pH was adjusted to 7.0 with sodium hydroxide.

Instrumentation and software

HPLC analyses were carried out using a KNAUER HPLC system (Berlin, Germany) equipped with a LC-pump 1000, a 20 µL sample loop volume and UV/Vis detector (2550 model) set to 270 nm. FNT was separated on a Zorbax SB-C18 (150 mm × 4.6 mm, 5 µm) column. An EZChrom software for LC was used to process chromatographic data. The composition of the mobile phase was a mixture of acetonitrile–water in the ration of 70:30 v/v, with the flow rate of 1.00 mL min−1. The characterization of the prepared MMIP was done using scanning electron microscope (SEM, JEOL, JSM-7001F, Japan), Fourier transform infrared (FTIR) (Thermo Scientific, Nicolet, model iS10, USA) and XRD analysis (Rigaku D-max XRD equipped with Cu Kα radiation, Canada, USA). The UV–Vis absorption measurements were taken using a UV–Vis spectrophotometer (model Cary 100, Varian, Australia). A pH meter (AZ, model 86502, Mainland, China) equipped with a combined glass calomel electrode was used to control the pH of the buffer solutions. The MultiSimplex program was acquired from Grabitech Solutions AB Company (Sweden) (www.MultiSimplex.com).

Synthesis of the sorbent

Fe3O4 nanoparticles were synthesized by coprecipitation procedure according to our previous work with some modifications [21]. Briefly, 1.5 g FeCl2·4H2O and 4.1 g FeCl3·6H2O were dissolved in 80.0 mL of ultrapure water with vigorous stirring (800 rpm). Then, the temperature was elevated to 80 °C and 10.0 mL of ammonium hydroxide (25%, w/w) was added dropwise to the solution under stirring and nitrogen atmosphere. The reaction was carried out for 20 min, and the prepared black Fe3O4 nanoparticles were collected by an external magnet, repeatedly washed with ultrapure water and ethanol and dried at 60°C for the further use.

Then, the core–shell nanoparticles, Fe3O4@SiO2, were synthesized using Stöber method [26]. Thus, 0.5 g of nano-Fe3O4 was dispersed in a mixture of 80.0 mL of 2-propanol and 10.0 mL of deionized water by ultrasonic treatment for 15 min, followed by addition of 6 mL ammonia solution (25% w/w) and 2.0 mL of TEOS. The reaction was performed for 12 h at the room temperature. Finally, the Fe3O4@SiO2 NPs were collected by an external magnetic field, successively rinsed with ethanol and water, and dried under vacuum at 60°C overnight. Next, in order to prepare the vinyl-modified Fe3O4@SiO2 and introduce the polymerizable double bonds, 200 mg of the prepared Fe3O4@SiO2 NPs was dispersed in a mixture of 53.2 mL ethanol and 13.2 mL deionized water under sonication for 15 min. Then, 3.52 mL of VTES was added, followed by dropwise addition of 1 mL of ammonia solution (25%), and the mixture was stirred for 2 h at room temperature and heated for 2 h at 50 °C. After the reaction was completed, the modified Fe3O4@SiO2 NPs were collected by a magnet and rinsed three times with ethanol and the product was dried at 60 °C under vacuum.

Finally, the MMIP sorbent was prepared as by mixing 0.4 mmol of FNT as the template molecule and 2.0 mmol of MAA as the functional monomer in 25.0 mL of chloroform. The mixture was then stirred at 300 rpm for 1 h at room temperature to form a pre-assembly solution. Afterward, the modified Fe3O4@SiO2 (500.0 mg) and EGDMA (20.0 mmol) were dispersed in 50.0 mL of chloroform under sonication for 10 min and the resulting mixture was added to the pre-assembly solution under a nitrogen stream. After purging with N2 gas for 10 min, 20.0 mg of the AIBN as the initiator was added to the mixture and the reaction was performed at 60 °C for 24 h under stirring. When polymerization was completed, the synthesized MMIP was collected from the mixture magnetically, washed with methanol and dried under vacuum at 60 °C.

To remove the template molecule, the MMIP was washed with a mixture of methanol/acetic acid (9:1, v/v) and the removal of FNT was monitored by measuring the absorption of the resulting solution at 270 nm by UV spectrophotometer until no FNT was detected in the eluent. Finally, the synthesized MMIP was rinsed with methanol several times and dried at 60 °C for 24 h. For comparison, magnetic non-molecularly imprinted polymer (MNIP) was synthesized following the same procedure but in the absence of FNT.

Samples preparation

Standard stock solution of each OPP was prepared at the concentration level of 1000 mg L−1 in HPLC-grade methanol and stored in a refrigerator. Working solutions were prepared freshly by serial dilutions of the stock standard solutions with methanol.

Fruit samples were digested by the modified QUECHERS (Quick, Easy, Cheap, Effective, Rugged and Safe) method [27]. Briefly, 10.0 g of thoroughly homogenized fruit samples (apple, tomato or watermelon) was accurately weighed and placed in a 50-mL conical centrifuge tube. Then, 10.0 mL acetonitrile was added and the tube was vortexed for 10 min. After that, anhydrous MgSO4 (4.0 g) and NaCl (1.0 g) were added followed by vigorous stirring for an extra 2 min. The tube was then centrifuged at 5000 rpm for 3 min, and the mixture was passed through a 0.45-μm filter paper. The filtrate was first evaporated with a mild stream of nitrogen gas to 1 mL and then was diluted to 10 mL with ultrapure water. Finally, the pH and ionic strength of the resulting solution was regulated with the BR buffer (pH = 7.0) and NaCl, respectively, and was subjected to the MMIP-SPME–HPLC method for extraction and quantification of FNT.

The water samples were filtered using a 0.45-µm filter. Then, 10 mL aliquot of each sample was subjected to the proposed MMIP-SPME–HPLC method.

Extraction procedure

The pH and ionic strength of 10 mL of standard or sample solution containing not more than 0.5 µg of FNT were adjusted to ~ 7 and 1.6 mol L−1 using Britton–Robinson (BR) buffer and NaCl solution, respectively. Subsequently, 17.5 mg of the synthesized sorbent was transferred to the solution and the mixture was shaken by a mechanical stirrer for 11 min. The sorbent was then isolated with a magnet, followed by the decantation of the supernatant solution. The preconcentrated FNT was then desorbed from the sorbent by 0.2 mL of methanol/acetic acid solution (7.8:2.2, v/v) under sonication for 25 min. Finally, the sorbent was separated with a magnet and the desorbed FNT in the solution was quantified by HPLC–UV.

Results and discussion

Characterization studies

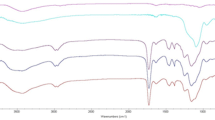

In order to assess the successful synthesis of magnetic molecular imprinted polymer sorbent, the FTIR spectra of Fe3O4, Fe3O4@SiO2, vinyl-modified Fe3O4@SiO2, MMIP (before and after leaching) and MNMIP were recorded (Fig. 1). The absorbance band at about 591 cm−1 in Fig. 1a is characteristic of the Fe–O bond in Fe3O4 NPs. In Fig. 1b, the absorbance band about 800, 950 and 1092 cm−1 is assigned to the stretching vibration of Si–O, Si–O–H and Si–O–Si, respectively, indicating the SiO2 is grafted on the surface of Fe3O4 NPs. The vinyl-modified Fe3O4@SiO2 (Fig. 1c) showed additional absorbance bands around 2950 and 1603 cm−1 corresponding to the C–H and –C=C– stretching vibration, respectively, demonstrate that VTES has been successfully coated onto the surface of Fe3O4@SiO2. The appearance of absorbance bands around 1730, 1259 and 1158 cm−1 in Fig. 1d–f, attributed to C=O stretching vibration, C–O symmetric and asymmetric stretching vibration of EGDMA, respectively, as well as the characteristic band of Fe3O4 around 500 cm−1 indicate the successful synthesis of polymers on the Fe3O4@SiO2 bases. Furthermore, the absorbance band at 3400–3600 cm−1 (Fig. 1d–f) corresponding to the O–H stretching is observed in MNMIP, leached and unleached MMIP; however, its intensity in unleached MMIP is lower. This is due to the formation of hydrogen bond between FNT and the OH functional group in the unleached polymer that after removal of the FNT, the OH group becomes free and consequently its intensity becomes the same as in MNMIP.

The morphological features of unleached and leached prepared sorbent were investigated by SEM (Fig. 2). The SEM image (Fig. 2a) clearly shows that the average particle size of sorbent is about 55 nm in diameter. Thus, the synthesized sorbent can be categorized as nano-dimension selective sorbent. Also, the comparison of SEM images of the unleached and leached MMIP indicates that removal of the template molecule from the polymer increased the porosity of the sorbent surface which makes it suitable for the sorption of the analyte. The XRD pattern of the synthesized MMIP was also recorded (Fig. 3), and five characteristic reflection peaks for Fe3O4 with the Miller indices of (220), (311), (400), (422) and (511) (JCPDS Card 01-075-0449) were observed which further prove the victorious synthesis of MMIP.

MultiSimplex optimization of fenitrothion MMIP-DSPME

It is widely known that the nature of eluent has a considerable effect on desorption of target analyte from the sorbent and the efficiency of the extraction process. Therefore, the ability of different eluents including acetic acid, methanol, acetonitrile/acetic acid solution (9:1, v/v) and methanol/acetic acid solution (9:1, v/v) for desorption of FNT from the MMIP was investigated. One-way analysis of variance test (one-way ANOVA) was applied for examination of the difference between the sample means. Since the calculated value of F (270.71) was greater than the critical value of F (4.066), the null hypothesis was rejected. Thus, the difference between the eluents is significance. This observation can be related to the synergic effect of high solubility of FNT in methanol and protonation of FNT by acetic acid which weakens its interaction with the sorbent [28, 29]. Next, the variables that influence the extraction efficiency of FNT such as pH, sorption and desorption time, the volume of eluent, the percentage of acetic acid in the eluent and the amount of sorbent were optimized by MultiSimplex method and the results were compared with those acquired by univariable optimization.

The MultiSimplex program was utilized as explained by Shakerian et al. [25] using standard aqueous solution at 30 µg L−1 of FNT. Thus, at first, the uniform design (UD) was done to minimize the risk of local optimization of MultiSimplex and find a sample that is a great representative of experimental domain as well as to select experimental points that are uniformly distributed in a bonded area of experimental domain. Then, the best response obtained by UD was chosen as the reference value for the MultiSimplex program, the maximum, minimum and step size value of each control variable was determined; the program was run and the trials were carried out according to the conditions proposed by MultiSimplex program. The process was continued until the optimal conditions, where the membership value gets close to 1, was achieved. The optimum conditions obtained after performing 24 experiments. The defined control variables and the resulting optimum value are given in Table 1. Also, the results of optimization by the univariable method are shown in Table 1. As can be seen, the optimal values of MultiSimplex optimization are within the optimal range of univariable method; thus, the results of both methods confirm each other. Thus, based on the outcomes of both optimization methods a pH of ~ 7, sorption time of 11 min, desorption time of 25 min, volume of eluent of 0.2 mL, percentage of acetic acid in eluent of 22%, NaCl concentration of 1.6 mol L−1 and amount of sorbent of 17.5 mg were chosen as the optimal conditions for extraction of FNT by MMIP-SPME method.

In order to display the capability of the system in the extraction of trace amounts of FNT from large sample volume, 0.3 µg of FNT was extracted from different sample volumes (5–30 mL) under optimized conditions. The results (Fig ESM1) showed that the peak area of FNT was constant and maximum up to a sample volume of 10 mL, and then, the analytical responses decreased by a further increase in the sample volume. Thus, a sample volume of 10 mL was selected as the maximum sample volume in which the extraction of analyte was quantitative.

Selectivity evaluation

The selectivity and capability of MMIP and its corresponding MNMIP in recognition of FNT were investigated by extraction of analyte from water samples in the presence of different structurally similar organophosphate pesticides including diazinon and chlorpyrifos. The results (Fig. 4) illustrate that the MMIP has higher selectivity in the extraction of FNT in comparison with MNMIP and the sorption affinity of MMIP for FNT is greater than the other examined organophosphate pesticides. The high selectivity of MMIP toward FNT can be related to the effective imprinting process of the prepared sorbent.

Sorption selectivity of the MMIP and MNIP for fenitrothion, diazinon and chlorpyrifos. Conditions: pesticides concentration, 30 µg L−1; pH, 7; eluent, 0.2 mL of methanol/acetic acid (7.8:2.2, v/v); adsorption time, 11 min; desorption time, 25 min; amount of the sorbent, 17.5 mg; sample volume, 10.0 mL, n = 3

Sorbent capacity and reusability

The maximum sorption capacity of the prepared MMIP is defined as the maximum amount of the analyte that can be retained by a certain amount of it. For determination of the sorption capacity, 15 mg of MMIP was added to 20.0 mL of FNT solution (30 mg L−1) under the optimum condition of pH. The mixture was stirred for 30 min; the sorbent was isolated by application of an external magnet and the concentration of FNT remained in the supernatant solution was calculated by measuring its absorption at 270 nm. The sorption capacity of synthesized MMIP was calculated from the differences in the amount of FNT in the initial and final solutions and was found to be 31.5 mg g−1 of the sorbent. Thus, the prepared sorbent has a high capacity for FNT.

Reusability is an important factor in the evaluation of the performance and stability of the sorbent materials. The possibility of regeneration and reusability of the prepared. MMIP was investigated through performing five successive sorption–desorption cycles under the optimized conditions. It was found that the obtained MMIP was stable and reusable in at least five operation processes without obvious loss in its extraction efficiency.

Method validation: calibration curves, precision and accuracy

In order to investigate the matrix effect of real samples, calibration curves were plotted for fenitrothion using matrix-match calibration procedure. The matrix effect (ME) was obtained by comparing the ratio of the slope of the matrix-matched curve to that of solvent according to the following equation [30]

Generally, ME between 80 and 120% shows negligible matrix effects, ME between 50–80% or 120–150% refers to minor matrix effects, and ME < 50% or > 150% indicates major matrix effects [31]. The matrix-matched calibration curves are presented in Table ESM1. As can be seen, no matrix effect for apple, watermelon, tomato and water samples was observed which can be related to the selectivity of MMIP. Calibration curve for fenitrothion standard solution was linear in the range of 0.3–50.0 μg L−1. The LOD and the LOQ calculated based on 3Sb/m and 10Sb/m (where Sb is the standard deviation of the blank and m is the slope of the calibration graph) for the calibration curve in standard solution were found to be 0.1 and 0.3 µg L−1, respectively. The relative standard deviations (RSDs) at 10.0 µg L−1 level of standard solution (n = 5) for intra- and inter-day assays were 1.6 and 3.1%, respectively. The accuracy of the method was checked using the recovery experiments by spiking the samples at two concentration levels of FNT. The results (Table 2) of this study revealed that the recoveries of the spiked samples were good (96.0–104.0%). Thus, the method is reliable and accurate for determination of FNT in the sample types examined. The enhancement and preconcentration factors computed as the ratio of the slope of calibration graphs with and without preconcentration and the ratio of maximum volumes of aqueous phase (10 mL) to the eluent (0.2 mL) were found to be 47 and 50, respectively. The closeness of enhancement factor to preconcentration factor demonstrates that the extraction process is quantitative (> 94%).

Analysis of real samples

The applicability of the developed MMIP-DSPME method in the analysis of real samples was investigated by determination of FNT in various samples including natural water, apple, watermelon and tomato samples. All measurements were taken in 3 replicates. As the recoveries of the spiked samples indicate (Table 2), there are no significant matrix effects in the sample types examined. Thus, the method is reliable and accurate for determination of FNT in analyzed samples. The chromatograms of the standard solution and spiked apple samples after the extraction by the MMIP-SPME method are shown in Fig. 5. As can be seen, the retention times of FNT in standard and real samples are constant, indicating that the matrices of the extracted samples have no significant effect on the determination of FNT.

Comparison of developed method with others extraction methods

Some of the analytical characteristics of the developed method were compared with those of other published methods for the determination of FNT (Table 3). As it can be seen, the developed method provides a lower detection limit with a good precision and with one exception [9] the developed method has a broader linear range than the other reported methods. Furthermore, the surface imprinting conditions of synthesized MMIP caused the imprinted binding sites to be built on the surface of MMIP resulting in the formation of a sorbent with high binding capacity, quicker mass transfer and lower diffusion barrier.

Conclusions

In this work, the MMIP was successfully synthesized as a selective sorbent for FNT using one-step surface imprinting technique and precipitation polymerization. The sorbent was used for SPME of FNT followed by its determination by HPLC–UV analysis. The prepared sorbent was characterized by FTIR, SEM and XRD spectroscopy. The synthesized MMIP exhibits good chemical and physical stability, high sorption capacity and high selectivity toward FNT and provides ease of separation from bulk solution by a magnet. In addition, the use of uniform design along with MultiSimplex optimization reduces the number of experiments needed for optimization and provides a true set of optimum conditions. The developed method was fast, accurate and selective for the determination of trace amounts of FNT in apple, watermelon, tomato and water samples.

References

J. Fenik, M. Tankiewicz, M. Biziuk, TrAC Trends Anal. Chem. 30, 814 (2011)

M. Peyrovi, M. Hadjmohammadi, J. Iran. Chem. Soc. 14, 995 (2017)

H. Tsoukali, G. Theodoridis, N. Raikos, I. Grigoratou, J. Chromatogr. B 822, 194 (2005)

M. Erdem, R. Say, A. Ersöz, A. Denizli, H. Türk, React. Funct. Polym. 70, 238 (2010)

M.P. García de Llasera, M.L. Reyes-Reyes, Food Chem. 114, 1510 (2009)

A. Sánchez-Ortega, M.C. Sampedro, N. Unceta, M.A. Goicolea, R.J. Barrio, J. Chromatogr. A 1094, 70 (2005)

A. Gure, N. Megersa, N. Retta, Anal. Methods 6, 4633 (2014)

L.A. de Barros, I. Martins, S. Rath, Anal. Bioanal. Chem. 397, 1355 (2010)

Z.-W. Yao, G.-B. Jiang, J.-M. Liu, W. Cheng, Talanta 55, 807 (2001)

C. Hu, M. He, B. Chen, B. Hu, J. Chromatogr. A 1275, 25 (2013)

L. He, X. Luo, X. Jiang, L. Qu, J. Chromatogr. A 1217, 5013 (2010)

S.R. Dave, H. Kaur, S.K. Menon, React. Funct. Polym. 70, 692 (2010)

J. Shah, M. Rasul Jan, M. Zeeshan, M. Iqbal, Sep. Sci. Technol. 51, 1480 (2016)

X. Feás, J.A. Seijas, M.P. Vázquez-Tato, P. Regal, A. Cepeda, C. Fente, Anal. Chim. Acta 631, 237 (2009)

S.M. Sorouraddin, M.R. Afshar, Mogaddam. J. Iran. Chem. Soc. 13, 1093 (2016)

Y.-M. Yin, Y.-P. Chen, X.-F. Wang, Y. Liu, H.-L. Liu, M.-X. Xie, J. Chromatogr. A 1220, 7 (2012)

P. Yang, W.D. Hou, H.D. Qiu, X. Liu, S.X. Jiang, Chin. Chem. Lett. 23, 615 (2012)

Z. Xu, L. Ding, Y. Long, L. Xu, L. Wang, C. Xu, Anal. Methods 3, 1737 (2011)

T. Jing, H. Du, Q. Dai, H. Xia, J. Niu, Q. Hao, S. Mei, Y. Zhou, Biosens. Bioelectron. 26, 301 (2010)

F. Lu, H. Li, M. Sun, L. Fan, H. Qiu, X. Li, C. Luo, Anal. Chim. Acta 718, 84 (2012)

A. Bazmandegan-Shamili, S. Dadfarnia, A.M. Haji Shabani, M. Saeidi, M. Rohani Moghadam, Food Anal. Methods 9, 2621 (2016)

J.A. Nelder, R. Mead, Comput. J. 7, 308 (1965)

M. Otto, Anal. Chim. Acta 235, 169 (1990)

J. Sanz, A. de Diego, J.C. Raposo, J.M. Madariaga, Anal. Chim. Acta 486, 255 (2003)

F. Shakerian, S. Dadfarnia, A.M.H. Shabani, M. Rohani, Talanta 77, 551 (2008)

W. Stöber, A. Fink, E. Bohn, J. Colloid Interface Sci. 26, 62 (1968)

A. Angioni, L. Porcu, F. Dedola, Pest Manag. Sci. 68, 543 (2012)

W. Peng-Ju, Y. Jun, S. Qing-De, G. Yun, Z. Xiao-Lan, C. Ji-Bao, Chin. J. Anal. Chem. 35, 484 (2007)

M.M. Sanagi, S. Salleh, W.A.W. Ibrahim, A.A. Naim, D. Hermawan, M. Miskam, I. Hussain, H.Y. Aboul-Enein, J. Food Compos. Anal. 32, 155 (2013)

B. Matuszewski, M. Constanzer, C. Chavez-Eng, Anal. Chem. 75, 3019 (2003)

M. Chen, Q. Yi, J. Hong, L. Zhang, K. Lin, D. Yuan, Anal. Methods 7, 1896 (2015)

T.M. Gutiérrez Valencia, M.P. García de Llasera, J. Chromatogr. A 1218, 6869 (2011)

C. Pellicer, A. Gomez-Caballero, N. Unceta, M.A. Goicolea, R.J. Barrio, Anal. Methods 2, 1280 (2010)

L.A. Pereira, S. Rath, Anal. Bioanal. Chem. 393, 1063 (2009)

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bazmandegan-Shamili, A., Dadfarnia, S., Haji Shabani, A.M. et al. MultiSimplex optimization of the dispersive solid-phase microextraction and determination of fenitrothion by magnetic molecularly imprinted polymer and high-performance liquid chromatography. J IRAN CHEM SOC 15, 1181–1189 (2018). https://doi.org/10.1007/s13738-018-1316-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-018-1316-0