Abstract

Biomass and wastes are increasingly being used as major energy sources not only in Nigeria but also worldwide. Different wastes/biomass to energy technologies have been used in the past by several researchers but anaerobic digestion happens to be the best option due to its eco-friendliness and simplicity of its design. There are huge amounts of wastes generated from agriculture, municipalities and industries both in rural Nigeria and urban areas that are being underutilized due to lack of information on their potential for biogas production. Laboratory, pilot and full-scale studies have shown that agricultural, municipal solid and industrial wastes all have potential for bioenergy generation. The potential of bioenergy production from agricultural waste, municipal solid waste (MSW) and industrial waste within the country has been sought in various scientific databases from 1997 to 2020 and related information was obtained. This review article examines the agricultural, municipal solid and industrial wastes found in Nigeria and the biogas production potential from these wastes usable as alternative to fossil fuels. Current trend, recent issues and future prospect of anaerobic digestion are also considered in this article.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

One of the major challenges facing the world today is the ever-increasing solid wastes generation as well as high energy demand [1, 2]. Lack of proper waste management leads to enviromental pollution as a result of emission of greenhouse gases such as methane and carbon dioxide [3, 4]. According to Van et al. [5], approximately 1.3 billion metric tons of municipal solid waste (MSW) was produced worldwide in 2010, and is expected to increase to 2.2 billion metric tons by 2025. Okoro et al. [6] stated that waste management in Nigeria has become a “tall order” despite the efforts of previous and current governments and even private sector. Increased waste production and management difficulties are the result of the rapid growth of many Nigerian cities [7, 8]. Waste generation in Nigeria is exponentially increasing day by day but it is arithmetically collected and disposed [6]. Nigeria as a country is located within latitudes 4°N to 14°N and longitudes 3°E to 14°E (as shown in Fig. 1) covering an area of about 924,000 km2 with the highest population in Africa estimated to be 198,583,016 that generates huge amount of wastes [9]. Okoro et al. [6] reported that 20–70% of the annual waste generated was properly collected. Converting these wastes into energy not only helps to reduce greenhouse gas emissions but also reduces enviromental pollution and waste management problems in Nigeria [10].

Map of Nigeria [17]

A report from Sokan-Adeaga and Ana [11] stated that 85% of world’s energy demand is currently being met by non-renewable energy sources (fossil fuels). According to them, by 2025, global demand for energy is expected to increase by about 50%. Also, Sibiya et al. [12] stated that more than 90% of the energy used by South Africans comes from non-renewable resources. Oyedepo [13] reported that of the energy used in Nigeria, oil accounts for 57%, natural gas accounts for 36% and hydroelectricity accounts for 7%. Over the years, fossil fuels have become a major source of energy, but with problems such as global climatic change, there is deterioration in human and animal heatlh as a result of greenhouse emissions and enviromental degradation [14]. Depletion of fossil fuels together with reduction in the emission of greenhouse gases have led to interest in converting waste biomass into biogas which is a non-conventional fuel [15].

Nigeria as a nation is blessed with renewable energy resources such as biomass which are environmentally friendly but not properly utilized. Some examples of biomass resources in Nigeria include grasses, trees, residues, aquatic waste, agricultural waste, municipal waste and industrial waste. These resources can be replenished, and when converted to biogas via anaerobic digestion (AD) to use as fuel, they pose no threat to the environment [13]. Biogas composition is determined by a number of factors including feedstock type and process design [16]. The amount of methane content produced depends on the types of feedstock introduced into the digester. Table 1 shows the different feedstock and percentage methane content produced by each feedstock. Biogas generated from substrates (feedstock) is being used daily in households, agriculture and industries for cooking, heating and even for generating electricity [19].

Several biological processes had been used in the past for the conversion of wastes to energy. Anaerobic digestion, which is a biochemical conversion of complex organic matter (such as waste) into biogas with the help of methanogenic bacteria, is one of the most well-known biological processes commonly used [20]. In addition to biogas produced by waste, digestate or soil conditioner which contains nutrients such as nitrogen and phosphorus, which are used as bio-fertilizers are also produced [21]. Over the years, various wastes from municipal waste to industrial waste and agricultural waste have been used as substrates for biogas production by various researchers.

Sawyerr et al. [22] stated that the success of anaerobic digestion processes depends on the avalability of substrates for sustainability. Biogas production will not be feasible if there is lack or insufficient suitable substrate to be fed into the anaerobic digester. Also, biogas quality and quantity depend on feedstock and AD technology. Furthermore, proper information and knowledge about the substrate to be introduced into a digester is very vital so as to obtain maximum biogas yield, although any biomass can be used for biogas production as long as it contains constituents such as carbohydrate, protein, lipid, cellulose and hemicellulose [23]. Therefore, this current study aims to present the potential of agricultural, municipal solid and industrial wastes for biogas production in Nigeria. The work comprehensively reviewed the empirical studies on biogas production from agricultural, municipal and industrial wastes in Nigeria.

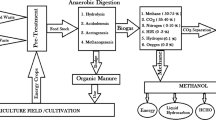

2 Mechanism of anaerobic digestion of wastes

Anaerobic digestion is a biological process which transforms organic matter into its most reduced (CH4) and most oxidized (CO2) state in the absence of air [24]. AD process occurs at temperature range of 25–60°C [25] with total solid (TS) content greater than 20% for dry solid or less than 10% for wet solid [24]. It involves different groups of microbes which make the process complex and sensitive. The transformation of large organic molecules found in organic wastes into CH4 and CO2 is as a result of activities of several bacteria which are carried out in hydrolytic, acidogenic, acetogenic and methanogenic stages of AD [26]. Anaerobic digestion process begins with hydrolytic bacteria that hydrolyze or break down carbohydrates into simple sugar, protein to amino acid and lipid to fatty acid. Acidogenic bacteria (acetogens) convert sugar, amino acid and fatty acid into intermediate volatile fatty acids, VFAs, (propionic acid, butyric acid, acetic acid and ethanol), carbon dioxide and hydrogen. Then, intermediate VFAs to acetic acid/acetate together with CO2 and H2 by acetogenic bacteria. The final stage of AD which is methanogenesis is achieved when acetic acid or CO2 and H2 from acetogenesis is converted to methane by acetoclastic and hydrogenotropic Archea [27].

3 Biomass/feedstock resources in Nigeria

The availability of biomass is abundant and widespread throughout the world and its distribution depends on location. In Nigeria, some of the feedstock producing biogas ranges from agricultural wastes (AW) to municipal solid wastes (MSW) to industrial wastes (IW) [28, 29]. Ben-Iwo et al. [30] reported that Nigeria produces biomass of about 144 million tonnes per annum. In addition, most rural dwellers in Nigeria according to the US Energy Information Administration depend heavily on biomass such as wood, charcoal and wastes from animals and municipals to meet their energy demand [30]. Table 2 shows various feedstock and their major sources in Nigeria.

3.1 Animal manure

One of the major agricultural practices is livestock production which happens to be the biggest source of animal waste. The amount of waste generated from livestock production depends on the type of animal rearing, methods of feeding, size of the animal and the breed [31]. According to Abdeshahian et al. [31], to reduce enviromental hazard or odour caused by large quantityof animal waste disposed daily, conversion to renewable gas via anaerobic digestion will be helpful. Some common animal wastes include cattle, poultry, pig, sheep, horse and goat manures to name a few. Yang et al. [32] reported that pig and poultry manures are rich in protein while cattle manure contains a lot of lignocellulose. Nigeria as a nation according to Aikhuele et al. [33] and Oyedepo et al. [34], produces 227,500 tons of animal manure daily, and on conversion, 6,800,000 m3 biogas is produced per day. Oyedepo et al. [34] stated further that, 450.48 PJ is the estimated bioenergy potential of animal manure in Nigeria. Ben-Iwo et al. [30] reported that animal waste accounts for 61 million tonnes per annum of Nigeria’s energy reserve. Livestock population in Nigeria together with biogas yield are shown in Table 3. It is clearly indicated from the table that Nigeria as a nation has large population of livestocks which has resulted into generation of large quantity of livestock manure. Inadequate/improper disposal of this large quantity of manure could be harmful to the enviroment, human and animal health. Manure/wastes from this large number of livestocks when converted by anaerobic digestion can ease the burden of high energy demand in the country.

3.2 Energy crops and crop residues

Energy crops and crop residues are mostly referred to as lignocellulosic wastes (containing 10–25% lignin) with complex structure, and are produced in large quantities (about 181.5 billion tonnes) all over the world yearly [36]. They are potential sources of biogas generation and are very common especially in rural areas of Nigeria where almost everybody engages in farming. Energy crops are crops with high dry matter yields, durable with low costs of production which are purposely planted for energy generation [37]. The potential for growth of energy crops (such as sugarcane, sorghum, cassava and maize) is high in Nigeria due to the availability of arable land and sufficient water [30]. Sibiya et al. [12] said grass was considered as the most suitable biomass due to its availability despite the seasonal changes. According to Atelge et al. [38], harvesting, processing and storage are some of the distinct steps to be taken before anaerobic digestion of energy crops for biogas production.

Agricultural crops are produced in large quantities for human consumption and exportation, and hence generate large amount of residues [39]. Agricultural crop wastes or residues include rotten crops due to lack of storage facilities, and are caused by infection of diseases and residues generated from crop processing after crop harvest [4]. Stalk, straw, cobs, husk and bark are crop residues used for energy generation throughout anaerobic digestion process. Akinbomi et al. [4] reported further that about 70% of crop residues from crop harvesting and processing are used as building materials and animal fodders. They reported that 58% of animal fodder is supplied by crop residues especially during the rainy season. Therefore, after the usage of crop residues for other purposes, it was recorded that approximately 52 million tonnes were left for biogas production from which 21 billion cubic metres of biogas could be produced. In Nigeria, some of agricultural wastes commonly found include groundnut shell, yam peels, coconut shell, mango peels, palm oil mill effluent, corn cob, cherry, orange peels, melon shell and black walnut hull to mention but a few [6]. According to Adepoju et al. [39], energy potential by these agricultural crop residues has not been properly exploited despite the worldwide increase in biogas production.

3.3 Municipal solid waste (MSW)

MSW also referred to household wastes are generated from sources where various activities of man are encountered [40]. They include wastes from households, institution, markets, industries, agriculture and human activities in urban centres [41]. MSW is heterogeneous which comprises of different discarded materials of different composition. Abdel-Shafy and Mansour [40] reported that the composition of MSW differs greatly from municipality to municipality, and from country to country. The quantity and composition of MSW can be affected by climate, extent of recycling, collection frequency, regional differences, season, cultural practices, technological changes or industrial structure [42]. Nigeria as a country has the highest population in Africa with 913,440 tonnes of methane produced from MSW which is equivalent to electricity 482 MW [43]. Increase in population, urbanization and industrialisation will definitely lead to increase in MSW generated annually. According to Jekayinfa et al. [35], in Nigeria, average rate of solid waste generated is approximately 0.50 kg/capita/day. However, waste generation in different cities varies. Akinbomi et al. [4] estimated the average MSW being generated in six geo-political zones of Nigeria as South-West (Lagos): 0.63 kg/capita/day; South-South (Port-Harcourt): 0.60 kg/capita/day; South-East (Aba): 0.40 kg/capita/day; North-West (Kano): 0.56 kg/capita/day; North-East (Bauchi): 0.86 kg/capita/day and North-Central (Abuja): 0.66 kg/capita/day. Also, Ezeudu et al. [9] reported per capita MSW generated in some cities in Nigeria as 0.54 kg/cap/day for Markudi, 0.638 kg/cap/day for Abuja and 0.13 kg/capita/day for Ogbomoso. MSW comprises of biodegradable fraction of kitchen waste, food waste, leaf, grass clipping, flower trimmings and yard waste [12, 44]. Peces et al. [45] reported two classes of MSW treatments to be biological and thermal treatments. According to them, biological treatment includes anaerobic digestion, composting, hydrogen fermentation and landfilling while thermal treatment includes incineration, pyrolysis or gasification. Furthermore, biological treatments are used for biodegradable moisture-rich waste while thermal treatments are employed for non-biogegradable waste.

3.4 Kitchen or food waste

According to Sahu et al. [46], about 1.3 billion tons of kitchen waste (KW) is being generated globally per annum. Longjan and Dehouche [47] reported that Nigeria produces 5.3 × 107 tonnes of cassava per annum, 4.0 × 107 tonnes of yam per annum, 5.1 × 107 tonnes of melon per annum, 2.9 × 107 tonnes of beans per annum, 3.5 × 107 tonnes of cocoyam per annum, 2.8 × 107 tonnes of plantain per annum and 1.0 × 107 tonnes of corn per annum. According to them, the higher the quantities of crops produced, the more the kitchen/food wastes generated. Makinde and Odokuma [48] stated that more wastes are generated from yams because 70% of global yam is produced in Nigeria. Also, plantain being a major food staple in Nigeria produces more wastes as it can be boiled, fried and even roasted [48]. Therefore, increase in kitchen waste/food waste generated daily and its management have become a concern due to lack of proper waste treatment. Kitchen/food waste as organic material has high biodegradability, calorific value and nutritive value to micro-organisms [49]. Therefore, it can be used as substrate to generate biogas which will reduce our dependency on non-renewable energy [49, 50]. In Nigeria, kitchen waste is discarded or disposed in landfill, and this method of disposal leads to health challenges such as typhoid, cholera and malaria [51]. It was reported by Longjan and Dehouche [47] that out of Nigerian households, 39% dispose their household wastes in unauthorized heaps, 38% within their neighbourhood through burning or burying the waste. Improper dumping of waste causes adverse consequences which include pollution of both surface and groundwater which promote breeding of mosquitoes, flies and rats. Furthermore, there is emission of greenhouse gases which lead to global warming and emission of unpleasant odour [50, 52]. Incinerator and pyrolysis techniques for disposing waste are costly and not efficient to recover energy from the food waste due to the large amount of water content in food or kitchen waste [52]. Therefore, anaerobic digestion, which is economical and efficient, is employed for waste treatment. Kitchen/food waste is a biodegradable organic matter with high contents of moisture, carbohydrate, protein and lipid. It can be introduced as lone substrate to the digester for biogas production but most times, its digestion fails without adding external nutrients and buffering agents [53]. The major limitation of digesting kitchen waste alone is the accumulation of organic acids which results into decrease in pH value in the digester. Accumulation of volatile fatty acids (organic acids) in the reactor inhibits the activity of methanogens for biogas production [54]. To minimize or avoid the inhibiting effect caused by accumulation of volatile fatty acids (VFAs) in anaerobic digestion of kitchen waste, co-digestion with agricultural wastes or sewage sludge should be considered [53, 54].

3.5 Sewage waste

Sibiya et al. [12] reported that sewage sludge is usually generated from municipal and industrial waste water treatment plants (WWTPs), and may be applied as manure as it has almost the same quantities of nutrients (nitrogen, phosphorus and organic matter) with the manure. Apart from the nutrients present in sewage, it also contains pathogens and micro-pollutants. Sewage, according to Akinbomi et al. [4] is of two parts. The first part of the sewage is black water part which comprises of human faeces and urine from a community, and grey water that comprises of wastewater from bathroom, kitchen and laundry without human faeces. The grey water usually contains contaminants such as soaps, detergents, shampoo, pharmaceutical and industrial wastes which make them not suitable substrate for production of biogas except if they are pretreated. Pan-American Health Organization (PAHO) reported that municipalities not up to 10% in developing countries adequately treat sewage before allowing it to flow into rivers [55]. In Nigeria according to Kayode et al. [55], there are absences of sewage systems except in some parts of Lagos and Federal Capital Territory, Abuja. The sewage sludge which may be solid, semisolid or liquid muddy residue generally contains proteins, sugars, lipids, detergents, phenols, toxic and hazardous organic and inorganic pollutants [56, 57]. Depending on the source, location or country, physico-chemical properties of sewage sludge vary. Though, variability in the physico-chemical properties of sludge makes it unfit to be used as substrate for biogas production but measures are being taken to process this type of waste [58].

3.6 Industrial waste

This is the type of waste generated from manufacturing and industrial plants such as pulp and paper, grain mill, slaughter house and dairies [12]. Most industries generate large amounts of wastes, by-products and residues that can be used as substrate for anaerobic digestion in biogas production [38]. Atelge et al. [38] stated further that wastes from industries are very rich in organic contents and can be used as methane booster. Abdel-Shafy and Mansour [40] stated that all organic end-products from industries can be used as substrates for biogas production. In Nigeria, plants used by most industries for the treatment of industrial effluents/wastes are not efficient, yet they discharge their effluents into rivers to harm both man and animals healthwise [55]. According to Kayode et al. [55], major industrial production processes contributing to industrial wastes in Nigeria include breweries, cement, slaughterhouses, chemical and paint manufacturing, textile, pharmaceuticals, oil refineries, steel and metal fabrication, tanneries as well as fertilizer production. They stated further that Kano, Lagos, Ibadan, Enugu and Port-Harcourt remain the cities with the large quantity of industrial wastes in Nigeria due to the high concentrations of industrial establishment.

Ibrahim et al. [59] reported that Benue Brewery PLC in Makurdi, Nigeria generates 5000 kg of waste (Brewery spent grain) weekly which is proven difficult to manage and resulting into environmental pollution. Likewise, locally made beer called burukutu which is found in most parts of Nigeria especially the northern parts is made from cereals, and can generate 35–90 kg of waste per week. Also, a non-alcoholic African drink called kunu can be produced commercially and domestically and generates 7–30 kg of waste per week. Wastes from these processes are being disposed in an unhealthy manner and thereby result into environmental pollution. The research conducted by Rasheed and Amuda [60] revealed that the extraction of gold using mercury amalgamation method being carried out in some parts of Zamfara state degrades the soil and generates huge amount of toxic wastes. Similarly, in Plateau state, tin mining industries generate radioactive elements such as monazite, xenotime and pyrochloreas wastes. These radioactive elements are potential health hazard, and exposure to them beyond tolerance limit could ultimately lead to death. All these toxic wastes are sent indiscriminately into the water bodies such as lakes, rivers and seas without treatment. Uwagbale [61] reported that Nigeria petroleum and petrochemical industry recovered about 15.91% of the total cumulative spill volume (2,382,373.7 barrels) of crude oil between 1976 and 1996 while about 84.09% was lost into the environment. Furthermore, in-between 1976 and 1991, in Ogoniland, Niger Delta region of Nigeria, about 2,100,000 barrels of oil spill was reported. The oil flowed into the neighbouring villages to pollute the rivers causing untold destruction to both the terrestrial and aquatic lives. According to Ayoola et al. [62], Nigeria has the second largest poultry industry in Africa (after South Africa) with estimated number of 165 million birds generating 932.5 metric tonnes of poultry manure yearly. This large quantity of wastes produced by poultry industries has raised concern for poultry waste disposal. According to Umar et al. [63] Nigeria has over 6000 tannery industries with estimated annual processing capacity of 700,000 tons of hides and skins. The amount of waste generated per animal slaughtered is about 35% of its weight. It was further revealed that, for every 1000 kg of carcass weight of slaughtered beef, 5.5 kg of manure and 100 kg of paunch manure are generated. Ekiye and Luo [64] stated that over 40% of Nigeria manufacturing activities takes place in Lagos, the second largest city in Africa and the largest in Nigeria, with 8000 tons of hazardous waste generated per annum which are directly released into bodies of water in Lagos without any treatment.

In Nigeria, treatment of industrial wastewater is not very common as most wastes are usually being released into the rivers [30]. Not many of Nigerian industries practise wastes treatment as only few of them employ either off-site or on-site disposal methods for handling wastes. Therefore, it has become a necessity to invest in waste management system so as to maximize these resources. According to Kundu et al. [65], the major contaminants of concern present in wastewater are organic carbon and nitrogen. As essential as nitrogen and phosphorus are for the growth of micro-organisms, high concentration of these two nutrients are not desirable as they are hazardous to both human and aquatic life and result into eutrophication. Therefore, anaerobic treatment which is cost-effective and the safest of all biological treatment options is essential for removal of organic carbon, nitrogen and phosphorus which are very harmful to the enviroment [66].

4 Biogas production potential from animal manure

Animal manures are mostly characterized with high nitrogen content, presence of sulfur, ammonia and hydrogen sulfide which inhibit biogas production [44]. Bharathiraja et al. [66] reported that animal manures contain diverse microbial flora, 75–92% moisture content and 72–93% volatile solids of total solids which make them highly biodegrdable. They stated further that their good buffering capacity and elimination of inoculated step make manures as ideal substrate for biogas production. In Nigeria, according to Ben-Iwo et al. [30] and Ozor et al. [67], it has been estimated that approximately 0.03 m3 of biogas is produced from every 1 kg of fresh animal manure. They reported that from 227,500 tonnes of animal manures generated daily, 6.8 million m3 of biogas is produced. Oguntoke et al. [68] reported that Nigeria as a country that generated 197.6 million tonnes cattle manure, 32.6 million tonnes poultry manure, 15.3 million tonnes swine manure and 39.6 million tonnes goat and sheep manure yearly. The estimated biogas potential per annum from cattle manure, poultry manure, swine manure and goat and sheep manure is respectively 6.25 billion m3, 2.5 billion m3, 0.92 billion m3 and 2.3 billion m3. These are very huge energy resources that easily can boost Nigeria’s energy supply.

The major disadvantage of using manures as substrates is the formation of high concentration ammonia that inhibits activity of methanogenic bacteria and slows down the digestion of animal manures [66]. Anaerobic digestion of raw manure as only substrate fed into the reactor might not be profitable due to the inhibition cause by high amount of nitrogen nutrient present in the animal manure than other organic wastes. Therefore, animal manure can be co-digested with substrate with low nitrogen content (but high in carbon content) such as plant biomas or kitchen waste to enhance the C/N ratio and balance the nutrient in order to improve biogas production [69]. According to Sibiya et al. [12], insufficient biogas will be produced if anaerobic mono-digestion of manure is practiced. Therefore, animal manure can be co-digested with other substrates so as to improve biogas production. In Nigeria, swine and poultry manures have become major enviromental pollutants as the rate at which people are engaging in piggery and poultry farming is alarming [70]. When Ogunwande et al. [70] co-digested swine manure with chicken manure, there was an increase in biogas production by 69.2% when compared to biogas from chicken manure alone and increase of 131.6% when compared to biogas from swine manure alone at mean substrate temperature and pH of 28.5 ± 2.5°C and 6.80 ± 0.55 respectively for 63 days.

5 Biogas production potential from energy crops and crop residues

Conversion of cassava or its residues to biofuel via anaerobic digestion process has been well established in Nigeria already as there are about 7.5 million tonnes of cassava residues being generated annually [30]. According to Oguntoke et al. [68] and Sokan-Adeaga and Ana [11], 83 million tonnes of crop residues are generated yearly with estimated biogas potential of 4.98 billion m3. Crops can either be mono-digested or co-digested. Although, mono-digestion of crops is not a common practice due to the complex structure of some crops which cause inhibition in AD and ultimately reduce biogas yield. Co-digestion of substrates is reported to have enhanced the cumulative biogas yield than mono-digestion of substrate [71]. Table 4 shows the major agricultural crops grown in Nigeria as at 2017 and their residues while Fig. 2 shows the heat content values of some of the agricultural crop residues. The energy potential of individual crop residue presented in Table 4 depends on rate of production of the related crop, residue to production ratio (RPR) and energy content. All these residues have high energy potential which greatly contributes to the economy of Nigeria as a nation especially residues from rice, maize and cassava. The estimated total energy potential derived from the agricultural crop residues is 3635.95 PJ. According to Ben-Iwo et al. [30], the use of crop residues such as bagasse, straw and stalk for biogas production is positively contributing food into the market since only crop residues are employed as feedstock for generation of biofuel.

Heat contents of some selected crop residues [6]

6 Biogas production potential from kitchen or food wastes

Aliyu [55] studied biogas potential of food wastes and fruit wastes within the Kaduna metropolis, Nigeria. The result of the study revealed that the highest biogas was produced by yam peels (89.37 mL/week) while the lowest biogas was produced by orange peels (18.26 mL/week). The study also revealed the range of mean values of biogas produced for all the food wastes as 32.15–92.43 mL/week while that of all fruit wastes is 18.26–36.20 mL/week. Longjan and Dehouche [47] in their work extracted waste fractions from local Nigeria food processing methods. The food wastes include yam peels, cassava peels, cocoyam peels, plantain peels, corn cob, egusi shell, beans skin, groundnut shell and ugwu stalk. The study showed that samples used have their methane potential varied ranging from 35 to 460 m3/tonnes on fresh weight and volatile solid basis of (5.4–6.2) × 105 m3/kg. It was also shown that methane potential is between 51 and 58% of biogas generated while the energy potential from the food wastes was 31 TWh/year which can meet up energy demand of Nigerian households of about 47 million. In Benin metropolis, Nigeria, food waste of about 305.075 tonnes is generated per day which yields biogas of about 28,836.91m3/day (49.023 MW of electricity/day) according to the study carried out by Akhatoret et al. [72]. With this quantity of biogas produced per day, energy demand of about 24,076.91 households in Benin can be met daily. Therefore, production of biogas from kitchen/food wastes using anaerobic digestion technology is very feasible in Nigeria.

7 Biogas production potential from sewage and industrial waste

Both the sewage sludge or industrial wastewater can be treated using anaerobic digester for the production of biogas. Hanum et al. [73] and Makisha and Semenova [74] stated that among all the waste treatments, anaerobic digestion process which is efficient, economical and environmental friendly is employed for sewage sludge treatment. In Nigeria, anaerobic digestion of sewage and industrial wastewater have not been popular as most industries disposed their wastes into rivers [30]. Therefore, Nigeria as a country needs to look into sewage and industrial wastes management using anaerobic digestion in order to maximize them. Some of the previous researches on anaerobic digestion of sewage and industrial wastes in Nigeria are discussed as follows: Adeniran et al. [75] evaluated the average biogas production rate from the domestic wastewater collected from the University of Lagos, Nigeria with population of about 55,000 to be 641.83 ± 88.26 m3/day. In an anaerobic treatment of petroleum sludge from petroleum industry carried out in Nigeria by Sampson [76], 5000 m3 (200 g) of petroleum sludge produced 10,500 m3 of biogas daily. This implies that for 16 days retention time, 1 g of sludge could produce 840 m3 of biogas. Due to its potential for biogas production, Nigeria industries are to be encouraged to stop petroleum sludge incineration and embraced anaerobic digestion of sludge as it could produce large amount of biogas. Ofoefule et al. [77] studied biogas production potential using waste paper collected from the University of Nigeria, Nsukka printing press. The cumulative biogas yield was 6.23 ± 0.07 dm3/kg of slurry.

8 Current barriers for deployment of anaerobic digestion technology in Nigeria

Though, there are various technologies for production of bioenergy for heat and power generation in Nigeria, but the deployment of these technologies in most African nations including Nigeria has achieved little success [43]. According to Oyedepo et al. [34], Nigeria bioenergy generation technologies are at research level, some are at demonstration stage while few at commercial stage. Adoption of bioenergy technologies in Nigeria is hindered by some barriers which cause failure and low level implementation of bioenergy technology development in Nigeria. These barriers are as enumerated in the following sections:

8.1 Limited access to funding

Kemausuor et al. [43] stated that acquiring a biogas plant involves huge amount of investment in terms of operation and maintenance costs. Average Nigerians in rural community depend on subsistence farming for living, the income accruable from such farming operation is not sufficient to acquire biogas plant. Hence, one of the most challenging barriers to uptake and develop bioenergy technologies in Nigeria is insufficient finance, since loan facilities and government incentives to farmers are not adequate. Therefore, only the rich farmers have the financial capacity to acquire biogas plant [28]. Financial institutions, including the Central Bank of Nigeria, are not willing to make financial packages available due to high risks and experiences of low recovery [43].

8.2 Limited technical know-how and infrastructural barrier

In Africa, there is a fair technical experience about family-sized biogas systems, but this cannot be said of commercial biogas systems due to their large capacity and complexity. Higher skills and expertise are required for the conception, design, construction and management of commercial biogas systems. The origin of technical and infrastructural barrier of biogas deployment in Nigeria is the feedstock supply. The poor transportation system in Nigeria is capable of distrupting feedstock supply chains to the site of operation [43]. Also, government failure to support bioenergy technology via energy policy, improper information dissemination on economic feasibility of bioenergy technology, inadequacy in research and development activities, lack/inadequate resource data, substandard product quality, many unresolve engineering problems, inadequate human and manufacturing capacities, lack of information on advanced production techniques and many more are some of the setback recorded on deployment of bioenergy technology. The setback in the bioenergy sector has dwindled the interest of many Nigerian engineers in the sector. The cummulative effect is limited knowledge in bioenergy technology design, maintenance and applications.

8.3 Poor grid network

Another critical issue affecting the deployment of biogas technology in Nigeria is poor grid network. Grid infrastructure in Nigeria and some parts of Africa is not robust and has posed serious challenge to the existing power plants. It also affects the capability of grid network to access renewable energy power plants.

8.4 Lack of adequate policy and legislative framework

The growth of Nigeria Energy Sector has been retarded due to lack of enabling legislation for the implementation of clean energy policies. Lack of policies and legislative framework can slow down the implementation of reliable and efficient biogas technology [13]. Presently, Nigeria as a nation does not have a well-detailed policy on bioenergy technology development, and according to Oyedepo et al. [34] successful implementation of bioenergy technology in a country requires well-formed policies. With well-formed policies together with enabling legislation in a well-regulated economy, biogas project with best international design practices, for securing efficient and effective enforcement and compliance with environmental laws will be promoted [11]. To develop a feasible bioenergy technology in Nigeria, strong and supportive policy, a firm legal, regulatory and institutional framework is required. In addition, both the private and public institutions need to be encouraged to make their own policy so as to promote the use of energy efficiently.

8.5 Lack of proper awareness

The attitude and perception of many people in Nigeria about biogas technology are not encouraging. This is due to poor information dissemination strategies compounded with low levels of education of people living in rural areas of the country and lack of access to modern day media. Also, awareness created about biogas technology and its benefits is not adequate. Most farmers and processing industries are ignorant of “energy generation and waste management” as the benefits and opportunities created by bioenergy technology [43]. Implementation and optimal operation of renewable (or bioenergy) energy systems in any country become difficult if the prospective end users are not well informed about their potential. The rural dwellers find it difficult to lay hands on relevant information about biogas technologies, so they are contented with their well-known traditional ways of generating energy. If biogas technology is to be sustainable, all forms of communication channels are to put into use for proper awareness on the benefits of employing biogas technology for energy generation.

8.6 Market barrier

Biogas competes in rural areas with traditional solid biomass such as firewood and animal dung which are cheaper and readily available to use as fuel for cooking. In urban centres, there is competitiveness between biogas and low-price electricity from coal and natural gas-fired power plants. Due to fixed feed-in tarrifs support from government, electric power generated from renewable sources such as hydro, wind and solar is cheaper than bioenergy generated from anaerobic digestion technology. That is, cost of electricity from biogas technology is higher than that of other renewable sources. Furthermore, other waste treatment technologies like composting and vermi-composting which can also be employed for treatment of organic municipal and industrial waste compete with anaerobic digestion technology.

8.7 Waste segregation barrier

Waste segragation is one of the major barriers to biogas technology adoption in Nigeria due to the non-availability of enough space inside homes for the segretation of wastes at source. Most Nigerians’ buildings are small in sizes and not properly designed to accommodate more than one waste container. This is a barrier to segretation at source and impedes the success of biogas technology. Also, scavengers who are looking for cans, irons/metals and plastics make segragation of wastes at source difficult as they disorganize and steal the segregated wastes at segregation points. Therefore, penalties need to be formulated to prevent the theft of segregated wastes by the scavengers.

9 Current trend and recent issue and future prospect of biogas production from agriculture, municipal solid and industrial wastes

In the past, many researchers had carried out anaerobic digestion of agricultural, municipal solid or industrial wastes for biogas production. Though, anaerobic digestion of industrial waste has not been that popular in Nigeria [30], but it has been reported that mono-digestion of any of agricultural waste, municipal solid waste and industrial waste could result in process instability and low biogas yield. This is due to either the presence of excessive nitrogen or carbon nutrients, volatile fatty acid (VFA) accumulation, heavy metal concentrations and so on. The performance efficiency of anaerobic digestion process can be improved via co-digestion of any of agricultural waste with municipal solid waste or industrial waste so as to establish nutrient balance and buffering capacity of the AD process for biogas enhancement. Co-digestion balances micro- and macro-nutrients, attenuates substrates inhibitory effects, raises organic loading that yields more biogas per unit volume of the reactor and synergizes the microbial consortia with substantial effect on methanogenesis. Therefore, future researchers should consider co-digestion of two or more wastes with characteristics that complement each other in order to achieve system stability and improve biogas yield.

In the last 20 years, anaerobic digestion of wastes has gained lots of attention all over the world. This is because it requires low energy for its operation, proffers solution to waste management problems, produces biogas which is renewable energy and very easy to implement. However, for its efficient performance, wastes treatment by anaerobic digestion depends on several operating conditions such as pH, hydraulic retention time (HRT), mixing ratio, organic loading rate (OLR), temperature and so on. If any of these operating parameters are not within the optimal range, low biogas/methane will be yielded [78]. Hence, in order to improve biogas yield from anaerobic digestion of waste, optimal values of these operating parameters need to be attained. Yusof et al. [79] stated that conventional method where a single variable factor is varied and other factors are kept constant at a given condition is laborious and time-consuming. Future works should employ statistical optimization methods such as response surface methodology (RSM) and artificial neural network (ANN) instead of conventional method to obtained optimal values of parameter operating conditions.

Over the years, attention has been shifted to exergetic analysis of anaerobic process. Exergy helps to quantify system irreversibilities but quantification of system irreversibilities alone is not enough to determine the costs of the physical flow of the plant. Exergy analysis does not reveal the exergy cost related with individual stream and component in the absence of real-world economic constraints. Therefore, it is necessary to establish accounting framework which will cover both the exergy and economic aspects of waste-to-energy projects. Future researchers should consider an exergoeconomic analysis (which is an exergy-aided cost accounting approach) of anaerobic digestion wastes. This will bring about invaluable insight on products cost and hotspots for the cost losses.

10 Conclusion

This review work reveals different biomass resources available in Nigeria and the potential to use these resources to meet high energy demand in the country if properly harnessed. The recurrent fuel scarcity and increase in demand for clean energy should serve as a “wake up call” for Nigeria to maximize its use of biomass resources which are abundantly available for diversification of fuel supply. The major sources of biomass resources are agriculture, municipal and industry. The results from this study show that animal manure of 227,500 tonnes/day, agricultural crop residues of 83 million tonnes/year and petroleum sludge of 5000 m3/day respectively generated biogas of 6.8 million m3/day, 4.98 billion m3/year and 10,500 m3/day. The total energy potentials for agricultural crop residues and animal manure are 3635.95 PJ/year and 450.48 PJ/day, respectively. Based on these results, agricultural, municipal solid and industrial wastes alone have the capacity to produce on annual basis, energy which is enough to sustain and meet the demand of the nation. Though, industrial waste has not been properly harnessed when compared with other sources, nevertheless, biofuel from agricultural, municipal solid and industrial wastes has potential to meet energy requirement for households, hostels, farms, industries and other units that generate sizeable amount of organic wastes in Nigeria. Previous researchers have worked on biogas production potential from agricultural wastes, municipal solid waste and industrial waste but there are some gaps to be filled. Future investigations should centre on optimization of operating parameters using statistical optimization methods. Exergoeconomic analysis of anaerobic digestion of agricultural, municipal solid and industrial wastes should be carried out so as to improve the system performance and give deep understanding on hotspots for cost losses.

Data availability

Not applicable.

Code availability

Not applicable.

References

Dąbrowska M, Świętochowski A, Lisowski A (2019) Physicochemical properties and agglomeration parameters of biogas digestate with addition of calcium carbonate. Agron Res 17(4):1568–1576

Vikrant D, Shekhar P (2013) Generation of biogas from kitchen waste-experimental analysis. Int J Eng Sci Invent 2(10):15–19

Majd S, Abdoli M, Karbassi A, Pourzamani H, Rezaee M (2017) Effect of physical and chemical operating parameters on anaerobic digestion of manure and biogas production: a review. J Envirom Health Sustain Dev (JEHSD) 2(1):235–247

Akinbomi J, Brandberg T, Sanni S, Taherzadeh M (2014) Development and dissemination strategies for accelerating biogas in Nigeria. Bioresources 9(3):5707–5737

Van DP, Fujiwara T, Tho BL et al (2020) A review of anaerobic digestion systems for biodegradable waste: configurations, operating parameters, and current trends. Environ Eng Res 25(1):1–17. https://doi.org/10.4491/eer.2018.334

Okoro E, Igwilo K, Sanni E, Orodu K (2018) A review on waste to biogas sources and its potential in Nigeria. Int J Eng Technol 7(4):5960–5966. https://doi.org/10.14419/ijet.v7i4.24458

Babayemi J, Dauda KT (2009) Evaluation of solid waste generation, categories and disposal options in developing countries: a case study of Nigeria. J Appl Sci Environ Manag 13(3):83–88

Oyelola OT, Babatunde AI (2008) Characterization of domestic and market solid wastes at source in Lagos metropolis, Lagos, Nigeria. Afr J Environ Sci Technol 3(12):430–437

Ezeudu O, Ozoegwu C, Madu C (2019) A statistical regression method for characterization of household solid waste: a case study of Awka municipality in Nigeria. Recycling 4(1):1–7. https://doi.org/10.3390/recycling4010001

Adelekan B, Bamgboye I (2009) Effect of mixing ratio of slurry on biogas productivity of major farm animal waste types. J Appl Biosci 22:1333–1343

Sokan-Adeaga A, Ana G (2015) A comprehensive review of biomass resources and biofuel production in Nigeria: potential and prospects. Rev Environ Health 30(3):143–162. https://doi.org/10.1515/reveh-2015-0015

Sibiya N, Muzenda E, Mbohwa C. Evaluation of potential substrates for biogas production via anaerobic digestion: a review. Proceedings of the World Congress on Engineering and Computer Science (WCECS)II, San Francisco, USA 2017.

Oyedepo S (2012) On energy for sustainable development in Nigeria. Renew Sust Energ Rev 16:2583–2598. https://doi.org/10.1016/j.rser.2012.02.010

Latinwo G, Agarry S (2015) Modelling the kinetics of biogas production from mesophilic anaerobic co-digestion of cow dung with plantain peels. Int J Renew Energy Dev 4(1):55–63

Achinas S, Euverink G (2016) Theoretical analysis of biogas potential prediction from agricultural waste. Resource-Efficient Technol 2:143–147

Anukam A, Mohammadi A, Naqvi M, Granström K (2019) A review of the chemistry of anaerobic digestion: methods of accelerating and optimizing process efficiency. Processes 7(504):1–19

Singh G, Jain V, Singh A (2017) Effect of temperature and other factors on anaerobic digestion process, responsible for biogas production. Int J Theoretic Appl Mech 12(3):637–657

Alfa M (2013) Comparative Study of Biogas Production from Cow dung, Chicken droppings and Cymbopogon citratus as alternative Energy sources in Nigeria, M. Sc Thesis Ahmadu Bello University, Department of Water Resources and Enviromental Engineering, Zaria, Nigeria

Shaaban M, Petinrin J (2014) Renewable energy potentials in Nigeria: meeting rural energy needs. Renew Sust Energ Rev 29:72–84

Wang X, Lu X, Li F et al (2014) Effects of temperature and carbon-nitrogen (C/N) ratio on the performance of anaerobic co-digestion of dairy manure, chicken manure and rice straw: focusing on ammonia inhibition. PLoS One 9(5):1–7

Kwietniewska E, Tys J (2014) Process characteristics, inhibition factors and methane yields of anaerobic digestion process, with particular focus on microalgal biomass fermentation. Renew Sust Energ Rev 34:491–500

Sawyerr N, Trois C, Workneh T (2019) Identification and characterization of potential feedstock for biogas production in South Africa. Journal of. Ecol Eng 20(6):103–116. https://doi.org/10.12911/22998993/108652

Achinas S, Achinas V, Euverink GA (2017) Technological overview of biogas production from biowaste. Engineering 3:299–307. https://doi.org/10.1016/J.ENG.2017.03.002

Karellas S, Boukis I, Kontopoulos G (2010) Development of an investment decision tool for biogas production from agricultural waste. Renew Sust Energ Rev 14:1273–1282. https://doi.org/10.1016/j.rser.2009.12.002

Sandhu S, Kaushal R (2019) Anaerobic digestion of vegetable, fruit and cafeteria wastes with cow dung by chemical pretreatment for biogas production in batch digester. IOP Conf Series 1240:1–8. https://doi.org/10.1088/1742-6596/1240/1/012132

Teklehaimanot T (2018) Biogas generation and main factors affecting in the production of biogas: review. Int J Advanced Technol Innov Res 10(1):22–25

Goswami R, Chattopadhyay P, Shome A, BanerjeeS CA, Mathew A et al (2016) An overview of physico-chemical mechanisms of biogas production by microbial communities: a step towards sustainable waste management. 3 Biotech 6(72):1–12

Akinbami J, Ilori M, Oyebisi T, Akinwumi I, Adeoti O (2001) Biogas energy use in Nigeria: current status, future prospects and policy implications. Renew Sust Energ Rev 5:97–112

Elum Z, Mjimba V (2020) Potential and challenges of renewable energy development in promoting a green economy in Nigeria. Africa Review:1–20. https://doi.org/10.1080/09744053.2020.1755094

Ben-Iwo J, Manovic V, Longhurst P (2016) Biomass resources and biofuels potential for the production of transportation fuels in Nigeria. Renew Sust Energ Rev 63:172–192. https://doi.org/10.1016/j.rser.2016.05.050

Abdeshahian P, Lim J, Ho W, Hashim H, Lee C (2016) Potential of biogas production from farm animal waste in Malaysia. Renew Sust Energ Rev 60:714–723. https://doi.org/10.1016/j.rser.2016.01.117

Yang Q, Wu B, Yao F, He L, Chen F, Ma Y et al (2019) Biogas production from anaerobic co-digestion of waste activated sludge: co-substrates and influencing parameters. Rev Environ Sci Biotechnol. https://doi.org/10.1007/s11157-019-09515-y

Aikhuele J, Eniola V, Fasipe O, Awuapila N (2020) The implementation of biogas production from municipal solid wastes in Nigeria. J Energy Technol Policy 10(1):61–68

Oyedepo S, Dunmade S, Adekeye T, Attabo A, Olawole O, Babalola P et al (2019) Bioenergy technology development in Nigeria- pathway to sustainable energy development. Int J Environ Sustain Dev 18(2):175–205

Jekayinfa S, Orisaleye J, Pecenka R (2020) An assessment of potential resources for biomass energy in Nigeria. Resources 9(92):1–41. https://doi.org/10.3390/resources9080092

Sayara T, Sanchez A (2019) A review on anaerobic digestion of lignocellulosic wastes: pretreatments and operational conditions. Appl Sci 9(4655):1–23

Rechberger P, Lötjönen T (2009) Energy from field energy crops – a handbook for energy producers. JYVÄSKYLÄ, Finland: Jyväskylä Innovation Oy, P.O. Box 27, FI - 40101

Atelge M, Krisa D, Kumar G, Eskicioglu C, Nguyen D, Chang S et al (2018) Biogas production from organic waste: recent progress and perspectives. Waste and Biomass Valorization. https://doi.org/10.1007/s12649-018-00546-0

Adepoju T, Olatunbosun BE, Olawale O (2016) Statistical analysis of biogas production from co-digestion of cornstalk with goat dung using a one factor design. Chem Res J 1(4):1–10

Abdel-Shafy H, Mansour M (2018) Solid waste issue: sources, composition, disposal, recycling, and valorization. Egypt J Pet. https://doi.org/10.1016/j.ejpe.2018.07.003

Egbere J, Omogo E, Henry M, Henry U, Chollom P (2011) Generation of biogas from segregates of municipal solid wastes in Jos, Nigeria. Global J Pure Appl Sci 17(1):41–45

Gunaseelan V (1997) Anaerobic digestion of biomass for methane production: a review. Biomass and Biornergy 13(1/2):83–114

Kemausuor F, Adaramola M, Morken J (2018) A review of commercial biogas systems and lessons for Africa. Energies 11(2984):1–21. https://doi.org/10.3390/en11112984

Chow W, Chong S, Lim J, Chan Y, Chong M, Tiong T et al (2020) Anaerobic co-digestion of wastewater sludge: a review of potential co-substrates and operating factors for improved methane yield. Processes 8(39):1–21. https://doi.org/10.3390/pr8010039

Peces M, Astals S, Mata-Alvarez J (2014) Assessing total and volatile solids in municipal solid waste samples. Environ Technol 35(24):3041–3046. https://doi.org/10.1080/09593330.2014.92918

Sahu N, Sharma A, Mishra P, Chandrashekhar B, Sharma G, Kapley A et al (2017) Evaluation of biogas production potential of kitchen waste in the presence of spices. Waste Manag. https://doi.org/10.1016/j.wasman.2017.08.045

Longjan G, Dehouche Z (2018) Nutrient characterisation and bioenergy potential of common Nigerian food wastes. Waste Manag Res:1–10. https://doi.org/10.1177/0734242X18763527

Makinde O, Odokuma L (2015) Comparative study of the biogas potential of plantain and yam peels. British J Appl Sci Technol 9(4):354–359. https://doi.org/10.9734/BJAST/2015/18135

Iqbal S, Rahaman S, Rahman M, Yousuf A (2014) Anaerobic digestion of kitchen waste to produce biogas. Procedia Engineering 90:657–662

Ziana Z, Rajesh P (2015) Production and analysis of biogas from kitchen waste. Int Res J Eng Technol (IRJET) 02(04):622–632

Aliyu A (2017) Biogas potential of some selected kitchen wastes within Kaduna metropolis. Am J Eng Res (AJER) 6(5):53–63

Apte A, Cheernam V, KamatM KS, Kashikar P, Jeswan H (2013) Potential of using kitchen waste in a biogas plant. Int J Environ Sci Dev 4(4):370–374. https://doi.org/10.7763/IJESD.2013.V4.373

Li R, Chen S, Li X (2009) Anaerobic co-digestion of kitchen waste and cattle manure for methane production. Energy Sources, Part A: Recovery, Utilization, Environ Effects 31(20):1848–1856

Ye J, Li D, Sun Y, Wang G, Yuan Z, Zhen F et al (2013) Improved biogas production from rice straw by co-digestion with kitchen waste and pig manure. Waste Manag 33:2653–2658

Kayode O, Luethi C, Rene. (2018) Management recommendations for improving decentralized wastewater treatment by the food and beverage industries in Nigeria. Environments 5(41):1–16. https://doi.org/10.3390/environments5030041

Kiselev A, Magaril E, Magaril R, Panepinto D, Ravina M, Zanetti M (2019) Towards circular economy: evaluation of sewage sludge biogas solutions. Resources 8(91):1–19. https://doi.org/10.3390/resources8020091

Demirbas A, Taylan O, Kaya D (2016) Biogas production from municipal sewage sludge (MSS). Energy Sources, Part A: Recovery, Utilization, and Environ Effects 38(20):3027–3033. https://doi.org/10.1080/15567036.2015.1124944

Pawlita-Posmyk M, Wzorek M (2017) Assessment of application of selected waste for production of biogas. E3S Web of Conferences 19:1–6. https://doi.org/10.1051/e3sconf/20171902017

Ibrahim J, Edeoja A, Aliyu S (2015) A comparative study of biogas yield from various brewery wastes and their blends with yam peels. J Energy Technol Policy 5(11):38–46

Rasheed A, Amuda A (2014) Impacts of artisanal mining on some heavy metals concentration in surface water in Kutcheri, Zamfara state north-western Nigeria. AJIS 3(7):74–82

Uwagbale E (2016) Hazardous waste management and challenges in Nigeria. Public Health International 1(1):1–5. https://doi.org/10.11648/j.phi.20160101.11

Ayoola P, Ogundari I, Akarakiri J, Akinbami J (2018) Techno-economic analysis of poultry droppings fuelled biogas generation in southwestern Nigeria. Int J Energy Sustain Dev 3(4):72–80

Umar M, Yusuf G, Yaya A, Bello H, Uwakwe V, Mohammed I et al (2016) Comparative analysis and quality assessment of treated and untreated tannery effluents discharged from NILEST tannery, Zaria, Kaduna, Nigeria. Int J Scientific Res Eng Stud (IJSRES) 3(1):29–34

Ekiye E, Luo Z (2010) Water quality monitoring in Nigeria; case study of Nigeria’s industrial cities. J Am Sci 4:22–28

Kundu P, Debsarkar A, Mukherjee S, Kumar S (2014) Artificial neural network modelling in biological removal of organic carbon and nitrogen for the treatment of slaughterhouse wastewater in a batch reactor. Environ Technol 35(10):1296–1306. https://doi.org/10.1080/09593330.2013.866698

Bharathiraja B, Sudharsana T, Jayamuthunagai T, Praveenkumar R, Chozhavendhan S, Iyyappan J (2018) Biogas production – a review on composition, fuel properties, feed stock and principles of anaerobic digestion. Renew Sust Energ Rev 90:570–582. https://doi.org/10.1016/j.rser.2018.03.093

Ozor O, Agah M, Ogbu K, Nnachi A, Udu-ibiam O, Agwu M (2014) Biogas production using cow dung from Abakaliki abattoir In south-eastern Nigeria. Int J Sci Technol Res 3(10):237–239

Oguntoke O, Amaefuna B, Nwosisi M, Oyedepo S, Oyatogun M (2019) Quantification of biodegradable household solid waste for biogas production and the challenges of waste sorting in Abeokuta Metropolis, Nigeria. Int J Energy Water Resour. https://doi.org/10.1007/s42108-019-00033-9

Kory's K, Latawiec A, Grotkiewicz K, Kubo´n M. (2019) The review of biomass potential for agricultural biogas production in Poland. Sustainability 11(6515):1–13. https://doi.org/10.3390/su11226515

OgunwandeGA OJA, Adeagbo AO, Fakuyi OF (2013) Effects of co-digesting swine manure with chicken manure on biogas production. IFE J Sci 15(1):1–8

Aworanti O, Agarry S, Ogunleye O (2017) Biomethanization of cattle manure, pig manure and poultry manure mixture in co-digestion with waste of pineapple fruit and content of chicken-gizzard- Part I: kinetic and thermodynamic modelling studies. Open Biotechnol J 11:36–53. https://doi.org/10.2174/1874070701711010036

Akhator E, Igbinomwanhia D, Obanor A (2016) Potentials for commercial production of biogas from domestic food waste generated in Benin metropolis, Nigeria. J Appl Sci Environ Manag 20(2):2369–2373

Hanum F, Yuan L, Kamahara H, Abdul Aziz H, Atsuta Y, Yamada T et al (2019) Treatment of sewage sludge using anaerobic digestion in Malaysia: current state and challenges. Frontiers in Energy Research 7(19):1–7. https://doi.org/10.3389/fenrg.2019.00019

Makisha N, Semenova D (2018) Production of biogas at wastewater treatment plants and its further application. MATEC Web of Conferences 144:1–7. https://doi.org/10.1051/matecconf/201814404016

Adeniran A, Adetinuke A, Oshunrinade O (2016) An evaluation of biogas production from anaerobic digester of a constructed wetland domestic wastewater treatment plant. Afr J Environ Sci Technol 10(10):329–337. https://doi.org/10.5897/AJEST2016.2153

Sampson I (2018) Production of biogas using petroleum sludge. Int J Advanced Acad Res Sci Technol & Eng 4(2):28–40

Ofoefule A, Nwankwo J, Ibeto C (2010) Biogas production from paper waste and its blend with cow dung. Adv Appl Sci Res 1(2):1–8

Safari M, Abdi R, Adl M, Kafashan J (2017) Optimization of biogas productivity in lab-scale by response surface methodology. Renew Energy. https://doi.org/10.1016/j.renene.2017.11.025

Yusof T, Man H, Abdul Rahman N, Hafid H (2014) Optimization of methane gas production from co-digestion of food waste and poultry manure using artificial neural network and response surface methodology. J Agric Sci 6(7):27–37. https://doi.org/10.5539/jas.v6n7p27

Author information

Authors and Affiliations

Contributions

All authors contributed to the idea of the article. The literature search, data analysis and draft were carried out by Olajide Olukayode AJALA. The revision of the draft was critically done by Oludare Johnson ODEJOBI and Funmilayo Nihinlola OSUOLALE.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Conflict of interest

We declare that the authors have no affiliations or financial involvement with anyone or any organization with a financial interest or conflict with the subject or material discussed in this manuscript. We also confirm that this manuscript has not been published in any other journal and is not under consideration for publication elsewhere. The authors approved the manuscript and agreed to its submission in “Biomass Conversion and Biorefinery”.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Odejobi, O.J., Ajala, O.O. & Osuolale, F.N. Review on potential of using agricultural, municipal solid and industrial wastes as substrates for biogas production in Nigeria. Biomass Conv. Bioref. 14, 1567–1579 (2024). https://doi.org/10.1007/s13399-022-02613-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02613-y