Abstract

This paper presents a very simple and cheap off-line technique that is able to evaluate the aluminum electrolytic capacitors condition. Aluminum electrolytic capacitors equivalent circuit is composed by an internal resistance and a capacitance. The capacitors internal resistance increases with aging while the capacitance decreases. Manufacturers define the end of life limit of the capacitor when its internal resistance doubles its initial value or the capacitance changes more than 20% when it is compared with the initial one. The proposed technique evaluates the capacitor condition through the identification of both capacitor internal resistance and capacitance. To compute both capacitor internal resistance and capacitance a very simple, cheap, and practical experimental setup is proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

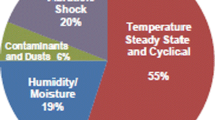

In the last years several researchers have been working on the subject of fault diagnosis of aluminum electrolytic capacitors (Harada et al. 1993; Lahyani et al. 1998; Venet et al. 2002; Gasperi 2005; Amaral and Cardoso 2009). This is mainly due to the fact that these capacitors are one of the preferred capacitors in electronics and simultaneously one of the weakest elements. Figure 1 shows the distribution of faults in a common switch mode power supply (half-bridge DC–DC forward-type power supply) (Lahyani et al. 1998; Venet et al. 2002).

From the analysis of Fig. 1 it is possible to conclude that these capacitors represent the weakest element of power supplies. In this way, it becomes of paramount importance the development of fault diagnostic techniques that are able to evaluate the state condition of aluminum electrolytic capacitors, in order to avoid unexpected breakdowns of the equipment.

2 Capacitors

A capacitor is an electronic component that is able to store electrical energy in a form of an electrical field. It is constituted by a pair of conductors (two plates) separated by an insulator (dielectric).

When a voltage source is connected to the capacitor some rearrangements occur in the electrical charge of both capacitor plates. The positive terminal of the power supply attracts the electrons of the capacitor plate that is closest to it. The other terminal of the power supply, which is connected to the other plate, repels the plate electrons. During this process the capacitor is charging.

To discharge the capacitor it is necessary to connect a conductor between both plates in order to achieve the charge equilibrium between both plates.

The capacitor capacitance, C, can be defined as:

where Q and V represent the capacitor electrical charge and capacitor voltage, respectively. However, the capacitance can also be defined in a geometrical way as:

where ε o, ε r, S, and d represent the dielectric constant of the free space (8.854 × 10−12 F/m), the relative dielectric constant of the dielectric material, the surface area of the dielectric (m2) and the thickness of the dielectric (m).

The capacitor current, i C, due to charge rearrangements in the capacitor plates during the charge or discharge process can be obtained by differentiating (1):

where \( \frac{dv}{dt} \) represent the rate of change of capacitor voltage with time.

3 Capacitors technologies

Capacitors are available in three basic technologies:

-

1.

Electrolytic capacitors;

-

2.

Film capacitors;

-

3.

Ceramic capacitors.

The electrolytic capacitors have very high volumetric efficiency, an excellent price/performance ratio and a very wide range of voltage and capacitance ratings, which make them the preferred capacitor type for power electronic applications (Fodor et al. 2006). However, they have high losses and are polarity dependent, so they are essentially used in DC circuits (Sarjeant et al. 1998). These capacitors can be subdivided into, tantalum electrolytic capacitors and aluminum electrolytic capacitors. The first ones have a higher dielectric constant; however, they are more expensive when compared with the second ones (Poole 1981). Besides, their maximum voltage rating is limited to 50 V, which limits their application to low and medium voltage ranges. Aluminum electrolytic capacitors have a much higher range of capacitances (0.1 μF–3 F), and voltages (5–500 V) (Application guide, Cornell Dubilier). The very high volumetric efficiency of electrolytic capacitors is achieved due to the very thin dielectric and to a process of etching the foils that can enlarge the surface area of the foil in 100 times (Application guide, Cornell Dubilier).

Film capacitors offer tight capacitance tolerance, which does not change much with temperature, low losses, and are polarity independent. However, they are expensive, large, and weight (Application guide, Cornell Dubilier); the most popular polymer is the polypropylene.

Ceramic capacitors are used in very high frequency applications due to their non-inductive behavior. These capacitors can be sub-divided in classes 1 and 2. The first ones are very precise, stable, and have very low losses; however, they have low volumetric efficiency when compared with class 2 ones. Class 1 capacitors are used in circuits that operate close to 1 GHz. Class 2 capacitors are especially suited for AC applications that operate till 1 MHz (Dai et al. 2005).

4 Aluminum electrolytic capacitors

According to the Industrial Technology Research Institute of Taiwan (Tsai et al. 2002), the demand of aluminum electrolytic capacitors is estimated to growth by 8–10% per year, due to their excellent characteristics. Besides, some of their disadvantages can be overcome. For instance, the fact of this capacitor be polarity dependent, do not avoid it from being used in AC applications, if two aluminum electrolytic capacitors are connected in anti-series (back-to-back with the positive terminals or the negative terminals connected). The result is a non-polarity single capacitor with half of the capacitance (Application guide, Cornell Dubilier). The high losses can be reduced if low resistivity electrolytes are used (Efford et al. 1997), and the capacitor inductive effects can be reduced if a smaller capacitor with lower inductive effect is connected in parallel with the first one or if special design terminal electrolytic capacitors are used instead (Will and Fischer 2000).

4.1 Composition

An aluminum electrolytic capacitor consists of a wound element, impregnated with liquid electrolyte, connected to the terminals and sealed in a can (Fig. 2).

Aluminum electrolytic capacitor composition (Precautions and guidelines, Nippon Chemi-con)

The internal element comprises two foils (anode and cathode foils) that are separated by separator paper impregnated in the electrolyte. The foils are etched with billions of microscopic tunnels to increase their surface (Fig. 3) (Application guide, Cornell Dubilier).

Anode foil for high voltage (a) and low voltage (b) aluminum electrolytic capacitors (magnification of ×400) (Epcos and January 2008)

This construction gives an enormous capacitance, since the dielectric surface can increase more than hundred times, which can be easily understood through (2).

4.2 Equivalent circuit

Real capacitors have some parasitic elements that influence their behavior, like the internal equivalent series resistance (ESR) or the equivalent series inductance (ESL).

Figure 4 models the behavior of an aluminum electrolytic capacitor under normal operation, as well as overvoltage and reverse-voltage behavior.

Aluminum electrolytic capacitor equivalent circuit (Application guide, Cornell Dubilier)

The capacitance of the capacitor is represented by C.

ESL models the inductive effect of the capacitor, and is mainly due to the loop formed by the terminals and tabs. Its value is typically 1–2 nH/mm for terminal spacing (Parler 2003).

The resistance R S represents the sum of terminals resistance, foils resistance, tabs resistance, paper resistance, and electrolyte resistance.

The resistance R P models the leakage current in the capacitor, and its typical value is 100/C MΩ with C in μF (Application guide, Cornell Dubilier).

The zener diode D models the reverse and under voltage behavior of the capacitor. So, if the capacitor is submitted to a voltage higher than its nominal value, the leakage current will increase significantly; similar behavior has a zener diode when reverse biased over its zener voltage. On the other side, an application of a reverse voltage to the capacitor would lead to a behavior very similar to the zener diode when forward biased.

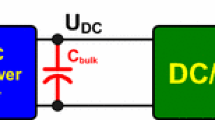

However, if the capacitor is working under normal operation, the circuit of Fig. 4 can be simplified to the one shown in Fig. 5.

Simplified model of an aluminum electrolytic capacitor equivalent circuit (Application guide, Cornell Dubilier), under normal operation

ESR represents the influence of R P and R S and represents the ohmic losses in the capacitor:

The ESR value decreases with temperature and frequency. Higher temperatures make the electrolyte conductivity increase which explains the decrease of ESR. This effect can be modeled through:

where T represents the operating temperature and α, β, and δ are constants that depend on the capacitor type (Venet et al. 2002).

On the other hand, the decrease of ESR with frequency can be justified by (4). Both effects can be observed in Fig. 6.

ESR versus frequency and temperature for a capacitor of 4700 μF, 450 V (Application notes, BHC Components)

4.3 Aging process

The aging of aluminum electrolytic capacitors is expressed by the increase of their ESR and a decrease of C. This phenomenon can be explained by the reduction of the electrolyte volume which decreases the conductivity as well as the effective area between the dielectric and the electrolyte (Fig. 7).

ESR (a) and ∆C/C (b) characteristics under high temperature load tests (Harada et al. 1993)

In fact, the evolution of ESR with aging time, t, for a constant temperature, T, can be modeled through Arrhenius law:

where k represents a constant which depends on the design and construction of the capacitor (Lahyani et al. 1998).

The dielectric formed on the anode side is not uniform, thus there are regions where the thickness is lower than the medium one. Those regions do not stand voltages close to the nominal one, and so a leakage current will be created. However, these capacitors have a mechanism to restore the dielectric defects, the so called self-repairing mechanism (Technical guide, Panasonic). This mechanism consists in the formation of dielectric in the affected regions. For that, the oxygen of the electrolyte combines with the aluminum of the foils to form aluminum oxide. During this process some hydrogen will be released on the cathode side. The self-repairing mechanism increases with time, since the dielectric defects will increase with the aging process, and it is necessary to repair them. Therefore, the electrolyte reduces its volume, and consequently C decreases and ESR increases. Eventually, if the capacitor is not replaced in due time the electrolyte volume is so reduced that will lead to an open circuit failure.

5 Previous work

In the last years many authors have been working in the area of fault diagnosis of aluminum electrolytic capacitors. The major contributions are related to on-line diagnostic techniques, which are very complex, many times difficult to be implemented and dependent on the application. This is mainly due to the fact that capacitor ESR and C change considerable with temperature, frequency, voltage, current ripple, among other factors. To develop an accurate on-line fault diagnostic technique it is required to consider all these factors (Lahyani et al. 1998; Venet et al. 2002; Gasperi 2005).

Other solutions that do not have to consider the previous factors are the off-line diagnostic techniques, since the measurements can be performed always under the same operating conditions.

In (Amaral and Cardoso 2008) the authors presented an experimental technique that allows the computation of both ESR and reactance (X C ) intrinsic values of aluminum electrolytic capacitors for a wide range of frequencies. The proposed technique requires the use of a RC circuit connected to a signal generator followed by a power amplifier. The objective is to create a sinusoidal waveform with enough power and the desired frequency to feed the RC circuit, in order to extract both ESR and X C. The ESR and X C are obtained from a graphical analysis. In (Amaral and Cardoso 2009; Amaral and Cardoso 2008) the previous technique was made automatic through the use of the discrete Fourier transform and of the least mean squares algorithm, respectively. In this approach, the capacitor current and voltage were used instead. In (Amaral and Cardoso 2009) a very simple alternative charge–discharge circuit is also proposed to extract both ESR and X C of aluminum electrolytic capacitors.

The previous off-line diagnostic techniques are quite accurate and precise; however, they require the use of a digital oscilloscope connected to a PC.

In this paper the authors propose a simple fault diagnostic technique that is able to evaluate the capacitor condition without the need of a digital oscilloscope; instead a digital multimeter is used.

6 Proposed technique

The proposed technique uses only the capacitor impedance to estimate both ESR and C.

If the operating frequency is lower than the capacitor resonance frequency, the equivalent circuit of the capacitor can be simplified to the series of an ideal capacitor, C, and a resistor, ESR. Therefore, the impedance of the capacitor, Z CAP, can be defined as:

Using (7), the least mean squares algorithm, and several values of Z CAP at different frequencies, it is possible to estimate the C and the ESR values that best fit Z CAP.

To obtain the Z CAP values at different frequencies a very simple, cheap, and practical experimental setup is used: a RC circuit, composed by the capacitor under test in series with a non-inductive thick film resistor, connected to a signal generator followed by a power amplifier. Following, the root mean square values of the capacitor current, i crms, and voltage, v crms, are measured using a digital multimeter, a Tektronix TX3 True RMS. The impedance is then obtained through:

After the computation of Z CAP for several frequencies, the least mean squares algorithm, LMS, is used to compute the values of ESR and C that better fit Eq. 7.

6.1 Least mean squares algorithm

One strategy for fitting a “best” line through the data would be to minimize the sum of the squares of the residuals, S r:

In order to simplify the process of estimating ESR and C, Eq. 7 is rewritten as:

In order to minimize the sum of the square of the S r (9) is minimized with respect to the coefficients (K X, K Y). Thus, the coefficients can be computed through:

where N, Z CAPi and w i represent the number of tested frequencies, the capacitor impedance at the different tested frequencies, and the corresponding angular frequencies at the different test frequencies.

The values of ESR and C can be computed using:

7 Experimental results

In these experiments three different capacitors with different degrees of aging were used. Thus, capacitor C A represents a sound capacitor, while C B and C C represent two aged capacitors, of the same type of C A, however, with different degrees of aging. Capacitor C C was submitted to a more severe aging test than C B.

Table 1 shows the capacitor characteristics given by the manufacturer:

Table 2 shows the i crms and v crms values obtained through a digital multimeter, for different tested frequencies.

From Table 2 it is possible to compute the Z CAP, at the different tested frequencies, using (8). In this way, using Table 2 together with (11), it is possible to estimate the values of ESR and C that better fit Eq. 7, as can be seen in Table 3.

Figures 8, 9, and 10 show the experimental values Z CAP obtained from Table 2, as well as the fitting Z CAP based on the estimated ESR and C values (Table 3), for C A, C B, and C C, respectively.

Figures 8, 9, and 10 show a very good fitting of the experimental values of Z CAP.

7.1 Accuracy of the proposed technique

In order to evaluate the accuracy of the proposed technique both ESR and C values were obtained at 20 kHz and 100 Hz, respectively, with an Impedance Gain Phase Analyzer Agilent HP 4294 (Table 4).

Afterwards the results of Table 3 and 4 were compared in order to evaluate the accuracy of the proposed technique.

Table 5 clearly shows that the proposed technique is sufficiently accurate. Particularly, it can be observed that the ESR value doubles, and C almost changes 20% when the capacitor is close to its end of life limit. Besides, the error increases with aging, so it is possible to conclude that the proposed technique is conservative.

7.2 Fault diagnosis

In order to evaluate the capacitors condition the experimental results obtained from the proposed technique were analyzed (Table 3).

Figure 11 compares the ESR and C values of C B and C C, with the typical ones for a sound capacitor, and for that a new capacitor was used (C A).

From Fig. 11 it is clear that the ESR of capacitor CC is greater than twice the ESR of a sound capacitor of the same type, and so, capacitor C C should be replaced. However, the ESR of capacitor C B is lower than the limit, thus, it can still be used. Anyway, some attention should be given to this capacitor since the aging process is faster nearby the end of life period.

The capacitance of both aged capacitors (C B and C C) is lower than the limit, which could lead to the opposite conclusion with respect to C C. However, to warrant the reliability of the equipments, when one of the two conditions related to the ESR or C limit is satisfied, the capacitor should be removed.

The proposed technique can also be used to predict the capacitor remaining useful life. For that, the following steps should be implemented:

-

1.

First, several measurements at different aging time periods should be made using the proposed technique, during the initial lifetime. This allows the representation of function (6).

-

2.

In a second step, by using the previous curve together with a fitting algorithm it would be possible to compute K X:

$$ K_{\text{X}} = k \times e^{{ - \frac{4700}{T + 273}}} $$(14) -

3.

Finally, the capacitor remaining useful lifetime can be estimated from (6).

This methodology assumes that the capacitors average operating temperature is almost constant between the measurement periods, so that when computing K X it is assumed a capacitor average operating temperature.

8 Conclusions

In this paper a very simple and cheap off-line technique that is able to evaluate the aluminum electrolytic capacitors condition was proposed.

Aluminum electrolytic capacitors equivalent circuit changes considerable with the operating conditions and aging.

The capacitors internal resistance increases with aging while the capacitance decreases. However, the operating conditions can also influence their values; so, the development of on-line fault diagnostic techniques is many times difficult, expensive, and complex.

Manufacturers define the end of life limit of a capacitor when its internal resistance doubles its initial value or the capacitance changes more than 20% when it is compared with the initial one.

The proposed technique evaluates the capacitor condition through the identification of both capacitor internal resistance and capacitance. To determine both values, the capacitor impedance values at different frequencies are computed using a digital multimeter. Afterwards, using the least mean squares algorithm it is possible to estimate the values of ESR and C that better fit the capacitor impedance.

References

Aluminum electrolytic capacitors. Application notes–TD003, BHC Components, Evox Rifa Group

Aluminum electrolytic capacitors. Technical guide, TGAr-7, Panasonic, Matsushita Electronic Components

Aluminum electrolytic capacitors: general technical information. Epcos, January, 2008

Aluminum electrolytic capacitors: precautions and guidelines, CAT. No. E1001H, Nippon Chemi-con, pp. 3–10

Amaral A, Cardoso A (2008a) An economic offline technique for estimating the equivalent circuit of aluminum electrolytic capacitors. IEEE Trans Inst Meas 57(12):2697–2710

Amaral A and Cardoso A (2008) An automatic technique to obtain the equivalent circuit of aluminum electrolytic capacitors. Proceedings of the 34th annual conference of IEEE Industrial electronics, Orlando, Florida, USA, 10–13 November, 2008, pp. 539–544

Amaral A, Cardoso A (2009a) A simple off-line technique for evaluating the condition of aluminum-electrolytic-capacitors. IEEE Trans Ind Electron 56(8):3230–3237

Amaral A, Cardoso A (2009) Using a simple charge-discharge circuit to estimate capacitors equivalent circuit at their operating conditions. Proceedings of the IEEE International instrumentation and measurement technology conference, Singapore, 5–7 May 2009, pp. 737–742

Application guide, Aluminum electrolytic capacitors, Cornell Dubilier, pp. 2.183–2.202

Dai L, Lin F, Zhu Z, Li J (2005) Electrical characteristics of high energy density multilayer ceramic capacitor for pulse power application. IEEE Trans Magn 41(1):281–284

Efford T, Shibata Y, Ando S and Kanezaki A (1997) Development of aluminum electrolytic capacitors for EV inverter applications. Proceedings of the 32th IEEE industry applications society, annual meeting, New Orleans, Louisiana, 5–7 October 1997, pp. 1035–1041

Fodor D, Klug O, Balint I, Horvath A and Riz A (2006) Electrolyte measurements automation for capacitor research and development. Proceedings of the 12th power electronics and motion control conference (EPE-PEMC 2006), Portoroz, Slovenia, 30 August–1 September, 2006, pp. 1277–1282

Gasperi M (2005) Life prediction model of bus capacitors in AC variable-frequency drives. IEEE Trans Ind Appl 41(6):1430–1435

Harada K, Katsuki A, Fujiwara M (1993) Use of ESR for deterioration diagnosis of electrolytic capacitor. IEEE Trans Power Electron 8(4):355–361

Lahyani A, Venet P, Grellet G, Viverge P (1998) Failure prediction of electrolytic capacitors during operation of switchmode power supply. IEEE Trans Power Electron 13(6):1199–1207

Parler S (2003) Improved spice models of aluminum electrolytic capacitors for inverter applications. IEEE Transactions on industry applications, vol. 39, 4 July/August 2003, pp. 929–935

Poole R (1981) Aluminum electrolytic capacitors: an alternative to tantalum electrolytic capacitors? IEEE Trans Consum Electron CE-27(3):424–432

Sarjeant W, Zirnheld J, MacDougall F (1998) Capacitors. IEEE Trans Plasma Sci 26(5):1368–1392

Tsai M, Lu Y, Do J (2002) High-performance electrolyte in the presence of dextrose and its derivatives for aluminum electrolytic capacitors. J Power Sources 112:643–648

Venet P, Perisse F, Husseini M, Rojat G (2002) Realization of a smart electrolytic capacitor circuit. IEEE Ind Appl Mag 8:16–20

Will N and Fischer E (2000) New electrolytic capacitors with low inductance simplify inverter. Proceedings of the IEEE industry applications conference, Rome, Italy, 2000, vol. 5, pp. 3059–3062

Acknowledgments

The authors wish to thank Professor Beatriz Borges and Eng. Hugo Ribeiro for providing the Impedance Gain-Phase analyzer for the experimental tests. This work was supported in part by the Portuguese Foundation for Science and Technology (FCT) under Project No: SFRH/BD/37093/2007 and Project No: SFRH/BSAB/950/2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amaral, A.M.R., Marques Cardoso, A.J. Condition monitoring of electrolytic capacitors. Int J Syst Assur Eng Manag 2, 325–332 (2011). https://doi.org/10.1007/s13198-012-0085-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-012-0085-x