Abstract

Treatment of organic waste has gain importance in the last decade due to stringent environmental laws. Fruit and vegetable waste (FVW) is potent substrate to be utilized for the recover energy via anaerobic digestion, a sustainable approach for the waste to energy transformation. Co-digestion of FVW and anaerobic sludge (AS) was explored in batch anaerobic digestion for a retention time of 31 days. Mixing ratio of (AS:FVW) 25:75 claimed 22% and 43% higher biogas yield as compared to 50:50 and 75: 25 ratio, respectively. Highest methane yield of 62% which is equivalent to 275.9 NmL/g VS was observed for (AS:FVW) 25:75 ratio. Further, application of microwave (MW) treatment enhanced the solubilization of the feedstock and rendered 10% higher methane yield as compared to untreated (AS:FVW) 25:75 ratio at operating power of 300W. Performance analysis indicated highest VS reduction of 77% for MW-treated FVW at optimal ratio of FVW and AS. Kinetic modelling was done, and experimental data fits well to the first-order model as compared to modified Gompertz model. Rate constant at optimal ratio with microwave pre-treatment was found to be 0.111, while the value for untreated optimal ratio was found as 0.1085.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

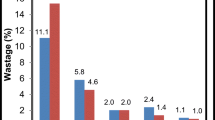

Alarming increase in population coupled with industrialization and urbanization has led to increase in per capita generation of municipal solid waste and energy demand. Energy security and climate change are the two major challenges which are faced globally. Conventional energy sources such as fossil fuels, coal, and gas are depleting fast, and their extensive use has led to climate change, health disorders, and environmental degradation. Moreover, their finite supply, rising price, and geopolitical dominance in some parts of the world have drawn inclination of the scientific community towards the need for greater usage of sustainable renewable energy sources. Among the numerous renewable energy sources, wind and solar are dominant; however, the role of bioenergy is still a quest. Bioenergy generated from biomass can play a significant role in bridging the gap between energy demand and supply. Biomass is cheaply and abundantly available in most of the countries including India. Their utilization for generation of energy will resolve their disposal issue and will reduce the nation’s dependency on the oil-producing countries. By 2023, 5000 biomethane plants in India are expected to be operational under the Sustainable Alternative towards Affordable Transport (SATAT) initiative. These facilities will be able to use municipal solid waste, agricultural waste, and cattle manure as feedstock to produce roughly 15 million tonnes of biomethane annually [1]. FVW is major component of the municipal solid waste (MSW). Almost 30% of the FVW that is produced is being lost during the supply chain [2]. In present scenario, almost 75% of the FVW that is being generated are dumped to landfill site. Currently, the conventional techniques such as landfilling and incineration have negative impact on environment due to release of greenhouse gas emissions and requires huge operational cost [3]. However, due to stringent environmental laws, disposal of FVW in sanitary landfill becomes difficult, and also high biodegradability of FVW poses serious threat to the environment. Even, owing to high biodegradability of FVW, it holds huge potential to generate green energy [4]. AD is an environmental friendly sustainable technology that converts waste to energy. AD involves series of biochemical reaction that convert complex organic substances via enzymatic and bacterial activities to biogas. Biogas is mainly composed of methane and carbon dioxide along with trace gases [5] and digestates. Biogas is a promising source of green energy as compared with conventional fossil fuels. Biogas can be utilized in numerous day-to-day applications such as fuels for transportation, electricity, and heat generation while mitigating the emission of greenhouse gases (GHGs) [6]. Also, digestate is by-product of both acidogenesis and methanogenesis process; however, both of them differ in their characteristics. Acidogenesis and methanogenesis process basically differ in terms of liquid separation and the way the microorganisms are retained in the reactors. Since acidogenesis is the early stage of AD, most of the organics have not been fully degraded and mainly retained in the solid phase. Hence, acidogenic digestate is commonly referred as the solid digestate. The methanogenesis is the final stage of anaerobic digestion in which most of the organics break down, degraded, and converted into the liquid digestate [7]. Digestate can be efficiently utilized as soil conditioner. In current era, many researchers are attempting to address the challenges associated with AD and to optimize the process parameters for its successful application towards waste management [8]. FVW is rich in biopolymer content which makes it an ideal substrate for the production of biogas via AD [9]. On the other hand, the presence of high biodegradable organic matter in FVW results in generation of excess volatile fatty acids, which are detrimental for methanogenic bacteria, and results in inhibition of the AD process. To overcome the former limitation, co-digestion of FVW along with other waste streams will not only resolve VFA inhibition but also enhance the natural buffering capacity of the digester [10, 11]. Co-digestion of FVW with municipal sewage sludge has been investigated by Arhoun et al. [12], and it was reported that co-digestion of the two improved methane yield as well as digester performance. Co-digestion of the FVW and food waste was explored in the past by Lin et al. [13], which proved to be a potent substrate for co-digestion; moreover, it not only improved the digester stability but also nullified the drawbacks of the monodigestion of FVW. FVW contains lignin in their skin and seed [14, 15], which makes the bacterial hydrolysis difficult. Presence of the lignin barrier and cellulose restrict the hydrolytic enzymes and methanogens and have limited access to the feedstock during AD [16]. Hence, bacterial hydrolysis is the rate-limiting step for the organic waste that is rich in polysaccharides [17]. Furthermore, to expedite hydrolysis and consequently the entire AD process, numerous pre-treatment methods such as physical, chemical, physiochemical, and biological have been developed [2, 18], which not only enhance the biogas yield but also helped to reduce reaction time and decrease the volume of residual particles for final disposal. Pre-treatment methods break down the lignin barrier present in the skin and seed of the FVW which are otherwise difficult to be accessed by bacterial community and therefore prolong the hydrolysis period [2, 14, 15]. Among all the pre-treatment methods, thermal pre-treatment of the FVW has gain interest owing to its enhanced sludge solubilization, digestion performance, and improved dewaterability [19, 20]. Microwave treatment particularly in the category of thermal treatment has gained popularity due to its environmental and energy conservation properties [21], because it prevents heat losses that happen during energy transmission in conventional heating. In microwave heating, direct vibration and rotation of dielectric molecule are feasible which maximize heat transfer. Microwave treatment enhances the solubilization of the feedstocks and breaks down intermolecular bond of the substrates as it becomes weak during the microwave treatment. Effect of microwave treatment on biogas yield has been studied by some researchers [19]. The effect of MW thermal treatment on AD of anaerobic sludge has been investigated by Coelho et al. and Eskicioglu et al.[22,23] [23]. Microwave pre-treatment of activated sludge was investigated by Apples et al. [24], and they pointed out an increase in total solid and sCOD content by 214% by application of heating duty of 336 kJ/kg, and subsequently 50% increase in the biogas production was observed during the mesophilic anaerobic digestion. A pilot-scale study of thermal pre-treated activated sludge at 65 °C for 20 min showed a 2- to 3-fold increase in the solubility ratio and, as expected, an increment of 30–40% in biogas production [25]. From the literature, it is evident that microwave treatment is mainly deployed either for sludge treatment or agricultural biomass [26, 27], and no study has been found yet for the highly biodegradable waste like FVW. Therefore, this study was targeted to explore the potential of the microwave treatment during anaerobic co-digestion of three different mix ratios of the FVW and AS under mesophilic regime.

2 Materials and methods

2.1 Materials

2.1.1 Substrate

Fruit and vegetable wastes of seasonal vegetable and fruits, viz., cabbage leaves (20%), tomato (10%), capsicum (10%), bottle gourd (15%), cauliflower leaves (15%), eggplant (10%), banana (10%), and papaya ( 10%), used in the current study was procured from the wholesale vegetable and fruit market. The ratio depicted the amount of waste being generated in the market on that particular day; however, it varies daily. All the vegetable and fruit wastes were washed to get rid of any impurity being present. Parts of the vegetable and fruits which were more decayed were discarded. This FVW is subjected to mechanical pulverization to felicitate size reduction. The selected waste was then cut into size of approx.10 cm and then grinded using domestic grinder to make smooth paste. These wastes were stored in freezer at 4 °C until further use.

2.1.2 Inoculums

Anaerobic sludge (AS) as a source of inoculum was collected from anaerobic digester of Vachan Dairy and Food Products Ltd. Kharora, district Raipur, Chhattisgarh, India, of capacity 1000 m3. Inoculum plays a vital role in AD. Absence of the inoculum delays the digestion period and reduces the biomethane production. It is the main source of the microorganism which carries out biodegradation [28]. Anaerobic sludge was subjected to degasification for a period of 5 days prior to experiment to deplete the residual biodegradable organic matter present. The characteristics of AS and FVW are presented in Table 1.

2.2 Methods

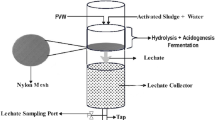

Experimental set-up

Batch anaerobic digesters are made up of PET bottles of capacity 500 ml. Two sampling ports were provided, one at the top for measuring biogas and another at the height of 30% for the measurement of pH and VFA. The digesters were flushed with nitrogen gas at the headspace to ensure anaerobic condition in the digester. These digesters were kept inside the water bath at 37 °C to maintain constant temperature. Biogas was measured daily by water displacement method. Experimental set-up used in the experiment are depicted in Fig. 1. The biogas samples were ejected from the septum (made up of butyl rubber) self-sealing cap, which is provided at the top for the purpose of measuring methane content. Methane content of the biogas was determined using gas chromatograph (Nucon5700, India) equipped with a thermal conductivity detector (TCD). The hydrogen was used as carrier gas at a constant flow rate of 30 mL/min. The oven and injector temperature was maintained at 40°C, while that of TCD was maintained at 60°C. For taking a sample of biogas from digesters and injection of the gas sample into the gas chromatograph, a 500-μL gastight syringe (Hamilton, USA) was used. Volatile fatty acid was also measured according to ferric hydroxamate method, described by Chatterjee et al. [29] using a single-beam spectrophotometer.

2.2.1 Chemicals and instruments for pre-treatment

Laboratory-grade sodium bicarbonate was procured from Avantor, Rankem, India. 2N solution of sodium bicarbonate was prepared by dissolving stoichiometric amounts of sodium bicarbonate in deionized water for maintaining pH. Microwaving was done by a laboratory grade microwave system provided by NuWav Pro Nutech Analytical Technologies Pvt. Ltd., India (SL. no.8-19 pro 114). Deionized ultrapure water (Merck Millipore, Germany) was used for pre-treatment as well as for AD whenever required.

2.2.2 Microwave pre-treatment

MW pre-treatment was performed to speed up the hydrolysis of the waste. For this purpose, laboratory grade microwave was deployed, and the pre-treatment was carried out under varying microwave power from 200 to 500 watt for a period of 10 min. Desired ratio of the substrate and inoculum was taken in 500-ml beaker and is subjected to MW treatment. During microwaving process, continuous automatic stirring was done at a moderate speed of 900 rpm, and the higher limit of temperature (safety temp.) was fixed at 98°C. After completion of microwaving, the content was allowed to cool at room temperature, and water was added to make up the losses due to the microwave heating process.

2.2.3 Analytical methods

The leachate was withdrawn periodically from the sampling port for the analysis of the pH, volatile fatty acid (VFA), and alkalinity. Proximate and ultimate analysis of the FVW and inoculums was carried out to determine their moisture content, total solids, and volatile solids as per National Renewable Energy Laboratory (NREL) protocol. Elemental analysis was done by a CHNS analyzer (Thermo Finnigan-Flash EA-1112, USA). The volume of biogas generated was measured by the water displacement method. The composition of biogas was measured by a gas chromatograph (Nucon5700, India) equipped with a thermal conductivity detector (TCD).

Calculation

Performance of the anaerobic digestion was analyzed through reduction in volatile solids (VS) which is determined using the following equation.

The stability of the digester is determined using VFA/alkalinity ratio, for the smooth operation of the digester, and it should lie between 0.2 and 0.4 [30].

3 Results and discussion

3.1 Optimization of mixing ratio for co-digestion of FVW and anaerobic sludge

Many researchers have investigated the efficiency of the co-digestion of FVW and AS [11, 31]. Presence of high percentage of volatile solids and moisture content makes it a potent candidate for the biomethane production [2]. However, the higher percentage of the volatile solids assures the presence of highly biodegradable organic matter and often suffers the quick hydrolysis. This results in accumulation of the VFA which is detrimental for the methanogenesis process [32, 33]. This shortage can be overcome by implying different strategies, namely, co-digestion of different waste streams, reducing OLR, and deploying multistage digester [34]. Present study aims at evaluating the feasibility of the anaerobic co-digestion of the FVW and AS in different proportion towards maximizing the biogas yield using single-stage anaerobic digester. Batch study was carried out to optimize the different co-digestion ratios of (AS:FVW), (25:75), (50:50), and (75:25) for a retention time of 31 days. Daily biogas yield for different ratios were recorded using water displacement method. The biogas production started from second day itself in all the digester. Results revealed that (25:75) achieved highest biogas yield equivalent to 38.2 NmL/gVS on third day itself, which is attributed to presence of easily biodegradable organics. The (50:50) ratio achieved highest biogas yield as 29.5 NmL/g VS on day 5, and (75:25) ratio achieved highest biogas yield as 21.5 NmL/gVS on day 14, respectively. The biogas produced during the entire course of the digestion varied from high to low; this is attributed to the shift in pH of the digester which kept fluctuating from time to time. Reduced biogas yield for the mix ratios (50:50) and (75:25) may be attributed to the decreased concentration of the substrate, lower C/N ratio, and digesters’ buffering capacity. Result shows the monodigestion of the FVW achieved 58% lower biogas yield when compared with co-digestion of the FVW and AS at (25:75) ratio, which confirms that inclusion of the AS enhances the biomethane yield of the waste. Inclusion of the AS provides the necessary microbial consortia present for the conversion of the organic matter to biogas. The numbers of peaks were also different for each digester; there were5, 7, 7, and 6 peaks for different mix ratios as depicted in Fig. 2 pointing out the daily and cumulative biogas yield for mix ratios. The number of peaks shows the activity level of microbes. The results obtained are in accordance with Arhoun et al. and Pavi et al. [12, 35]. Cumulative biogas for the AD of FVW and AS for all the different ratios are depicted in Fig. 4b. Result indicated that cumulative biogas yield was influenced by mixing ratios of the FVW and AS. Highest cumulative biogas yield was noted for the mix proportion of the (25:75) which is equivalent to 445.3 NmL/gVS. On the other hand, other ratios displayed cumulative biogas yield equivalent to 368.7 NmL/gVS and 279.8 NmL/gVS for (50:50) and (75:25) ratios, respectively, while the monodigestion of FVW recorded the lowest cumulative biogas yield as 185.8 NmL/gVS.

3.2 Effect of microwave pre-treatment on the biogas production

The rate of soluble organic formation and its subsequent conversion into volatile fatty acids determine the efficiency of the AD process. In present study, differently hydrolyzed substrates were subjected to AD. The VFA produced are the product of hydrolysis and acidification and a precursor for methane production. MW pre-treatment was carried out for the optimal co-digestion ratio of 25:75 at different irradiation power for 10 min. Figure 3a and b represent the daily and cumulative biogas yield at optimum 25:75 (ISR) for MW pre-treatment at different irradiation power. Results revealed that microwave pre-treatment enhances the hydrolysis of the FVW which maximizes the biogas and methane yield. The rate for biogas production fluctuated from higher value to lower value for untreated as well as pre-treated feedstock. The fluctuation in the rate of biogas production and methane content is mainly because of the increased solubility and of the pH shift brought on by microbial activity in the digester. Since, AD is the series of the microbial assisted biochemical process including hydrolysis, acidogenesis, acetogenesis, and methanogenesis, involving different microbial consortia in each phase [36]. The highest volume of biogas obtained was 38.2 NmL/gVS for untreated feedstock on day 3 and 40.2, 44.6, 36.45, and 32.25 NmL/gVS on day 2 for 200, 300, 400, and 500W microwave-treated feedstock, respectively. Result revealed that biogas production started on day 2 for all the combination of the different ratios and pre-treatment, whereas for untreated reactor, biogas production started on day 3. Biogas production was not constant for any of the combination and kept fluctuated from higher to lower; this may be due to the change in the pH, alkalinity, and the digester internal environment that influences the biogas production. Results demonstrate the effectiveness of the microwave pre-treatment, since roughly 75% of the hydrolysis and AD were finished in the allotted 20 days of HRT. Cumulative biogas yield for untreated FVW was recorded as 445.3 NmL/gVS, whereas for 200, 300, 400, and 500W, MW-treated FVW biogas yield was recorded as 472.8, 542.26, 486.5, and 394.84 NmL/gVS, respectively. This confirms that microwave pre-treatment enhances the digestibility of the feedstock, and maximum increment of 21.77 % was observed in the biogas yield for 300 W as compared to untreated FVW. The maximum biogas yield was 542.26 NmL/gVS (equivalent to 283.68 NmL of biomethane) from FVW pre-treated with 300W MW radiation for 10 min. Our findings are in accordance with the findings of Ambrose et al. [19]; according to their finding, the maximum hydrolysis of FVW was obtained at a microwave power of 660 W for a period of 2 min. The methane yield obtained by Ambrose et al. was 276 NmL/gVS. The purification cost of the biogas having higher methane content and lower carbon dioxide will also be lesser.

3.3 Composition of the biogas for the different mix ratio

Maximizing the methane production is one of the major goals for the conversion of the biomass to methane. Biogas is mainly composed of methane and carbon dioxide along with some trace gases. Figures 4 and 5 show the composition of the biogas produced during the course of digestion for the different mix ratios without pre-treatment and after pre-treatment, respectively. As can be seen from the plots, the amount of the methane production increases with the duration; however, the percentage of carbon dioxide reduces. Methane content was lower at first, but it steadily increased and stabilized near the end of the AD process. Co-digestion of the AS and FVW mix ratio of (25:75) gave higher methane content 62%; this is mainly because of the positive synergetic effect of both the co-substrates, which enhanced the biomethane yield, whereas other ratio recorded maximum methane content of 58% and 54%, respectively. However, for microwave pre-treated FVW and AS, the methane content was monitored periodically at the interval of 3 days. Results suggested that MW treatment could increase the daily methane production of Co-AD of AS and FVW, and the best effect in terms of increasing the daily methane production was obtained for MW-treated FVW at 300W. The highest methane content of 72% was recorded; this may be attributed to the fact that MW pre-treatment enhanced the solubilization (%) of the feedstock and reduces the lignin and cellulose content of the FVW which is normally present in the skin and the seed of the fruits. However, the methane content for the other MW treatment lies between 31 and 57%. The methane content in the digesters increased during the course of digestion. Results revealed that the MW treatment enhance the methane yield for the co-digestion of AS and FVW. The cumulative methane production showed a similar trend as those in previous studies [37, 38]. The synergistic effect of the co-digestion of AS and FVW could increase methane production, while MW pre-treatment enhances production of VFA [39]. Habiba et al. [40] assessed co-digestion of AS with FVW, in which methane content fluctuated around 60% in all of the bioreactors.

3.4 Methane content for various pre-treatment

3.4.1 Evolution of pH, NH4-N, and VFA on anaerobic co-digestion of FVW and WAS

The pH of the microwave-treated FVW and AS at different ratio was found between 7 and 8.2. The increment in the pH values is mainly due to degradation of the protein which is responsible for the release of the ammonia into the solution, which contributes to the alkalinity of the digester. Effect of the co-digestion on the pH of the digester was monitored regularly at an interval of 3 days and is as shown in Fig. 6a. During the course of digestion, initially in first 5 days, the pH of all the combination ratios decreased drastically; this is due to the conversion of the easily biodegradable organic matter into intermediate product, i.e., VFA which reduces the pH of the reactor. The pH of the MW-treated FVW and AS at optimal power reached to 4.5, which was the lowest among the four different powers (W). After this, the pH started rising and attained a final value of 7.5–8.0. The concentrate ions of NH4-N in the four groups gradually increased and reached 1700.33–1896.35 mg/L at the end of the reaction. The MW-AS and FVW group at 300 W had the highest value, followed by MW-AS and FVW at 200 W. The control had the lowest value. Significantly, MW pre-treatment of FVW is more beneficial, as it releases ammonia nitrogen and increases the degradation of protein in the process of co-digestion of AS and FVW [41]. The ammonia nitrogen concentration of the MW-treated FVW group was higher than that of the untreated FVW group, which may be related to the low protein content in the FVW. The changes in the total VFAs for the all the mix ratios are depicted in Fig. 6b. The variation of the VFA for all the MW-pre-treatment ratios showed a first increasing and then decreasing trend. This result was similar to previous studies [38, 42, 43]. The total VFA reached the maximum on the 6th day (from 10 to 13.5 g/L) with that of the group MW–FVW and AS at the ratio of 25:75 at the power of 300 W being the highest and that of the control being the lowest and then began to decrease. The VFA contents corresponded to changes in pH, and results suggested that MW pre-treatment of AS and FVW is beneficial to the production of VFAs and can maximize the biogas yield. The TVFA was measured in terms of acetic acid as per the method described by Chatterjee et al. [29].

4 Kinetic study

Kinetic modelling is the most suitable tool for industrial anaerobic reactor design. It makes it possible to comprehend the design, operation, and conversion of anaerobic reactors [44]. Kinetic modelling can be utilized to optimize the plant-based outcomes of pilot studies and to predict and control the performance of the anaerobic digesters [45]. Kinetics provide an in-depth idea of reaction rate explaining how a microbial community turns the organic matter present in the substrate into biogas [46]. Kinetics can be fragmented into four phases, namely, lag phase, the log phase, the stationary phase, and the death phase [45]. Various kinetic models have been used to study the anaerobic digestion (AD) process. In this study, two of them have been used, namely, the first-order model and modified Gompertz model (MGM model). MGM model is based on the assumption that biogas increases to its peak exponentially, whereas the first-order model is based on assumption that biogas increased to its peak linearly [35]. The validity of the models was determined using (R2) value. The first-order model is given by Eq. (2), and the MGM model is given by Eq. (3).

First-order model

Modified Gompertz model

where:

Y(t) = cumulative biogas at digestion time t days (mL/g VS)

Y 0 = ultimate biogas production potential (mL/g VS)

k = first-order rate constant for biogas appearance (1/day)

Rm = maximum biogas production rate (mL/g VS·day)

λ = lag phase period or minimum time to produce biogas (days)

t = cumulative time for biogas production (days)

e = mathematical constant (2.718)

Out of the above constants and variables, all values are known except first-order rate constant k which is calculated by transforming Eq. (2) in form of Eq. (4).

Plot between \(\mathit{\ln}\frac{\left( Yt-Y0\right)}{Y0}\) and time t gives the value of k.

The experimental value of cumulative biogas at the end is taken as Y0. The experimental cumulative biogas yield according to first-order model and modified Gompertz model are as depicted in Fig. 7a and b. Graphs illustrate that the result are best fitted to first-order model as compared with the modified Gompertz model. The biogas production started immediately; therefore, no lag phase (λ) was noticed during our experiment, which is due to the high biodegradability of the FVW. Also, MW treatment enhanced the solubilization of the waste which resulted in immediate biogas production. The value of Rm for untreated FVW, 25:75, 50:50, and 75:25 ratio was found to be 17.2 ml/g VS on day 15, 38.2 ml/g VS on day 3, 29.5 ml/g VS on day 3, and 21.5 on day 14. On the other hand, the value of Rm for microwave-treated FVW was found as 38.2 ml/g VS, 40.2 ml/g VS, 44.6 ml/g VS, 36.45 ml/g VS, and 32.25 ml/g VS for 0, 200, 300, 400, and 500 Watt, respectively. First-order rate constant for FVW was noticed as 0.1085 for FVW (25:75) ratio and 0.111 for MW-treated FVW at 300W.

The summary of the results obtained in the present study is presented in Table 2.

5 Conclusions

MW pre-treatment enhanced the daily and cumulative biogas yield as well as the methane production for co-digestion of FVW and AS. This also improved the digesters’ stability by raising the buffering capacity of the digester. AS:FVW (25:75) with MW pre-treatment at the power of 300 W had the highest nutrient dissolution and methane production by 10%. Moreover, MW pre-treatment increased the VS reduction rates of co-digestion matrix of AS:FVW (25:75) from 65 to 77%. In this experiment, co-digestion and MW pre-treatment made hydrolysis no longer a limiting step for AD, and methanogenesis became the new limiting step, which indicated that MW pre-treatment is beneficial to improve AD performance. All experimental results fit well to the first-order model as compared to the modified Gompertz model.

Data availability

Data will be made available on request.

References

Naik GP, Poonia AK, Chaudhari PK (2022) Maximization of biogas by minimal microwave and alkaline pretreatment of rice straw. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-022-03539-1

Agrawal A, Chaudhari PK (2022) Ghosh Prabir, Anaerobic digestion of fruit and vegetable waste: a critical review of associated challenges. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-022-21643-7

Raksasat R, Abdelfattah EA, Liew CS, Rawindran H, Kiatkittipong K, Mohamad M, Mohd Zaid HF, Jumbri K, Lam MK, Lim JW (2022) Enriched sewage sludge from anaerobic pre-treatment in spurring valorization potential of black soldier fly larvae. Environ Res 212:113447. https://doi.org/10.1016/j.envres.2022.113447

Dhar H, Kumar P, Kumar S, Mukherjee S, Vaidya AN (2016) Effect of organic loading rate during anaerobic digestion of municipal solid waste. Bioresour Technol 217:56–61. https://doi.org/10.1016/j.biortech.2015.12.004

Gulhane M, Pandit P, Khardenavis A, Singh D, Purohit H (2017) Study of microbial community plasticity for anaerobic digestion of vegetable waste in anaerobic baffled reactor. Renew Energy 101:59–66. https://doi.org/10.1016/j.renene.2016.08.021

Chong JWR, Chan YJ, Chong S, Ho YC, Mohamad M, Tan WN, Cheng CK, Lim JW (2021) Simulation and optimisation of integrated anaerobic-aerobic bioreactor (IAAB) for the treatment of palm oil mill effluent. Processes 9:1–19. https://doi.org/10.3390/pr9071124

Chong CC, Cheng YW, Ishak S, Lam MK, Lim JW, Tan IS, Show PL, Lee KT (2022) Anaerobic digestate as a low-cost nutrient source for sustainable microalgae cultivation: a way forward through waste valorization approach. Sci Total Environ 803:150070. https://doi.org/10.1016/j.scitotenv.2021.150070

Zhang C, Su H, Baeyens J, Tan T (2014) Reviewing the anaerobic digestion of food waste for biogas production. Renew Sust Energ Rev 38:383–392. https://doi.org/10.1016/j.rser.2014.05.038

Gunaseelan VN (2004) Biochemical methane potential of fruits and vegetable solid waste feedstocks. Biomass Bioenergy 26:389–399. https://doi.org/10.1016/j.biombioe.2003.08.006

Agrawal A, Chaudhari PK, Prabir G (2023) Effect of mixing ratio on biomethane potential of anaerobic co-digestion of fruit and vegetable waste and food waste. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-023-03737-5

Chatterjee B, Mazumder D (2018) Performance evaluation of three-stage anaerobic digestion (AD) for stabilization of fruit and vegetable waste (FVW). J Indian Chem Soc 95:65–80

Arhoun B, Villen-Guzman M, Gomez-Lahoz C, Rodriguez-Maroto JM, Garcia-Herruzo F, Vereda-Alonso C (2019) Anaerobic co-digestion of mixed sewage sludge and fruits and vegetable wholesale market waste: composition and seasonality effect. J Water Process Eng 31. https://doi.org/10.1016/j.jwpe.2019.100848

Lin J, Zuo J, Gan L, Li P, Liu F, Wang K, Chen L, Gan H (2011) Effects of mixture ratio on anaerobic co-digestion with fruit and vegetable waste and food waste of China. J Environ Sci 23:1403–1408. https://doi.org/10.1016/S1001-0742(10)60572-4

Paudel SR, Banjara SP, Choi OK, Park KY (2017) Pretreatment of agricultural biomass for anaerobic digestion: current state and challenges. Bioresour Technol. https://doi.org/10.1016/j.biortech.2017.08.182

Shanthi M, Rajesh Banu J, Sivashanmugam P (2018) Effect of surfactant assisted sonic pretreatment on liquefaction of fruits and vegetable residue: characterization, acidogenesis, biomethane yield and energy ratio. Bioresour Technol 264:35–41. https://doi.org/10.1016/j.biortech.2018.05.054

El Achkar JH, Lendormi T, Salameh D, Louka N, Maroun RG, Lanoisellé JL, Hobaika Z (2018) Influence of pretreatment conditions on lignocellulosic fractions and methane production from grape pomace. Bioresour Technol 247:881–889. https://doi.org/10.1016/j.biortech.2017.09.182

Jeihanipour A, Niklasson C, Taherzadeh MJ (2011) Enhancement of solubilization rate of cellulose in anaerobic digestion and its drawbacks. Process Biochem 46:1509–1514. https://doi.org/10.1016/j.procbio.2011.04.003

Jain S, Jain S, Wolf IT, Lee J, Tong YW (2015) A comprehensive review on operating parameters and different pretreatment methodologies for anaerobic digestion of municipal solid waste. Renew Sust Energ Rev 52:142–154. https://doi.org/10.1016/j.rser.2015.07.091

Ambrose HW, Philip L, Suraishkumar GK, Karthikaichamy A, Sen TK (2020) Anaerobic co-digestion of activated sludge and fruit and vegetable waste: evaluation of mixing ratio and impact of hybrid (microwave and hydrogen peroxide) sludge pre-treatment on two-stage digester stability and biogas yield. J Water Process Eng 37:101498. https://doi.org/10.1016/j.jwpe.2020.101498

Zhou Y, Takaoka M, Wang W, Liu X, Oshita K (2013) Effect of thermal hydrolysis pre-treatment on anaerobic digestion of municipal biowaste: a pilot scale study in China. J Biosci Bioeng 116:101–105. https://doi.org/10.1016/j.jbiosc.2013.01.014

Shahriari H, Warith M, Hamoda M, Kennedy K (2013) Evaluation of single vs. staged mesophilic anaerobic digestion of kitchen waste with and without microwave pretreatment. J Environ Manag 125:74–84. https://doi.org/10.1016/j.jenvman.2013.03.042

Coelho NMG, Droste RL, Kennedy KJ (2011) Evaluation of continuous mesophilic, thermophilic and temperature phased anaerobic digestion of microwaved activated sludge. Water Res 45:2822–2834. https://doi.org/10.1016/j.watres.2011.02.032

Eskicioglu C, Terzian N, Kennedy KJ, Droste RL, Hamoda M (2007) Athermal microwave effects for enhancing digestibility of waste activated sludge. Water Res 41:2457–2466. https://doi.org/10.1016/j.watres.2007.03.008

Appels L, Houtmeyers S, Degrève J, Van Impe J, Dewil R (2013) Influence of microwave pre-treatment on sludge solubilization and pilot scale semi-continuous anaerobic digestion. Bioresour Technol 128:598–603. https://doi.org/10.1016/j.biortech.2012.11.007

Liew CS, Yunus NM, Chidi BS, Lam MK, Goh PS, Mohamad M, Sin JC, Lam SM, Lim JW, Lam SS (2022) A review on recent disposal of hazardous sewage sludge via anaerobic digestion and novel composting. J Hazard Mater 423:126995. https://doi.org/10.1016/j.jhazmat.2021.126995

Eswari P, Kavitha S, Kaliappan S, Yeom IT, Banu JR (2016) Enhancement of sludge anaerobic biodegradability by combined microwave-H2O2 pretreatment in acidic conditions. Environ Sci Pollut Res 23:13467–13479. https://doi.org/10.1007/s11356-016-6543-2

Liu J, Yang M, Zhang J, Zheng J, Xu H, Wang Y, Wei Y (2018) A comprehensive insight into the effects of microwave-H2O2 pretreatment on concentrated sewage sludge anaerobic digestion based on semi-continuous operation. Bioresour Technol 256:118–127. https://doi.org/10.1016/j.biortech.2018.01.126

Krishna D, Kalamdhad AS (2014) Pre-treatment and anaerobic digestion of food waste for high rate methane production - A review. J Environ Chem Eng 2:1821–1830. https://doi.org/10.1016/j.jece.2014.07.024

Chatterjee B, Radhakrishnan L, Mazumder D (2018) New approach for determination of volatile fatty acid in anaerobic digester sample. Environ Eng Sci 35:333–351. https://doi.org/10.1089/ees.2017.0190

Kesharwani N, Bajpai S (2020) Batch anaerobic co-digestion of food waste and sludge: a multi criteria decision modelling (MCDM) approach. SN Appl Sci 2:1–11. https://doi.org/10.1007/s42452-020-03265-1

Ji C, Kong CX, Mei ZL, Li J (2017) A review of the anaerobic digestion of fruit and vegetable waste. Appl Biochem Biotechnol 183:906–922. https://doi.org/10.1007/s12010-017-2472-x

Garcia-Peña EI, Parameswaran P, Kang DW, Canul-Chan M, Krajmalnik-Brown R (2011) Anaerobic digestion and co-digestion processes of vegetable and fruit residues: process and microbial ecology. Bioresour Technol 102:9447–9455. https://doi.org/10.1016/j.biortech.2011.07.068

Li Y, Wang Y, Yu Z, Lu J, Li D, Wang G, Li Y, Wu Y, Li S, Xu F, Li G, Gong X (2018) Effect of inoculum and substrate/inoculum ratio on the performance and methanogenic archaeal community structure in solid state anaerobic co-digestion of tomato residues with dairy manure and corn stover. Waste Manag 81:117–127. https://doi.org/10.1016/j.wasman.2018.09.042

Esparza I, Jiménez-Moreno N, Bimbela F, Ancín-Azpilicueta C, Gandía LM (2020) Fruit and vegetable waste management: conventional and emerging approaches. J Environ Manag 265:110510. https://doi.org/10.1016/j.jenvman.2020.110510

Pavi S, Kramer LE, Gomes LP, Miranda LAS (2017) Biogas production from co-digestion of organic fraction of municipal solid waste and fruit and vegetable waste. Bioresour Technol 228:362–367. https://doi.org/10.1016/j.biortech.2017.01.003

Gulhane M, Khardenavis AA, Karia S, Pandit P, Kanade GS, Lokhande S, Vaidya AN, Purohit HJ (2016) Biomethanation of vegetable market waste in an anaerobic baffled reactor: effect of effluent recirculation and carbon mass balance analysis. Bioresour Technol 215:100–109. https://doi.org/10.1016/j.biortech.2016.04.039

Algapani DE, Wang J, Qiao W, Su M, Goglio A, Wandera SM, Jiang M, Pan X, Adani F, Dong R (2017) Improving methane production and anaerobic digestion stability of food waste by extracting lipids and mixing it with sewage sludge. Bioresour Technol 244:996–1005. https://doi.org/10.1016/j.biortech.2017.08.087

Liu WY, Liao B (2019) Anaerobic co-digestion of vegetable and fruit market waste in LBR + CSTR two-stage process for waste reduction and biogas production. Appl Biochem Biotechnol 188:185–193. https://doi.org/10.1007/s12010-018-2910-4

Gu J, Liu R, Cheng Y, Stanisavljevic N, Li L, Djatkov D, Peng X, Wang X (2020) Anaerobic co-digestion of food waste and sewage sludge under mesophilic and thermophilic conditions: focusing on synergistic effects on methane production. Bioresour Technol 301:122765. https://doi.org/10.1016/j.biortech.2020.122765

Habiba L, Hassib B, Moktar H (2009) Improvement of activated sludge stabilisation and filterability during anaerobic digestion by fruit and vegetable waste addition. Bioresour Technol 100:1555–1560. https://doi.org/10.1016/j.biortech.2008.09.019

Shahriari H, Warith M, Hamoda M, Kennedy KJ (2012) Anaerobic digestion of organic fraction of municipal solid waste combining two pretreatment modalities, high temperature microwave and hydrogen peroxide. Waste Manag 32:41–52. https://doi.org/10.1016/j.wasman.2011.08.012

Lv W, Schanbacher FL, Yu Z (2010) Putting microbes to work in sequence: recent advances in temperature-phased anaerobic digestion processes. Bioresour Technol 101:9409–9414. https://doi.org/10.1016/j.biortech.2010.07.100

Wen HL, Wachemo AC, Zhang L, Zuo XY, Yuan HR, Li XJ (2019) A novel strategy for efficient anaerobic co-digestion based on the pretreatment of corn stover with fresh vinegar residue. Bioresour Technol 288:121412. https://doi.org/10.1016/j.biortech.2019.121412

Njoya M, Basitere M, Ntwampe SKO, Lim JW (2021) Performance evaluation and kinetic modeling of down-flow high-rate anaerobic bioreactors for poultry slaughterhouse wastewater treatment. Environ Sci Pollut Res 28:9529–9541. https://doi.org/10.1007/s11356-020-11397-5

Verma AK, Bhunia P, Dash RR (2015) Carbonaceous organics removal kinetics in an upflow anaerobic sludge blanket (UASB) reactor treating physico-chemically pre-treated textile wastewater. Desalin Water Treat 54:1577–1588. https://doi.org/10.1080/19443994.2014.888687

Batstone DJ, Keller J, Blackall LL (2004) The influence of substrate kinetics on the microbial community structure in granular anaerobic biomass. Water Res 38:1390–1404. https://doi.org/10.1016/j.watres.2003.12.003

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material characterization, data analysis, and experimental analysis were performed by Akanksha Agrawal. The first draft of the manuscript was written by Akanksha Agrawal. Data validation and supervision were done by Dr. P.K. Chaudhari and Dr. Prabir Ghosh. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

NA

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

•Co-digestion of AS:FVW was explored, and (25:75) ratio was found to give best result.

•MW pre-treatment method was used to enhance the biogas production of substrate matrix by means of batch AD at 37°C.

•MW pre-treatment was proved to be beneficial to the dissolution of organic matter, conversion of protein to NH4+-N, and enhancing unit methane yield, in the AS and FW anaerobic co-digestion system.

•MW irradiation @ power of 300 W was found to provide optimal results as compared with other ratios.

•Ten percent increment in the methane yield was observed for the co-digestion system using MW treatment.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Agrawal, A.V., Chaudhari, P.K. & Ghosh, P. Effect of microwave treatment on maximizing biogas yield for anaerobic co-digestion of fruit and vegetable waste and anaerobic sludge. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04114-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04114-y