Abstract

The annual global oil market is about 40 million tons, including vegetable oil-based lubricants, and modified esters currently account for only about 10–15%. Half of these lubricants are getting into the atmosphere, water, and soil. That is why environmentally friendly lubricants present a rapidly expanding branch of industrial lubricants, which will become increasingly important over the next century. The aim of this work is to make a comparative analysis of fats. Animal fats and fish oil which are inappropriate for food industry were selected for the investigation purposes. The base and ferment hydrolysis were made in order to separate free fatty acids from selected fats. The produced esters, animal fats, and fish oil were studied by evaluation of their physicochemical properties. As a result, octyl esters which were produced from animal fats and fish oil are ascribed to 22, fish fats to 32, and animal fats to 46 classes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

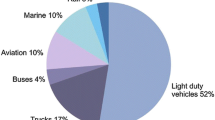

Over the last centuries, the world population growth has led to greater demand for new resources. Development of the society has caused the depletion of fossil fuel reserves. People and especially governments start to realize the high level of pollutants and harmful substances of fossil fuel resources; therefore, stringent environmental requirements are being set. The scientific community intensively explores environmentally friendly alternative resources [21, 22, 27].

In modern market, the majority of lubricants are mineral-based, and the rest are chemically synthesized. It is important to note that availability of these mineral resources is rapidly declining, and the traditional oil products emit greenhouse gases. Though scientific studies have confirmed that synthetic oils have a higher rate of biodegradation, their use is still limited due to their toxicity and high price [29].

The annual global demand of oil and hydraulic fluid is more than 40 million tons [2]. Meanwhile, bio-oil consumption is only about 130 thousand tons. It is expected that by 2020, the bio-oil consumption will increase more than 3 times and reach 420 thousand tons. Such increase of biological material consumption is due to environmental issues and the public perception that the majority of waste oil gets into the environment and contaminates the soil, air, and water [33]. In order to overcome these problems, one of the most reasonable choices is to change the current mineral oils, i.e., oils derived from crude or petroleum reserves, such as paraffinic, naphthenic, aromatic oils, to biological oils, which are biodegradable, economical, and environmentally friendly [18, 23, 29]. The aim of this study is to assess the possibility of usage of non-food animal fats (rendered animal fats and fish oil) for production of bio- lubricants.

2 Methodology

The study examined the usage of non-food animal fats for production of bio-lubricants. For this purpose, the scientific research of Akerman et al. 2011 [1], Duangkaewmanee et al. 2011 [7], Salimon et al. 2011 [23], Avisha et al. 2012 [4], Bilal et al. 2013 [5], Jinho et al. 2013 [13], Lage et al. 2016 [14], and Saboya et al. 2017 [22] was analyzed and a research methodology of production of bio-lubricants from renewable resources was created.

For the production of bio-lubricants, non-food residual fats such as rendered animal fats and fish oil were chosen (Table 1).

In the study leading to the paper and in order to produce bio-lubricants, free fatty acids (FFA) were separated from the fat and esterified with alcohols by using an acid catalyst; the water from the reaction mixture was removed and the unreacted alcohol was separated by distillation. A conceptual scheme of the experiment is presented in Fig. 1.

2.1 Separation of free fatty acids

During the experiment, hydrolyses were used for FFA separation employing an alkali and enzyme catalyst. Potassium hydroxide was chosen as an alkaline catalyst and the lipase enzyme as the enzymatic hydrolysis catalyst, which decomposes mono-, di-, and triglycerides to glycerol and FFA.

2.2 Alkaline hydrolysis

Animal fats and fish oil were filtered in order to remove carbon particles and other suspended impurities. Fifty grams of fat or oil was mixed with 300 ml of KOH solution. The reaction was carried out at 70 °C with stirring at 600 rpm speed. In order to determine the optimal reaction parameters, the KOH concentration of the solution was increased from 2 to 3 M, and the reaction time increased from 2. 5 to 3.5 h. After the reaction, 200 ml of distilled water was added. The unsaponified fat or oil was removed by adding 100 ml of hexane; the mixture was allowed to settle and the upper layer was separated. The lower layer was acidified with 6 N hydrochloric acid to pH 1. FFA was extracted with hexane excess and the extract was washed with distilled water to neutral pH. Traces of water were removed by filtering the extract through anhydrous sodium sulphate layer. The solvent was separated in a vacuum distillatory at 35 °C and 0.8 bar vacuum. The received FFA was weighed.

2.3 Enzymatic hydrolysis

During the experiment, an aqueous solution of the lipase with enzyme concentration of 1 g L−1 was produced. Animal fats and fish oil were filtered off and mixed with the lipase solution at a ratio of 1:4. The mixture was stirred for 30 h with a magnetic stirrer at 500 rpm speed and at 30 °C temperature. After 30 h of hydrolysis reaction, the hexane excess was added to the mixture. After the mixture settled, the resulting solvent layer comprising the FFA was separated from the glycerol and the water layer. At this phase, traces of water were removed by anhydrous sodium sulfate, the mixture was filtered, and the hexane was removed by distillation. The received FFA was weighed.

2.4 Ester synthesis

The FFA isolated during the experiment was combined with octanol and decanol at a molar ratio of 1:3. A catalyst of 3% of FFA weight was added. Amberlyst 15H solid acid catalyst was used as a catalyst. The mixture was stirred at 500 rpm, while maintaining 80 °C temperature. Every 30 min, the acid value was measured and its decrease was observed. The decrease of the acid in the medium indicates the amount of the reacted acid; when the value is constant, the reaction is stopped.

2.5 Measurement of the acid value (mg KOH · g−1)

One to 10 g of sample was taken and dissolved in 20 ml of ethanol-acetone (1:1); if necessary, the solvent can be slightly heated. The mixture was titrated with 0.1 M KOH solution using a phenolphthalein indicator so that the resulting pink color remained for more than 30 s.

Acid value is calculated according to the formula:

where AV is acid value (mg KOH · g−1); MKOH is molar mass of KOH (g · mol−1); cM is KOH molarity (mol·L−1); V is the volume of titrant (ml); and w is sample weight (g).

The conversion of free fatty acids into the ester is calculated according to the following formula [4]:

where C is conversion degree (%); AVO is the acid value at the beginning of the reaction (mg KOH · g−1); and AVt is acid value at time t (mg KOH · g−1).

After the reaction, the catalyst was separated by filtration. Water was removed by heating the mixture to 105 °C, and stirring vigorously. Traces of water were removed with anhydrous sodium sulfate. The unreacted excess of the alcohol was separated by distillation: 195 °C – octanol; 233 °C – decanol.

The sample viscosity during the study was determined according to DIN EN ISO 3104 + AC: 1996, viscosity index—ASTM D2270-10, sample density—ASTM D 1298-99, pour point—ASTM D 97-96, oxidation stability period—ASTM D 525-01, and the ash-content of the bio-lubricants—ASTM D 482-03 standard techniques.

3 Study results and their review

The bio-lubricants in the global market must comply with the requirements of ISO 15380 2011 standard, which specifies the main parameters of the bio-lubricants and their values. The most important of these characteristics are viscosity and density. The latter parameter limits are not defined, but its value must be specified in the technical characteristics of the bio-lubricants. This standard does not indicate the pour point, oxidation stability, and the ash-content level. The standard states that these values should be determined by the consumer and the manufacturer has to meet the user’s needs.

For the production of bio-lubricants, FFA were separated from animal fats and fish oil, esterified with long-chain alcohols, and four different synthetic esters were produced: fish oil octyl ester (FOOE), animal fats octyl ester (AFOE), fish oil decyl ester (FODE), and animal fats decyl ester (AFDE); and their quality characteristics were examined: viscosity at 40 and 100 °C temperatures, density at 15 °C and room temperature, oxidation stability, the pour point, the ash- content; and the viscosity index was calculated. The primary fat and oil quality characteristics were also studied and compared with the properties of the produced esters and the requirements of the standard.

3.1 Synthesis of synthetic esters

FFA were separated from animal fats and fish oil by alkaline and enzymatic hydrolysis. In order to study the effect of the alkaline hydrolysis process parameters on the FFA yield, a test was carried out by changing the reaction time from 2.5 to 3.5 h, with the KOH concentration from 2 and 3 M. The data of the FFA yield is presented in Fig. 2.

The data in Fig. 2 shows that 20–30% more FFA is extracted from animal fats than from fish oil hydrolyzed under the same conditions. It is also noted that enzymatic hydrolysis of 30-h duration provides 10–15% higher FFA yield than alkaline hydrolysis lasting 2 h and 30 min.

The results show that increasing the concentration of KOH from 2 to 3 M without changing the reaction time (2.5 h) increased the FFA yield by 10%, though the influence of the change in the concentration of KOH did not practically affect the FFA yield when the reaction time was increased by an hour. The maximum FFA yield of 84 and 52% of the animal fats and fish oil was achieved from the alkaline hydrolysis with 3 M KOH when the reaction time was 3.5 h.

While comparing the FFA yield during the enzyme hydrolysis with the results presented by Avisha et al. article of 2012 [4], and the results of the study when the oils used in food production were hydrolysed in identical conditions and 92% FFA yield was obtained, it is noted that during the study the animal fats FFA yield is up to 40%, and fish oil - up to 60% lower. Based on these results, it can be stated that enzymatic hydrolysis is not suitable for animal fats and fish oil FFA isolation.

Comparing the FFA yield of the alkali hydrolysis to the results obtained by Salimon et al. 2011 [24] study, when the FFA was separated from the barn jatropha (Jatropha curcas) seeds, and the oil was hydrolyzed with ethanolic KOH, it was observed that animal fats and fish oil FFA yield was 10–40% lower, which indicates that using the alkaline hydrolysis the vegetable oil hydrolysis easier than animal fats or fish oil.

While carrying out the hydrolyses during the experiment, fat molecules failed to split into FFA and glycerol, but after the reaction oils can be easily extracted with hexane and re-hydrolyzed. During the hydrolysis reaction, in order to obtain FFA, glycerol is formed as waste, but it can be used for the synthesis of mono- and diglycerides, which can be used in production of bio-lubricants [33]. Glycerol has a wide applicability in cosmetics, pharmaceutical, and food industries [12, 30, 32, 34]. A high caloric hydrogen gas, which can be produced from glycerol by pyrolysis, can be used for combined heat and power generation or as a fuel for transport [10].

During the ester production reactions, while using FFA, isolated from animal fats and fish oil, as well as octanol and decanol, the acid value of samples, taken at different experimental period, was determined by titration and the conversion ratio was calculated, which indicates the percentage of FFA merged with alcohol. The FFA ratio change in time is shown in Fig. 3.

The data in Fig. 3 shows that fish oil and animal fat FFA reaction with decanol is the fastest in the first 30 min and reached 52–53% of FFA conversion into esters. The continuation of the reaction results in the reaction rate fall by about two times. After 2 h from the beginning of the reaction between fish oil and decanol, the conversion of the FFA into ester was 80% and then there was no decrease of acidity, which means that the reaction stopped.

The reaction of animal fats FFA with decanol lasted for 2.5 h and 82% conversion was achieved.

During the fish oil and animal fats FFA esterification with octanol reactions, no significant reaction rate fluctuation was observed; the reaction rates remained constant. Fish oil and animal fats FFA reaction with octanol lasted for 2.5 h and 82% and 83% conversion of FFA into esters was achieved. During the study conducted by Bilal S., Mohammed-Daba I.A., Nuhu M. et al., when methanol was used in the esterification reaction, and KOH was used as a catalyst, 65% degree of conversion was achieved after a 3-h reaction [5]. According to the obtained results, it can be stated that the use of Amberlyst 15H for the catalysis of the esterification reaction is more advantageous, because 18% higher degree of conversion can be achieved. However, when using KOH catalyst, after the esterification reaction which lasted for 6 h, 97% conversion of FFA into the ester was achieved [5]. Given the fact that FFA is an additive for increasing the lubricity of bio-lubricants, it can be stated that the use of Amberlyst 15H in FFA esterification reaction as a catalyst, is appropriate as a higher degree of conversion is achieved in a shorter period of time, which reduces energy costs and shortens the production time, in addition, Amberlyst 15H is easily separated after the reaction and can be used repeatedly.

3.1.1 Viscosity testing results

Viscosity is the most important feature when choosing a lubricant for hydrodynamic lubrication. High-viscosity oils, due to their intermolecular forces, require more energy for movement of lubricated parts of machinery; and if the oil viscosity is too low it is unable to reduce the friction between the surfaces, therefore, equipment or its parts can be damaged [31]. Bio-lubricants according to their kinematic viscosity at 40 °C are divided into viscosity grades as presented in Table 2.

The kinematic viscosity of synthetic esters produced during the study, animal fats and fish oil, and ISO 15380:2011 viscosity class ranges are shown in Fig. 4.

From the data in Fig. 4, we can see that the viscosity of the animal fats is 45.45 mm2 s−1; and fish oil – 32.36 mm2 s−1, so they can be attributed to 46 and 32 viscosity grades respectively. The viscosity of the synthetic esters produced during the study is half lower than animal fats and one-third lower than fish oil viscosity. However, animal fats octyl ester and fish oil octyl ester of can be attributed to an ISO 15380 22 2011 viscosity grade. The viscosity of animal fats and fish oil decyl esters, produced during the study, does not fit into the viscosity classification range. The animal fats decyl ester oil viscosity is 7%, and fish oil 11% lower than the minimum threshold of 22nd viscosity grade. It is important to note that the difference is not significant, and the viscosity of these esters can be modified by additives in order to meet the standard bio-lubricant viscosity requirements.

During the ester production experiment, it was observed that after the decanol esterification reaction, the amount of the unreacted alcohol was two times lower than the used alcohol excess, which could have reduced the viscosity of the decyl esters. As the alcohol unreacted during distillation could not be isolated, it is considered that an azeotropic mixture was formed, which could be separated by adding an additional solvent, which would decrease the interaction of the components of the mixture [20].

The bio-lubricant viscosity at 100 °C is a very important characteristic, since the oil is used not only to reduce the friction between the lubricated parts of a mechanism, but also to cool the surfaces heated by friction and throttling [31], as the viscosity of the heated bio-lubricants decreases. The ISO 15380 2011 bio-lubricant quality standard regulates the minimum viscosity values at 100 °C, these values are given in Table 2.

The kinematic viscosity at 100 °C for the synthetic esters, produced during the study, animal fats and fish oil; and the ISO 15380: 2011 viscosity ranges are presented in Fig. 5.

Figure 5 illustrates that viscosity at 100 °C of four samples: AFOE, FOOE, AF, FO satisfies the standard requirements; and viscosity of AFDE and FODE samples is below the lower limit by 7 and 13% respectively. It is important to note that the differences are not large, which means that the viscosity can be increased by additives resistant to temperature fluctuations. By the way, these were the samples with the lowest viscosity at 40 °C and could not be attributed to the ISO 15380 2011 standard classification. It can be noted that in AFOE and FOOE samples, which can be attributed to 22 viscosity grade, viscosity exceeds the threshold set for the grade by 17 and 26%, and FOOE viscosity by 1% exceeds the threshold of grade 32, which is a much higher viscosity grade. The viscosity of filtered animal fats and fish oil, which can be respectively attributed to 46 and 32 grades, at 100 °C, meets the requirements of the standard and is higher: 55 and 53% respectively. These results demonstrate that AFOE, FOOE, AF, and FO can be assigned to the environmentally friendly lubricant viscosity grades of ISO 15380 2011.

The ISO 15380 2011 bio-lubricant standard does not include the viscosity index parameter, but this characteristic is very important because a high viscosity index indicates a low viscosity variation depending of temperature, therefore, bio-lubricants are more stable and ensure proper lubrication, even with rising temperature [25]. According to Brazilian National Petroleum Agency (ANP), the viscosity index of synthetic basic oils (synthetic esters) must be higher than 120 [22].

As it can be seen from results presented in Fig. 6, decanol esters have the lowest viscosity indices, but as mentioned above, in order to use them the viscosity has to be improved by additives. The data indicates that fish oil has the highest viscosity index, i.e., 217, and animal fats viscosity index is 9% lower. It can be stated that unsaturated fatty acids in fish oil are more resistant to the rise of temperature than the saturated fatty acids in animal fats. The viscosity of octyl ester, which was produced during the study, exceeds the ANP viscosity threshold by 27–63%. The FOOE viscosity index is 33% higher than AFOE. According to Salimon et al. 2012 [25], hydrocarbons with more carbon atoms in the chain have a higher viscosity index; therefore, it could be presumed that FFA of fish oil have longer chains than animal fats. The viscosity indices of the AFOE and FOOE produced during this study are respectively 42 and 14% lower than the viscosity index of sunflower oil octyl ester which is 226 [17].

It was found that the sunflower oil contains about 70% mono- and polyunsaturated fatty acids [16], so it can be stated that the fish oil used in the study has about 60% of unsaturated fatty acids.

Density study results

The density value must be specified in bio-lubricant documentation; however, there are no bio-lubricant density value restrictions. Knowing the density and volume of bio-lubricant, it is possible to calculate the mass, which is important for bio-lubricant transportation and supply in the system [7]. Considering this, lower density is desired. Mineral oil density at 15 °C ranges from 832 to 1125 kg m−3 [28].

The results presented in Table 3 reveal that the density of the produced esters is 20–50% lower than of animal fats, which make them more attractive due to lower transportation costs. It can be noted that the animal fats esters are characterized by 5–10% less density compared to fish oil esters. It is also evident that density of esters produced from longer chain alcohol is lower, which is confirmed by the results presented in literature: density of castor oil methyl ester is 930 kg m−3 [6] and density of castor oil octyl ester is 910 kg m−3 [22]. Based on these results, it can be stated that in order to produce lower density bio-lubricants long-chain alcohols should be used for FFA esterification.

Results of pour point study

The temperature limit for bio-lubricant pour point is not defined, though it indicates the lowest temperature of the working environment of bio-lubricants. The pour point must be as low as possible in order to ensure the possibility of supplying bio-lubricants even for starting equipment operation at low temperature [26].

The identified pour points indicate that fish oil and esters made from them set at temperatures lower than 0 °C, and animal fats and their esters lost fluidity at positive temperature range. This proves that animal fats contain more saturated fatty acids than fish oil. Although animal fats do not have good low temperature properties, its application possibilities remain and they can be used in warmer climates, the internal equipment lubrication and are suitable for plastic lubricant production, because their thickening required less thickener [11, 19].

The pour point of FOOE is 50% lower than of FODE, due to the alcohol chain length. It is noted that alcohol having more carbon atoms in its chain increases the pour point temperature. The pour point temperature significantly depends not only on the length of the alcohol chain, but also on its branching—the wider is the spatial structure of hydrocarbon groups, the lower pour point can be expected [3, 22].

With the consideration of these results and the fact that the pour point, as specified by ISO 15380: 2011 standard, is set by a user, a manufacturer may choose the components for bio-lubricant production to meet customer satisfaction.

Results of oxidation stability study

Oxidation stability is an important indicator describing the quality of bio-lubricants. The oxidation stability of bio-lubricants depends on how much unsaturated fatty acid esters it contains. Double hydrocarbon connections exposed to oxygen in air rapidly oxidizes, forms resin, and increases the bio-lubricant viscosity [15].

The study results indicate that the produced esters have better oxidation stability than pure fats. Fish oil oxidation started faster, and animal fats oxidation stability was by 35% higher. Although animal fat oxidation stability was greater than that of fish oil, this trend decreases while producing esters. It appears that AFOE oxidation stability is 10% lower than FOOE, and AFDE stability is 30% less FODE. It is apparent that decanol esters have 15–40% greater oxidation stability than octanol esters, and for this reason, a longer chain alcohol improves the oxidation stability of bio-lubricants.

In Erhan et al. 2006 [9] study, soybean oil, sunflower oil, and commercial bio-lubricant oxidative stability was researched. Comparing the results of this study with results of other researchers, the FODE known for the highest oxidative stability has 9% higher stability than the studied bio-lubricants in the market. The comparison of animal fats and fish oil with soybean oil, animal fats, and fish oils showed respectively 91 and 76% better oxidation stability. This is based on the fact that vegetable oils are high in polyunsaturated acids, which reduce the oxidation stability of bio-lubricants.

Results of ash content study

According to ISO 15380 2011 standard, the ash content in bio-lubricants is analyzed and its value is set by the user.

In this study, the ash content value of the animal fats and fish oil, and the produced esters varies from 0.02 to 0.12 mass % range. The greatest ash content was in fish oil, and animal fats ash content was 52% lower. The ash content of fish oil esters is 50–60% less than in the primary fat. The ash content of animal fats esters is 40–60% less than of animal fats. It is also noted that ash content of decanol esters is higher than of octanol esters. This shows that in order to produce a lower ash content bio-lubricants, it is appropriate to use shorter-chain alcohol for the esterification reaction.

Though the ash content of the tested bio-lubricant components is not high, the amount of ash is strongly influenced by additives modifying rheological, tribological and other properties [8].

3.1.2 Summary of the results

The study revealed that the maximum FFA yield is obtained using alkaline hydrolysis, when the concentration of the catalyst KOH is 3 M, and the reaction time is 3.5 h. However, for the FFA, extraction is recommended to use 2 M KOH, as during the same reaction time only 1% lower yield is achieved. The optimum duration of the esterification reaction is 2.5 h, and during this reaction time, 80–82% FFA conversion to ester is achieved.

The analysis of the viscosity of the produced bio-lubricants and the filtered fat shows that animal fats octyl ester and fish oil octyl ester can be attributed to 22, fish oil to 32, and animal fats to 46 15380 ISO 2011 viscosity grades. Meanwhile, the highest viscosity index was of fish oil and fish oil octyl ester. The density of the investigated bio-lubricants density ranges from 843 to 918 kg m−3.

It was found that fish oil and their esters had the lowest pour point, and the pour point temperature of animal fats, which even in the room temperature are in a solid form, can be reduced by producing them from lower molecular weight esters.

It was determined that fish oil and its decyl ester have the best oxidation stability and, in order to increase the oxidation stability of bio-lubricants, it is appropriate to use esters in their composition. Fish oil has the largest ash content, and the ash content of their esters is higher than of animal fats esters; in order to reduce the ash content in bio-lubricants, it is appropriate to choose animal fats for their production.

It is recommended to further study the produced bio-lubricants and improve their quality with additives.

4 Conclusions

-

1.

The comparative analysis shows that the fat containing large amounts of unsaturated acids decreases the pour point of the produced bio-lubricants; saturated acids improve oxidation stability and lubricity properties of bio-lubricants. For these reasons, animal fats, containing a lot of saturated fatty acids, and fish oil containing more unsaturated acids were chosen for bio-lubricant production.

-

2.

During the study by enzymatic and alkaline hydrolysis, free fatty acids were separated from fats and were esterified with octanol and decanol using a heterogeneous catalyst having acidic properties. Four different synthetic esters were obtained: animal fats octyl ester, fish oil octyl ester, animal fats decyl ester, and fish oil decyl ester.

-

3.

The comparative analysis of the quality indicators of the produced esters and pure fat showed the following:

-

Animal fats and fish oil octyl esters can be attributed to 22, fish oil to 32, animal fats to 46 viscosity grades of ISO 15380 2011;

-

The highest viscosity index is of fish oil, animal fats and fish oil octyl esters 217, 197, and 195, respectively;

-

Bio-lubricant density ranges from 843 to 918 kg m−3;

-

Fish oil and fish oil esters of pour point range − 12–− 3 °C, have better low temperature properties;

-

Oxidation stability of the produced esters is 60–80% higher compared to fish oil;

-

Ash content of fish oil esters is 30–50% higher than of animal fats esters.

-

-

4.

For extraction of free fatty acids, we recommend to use 3.5-h duration alkaline hydrolysis, with aqueous 2 M KOH catalyst solution. The optimum duration of the esterification reaction is 2.5 h. During this reaction time, 80–82% conversion of free fatty acids into ester is achieved. It is recommended to further explore and develop the produced bio-lubricants. These lubricants can be used in maintenance of fishery, forestry, and agriculture equipment, as these are economy sectors most sensitive to indecomposable biological pollutants that can travel through the food chain.

References

Akerman CO, Hagstrom AEV, Mollaahmad MA, Stefan Karlsson S, Hatti-Kaul R (2011) Biolubricant synthesis using immobilised lipase: process optimisation of trimethylolpropane oleate production. Process Biochem 46:2231–2225

Akerman CO, Gaber Y, Ghani NA, Lämsä M, Hatti-Kaul R (2011) Clean synthesis of biolubricants for low temperature applications using heterogeneous catalysts. J Mol Catal B Enzym 72:269–263

Arbain NH, Salimon J (2011) Synthesis and characterization of ester trimethylolpropane based Jatropha Curcas oil as biolubricant base stocks. J Sci Technol 2(2):58–47

Avisha C, Debarati M, Dipa B (2012) Biolubricant synthesis from waste cooking oil via enzymatic hydrolysis followed by chemical esterification. J Chem Technol Biotechnol 144–139(2012):88

Bilal S, Mohammed-Daba IA, Nuhu M, Kasim SA, Almustapha IH, Yamusa YA (2013) Production of biolubricant from Jatropha curcas seed oil. J Chem Eng Ant Mater Sci 4(6):79–72

Borugadda VB, Goud VV (2014) Epoxidation of castor oil fatty acid methyl esters (COFAME) as a lubricant base stock using heterogeneous ion-exchange resin (IR-120) as a catalyst. Energy Procedia 54:84–75

Duangkaewmanee S, Petsom A (2011) Synergistic and antagonistic effects on oxidation stability of antioxidants in a synthetic ester based oil. Tribol Int 44:266–271

Erhan SZ, Asadauskas S (2000) Lubricant basestocks from vegetable oils. Ind Crop Prod 11(2–3):282–277

Erhan SZ, Sharma BK, Perez JM (2006) Oxidation and low temperature stability of vegetable oil-based lubricants. Ind Crop Prod 24(3):299–292

Fantozzi F, Frassoldati A, Bartocci P, Cinti G, Quagliarini F, Bidini G et al (2016) An experimental and kinetic modeling study of glycerol pyrolysis. Appl Energy 76–68(2016):184

García-Zapateiro LA, Valencia C, Franco JM (2014) Formulation of lubricating greases from renewable basestocks and thickener agents: a rheological approach. Ind Crop Prod 54:121–115

Garlapati VK, Shankar U, Budhiraja A (2016) Bioconversion technologies of crude glycerol to value added industrial products. Biotechnol Rep 9:14–19

Jinho O, Sungeun Y, Chanyeon K, Inchang C, Jae HK, Hyunjoo L (2013) Synthesis of biolubricants using sulfated zirconia catalysts. Appl Catal A Gen 455:171–164

Lage FAP, Bassi JJ, Corradini MCC, Todero LM, Luiz JHH, Mendes AA (2016) Preparation of a biocatalyst via physical adsorption of lipase from Thermomyces lanuginosus on hydrophobic support to catalyze biolubricant synthesis by esterification reaction in a solvent-free system. Enzym Microb Technol 84:67–56

Liu Z, Sharma BK, Erhan SZ, Biswas A, Wang R, Schuman TP (2015) Oxidation and low temperature stability of polymerized soybean oil-based lubricants. Thermochim Acta 601:16–19

Marmesat S, Morales A, Velasco J, Dobarganes MC (2012) Influence of fatty acid composition on chemical changes in blends of sunflower oils during thermoxidation and frying. Food Chem 135(4):2339–2333

McNutt J, He Q (2016) Development of biolubricants from vegetable oils via chemical modification. J Ind Eng Chem 36:1–12

Mobarak HM, Mohamad EN, Masjuki HH, Kalam MA, AlMahmud KAH, Habibullah M et al (2014) The prospects of biolubricants as alternatives in automotive applications. Renew Sust Energ Rev 33:43–34

Panchal T, Chauhan D, Thomas M, Patel J (2014) Bio based grease A value added product from renewable resources. Ind Crop Prod 63:52–48

Pereiro AB, JMM A, JMSS E, Marrucho IM, Rebelo LPN (2012) Ionic liquids in separations of azeotropic systems. J Chem Thermodyn 46:28–22

Quinchia LA, Delgado MA, Valencia C, Franco JM, Gallegos C (2010) Viscosity modification of different vegetable oils with EVA copolymer for lubricant applications. Ind Crop Prod 32:612–607

Saboya RMA, Cecilia JA, García-Sancho C, Sales AV, Tavares de Luna FM, Rodríguez-Castellón E et al (2017) Assessment of commercial resins in the biolubricants production from free fatty acids of castor oil. Catal Today 279:285–274

Salih N, Salimon J, Yousif E, Abdullah BM (2013) Biolubricant basestocks from chemically modified plant oils: ricinoleic acid based-tetraesters. Chem Cent J 7(128):13–11

Salimon J, Abdullah BM, Salih N (2011) Hydrolysis optimization and characterization study of preparing fatty acids from Jatropha curcas seed oil. Chem Cent J 5(67):9–1

Salimon J, Salih N, Yousif E (2012) Biolubricant basestocks from chemically modified ricinoleic acid. J King Saud Univ – Sci 24(1):17–11

Salimon J, Salih N, Yousif E (2012) Improvement of pour point and oxidative stability of synthetic ester basestocks for biolubricant applications. Arab J Chem 5(2):200–193

Shahabuddin M, Masjuki HH, Kalam MA, Bhuiya MMK, Mehat H (2013) Comparative tribological investigation of bio-lubricant formulated from a non-edibleoilsource (Jatropha oil). Ind Crop Prod 47:330–323

SHELL Australia lubricants product data guide 2013. Industry. http://epoxyoil.com/downloads/shell-product-data-guide-industry-2013.pdf. Accessed 2016.12.23

Syaima MTS, Onga KH, Noora IM, Zamratula MIM, Brahima SA, Hafizul MM (2015) The synthesis of bio-lubricant based oil by hydrolysis and non-catalytic of palm oil mill effluent (POME) using lipase. Renew Sust Energ Rev 44:675–669

Talebian-Kiakalaieh A, Amin NAS, Hezaveh H (2014) Glycerol for renewable acrolein production by catalytic dehydration. Renew Sust Energ Rev 40:59–28

Ting CC, Chen CC (2014) Viscosity and working efficiency analysis of soybean oil based bio-lubricants. Measurement 44(8):1341–1337

Waghmare GV, Vetal MD, Rathod VR (2015) Ultrasound assisted enzyme catalyzed synthesis of glycerol carbonate from glycerol and dimethyl carbonate. Ultrason Sonochem 22:316–311

Zaccheria F, Mariani M, Psaro R (2016) Environmentally friendly lubricants through a zero waste process. Appl Catal B Environ 181:586–581

Zielinska A, Nowak I (2014) Fatty acids in vegetable oils and their importance in cosmetic industry. Chem Aust 68(2):110–103

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Statement of Novelty

The Novelty consists in usage of non-food animal fats and fish oil for production of bio-lubricants.

Rights and permissions

About this article

Cite this article

Matiliunaite, M., Paulauskiene, T. From concept to practice: manufacturing of bio-lubricants from renewable resources. Biomass Conv. Bioref. 9, 353–361 (2019). https://doi.org/10.1007/s13399-018-0356-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-018-0356-0