Abstract

Organic production of agricultural waste and animal manure lead generation of vast quantity of wastes. Inefficient management of these agroindustrial wastes causes a serious threat to the environment. Biological waste treatment technology cocomposting is an aerobic digestion (AD) of organic wastes mixes, aiming to obtain compost regarded as a sustainable and clean environment method for nutrient recovery. Compared with conventional cocomposting methods, integrated composting is not merely the cocomposting of organic biomass amended with inorganic contents to initiate and sustain the biodegradation process but also to obtain added value compost with designed characteristics. The setup of appropriate integrated composting protocols can be the way to optimize the management of organic waste and to improve production process and also product nutritional contents. Therefore, this research study focused on the viability of cocomposting organic biomass with or without inorganic amendments to obtain added-value compost with enhanced nutritional characteristics. Substrate combinations derived from the solid fraction of digestate (SFD), agricultural (lignocellulosic) biomass, and bulking material (sawdust, peanut shell, and green yard waste) with or without inorganic amendments were cocomposted in a controlled composting system. During the composting process, the temperature of composting material and physicochemical, chemical, and maturity characteristics were monitored. Potential added-value characteristics such as biomethane production (BMP) and physical and microbial characteristics of matured compost were determined. Maximum temperatures reached a thermophilic range (< 60°C), which was lower than sanitizing temperatures set by the United States Environmental Protection Agency (USEPA). The bulking material showed the positive effect, reducing the EC (less than 5 dS m−1) and N losses up to (10–13%) during integrated composting, while amendment of inorganic content did not alter the composting process but enhanced nutritional characteristics (micro- and macro elements) of the compost obtained. This pilot scale integrated composting facility evaluated production characteristics of composting process; the integrated composts showed optimal degree of stability and maturity depicting appropriate physical characteristics to be used as organic fertilizer. Further studies into the optimal rate of amending inorganic ingredients and evolution of nutritional values are recommended for integrated composting.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Agricultural soil has continuous fertility problem (low organic matter) due to greater mineralization process. Soil organic matter (SOM) is considered an important factor which indicates soil quality. To improve soil fertility condition, various organic soil amendments are used to improve soil physicochemical properties [1]. Composting is an aerobic method of organic fertilizer formation using bacterial action. Composting of biowaste converts active organic fraction into stabilized byproducts that enhance soil characteristics and provide nutrient supplement for crop growth. The final product of composting is humus-like mixture that improves soil physical, chemical, and organic characteristics of soil [2, 3]. Application of compost fertilizer increases the soil organic matter, suppresses soil-born plant pathogens, and improves plant growth [4].

Organic amendments such as compost, green manure, and animal manure are a quick way to improve organic matter in soil [5]. In addition, compost suppresses the soil born disease caused by different phytopathogenic microorganism making another added-value characteristic of compost. A composting process is a prolonged digestive process; various additives such as ash, fertilizers, phosphogypsum, jiggery, lime, charcoal, FGD gypsum, polyethylene glycol, and various bacterial strains are frequently used to speed up compost decomposition [6, 7]. In the last few decades, the use of inorganic amendments in composting process has gained a significant importance to enhance nutritional values of the compost to fulfill the soil nutrient requirement and to improve soil properties [8, 9]. The quality of mature compost is improved through inorganic amendments because of reduction in ammonia and greenhouse gas emissions [10]. There are some inorganic contents which are very beneficial to amend organic matter in composting [11]. Such mineralization of phosphorus (P) by microorganisms converts the organic form of P to a plant-available form [12]. The moisture content of composted material can be maintained by evaluating changes occurred in the composition of organic carbon. Compost contains cellulose, hemicellulose, lignin, water-soluble organic materials, and carbon that is biological in nature. Amino acids, starch, sucrose, and low fructose are all components of water-soluble organics, and microorganisms get their direct materials and energy from water-soluble organic substances. The conversion rate and component lifespan of 4-degree organic matter during fertilizing methods may be reflected by changes in water-soluble organic matter [13]. Lignin is typically not biodegradable and partially transformed into other chemicals by bacteria while cellulose is more difficult to biodegrade than hemicellulose [14].

Evaluating changes in nitrogen constituents is useful in refining the composting procedure, which adds to the feature of the compost. Generally, nitrogen is available in the form of organic nitrogen and inorganic nitrogen. Inorganic nitrogen is mainly composed of ammonia and nitric nitrogen while organic nitrogen is composed of acid-hydrolyzed and nonhydrolyzed nitrogen. Several studies have focused on the role of inorganic fertilizers amendments in the composting process to decrease nitrogen losses although some studies have clarified the addition inorganic fertilizer into the compost to improve the compost fertility level. The goal is to increase the efficiency of the use of integrated fertilizers. Changes in biomass, nitrogen composition, and humus during organic-inorganic cocomposting are also rarely studied. Clarifying these differences will help improve production processes, fertilizer biomass, and compost nutrient content [6,7,8]. Lime is an inexpensive and accessible resource that may be used as a composting ingredient, making it an appealing way to repurpose solid waste. In sewage sludge composting, lime enhanced the highest temperature, lengthened the duration of the thermophilic stage, and sped up the composting process [6]. However, very little is known about how organic matter degrades when lime is added during the composting process, let alone how antibiotics and heavy metals evolved and how they affect microbes.

Therefore, in the current investigation, an aerobic composting experiment using lignocellulosic biomass and animal dung was carried out with or without inorganic amendments (NPK fertilizer) (1) to examine the feasibility and impact of biological transformation of farmyard and agricultural crop by its cocomposting with or without inorganic amendments (NPK fertilizer) and (2) to monitor and quantify the nutritional dynamics and physicochemical and biological characteristics of composting produced during the decomposition of organic waste with and without NPK ingredients. The effects of inorganic amendment on microbiological activities were examined in order to identify the underlying causes of the performance improvement using NPK contents to increase composting efficiency.

2 Materials and methods

2.1 Feedstock collection

The raw materials (biomass) used in this cocompost technology were animal farm waste/animal dung (AD), solid fraction from digestater (SFD), and agricultural biomass (wheat straw, rice husk, and corn stalks), while animal bedding waste, green waste/yard waste, peanut shell, and sawdust were used as bulking materials to provide the specific bulk density to composting mixtures [15]. The SFD produced from anaerobic codigestion of cattle manure and agricultural waste (fresh mass basis) at farmer’s field (29° 30′ 59.54″ N 70° 51′ 1.15″ E) was collected and used immediately as a feedstock in the composting material. Agricultural (lignocellulosic) biomass was collected from a farmer’s field in the vicinity of study site. Technically, it is economically beneficial to used discarded wheat straw in the compost [16]. The collected wheat straw was a residue from animal feeding and wasted straw at the bottom layer of wheat straw pile/storage. Usually, it is the common practice to use rice husk along with animal dung as animal bedding in the villages. This animal bedding is a rich source of organic matter and moisture and carries nutrients that can stimulate the composting process. Green waste or Yard waste was collected from lawn and orchards, crushed to a size of 10–25mm and added as bulking agents because of high moisture contents to optimize composting process. Peanut shell and sawdust (fine size) were taken from peanut oil extraction plant and wood saw plant, respectively. Diamonium phosphate (18% N, 46% P) and urea (46% N) fertilizers are a good source of N, P, and K. A small quantity (at 0.2%) of sulfur was also used as a process stabilizer in composting. The inorganic modifiers were purchased from the agrochemical industry in the Multan Industrial Zone, Pakistan. The main physicochemical characteristics of the organic wastes used in cocomposting system are listed in the Table 1.

2.2 Composting structure

The experiments of integrated composting of lignocellulosic crop waste and animal waste with inorganic amendments were carried out in a cemented RBC pit, insulated from inside with polythene sheet [16] as shown in Fig. 1. The maximum designed volume of the compost pit was 1500 ft3 with 150 ft2 base area. The compost structure system was equipped with a leachate collection system at the basement of the compost pit. The moisture content in the composting pits was controlled using sprinkler system installed over composting pit. The required amount of water was sprinkled to maintain the moisture level >40% to optimize biological activity. Biogas extraction system consisted of perforated PVC network installed in three different layers of composting structure. It was also provided with an aeration system to maintain the oxygen rate for better microbial activity using a sequential aeration program which depends on composting temperature. To analyze and quantify the biogas constituents, a biogas analyzer was mounted on the biogas drainage line. Temperature measuring probes were fixed at different locations of each layer (3 per layer) of composting mixture.

2.3 Experimental procedure

A pilot scale study was carried out on organic and integrated cocomposting experiments to evaluate the effects of inorganic amendments and bulking materials on process and end-product quality of integrated composting of organic biomass with inorganic nutrients. Four composting treatments were performed in triplicate: Treatment 1 (O-T) was the sole lignocellulosic/organic biomass cocomposting, and Treatments 2-4 (I-T1-3) were the cocomposting of organic materials with inorganic amendments. The mixing ratio of organic biomass and inorganic nutrients was adjusted according to previous studies [17, 18], considering two criteria: (i) the dominance of lignocellulosic/organic material in the mixture as it is the main substrate in the compost (% of total organic carbon and total nitrogen) and (ii) to achieve good C/N ratio (around 20) in the composting mixture. Additionally, all integrated composting treatments were added with a small amount of sulfur (at 0.2%) to lowers/regulate the pH of integrated cocomposting mixtures. Sawdust used in composting as a bulking material enhances porosity, controls moisture, and maintains C/N ratio [15].

Prior to composting, the animal waste, lignocellulosic biomass, and inorganic nutrients were mixed uniformly according to the treatments (Table 2). The moisture contents in the cocomposting mixtures were maintained (50-60%) throughout the composting process [19]. Each composting pit was provided a one-foot layer of unshredded tree leave and branches to act as porous media for leachate drainage. The compost mixtures (400 kg/ per treatment) were then fed into the composting pit and covered with polythene sheet. To facilitate thermophilic range, the composting material was aerated through perforated pipes supplied at bottom of composting pit. The oxygen rate in the composting pit was maintained 5% (v/v). Based on the C/N ratio, it was evaluated that the compost took about 75 days to maturity [20].

The biooxidative phase of the compost is considered complete when the temperature approaches ambient temperature and aeration was stopped to allow the compost to mature. Approximately 1000g of fresh compost samples was collected from each compost pit on days 0, 15, 30, 45, 60, and 75. Samples were obtained by mixing seven subsamples from seven locations in the entire section (top to bottom) pit. Each sample was divided into two parts: one was air-dried and ground to 0.5 mm for analysis, and the other was immediately frozen for later use. All analyses were performed in triplicate.

2.4 Characterization of composting

In this integrated composting study, the characteristics evaluated were physical, physicochemical, chemical, microbial, and biomethane. Monitoring started right after the preparation of compost treatments.

2.5 Composting temperature

Temperature evolutions in the composting treatments were noted daily using digital temperature probes (accuracy, ±01). The average temperature and ambient temperature of each compost layer (2-ft layer) were measured six times a day (0:00 to 24:00 hours) and recorded by data loggers.

2.6 Physicochemical and chemical analysis

The electrical conductivity and pH of air-dried lignocellulosic substrate and compost mixtures were analyzed using an OEM digital water tester (China). An oxygen meter (HORIBA OM-71, Japan) was used for the determination of oxygen content; moisture content was measured by drying the samples in an oven at 105°C for 24 hours. The OM fraction was evaluated by determining the loss on ignition at 500 °C for 24 hours; total carbon (CT) and total nitrogen (NT) were measured by microanalysis (Euro-vector elemental analyzer).

An automatic liquid analyzer (TOC-V CSN Analyzer, Shimadzu) was used to determine the humic acid-like components, extractable carbon (Ce), fulvic acid-like carbon (Cf), and humic acid-like carbon (Ch). The same analyzer was used for determining the water-soluble carbon (Cw) and nitrogen (Nw) in the water extract (1:10, w/v) using synthetic filtration (0.45 μm diameter) [21]. The cation exchange capacity (CEC) was measured according to the method discussed [22]. NO3-N and NH4+-N were measured through electrophoresis and calorimetric method, respectively, as discussed by Berthelots’s reaction [23].

The organic nitrogen (Norg) was calculated from subtraction of inorganic N contents (NO3—N and NH4+-N) from total nitrogen (NT). Phosphorous (P) and sodium (Na) were determined using calorimetric method (molybdovanadate phosphoric acid) [24] and flame photometry, respectively, while Ca, Mg, Fe, Cu, Mn, and Zn were measured by ICP-OES spectrometry (Thermo-elemental Co. Iris Intrepid II-XDL). The germination index (GI) was determined using Lepidium sativum L. seeds [25]. Losses in OM and NT were determined by difference in ash concentrations as discussed by Paredes et al. [26].

where x1-2 and N1-2 are initial-final ash and NT concentrations.

The following expressions were employed to calculate humification indices [27, 28]:

2.7 Physical and microbial characteristics

Bulk density (BD), real density, and porosity of compost mixtures, total water holding capacity (TWHC), shrinkage, and air capacity were evaluated at compost maturity stage as presented by Bustamante et al. [29]. The microbial community, Salmonella, was evaluated using a method developed by the USEPA [30]; total coliforms and fiscal coliforms (E. coli) were examined using a method developed by Chroni et al. [31]. The results obtained were presented in colony-forming units (numbers) per gram of fresh composting mixture (CFU g−1), but Salmonella (detected/not detected).

2.8 Biochemical methane production

The biochemical biomethane productions (BMP) in composting process were stored in PVC biogas bags for further quantification after gaseous composition analysis. The total volume of biomethane produced was measured using biogas flow meter while a portable biomethane analyzer (GA5000, Geotech, China) was used to identify biomethane compositions.

2.9 Statistical analysis

The one-way analysis of variance (ANOVA) with least significant difference (LSD) at p = 0.05 was used to analyze the data on the production and characterization of compost, and the Tukey B test was used to determine whether there were statistically significant variations in the compost physical characteristics. Normality and homogeneity of variances were investigated using the Shapiro-Wilk and Levene tests, respectively. The SPSS Statistics-20 software package was used for analysis.

3 Results and discussion

3.1 Development of cocomposting process

3.1.1 Evolution of compost temperature

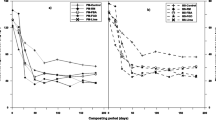

The variations in temperatures of different composting treatments are presented in Fig. 2. After the composting process started, all of the composting treatments showed rapid temperature increases [32], with the O-T attaining a compost temperature of over 50 °C in the first week. This rapid temperature rise is due to the initiation of microbial activity in organic biomass mixtures and indicates favorable conditions (pH, MC, TOC, TPS, and nutrients) of the composting substrate. All the composting treatments presented similar temperature evolution trends; the usual chronological stages (mesophilic, thermophilic, cooling, and maturity) were identified, which are the characteristics of composting [33]. The treatment O-T (organic mixtures) attained the maximum temperature and for a longer time than that in all other integrated treatments; this thermophilic phase lasted till the 36th day in this organic composting treatment. This indicated the effect of bulking material incorporated into the composting mixtures [33]. So, the characteristics of the composting mixture could be improved as Serramia et al. [34] stated that the lignocellulosic material in composting enhanced the degradation and humification of organic biomass in cocomposting. In all the integrated composting treatments, the compost mixture temperatures were attained > 50°C for 2-3 weeks, consecutively, helping the mixtures’ sanitization. As expected, each treatment showed a higher digestion rate in mesophilic and thermophilic phases, which is due to the disintegration of lignin and cellulose (recalcitrant organic biomass) in the later phases [35]. The optimum degradation of composting mixtures can be linked to the addition of bulking agent [33] due to the growth of microorganisms solubilizing phosphate into organic acids [36]. In this study, compost mixture temperatures in all the treatments were the same in the cooling stage after 45 days, which indicated the decomposition of hard to degrade composting substrate. Furthermore, in the thermophilic range, higher nitrogen losses may occur due to NH3 volatilization (i.e., associated with high temperature and alkaline pH) [37]. The overall composting process time (75 days) was longer for both single and combined treatments than reported by other previous studies [33, 38].

As more bioresistant substances like cellulose and lignin replace easily biodegradable substrate and microbial activity declines, the temperature should ideally drop as a result. Therefore, it has been proposed that a temperature drop to near-ambient may signal that the compost is getting close to reaching a stable and mature condition (provided that reheating does not occur upon turning the pile) [33]. Because it is easy, quick, and affordable, temperature monitoring is appealing as a potential stability-maturity evaluation tool [38] and since the majority of compost monitoring methods routinely include pile temperatures. Other research revealed that a number of variables frequently used to assess the stability and maturity of compost showed good correlation with the final fall in pile temperature [38]. These researchers came to the conclusion that temperature monitoring might be applied as a quick and easy way to gauge compost maturation.

3.2 Mineralization of organic matter (OM)

Table 3 indicates, during the biooxidative stage, the OM losses in the sole organic and integrated treatments were substantial, from initial values of 823, 861, 855, and 859 g kg−1 to the values of 640, 719, 711, and 716 g kg−1 for O-T, I-T1, I-T2, and I-T3 treatments showed the OM mineralization process, respectively.

The OM losses in both sole organic and integrated treatments were statistically significant in biooxidative stage, linked with maximum microbial activity; this was significantly higher in O-T due to the high-temperature reach. During the initial stages of the cocomposting process, the lowest percentages of OM mineralization were measured in treatments with a larger proportion of bulking material, indicating that a bulking agent slowed the rate of OM degradation. Furthermore, among all compost treatments, the lowest percentage of OM mineralization was measured during the mature stage, demonstrating the compost mixture’s stability after the biooxidative phase. All composting treatments displayed comparable OM losses (by mass) at the completion of the process: 57–59% (Fig. 3). When olive waste and winery waste were cocomposed with manure, respectively, the investigations by Paredes et al. [26] and Bustamante et al. [22] found decreased organic matter mineralization and similar final organic matter loss during the maturity stage. The formation of H+ during the nitrification process, the degradation of high molecular organic matter to organic and inorganic acids, the volatilization of NH3, and the mineralization of nitrogen and phosphorus are the causes of the pH drop [16].

3.3 Nitrogen transformation

The Norg concentration significantly increased across the board for all composting treatments, particularly during the biooxidative stage. According to Fig. 4a–d, this may be connected to the concentration effect brought on by the significant mineralization of OM, resulted in the weight loss of the compost mixture [9]. By day 30, the NH4+-N concentration had dramatically dropped in each of the composting treatment, especially in O-T, which had the highest beginning NH4+-N concentration. It then became steady until the composting process is complete. Although there was no visible rise in NO3-N concentration, this drop in NH4+-N concentrations may have been caused by the process of NH3-concentration volatilization. The temperature of composting treatments during the first month (30 days) was found to be high (Fig. 2) and pH > 7, notably in O-T, which facilitated the volatilization of NH3. A considerable N loss from NH3 volatilization was also found [39] at pH levels above 7.0 and higher temperatures (> 40 °C). All the compost treatments had NH4+-N concentrations at or below the recommended maximum for mature composts, which is 100 mg kg−1, at the time of compost maturity [40]. The first 30 days of composting saw NO3-N concentrations below 500 mg kg−1 in all treatments, which is attributable to high temperatures and excess NH3 slowing down nitrification, respectively [39, 41]. Following this stage, NO3-N concentration exhibited a considerable increase in all treatments, indicating nitrification.

As shown in Fig. 5, the NT losses were less than that typically observed during composting (50% loss of N mass fraction). These findings are supported by studies by Paredes et al. [26] when oil mill effluent is composted including the solid organic biomass, Bustamante et al. [22] when brewery waste and liquid manure are cocomposted, and Bernal et al. [40] when animal manure is composted. These losses could be caused by NH3 volatilization, which is encouraged by the alkaline pH and high temperature reached in the early stages of composting. However, the N loss is reduced the more bulking agent there is in the compost composition. Therefore, the inclusion of bulking material seems to dramatically reduce N loss. At the beginning of the process, an increase in N contents was observed in all treatments with the addition of bulking material, possibly due to biofixation of N [22]. It is desirable to minimize N loss during composting to obtain maximum N concentration in the end product and to suppress odor and environmental concerns [42].

3.3.1 Evolution of physicochemical, chemical, and maturity characteristics in cocomposting

In the initial phase of all composting treatments, high pH values of 6.8 to 8.18 were displayed as shown in Table 3, due to the high solid fraction of anaerobic digester with alkaline in nature. However, the pH was significantly decreased as the composting process carried on, which is the consequence of nitrification at the completion of the composting process and oxidation of the additional sulfur content in compost mixtures other than pure organic biomass (O-T) composting [43]. Except for O-T, all S-amended integrated compost treatments exhibited pH final values as neutral or slightly acidic (Table 3). According to Wang et al. [1], the pH should be maintained around 7.5 to 8.5 throughout the composting process, especially in the beginning. There are similar findings of good microbial activity at pH values between 6.7 and 9 [16]. Low pH would delay or even prevent the transition from the mesophilic phase to the thermophilic phase [13], which would also restrict microbial activity [31].

In all composting formulations, the beginning EC readings were high (> 3 dS m−1), with I-T2 having the noticeably highest value. As the growth of inorganic compounds and the rising relative concentration of ions brought on by the mass of composting mixtures, the EC increased during the composting process in both organic and integrated composting treatments [26]. The integrated composting treatments had the highest EC values at the maturation stage, demonstrating the significant positive impact of the bulking material added to the integrated treatments on the reduction of salinity in the composted product. All treatments had EC values higher than 5 dS m−1 at this stage.

The end-values attained in all integrated composting treatments were close to 19, while 12 in O-T composting, which indicated a good degree of compost maturity [68]. Primarily in the start of the composting process, the OM degradation led to a decrease in the CT/NT ratio. All of the treatments saw a decrease in the amount of water-soluble organic C (Cw) and the ratio of soluble organic C to soluble organic N (Cw/Nw) as the composting process progressed, particularly in the biooxidative stage. This may result from the breakdown of simple, water-soluble chemical components including sugars, amino acids, and peptides. The final Cw readings for all of the treatments were close to 5 g kg−1, which satisfies the upper limits suggested by various authors for compost.

The cation exchange capacity (CEC), humification index (HI), and germination index (GI) were used to indicate compost maturity; all the parameters significantly improved in composting for all treatments (Table 4). This illustrates phytotoxins are absent and OM humification. As compost maturity attained, all the composting treatments pretended a significant maturity level because all the studied variables have higher values as mentioned in the different literature as indicative of maturity [25, 27]. However, our article’s evolution about these parameters is a clear indicator of the OM humification process and the absence of any phytotoxicity. At the start of the composting process, however, the HI and GI exhibited values that were greater than the limit values, so these values for compost maturity cannot be used in this study. The most crucial elements affecting the quality of the compost are the initial carbon to nitrogen (C/N) ratio [40]. In general, composting experts believe that beginning C/N ratios of 25 to 30 are appropriate [27]. Nevertheless, several researchers recently accomplished composting at lower beginning C/N ratios with success. Composting at lower beginning C/N ratios can cure more manure but also cause more nitrogen to be lost as ammonia gas.

The two main chemical components of humic substances are fulvic acids (FA) and humic acid (HA), with HA having a more complicated structure than FA. FA can dissolve in both acidic and alkaline solutions, but HA cannot, and vice versa. The variations observed in HA and FA during the composting process are presented in Fig. 6. The continuous rise in HA content and falling of FA content showed the stability of OM in composting process. These results were validated by similar studies conducted by Li et al. [44] and Wang et al. [45]. The production of humus substance in the composting process might be in two ways; (1) as the substance’s core and skeleton, lignin derivatives were created by oxidizing lignin, and (2) humus substance was created through the polymerization of monomers that were disintegrated by microorganisms. Under the influence of diverse bacterial processes, HA and FA can change into one another [46]. The thermophilic phase was primarily responsible for the rise in HA contents and fall in FA contents. The HA content in I-T3 was significantly the highest, and the I-T2 show no significant difference with I-T3, while O-T composting had the lowest HA values found. NPK is typically adsorbed by HA because it typically carries a lot of acidic functional groups and has a large amount of CEC [47, 48]. In order to increase the effectiveness of fertilizer usage, it is therefore advantageous to activate and fix the fertilizer nutrients as well as to promote slow-release inorganic nutritional (inorganic fertilizer) values. During the composting process, inorganic nutrients can also be used by microorganisms to transform them into organic nutrients and create slow-release fertilizer.

In all of the composting treatments, oxygen content was observed to continue declining until it reached a rather constant value, declining from 14.5 percent to 2.7 percent before stabilizing as shown in Fig. 7(b). All of the sole organic and integrated composting treatments showed a decreasing trend in oxygen concentrations during composting. This was due to the composting of bulking agent (peanut shell) decreasing compost mixtures density [49, 50], minimizing the development of big clumps and enabling for the compost feedstock to get oxygen [51].

Additionally, the moisture content (MC) showed a gradually decreasing trend in the cocomposting process of both sole organic and integrated treatments during the fermentation stage (Fig. 7a). In all of the composting mixtures, moisture contents were over 60% at the start of the experiment, while generally tended to drop as the composting process proceeded on. In the initial stages of composting (0–30 days), MC reduced with a gradual trend while during the middle stage MC decrease slightly quickly. It is because quick microbial activities occurred in the composting mixture. MC was stable and accounted up >30% of the compost pile at the maturity stage. The duration of time when MC tended toward stability was the key distinction between the composting treatments. The treatments took 10–15 days for MC stability.

3.3.2 Evolution of carbon components in cocomposting

Changes in carbon composition (i.e., total organic carbon (TOC), water-soluble organic carbon (WSOC), hemicellulose, lignin, and cellulose) during composting were assessed (Fig. 8). The TOC content continued to decrease until it reached a relatively stable value. This phenomenon is due to the decomposition and utilization of organic matter by microorganisms and CO2 released during the fermentation period. TOC contents were higher in integrated treatments than that in sole organic treatment. The trend found was O-T < I-T1 < I-T2 < I-T3, as the bulking material has enhanced carbon absorption capacity (Fig. 8a). An effective C/N ratio for microorganisms and a bulking agent both reduce nitrogen losses.

The changes of WSOC during composting are shown in Fig. 8b.WSOC in all the treatments showed a gradually decreasing trend because of the continual consumption of WSOC by microorganism. In all composting combinations, WSOC decreased more rapidly within the thermophilic temperature range, due to the highest fermentation rate during this stage. The hemicellulose content first decreased and then increased and continued until the maturity stage of composting (Fig. 8c). This indicated the partial decomposition of hemicellulose of the easily degradable hemicellulose is depleted while the hemicellulose content begins to increase again. In the late stage of composting, the content of hemicellulose began to decrease, and the content of WSOC decreased significantly, which could not provide the required nutrients for microorganisms, and the hemicellulose was decomposed again.

The variation observed in cellulose and lignin contents is presented in Fig. 8d, e, respectively. This demonstrated that the thermophilic stage is the stage in which cellulose and lignin are primarily disintegrated. Thermophilic actinomycetes and fungi under unfavorable development conditions have been proven to be the primary biodegradable microorganisms for cellulose and lignin as elaborated in previous research [52, 53]. Actinomycetes develop bacteria with thicker spores that are resistant to radiation, high temperatures, and chemical sterilization. Glucose, hemicellulose, and lignin are all readily decomposed by high-temperature fungus [54]. Previous studies have shown that white-rot fungus can effectively disintegrate lignin [55]. The results showed that the addition of bulk material was beneficial to the decomposition of cellulose and lignin.

3.3.3 Biomethane production

Figure 9a presents the total biomethane production (BMP) and its burning time against all the composting treatments. The methane was collected in biogas bags after the 10th–12th day of composting. Compared with sole organic composting, integrated composting showed a similar total volume of biomethane production except for the I-T3 composting treatment. On the other hand, O-T and I-T1 gave maximum burning time for unit biogas burning, which may be due to the more biomethane contents in the biogas mixtures. The biogas production was observed and collected during the first month (30 days) of composting; later, no BMP was generated from composting. The maximum BMP generated was 8.95 m3 in O-T composting followed by 8.55 m3 in I-T1 composting. The BMP composition analysis (Fig. 9b) for CH4, CO2, H2S, and O2 revealed that the maximum CH4 gas (34.37 %) was produced in O-T composting followed by all integrated composting treatments (Fig. 9b). Due to the properties of raw substrate, building compost technology alone is more challenging than installing compost technology and biogas technology simultaneously. It would be essential to build run-off water retention ponds, a perimeter drain, and underground piping systems to handle surplus water at the composting site [7]. According to the calculation made under the identical operating conditions, the integrated technology is more economically appealing than installing either technology separately. When both technologies are installed at once, a synergistic effect occurs that allows each technology to complement the other, resulting in better products and increased revenue.

3.3.4 Compost quality and added-value characteristics

Table 5 presents some relevant characteristics of composted material related to nutritional (micro and macro elements) and hygienic aspects. The macroelement concentrations were found significantly higher: the final NT values were >20 g kg−1 in all composting treatments while the P and K contents had the same values found in frequently utilized organic mixtures (agroindustrial waste and manures) [56] and municipal solid waste [57]. However, the micronutrients measured in our study were similar to those measured in the studies conducted on agroindustrial waste and were found lower than municipal solid waste [56, 57]. For the hygienic safety of mature compost, compost quality microbial indicators for instance fecal-coliform (Escherichia coli), total-coliform, and pathogenic micro-organism (Salmonella) in mature compost were evaluated. Microbiological analysis results confirmed significant reductions in total and fecal coliform (E. coli) levels according to review literature limits for composting hygienic properties, while Salmonella was not found in any of the composting treatments.

Stability and maturity of compost are the two primary factors addressed before using compost for agriculture which can be studied using a number of approaches at a chemical and/or biological level [22]. Additionally, a number of agricultural industries, such as the soilless crop production industry, demand composts with additional benefits that both justify the compost’s associated production costs and meet the demands of these particular agricultural activities, such as the capacity to suppress phytopathogenic microorganisms [13, 31]. For this, many techniques (analytical, instrumental, and biological) have been employed to assess the resulting composts’ characteristics and potential added value.

3.3.5 Physical characteristics of matured compost

Table 6 shows the physical properties of mature composts obtained from different treatments and compared with the values reviewed for the substrate [58]. In general, both the sole organic and the integrated compost treatments showed appropriate physical characteristics under the optimal range particularly shrinkage: total pore spaces (TPS) and bulk density (BD). There was no significant difference found between all composting treatments studied. The mature compost obtained for each treatment had higher air capacity values and therefore lower total water holding capacity values, which were lower than those specified in the literature for the substrate. It can be concluded that the utilization of substrate is constrained by aeration. Consequently, considering the reduced water holding capacity, the high air capacity values found in the research treatments are beneficial for use as substrates, but also mean that low levels of moisture are often used because leaching can easily occur.

Compost stability and maturity were determined by changes in the color and smell of the compost. When compost reaches maturity, it turns dark brown (although this is a result of the feedstock material), and the smells change from obnoxious and ammonia-like to rich and earthy. The stability and maturity of these sensory indicators are not particularly specified [13]. These two indexes, when combined, could potentially give a very rough idea of stability and maturity. [31].

4 Conclusion

Integrated composting of animal waste (including the solid fraction of digestate) and lignocellulosic biomass with or without inorganic amendments sets up a more feasible composting method not only for sustainable organic waste utilization but also for the production of compost that can be applied as a soil organic fertilizer due to increased stability and maturity and the presence of value-added properties. Moreover, the addition of bulking materials to the compost mixtures improved various properties of compost production, such as lowering the composting temperature and EC of the composting process, the percentage of OM degradation, and N losses, which are often apparent when farm waste and lignocellulosic waste are cocomposted. This study was conducted to investigate the effect of addition of inorganic amendments on various production characteristics, maturity/stability characteristics, and nutritional significance in composting of organic material (integrated composting). The specific finding indicated that the addition of inorganic material into the composting of biowaste produced no significant effect on production characteristics of compost. Integrated compost revealed more disintegration of hemicellulose, cellulose, and lignin, stimulated humification process in composting, reduced N conversion (N loss), and also improved nutrient content in mature compost. Integrated compost showed low OM and N losses along with the addition of bulking material which is a good source to improve soil health as integrated soil fertilizer. This could be the best and most economical way to fulfill the local demand of fertilizer towards organic farming. The compost showed good maturity and stability characteristics according to the safe limits of characteristics as mentioned by the previous related literature. Overall, integrated composting was found to be the good option to enhance the nutritional level of compost and best way of “waste to money.” An addition of 10-25% inorganic contents (w/w) is optimal for integrated composting of organic-inorganic mixtures.

Data availability

The manuscript contains all the experimental data; no associated data is available for this manuscript.

References

Wang L, Sun X, Li S, Zhang T, Zhang W, Zhai P (2014) Application of organic amendments to a coastal saline soil in North China: effects on soil physical and chemical properties and tree growth. PLoS One 9(2):e89185. https://doi.org/10.1371/journal.pone.0089185

Lim SL, Lee LH, Wu TY (2016) Sustainability of using composting and vermicomposting technologies for organic solid waste biotransformation: recent overview, greenhouse gases emissions and economic analysis. J Cleanv Prod 111:262–278

Atalia KR, Buha DM, Bhavsar KA, Shah NK (2015) A review on composting of municipal solid waste. IOSR J Environ Sci 9(5):2319–2399

Noble R, Coventry E (2005) Suppression of soil-borne plant diseases with composts: a review. Biocon Sci Technol 15(1):3–20

Lim SL, Wu TY, Lim PN, Shak KPY (2015) The use of vermicompost in organic farming: overview, effects on soil and economics. J Sci Food and Agri 95(6):1143–1156

Febrisiantosa A, Ravindran B, Choi HL (2018) The effect of co-additives (Biochar and FGD Gypsum) on ammonia volatilization during the composting of livestock waste. Sustainability 10(3):795

Noor RS, Sun Y, Qu J, Hussain F, Waqas MM, Shah AN, Noor R (2021) Quantifying the effects of co-composting organic biomass mixtures with inorganic amendments to obtain value-added bio-products. PLoS ONE 16(7):e0253714. https://doi.org/10.1371/journal.pone.0253714

Sánchez-Monedero MA, Cayuela ML, Roig A, Jindo K, Mondini C, Bolan N (2018) Role of biochar as an additive in organic waste composting. Biores Technol 247:1155–1164

Xiao R, Awasthi MK, Li R, Park J, Pensky SM, Wang Q, Wang JJ, Zhang Z (2017) Recent developments in biochar utilization as an additive in organic solid waste composting: a review. Biores Technol 246:203–213

Vandecasteele B, Sinicco T, D'Hose T, Nest TV, Mondini C (2016) Biochar amendment before or after composting affects compost quality and N losses, but not P plant uptake. J Environ Manage 168:200–209

Bong CPC, Lim LY, Lee CT, Ong PY, Fan YV, Klemeš JJ (2021) Integrating compost and biochar towards sustainable soil management. Chem Eng Trans 86:1345–1350

Li X, Wen Q, Zhang S, Li N, Yang J, Romanyà J, Han X (2022) Long-term changes in organic and inorganic phosphorus compounds as affected by long-term synthetic fertilisers and pig manure in arable soils. Plant and Soil 472(1):239–255

Said-Pullicino D, Erriquens FG, Gigliotti G (2007) Changes in the chemical characteristics of water-extractable organic matter during composting and their influence on compost stability and maturity. Biores Technol 98(9):1822–1831

Loow Y-L, New EK, Yang GH, Ang LY, Foo LYW, Wu TY (2017) Potential use of deep eutectic solvents to facilitate lignocellulosic biomass utilization and conversion. Cellulose 24(9):3591–3618

Adhikari BK, Barrington S, Martinez J, King S (2008) Characterization of food waste and bulking agents for composting. Waste Manage 28:795–804

Noor RS, Hussain F, Abbas I, Umair M, Sun Y (2020) Effect of compost and chemical fertilizer application on soil physical properties and productivity of sesame (Sesamum Indicum L.). Biomass Conv. Bioref. 16:1–1. https://doi.org/10.1007/s13399-020-01066-5

Oviedo-Ocaña ER, Dominguez I, Komilis D, Sánchez A (2019) Co-composting of green waste mixed with unprocessed and processed food waste: influence on the composting process and product quality. Waste Biomass Valoriz 10:63–74

Hernández-Gómez A, Calderón A, Medina C, Sanchez-Torres V, Oviedo-Ocaña ER (2021) Implementation of strategies to optimize the co-composting of green waste and food waste in developing countries. A case study: Colombia. Environ Sci Pollut Res 28:24321–24327

Jeris JS, Regan RW (1973) Controlling environmental parameters for optimum composting. Compost Science 14:8–15

Noor RS, Ahmed A, Abbas I, Hussain F, Umair M, Noor R, Sun Y (2020b) Enhanced bio-methane production by 2-stage anaerobic co-digestion of animal manure with pre-treated organic waste. Biomass Conv. Bioref 3:1–5. https://doi.org/10.1007/s13399-020-01210-1

Zhou Y, Selvam A, Wong JW (2014) Evaluation of humic substances during composting of food waste, sawdust, and Chinese medicinal herbal residues. Bioresour.Technol 168(3):229–234

Bustamante MA, Paredes C, Marhuenda-Egea FC, PerezEspinosa A, Bernal MP, Moral R (2008) Co-composting distillery wastes with animal manure: carbon and nitrogen transformations and evaluation of compost stability. Chemosphere 72(4):551–557

Sommer SG, Kjellerup V, Kristjansen O (1992) Determination of total ammonium nitrogen in pig and cattle slurry: sample preparation and analysis. Acta Agriculturae Scandinavica, Section-B – Soil & Plant. Science 42(3):146–151

Kitson RE, Mellon MG (1994) Colorimetric determination of P as molybdovanadato phosphoric acid. Ind Eng Chem 16(6):379–383

Zucconi F, Pera A, Forte M, de Bertoldi M (1981) Evaluating toxicity of immature compost. BioCycle 22(2):54–57

Paredes C, Roig A, Bernal MP, Sanchez-Monedero MA, Cegarra J (2000) Evolution of organic matter and nitrogen during co-composting of olive mill wastewater with solid organic wastes. Biol Fert Soils 32(3):222–227

Roletto E, Barberis R, Consiglio M, Jodice R (1985) Chemical parameters for evaluating compost maturity. BioCycle 26(2):46e7

Ciavatta C, Vittori Antisari V, Sequi P (1988) A first approach to the characterization of the presence of humified materials in organic fertilizers. Agrochimic 32:510e7

Bustamante MA, Paredes C, Moral R, Agullo E, PerezMurcia MD, Abad M (2008b) Composts from distillery wastes as peat substitutes for transplant production. Res, Conserv Recycling 52(5):792–799

U.S. Environmental Protection Agency (USEPA) (2006) Method 1682: Salmonella in sewage sludge (Biosolids) by modified semisolid Rappaport-Vassiliadis (MSRV) medium. USEPA Office of Water (4303T), 1200 Pennsylvania Avenue, NW Washington DC EPA-821-R-06-14.

Chroni C, Kyriacou A, Manios T, Lasaridi K (2009) Investigation of the microbial community structure and activity as indicators of compost stability and composting process evolution. Bioresour Technol 100(15):3745e50

Oviedo-Ocaña ER, Dominguez I, Komilis D, Sánchez A (2019) Co-composting of green waste mixed with unprocessed and processed food waste: influence on the composting process and product quality. Waste Biomass Valoriz 10:63–74

Zhang L, Sun X (2016) Influence of bulking agents on physical, chemical, and microbiological properties during the two-stage composting of green waste. Waste Manag 48:115–126

Serramiá N, Sánchez-Monedero MA, Fernández-Hernández A, Civantos CG, Roig A (2010) Contribution of the lignocellulosic fraction of two-phase olive-mill wastes to the degradation and humification of the organic matter during composting. Waste Manage 30(10):1939e47

Gong X, Li S, Sun X, Zhang L, Zhang T, Wei L (2017) Maturation of green waste compost as affected by inoculation with the white-rot fungi Trametes versicolor and Phanerochaete chrysosporium. Environmental Technol 38:872–879

Prabhu N, Borkar S, Garg S (2019) Phosphate solubilization by microorganisms: Overview, mechanisms, applications and advances. In: Meena SN, Naik M (eds) Advances in Biological Science Research: A Practical Approach. Academic Press, Cambridge, MA, USA, pp 161–176

Wang J, Liu Z, Xia J, Chen Y (2019) Effect of microbial inoculation on physicochemical properties and bacterial community structure of citrus peel composting. Bioresour. Technol 29:121843

Wang W, Zhang L, Sun X (2021) Improvement of two-stage composting of green waste by addition of eggshell waste and rice husks. Bioresour. Technol. 320:124388

Tiquia SM, Tam NFY (2000) Fate of Nitrogen during composting of Chiken Liter. Environ Pollut 110(3):535–541

Bernal MP, Alburquerque JA, Moral R (2009) Composting of animal manures and chemical criteria for compost maturity assessment. A review. Bioresour Technol 100(22):5444e53

Huang GF, Wong JWC, Wu QT, Nagar BB (2004) Effect of C/N on composting of pig manure with sawdust. Waste Manage 24(8):805e13

Tognetti C, Mazzarino MJ, Laos F (2007) Cocomposting biosolids and municipal organic waste: effects of process management on stabilization and quality. Biol Fert Soils 43(4):387e97

Roig A, Cayuela ML, Sanchez-Monedero MA (2004) The use of elemental sulphur as organic alternative to control pH during composting of olive mill wastes. Chemosphere 57(9):1099e105

Li Y, Luo W, Li G, Wang K, Gong X (2018) Performance of phosphogypsum and calcium magnesium phosphate fertilizer for nitrogen conservation in pig manure composting. Biores Technol 250:53–59

Wang Q, Awasthi MK, Ren X, Zhao J, Li R, Wang Z et al (2017) Comparison of biochar, zeolite and their mixture amendment for aiding organic matter transformation and nitrogen conservation during pig manure composting. Biores Technol 245(Pt A):300–308

Huang HL (2006) Lignin biodegradation and its relationship with humus formation in composting. Hunan University, Changsha

Thorn KA, Mikita MA (1992) Ammonia fixation by humic substances: a nitrogen-15 and carbon-13 NMR study. Sci Total Environ 113(1):67–87

Antelo J, Arce F, Avena M et al (2007) Adsorption of a soil humic acid at the surface of goethite and its competitive interaction with phosphate. Geoderma 138(1):12–19

Liu N, Zhou J, Han L, Ma S, Sun X, Huang G (2017) Role and multi-scale characterization of bamboo biochar during poultry manure aerobic composting. Bioresour.Technol 241:190–199

Steiner C, Das K, Melear N, Lakly D (2010) Reducing nitrogen loss during poultry litter composting using biochar. J. Environ. Qual 39:1236–1242

Sánchez-García M, Alburquerque J, Sánchez-Monedero M, Roig A, Cayuela M (2015) Biochar accelerates organic matter degradation and enhances N mineralization during composting of poultry manure without a relevant impact on gas emissions. Bioresour. Technol 192:272–279

Crawford JH (1983) Composting of agricultural wastes-a review. Process Biochem 18:14–18

Godden B, Ball AS, Helvenstein P, Mccarthy AJ, Penninckx MJ (1992) Towards elucidation of the lignin degradation pathway in actinomycetes. J Gen Microbiol 138(11):2441–2448

Cross T (2010) Thermophilic actinomycetes. J Applied Microbiol 31(1):36–53

Hatakka A (2010) Lignin-modifying enzymes from selected white-rot fungi: production and role from in lignin degradation. Fems Microbiol Rev 13(2-3):125–135

Bustamante MA, Suarez-Estrella F, Torrecillas C, Paredes C, Moral R, Moreno J (2010) Use of chemometrics in the chemical and microbiological characterization of composts from agroindustrial wastes. Bioresour Technol 101(11):4068e74

Farrell M, Jones DL (2009) Critical evaluation of municipal solid waste composting and potential compost markets. Bioresour Technol 100(19):4301e10

Abad M, Noguera P, Bures S (2001) National inventory of organic wastes for use as growing media for ornamental potted plant production: case study in Spain. Bioresour Technol 77(2):197–200

Acknowledgements

The authors are thankful and acknowledged the Northeast Agricultural University, Harbin, China, for their technical scientific support. The authors are also thankful to Haziq Murtaza for his efforts and support during different research works.

Author information

Authors and Affiliations

Contributions

Rana Shahzad Noor conceived the conceptualization of research study, design and development of the experiment, data collection, formal analysis, investigation, methodology, and visualization; wrote the original draft; and reviewed, supervised, and edited the write-up. Waqas Aslam and Muhammad Umair contributed to the review and editing of the draft. Yong Sun supervised the entire research work and contributed as an internal reviewer for the manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Noor, R.S., Sun, Y., Aslam, W. et al. Sustainable production and characterization of integrated composting systems of organic biomass and inorganic amendments. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-03883-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-03883-w