Abstract

Elm bark (Ulmus pumila L.) flour is a nutritious and sustainable edible material for developing the macromolecular network in the food matrix. In this study, the effects of Elm bark flour and water addition on technological and sensory characteristics of gluten-free whole foxtail millet bread were investigated. Structural analysis methods such as SEM, X-ray diffraction, and FTIR were used to supplement the rheological properties and baking quality. Results showed that Elm bark flour improved gelatinization characteristics and rheological properties (tanδ < 1) of gluten-free dough. Moreover, the porous and network structure of gluten-free bread was observed by image analysis and further confirmed by Fourier transform infrared spectroscopy and X-Ray diffraction, endowing higher specific volume (1.98 ± 0.13 cm3/g), and a decrease hardness from 97.43 to 11.56 N. Additionally, with the incorporation of Elm bark flour–water combination, specific volume (2.15 ± 0.09 cm3/g) and hardness (6.83 ± 0.50 N) were further optimized. Combined with the results of rheological properties and bread structure, Elm bark flour at 15% ratio and water addition at 120% level exhibited the most potent improvement of gluten-free bread. These results might contribute to the potential utilization of Elm bark flour as the sustainable resource in gluten-free products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Celiac disease (CD) is an autoimmune condition triggered by gluten proteins in the wheat, rye, or barley, which affects approximately 1.4% of the global population (Ludvigsson and Murray 2019). Currently, the only effective and safe treatment for CD patients is a strict lifelong glute-free diet. Bread is a staple food in western countries and is widely consumed around the world. However, due to the lack of gluten, producing high quality glute-free bread remains a technical challenge. Gluten plays a vital role in bread making as it forms a viscous, elastic and stretchy dough that aids in gas retention and structure formation. Many studies have been conducted to investigate the potential of food additives such as hydrocolloids, emulsifiers, proteins, and cross-linking enzymes to improve the technological characteristics of gluten-free bread (Capriles and Areas 2014). In addition, researchers have looked into new natural gluten-free edible resources like pseudocereals and insects to improve the nutritional value of gluten-free bread (Martinez-Villaluenga et al. 2020; Nissen et al. 2020). However, the vast majority of gluten-free breads are made primarily from refined flours and starches, which contribute to a high level of fat and sugar, as well as a lack of protein and dietary fiber, resulting to a high risk of chronic diseases such as hyperglycemia and diabetes. Therefore, developing a healthy glute-free bread based on whole grains using functional and nutritional ingredients is of great interest.

Foxtail millet (Setaria italica) is a natural gluten-free cereal that is underutilized. The protein characterization of foxtail millet revealed that its protein concentrate is a potential functional food ingredient, and the essential amino acid pattern suggests that due to its high lysine content, it could be used as a supplementary protein source in most cereals (Saleh et al. 2013). Considerable amounts of dietary fiber (total 7.7 g/100 g, soluble 1.3 g/100 g, insoluble 6.5 g/100 g) and antioxidants, such as polyphenols (1.7 g/kg) and carotenoids (xanthophyll 0.0082 g/kg and zeaxanthin 16.3 g/kg), are present in foxtail seeds (Devisetti et al. 2014; Zhang and Liu 2015). Furthermore, foxtail millet is notable for its ability to grow in dry climates (Sharma and Gujral 2019). Nowadays, the applicability of millet in markets for gluten-free products is gaining popularity (Pessanha et al. 2021).

The Elm (Ulmus pumila L.) tree is a deciduous plant that is widely cultivated for furniture manufacturing in many parts of Asia. The inner bark is the by-product of Elm tree industry and is the only edible part of a tree trunk. Elm inner bark has traditionally been used for making noodles in China, while for making bark bread in western countries due to famine (“Bark Bread” 1886). Nowadays, people attach importance to bark bread not only for daily diet but also for following a sustainable, environmentally friendly and healthy food system. The inner bark contains special mucilage-containing sacs, and the hot water extract of the inner bark consists of pectic substances with excellent gelling and thickening properties, which contribute to the cohesion and network structure formation of crumbly bark bread (Barsett et al. 1992). Additionally, previous reports have confirmed that Elm bark contains a large number of bioactive compounds such as phenols, flavonoids, and triterpenoids, which improve immunocompetence (Ghosh et al. 2012; Kim et al. 2010). Elm (Ulmus pumila L.) bark flour (UBF) has the potential to be a new sustainable, healthy, and nutritious gluten-free bread ingredient based on the characteristics listed above. Water is also an important component in food matrices because it influences food processing properties, shelf life, and sensory acceptability. There have been no studies on the effect of Elm bark flour–water combinations on gluten-free bread to our knowledge.

Therefore, this study aimed to investigate the breadmaking potential of Elm bark flour when incorporated into a gluten-free whole foxtail millet formulation. The effects of various water addition levels on technological and sensory characteristics were also investigated further. We hypothesized that at the optimal level of Elm bark flour–water combination, Elm bark flour could simulate the functional properties of gluten and improve the quality of gluten-free whole foxtail millet bread. This research could help to advance the use of Elm bark flour as a sustainable resource in gluten-free products.

Materials and methods

Materials

Commercial Elm bark flour (UBF, moisture 4.79%, protein 9.75%, fat 0.91%, dietary fiber 12.71%, and carbohydrate 55.35% on a dry basis) with water holding capacity, solubility, and swelling capacity of 300.38%, 75.50%, 1367.61% on dry basis respectively were purchased from the Pastoral Vegetable Company (Changye, China). Foxtail millet “yugu 18” flour (moisture 10.78%, protein 9.22%, amino acid 6.34%, fat 0.06%, and starch 64.87% on a dry basis) were purchased from BGI Millet Co., Ltd. (Shenzhen, China). Millet flour was ground by a lab mill (SY-3000A, Shanyou Machinery Co., Ltd., China). After passing through a 100-mesh sieve (particle size < 0.15 mm), the millet flour was sealed and stored in a valve bag until further production. Sugar, salt, oil, and dry yeast were all purchased from the local market (Nanchang, China).

Pasting properties of mixed raw flour

Pasting properties were determined using a rapid visco analyzer (Perten Ltd, Sweden). The mixed flour (3 g, 14% moisture basis) was transferred into the canister where 25 mL ± 0.1 mL of distilled water was added. Each sample was analyzed at least in triplicate. The curves were recorded, and the peak viscosity, trough viscosity, final viscosity, breakdown viscosity, setback viscosity, peak time, and pasting temperature (Kaur et al. 2016) were calculated by the rSpace ver. 1.72 software (Malvern Instruments Ltd, UK).

Rheological properties of gluten-free dough

The dynamic rheological properties of the dough were tested using a strain-controlled MCR302 rheometer (Anton Paar, Austria). The measuring system was consisted of parallel plate geometry (50 mm diameter, 2 mm gap). Doughs were prepared as described in Table S1 (See Supplementary file) but without yeast addition to avoid bubbles during fermentation. The dough (50 g) was rolled out to a thickness of 2–3 mm before being loaded between the plates for 5 min to equilibrate. The edge of the dough was coated with a thin layer of silicone oil to prevent dehydration during the tests. Small-amplitude oscillatory strain sweep experiments (0.01–100%) were performed and a frequency of 1 Hz was selected to determine the region of linear viscoelasticity for the dough samples. Frequency sweep measures (0.01–10 Hz) were performed at a constant strain of 0.1% in the linear viscoelastic region (Li et al. 2019). The experiment was performed at 25 °C and the dough was measured within 1 h.

Gluten-free bread making

Wheat bread (WB) was compared to gluten-free bread under the same production conditions. The wheat bread formulation was based on 100 g of wheat flour with 100 g of water added, and other ingredients are the same as in gluten-free bread. The recipe of all gluten-free bread contained UBF and foxtail millet flour that was considered as 100% flour. Based on previous work in the authors' laboratory (unpublished), the amount of UBF and water addition to the formulation was tentatively determined. Firstly, four UBF substitution levels (5%, 10%, 15%, 20%) at a fixed water level (100%) were tested. Then, the effect of adding water (90%, 100%, 110%, 120%, 130%) on the quality of gluten-free foxtail millet bread was investigated at the fixed UBF level (15%). Other ingredients such as dry yeast (2 g), salt (1 g), vegetable oil (3 g), and sugar (2 g) (on a 100 g of flour mixture) were also added to each recipe.

Sugar and salt were dissolved in water at 40 °C, and yeast was activated in water at 38 °C in advance. All ingredients were mixed for 3 min on low speed and 2 min on high speed in a dough mixer (Jiuyang Co., Ltd., China). The divided dough (300 g) was then proofed for 1.5 h at 37 ± 1 °C in a proofing box (Cass Electric Co., Ltd., China) with a relative humidity of 85%. The proofed dough was then baked in an oven (Cass Electric Co., Ltd., China) at 170 °C for 40 min. Measurements of specific volume and crumb color in bread were performed at least 2 h after baking when they reached room temperature. Sensory analysis was evaluated after storing at room temperature for 18 h. For other quality measurements, bread loaves were sealed in polypropylene bags and stored at 4 °C until further analysis.

Determination of gluten-free bread properties

Bread specific volume

The volume of gluten-free bread was determined using the rapeseed displacement method (AACCI 2000), and the specific volume (cm3/g) was the ratio of the volume (cm3) to the weight of the bread (g).

Crumb color determination

The bread was cut into uniform slices with a thickness of 2.5 cm, and the crumb color was measured using a portable colorimeter (Sanenchi Technology Co., Ltd. China). Five azimuth points were measured for each sample (upper left, lower left, upper right, lower right and center). L* denotes brightness (0 was black, 100 was white), a* means hue on a green (−) to red (+), and b* denotes hue on a blue (−) to yellow (+) (Djordjevic et al. 2019).

Crumb image analysis

The center of the bread slice was scanned at 150 dpi (dots per inch) with a scanner (Hp Officejet MFP M132nw series), and the internal texture structure of the bread was analyzed using the software Image J. The analysis was performed independently for each image, which consisted of an area (3 × 3 cm2) from the center of the slice. The selected crumb characteristics were the total number of pores in 3 × 3 cm2 (Count), pore number per square centimeter (CD), average pore area (AS), and the percentage of the pore area in the total area (AF).

Texture profile analysis

Texture profile analysis (TPA) was performed using a CT3 texture analyzer (Brookfield, US). After storage for 18 h, three bread slices (25 mm thickness) taken from the center of each loaf were cut into 25 × 25 × 25 mm3 cubes, then measured three times at selected parameters (P/30 probe, pre-test speed of 2.0 mm/s, test speed of 2 mm/s, return speed of 2 mm/s, compression deformation of 40%, induction force of 5 g, and two compression time intervals of 5 s) reported by da Rosa Machado and Thys (2019). Finally, the hardness, springiness, chewiness, and resilience of the bread crumbs were calculated and represented by the average value.

Scanning electron microscopy

The bread samples for scanning electron microscopy (SEM) analysis were stored for 18 h before being frozen (− 20 °C) and freeze-dried. The freeze-dried bread crumb pieces were then scanned and photographed using a JSM-6701F cold field emission scanning electron microscope (Electronics Corporation, Japan) in variable-pressure mode at a 10 kV accelerating voltage and a 30 Pa vacuum. The samples were sprayed with a golden coating during the test. Scanning electron micrographs were taken at various magnifications (300× and 1000× for bread with different UBF addition levels; 500× and 1500× for bread with different water addition) (Ozkoc et al. 2009).

X-ray diffraction

A D8 Advance X-ray Diffractometer (BRUKER, Germany) was used to examine the crystallinity of the retrograded starch due to staling. Bread slices were freeze-dried and ground into a fine powder after being stored at 4 °C for four days. The X-ray diffraction (XRD) analysis of the sample (200 mg) was carried out at selected parameters (tube voltage of 45 kV, tube current of 40 mA, scan speed of 0.008°/s, scan area of 6°–46° (2θ), step size of 0.04, divergence slit of 1°, antiscatter slit of 2°, receiving slit of 0.4 mm) reported by Skendi et al. (2018).

Fourier-transform infrared spectroscopy

Fourier-transform infrared spectroscopy (FTIR) spectra of the freeze-dried bread crumbs were obtained using a Nicolet iS50 IR spectrometer (Thermo Fisher, US). The freeze-dried and grounded bread sample (2.0 mg) was mixed with KBr (0.2–0.4 mg) before being scanned in the 500–4000 cm−1 range (Skendi et al. 2018).

Differential scanning calorimetry

The thermal properties of the bread samples (7–13 mg) were determined using a TGA 4000 thermogravimetric analyzer (PE, US), with the onset temperature (TO), peak temperature (TP), conclusion temperature (TC), and enthalpy (ΔH) recorded. The scanning temperature was set in a range of 25–150 °C with a heating rate of 10 °C/min (Kiumarsi et al. 2019).

Sensory evaluation

Sensory evaluation of bread was performed after 18 h of storage. Three bread slices (25 mm thickness) taken from the center of each loaf were cut into 25 × 25 × 25 mm3 cubes. Samples were coded and placed randomly on the trays and scored by each team member in different compartments under normal light conditions at room temperature (25 °C). The sensory evaluation member team consisted of 10 master's students (5 males and 5 females) from Nanchang University, China, majoring in Food Science and Technology.

The analysis standard was modified by referring to the method of Djordjevic et al. (2019). For evaluation, the sample was scored on the scale of 1.0–5.0 and multiplied by the weighting factor (IC). The following quality parameters were evaluated: external appearance (shape, color, surface, and crust properties) IC = 20.0%; crumb appearance (color uniformity, uniformity and fineness of pores, elasticity) IC = 30.0%; smell IC = 17.5%; taste IC = 32.5%. Based on the total score, the bread was classified as excellent (4.5–5.0); very good (3.9–4.4); good (3.4–3.8); acceptable (2.8–3.3); and unacceptable (< 2.8).

Statistical analysis

All data were reported as mean ± standard deviation and compared using one-way ANOVA with Fisher's least significant difference (LSD) and Tamhane's T2 test at a significance level of 0.05 (p < 0.05). SPSS statistical software (IBM SPSS Statistics version 24) was used to perform the statistical methods.

Results and discussion

Effects of UBF substitution ratio on the rheological properties of raw material

Pasting properties

Gelatinization, which is closely related to product quality, is one of the important parameters that characterize the processing adaptability of starch raw materials (Kaur et al. 2016). The trough and final viscosities were significantly higher in the UBF replacement group than in the control group (Table S2 in the Supplementary file), while the breakdown viscosity and setback viscosities were significantly lower (p < 0.05), which was consistent with previous research that adding hydrocolloids could reduce the setback value of the composite dough (Li et al. 2019). The 10% UBF level had the highest through viscosity and final viscosity (2523 ± 200 cp and 3739 ± 137 cp, respectively), while the 20% UBF level had the lowest breakdown viscosity and setback viscosity (816 ± 175 cp and 1031 ± 197 cp, respectively). There was no statistical difference in breakdown and setback values between the UBF replacement group and the wheat group (p > 0.05), indicating that the UBF-containing mixed flour had similar processing properties to wheat flour and could be the promising material for making gluten-free bread.

Rheological behavior

Frequency sweep analysis can be used to assess viscoelasticity over a wide frequency range. The solid-like behavior of the dough, which was expressed by the storage and loss modulus (G′ and G″, respectively) could reflect elasticity and viscosity. As shown in Figure S1 (See Supplementary file), the storage modulus (G') was higher than the loss modulus (G") for all dough samples in all tested frequency ranges, thus demonstrating the behavior of the viscoelastic solid. Furthermore, the G′ value of the control group was clearly higher than that of other groups. The addition of UBF reduced the G′and G″ of each group, indicating that UBF decreased the elasticity of the dough. Because of the addition of UBF, the dough had a tendency to transform into a liquid structure. The loss factor (tanδ = G″/ G′) represented the relationship between storage modulus and loss modulus. Fig. S1C demonstrated that the loss factor (tanδ) of all the dough was less than 1, which was consistent with the results of storage and loss modulus, indicating the dough had low fluidity and resembled a solid state. The changing trend of the rheological properties of dough in this study was similar to that of the modified gluten-free bread with α-amylase (Sadeghian Motahar et al. 2021).

Effects of UBF level on the quality of gluten-free foxtail millet bread

Specific volume

As the UBF ratio increased, the specific volume of bread increased from 1.25 cm3/g for control to 1.98 ± 0.13 cm3/g for 15% UBF (p < 0.05), which was close to wheat bread (WB) (2.11 ± 0.07 cm3/g), indicating that UBF could act as a gluten substitute, effectively improving the specific volume of gluten-free bread (Table 1). The increase of bread specific volume might be related to the formation of reducing sugar in the fermentation process, the decrease of viscosity of starch in the gelatinization process, or the influence of dietary fiber content on the redistribution of water in bread components, which was confirmed by previous researches (Skendi et al. 2018). Furthermore, the Elm bark flour bread had high water-holding and swelling capacities during baking (300.38% and 1367.61%, respectively), locking the water in the crumb network, which was the main reason for the increased specific volume of Elm bark flour bread. However, at a 20% UBF substitution ratio, the specific volume of bread decreased slightly. This result could be attributed to the presence of excessive hydrocolloids, which could result in limited air chamber expansion, lowering bread specific volume (Djordjevic et al. 2019).

Crumb color

The addition of UBF had a significant effect on the color of gluten-free bread (p < 0.05) (Table S3 in the Supplementary file). As the proportion of UBF in gluten-free foxtail millet bread increased, the L* and b* values decreased, and the a* value increased. At 15% UBF addition, the values of L* and b* were reduced by 14.53% and 39.45%, respectively, while the of a* was increased by 201.97%. The color change in this study was caused by the brown color of UBF itself, as well as the caramel reaction and Maillard reaction produced by the polysaccharides and proteins in UBF during fermentation and baking.

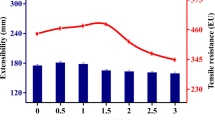

Crumb structure

Gluten-free bread of high quality should have uniform, small, and numerous gas cells. Figure 1 depicts the images used for software analysis, and the image analysis data were presented in Table 1. After adding UBF, the value of pore number per square centimeter (CD) and the percentage of the pore area in the total area (AF) of bread increased significantly (p < 0.05), while the value of average pore area (AS) decreased significantly (p < 0.05), indicating that UBF improved the structure of whole foxtail millet dough during fermentation, stabilized the stomatal interface film, and formed dense and delicate pores. Bread containing 20% UBF had no statistically significant difference from wheat bread in terms of the CD and AS values (p > 0.05), while the AF value was lower (p < 0.05). The pore structure of millet bread containing UBF was found to be very similar to that of wheat bread, and UBF played a positive role in improving the core structure of bread. SEM results confirmed this phenomenon even more (Fig. 2). This could be due to the combination of the UBF polysaccharides and the macromolecules (such as protein) in the bread during the bread-making, which resulted in the formation of filamentous networks. The crumb structure was closely related to the specific volume of the bread. The more gas retained in the bread, the large its specific volume.

Crumb texture

Textural characteristic was an important factor for baked products because they were related to consumers' perception of bread freshness. The control bread had a firm and compact texture, with hardness and chewiness of 97.43 N and 37.93 N, respectively. TPA results showed that UBF has a softening effect on the hardness of bread crumbs (Table 1). The hardness and chewiness of bread were reduced by 88.13% and 87.77% at a 20% UBF level, respectively (p < 0.05). The water holding capacity of UBF was as high as 300.38%, which increased the amount of freezable water in the bread during baking by trapping water in the crumb network, and these actions contributed to a softer crumb by reducing the hardness. It was reported that gluten-free bread had a shorter shelf life than wheat bread, which is related to high hardness caused by the loss of the gluten protein network (Capriles et al. 2016). As a result, reducing the hardness of crumbs in UBF bread may extend the shelf life of gluten-free bread. However, UBF was less effective in improving the springiness and resilience of whole foxtail millet bread, which is consistent with the reduced storage and loss modulus in the previous rheological properties of the dough. Glutenin and gliadin in wheat flour strengthened the gluten network, whereas the structure of gluten-free flour is primarily determined by macromolecule interactions.

Analysis of thermodynamic properties of bread

Starch retrogradation causes rapid recrystallization of amylose and slow recrystallization of amylopectin. Differential scanning calorimetry (DSC) was used to analyze the thermal properties of starch in bread during storage. The gelatinization enthalpy (ΔH) value reflected the energy required to gelatinize the starch granules, the higher the energy value, the more severe the starch aging. It was discovered that all millet bread samples replaced with UBF had lower enthalpy than the control (Table S4 in the Supplementary file). Witczak et al. (2019) observed a high linear correlation between bread hardness and enthalpy of retrograded amylopectin decomposition could be found (r = 0.81). In addition, the TO, TP, and TC were also decreased with the addition of UBF. The reduction in amylose recrystallization in UBF bread might be due to the high crude polysaccharides (55.35%) in UBF as sugar has been shown to inhibit starch regeneration and the aging of starchy foods (Baek et al. 2004).

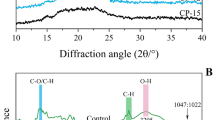

X-ray diffraction analysis of bread

Figure 3A shows an XRD analysis of bread flour after 4 days of storage at 4 °C. The XRD pattern revealed that the bread flour exhibited distinct diffraction peaks at 2θ = 17° and 20°. The diffraction peak of the control group was the highest and had the greatest width. As the proportion of UBF increased, the diffraction peak gradually weakened and the width narrowed. The half-width and peak height of the XRD pattern were related to the crystallinity of starch. The higher peak and larger peak area indicated higher crystallinity and more severe starch aging and retrogradation. According to Fig. 3A, higher UBF addition resulted in a less recrystallized structure in the bread, which could be due to the polysaccharides in the UBF inhibiting the re-association of starch macromolecules. This was consistent with the DSC results (Table S4), which indicated that UBF could delay starch aging and thus extend bread shelf life.

Fourier transform infrared spectroscopy analysis of bread

The vibrational form of molecular groups (chemical bonds) and the chemical environment in which they were located determine the position and intensity of absorption peaks in the infrared spectrum. The absorption peak at 3500–3200 cm−1 in the spectrum represented hydrogen bonding between molecules and –OH stretching vibration, which was mainly bound between water and starch matrix. The absorption peak intensity in the UBF group was higher than that in the control group, indicating the interaction between water and matrix was more powerful (Fig. 3B). Water molecules were more likely to form hydrogen bonds with functional groups in high-molecular polymers, which required for lower energy of -OH stretching vibration.

The UBF polysaccharides increased the intensity of the double peak at 1070 cm−1, which was the characteristic absorption of furanoside, Moreover, previous research found that a higher and sharper peak in the 950–1100 cm−1 range indicated a more ordered polysaccharide conformation with fewer conformations (Sivam et al. 2013). Furthermore, the absorption peaks at 2900 cm−1 and 1750 cm−1 represented the aldehyde group and carbonyl stretching vibration absorption peaks respectively. Comparing with the control bread, the intensity of the aldehyde group vibration absorption peak of UBF-containing bread increased, which could be attributed to the increased content of reducing sugar in the UBF group. The reducing sugar may transform into substances containing aldehyde groups during the fermentation and baking processes.

Sensory evaluation

Sensory evaluation of bread was performed after 18 h of storage (Fig. 3). Panelists gave scores from 1.0 to 5.0 on four characteristics: external appearance, crumb appearance, smell, taste, and the average values were calculated. Control bread after 18 h of storage was evaluated negatively with respect to external appearance (1.9 points) and taste (2 points). All breads containing UBF had significantly higher crumb appearance score and taste score compared to the control bread (p < 0.05). The addition of Elm bark flour decreased the bread smell score due to the bitter taste of Elm bark itself but did not result in a statistical change. The overall acceptance score of UBF bread (3.3, 3.3 and 3.2 point for 20%, 15% and 10% UBF level respectively) was higher than that of control group (2.6 point) (p < 0.05), but lower than wheat bread group (4.2 points). Torbica et al. (2019) found that all breads made from gluten-free flours were harder and more granular mouth feel. The addition of Elm bark flour made the originally unacceptable whole foxtail millet bread acceptable; however, there was still a gap with wheat bread, and further improvement of Elm bark bread's sensory aspect was necessary to make it more marketable.

Effects of water addition on the quality of gluten-free foxtail millet dough and bread

Rheological properties of gluten-free dough

The rheological properties of dough could be affected by adding water. As shown in Fig. S2 (See Supplementary file), G′and G″of dough with 90% water addition were the highest, followed by 120% water content, while G′ and G″ of dough with 130% water addition were the lowest. When the water content in bread was low (90%), the polysaccharides and fibers of UBF could absorb water and swell, making the dough more viscoelastic. At the moderate water level (100–120%), the water-absorbing particles infiltrated into the water, and the dough absorbed water sufficiently and crosslinked to form a network structure, endowing it with good viscoelasticity. However, too much water (130%) may weaken the intermolecular coupling in the dough, resulting in poor viscoelasticity.

Macro and micro-structure of dough and bread

As shown in Fig. S3 (See Supplementary file), the surface of the dough before fermentation became more viscous with the addition of water. The dough with 130% water addition in particular, was too viscous to shape, which was not conducive to bread processing. The pores on the surface of the dough became more visible after fermentation, and the volume increased significantly as the water addition increased, particularly for 120% and 130% water addition. This possibly due to the high water-holding capacity and swelling capacity of UBF (300.38% and 1367.61%, respectively). Water molecules interacted with the hydrophilic groups of UBF polysaccharides during fermentation, causing the hydrophilic colloid to expand and crosslink to form a network skeleton. In a word, the dough with 120% or 130% water addition performed better during fermentation. However, according to the baking bread photographs, huge holes appeared in the bread after adding too much water, which was related to the unstable structure of the gluten-free matrix. A study reported by de la Hera et al. (2014) also showed that too much water could cause large holes in bread crumbs.

The round starch granules were wrapped in the network structure formed by UBF polysaccharides, indicating that the UBF polysaccharides could simulate the formation of a three-dimensional network of gluten protein (Fig. 4). The network structure formed by mutual cross-linking between starch molecules was visible at 500× magnification in doughs with water additions of 120% and 130%, respectively. Furthermore, the pore structure between starch molecules could be found at 1500× magnification, indicating that with the increase of water addition, the water absorption and the swelling and gas-holding capacity of polysaccharides in bread increased. In addition, the pores in the bread crumbs with 90–110% moisture addition were not visible, the bread crumb with 120% water addition had a uniform cell structure, and the bread crumb with 130% water addition had a visible fractured and hollow structure.

Water addition was negatively correlated with the number of pores (CD) and positively correlated with the average area of pores (AS) (Table 2). The CD value of bread reached the lowest (19.66 ± 0.73 cell/cm2), and AS value reached the highest (1.45 ± 0.01 mm2) at the water level of 130%. Previous research also found that higher water levels could ameliorate the structure of bread (Skendi et al. 2018).

Specific volume

The specific volume of bread increased with water addition, reaching its maximum at 130% water addition (2.15 cm3/g). There was no significant difference between bread with 100–120% water addition. Because too much water (130%) could result in a fractured and hollow structure, the optimal water addition was about 100–120% (Table 2).

Crumb texture

The hardness of bread crumbs decreased significantly (p < 0.05) with the water addition, and reached the lowest at 130% water level (6.83 ± 0.50 N). Moreover, the downward trend of chewiness also indicated that the bread crumb structure had become softer (Table 2). Thus, high water addition could have a positive effect on the mouthfeel. A previous study also found that water addition could significantly reduce the hardness of gluten-free bread prepared with oat and quinoa bran (Aprodu and Banu 2015). In addition, the resilience of bread was also increased, which might be related to the improvement of crumb elasticity.

Conclusion

In summary, the optimization of Elm bark flour and water significantly improved the technological characteristics of the foxtail millet bread, resulting in a larger specific volume and a softer texture. During fermentation, water molecules interacted with the hydrophilic groups of UBF polysaccharides, causing the hydrophilic colloids to swell and crosslink to form a network skeleton, which significantly improved the texture of the bread. These findings suggested that Elm bark flour is a promising material for making gluten-free products. However, further investigation of the public's acceptance of elm bark bread is needed to accommodate consumers and the market.

References

AACCI (2000) Approved methods of the AACCI. Method 10-05.01, 11th edn. The American Association of Cereal chemists, St. Paul

Aprodu I, Banu I (2015) Influence of dietary fiber, water, and glucose oxidase on rheological and baking properties of maize based gluten-free bread. Food Sci Biotechnol 24(4):1301–1307

Baek MH, Yoo B, Lim ST (2004) Effects of sugars and sugar alcohols on thermal transition and cold stability of corn starch gel. Food Hydrocolloids 18(1):133–142

Bread B (1886) Nature 33(853):429–429

Barsett H, Aslaksen T, Bratvedt A, Paulsen BS (1992) Enzymatic degradation of pectic substances isolated from the inner bark of Ulmus-Glabra Huds. Carbohydr Polym 18(3):209–216

Capriles VD, Areas JAG (2014) Novel approaches in gluten-free breadmaking: interface between food science, nutrition, and health. Compr Rev Food Sci Food Saf 13(5):871–890

Capriles VD, dos Santos FG, Areas JAG (2016) Gluten-free breadmaking: improving nutritional and bioactive compounds. J Cereal Sci 67:83–91

da Rosa MC, Thys RCS (2019) Cricket powder (Gryllus assimilis) as a new alternative protein source for gluten-free breads. Innov Food Sci Emerg Technol 56:102–180

de la Hera E, Rosell CM, Gomez M (2014) Effect of water content and flour particle size on gluten-free bread quality and digestibility. Food Chem 151:526–531

Devisetti R, Yadahally SN, Bhattacharya S (2014) Nutrients and antinutrients in foxtail and proso millet milled fractions: evaluation of their flour functionality. LWT - Food Sci Technol 59(2):889–895

Djordjevic M, Soronja-Simovic D, Nikolic I, Djordjevic M, Seres Z, Milasinovic-Seremesic M (2019) Sugar beet and apple fibres coupled with hydroxypropylmethylcellulose as functional ingredients in gluten-free formulations: rheological, technological and sensory aspects. Food Chem 295:189–197

Ghosh C, Chung HY, Nandre RM, Lee JH, Jeon TI, Kim IS, Yang SH, Hwang SG (2012) An active extract of Ulmus pumila inhibits adipogenesis through regulation of cell cycle progression in 3T3-L1 cells. Food Chem Toxicol 50(6):2009–2015

Kaur A, Shevkani K, Katyal M, Singh N, Ahlawat AK, Singh AM (2016) Physicochemical and rheological properties of starch and flour from different durum wheat varieties and their relationships with noodle quality. J Food Sci Technol 53(4):2127–2138

Kim SI, Sim KH, Choi H-Y (2010) A comparative study of antioxidant activity in some Korean medicinal plant used as food materials. Mol Cell Toxicol 6(3):279–285

Kiumarsi M, Shahbazi M, Yeganehzad S, Majchrzak D, Lieleg O, Winkeljann B (2019) Relation between structural, mechanical and sensory properties of gluten-free bread as affected by modified dietary fibers. Food Chem 277:664–673

Li J, Zhu Y, Yadav MP, Li J (2019) Effect of various hydrocolloids on the physical and fermentation properties of dough. Food Chem 271:165–173

Ludvigsson JF, Murray JA (2019) Epidemiology of celiac disease. Gastroenterol Clin North Am 48(1):1–18

Martinez-Villaluenga C, Penas E, Hernandez-Ledesma B (2020) Pseudocereal grains: nutritional value, health benefits and current applications for the development of gluten-free foods. Food Chem Toxicol 137:111178

Nissen L, Samaei SP, Babini E, Gianotti A (2020) Gluten free sourdough bread enriched with cricket flour for protein fortification: antioxidant improvement and Volatilome characterization. Food Chem 333:127410

Ozkoc SO, Sumnu G, Sahin S (2009) The effects of gums on macro and micro-structure of breads baked in different ovens. Food Hydrocoll 23(8):2182–2189

Pessanha KLF, Menezes JPD, Silva ADA, Ferreira MVDS, Takeiti CY, Carvalho CWP (2021) Impact of whole millet extruded flour on the physicochemical properties and antihyperglycemic activity of gluten free bread. LWT Food Sci Technol 147:111495

Sadeghian Motahar SF, Ariaeenejad S, Salami M, Emam-Djomeh Z, Sheykh Abdollahzadeh Mamaghani A (2021) Improving the quality of gluten-free bread by a novel acidic thermostable alpha-amylase from metagenomics data. Food Chem 352:129307

Saleh ASM, Zhang Q, Chen J, Shen Q (2013) Millet grains: nutritional quality, processing, and potential health benefits. Compr Rev Food Sci Food Saf 12(3):281–295

Sharma B, Gujral HS (2019) Influence of nutritional and antinutritional components on dough rheology and in vitro protein and starch digestibility of minor millets. Food Chem 299:125115

Sivam AS, Sun-Waterhouse D, Perera CO, Waterhouse GIN (2013) Application of FT-IR and Raman spectroscopy for the study of biopolymers in breads fortified with fibre and polyphenols. Food Res Int 50(2):574–585

Skendi A, Mouselemidou P, Papageorgiou M, Papastergiadis E (2018) Effect of acorn meal-water combinations on technological properties and fine structure of gluten-free bread. Food Chem 253:119–126

Torbica A, Belovic M, Tomic J (2019) Novel breads of non-wheat flours. Food Chem 282:134–140

Witczak M, Korus J, Ziobro R, Juszczak L (2019) Waxy starch as dough component and anti-staling agent in gluten-free bread. LWT Food Sci Technol 99:476–482

Zhang LZ, Liu RH (2015) Phenolic and carotenoid profiles and antiproliferative activity of foxtail millet. Food Chem 174:495–501

Funding

This work was supported by the International Science and Technology Cooperation Program of China [Grant number 2013DFG31380]; Central Government Guide Local Special Fund Project for Scientific and Technological Development of Jiangxi Province [Grant number 20212ZDD02008]; and the Interdisciplinary Innovation Fund of Natural Science, Nanchang University [Grant number 9166–27060003-YB15].

Author information

Authors and Affiliations

Contributions

JL, YW contributed to the conception of the study; JL, MX, SH performed the experiments; JL, FM, TY, JY contributed significantly to analysis and manuscript preparation; YW, JG, HC helped perform the analysis with constructive discussions.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, J., Hu, S., Xu, M. et al. Elm (Ulmus pumila L.) bark flour as a gluten substitute in gluten-free whole foxtail millet bread. J Food Sci Technol 60, 1163–1174 (2023). https://doi.org/10.1007/s13197-023-05670-x

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-023-05670-x