Abstract

This study focused on the microencapsulation of enterocin from Enterococcus durans (E. durans MF5) in whey powder (WP) using a spray-drying technique followed by the evaluation of how complexation can preserve the enterocin structure and antimicrobial activity against food-borne pathogens. Crude enterocin samples (1 and 5%) were microencapsulated in 10% WP. The antimicrobial activity of unencapsulated (crude) enterocin and microencapsulated enterocin was tested against the target bacteria Salmonella Typhimurium, Escherichia coli, Listeria monocytogenes, Listeria innocua, and Listeria ivanovi. The microencapsulation yields were 31.66% and 34.16% for concentrations of 1 and 5% enterocin, respectively. There was no significant difference between these concentrations. Microencapsulated enterocin was efficient for up to 12 h of cocultivation with Listeria sp., and the concentration required to inhibit the growth of target bacteria presented values of 6400 AU/mL (arbitrary unit). Microencapsulated enterocin demonstrated enhanced efficacy against Listeria species and E. coli when compared with crude enterocin (p < 0.05). Fourier transform-infrared spectroscopy and differential scanning calorimetry results confirmed the presence of enterocin in the microparticles. Scanning electron microscopy showed cell damage of the target bacteria. The results showed that complexation with WP preserved enterocin antimicrobial activity during spray-drying, indicating its potential use as a food preservative.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Increased consumer demand for artificial additive-free and long shelf-life foods places pressure on the industry for the development of alternative additives to obtain safe and healthy food. Therefore, the importance of natural preservative compounds is increasing due to the more extensive use of such compounds in food rather than synthetic compounds (Sidhu and Nehra 2020).

Bacteriocins are antimicrobial peptides (AMPs) ribosomally synthesized on lactic acid bacteria that are capable of inhibiting both food pathogens and bacteria from gram-negative and gram-positive groups and represent a very promising strategy in food conservation (Calo-Mata et al. 2008; Acuña et al. 2015). They can be produced by several bacterial species, including nisin, subtilin, lichenicidin, cinnamycin, actagardine, epidermin, lacticin, carnobacteriocin, piscicolin, divergicin, mutacin, mundticin, mesenterocin, enterocin, sakacin, leucocin, curvacin, enterocin, lysostaphin, duramycin, brevinin, ruminococcin, curvaticin, and columbicin (Kumariya et al. 2019). The main target of bacteriocins is the bacterial cell membrane, causing cell permeabilisation and pore formation, thus leading to cell death (Nilsen et al. 2003).

The interest in the use of enterocins from the genus Enterococcus as bio-preservatives has increased considerably because of their high antilisterial activity (Jaouani et al. 2014). Most bacteriocins are heat stable, stable at low pH values, nontoxic to humans, and sensitive to proteases present in the human gut; thus, their use as a food preservative can meet the demands of consumers for safe food (Sidhu and Nehra 2020). Enterocin antimicrobial activity can be efficient against some gram-negative pathogenic bacteria, such as Salmonella sp. and Escherichia coli, causing cell wall alteration (Tosoni et al. 2019).

However, despite having several advantages, the association of bacteriocins with the food matrix can compromise their antimicrobial action. These stresses include the action of proteases, pH, and other matrix actions and can result in the unfolding of peptides with subsequent aggregation or denaturation, creating substantial problems regarding a possible loss of their antimicrobial activity (Lee 2002).

In this context, microencapsulation techniques have received special attention for protecting the encapsulated material from adverse environmental conditions, such as high acidity, the presence of hydrolytic enzymes, extreme temperatures, chemicals, bile salts, molecular oxygen, and antimicrobial agents (Srivastava et al. 2013). Among the different approaches used for microencapsulation, the spray-drying process represents the principal technique frequently applied for microencapsulation due to its available equipment and low cost (Tavares et al. 2019). Similar to the choice of technique, the encapsulating material is also important. Choosing a material that is low cost, easy to obtain, and has well-established nutritional value for consumers is extremely significant in the encapsulation process (Korma et al. 2019). Therefore, in our work, whey protein (WP) was chosen as an encapsulating agent for enterocin.

WP is a dairy protein prepared from by-products of cheese production, formed by a mixture of β-lactoglobulin, α-lactalbumin, bovine serum albumin, immunoglobulins, and other minor proteins. Thus, it is commonly applied in encapsulation to enhance the stability of compounds, such as essential oils, probiotics, and bacteriocins (Wang et al. 2018; Condurache et al. 2019; Puttarat et al. 2021). In contrast, the encapsulation of enterocin in whey protein is poorly reported.

The interest in species of the genus Listeria is because it contains more thermoresistant species; among them, L. monocytogenes has been widely related to postprocessing contamination (Luque-Sastre et al. 2018). In the genus Listeria, L. monocytogenes and L. ivanovii are two pathogenic food-borne pathogens involved in several listeriosis outbreaks, and they represent a severe human and animal disease with high mortality rates among elderly and immunocompromised individuals (Beye et al. 2016; Jordan and McAuliffe 2018). Additionally, other Listeria species have gained attention as pathogens. For instance, L. innocua has been shown to be capable of infecting mouse and zebrafish cells (Moura et al. 2019) and have the ability to invade Caco-2 cells at the same levels as L. monocytogenes (den Bakker et al. 2010).

Thus, the purpose of this study was to investigate the viability of enterocin microencapsulation by spray drying with whey protein and the antimicrobial efficiency of the resulting microencapsulated enterocin against foodborne pathogens Listeria sp. and others.

Material and methods

Samples

The study was conducted with bacteriocin-producing strain E. durans strain MF5. It was isolated from whey in previous studies (Tosoni et al. 2019). Enterotoxigenic Escherichia coli (E. coli ETEC, Salmonella Typhimurium strain ATCC 68,169/UK-1, L. monocytogenes, L. innocua strain CLIP 12,612, and L. ivanovi were used as indicator microorganisms (foodborne pathogens).

Strains belong to the Laboratory of Basic and Applied Microbiology (LAMBA) of the Federal University of Technology-Paraná (Londrina, PR, Brazil) and were maintained at – 80 °C in Brain Hearth Infusion (BHI Neogen Culture Media, USA) broth supplemented with 20% glycerol. Before use, the frozen stock was inoculated into 10 mL in De Man, Rogosa and Sharpe (MRS—Neogen Culture Media, USA) medium for E. durans MF5 and BHI to other strains, maintained at 37 ºC for 24 h.

Production and precipitation of enterocin

The strain E. durans MF5 was cultured in MRS (pH 6.2) adjusted to 1.0 × 108 colony forming unit/mL (CFU/mL) and maintained at 180 rpm for 24 h at 37 °C. The culture was centrifuged at 7000 rpm for 15 min. The supernatant was adjusted to pH 6.5 with 1 N NaOH and lyophilized (Liotop, L101 Liobrás) for precipitation. The obtained powder was diluted in sterile ultrapure water to a final concentration of 100 mg/mL.

Microencapsulation of enterocin and determination of powder yield

Enterocin encapsulation was performed following the protocol described by Xiao et al. (2011) with modifications. The encapsulating matrix (10%wt/v WP, SOORO®, Brazil) was aseptically added to vials containing sterile water and kept under magnetic stirring for 30 min to hydrate the powder. Two concentrations of enterocin were prepared at 1 and 5 wt% of the lyophilized enterocin in relation to the whey encapsulation solution.

The solutions were subjected to spray drying (LabMaq MSD1.0), under the following conditions: 150 °C at the inlet temperature; outlet temperature equal to 110 °C; air pressure 5.0 kgf/cm2 and flow rate of 0.8 L/h. The negative control was produced using only the encapsulating agent (WP powder). The microcapsule powders were collected from the cyclone chamber to sterile bottles and stored at 4 °C.

After the spray-drying process, the mass of dry powder was measured to calculate the percentage of powder yield (η %) according to the Eq. 1 (Xiao et al. 2011):

Antimicrobial activity and determination of the arbitrary units

The antimicrobial activity of crude and encapsulated enterocin were determined as described by Furlaneto-Maia et al. (2020). Thus, 20 mL of 0.8% semi-solid BHI medium containing the target bacteria (Salmonella Typhimurium, E. coli, L. monocytogenes, L. innocua, L. ivanovi) at a concentration of 1.5 × 108 cells/mL, were transferred to Petri dishes. After solidification, 5 mm wells were made. The two microencapsulated enterocin formulations (E10 and E50) were diluted in sterile water at concentrations of 1 and 5 wt%, and 40 μL of these solutions were deposited in wells on BHI-containing target bacteria. Unencapsulated crude enterocin was tested at the same concentrations. The plates were incubated at 37 °C for 24 h. Inhibition halos around the wells were measured and presented in millimeters (mm). The inhibitory activity of enterocin against Listeria sp was also expressed as AU per milliliter. For this, crude and microencapsulated enterocin 5 wt% at 1:2 (v/v) dilutions were deposited on 5 mm wells on BHI agar containing Listeria sp. and incubated at 37 °C for 18 h. The AU/mL was defined as the reciprocal of the last dilution that showed growth compared to the control, multiplied by 100.

The action of microencapsulated enterocin

The time-killing kinetics of crude and encapsulated enterocin followed the protocol described by Furlaneto-Maia et al. (2020). L. monocytogenes, L. innocua and L. ivanovi were grown at 1.5 × 108 cells/mL. The strains were exposed to 5%wt/v (E50) enterocin for up to 12 h. Optical density (OD600) (S60 Libra, Biochrom) values were measured at proper time intervals. The control group, without exposure to enterocin, was used as an indicator of bacteria growth.

Scanning electron microscopy (SEM)

The ultrastructural alterations of L. monocytogenes, L. innocua and L. ivanovi cells exposed to crude and encapsulated enterocin were investigated by SEM (Furlaneto-Maia et al. 2020). The control group was grown without the enterocin. After incubation for 12 h at 30 °C, the treated and control cell samples were harvested, washed with potassium phosphate buffer, and fixed with 2.5% (v/v) glutaraldehyde at 4 °C for 18 h. Post-fixation was carried out for 1 h at 25 °C with 1% osmium tetroxide and was dehydrated with gradient alcohol solutions (50%, 70%, 90%, and 100%) critical-point-dried in CO2 (BALTEC DCP 030 Critical Point Dryer), and finally coated with gold (BALTEC SDC 050 Sputter Coater). The samples were examined by scanning electron microscopy (FEI Quanta 200 Scanning Electron Microscope).

Fourier transform infrared spectroscopy (FTIR) and differential scanning calorimetery (DSC) analysis

The chemical interactions between whey powder and the enterocin structure were identified using the FTIR (IRAffinity, Shimadzu). The sample powder was blended with KBr (potassium bromide- Merck) powder and pressed into pellets. The FTIR spectrum of the samples was measured at a resolution of 4 cm−1, with 32 accumulations, in transmission mode from 400 to 4000 cm−1 wavelength range (Aghbashlo et al. 2013).

The DSC thermograms of the samples were performed obtained using a calorimeter (Perkin Elmer DSC4000). Samples (4 mg) were sealed in aluminum pans and were heated from 0 to 300 °C at a scanning heating rate of 20 20 °C/min under a nitrogen atmosphere (flow rate, 20 mL/min).

Statistical analysis

Three independent experiments were performed for both biological analysis (antimicrobial activity and bacterial growth). The means of the variables were compared using one-way ANOVA and Tukey’s test. A p value < 0.05 was considered statistically significant.

Results and discussion

Determination of the powder yield

The resulting powder yields of the spray-drying encapsulation process were equal to 31.66% and 34.16% for E10 and E50, respectively. These values corroborated the encapsulation studies of probiotics in WP using the spray-drying method (Bordini 2019). This range of powder yield was mainly due to flaking of the dried powder. Nevertheless, according to Nambiar et al. (2017), higher wall material concentrations resulted in a soaring solid content that led to a surge in the feed viscosity, thus enhancing the feed viscosity up to an optimum point that suppressed the internal circulation and oscillation of droplets and prevented the colliding of wet droplets onto the drying surface, thereby improving the encapsulation yield. On the other hand, Puttarat et al. (2021) obtained a powder yield value of 64% when encapsulating Lactobacillus reuteri in WP, even using 7% wt/v, in contrast with the present work (10% wt/v of WP).

Another important parameter that influences the hygroscopicity of the produced encapsulated material is the spray dryer inlet temperature (Pui et al. 2020); however, in the present study, the inlet temperature applied was equal to 150 °C, in contrast with the 120 °C used by Puttarat et al. (2021). Thus, the values in the literature are divergent in relation to the powder yield obtained, as this yield must be associated with the highly hygroscopic nature of the whey powder when compared to the whey protein used by some authors (Puttarat et al. 2021). Handling whey powder products is often difficult due to the presence of lactose which solidifies into an amorphous state during rapid drying (eg spray drying). This amorphous state is thermodynamically unstable and hygroscopic, absorbing moisture from the environment and later plasticizing. This causes the individual whey powder particles to become sticky, reducing energy yield (Ibach and Kind 2007). However, regardless of this behavior, in this study, enterocin microencapsulated in whey powder had a very satisfactory yield, demonstrating its value as an encapsulating agent.

Antimicrobial activity and determination of arbitrary units

E. durans MF5 crude enterocin and encapsulated enterocin were evaluated for their antimicrobial activity against two gram-negative bacteria, E. coli and S. Typhimurium, and three gram-positive strains, L. monocytogenes, L. innocua and L. ivanovi, by the agar well diffusion method. E. durans MF5 harbours enterocin-encoding genes (entA, entB, and entX), as previously described by our group (Tosoni et al. 2019). Bacterial strains comprised of multiple enterocin-encoding genes may possess unique combinations of desirable biotechnological properties, particularly antimicrobial properties. In this study, the use of crude enterocin samples resulted in a quick and low-cost way to obtain this natural bioactive compound for microencapsulation.

All three tested conditions (crude enterocin sample and 1% and 5% encapsulated enterocin) were effective against the majority of the tested microorganisms (E. coli and Listeria species), as indicated by the inhibition zones (Fig. 1a). The antibacterial activities of microencapsulated enterocin were higher than the activity of crude bacteriocin (Tukey’s test, p < 0.05) (Fig. 1c). L. monocytogenes showed inhibition halos of 10.0 ± 1.1 mm for crude enterocin, while encapsulated enterocin (1% and 5%) produced inhibition halos of 18.0 ± 1.8 and 16.7 ± 1.9 mm, respectively. For L. innocua, inhibition halos were 15.0 ± 1.2 mm for crude enterocin, and 19.8 ± 1.7 and 23.1 ± 1.9 mm for 1% and 5% encapsulated enterocin, respectively. L. ivanovi showed inhibition halos of 13.9 ± 1.3 mm for crude enterocin, while encapsulated enterocin (1% and 5%) produced inhibition halos of 25.4 ± 1.8 and 23.1 ± 1.9 mm, respectively. Finally, for E. coli, the crude bacteriocin produced inhibition halos diameter = 9.2–12.0 mm, while 1% and 5% encapsulated enterocin produced halos = 15.0–19.2 and 13.0–18.0 mm, respectively. The crude enterocin did not present inhibitory activity against S. Typhimurium. On the other hand, an inhibition zone around encapsulated enterocin was observed (data not shown), indicating that complexation with WP improved the antimicrobial efficiency against this species. Similar results have been reported by Abid et al. (2019) since they found that exopolysaccharides may act as protective agents of nisin under spray-drying conditions.

a Antibacterial activity (growth inhibition zone after 24 h incubation at 37 °C) of spray-dried encapsulated E. durans MF5 enterocin and crude enterocin against Listeria monocytogenes; b arbitrary units of crude and encapsulated enterocin (5%) against Listeria species; c growth inhibition zones of crude enterocin and encapsulated enterocin (1% and 5%), measured in mm, against Escherichia coli, Listeria monocytogenes, Listeria innocua and Listeria ivanovi. The results represent the average of three independent experiments

When measuring growth inhibition (mm) (Fig. 1c) in relation to the corresponding bacteriocin activities (Fig. 1b), the inhibition zone diameters coincided with the peak bacteriocin activity of 6400 AU/mL. Consistent with the results of our study, García-Toledo et al. (2019) and Abid et al. (2019) also reported a greater antimicrobial efficiency of the microencapsulated bacteriocin. The net charge of the bacteriocin allows it to form complexes with anionic or cationic proteins, which occurs mainly via electrostatic interactions under different conditions, promoting the stability of the bacteriocin in the environment in which it is found (Amara et al. 2017).

Although enterocin had no antimicrobial effect against Salmonella, it was efficient against E. coli and Listeria, giving it greater potential as a biological preservative candidate. The inhibition spectrum of enterocin is relatively broad, preventing the growth of Listeria sp. and many other gram-negative and gram-positive bacteria (Rehaiem et al. 2010; Rocha et al. 2019; Qiao et al. 2020). L. monocytogenes and Listeria sp. remain a significant challenge for the food industry due to their ubiquitous nature, ability to grow at refrigeration temperatures, and ability to persist during many manufacturing processes (Smith et al. 2016), justifying the relevance of studying physical and biological mechanisms to control these food pathogens.

Action of microencapsulated enterocin

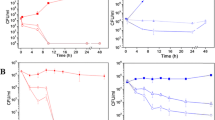

A time-kill curve assay was used to reveal the duration of the activity of crude and encapsulated enterocin. As observed in Fig. 2, the encapsulated enterocin prevented or killed Listeria sp. within 12 h compared to the control (absence of enterocin). Although crude enterocin affected the growth of Listeria sp., the results obtained with encapsulated enterocin were more satisfactory, amalgamating with the results described above, i.e., encapsulated enterocin had a stronger antimicrobial effect (Tukey’s test, p < 0.05) (Fig. 2). Similar results were also obtained by Furlaneto-Maia et al. (2020) and Qiao et al. (2020), who showed the inhibitory action of the bacteriocin for up to 5 h of incubation. Studies performed by our group showed that enterocin controlled the growth of Shiga toxin-producing E. coli for up to 24 h (Tosoni et al. 2019).

Optical density (OD), as a function of time, of Listeria monocytogenes, Listeria inoccua and Listeria ivanovi growth in the presence of crude and microencapsulated enterocin. Controls comprised Listeria species growth in absence of enterocin. The results represent the average of three independent experiments

In fact, the use of enterocin is of particular interest to the food industry, as it contributes to biologically guaranteeing the microbial safety of food products and increasing their shelf-life instead of chemical additives (Jaouani et al. 2015).

Scanning electron microscopy (SEM)

Figure 3 shows SEM images of L. monocytogenes, L. innocua and L. ivanovi treated with encapulated enterocin at 12 h of incubation. As shown in Fig. 3a, untreated L. monocytogenes cells exhibited intact cell structures with smooth membrane surfaces. When exposed to enterocin, the cell morphology was altered, suggesting damage to cell membrane integrity, as indicated by shrinkage or disruption of the cell (Fig. 3b–d).

Effect of encapsulated enterocin (5%) on Listeria species. Scanning electron microscopy (SEM) micrographs images show untreated cells of L. monocytogenes (control) (a), Listeria monocytogenes (b) Listeria innocua (c) and Listeria ivanovi (d) cells treated with encapsulated enterocin (5%) for 12 h. Cell damage and flocculant extracellular material are highlighted; micrographs of spray-dried whey powder (e), encapsulated enterocin (5%) (f) (Magnification of 4000–10,000×). Two independent experiments were performed to monitor the reproducibility of the results

These results indicated that encapsulated enterocin increased the cell membrane permeability, pore formation, and destruction of the cell structure, with consequent cell death. Similar results were reported for the bacteriocin from Lactobacillus (Klayraung and Okonogi 2009; Lu et al. 2014) and enterocin (Sheoran and Tiwari 2009; Furlaneto-Maia et al. 2020).

According to Masias et al. (2017), class-IIa bacteriocins bind to the bacterial cell envelope-associated mannose phosphotransferase system, leading to pore formation and the leakage of intracellular macromolecules. Taken together, our results suggest that encapulated enterocin has characteristics that are promising for future applications to control pathogenic Listeria species.

SEM images of the whey powder and encapsulated enterocin are illustrated in Fig. 3e, f. The spray-dried microcapsules had a diversity in size and spherical shapes. According to Fernandes et al. (2016), Chew et al. (2018) and Karrar et al. (2021), the microstructure of the formed particles depended on the drying conditions, such as the drying temperature, and the use of low temperatures led to the formation of microparticles with rough surfaces.

Characterization of microparticles by FTIR and DSC

FTIR analysis was performed to investigate the interaction between enterocin and whey protein powder (Fig. 4a). The obtained results highlighted that enterocin was successfully grafted into WP samples. The characteristic peak band of enterocin was attributed to the N-terminal disulfide bond (at 530/cm) (Morisset et al. 2004). The peak bands in the region of 3100–2800 cm−1 indicated the presence of hydrogen-bonded OH stretching and NH2 group stretching. In addition, the vibration of the angular deformation (bending) of the C=C aromatic bond was detected at 1411 cm−1, the out-of-plane angular deformation of the ring by the C=C group was detected at 664 cm−1, and the out-of-plane angular deformation of the C–H aromatic group was detected at 622 cm−1, all referring to tyrosine. In the region of 1600 cm−1, the vibration corresponding to the C=O stretching of the amide group of asparagine was observed, which was similar for enterocin (Abdel-Hamid et al. 2018).

In Fig. 4b, the region between 1200 and 1350 cm−1 was enlarged to highlight the bands located at 1307 and 1296 cm−1 that correspond to the α-helix structure and the disordered structure as well as the band referring to the β-pleated conformation structure at 1261 cm−1. Comparison of the whey powder sample with the encapsulated enterocin revealed that there was a significant reduction in the intensity of the band relative to the β-pleated structure, indicating that the interaction of the encapsulated enterocin in the whey led to a modification of the protein structure (Dhumal et al. 2019; Yin et al. 2020).

The results revealed that the addition of enterocin to WP solution and spray-drying resulted in an increased peak at 1600 cm−1 related to that electrostatic interactions and hydrogen bonding that occurred between enterocin and WP, and its antimicrobial action was not affected (Fig. 4b–e). The DSC curve for crude enterocin indicated that the residual moisture in the sample was eliminated at 110 °C, observing the beginning of an endothermic peak. From 118 °C, the thermal degradation behaviour of the sample could be identified. For the whey sample, the beginning of the endothermic peak occurred at 140 °C, with a maximum at 150 °C, and it showed a broad peak at 203 °C relative to protein denaturation (Gharanjig et al. 2020).

In the encapsulated enterocin sample, it can be seen that there was an increase in the thermal stability of the sample, with the displacement of degradation to 137 °C and 154 °C. These results may be due to the interaction between encapsulated enterocin and whey protein, which was favoured by spray-drying processing. According to Ramos et al. (2019), heat or pressure can promote changes in the conformational structure of the protein, exposing its free SH groups initially covered by the structure of the native protein.

Conclusion

Crude enterocin produced by E. durans MF5 and enterocin microencapsulated in whey protein were active against the foodborne pathogens gram-positive Listeria species and gram-negative E. coli ETEC. This is the first report to demonstrate microencapsulation of enterocin in whey protein powder, and its preserved/increased antibacterial activity indicates its potential use as a food preservative. Further studies on food systems are encouraged for the application of this microencapsulated enterocin.

Availability of data and material

None.

Code availability

All content presented in this article is approved by the authors.

Abbreviations

- AMPs:

-

Antimicrobial peptides

- WP:

-

Whey protein

- AU:

-

Arbitrary units

- SEM:

-

Scanning electron microscopy

- E10:

-

Concentrations of 1 wt%

- E50:

-

Concentrations of 5 wt

References

Abdel-Hamid MS, Anis A, Elbawab RH, Mohammed AAB, Orabi SH, Fathalla SI (2018) Distinctive antagonistic role of new Enterococcus faecium ER-3M strain and its bacteriocin effect against Staphylococcus aureus pneumonia. Rend Fis Acc Lincei 29:675–690. https://doi.org/10.1007/s12210-018-0722-7

Abid Y, Gharsallaoui A, Dumas E, Ghnimi S, Attia H, Azabou S (2019) Spray-drying microencapsulation of nisin by complexation with exopolysaccharides produced by probiotic Bacillus tequilensis-GM and Leuconostoc citreum-BMS. Colloids Surf B 181:25–30. https://doi.org/10.1016/j.colsurfb.2019.05.022

Acuña L, Corbalan NS, Fernandez-No IC, Morero RD, Barros-Velazquez J, Bellomio A (2015) Inhibitory effect of the hybrid bacteriocin Ent35-MccV on the growth of Escherichia coli and Listeria monocytogenes in model and food systems. Food Bioprocess Technol 8:1063–1075. https://doi.org/10.1007/s11947-015-1469-0

Aghbashlo M, Mobli H, Madadlou A, Rafiee S (2013) Influence of wall material and inlet drying air temperature on the microencapsulation of fish oil by spray drying. Food Bioprocess Technol 6:1561–1569. https://doi.org/10.1007/s11947-012-0796-7

Ben Amar C, Kim L, Oulahal N, Degraeve P, Gharsallaoui A (2017) Using complexation for the microencapsulation of nisin in biopolymer matrices by spray-drying. Food Chem 236:32–40. https://doi.org/10.1016/j.foodchem.2017.04.168

Beye M, Gouriet F, Michelle C, Casalta JP, Habib G, Raoult D, Fournier P-E (2016) Genome analysis of Listeria ivanovii strain G770 that caused a deadly aortic prosthesis infection. New Microbes New Infect 10:87–92. https://doi.org/10.1016/j.nmni.2016.01.005

Calo-Mata P, Arlindo S, Boehme K, de Miguel T, Pascoal A, Barros-Velazquez J (2008) Current applications and future trends of lactic acid bacteria and their bacteriocins for the biopreservation of aquatic food products. Food Bioprocess Technol 1:43–63. https://doi.org/10.1007/s11947-007-0021-2

Chandralekha A, Tavanandi AH, Amrutha N, Hebbar HU, Raghavarao KSMS, Gadre R (2016) Encapsulation of yeast (Saccharomyces cereviciae) by spray drying for extension of shelf life. Dry Technol 34:1307–1318. https://doi.org/10.1080/07373937.2015.1112808

Chew YL, Mahadi AM, Wong KM, Goh JK (2018) Anti-methicillin-resistance Staphylococcus aureus (MRSA) compounds from Bauhinia kockiana Korth. And their mechanism of antibacterial activity. BMC Complement Altern Med 18:70. https://doi.org/10.1186/s12906-018-2137-5

Condurache NN, Aprodu I, Crăciunescu O, Talia R, Horincar G, Barbu V, Enachi E, Rapeanu G, Bahrim G, Oancea A, Stanciuc N (2019) Probing the functionality of bioactives from eggplant peel extracts through extraction and microencapsulation in different polymers and whey protein hydrolysates. Food Bioprocess Technol 12:1316–1329. https://doi.org/10.1007/s11947-019-02302-1

den Bakker HC, Cummings CA, Ferreira V, Vatta P, Orsi RH, Degoricija L, Barker M, Petrauskene O, Furtado MR, Wiedmann M (2010) Comparative genomics of the bacterial genus Listeria: genome evolution is characterized by limited gene acquisition and limited gene loss. BMC Genom 11:688. https://doi.org/10.1186/1471-2164-11-688

Furlaneto-Maia L, Ramalho R, Rocha KR, Furlaneto MC (2020) Antimicrobial activity of enterocins against Listeria sp. and other food spoilage bacteria. Biotechnol Lett. https://doi.org/10.1007/s10529-020-02810-7

García-Toledo JA, Torrestiana-Sánchez B, Martínez-Sánchez CE, Tejero-Andrade JM, Garcia-Bórguez A, Mendoza-Garcia PG (2019) Nanoencapsulation of a bacteriocin from Pediococcus acidilactici ITV26 by microfluidization. Food Bioprocess Technol 12:88–97. https://doi.org/10.1007/s11947-018-2184-4

Gharanjig H, Gharanjig K, Hosseinnezhad M, Jafari SM (2020) Differential scanning calorimetry (DSC) of nanoencapsulated food ingredients. Nanoencapsul Food Ind 4:295–346. https://doi.org/10.1016/B978-0-12-815667-4.00010-9

Ibach A, Kind M (2007) Crystallization kinetics of amorphous lactose, whey-permeate and whey powders. Carbohydr Res 342:1357–1365. https://doi.org/10.1016/J.CARRES.2007.03.002

Jaouani I, Abbassi M, Alessandria V, Bouraoui J, Ben Salem R, Kilani H, Mansouri R, Messadi L, Cocolin L (2014) High inhibition of Paenibacillus larvae and Listeria monocytogenes by Enterococcus isolated from different sources in Tunisia and identification of their bacteriocin genes. Lett Appl Microbiol 59:17–25. https://doi.org/10.1111/lam.12239

Jordan K, McAuliffe O (2018) Listeria monocytogenes in foods. Adv Food Nutr Res 86:181–213. https://doi.org/10.1016/bs.afnr.2018.02.006

Karrar E, Mahdi AA, Sheth S, Ahmed IAM, Manzoor MF, Wei W, Wang X (2021) Effect of maltodextrin combination with gum arabic and whey protein isolate on the microencapsulation of gurum seed oil using a spray-drying method. Int J Biol Macromol 171:208–216. https://doi.org/10.1016/j.ijbiomac.2020.12.045

Korma SA, Wei W, Ali AH, Abed SM, Zheng L, Jin Q, Wang X (2019) Spray-dried novel structured lipids enriched with medium-and long-chain triacylglycerols encapsulated with different wall materials: characterization and stability. Food Res Int 116:538–547. https://doi.org/10.1016/j.foodres.2018.08.071

Kumariya R, Garsa AK, Rajput YS, Sood SK, Akhtar N, Patel S (2019) Bacteriocins: classification, synthesis, mechanism of action and resistance development in food spoilage causing bacteria. Microb Pathog 128:171–177. https://doi.org/10.1016/j.micpath.2019.01.002

Lee G (2002) Spray-drying of proteins. In: Carpenter JF, Manning MC (eds) Rational design of stable protein formulations: theory and practice. Springer, Boston, pp 135–158

Lü X, Hu P, Dang Y, Liu B (2014) Purification and partial characterization of a novel bacteriocin produced by Lactobacillus casei TN-2 isolated from fermented camel milk (Shubat) of Xinjiang Uygur Autonomous region, China. Food Control 43:276–283. https://doi.org/10.1016/j.foodcont.2014.03.020

Luque-Sastre L, Arroyo C, Fox EM, McMahon BJ, Bai L, Li F, Fanning S (2018) Antimicrobial resistance in Listeria species. Microbiol Spectr. https://doi.org/10.1128/microbiolspec.ARBA-0031-2017

Masias E, Dupuy FG, Sanches PRS, Farizano JV, Cilli E, Bellomio A, Saavedra L, Minahk C (2017) Impairment of the class IIa bacteriocin receptor function and membrane structural changes are associated to enterocin CRL35 high resistance in Listeria monocytogenes. Biochim Et Biophys Acta (BBA) 1861:1770–1776. https://doi.org/10.1016/j.bbagen.2017.03.014

Morisset D, Berjeaud JM, Marion D, Lacombe C, Frère J (2004) Mutational analysis of mesentericin Y105, an anti-listeria bacteriocin, for determination of impact on bactericidal activity, in vitro secondary structure, and membrane interaction. Appl Environ Microbiol 70:4672–4680. https://doi.org/10.1128/AEM.70.8.4672-4680.2004

Moura A, Disson O, Lavina M, Thouvenot P, Huang L, Leclerq A, Fredriksson-Ahomaa M, Eshwar AK, Stephan R, Lecuit M (2019) Atypical haemolytic Listeria innocua isolates are virulent, albeit less than Listeria monocytogenes. Infect Immun 87(4):e00758-e818. https://doi.org/10.1128/IAI.00758-18

Nambiar RB, Sellamuthu PS, Perumal AB (2017) Microencapsulation of tender coconut water by spray drying: effect of moringa oleifera gum, maltodextrin concentrations, and inlet temperature on powder qualities. Food Bioprocess Technol 10:1668–1684. https://doi.org/10.1007/s11947-017-1934-z

Pui LP, Karim R, Yusof YA, Wong CW, Ghazali HM (2020) Optimization of spray-drying parameters for the production of ‘Cempedak’ (Artocarpus integer) fruit powder. J Food Meas Charact 14:3238–3249. https://doi.org/10.1007/s11694-020-00565-3

Puttarat N, Thangrongthong S, Kasemwong K, Kerdsup P, Taweechotipatr M (2021) Spray-drying microencapsulation using whey protein isolate and nano-crystalline starch for enhancing the survivability and stability of Lactobacillus reuteri TF-7. Food Sci Biotechnol 30:245–256. https://doi.org/10.1007/s10068-020-00870-z

Qiao X, Du R, Wang Y, Han Y, Zhou Z (2020) Purification, characterization 36 and mode of action of enterocin, a novel bacteriocin produced by Enterococcus faecium TJUQ1. Int J Biol Macromol 144:151–159. https://doi.org/10.1016/j.ijbiomac.2019.12.090

Ramos FM, Silveira Júnior V, Prata AS (2019) Assessing the vacuum spray drying effects on the properties of orange essential oil microparticles. Food Bioprocess Technol 12:1917–1927. https://doi.org/10.1007/s11947-019-02355-2

Rocha KR, Perini HF, de Souza CM, Schueler J, Tosoni NF, Furlaneto MC, Furlaneto-Maia L (2019) Inhibitory effect of bacteriocins from enterococci on developing and preformed biofilms of Listeria monocytogenes, Listeria ivanovii and Listeria innocua. World J Microbiol Biotechnol 35:96–107. https://doi.org/10.1007/s11274-019-2675-0

Rosolen MD, Bordini FW, Oliveira PD, Conceição FR, Pohndorf RS, Fiorentini AM, Silva WP, Pieniz S (2019) Symbiotic microencapsulation of Lactococcus lactis subsp. lactis R7 using whey and inulin by spray drying. LWT 115:108411. https://doi.org/10.1016/j.lwt.2019.108411

Sheoran P, Tiwari SK (2019) Enterocin LD3 from Enterococcus hirae LD3 causing efflux of intracellular ions and UV-absorbing materials in Gram-negative bacteria. J Appl Microbiol 126:1059–1069. https://doi.org/10.1111/jam.14203

Sidhu PK, Nehra K (2020) Bacteriocin-capped silver nanoparticles for enhanced antimicrobial efficacy against food pathogen. IET Nanobiotechnol 14:245–252. https://doi.org/10.1049/iet-nbt.2019.0323

Smith MK, Draper LA, Hazelhoff PJ, Cotter PD, Ross RP, Hill C (2016) A bioengineered nisin derivative, M21A, in combination with food grade additives eradicates biofilms of Listeria monocytogenes. Front Microbiol 7:1939. https://doi.org/10.3389/fmicb.2016.01939

Tavares L, Barros HLB, Vaghetti JCP, Norena C (2019) Microencapsulation of garlic extract by complex coacervation using whey protein isolate/chitosan and gum arabic/chitosan as wall materials: influence of anionic biopolymers on the physicochemical and structural properties of microparticles. Food Bioprocess Technol 12:2093–2106. https://doi.org/10.1007/s11947-019-02375-y

Tosoni NF, Perini HF, Terra MR, Katsuda MS, Furlaneto MC, Maia LF (2019) Antimicrobial activity of enterocin obtained from Enterococcus durans on Shiga-like toxin-producing Escherichia coli. Cienc Rural. https://doi.org/10.1590/0103-8478cr20190297

Xiao LJ, Kamau E, Donze D, Grove A (2011) Expression of yeast high mobility group protein HMO1 is regulated by TOR signaling. Gene 489:55–62. https://doi.org/10.1016/j.gene.2011.08.017

Yin X, Fu X, Cheng H, Liang L (2020) α-Tocopherol and naringenin in whey protein isolate particles: partition, antioxidant activity, stability and bioaccessibility. Food Hydrocolloids 106:105895. https://doi.org/10.1016/j.foodhyd.2020.105895

Funding

This work was supported by Fundação Araucária/Governo do Paraná—Brazil, UTFPR-Londrina Campus and State University of Londrina-Paraná. The authors thank the “Central Analítica Multiusuário da UTFPR Campo Mourão (CAMulti-CM)¨ and “Laboratório Multiusuário da UTFPR Campus Londrina (LabMulti-LD)¨ for the analyses. Fernanda V. Leimann (process 039/2019) thanks to Fundação Araucária (CP 15/2017- Programa de Bolsas de Produtividade em Pesquisa e Desenvolvimento Tecnológico) and to CNPq (process number 421541/2018-0, Chamada Universal MCTIC/CNPq n.° 28/2018).

Author information

Authors and Affiliations

Contributions

RR, NAA de S, TFMM and A De O: Methodology and Investigation; HFP: MEV Investigation; MCF and FVL : Writing–review; LF-M: Writing–original draft, Funding acquisition and Project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work.

Consent to participate

The authors express their consent to cooperate in this article.

Consent for publication

The authors express their consent to the publication on Journal of Food Science and Technology.

Ethics approval

We declare no ethical issue related with this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ramalho, R., de Souza, N.A.A., Moreira, T.F.M. et al. Antibacterial efficacy of Enterococcus microencapsulated bacteriocin on Listeria monocytogenes, Listeria innocua and Listeria ivanovi. J Food Sci Technol 60, 262–271 (2023). https://doi.org/10.1007/s13197-022-05611-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05611-0