Abstract

Pectin is a complex polysaccharide that makes up about one third of the cell wall of higher plants. It was extracted from fruit peels of Irvingia gabonensis and pulp of Cola milleni and Theobroma cacao using acid extraction and alcohol precipitation methods. The effects of temperature and time on the yield and physicochemical properties of the extracted pectin were evaluated. Optimum yields of pectin from C. milleni, I. gabonensis, and T. Cacao were 10.73%, 19.83%, and 11.73% respectively at extracting period of 150 min and temperature of 100 °C. Although there was significant difference in moisture content, degree of esterification, equivalent weight, and methoxyl content of the extracted pectins, there was no significant difference in yield, protein, and ash content at 95% confidence interval. The monosaccharide composition of the three pectins shows that the extracted pectin composed of galacturonic acid and minor neutral sugars. Major functional groups in the extracted pectin show peaks in the region between 1000 and 2000 cm−1. The bands observed between 1627–1651 cm−1 and 1739–1793 cm−1 indicated the presence of the carbonyl group stretching. The surface morphologies of the extracted pectins show irregular shapes, non-smooth surfaces, and unequal sizes which also reveals more silica nodes in cocoa pulp pectin than in other pectins. Thermogravimetric analysis of the pectin samples shows multi-step stages of thermal decomposition, indicating wide range of thermal stability. The overall results specified that the pectins extracted from these plants are suitable for industrial applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Primarily, higher plants contain pectin, hemicellulose, lignin, cellulose, and minor trace of other organic matters [1]. Chemical composition of pectin consists of linear polymers of α-D– (1–4) anhydrogalacturonic acid. Part of the carboxyl group of the anhydrogalacturonic acid can be esterified with methanol. They may also be O–acetylated at the C–2 and C–3 positions. This heterogeneous grouping of acidic structural polysaccharide can be found in middle lamella of fruits and vegetables [2]. Pectin also carries non-sugar substituents, essentially methanol, acetic acid, phenolic acids, and occasionally amide groups. The esterification of galacturonic acid residue with methanol or acetic acid is a very important structural characteristic of pectin substances. The degree of methylation (DM) is defined as the percentage of carbonyl groups esterified with methanol. If more than 50% of the carboxyl group is methylated, the pectin is called high methoxy (HM) pectin, and if less than 50% degree of methylation, it is called low methoxy (LM) pectin [3]. Methyl esterification is common in native pectin but acetylation is rare in natural extracts. Overall, the degree of substitution is known as the degree of esterification (DE). The overall polysaccharide is therefore ionic but with large neutral regions giving interesting functionalities [2].

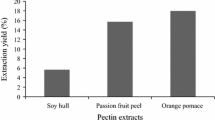

Literature revealed that fresh postharvest plant wastes contain 0.5–4.0% of pectin substances [4,5,6]. Sources of pectin include banana, beets, cabbage, and carrots. However, the main raw materials used to produce commercial pectin are apple pomace and citrus peels [7]. Industrially, pectin has been extensively used in a number of food products such as ice creams, beverages, and jellies, due to its typical gelling, thickening, and stabilizing properties [8].

Cola milleni (Monkey cola) is a member of the family Sterculiaceae, genus Cola. It is a tree that grows from 7 to 15 m in height, twisted, and branchy with round and open crown [9]. C. milleni pod houses sweet mucilaginous seeds which are highly viscous and sticky. The pulp is edible, due to presence of no toxin matter [9].

Irvingia gabonensis (wild mango) grows wild in forests of tropical Africa. It is truly a multipurpose tree as it provides food, fuel, fiber, medicines, and timber. I. gabonensis grows to a height of 15–40 m, slightly buttressed. It is an edible African indigenous fruit tree that produces edible fruits and seeds [10, 11].

Theobroma cacao (cocoa) belongs to the genus Theobroma classified under the sub-family Sterculioidea of the mallow family Malvaceae. Its seeds (cocoa beans) are used to make cocoa mass, cocoa powder, confectionery, ganache, and chocolate. The recovery of cocoa beans from the cocoa fruit generates large amount of waste in form of pod, shell, or husk [12].

The suitability of pectin for different purposes is determined by its characteristics, namely, anhydrouronic acid content, methoxyl content, ash, moisture, and degree of esterification. The fruit peels (waste) from the fruit juice processing industry are normally discarded, which are highly perishable. It is also problem to the processing industries and pollution monitoring agencies. Thus, these waste materials may create environmental problems, particularly water pollution and offensive odor. The presence of biomaterials such as oil and pectin as well as sugar in fruit peels (waste) can stimulate aerobic bacterial that enhances decomposition of biodegradable organic matters into products such as carbon dioxide, nitrates, sulfates, and phosphates in water. Suitable methods have to be adopted to convert agro-wastes into an asset. [13]. The main objectives of the study were to examine the physicochemical properties, characterize the extracted pectin from the fruit peels of I. gabonensis and pulp of C. milleni and T. cacao, investigate the various factors that affect the yield of the pectin, and assess their industrial beneficiations. This study was aimed at investigating possibility of obtaining pectin from postharvest agro-wastes of I. gabonensis, C. milleni, and T. cacao fruits as potential additive in food and pharmaceutical industries to reduce production cost.

2 Materials and methods

2.1 Materials

Fresh fruit samples of C. milleni, T. cacao, and I. gabonensis were obtained from Idasen farm in Owo, Ondo State, Nigeria. They were authenticated at Department of Crop, Soil, and Pest Management, Federal University of Technology, Akure. All reagents used were of analytical grade obtained from Sigma-Aldrich Chemie, Steiaheim, Germany.

2.2 Methods

2.2.1 Material preparation

The fruit samples were cleaned with water and air-dried for 3 days at 30 °C and 45% relative humidity. Peels of I. gabonensis and pulp of C. milleni and T. cacao were separated from the fruit and pod respectively using a sterile knife. The isolated I. gabonensis peels and pulp of C. milleni and T. cacao were milled separately with a marlex electrical blender. Each of them was sieved to particle size between 0.6 and 0.8 mm (stainless mesh, model 304). The ground samples were kept in an airtight container and stored prior to extraction process.

2.2.2 Extraction of pectin

Extractions of pectin from the samples were performed under acid condition using the methods of Koubala et al. [14] with little modification. Each of the peels of I. gabonensis and pulp (scooped from pod inner part) of C. milleni and T. cacao was subjected to aqueous extraction separately in acidic medium (2M HNO3) at pH 2.5, temperature range (30–100 °C), and time range (30–150 min). The extracted samples were filtered through cheese cloth and allowed to cool to room temperature. The filtrates were then centrifuged for 20 min at 3500 rpm. Ethanol (96%) was added to each of the supernatant and allowed to stand for 1 h for pectin precipitation. The precipitated pectins were separated by filtration and washed thrice with absolute ethanol. The isolated pectins were dissolved in ethanol (96%), re-precipitated (for complete removal of impurities), filtered, washed with distilled water, and oven-dried at 55 °C. The pectins were dried to a constant weight in an air-circulate oven at 55 °C for 12 h. The isolated pectins were then cooled in a dessicator, broken up, ground, and sieved to powder form. The pectin yield was determined using Eq. 1. The dried pectin samples were wrapped in aluminum foil and stored in freezer at 4 °C until used.

where Y is pectin yield (%), w1 is weight of peel/pulp from agro-waste taken for extraction (g), and w2 is weight of dried isolated pectin (g).

2.2.3 Solubility test on extracted pectins

Solubility of I. gabonensis extracted pectin in water was investigated by weighing 0.5 g of the sample separately in two conical flasks containing distilled water (40 mL) and 96% ethanol (10 mL). One of the conical flasks containing pectin in water/alcohol was heated for 15 min at 85–95 °C, and the contents of the two conical flasks were observed at the end of 15 min [15]. These same experiments were carried out on C. milleni and T. cacao pectins.

Solubility of I. gabonensis, C. milleni, and T. cacao extracted pectins in 0.1-M NaOH was investigated with the same procedure used in water solubility test on pectin, but with replacement of distilled water (40 mL) and 96% ethanol (10 mL) with 0.1-M NaOH (50 mL).

2.2.4 Physicochemical characterization of the extracted pectin

Physicochemical characterization of the extracted pectin was determined according to Ofosua et al. [12]. The moisture content was determined by weighing 1 g of pectin into three Petri dishes and dried in an oven at 105 °C to constant weight. The moisture content was determined as the ratio of the weight of moisture loss to weight of sample expressed as a percentage (AOAC, 2005).

Protein content was determined according to AOAC (2000), while the total ash content was determined according to the method of AOAC (2005). One gram of pectin sample was weighed and ignited in a furnace at 550 °C. The ash obtained was weighed and boiled in 25 mL of 2-M HNO3 for 5 min. The insoluble matter was filtered and washed with hot water and ignited. The subsequent weight was then determined as ash content.

The swelling index of the pectin sample was determined according to WHO (1998). One gram of the sample was weighed into a 25-mL measuring cylinder; 20-mL distilled water was added and volume occupied noted (v1). The mixture was shaken intermittently for 1 h and allowed to stand for next 2 h, while volume occupied was noted as v2. The swelling capacity was calculated as shown in Eq. 2.

Equivalent weight

This was determined according to method of Food Chemical Codex (2019). Pectin sample (0.5 g) was weighed into a 250-mL conical flask and moistened with 5-mL ethanol. About 1.0-g NaCl was added to the mixture, followed by addition of 100-mL distilled water and few drops of phenol red indicator. Care was taken to ensure that all the pectin had dissolved and that no clumping occurred. The solution was then titrated with 0.1-M NaOH to an end point of pale permanent pink color. Equivalent weight was calculated as shown in Eq. 3.

Methoxyl content

This was done using the neutralized solution obtained from equivalent weight determination (by the saponification of pectin followed by titration of the liberated acid). Twenty-five milliliters of 0.25-M NaOH was added to the neutralized solution and the mixture was stirred thoroughly and allowed to stand for 30 min at ambient temperature. A 25 mL of 0.25-N HCl was added with two drops of phenolphthalein indicator and titrated with 0.25-N NaOH to end point (at pH 7, when a slight appearance of light pink color occurred). The percentage methoxyl content was calculated as shown in Eq. 4.

2.2.5 Determination of the degree of esterification

Degree of pectin esterification was determined using the acid-base titration method of the Food Chemical Codex. Pectin samples were washed in ethanol and dried. Of the washed and dried pectin material, 0.5 g was dissolved in 100-mL boiling deionized water and the sample was titrated with 0.1-M NaOH using phenolphthalein as an indicator (the volume of 0.1-M NaOH used was recorded as V1). Then, the sample was saponified by addition of 10-mL 1-M NaOH, followed by mixing for 15 min. Ten milliliters of 1-M HCl was added to the sample and the mixture was again titrated with 0.1-M NaOH until color change (volume V2). The DE was calculated according to Eq. 5.

2.2.6 Bulk, tapped densities, Hausner ratio, and compressibility index

The bulk, tapped densities, Hausner ratio, and compressibility index were determined using the methods of Ofosua et al. [12]. Five grams of pectin powder was weighed into a 10-mL measuring cylinder and the volume occupied was noted. The sample was tapped and the volume after tapping was recorded. The values were then calculated as shown in Eqs. 6-9.

The angle of repose was determined by weighing 20 g of pectin powder into a funnel clamped to a stand with its tip 10 cm from a plane paper surface. The powder was allowed to flow freely onto the paper surface. The height of the cone formed after complete flow and the radius of the cone were used to calculate the angle of repose (휃).

where 퐻 is the height of the heap and 푅 is the radius of the heap.

2.2.7 SEM analysis

Each of the powdered samples of the extracted pectins (10 mg) was dehydrated in an alcohol, dried, and finally coated with 10-nm thin layer of carbon using carbon-coating machine and mounted separately on sample stub of SEM (XL 20 Philips) operated at 16.0 kV. The surface morphology of each of the samples was revealed automatically with the aid of the attached computer software.

2.2.8 FTIR analysis

Each of the three extracted pectin samples was mixed with potassium bromide at ratio 1:100 in a mortar pestle. Each of the mixture was molded to a dice of specific dimension to form pellet by pressing with a hand press machine. They were placed separately on the sample holder of the IR spectrometer (Bruker Alpha) operated between spectral range 4000 and 400 cm–1 to obtain functional groups in the extracted pectin samples.

2.2.9 Thermogravimetric analysis of the pectin samples

Thermogravimetry is one of the most widely used techniques to monitor the composition and thermal stability of material. Thermogravimetric analysis of the pectin samples was performed using a Mettler Toledon Star System, Columbus, USA. The samples were weighed and placed into the platinum cups and sealed. The operated temperature ranges from 0 to 900 °C under nitrogen atmosphere at a heating rate of 10 °C/min.

2.2.10 Monosaccharide composition

Sugar composition of extracted pectin was determined according to Carvajal-Millan et al. [16]. Monosaccharide in pectin was hydrolyzed with absolute ethanol, and filtered through 0.45 mm (Whatman); the solvent was evaporated under air at 40 °C and weight of dried monosaccharide determined. Monosaccharide was re-hydrolyzed in absolute ethanol, rinsed with 100 mL of distilled water, and the composition analyzed through high-performance liquid chromatography (HPLC). The HPLC used a Supelcogel Pb column (300 × 7.8 mm; Supelco, Inc., Bellefont, PA) eluted with 5-M H2SO4 (filtered 0.2 mm, Whatman) at 0.6 mL/min and 50 °C. Inositol internal standard, refractive index detector (Star 9040), and a Star Chromatography Workstation system control version 5.50 were used.

3 Results and discussion

The results of qualitative analysis carried out on the extracted pectin samples are presented in Table 1. The extracted pectins from the three samples were brown in color, insoluble in ethanol, cold water, and NaOH, but soluble in hot water and NaOH. These observations confirmed the plant extracts to be pectins.

Table 2 presents the optimum pectin yield to be 19.83%, 11.73%, and 10.73% (on dry weight basis) for I. gabonensis, T. cacao, and C. milleni pectin respectively. The yield of pectin is known to vary depending on some extraction conditions used [17, 18], and recent studies have shown yields as low as about 2% and as high as about 20%. Highest yield of pectin was obtained at 100 °C and 150 min from I. gabonensis peels, followed by T. cacao pulp and least from C. milleni pulp. The yield was influenced by extraction temperature and time, because the protopectin that is present in the cell wall takes time to solubilize and come into solution [19].

The moisture content of the pectin from T. cacao, C. milleni, and I. gabonensis pods were 7.18%, 3.79%, and 6.27% respectively (Table 3). Moisture content is the measure of the water content in the sample. Pectin should have low to moderate moisture content as possible for safe storage without developing molds. Higher moisture content is an index of spoilage as it will aid the growth of microorganisms which can affect the pectin quality due to the production of pectinase enzymes. The moisture contents of the extracted pectins are within recommended moisture content for commercial pectin [20].

The ash contents for C. milleni, T. cacao, and I. gabonensis were 5.07%, 4.86%, and 4.14% respectively (Table 3). Ash content is the proportion of inorganic materials that is left after pectin has been burnt at high temperature. Low ash content is good for gel formation. The maximum limit for ash content for good quality gel criteria is 10% [21, 22]. The ash contents for the three pectins fell within the recommended value of 10% according to Azad et al. [21].

Table 3 shows protein content in T. cacao pulp pectin to be the highest, followed by C. milleni, and I. gabonensis pectin was the lowest. The overall high protein content of the samples might be associated with insolubility of protein in acid medium used in extraction process and pectin polysaccharides or exist in free form [23].

The swelling index of T. cacao pectin was 377.24%; those of C. milleni and I. gabonensis were 559.27 and 492.41%, respectively, with C. milleni having the highest swelling index followed by I. gabonensis. The swelling behavior of the three extracted pectins showed that they could function as binder or matrix agent in drug-controlled release formulations [24].

The degree of esterification (DE) of C. milleni, T. cacao, and I. gabonensis pectin are 62.89, 39.25, and 70.43% respectively (Table 3). According to classification of DE, low methoxyl pectins have a DE of < 50%, while high methoxyl pectins have DE > 50% [25, 26]. C. milleni and I. gabonensis pectins belong to high methoxyl pectins (DE > 50). Pectins from these sources have greater ability to form gel. Due to this quality, they are readily useful in food and pharmaceutical industries as an additive. Pectin derived from T. cacao has low methoxyl pectin (DE < 50). These observations are similar to the findings of Ofosua et al. [12]. Slight difference in the increase in DE T. cacao pectin from the findings of Ofosua et al. [12] might be as a result of the source of the material or/and environmental influence. The degree of esterification determines the behavior of pectin and influences its mechanism of gelation [26].

The methoxyl content of pectin samples from C. milleni pulp and I. gabonensis fruit peels were 5.20% and 4.50%, respectively, while the one from T. cacao pulp was 3.20%. The low methoxyl pectin from T. cacao pulp confirmed its DE < 50. While high methoxyl pectin undergoes gelation in the presence of sugar, low methoxyl pectin requires addition of a controlled amount of divalent cation (such as Ca2+ and Mg2+) to achieve desired gelation [24]. According to Prabhudev and Sneharani [27], treatment of pectin with pectin methylesterase enzyme enhances methoxyl content of pectin by at least 0.5%.

The precompression parameters of C. milleni, T. cacao, and I. gabonensis pectins are the angle of repose, bulk density, tapped density, Hausner ratio, and compressibility index. The ease of flow of powder is of paramount importance in tablets and capsules formulation. The free-flowing property of these extracted pectins ensured reproducible filling of tablet dies and capsule dosators, thereby improving weight uniformity and consistency in physical properties according to Aulton [28].

Hausner ratio is related to inter-particle friction in a powder, and values close to 1.2 are indicative of less cohesive and free-flowing powder, while value greater than 1.6 confirms that pectin is cohesive and has poor flow properties. In terms of flowability, powders with compressibility index of 5–15% are regarded as excellent, 12–16% good, 18–21 fair, and > 40% extremely poor [28]. A high angle of repose is indicative of a cohesive powder, while a low angle of repose connotes a non-cohesive powder. In general, powders with angles of repose >50° have unsatisfactory flow properties, whereas minimum angles close to 25° have very good flow properties [29]. In the current study, C. milleni, T. cacao, and I. gabonensis pectin powder had Hausner ratio of 1.16, 1.17, and 1.08, respectively, compressibility index of 14.50%, 12.00%, and 7.00% respectively, and angle of repose of 18°, 26.10°, and 22.64° respectively. These values confirmed the extracted pectins to be less cohesive with good flow properties.

The galacturonic acid, which is an important parameter that indicates the suitability of pectin for its use in jams, jellies, etc., was found to be 74.2%, 62.5%, and 69.4% (w/w) for C. milleni, T. cacao, and I. gabonensis (Table 4). The main neutral sugars present in the pectin samples were galactose, arabinose, and rhamnose. The monosaccharide composition of the three pectins is similar to the sugar composition of pectin obtained from chickpea reported by Willats et al. [30]. The moderate levels of arabinose and galactose indicated the presence of galactans, arabinans, arabinogalactans, and rhamnogalacturonan [30]. Neutral sugar, like glucose, mannose, and xylose, was also found to be present, but in concentrations below 3.2%. During the acid extraction of pectin, neutral sugar side chains and glycosidic linkages of some cell wall polymers could undergo partial hydrolysis and be converted into free sugars, which are not readily precipitated by ethanol [31]. In addition, heat labile neutral sugars, such as arabinose, could undergo degradation during the extraction [32]. These reasons might be responsible for the low neutral sugar levels observed in the extracted pectins. It could also be attributed to contaminants from other polysaccharides. This result showed that the extracted pectin composed of galacturonic acid and a lower percentage of neutral sugars.

The FTIR spectra of the three extracted pectins from the chosen agro-wastes are shown in Fig. 1. The major functional groups in pectin usually showed characteristic peaks in the region between 1000 and 2000 cm−1. The bands at 1627–1651 cm−1 and 1739–1793 cm−1 indicated the presence of carbonyl group C=O stretch in the free and esterified carboxyl groups. The absorption bands between 1101 and 1143 cm−1 was due to the presence of ether (R-O-R) bonds in the ring structure of pectin molecules. The spectra obtained for the pectins were similar; there is no major difference in the FTIR spectra of the pectin samples produced by various sample sources, except in the absorption bands between 2656 and 2561 cm−1 in C. milleni pectin. The broad band around 3417 and 3458 cm−1 might be due to presence of –OH group present in the pectin samples. The band from 2922 and 2852 cm−1 was due to the presence of C-H stretching in the lignin. A doublet peaks in the region 2399 to 2360 cm−1 observed in the extracted pectin samples suggests an S–H or C–S bond.

The surface morphologies of the three extracted pectins were observed using scanning electron microscope and are shown in Fig. 2a–c. The surface morphology of the samples shows irregular shapes, unsmooth surfaces, and unequal sizes. Unequal/rough surfaces will allow drug particles to adhere tightly into the pores and crevice, resulting in sustainability of drug release. Drug release from a dosage form is affected by the surface characteristics of the excipients used [12]. The three extracted pectins would be able to sustain drug release due to the rough surfaces in Fig. 2. The surface nature of both C. milleni and I. gabonensis pectin was rougher than T. cacao pectin. The images revealed the presence of more silica nodes in T. cacao pectin than in C. milleni and I. gabonensis pectins according to Sivakumar et al. [33].

Thermogravimetric analysis (TGA) analysis was identified as a sensitive technique to record the thermal properties such as degradation, decomposition, and weight loss of the given sample. It was observed from Fig. 3 that the pectin samples were stable to heat from 50 to 200 °C. The decomposition of the samples occurred in multi-step stages for the three pectin samples. The first thermal decomposition occurred between 200 and 350 °C with a weight loss of about 10%. The second weight loss occurred from 400 to 620 °C (25%). Final thermal decomposition of pectin occurred between 650 and 900 °C. This is an indication that the pectin samples were able to withstand heat at high temperature. The thermal stability was one of the properties being considered in industrial applications.

4 Conclusion

In this study, it can be concluded that I. gabonensis peels gave the highest yield of pectin out of the three pectins, followed by T. cacao and C. milleni using acid extraction and ethanol aided precipitation. However, extraction yield increased significantly with increase in temperature and time. Pectin extracted at the optimum conditions gave rise to a high galacturonic acid with a large molecular weight and low content of neutral sugar residues. The extracted pectins from C. milleni pod, T. cacao, and I. gabonensis have physicochemical properties that make them an attractive option to be used as a multifunctional excipient in the pharmaceutical, food, and cosmetics industries. The use of FTIR reveals the structural and functional properties of the pectins, and SEM analysis shows the surface morphology of the samples as irregular shapes, non-smooth surfaces, and unequal sizes. Thermal analysis reveals that the pectins have the capacity to withstand heat at high temperature during industrial processes. The overall results from the research indicated that the pectins extracted from these sources are suitable precursors for industrial applications.

References

McNeil M, Danville AG, Fry SC, Albersheim P (1984) Structure and function of the Primary cell walls of plants. Annu Rev Biochem 53:625–663

Sharma BR, Naresh L, Dhuldhoya NC, Merchant SU, Merchant UC (2006) An overview on pectins. Times Food Processing J. June-July Issue, Page no. 44-51

Kuuva T, Lantto R, Reinikainen T, Buchert J, Autio K (2003) Rheological properties of laccase-induced sugar beet pectin gels. Food Hydrocoll 17:679–684

Sanati RA, Zokaee FF (2007) The effect of pH, ethanol volume and acid washing time on the yield of pectin extraction from peach pomace. Int J Food Sci Technol 42:1177–1187

Kashyap DR, Vohra PK, Chopra S, Tewari R (2001) Applications of pectinases in the commercial sector: a review. Bioresour Technol 77:215–227

Sakai T, Okushima M (1989) Process for preparing pectin U.S. Patent 4835262

Wang S, Chen F, Wu J, Wang Z, Liao X, Hu X (2007) Optimization of pectin extraction assisted by microwave from apple pomace using response surface methodology. J Food Eng 78:693–700

Thakur BR, Singh RK, Handa AK (1997) Chemistry and uses of pectin – a review. Crit Rev Food Sci Nutr 37:47–73

Ratsch C (2005) The encyclopedia of psychoactive plants: ethno pharmacology and its applications. Rochester, Vermont

Atangana AR, Tchoundjeu Z, Foldout JM, Asaah E, Dumb M, Leakey RRB (2001) Domestication of Irvinga gabonesis: phenotypic variation in fruit and kernels in two populations from Cameroon. Agrofor Syst 53:55–64

Ndjouenkeu R, Goycoolea FM, Morris ER, Akingbala JO (1996) Okra (hibiscus esculentus) dika nut (Irvingia gabonensis) polysaccharides. Carbohydr Polym 29:263–269

Ofosua A, Ofori-Kwakye K, Manso SF, Boakye-Gyasi M, Sasu C, Pobee M (2016) Physicochemical and antimicrobial properties of cocoa husk pectin intended as versatile pharmaceutical excipient and nutraceutical. J Pharm:1–12. https://doi.org/10.1155/2016/7608693

Ermias, Teshome (2016) Extraction and characterization of pectin from selected fruit peels waste. Int J Sci Res 6(2):2250–3153

Koubala BB, Kansci G, Mbome LI, Crepeau MJ, Thibault JF, Ralet MC (2008) Effect of extraction conditions on some physicochemical characteristics of pectins from améliorée and mango peels. Food Hydrocoll 22(7):1345–1351

Sood N, Mathur A (2014) Evaluation of pharmacological activities of pectin extracted from apple and citrus pomace. Biolife J 2(4):1203–1217

Carvajal-Millán E, Rascón-Chu A, Márquez-Escalante J, Ponce de León N, Micard V, Gardea A (2007) Maize bran gum: extraction, characterization and functional properties. Carbohydr Polym 6:280–285. https://doi.org/10.1016/j.carbpol.2006.10.006

Vriesmann L, Petkowicz C (2013) Highly acetylated pectin from cacao pod husks (Theobroma cacao L.) forms gel. Food Hydrocoll 33:58–65

Yapo BM, Koffi KL (2013) Extraction and characterization of highly gelling low methoxy pectin from cashew apple pomace. Foods J 3:1–12

Rha HJ, Bae IY, Lee S, Yoo SH, Chang PS, Lee HG (2011) Enhancement of anti-radical activity of pectin from apple pomace by hydroxamation. Food Hydrocoll 25:545–548

Muhamadzadeh J, Mahoonak SAR (2010) Extraction of pectin from sunflower head residues of selected iranian cultivars. World Appl Sci J 8:21–24

Ismail NSM, Ramli N, Hani NM, Meon Z (2012) Extraction and characterization of pectin from dragon fruit (Hylocereus polyrhizus) using various extraction conditions. Sains Malaysiana 41:41–45

Azad AK, Ali MA, Akter S (2014) Isolation and characterization of pectin extracted from lemon pomace during ripening. J Food Nutri Sci 2(2):30–35

Trease GE, Evans WC (1989) Pharmacognosy, 13th edn. ELBS/ Bailliare Tindall, London, pp 345–773

Akpabio E, Jackson C, Ubulom P, Adedokun M, Umoh R, Ugwu C (2011) Formulation and in vitro release properties of va plant gum obtained from Sesamum indicum. Int J Pharm Biomed Res 2(3):166–171

Joye DD, Luzio GA (2000) Process for selective extraction of pectins from plant material by differential pH. Carbohydr Polym 43(4):337–342

Sriamornsak P (2003) Chemistry of pectin and its pharmaceutical uses: a review. Silpakorn Uni Int J 3(1-2):206–228

Prabhudev H, Sneharani AH (2020) Extraction and characterization of pectin methylesterase from muskmelon biowaste for pectin remodeling. J Food Biochem 44:e13237. https://doi.org/10.1111/jfbc.13237

Staniforth JN (1996) Powder flow. In: Aulton ME (ed) Pharmaucetics. The science of dosage form design, 1st edn. Churchill, Livingstone, Longman Group, United Kingdom, pp 600–601

Aulton MA (2007) Aulton’s pharmaceutics: the design and manufacture of medicines. Churchill Livingstone, London

Willats WG, Knox JP, Mikkelsen JD (2006) Pectin: new insights into an old polymer are starting to gel. Food Sci Technol 17:97–104

Garna H, Mabon N, Robert C, Cornet C, Nott K, Legros H, Wathelet B, Paquot M (2007) Effect of extraction conditions on the yield and purity of apple pomace pectin precipitated but not washed by alcohol. J Food Sci 72:C1–C9

Marcon MV, Vriesmann LC, Wosiacki G, Beleski-Carneiro E, Petkowicz CL (2005) Pectins from apple pomace. Polímeros 15:127–129

Sallam E, Ibrahim H, Takieddin M, Shamat MA, Baghal T (1998) Dissolution characteristics of interactive powder mixtures. Part two: effect of surface characteristics of excipients. Drug Dev Ind Pharm 14(9):1277–1302

Acknowledgements

The authors hereby acknowledge Chemistry Department of The Federal University of Technology Akure and Achievers’ University, Owo, Ondo State, Nigeria, for providing an enabling environment for this research work.

Author information

Authors and Affiliations

Contributions

Lajide L. and Adetuyi A. O. provided study concept and design. Material preparation, data collection, and analysis were performed by Oloye M. T. First draft of manuscript was written by Oloye M. T. All authors commented on the previous version of the manuscript; the revised and final version of the manuscript was prepared by Jabar J. M. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Statement of novelty

The study has established possibility of converting waste to wealth through economically friendly precursor (pectin) obtained from postharvest agro-waste materials for local chemical and allied industries.

Rights and permissions

About this article

Cite this article

Oloye, M.T., Jabar, J.M., Adetuyi, A.O. et al. Extraction and characterization of pectin from fruit peels of Irvingia gabonensis and pulp of Cola milleni and Theobroma cacao as precursor for industrial applications. Biomass Conv. Bioref. 13, 2125–2133 (2023). https://doi.org/10.1007/s13399-021-01366-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01366-4