Abstract

In the present study, fungal biotransformation of synthetic levodopa to stable dopamine in an l-ascorbate-mediated thermophilic-aerobic biochemical reaction was investigated. A mutant strain of Aspergillus oryzae EMS-6 was used for the preparation of mycelial biomass. The mutant was previously developed through EMS-induced mutagenesis and repressed against l-cysteine HCl. Growth parameters such as rate of cultivation (48 h), initial pH (6) and incubation temperature (30 °C) supported 18.84 g/l biomass with 23 g/l glucose consumption. Thermophilic behaviour of culture was observed at 25–40 °C. Kinetic variables notably µ = 0.385 /h and Qs, exhibited consistent growth pattern. Biochemical reactions were performed aerobically using mycelial biomass as the source of enzyme ‘tyrosinase’ in a digital hotplate equipped with magnetic stirrers. The reaction conditions included 5 mg/ml biomass and 2.5 mg/ml levodopa as basal substrate in a thermophilic reaction of 25 min duration acidified with l-ascorbic acid. TLC and HPLC analysis of reaction mixture confirmed the presence of levodopa and dopamine using a CN-9dth (R) column. Activation enthalpy and entropy of dopa decarboxylase (DDC) and its thermal inactivation showed an improved biotransformation of levodopa to dopamine at the optimal temperature (30 °C) as compared to other temperatures being employed. Overall, 3.68 mg/ml dopamine (4.55 mg/ml proteins) synthesis from 2.38 mg/ml levodopa was accomplished. The enhancement in metabolic activity of the mutant strain is ~ 2.75-fold improved when compared to the unoptimized reaction conditions, which is highly significant (HS) indicating an eco-commercially viable (LSD ~ 0.412) bioprocess.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dopamine, a sympathomimetic amine vasopressor, belongs to catecholamines. It is a precursor for norepinephrine particularly in noradrenergic neurons along with those in the adrenals (Hyland et al. 1992; Sirivelu et al. 2006). Its role in synchronization of movement could be understood by inspecting Parkinson’s disease. This ailment is associated with the very minute quantities of dopamine in nervous system (Charteris and John 1975; Piccini et al. 1999). It is an integral component of the brain biochemistry (Kanteev et al. 2015) and is believed to have a significant role in drug addiction associated with cocaine, amphetamine, marijuana, alcohol and nicotine use (Haq et al. 2002). Naturally, levodopa is produced from tyrosine by tyrosine hydroxylase. Levodopa is then transformed to dopamine by the dopa decarboxylase (Raju et al. 1993). Dopa decarboxylase (EC 4.1.1.28; DDC) is the first useful enzyme of melanogenic pathway to be characterized. It is an intracellular enzyme and is generally found in the cytoplasm of cells (Christensen 1972). The enzyme plays a central role in wound healing, pigmentation, parasite defense and the hardening of cuticle (Bertoldi and Voltattorni 2000). It acts as an undissipated protein, and its activity in microorganisms is generally weak (Hodgetts and O’Keefe 2006). Dopamine is fairly unstable when produced and rapidly oxidized to other metabolites, thus its stoichiometric synthesis has been difficult to achieve (Salinas et al. 2016). Due to the some allergic reactions of levodopa intake in Parkinson’s patients, the direct dopamine intake is gaining interest in health biotechnology.

Although, some reports in the literature have appeared which described the chemical conversion of l-tyrosine to levodopa that ultimately converted into dopamine and some other intermediates of the melanogenesis’ cycle (Minelli et al. 1979; Ali et al. 2005; Tang et al. 2017). However, work is still needed to produce dopamine from the substrate levodopa by microbiological techniques. Production of dopamine from the harvested cells in an acidic reaction with l-ascorbic reaction would not only be economically significant but may be a more stable production process. Aspergillus oryzae mold mycelia after harvesting in broth culture are prerequisite for biochemical transformation of levodopa to dopamine (Haneda et al. 1973; Kaljunen et al. 2011). The present investigation is a novel biochemical transformation of levodopa to dopamine by l-cysteine HCl resistant mutant filamentous fungus A. oryzae EMS-6. The putative culture was investigated for improved substrate uptake and enzyme production rates, respectively. Various kinetic parameters or variables particularly product formation rates and substrate consumption constants were also determined. Activation enthalpy and entropy of the product were targeted for the kinetics of fermentation system and to further elucidate the key phenomenon involved in empirical approach.

Materials and methods

Levodopa, ethyl methane sulphonate (EMS) and l-cysteine HCl were procured from Sigma Chemicals Inc. (St. Louis, USA) and preserved at 4 °C in a lab-cool (Model: MP-153, Sanyo, London, UK). Other chemicals were also of maximum purity.

Microorganism

Aspergillus oryzae mutant EMS-6 was acquired from the available stock culture of Institute of Industrial Biotechnology (IIB), GC University Lahore (Pakistan). The fungal strain was grown on potato dextrose agar (PDA) slopes, pH 5.6. After growth, the slope cultures were stored at 4 °C using a mini cold lab (153-MP, Manchester, UK). It was made resistant against l-cysteine HCl as a non-standard amino acid after treatment with ethyl methane sulphonate (EMS) to the 36 h old vegetative mycelia using Vogel’s medium (Pontecarvo et al. 1969).

Inoculation and biomass harvesting

The submerged fermentation (SmF) technique using 250 ml conical flasks was used for all batch-culture cultivations. The spore inoculum was developed using 10 ml of diacectyl ester of sulpho succinic acid (Monoxal OT). Twenty-five milliliters of Vogel’s medium comprising 30 g/l glucose, 2 g/l peptone, 2.5 g/l trisodium citrate, 1 g/l yeast extract, 2 g/l NH4NO3, 5 g/l KH2PO4, 4 g/l (NH4)2SO4 and 0.2 g/l MgSO4·7H2O, and pH 5.5 were taken in 250 ml conical flasks. It was autoclaved at 15 psi (121 °C) for 15 min. Later, it was seeded with 1 ml of conidial suspension (1.5 × 106 CFU/ml). CFU was determined by a haemocytometer. The culture media were then incubated in an orbital shaking incubator (160 rpm) at 28 °C for 48 h.

Fungal mycelia were collected by filtering the fermented broth through filter paper in a funnel. These were washed free of the medium with ice-cold distilled water (4 °C). The mycelium was air-dried to make it 90% moisture free using sheets of filter papers (Whatman No. 44, Brazil) and stored at 4 °C.

Critical phases of aerobic biochemical reactions

The biochemical reaction for levodopa synthesis from l-tyrosine was undertaken using a mycelial suspension of the fungus growth. The mycelia were dispensed in the reaction mixture following the procedure of Haneda et al. (1969). Twenty-five milliliters of 50 mM acetate buffer (pH 3.5) comprising 2.5 mg/ml l-tyrosine, 5 mg/ml l-ascorbic acid and 7.5 mg/ml intact mycelia were added to 100 ml capacity Erlenmeyer flask. The reactions were performed aerobically (1 vvm fresh air supply) at 50 °C for a range of time periods (30–70 min.) using a hotplate having magnetic stirrers (Perkins Elmer, USA). The biochemical samples were collected and centrifuged (6000×g for 15 min). The supernatant was placed under dark at an ambient temperature (20 °C).

Analytical techniques

Residual levodopa was determined after Arnow (1973). DDC and dopamine activities were measured using thin layer chromatography (TLC) and high-performance liquid chromatography (HPLC) interphase fitted with electrochemical and biochemical detection (HPLC-BIO-ECD) systems as performed in some earlier reports (Sherald et al. 1973; Li and Christensen 1993). The HPLC-BIO-ECD system consisted of an interphase attached to LC-100 (Perkin Elmer, Series-200, USA) pump, CN-9dth (R) column, a glassy carbon electrode, maintained at 25 °C and a UV/VIS detector. The data were incorporated using computer with an automated software system (Charteris and John 1975). The mobile or liquid phase was prepared with pyrogen-free distilled water and delimited by 10 g/l monochloroacetic acid, 6.5 NaOH, 0.16 g/l EDTA along with 1% ethanol. It was filtered and degassed using ultrasonic filtration assembly (Model: Hielscher, KL-132-4, Bonn, Germany). The electrode was operated at 75 V and full-scale detector after Sirivelu et al. (2006). The total protein content in the supernatants was determined after Bradford (1976).

Kinetic and statistical analysis

Kinetic parameters were examined according to the methods of Pirt (1975). The data of at least three different experiments were employed for statistical analysis. The enzyme activity and metabolite reactivity along with mean specific activity between the samples and standard controls were equated using the classical Duncan’s multiple range test after Snedecor and Cochran (1980).

Thermodynamical characterization

Arrhenius empirical approach was used to analyse the relationship of temperature-dependent inactivation of dopamine (Aiba et al. 1973). The specific rate for metabolite formation (qp, units/g cells/h) was employed to compute the different parameters following Arrhenius equations,

The plot of ln(qp/T) vs.1/T exhibited a straight scattered line whose curve slope was − ΔH*/R while intercept was ΔS*/R + ln(KB/h). The letter ‘h’ is Planck’s constant which is 6.63 × 10−34 Js. Similarly, KB is Boltzman constant [R/N] with 1.38 × 10−23 J/K where N denotes the Avogadro’s No being numeric 6.02 × 1023 per mol.

Results and discussion

Biomass harvesting and optimizations of A. oryzae EMS-6

Biomass cultivation is critical for intracellular enzymes, so in the present study filamentous fungus A. oryzae mutant strain EMS-6 was grown at various conditions such as rate of cultivation, initial pH and incubation temperature. The rate of cultivation was studied from 12 to 84 h after the inoculation (Fig. 1). The amount of biomass was very low (1.82 and 4.5 g/l, respectively) when cultivated for 12–24 h and it was increased with the passage of time, upto a certain extent. The maximum biomass development was, however, observed at 48–72 h of cultivation. A sharp decline in mycelial growth was noticed 72 h after incubation which became 13.86 g/l at 84 h. Glucose consumption was improved during the course of cultivation; however, 20.88 g/l was found to be optimal. Therefore, biomass cultivation for 48 h was optimized as further increase in time duration notably 60–72 h did not reveal any positive impact on mycelial development rather it started declining. In a similar kind of study, Haneda et al. (1973) reported the cultivation of various microorganisms and optimized batch conditions including rate of cultivation, initial pH and incubation temperature.

Initial pH has a direct effect on the biomass development and metabolic behaviour of organism (Sirivelu et al. 2006). Effect of initial pH (3.5–7) was investigated on mycelial harvesting of A. oryzae EMS-6 (Fig. 2). A biomass of 6.82 g/l with a glucose consumption of 9.85 g/l was obtained when pH was adjusted to 3.5. Biomass development was enhanced when medium pH was increased from 4 to 6; a gradual decline in mycelial weight was observed afterwards. The maximum biomass development (18.98 g/l) at an initial pH of 6 was about threefold higher compared to pH 3.5. Glucose consumption was noted to be 20.18 g/l. A neutral pH of cultivation medium did not reveal a positive impact or enhancement in mycelial development as reported by Haq et al. (2002). It was rather decreased to 10.08 g/l with a concomitant decrease in substrate uptake rate. A pH of 6 was therefore found to be highly significantly (HS, p ≤ 0.05) for biomass production compared to all other values when cultivated for 48 h.

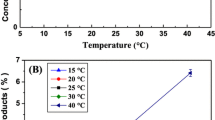

Thermophilic behaviour of A. oryzae EMS-6 for biomass development was studied at a temperature between 20 and 55 °C (Fig. 3). The mycelial growth was not sufficient (9.1 g/l) when temperature of the cultivation medium was adjusted at 20 °C during the course of incubation. Substrate consumption was also very poor (less than 4 g/l). However, a notable observation was that an incubation temperature range between 25 and 40 °C promoted optimal growth, and no major change in net dry weight was found (18.25–18.84 g/l biomass). Glucose consumption was improved with the increase in temperature (7 g/l found optimal). A sharp decline in the biomass was noticed when temperature was further increased beyond 40 °C and it became very low (9.2 g/l) almost equal to the amount obtained at 20 °C. Similar kind of findings has also been reported by Raju et al. (1993). Glucose consumption was quite high regardless of temperature severity (22.12 g/l substrate was consumed at 55 °C). As the organism showed optimal growth at a broad temperature range of 25–40 °C, so it was concluded that this thermophilic characteristic may be an additional benefit for the second step, i.e., extraction of DDC from the mycelial cells in an acidic reaction and biochemical transformation of levodopa to dopamine with concomitant increase in the product stability as substantiated by the previous findings of Ali et al. (2005).

Comparison of kinetic variables

A comparison of kinetic variables for biomass development of A. oryzae EMS-6 at various incubation temperatures such as 25, 30, 35 and 40 °C was made (Table 1). Specific growth rate (µ /h) was almost constant with a little enhancement at 30 °C (0.392 ± 0.11 /h). The biomass yield coefficient (Yx/s) was, however, better (1.46 ± 0.42 g/g) at 25 °C, compared to all other temperatures particularly to that of 35 or 40 °C (Pirt 1975). The improvement was significant (p ≤ 0.05). When the microbial culture was observed for volumetric rates of biomass formation (Qx) and substrate utilization (Qs), the values obtained in the temperature range between 25 and 30 °C were economically encouraging; however, no remarkable difference was noticed. Qx and Qs directly relates to higher product formation and substrate consumption rates as reported by Pirt (1975). The specific rate constants (qs, qx) were almost constant regardless of increase in temperature all the way from 25 to 40 °C. The value of specific rate constant for biomass formation (qx = 0.441 ± 0.14 g/g/h) obtained at 30 °C was, however, highly significant (HS, LSD 0.412) as reported by Felger and Miller (2012). The kinetic variables thus revealed an improvement in biomass production and better glucose consumption rate following growth of the culture at a temperature range of 25–40 °C.

DDC excretion and biochemical transformation of levodopa to dopamine

The microbiological transformation of levodopa to dopamine was undertaken in an aerobic reaction. The initial concentration of levodopa was 2 mg/ml and the reaction was carried out at a pH of 3.5 for 30 min. Effect of different biomass level on the biochemical conversion of levodopa into dopamine by A. oryzae EMS-6 was then investigated (Fig. 4). The concentration of biomass varied from 1 to 8 mg/ml in each aerobic reaction. Dopamine of 0.07 mg/ml was produced when 1 mg/ml biomass was used as DDC source. Levodopa consumption and total protein content formed were 0.05 and 0.14 mg/ml, respectively. The production of dopamine was increased in the reaction mixture as the biomass concentration was increased from 2 mg/ml but up to a certain extent. The maximum conversion of levodopa to dopamine (2.86 mg/ml with 4.05 mg/ml protein content) was achieved at 5 mg/ml biomass level. Dopamine production was sharply declined when biomass concentration was increased from the optimal and became very low (1.06 mg/ml) at 8 mg/ml cell biomass. Levodopa consumption was, however, gradually increased except at 8 mg/ml mycelial weight where substrate consumption rate was noted to be marginally lower (1.78 mg/ml) compared to the optimal, concomitantly protein contents were reduced from maximal value (4.05 mg/ml) to 2.46 mg/ml only. So, a biomass level of 5 mg/ml was optimized, as demonstrated by the findings of Vaillancourt et al. (2013).

Substrate is the basal ingredient or metabolic component which not only supports the growth of an organism but it also provides the raw material to be converted into product by specific enzymes (Tang et al. 2017). Figure 5 depicts the effect of different concentrations of levodopa on its biochemical conversion into dopamine by A. oryzae EMS-6. The concentration of levodopa ranged from 0.5 to 4 mg/ml for each biochemical trial. Dopamine production was very low (0.28–0.71 mg/ml) at initial levels of levodopa (0.5–1 mg/ml). Levodopa consumption and total protein produced were in the range between 0.14 and 0.31 and 0.45–0.91 mg/ml, respectively. The maximum amount of dopamine (3.42 mg/ml with 2.28 mg/ml levodopa consumption) was, however, obtained when 2.5 mg/ml substrate was added into the reaction mixture. Total protein contents were found to be 4.56 mg/ml which were about tenfold improved compared to the initial levels of levodopa added. A further increase in levodopa concentration other than the optimal did not reveal any bearing on substrate consumption; it was rather a straight line showing that higher substrate concentration is economically not suitable. It was however evident that dopamine biosynthesis markedly declined (1.95–2.7 mg/ml) at levodopa concentration (3.5–4 mg/ml) greater than the optimal (2.5 mg/ml). Similarly, a higher substrate level in the reaction broth adversely affected the total protein contents being produced by the organism. A substrate concentration of levodopa (2.5 mg/ml) was optimized, and substantiated with the findings of Felger et al. (2015).

Incubation period is one of the most critical factors which determine the quantity and quality of the actual product required as any imbalance or disturbance during the course of reaction might have strong adverse effects on the production as well as stability of the product (Nakamura et al. 2000). The effect of reaction time on the biochemical conversion of levodopa into dopamine by A. oryzae EMS-6 was also undertaken (Fig. 6). The biochemical reaction was carried out for different time periods such as 5, 10, 15, 20, 25, 30, 35, 40 min. The production of dopamine was not encouraging (0.32–1.84 mg/ml) at 5–15 min of reaction. Protein content was, however, improved after 15 min of reaction and found to be 3.05 mg/ml. The maximum product (3.68 mg/ml dopamine) was obtained when the reaction continued for a period of 25 min. Levodopa consumption and total protein contents formed during the optimal course of reaction were 2.38 and 4.55 mg/ml, respectively. The dopamine formation was thus 1.48-fold (38.5%) improved compared to the product obtained in 30 min after reaction with 2 mg/ml of levodopa and 5 mg/ml of biomass used. Dopamine formation, however, declined when the reaction time was further increased beyond 25–30 min which became very low (0.95 mg/ml) after 40 min. Levodopa consumption and total proteins were also considerably reduced at a longer reaction time period.

TLC and HPLC studies have confirmed the metabolite synthesis (Fig. 7) as reported by Raju et al. (1993). l-Phenylalanine, l-tyrosine and levodopa were also observed in the reaction mixture during the course of reaction (25 min optimal); however, their highest activities were recorded to be only 0.0042, 0.0255 and 0.148 mg/ml, respectively.

Thermodynamics and characterization of DDC

The requirement of relatively lower activation energy (Ea) for fungal growth vis-a-vis less demand of enthalpy or entropy of activation for metabolite synthesis could be assumed as the prospective indices of microbial thermostability during the cultivation and development processes, as these variables are the possible measures for thermostable or extremophile enzymes. In the present investigation, A. oryzae EMS-6 exhibited 6.34-fold more stable metabolite (Ea = 7.6 ± 1.2 kJ/mol) at 30 °C compared to relatively lower temperature (like 20 °C). It was attributed towards its required lower activation energy for the microbial growth in the harvesting medium. The data are depicted in Table 2. This was considerably lower compared to that required by the cells or mycelia of mutated fungal cultures or batch systems (Charteris and John 1975). The different quantitative values of the process parameters for thermodynamics indicated that activation enthalpy of tyrosinase formation by the fungus (ΔHD = 4.82 ± 1.2 kJ/mol) is extremely lower than at 30 °C (Aiba et al. 1973; Converti and Dominguez 2001). The value of activation entropy for thermal inactivation by the fungal mutant mycelial pellets (− 24.55±1.5 J/mol/K) remained extremely low and was equivalent to that for dopaquinone formation by a thermotolerant filamentous fungal culture (Trichoderma spp.) that imitated that the inactivation portent indicated a lower disorderness (Aiba et al. 1973) during the liquid growth or subsequent metabolic formation.

Conclusions

Biotransformation of levodopa to dopamine in an l-ascorbate mediated thermophilic-aerobic biochemical reaction was accomplished successfully. A mutant strain of A. oryzae EMS-6 was used to harvest mycelial biomass in 48 h at 30 °C. Thermophilic behaviour was observed up to 40 °C exhibiting kinetic variables (µ and Qs) to be consistent for growth patterns. Biomass, levodopa and reaction time were optimized. The product mediation and reaction stability was correlated to the direct acidic reaction conditions prevailed by l-ascorbic acid. TLC and HPLC analysis of reaction mixture confirmed the presence of stable dopamine. Activation enthalpy and entropy of DDC and its thermal inactivation revealed a little disorderness in product. A notable biosynthesis of dopamine (3.68 mg/ml) was achieved indicating a viable metabolic transformation bioprocess.

References

Aiba S, Humphrey AE, Millis NF (1973) Biochemical engineering, 2nd edn. Academic Press, New York, pp 92–127. https://doi.org/10.1002/jobm

Ali S, Haq I, Qadeer MA, Rajoka MI (2005) Double mutant of Aspergillus oryzae for improved production of 3,4-dihydroxy phenyl-l-alanine from l-tyrosine. Biotechnol Appl Biochem 42:143–149. https://doi.org/10.1042/BA20040180

Arnow LE (1973) Colorimetric determination of the components of l-3,4-dihydroxy phenylalanine in tyrosine mixtures. J Biochem 88:531

Bertoldi M, Voltattorni CB (2000) Reaction of dopa decarboxylase with l-aromatic amino acids under aerobic and anaerobic condition. Biochem J 352:533–538

Bradford MM (1976) A rapid method for the quantification of program quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Charteris A, John RA (1975) An investigation of the assay of dopamine using trinitrobenzenesulphonic acid. Anal Biochem 66:365–371

Christensen G (1972) Effects of metal cations and other chemicals upon the in vitro activity of two enzymesin the blood plasma of the white sucker Catostomus commersoni. Chem Biol Interact 4:351–361

Converti A, Dominguez JM (2001) Influence of temperature and pH on xylitol production from xylose by Debarryomyces hansenii. Biotechnol Bioeng 75:39–45

Felger JC, Miller AH (2012) Cytokine effects on the basal ganglia and dopamine function: the subcortical source of inflammatory malaise. Front Neuroendocrinol 33:315–327. https://doi.org/10.1016/j.yfrne.2012.09.003

Felger JC, Hernandez CR, Miller AH (2015) Levodopa reverses cytokine-induced reductions in striatal dopamine release. Int J Neuropsychopharmacol 18:84–96. https://doi.org/10.1093/ijnp/pyu084

Haneda Y, Tsuji FI, Sugiyama N (1969) Luminescent systems in apogonid fishes from the Philippines. Science 165(3889):188–190

Haneda K, Watanabe S, Takeda P (1973) l-DOPA by microorganisms. J Ferment Technol 51:398–406

Haq I, Ali S, Qadeer MA (2002) Biosynthesis of l-Dopa by Aspergillus oryzae. Bioresour Technol 85:25–29. https://doi.org/10.1016/S0960-8524(02)00060-3

Hodgetts RB, O’Keefe SL (2006) Dopa decarboxylase: a model gene-enzyme system for studying development, behaviour and systematics. Annu Rev Entomol 51:259–284. https://doi.org/10.1146/annurev.ento.51.110104.151143

Hyland K, Surtees RAH, Rodeck C, Clayton PT (1992) Aromatic l-amino acid decarboxylase deficiency: clinical features, diagnosis and treatmentof a new born error of neurotransmitter amine synthesis. Neurol 42:1980–1988

Kaljunen H, Gasparetti C, Kruus K, Rouvinen J, Hakulinen N (2011) Crystallization and preliminary X-ray analysis of Aspergillus oryzae catechol oxidase. Acta Crystallogr Sect F Struct Biol Cryst Commun 67:672–674. https://doi.org/10.1107/S1744309107060721

Kanteev M, Goldfeder M, Fishman A (2015) Structure-function correlations in tyrosinases. Protein Sci 24:1360–1369. https://doi.org/10.1002/pro.2734

Li J, Christensen BM (1993) Identification of products and intermediates during l-dopa oxidation to dopachrome using pressure liquid chromatography. J LIq Chromatogr 16:1117–1133

Minelli A, Charteris AT, Voltattorni CB, John RA (1979) Reactions of Dopa (3,4-dihydroxyphenylalanine) decarboxylase with Dopa. Biochem J 183:2843–2851

Nakamura M, Nakajima T, Ohba Y, Yamauchi S, Lee BR, Ichishima E (2000) Identification of copper ligands in Aspergillus oryzae tyrosinase by site-directed mutagenesis. Biochem J 350:537–545

Piccini P, Brooks DJ, Bjorklund A, Gunn RN, Grasby PM, Rimoldi O, Brundin P, Hagell P, Rehnrona S, Widner H, Lindwall O (1999) Dopamine release from nigral transplants visualized in vivo in a Parkinson’s patient. Nat Neurosci 2:1137–1140

Pirt SJ (1975) Principles of cell cultivation. Blackwells Scientific Corporation, London

Pontecarvo J, Roper JA, Hemmous LM, Buftan W (1969) Basic techniques of UV-irradiation and chemical mutation. Adv Genet 5:141–183

Raju BG, Rao GH, Ayyanna C (1993) Bioconversion of tyrosine to melanin using mycelia of Aspergillus spp. CBS Publishers, Visakhapatnam

Salinas AG, Davis MI, Lovinger DM, Mateo Y (2016) Dopamine dynamics and cocaine sensitivity differ between striosome and matrix compartments of the striatum. Neuropharmacol 108:275–283. https://doi.org/10.1016/j.neuropharm.2016.03.049

Sherald AF, Sparrow JC, Wright TRF (1973) A spectrophotometric assay for Drosophila dopa decarboxylase. Anal Biochem 56:300–305

Sirivelu MP, Mohankumar SMJ, Wagner JG, Harkema JR, Mohankumar PS (2006) Activation of the stress axis and neurochemical alterations in specific brain areas by concentrated ambient particle exposure with concomitant allergic airway disease. Environ Health Perspect 114:870–874

Snedecor GW, Cochran WG (1980) Statistical methods, 7th edn. Ames, Iowa state University Press, Iowa.

Tang MC, Zou Y, Watanabe K, Walsh CT, Tang Y (2017) Oxidative cyclization in natural product biosynthesis. Chem Rev 117:5226–5333. https://doi.org/10.1021/acs.chemrev.6b00478

Vaillancourt DE, Schonfeld D, Kwak Y, Bohnen NI, Seidler R (2013) Dopamine overdose hypothesis: evidence and clinical implications. Mov Disord 28:43–57. https://doi.org/10.1002/mds.25687

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Ali, S. Fungal biotransformation of synthetic levodopa to stable dopamine in l-ascorbate-mediated aerobic-thermophilic biochemical process. 3 Biotech 8, 370 (2018). https://doi.org/10.1007/s13205-018-1398-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-018-1398-5