Abstract

Large amount of cassava pulp is produced as by-product of industrial tapioca production. The value-added process of this low-cost waste is to use it as a substrate for bioethanol production. However, during the pulp pretreatment by acidification combined with steam explosion, many yeast inhibitors including acetic acid, formic acid, levulinic acid, furfural and 5-hydroxymethylfurfural are generated and these compounds have negative effects on the subsequent fermentation step. Therefore, the objective of this study was to investigate whether the repeated cultures of Saccharomyces cerevisiae SC90 could alleviate this problem. To obtain the inhibitor tolerable cells, the repeated culture was performed by growing yeast cells to a specific growth rate (µ) of 0.22 h−1 or higher (80% of the µ in control) and then transferring them to progressively higher concentrations of hydrolysate ranging from 20 to 100% (v/v). The results showed a tendency of longer lag phase as well as time to reach maximum cell number (tmaxc) with an increase in hydrolysate concentration. However, the repeated culture at the same hydrolysate concentration could shorten both lag period and tmaxc. Interestingly, the growth and fermentation efficiency of adapted cells in 100% hydrolysate were significantly higher (p ≤ 0.05) than those of non-adapted cells by 38% and 27%, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bioethanol production from lignocellulosic materials, as an alternative energy source to fossil fuels, has been used for decades in many countries (El-Naggar et al. 2014). In Thailand, the government recently launched a 10-year plan, with private and public sector investment expected to reach $11.3 billion, to produce biochemicals, biopharmaceuticals and biofuels from sugarcane and cassava (Lane 2017). Lignocellulosic materials are waste products from many agro-processing industries and can be an inexpensive and abundant source of biomass (Balat 2011). Lignocellulose mainly comprises cellulose, hemicellulose and lignin and occurs in all plant materials where they are constituents of the structure of cell walls. Cellulose and hemicellulose are polysaccharide chains composed mainly of glucose, galactose, mannose, xylose and arabinose. The processes of releasing the sugars from structural carbohydrates during extraction are complex and not always complete (Kumar et al. 2009; Sun and Cheng 2002).

Cassava (Manihot esculenta Crantz) is an important crop in Thailand used mainly for the production of flour. Cassava flour production was reported to have had a pulp by-product of some 7.3 million tonnes in 2015 (Trakulvichean et al. 2017). In the past, this pulp by-product was largely discarded, but it is high in starch and fermentable sugars from lignocellulosic materials that can be used as a substrate in ethanol production (Balat 2011). Various treatments of cassava pulp have been tested to assist the process of breaking down these structural carbohydrates, before fermentation, including dilute acid hydrolysis combined with heating (Agu et al. 1997). During this process of exposure to acids at high temperatures, sugars derived from the lignocellulosic material are a major product, but there are other compounds from decomposition that are released including formic acid, acetic acid, levulinic acid, furfural and 5-hydroxymethylfurfural (5-HMF). These compounds may inhibit the metabolism of yeast cells used in fermentation of the hydrolysate and impact on growth, biomass production and their fermentation performance (Almeida et al. 2007).

Several methods have been successful in increasing fermentation efficiency from lignocellulosic hydrolysate by microorganisms (Fein et al. 1984; Landaeta et al. 2013; Larsson et al. 2001). In particular, Saccharomyces cerevisiae has been developed to achieve higher ethanol production since it is fast growing in both aerobic and anaerobic conditions and has a high tolerance to both high ethanol concentrations and inhibitors generated during hydrolysate extraction (Olsson and Hahn-Hägerdal 1993). S. cerevisiae SC90 has been previously selected for its high fermentation performance in the production of ethanol from sugarcane molasses and is being used for ethanol production on an industrial scale by several alcoholic beverage companies in Thailand (Pornpukdeewattana et al. 2014). However, it has not been used in industrial-scale production of ethanol from lignocellulosic materials.

Naturally, the yeast strains can be adapted to resist the inhibitors and have been successful in improving ethanol yield (Silva and Roberto 2001; Silva et al. 2011). Pornpukdeewattana et al. (2014) adapted cells of SC90 by culturing them for two cycles at various cassava pulp hydrolysate concentrations. Therefore, the objective of the research was to test whether the adaptation of SC90 to inhibitors could be improved further by increasing the number of culture cycles in the cassava pulp hydrolysate. The adaptation process involved passing SC90 through cycles of cassava pulp hydrolysate and testing its fermentation performance, growth rate and the conversion of inhibitors, starting at 20% concentration followed by progressive transfer to concentrations up to 100%.

Materials and methods

Raw material

Fresh cassava pulp was provided by Khow Chang Eah Tapioca and Sago Industry Co. Ltd., Chonburi, Thailand. The pulp was dried at 60 °C using a tray dryer until the weight was constant, milled and sieved through 40 mesh. It was then kept dry in a closed container at room temperature until required for use.

Yeast strain and growth medium

The yeast S. cerevisiae SC90 was obtained from the Faculty of Agro-industry, King Mongkut’s Institute of Technology Ladkrabang, Bangkok, Thailand. The culture was grown in yeast extract–peptone–dextrose (YPD) (10.0 g/L yeast extract, 20.0 g/L peptone, 20.0 g/L glucose, pH 5.5) agar slant and incubated at 30 °C for 48 h. The strain was then maintained at 4 °C.

Inoculum preparation

The inoculum preparation method was modified from Pornpukdeewattana et al. (2014). One loop of yeast cells from an agar slant was added to a 125 mL Erlenmeyer flask containing 25 mL of YPD medium and incubated at 30 °C with a shaking speed of 200 rpm for 24 h. Then the starter was transferred to a 500 mL flask containing 225 mL of YPD. The culture was incubated as described above for 48 h. Cells were recovered by centrifugation at 2683 × g at 4 °C for 20 min and then the supernatant was separated. The supernatant was added to the wet cell at a ratio of 1:1 (mL supernatant to g wet weight) and was used as the inoculum.

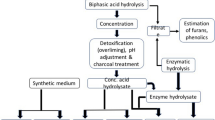

Cassava pulp hydrolysis

Preparation of cassava pulp hydrolysate was modified from the method described by Srinorakutara et al. (2006) which was shown to yield a high content of reducing sugars. Dried cassava pulp was hydrolyzed using diluted sulfuric acid (0.6 M) with the solid to liquid ratio of 1:10 (g dry weight to mL diluted acid), followed by heating in an autoclave at 120 °C for 30 min. The reaction mixture was cooled at room temperature. The residual solid was filtered using a white cloth before the pH of the filtrate was adjusted to 5.5 with 10 M NaOH. The pH adjusted hydrolysate was centrifuged at 9056×g at 4 °C for 20 min to remove the precipitate that had occurred during neutralization. The concentration of inhibitors (acetic acid, formic acid, levulinic acid, furfural and 5-HMF) and the total sugar presented in hydrolysate was then determined. Flux distribution of material during cassava pulp hydrolysis was evaluated by relying on the data obtained from the modified protocol for the determination of structural carbohydrates and lignin in biomass developed by the National Renewable Energy Laboratory (NREL) (Sluiter et al. 2012) (Supplementary I). The ready-to-use cassava pulp hydrolysate was stored at −20 °C until required for use.

Preparation of the adaptation media

The medium formulations for adaptation were designed to have a similar initial concentration of fermentable sugars and varied with the concentration of cassava pulp hydrolysate. However, the total sugar in cassava pulp hydrolysate was 62.95 g/L (Supplementary II, Table SII-1) consisting both fermentable and non-fermentable sugars. Glucose, fructose, sucrose and maltose are generally recognized as fermentable sugars for yeast Saccharomyces cerevisiae; therefore, the summation of these sugar concentrations can be presumable as the concentration of fermentable sugars (Luján-Rhenals and Morawicki 2016). The sugar composition in hydrolysate was analyzed using high-performance liquid chromatography (HPLC) which was modified from the protocol for the determination of structural carbohydrates and lignin in biomass developed by NREL (Sluiter et al. 2012) (Supplementary III). Glucose was only one of the fermentable sugars whereas xylose and arabinose were non-fermentable sugars in hydrolysate that can be detected by HPLC (Supplementary III, Table SIII-1). The concentrations of glucose, xylose, and arabinose were 45.47 ± 0.23, 2.52 ± 0.03, and 1.74 ± 0.06 g/L, respectively.

The assimilation of sugars was also analyzed by monitoring the reduction of total sugar during SC90 fermentation in cassava pulp hydrolysate medium to confirm the value of fermentable sugar concentration obtained by HPLC technique. The concentration of fermentable sugars estimated by monitoring the reduction of total sugar during fermentation of SC90 was 46.52 ± 0.56 g/L (Supplementary III, Table SIII-2) which was slightly higher than the value obtained from HPLC (Supplementary III, Table SIII-1). However, in this present work, the value obtained from total sugar was used because the concentration of sugar analysis by HPLC did not cover other sugars.

The adaptation media were prepared by diluting the cassava pulp hydrolysate to the concentrations of 0 (control), 20, 40, 60, 80 and 100% (v/v) of the initial concentration of the hydrolysate. The initial concentration of fermentable sugars in all media was adjusted to approximately 46.52 g/L using glucose. All media in 1 L were supplemented with 5.00 g/L yeast extract, 7.50 g/L (NH4)2SO4, 3.50 g/L KH2PO4, 0.75 g/L MgSO4⋅7H2O and 1.00 g/L CaCl2⋅2H2O, adjusted to pH 5.5 and autoclaved at 121 °C for 15 min (Kouteu Nanssou et al. 2016).

Adaptation of the yeast strain to improve the inhibitor tolerance

The adaptation procedure of S. cerevisiae SC90 was modified in accordance with Pornpukdeewattana et al. (2014) where the experiments were conducted in 1000 mL flasks containing 300 mL of adaptation media. The control medium was inoculated to obtain the initial cell concentration of 3 × 107 cell/mL and incubated at 120 rpm and 30 °C for 48 h. The samples were withdrawn at 0, 1, 2, 3, 4, 8, 12, 24, 36 and 48 h for measuring yeast growth. The specific growth rate (µ) and the time to achieve maximum cells (tmaxc) obtained from the control were used as the reference value for growth assessment.

The yeast cells from the control medium were collected and used for inoculation into a new adaptation medium with the lowest concentration of cassava pulp hydrolysate (20% v/v). Fermentation and growth were monitored as described above. Cells were continually cultivated in the same medium until the µ was equal to or higher than 80% of the reference value and tmaxc was not longer than tmaxc of the control experiment. Cells were then transferred to the new adaptation medium with higher concentrations of cassava pulp hydrolysate (40, 60, 80 and 100%). The initial cell concentration of every adaptation cycle was adjusted to 3 × 107 cell/mL. The samples were withdrawn at 0, 4, 8, 12, 24 and 48 h to determine cell growth, glucose consumption, ethanol production and content of inhibitors for each of the first and last cycles in each adaptation medium. The adaptations were performed in triplicate and consecutively for 960 h. At the end of the adaptation, the adapted cells were preserved by sub-culturing in 100% hydrolysate medium to maintain their ability of inhibitor tolerance. Then the adapted cells were investigated for growth and fermentation performance compared with the non-adapted cells.

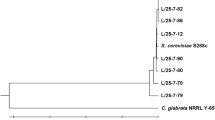

Examination for the pattern of adaptation

The spot plate technique was used to confirm that the adaptation procedure used to obtain yeast cells was a short-term adaptation. The adapted cells were sub-cultured in 0% hydrolysate agar medium every 48 h for ten times and preserved in this medium. Then the adapted cells, sub-cultured and preserved in 0% and 100% hydrolysate medium, were cultured in 0% and 100% hydrolysate liquid medium, respectively, at 30 °C with a shaking speed of 200 rpm for 24 h. The cell concentration was adjusted to 3 × 107 cell/mL and serially diluted to generate cell suspensions at concentrations 10−4, 10−5 and 10−6. A volume of 10 µL from each dilution was spotted onto the surface of the 0, 50 and 100% hydrolysate agar plates. The plates were incubated at 30 °C for 72 h and the results were recorded by a photograph.

Comparison of growth and fermentation performance of adapted and non-adapted cells in 100% hydrolysate medium

A non-adapted and an adapted S. cerevisiae SC90 were grown in 0% hydrolysate medium (control medium) and 100% hydrolysate medium, respectively. Both were incubated using the procedure as described above to prepare the non-adapted and adapted yeast inoculums. The experiments were conducted in 1000 mL flasks containing 300 mL of the 100% hydrolysate medium. Both strains were then separately inoculated into 100% hydrolysate medium to obtain the initial cell number of 3 × 107 cell/mL. The fermentation was at 30 °C with shaking of 120 rpm for 72 h. Cell growth was monitored at 0, 4, 8, 12, 18, 24, 36, 48, 60 and 72 h. The glucose and ethanol concentrations were determined during fermentation. The results of adapted and non-adapted cells were compared. The spot plate technique was also applied for assessing the ability of adapted and non-adapted cells to grow in the 100% hydrolysate agar medium.

Analytical methods and data analysis

Investigation of growth and viability

The growth and viability of the yeast cells were monitored by staining with methylene violet and observing them under a light microscopy where the dead cells were dyed violet and viable cells were not dyed (Smart et al. 1999). The number of dead and live cells was counted using a hemacytometer. The µ and lag time (tlag) were estimated using the graphical methods from a linear regression of the natural logarithm of a number of viable cells versus time (exponential growth curve) (El-Mansi and Bruce Ward 2006).

Ethanol fermentation performance

The fermentation performance of the experiments was assessed as kinetic parameters as previously described (Keating et al. 2006). Ethanol yield (YP/S; g ethanol/g glucose) was calculated from the maximum concentration of ethanol produced divided by sugar consumed. Volumetric productivity (Q; g/L h) was calculated from the maximum concentration of ethanol produced divided by attenuation time. Attenuation time was the time that achieved the highest concentration of ethanol. Fermentation efficiency (%) was calculated from the observed ethanol yield divided by the theoretical yield of ethanol fermentation from glucose (0.51 g ethanol/g glucose) multiplied by 100.

Total sugar

The total sugar concentration was determined by the phenol–sulfuric acid colorimetric method using glucose as a standard (Dubois et al. 1956). This is a rapid method for quantifying the total soluble sugars presented in hydrolysate samples that can break down sugars into monosaccharides with concentrated sulfuric acid. The reaction mixture was measured in a spectrophotometer (UV-1601 Shimadzu, Japan) at 480 nm.

Ethanol and inhibitors in acid form

The content of ethanol produced during fermentation and concentration of inhibitors (acetic acid, formic acid and levulinic acid) were quantified using high-performance liquid chromatography (HPLC) (Nexera Shimadzu, Japan). The supernatant was filtered through a 0.2-µm syringe filter before analysis and detected using a refractive index (RI) detector. A Supelcogel H 59346 column (250 × 4.6 mm, Sigma-Aldrich, France) was used with the column temperature of 30 °C. Phosphoric acid, 0.1% (w/v) in water at a flow rate of 0.17 mL/min, was used as the mobile phase.

Furfural and 5-HMF

Analysis of furfural and 5-hydroxymethylfurfural (5-HMF) was according to Martín et al. (2017) using a diode-array detector in the HPLC system. The ZORBAX RRHT SB-C18 column (3 × 50 mm, 1.8 µm) was operated with a flow rate of 0.5 mL/min. A formic acid solution (0.1% v/v) and acetonitrile solution (0.1% v/v) were used as eluents. The absorption was measured at 282 nm at a column oven temperature of 40 °C.

Statistical analysis

The experiments were performed in triplicate and expressed as mean values. The standard deviation (SD) of mean value was expressed as error bars. The mean and SD of a set of values were calculated using Microsoft Excel 2010 with the AVERAGE and STDEV functions. Statistical significance was assessed using an unpaired two-tailed t test at the (p ≤ 0.05) level.

Results and discussion

The contents of total sugar and inhibitors in cassava pulp hydrolysate

Several publications on acid hydrolysis for the pretreatment of biomaterial showed that a stronger hydrolysate condition generated higher concentrations of inhibitors (Supplementary II, Table SII-1). Cao et al. (2010) used corn stover hydrolyzed with 2.0% (v/v) sulfuric acid at 121 °C for 90 min. Huang et al. (2011) pretreated corn stover with dilute sulfuric acid 3.0% (g/g dry corn stover) at 190 °C for 3 min. Tian et al. (2011) used the wood of lodgepole trees (Pinus contorta) pretreated with bisulfite and sulfuric acid placing the wood pulp in a digester at 180 °C for 25 min. Soleymanpour et al. (2018) also noted that an increase in acid concentration resulted in increased formation of inhibitory compounds and rise of the sugar decomposition rate. The source of biomass and the harshness of the pretreatment could affect types and proportions of inhibitors and sugars produced in the hydrolysate.

In our study, cassava pulp hydrolysis yielded relatively high total sugar concentration (62.95 ± 0.76 g/L) in the hydrolysate, while gave out fewer types and lower concentrations of inhibitors (14.68 ± 0.01 mM acetic acid, 0.43 ± 0.00 mM levulinic acid and 0.10 ± 0.00 mM 5-HMF) than previously reported (Supplementary II, Table SII-1). These results might be due to mild hydrolysis (0.6 M sulfuric acid with the solid to liquid ratio of 1:10 and heating at 120 °C for 30 min), a condition that broke down less sugars and generated low inhibitor contents.

The analysis of material distribution during cassava pulp hydrolysis is presented in Supplementary I. Ten grams of cassava pulp (9.54 g of oven dry weight) was hydrolysed with 100 mL of 0.6 M sulphuric acid. The initial hydrolysate was collected and the insoluble residual was washed twice. The solutions from the first and second wash were then collected. The volume and chemical composition of the initial hydrolysate, the first wash and the second wash were analyzed and calculated for mass recovery and sugar yield. The mass recovery of the initial hydrolysate, the first wash, the second wash, insoluble residual and total mass recovery were 52.75, 16.78, 3.78, 18.67 and 91.98%, respectively (Supplementary I, Table SI-1). About 8% of an unaccounted mass was possible to contain other soluble components such as protein, lipid and other acid soluble minerals because the chemical composition analysis in this work was subjected to total sugar, total lignin, total inhibitors and insoluble residue. Therefore, the total soluble solid (TSS) in each fraction was analyzed and calculated for total mass recovery (Supplementary I, Table SI-2). The total mass recovery calculated based on TSS showed the reasonable value of 99.63%. This was a confirmation of the presence of other substances in the initial hydrolysate, the first wash and the second wash that were not total sugar, lignin and inhibitors.

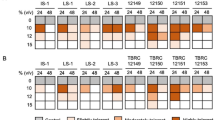

Changes in S. cerevisiae SC90 growth profiles during adaptation to cassava pulp hydrolysis

The number of cycles run in the media with 20, 40, 60, 80, and 100% hydrolysate was two cycles (1st and 2nd cycles), two cycles (3rd and 4th cycles), three cycles (5th–7th cycles), five cycles (8th–12th cycles), and seven cycles (13th–19th cycles), respectively. The maximum total cells and viability of SC90 from sequential adaptation in each medium are shown in Table 1. The maximum total cell number of the control medium was 1.99 × 108 cell/mL. Interestingly, in the media with 20% and 40% hydrolysate, the maximum total cell number was slightly increased to approximately 2.6 × 108 cell/mL and 2.4 × 108 cell/mL, respectively. This result was supported by the finding of Greetham (2014) in which acetic acid concentration as low as 10–25 mM had little or no negative impact on growth. Moreover, the acetic acid at 25 mM enhanced growth compared to the control without inhibitor. The time to achieve maximum cell number (tmaxc) in the first cycle of the media with 20% hydrolysate was 12 h which is equal to the control medium. The increase in tmaxc to 24 h was observed in the first cycle of the media with 40% hydrolysate compared to the control medium. The increase in the hydrolysis concentration above 40% resulted in both lower maximum total cell number and longer tmaxc. The maximum total number of cells in the last adaptation cycle in the 60, 80 and 100% hydrolysate was 11, 13 and 34% higher, respectively, than in the first cycle.

At low hydrolysate concentrations, there were lower levels of inhibitors, where the cells had not been acclimatized. Increasing the hydrolysate concentration led to have higher levels of inhibitors that resulted in a lower number of cells in the first cycle. The repeated cell adaptations in the same media, especially at 80 and 100% hydrolysate showed that cells can be more tolerant to the inhibitors. It can be supported by an increase in total cell numbers, shorter lag time (tlag) and tmaxc (Table 1). The reduction in the tlag that was observed when cells were repeatedly cultivated in the same concentration of inhibitors was also consistent with the findings of Wallace-Salinas and Gorwa-Grauslund (2013) and Koppram et al. (2012).

The specific growth rate (µ) of the control medium and low hydrolysate concentration at 20 and 40% was 0.27–0.30 h−1. The cells that had been moved to the new media contained 60, 80 and 100% hydrolysate showing a decrease in µ of the first cycle to 0.24, 0.21 and 0.20 h−1, respectively (Table 1). The decrease in growth rate when the culture was transferred to the media with the higher concentration of hydrolysate confirms the findings of Wallace-Salinas and Gorwa-Grauslund (2013). Koppram et al. (2012) also explained that the extended tlag prior to the cell recovery could be caused by a modification of the physiology of cells adapted under inhibitor stress. There was a gradual improvement in the growth rate because of increasing number of beneficial mutant cells that outnumbered the non-beneficial mutants. The results of the present study indicate that at higher concentrations of inhibitors, it was necessary to sub-culture in the same medium several times until µ was not less than 80% of that of the control condition (0.28 h−1), which was 0.22 h−1. Yeast cells from the control medium transferred into the media with 20, 40 or 60% hydrolysate provided a µ within the acceptable range of 0.22 h−1. However, when cells were transferred to the 80 or 100% hydrolysate, they showed lower µ than in the previous media running at lower hydrolysate concentrations. The cultures were consequently repeated for five and seven cycles to obtain a µ value > 0.22 h−1. This effect may be due to a higher concentration of inhibitors in the media with a higher concentration of hydrolysate.

Regarding our results, the amounts of acetic acid, levulinic acid and 5-HMF were 14.68 ± 0.01, 0.43 ± 0.00 and 0.10 ± 0.00 mM, respectively (Fig. 2 and Supplementary Table S1). All substances are known to be toxic compounds to microorganisms. The severity of the inhibitor depends on various factors including yeast strain used, the adaptation ability of yeast strain to inhibitors, fermentation process, type of inhibitors as well as combined synergistic effect of several toxic compounds (Mussatto and Roberto 2004). Furan derivatives, furfural and 5-HMF, are toxic compounds generated from pentose and hexose degradation, respectively (Mussatto and Roberto 2004). They could inhibit the functions of several glycolytic enzymes resulting in a reduction in the µ, biomass yield (YX/S), volumetric productivity (Q) as well as ethanol yield (YP/S) but instead increased in tlag (Almeida et al. 2007; Palmqvist and Hahn-Hägerdal 2000).

The major weak acids generated during hydrolysis are acetic acid, formic acid, and levulinic acid. They have been shown to possess inhibitory effects on yeast by reduction in biomass and ethanol yield (Larsson et al. 1999; Palmqvist and Hahn-Hägerdal 2000). Bauar et al. (2003) reported that the weak acids could inhibit cell growth by reducing aromatic amino acid assimilation from the medium. The level of acid toxicity depended upon the fermentation conditions (Mussatto and Roberto 2004).

The time to obtain the maximum cell numbers (tmaxc) was one of the parameters that indicated the adaptability of cells. In the control medium and 20% hydrolysate medium, tmaxc was as low as 12 h, but tmaxc increased when the hydrolysate concentration was increased to 40–100%. However, the repeated cycle in the same hydrolysate concentration resulted in a reduction in tmaxc. This implies that the adaptation of cells during the repeated cycles enhanced tolerance to the toxicity of the inhibitors (Table 1). The adapted cells obtained in this experiment were only a transient or short-term adaptation which has been previously reported as phenotypic plasticity of yeast (Narayanan et al. 2016). In the present work, the results of spot plate experiment in Fig. 1 were used as the evidence to confirm the pattern of adaptation. The adapted cells lost the ability to withstand inhibitors after they were sub-cultured in the 0% cassava hydrolysate medium. However, the adapted cells that were maintained in 100% hydrolysate medium can retain the ability to tolerate the inhibitors (Fig. 1). Thus, the preservation of the adapted strain in 100% hydrolysate medium was important to maintain its ability to tolerate inhibitors. The possible reasons for a higher concentration of inhibitors in the media with a higher concentration of cassava pulp hydrolysate during SC90 adaptation are presented in the next section.

Changes in the inhibitor concentration during S. cerevisiae SC90 adaptation in cassava pulp hydrolysate

The major inhibitors in cassava hydrolysate were acetic acid, levulinic acid and 5-HMF (Supplementary Table S1). The concentration of inhibitors increased with increasing concentration of hydrolysate used (Fig. 2). At the beginning of incubation, the concentrations of acetic acid were 4.08 ± 0.04, 7.75 ± 0.08, 10.13 ± 0.01, 14.16 ± 0.12 and 15.96 ± 0.09 mM and for 5-HMF they were 0.035 ± 0.004, 0.043 ± 0.002, 0.051 ± 0.003, 0.076 ± 0.002 and 0.103 ± 0.003 mM, respectively, for 20, 40, 60, 80 and 100% hydrolysate levels. The concentration of acetic acid was higher than that of formic and levulinic acid, which was consistent with the findings of Tian et al. (2011) and Tomás-Pejó et al. (2010). They also found that acetic acid was a major inhibitor in biomass hydrolysate. Nilvebrant et al. (2003) reported that furfural is normally found in lower concentration than 5-HMF. In this experiment, furfural was undetectable (Supplementary Table S1).

In pretreatment of lignocellulosic material, 5-HMF is generated from hexose sugar degradation and can be converted to formic acid and levulinic acid. Therefore, the lower concentration of levulinic acid and the inability to detect formic acid that was observed was related to the low breakdown level of 5-HMF (Palmqvist and Hahn-Hägerdal 2000; Thomas et al. 2002). Acetic acid is formed from the deacetylation of acetyl group in hemicellulose structures and may be generated from furfural under acid hydrolysis when heated. It has been reported that acetic acid is a minor product produced during yeast fermentation. In the present study, cassava pulp acid hydrolysis performed using 0.6 M sulfuric acid at 120 °C for 30 min resulted in a low concentration of 5-HMF (approximately 0.1 mM), which confirmed results reported by Lacerda et al. (2013). They studied the influence of acid concentrations on sisal pulp pretreated with 5% (v/v) sulfuric acid (approximately 0.5 M) at 100 °C with a reaction time of less than 120 min and detected very low amounts of both furfural (< 0.26 mM) and 5-HMF (< 0.04 mM). They also found that formic acid could be detected when using concentrations of sulfuric acid of between 15 and 25% (v/v) (approximately 1.5–2.5 M). Therefore, the type of inhibitors and their amount depend on both the type of lignocellulosic material and pretreatment methods.

In the present work, the patterns of the inhibitor concentration changes were similar in all hydrolysate concentrations for both the first cycle and last cycle of each hydrolysate concentration (Fig. 2). The acetic acid concentration was continuously decreasing from the beginning to 8 h of incubation and the concentration has again increased after 12 h of incubation. The acetic acid can be assimilated by the formation of acetyl CoA and then entering the Kreb’s cycle. However, it can be generated as by-product during yeast fermentation (Palmqvist and Hahn-Hägerdal 2000; Thomas et al. 2002). The levulinic acid was rapidly produced in the early stages during the first 8 h of incubation and then showed the constant concentration until the end of the process. It confirmed the findings of Thompson et al. (2016) who found that the concentration of levulinic acid was increased during fermentation.

For the concentration of 5-HMF, it was rapidly reduced in the first 8 h of incubation. Palmqvist and Hahn-Hägerdal (2000) have previously shown that S. cerevisiae was able to enzymatically convert HMF to less toxic compound. HMF was reduced to 2,5-bis-hydroxymethylfuran (HMF alcohol) under aerobic and anaerobic conditions (Liu et al. 2004). Koppram et al. (2012) found that cells acquired the ability of improving furan transformation during adaptation. The data of formic acid are not shown because its concentration was below the detection limits. This implies that the sequential adaptation of SC90 in converting inhibitors can be considered an important modification that might contribute to a higher tolerance against inhibitors released during cassava pulp pretreatment.

Ethanol fermentation performance during S. cerevisiae SC90 adaptation in cassava pulp hydrolysate

The highest ethanol concentration was reached at 8 h of fermentation. The gradual adaptation of SC90 in each adaptation medium resulted in an improvement in its rate of glucose utilization. However, a decrease in volumetric productivity (Q) and fermentation efficiency was observed at 80 and 100% hydrolysate medium (Table 2). These effects were caused by the toxicity from the inhibitors generated at the higher concentration of hydrolysate (Fig. 2). In the first step, the medium without hydrolysate was used as the control, which provided a very high fermentation efficiency of up to 96.15%. The adaptation in the first cycle in 20% hydrolysate showed a slight decrease in fermentation efficiency compared to the control. Although the 20% hydrolysate contained inhibitors formed during the pretreatment, they were present at a very low level, about 3 mM of the initial acetic acid concentration as described previously (Fig. 2). Several research works presented that low concentration of acetic acid could improve ethanol production. Thomas et al. (2002) found that fermentation in the presence of acetic acid provided a higher ethanol concentration than in its absence. Greetham (2014) also found that the acetic acid content of less than 25 mM had no effect on the metabolic output associated with growth and ethanol production of yeast. Larsson et al. (1999) provided additional information that low concentration of acids can increase the ethanol yield which may be caused by stimulating the production of ATP.

The fermentation efficiency during adaptation in 20% hydrolysate was 94.83% in the first run and 96.12% in the second run. There were no significant differences in fermentation ability, including the YP/S, Q, sugar consumption and fermentation efficiency during repeated cultivation cycle. Decreasing YP/S and fermentation efficiency were found in the last cycles of 60, 80 and 100% hydrolysate compared to those of the first cycle (Table 2). Meanwhile, the increase in maximum total cell number (Table 1) and YX/S (Table 2) was found in the last cycles of 60, 80 and 100% hydrolysate compared to those of the first cycle. This could be explained by the flux distribution into anabolism and energy metabolism of carbon during ethanol fermentation in the yeast. In the first cycle, cells might have to adapt to the higher concentration of inhibitors, which required more energy that could be obtained from ethanol fermentation. This was obviously shown by high YP/S in the first cycle compared to that of the last cycle (Table 2). Moreover, after the cells adapted to tolerate inhibitors in the last cycle, the cell growth increased and the carbon source available for ethanol fermentation decreased. This characteristic of fermentation confirmed the findings of Zhu et al. (2009) who showed yeast adaptation using a step-by-step gradual increase in the concentration over the range between 10 and 50% of corn stover filtrate loading. They observed that the content of residual xylose has gradually increased with increasing filtrate loading together with an increase of ethanol produced in the initial step and a decrease in its content in later steps.

Comparison of growth and fermentation performance of adapted and non-adapted cells in 100% hydrolysate medium

The biological method such as yeast adaptation became more attractive in overcoming inhibitors present in lignocellulose hydrolysate which practically resulted in reducing both the cost of detoxification process and loss of fermentable sugars in pre-treated hydrolysates (Parawira and Tekere 2011). In the present work, adapted cells of SC90 in the final run were obtained and then cultured in 100% hydrolysate to assess their growth and performance in ethanol fermentation compared to non-adapted SC90. This showed that the number of living cells and the viability of the adapted cells were higher than those of non-adapted cells (Fig. 3a, b; Table 3). The µ was then calculated at the log phase where the adapted cells had a growth rate of 0.22 ± 0.00 h−1 compared to 0.19 ± 0.00 h−1 for non-adapted cells (Table 3). The tlag of both, adapted and non-adapted, cells as relatively low, 0.3 and 0.7 h, respectively.

Comparison between the adapted and the original strains of SC90 in terms of glucose consumption and ethanol production is shown in Fig. 3c, d and Table 3. The adapted cells produced significantly higher (p ≤ 0.05) ethanol concentration, YP/S, fermentation efficiency and Q. These results were in line with the report of Silva and Roberto (2001) who suggested that the evolution of microorganisms to tolerate inhibitors can improve the fermentation efficiency of the lignocellulosic biomass.

The results of this study were compared to the work of Landaeta et al. (2013) who studied the adaptation of S. cerevisiae NRRL Y-265 by cell recycle batch fermentation. They adapted yeast using media with sequential increase in inhibitor concentrations (five different inhibitor concentrations). These media imitated the content of inhibitors to those in eucalyptus chip hydrolysate. The kinetic parameters (µ, YP/S and Q) of their experiment are presented in Table 3. They showed that adapted strain cultivated in steam-exploded eucalyptus hydrolysate can improve the µ and Q by 70% and 10%, respectively, over non-adapted strain. Our results showed that the adapted cell elevated the µ and Q to 17% and 46%, respectively, compared to those of non-adapted cell. However, the µ and Q of Landaeta et al. (2013) were much lower than our experiment for both adapted and non-adapted cells.

Our findings also were similar to those reported by Parekh et al. (1986). They demonstrated that adapted yeast cells of Candida shehatae and Pichia stipites from recycling the yeasts in fresh aspen wood hydrolysate medium several times increased ethanol production by 13% compared to non-adapted strains. Also Pornpukdeewattana et al. (2014) tested ethanol fermentation in cassava pulp that had been pretreated with dilute acid and showed 0.42 g/g of ethanol yield from adapted cells and 0.35 g/g from non-adapted cells.

The spot plate experiment of the adapted and non-adapted cells of SC90 on agar plates with different concentrations of hydrolysate was used to investigate the inhibitor tolerance ability. Strong growth was observed for both adapted and non-adapted cells in the 0% hydrolysate (control), but the medium containing 50% hydrolysate inhibited cell growth only in the non-adapted cells. When the hydrolysate concentration was increased to 100%, there was still growth of adapted cells but the growth of non-adapted cells was completely inhibited. Thus, it is clear that the adapted cells were more tolerant to inhibitors in cassava pulp hydrolysate than the non-adapted cells (Fig. 4).

Conclusion

From the overview, it can be concluded that SC90 can be adapted to improve its growth and production of ethanol from the hydrolysate of the waste from the cassava flour-processing industry. This adaptation was achieved by progressively increasing the concentration of the cassava pulp hydrolysate over repeated cultures of SC90. Several adaptation cycles were required to improve the µ and reduce tmaxc. This adaptation can be assumed to be acclimatization. The YP/S of adapted cells was significantly higher (p ≤ 0.05) than that of the non-adapted cells by approximately 27%. The reason for this improvement was that repeated cultures made the SC90 more able to tolerate metabolic inhibitors produced during the hydrolysis of cassava pulp. The inhibitors were acetic acid, levulinic acid and 5-HMF. This implies that adapted cells were acclimated by the repeated cultures giving a higher resistance to toxins compared to the parent cells. It would be more advantageous to use an adapted strain of SC90 in industrial ethanol fermentation from cassava pulp.

References

Agu RC, Amadife AE, Ude CM, Onyia A, Ogu EO, Okafor M, Ezejiofor E (1997) Combined heat treatment and acid hydrolysis of cassava grate waste (cgw) biomass for ethanol production. Waste Manag 17:91–96

Almeida JR, Modig T, Petersson A, Hähn-Hägerdal B, Lidén G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82:340–349

Balat M (2011) Production of bioethanol from lignocellulosic materials via the biochemical pathway: a review. Energ Convers Manag 52:858–875

Bauer BE, Rossington D, Mollapour M, Mamnun Y, Kuchler K, Piper PW (2003) Weak organic acid stress inhibits aromatic amino acid uptake by yeast, causing a strong influence of amino acid auxotrophies on the phenotypes of membrane transporter mutants. Eur J Biochem 15:3189–3195

Cao GL, Ren NQ, Wang AJ, Guo WQ, Xu JF, Liu BF (2010) Effect of lignocellulose-derived inhibitors on growth and hydrogen production by Thermoanaerobacterium thermosaccharolyticum W16. Int J Hydrogen Energy 35:13475–13480

Dubois M, Gilles DA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for the determination of sugars and related substances. Anal Chem 28:350–356

El-Mansi EMT, Bruce Ward F (2006) Microbiology of industrial fermentation. In: El-Mansi EMT, Bryce CFA, Demain AL, Allman AR (eds) Fermentation microbiology and biotechnology, 2nd edn. Taylor & Francis, Boca Raton, pp 11–46

El-Naggar NE, Deraz S, Khalil A (2014) Bioethanol production from lignocellulosic feedstocks based on enzymatic hydrolysis: current status and recent developments. Biotechnology 13:1–21

Fein JE, Tallim SR, Lawford GR (1984) Evaluation of d-xylose fermenting yeasts for utilization of a wood-derived hemicellulose hydrolysate. Can J Microbiol 30:682–690

Greetham D (2014) Presence of low concentrations of acetic acid improves fermentations using Saccharomyces cerevisiae. J Bioprocess Biotech 5:192

Huang X, Wang Y, Liu W, Bao J (2011) Biological removal of inhibitors leads to the improved lipid production in the lipid fermentation of corn stover hydrolysate by Trichosporon cutaneum. Bioresour Technol 102:9705–9709

Keating JD, Panganiban C, Mansfield SD (2006) Tolerance and adaptation of ethanologenic yeasts to lignocellulosic inhibitory compounds. Biotechnol Bioeng 93:1196–1206

Koppram R, Albers E, Olsson L (2012) Evolutionary engineering strategies to enhance tolerance of xylose utilizing recombinant yeast to inhibitors derived from spruce biomass. Biotechnol Biofuels 5:32

Kouteu Nanssou PA, Jiokap Nono Y, Kapseu C (2016) Pretreatment of cassava stems and peelings by thermohydrolysis to enhance hydrolysis yield of cellulose in bioethanol production process. Renew Energ 97:252–265

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729

Lacerda TM, Zambon MD, Frollini E (2013) Effect of acid concentration and pulp properties on hydrolysis reactions of mercerized sisal. Carbohyd Polym 93:347–356

Landaeta R, Aroca G, Acevedo F, Teixeira JA, Mussatto SI (2013) Adaptation of a flocculent Saccharomyces cerevisiae strain to lignocellulosic inhibitors by cell recycle batch fermentation. Appl Energ 102:124–130

Lane J (2017) Thailand announces $11.3 billion 10-year plan to build sugarcane and cassava bioeconomy. Biofuelsdigest. http://www.biofuelsdigest.com/bdigest/2017/01/25/thailand-announces-11-3-billion-10-year-plan-to-build-sugarcane-and-cassava-bioeconomy-2. Accessed 26 Nov 2018

Larsson S, Palmqvist E, Hahn-Hägerdal B, Tengborg C, Stenberg K, Zacchi G, Nilvebrant NO (1999) The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzyme Microb Technol 24:151–159

Larsson S, Cassland P, Jönsson LJ (2001) Development of a Saccharomyces cerevisiae strain with enhanced resistance to phenolic fermentation inhibitors in lignocellulose hydrolysates by heterologous expression of laccase. Appl Environ Microbiol 67:1163–1170

Liu ZL, Slininger PJ, Dien BS, Berhow MA, Kurtzman CP, Gorsich SW (2004) Adaptive response of yeasts to furfural and 5-hydroxymethylfurfural and new chemical evidence for HMF conversion to 2,5-bis-hydroxymethylfuran. J Ind Microbiol Biotechnol 31:345–352

Luján-Rhenals DE, Morawicki RO (2016) Production of fermentable sugars and a high protein meal by dilute acid hydrolysis of soybean meal at high temperatures. Bioresources 11(4):8155–8165

Martín C, Wei M, Xiong S, Jönsson LJ (2017) Enhancing saccharification of cassava stems by starch hydrolysis prior to pretreatment. Ind Crop Prod 97:21–31

Mussatto SI, Roberto IC (2004) Alternatives for detoxification of diluted-acid lignocellulosic hydrolyzates for use in fermentative processes: a review. Bioresour Technol 93:1–10

Narayanan V, Sànchez Nogué V, van Niel Ed WJ, Gorwa-Grauslund MF (2016) Adaptation to low pH and lignocellulosic inhibitors resulting in ethanolic fermentation and growth of Saccharomyces cerevisiae. AMB Expr 6:1–13

Nilvebrant NO, Persson P, Reimann A, De Sousa F, Gorton L, Jönsson LJ (2003) Limits for alkaline detoxification of dilute-acid lignocellulose hydrolysates. Appl Biochem Biotechnol 105–108:615–628

Olsson L, Hahn-Hägerdal B (1993) Fermentative performance of bacteria and yeasts in lignocellulose hydrolysates. Process Biochem 28:249–257

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. II: Inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33

Parawira W, Tekere M (2011) Biotechnological strategies to overcome inhibitors in lignocellulose hydrolysates for ethanol production: review. Crit Rev Biotechnol 31(1):20–31

Parekh SR, Yu S, Wayman M (1986) Adaptation of Candida shehatae and Pichia stipitis to wood hydrolysates for increased ethanol production. Appl Microbiol Biotechnol 25:300–304

Pornpukdeewattana S, Khamfun J, Phatyenchai N (2014) Adaptation of commercial yeast Saccharomyces cerevisiae SC90 to tolerate inhibitors generated during cassava pulp hydrolysis. Suranaree J Sci Technol 21:335–345

Silva CJ, Roberto IC (2001) Improvement of xylitol production by Candida guilliermondii FTI 20037 previously adapted to rice straw hemicellulosic hydrolysate. Lett Appl Microbiol 32:248–252

Silva JPA, Mussatto SI, Roberto IC, Teixeira JA (2011) Ethanol production from xylose by Pichia stipitis NRRL Y-7124 in a stirred tank bioreactor. Braz J Chem Eng 28:151–156

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2012) Determination of structural carbohydrates and lignin in biomass, laboratory analytical procedure (LAP). National Renewable Energy Laboratory (NREL) Web. https://www.nrel.gov. Accessed 17 Jan 2019

Smart KA, Chambers KM, Lambert I, Jenkins C (1999) Use of methylene violet staining procedures to determine yeast viability and vitality. J Am Soc Brew Chem 57:18–23

Soleymanpour Z, Nikzad M, Talebnia F, Niknezhad V (2018) Xanthan gum production from acid hydrolyzed broomcorn stem as a sole carbon source by Xanthomonas campestris. 3 Biotech 8:296

Srinorakutara T, Kaewvimol L, Saengow L (2006) Approach of cassava waste pretreatments for fuel ethanol production in Thailand. J Sci Res Chula Univ 31:77–84

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83:1–11

Thomas KC, Hynes SH, Ingledew WM (2002) Influence of medium buffering capacity on inhibition of Saccharomyces cerevisiae growth by acetic and lactic acids. Appl Environ Microb 4:1616–1623

Thompson OA, Hawkins GM, Gorsich SW, Doran-Peterson J (2016) Phenotypic characterization and comparative transcriptomics of evolved Saccharomyces cerevisiae strains with improved tolerance to lignocellulosic derived inhibitors. Biotechnol Biofuels 9:200

Tian S, Zhu J, Yang X (2011) Evaluation of an adapted inhibitor-tolerant yeast strain for ethanol production from combined hydrolysate of softwood. Appl Energy 88:1792–1796

Tomás-Pejó E, Ballesteros M, Oliva JM, Olsson L (2010) Adaptation of the xylose fermenting yeast Saccharomyces cerevisiae F12 for improving ethanol production in different fed-batch SSF processes. J Ind Microbiol Biot 37:1211–1220

Trakulvichean S, Chaiprasert P, Otmakhova J, Songkasiri W (2017) Comparison of fermented animal feed and mushroom growth media as two value-added options for waste cassava pulp management. Waste Manag Res 35:1210–1219

Wallace-Salinas V, Gorwa-Grauslund MF (2013) Adaptive evolution of an industrial strain of Saccharomyces cerevisiae for combined tolerance to inhibitors and temperature. Biotechnol Biofuels 6:151

Zhu JJ, Yong Q, Xu Y, Chen SX, Yu SY (2009) Adaptation fermentation of Pichia stipitis and combination detoxification on steam exploded lignocellulosic prehydrolyzate. Nat Sci 1:47–54

Acknowledgements

This research was financially supported by King Mongkut’s Institute of Technology Ladkrabang (KMITL) (A118-59-070) and National Research Council of Thailand. The contribution of Prof. Dr. Anthony Keith Thompson and Prof. Dr. George Srzednicki (visiting Professor at Faculty of Agro-Industry, KMITL) for critically editing the manuscript is acknowledged.

Author information

Authors and Affiliations

Contributions

PPNA: literature review, design of the research outline, design of research tools, analysis of data, interpretation of the data analysis, and drafting of the article (first draft). TC: design of the research outline, design of research tools, decision on the data analysis method, interpretation of the data analysis, revision of the draft of the article (second draft), and final approval of the article (final draft). WK: conception of the project, design of the research outline, interpretation of the data analysis, and final approval of the article (final draft). SP: conception of the project, literature review, design of the research outline, design of research tools, decision on the data analysis method, analysis of data, interpretation of the data analysis, revision of the draft of the article (second draft), and final approval of the article (final draft).

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Palakawong Na Ayutthaya, P., Charoenrat, T., Krusong, W. et al. Repeated cultures of Saccharomyces cerevisiae SC90 to tolerate inhibitors generated during cassava processing waste hydrolysis for bioethanol production. 3 Biotech 9, 76 (2019). https://doi.org/10.1007/s13205-019-1607-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-019-1607-x