Abstract

The study investigated the effect of albedo and flavedo extracts of grapefruit and pomelo on storage stability of turkey patties during refrigerated storage. Five different types of products were developed depending on the addition of extracts viz. control (C), albedo and flavedo extract of grapefruit (GA and GF), and albedo and flavedo extract of pomelo (PA and PF). The products were stored for 10 days and evaluated for lipid and protein oxidation, pH, colour and sensory properties. The extracts improved the lipid oxidative stability by decreasing (P < 0.05) the TBARS values of the samples compared to control group. No effect of the extract treatments (P > 0.05) was observed on pH and colour values of the products (a* and b*). The lowest TBARS values were found for the products containing GF (0.78 mg MA/kg) on day 4. The treatments showed a significant impact on flavour of the products and the highest scores were obtained for PA containing products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Turkey meat is gaining popularity due to its favourable nutritional profile. It contains high quality protein, significant amounts of minerals and vitamins and a low amount of fat and cholesterol. Turkey meat is also relatively high in polyunsaturated fatty acids (PUFA) considered important for human health (Gálvez et al. 2018). However, higher amounts of PUFA and free iron makes turkey meat and its products highly prone to lipid oxidation (Veberg et al. 2007). Lipid oxidation is considered as one of the main reasons for deterioration of the quality of meat and meat products during storage (Bhat and Pathak 2012; Singh et al. 2015). While several options are available to improve the lipid and microbial stability of meat products during storage (Singh et al. 2014a, b), addition of plant extracts is associated with higher consumer acceptance due to their natural origin (Jamwal et al. 2015; Kalem et al. 2018). While several studies have used different plant extracts and ingredients with significant effects on lipid stability such as oleuropein (Dua et al. 2015), pomegranate seed powder (Kaur et al. 2015), clove oil (Singh et al. 2014a, b) and mung bean (Bhat and Pathak 2012). Grapefruit and pomelo, the citrus fruits containing important phenolic compounds such as naringin, hesperidin, narirutin and neohesperidin, have received least scientific attention. The outer coloured layer of the citrus peel is called flavedo and the inner white layer is called albedo. The albedo and flavedo layers contain soluble/insoluble fibers, phenolic compounds, lipids and organic acids (Joglekar et al. 2019).

Grapefruit (Citrus aurantium) is a group of citrus fruits grown in some provinces of China, probably resulting from the hybridization of pomelo and sweet orange. It has been indicated that grapefruit peel is a rich source of flavones (Hashmi et al. 2012).

It is a widely grown and freshly consumed citrus variety known as “pomelo” (Citrus maxima) in certain regions of Asia, Africa, and Australia (Puglisi et al. 2017). Pomelo peel constitutes 30% of the fruit weight and has the thickest skin among other citrus fruits (Zain et al. 2014). It has been reported that pomelo peel has a higher antioxidant capacity than pulps (Toh et al. 2013).

Studies on various fruit and plant sources with natural antioxidant properties such as lemon, bitter orange, citrus albedo, citrus peel, pomegranate peel etc. in meat products are available in the literature (Viji et al. 2015; Nishad et al. 2018; Sabu et al. 2020; Disha et al. 2020; Fernandez-Lopez et al. 2005). Although there are studies on antioxidative and/or antibacterial properties of citrus extracts in meat products, the effects of albedo and flavedo extracts of pomelo and grapefruit on turkey meat on lipid and protein oxidation have not been studied before. Therefore, the aim of this study was to evaluate the effects of albedo and flavedo extracts of grapefruit and pomelo on lipid and protein oxidation, colour properties and sensory characteristics of turkey patties during refrigerated storage for 10 days.

Materials and methods

Materials

Turkey carcasses were purchased from a local butcher in Konya, Turkey. In order to represent the whole turkey carcass, turkey meats were taken from almost every part of the turkey carcasses and then, the skin and bones of meats were removed. The salt (Salina, Ankara, Turkey) used in the production of turkey patties was obtained from a local market in Konya, Turkey. The grapefruits (Citrus paradisi Macfadyen) and pomelos (Citrus grandis (L.) Osbeck) used for the preparation of albedo and flavedo extracts were purchased from a local greengrocer in Konya, Turkey.

Preparation of extracts

The grapefruit and pomelo peels were peeled off with a paring knife. The flavedo layers, the outer skin of the grapefruit and pomelo peels, were removed with a fruit peeler. The albedo and flavedo layers were cut into small pieces (4–7 mm) using a knife to shorten the drying time by reducing the surface area. They were then dried at room temperature for 72 h. Dried albedo and flavedo fragments were grinded into small pieces. The extracts were prepared by acetone–water extraction following the method of Rodríguez-Carpena et al. (2012) with a slight modification. 30 ml of acetone–water (70:10 v/v) was added to 10 g of dried albedo or flavedo fragments. After the mixture was homogenized using a homogenizer (Wisd Laboratory Instruments, HG‐15D, Germany), the homogenate was centrifuged (3000 rpm for 5 min at 4 °C). The supernatant was filtered and collected. The pellet (residue) was re-extracted once more. Both of the supernatants were combined and then evaporated with a rotary evaporator. This obtained extract was dissolved using 50 mL of distilled water.

Manufacture of turkey patties

The turkey meats were minced using a 3-mm plate in a meat grinder (Kitchen Aid, Classic Model, USA). The proximate composition and pH value of the turkey minced meat used in this study were as follows: 75.91 ± 0.14% moisture, 18.67 ± 0.42% crude protein, 1.16 ± 0.63% crude fat, 1.09 ± 0.06% total ash, and 6.22 ± 0.08 for pH value. Five different turkey patty treatments were prepared depending on the extract addition; C (Control), no added extract; GA, including albedo extract of grapefruit; GF, including flavedo extract of grapefruit; PA, including albedo extract of pomelo; PF, including flavedo extract of pomelo. The formulations of the turkey patties are given in Table 1. In the formulation of the turkey patties containing extracts, 7.5 g of the distilled water was substituted by 7.5 g of the corresponding extract solution (per 100 g turkey meat) (Table 1). All ingredients were mixed for 6 min and formed into patties (50 g per patty) using a Petri dish to obtain average dimensions (approximately a diameter of 9 cm and a thickness of 0.6 cm). The prepared raw turkey patties were placed in polypropylene trays wrapped with a PVC film (moisture permeability: 8 g/m2 day; oxygen permeability: 15 cm3/m2 day atm) (Cook, Ankara, Turkey) and stored for 10 days at + 4 °C in a refrigerator.

Experimental design

In this study, the free radical scavenging activities (DPPH), total phenolic and total flavonoid contents were determined in the prepared extracts. Moisture, crude protein, crude fat, total ash contents and pH values were determined in turkey meat (raw material).

Twenty-four patties per treatment were prepared in two independent replicates with triplicate sampling for analyses performed during storage. Fifteen patties were also produced for sensory evaluation. pH, TBARS, total carbonyl and colour analyses were performed on the 1st, 4th, 7th, and 10th days in the prepared turkey patties. Sensory analysis was performed on the 1st day.

pH determination

pH values of turkey patty samples were determined with a pH meter (WTW pHmeter 720, Weilheim, Germany) according to Ockerman (1985).

Antioxidative properties of extracts

Antioxidant activities of extracts were determined using DPPH (1,1-diphenyl-2-picrylhydrazyl) radical according to Lee et al. (1998). Results were expressed as μM Trolox equivalents per gram dry matter.

Total phenolic contents of extracts were determined by using the Folin–Ciocalteu method as described by Yoo et al. (2004). The results were given as mg gallic acid equivalents (GAE)/100 mL. Total flavonoid contents of extracts were determined according to the method reported by Chen and Chen (2011). The results were expressed as mg of catechin equivalents (mg CE/100 mL).

Determination of TBARS number and total protein carbonyls

The spectrophotometric determinations of the thiobarbituric acid (TBARS) number were conducted depending on the colorization of malonaldehyde present in the turkey patties with the TBARS reagent (Ockerman 1985). The TBARS numbers were expressed as milligrams of malonaldehyde per kilogram of samples (mg MA/ kg sample).

For the evaluation of protein oxidation, the total carbonyl content was determined using the DNPH (2,4-dinitrophenylhydrazine) method described by Levine et al. (1994). The content of carbonyls was expressed as nmol of carbonyl per mg of protein using an extinction coefficient of 21.0/(nM.cm) at 370 nm for protein hydrazones.

Colour measurements

Colour properties of the turkey patties were measured with a colorimeter (CR-400 Minolta Co., Osaka, Japan). L* (lightness), a* (redness) and b* (yellowness) values were determined according to the criteria given by CIELab (Commission Internationele de I’E Clairage). The total colour difference (ΔE) between the samples after 4, 7 and 10 days of storage were also evaluated.

Sensory evaluation

The sensory analysis was performed by a group of 15 panelists who had the habit of consumption of meat products. The panelists were informed about the study before the sensory evaluation. Randomly 3-digit coded samples were presented to the panelists after cooking (at 180 °C for 14 min). To neutralize the taste felt by the panelists, crackers and water were served with the samples. Panelists evaluated the characteristics of colour, odour, texture and flavour of turkey patty samples according to the scale given to them. In the sensory panel, a 9-point hedonic scale was used. According to this 9-point hedonic scale, the point of 9 indicated the highest acceptability, while the point of 1 demonstrated the lowest.

Statistical analysis

This study was conducted in two independent replicates with triplicate sampling and a completely randomized design was employed. A one-way analysis of variance (ANOVA) was performed for variables of pH, TBARS, total carbonyl, L*, a* and b* by using the MINITAB release 18.0 program. The interaction between the natural preservative treatment and storage was also analyzed with two-way Anova using the GLM procedure. The natural preservative treatments (C, GA, GF, PA and PF) and storage days (1, 4, 7 and 10 days) were analyzed as a fixed factor while the turkey meats were considered as a random factor. Tukey Multiple Comparison Tests were used to determine the differences among the means at a 5% significance level.

Results and discussion

Antioxidative properties of extracts

Table 2 indicates the contents of total phenolic (TPC), total flavonoid (TFC) and antioxidant activity (DPPH) in albedo and flavedo extracts of grapefruit and pomelo. Except for TPC of grapefruits’ flavedo extract, flavedo extracts had higher TPC, TFC and DPPH values than albedo extracts of grapefruit and pomelo.

Our TPC results were lower than the finding of Viji et al. (2015), Yerlikaya et al. (2016), Nishad et al. (2018) and Sabu et al. (2020) who determined total phenolic compounds in different citrus peel extracts. Our TFC results were also lower than the results of Diab (2016) who investigated TFC of grapefruit, lemon and mandarin peel extracts. These lower results of TPC and TFC could arise from the fruit varieties, drying and extraction methods. The obtained DPPH values of grapefruit peel extracts in this study accords with the previously recorded data on Xi et al. (2015) and Yerlikaya et al. (2016).

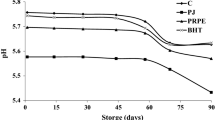

pH values

The pH values of turkey meatball samples kept in the refrigerator for 10 days are presented in Table 3. The addition of albedo and flavedo extracts of grapefruit and pomelo did not affect the pH values of the samples during the storage time for 10 days (P > 0.05). Similarly, Viji et al. (2015) reported that mint leaf and citrus (Citrus aurantium) peel extracts did not change the pH values of Indian mackerel samples during refrigerated storage (P > 0.05). On the contrary, Ibrahim et al. (2018) determined that the addition of 1% and 2% lemon and orange peels powder decreased the pH values of beef patties during refrigerated storage for 15 days. A possible explanation for this might be the differences in the variety of citrus fruits, addition levels and forms (fresh, extract, powder etc.) to meat products.

In this study, there were no significant changes in the pH values of the samples on days 1, 4, and 7. However, except for the group of PA, the pH values of the samples increased on the 10th day (P < 0.05). The increase in pH values of the samples with the progression of the storage period is attributed to the formation of basic compounds (amines and other compounds) by autolysis and microbial effect (Binsi et al. 2007). These results agree with the findings of Sabu et al. (2020), in which the pH values of the samples increased during refrigerated storage.

Lipid oxidation

TBARS is the main indicator of lipid oxidation seen in meat and meat products. TBARS numbers of turkey meatball samples stored in the refrigerator for 10 days are given in Table 3. TBARS numbers increased in all groups during the storage period and the highest TBARS numbers were determined on the 10th day of refrigerated storage (P < 0.05). Similarly, an increase of the TBARS numbers during storage were observed by Yerlikaya et al. (2016) in fish oil samples including citrus extracts. Gradually increased TBARS values during a 18-day storage were concluded by Viji et al. (2015) who treated Indian mackerel with citrus (Citrus aurantium) peel extracts. A Similar increase of TBARS numbers was also reported by Disha et al. (2020) who evaluated the effect of a lemon extract on the shelf life of chicken meatball samples during frozen storage.

The albedo and flavedo extracts of grapefruit and pomelo decreased the TBARS number as compared to the control samples. While the group of GF had the lowest TBARS number on the 4th day, GF, PA and PF had it at the 7th day (P < 0.05). The TBARS number was statistically insignificant in all groups on the 1st and 10th days of storage (P > 0.05). Our TBARS results are consistent with the findings of Nishad et al. (2018) on goat meatball including nutmeg and citrus peel extracts, Ibrahim et al. (2018) on beef patties including lemon and orange peel powders, and Sabu et al. (2020) on yellowfin tuna meat including chitosan and lemon peel extract.

Total protein carbonyls

Turkey patty samples were also analyzed for the accumulation of protein oxidation products (total protein carbonyls). The total protein carbonyl amounts of turkey patty samples are shown in Table 3. While the addition of extracts significantly affected the carbonyl contents of the samples on the 1st day (P < 0.05), unexpectedly, the effect of the extracts was insignificant in the other storage periods (P > 0.05). The lowest total carbonyl content was determined in the group of PA on the 1st day, followed by the group of GF, but the total carbonyl contents of GA and PF were higher than the control group. On the other hand, although the total carbonyl amounts of the samples increased with the progression of the refrigerated storage period, this increase was statistically insignificant (P > 0.05).

The formation of protein oxidation products in meat and meat products is indicated to take place along with the oxidation of lipids (Rodríguez-Carpena et al. 2012). Carbonyl compounds formed during the oxidation of proteins are involved in the cross-linking of damaged proteins via the formation of Schiff bases. Schiff bases are formed by the reactions between lipid oxidation products and amino groups from the side chain of proteins. Therefore, it has been reported that there is an interaction between lipid and protein oxidation (Davieset al. 1995).

In this study, in terms of both extract addition and refrigerated storage treatments, the lack of correspondence between the lipid oxidation (TBARS) and protein oxidation (total protein carbonyl—DNPH method) results was determined in the samples. Similarly, numerous researchers have reported that natural antioxidant treatments to meat products had a significant effect on lipid oxidation, but no significant effect was determined on protein oxidation which was conducted with the DNPH method (Rodríguez-Carpena et al. 2012). It has been reported that this lack of correspondence between the TBARS number and the total protein carbonyl amounts may be due to a lack of sensitivity of the DNPH method (Rodríguez-Carpena et al. 2012).

Colour attributes

The L*, a*, b* and ΔE values of the turkey patty samples stored in the refrigerator for 10 days are given in Table 4. Except for day 7 in terms of L* values, the extract treatment did not affect the colour parameters (L*, a* and b*) of the turkey patties (P > 0.05). With respect to lightness, the albedo extract of pomelo increased the lightness values of the samples when compared to the other groups on day 7 (P < 0.05).

While the highest a* values were on the initial day, the lowest a* values were measured on days 7 and 10. This decrease was attributed to the accumulation of metmyoglobin (Papuc et al. 2017) and the occurrence of oxidative reactions during storage in meat and meat products (Munekata et al. 2020). With regard to the a* values, a similar decrease was tabled by Inserra et al. (2014) who applied a dietary dried citrus pulp in lamb meat for 6 days storage time. A similar trend in a* values was confirmed by Nishad et al. (2018) who used citrus peel extracts in meatballs. According to the ΔE values, more intense color deterioration was observed in all samples on days 7 and 10 (P < 0.05) extracts.

Sensory scores

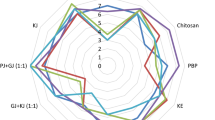

Figure 1 shows the sensory scores of the turkey patty samples. While the addition of the albedo and flavedo extracts of grapefruit and pomelo did not affect the colour, the texture and appearance scores (P > 0.05), flavour scores of samples were significantly different (P < 0.05). The control group had the highest flavour score, whereas the GA group had the lowest flavour scores. A possible explanation for this might be the presence of off flavour compounds in the citrus extracts which could contribute to the perceived rancidity (Fernandez-Lopez et al. 2005). It has been reported that the occurrence and perception of off-flavours in citrus fruits is closely related to the accumulation of acetaldehyde (AA) and ethanol during fruit ripening (Hagenmaier 2002).

Conclusion

The present study demonstrated that albedo and flavedo extracts of grapefruit and pomelo improved the storage quality of turkey patties during refrigerated storage for 10 days. The extract treatment did not affect the pH, a* and b* values of samples. The lowest TBARS values were found in the samples with the flavedo extract of grapefruit. The albedo extract of pomelo had a significant effect on protein oxidation of turkey patties on the first day. Additionally, the flavedo extract of pomelo significantly improved the sensory characteristics of turkey patties. It could be suggested that citrus peels, which are an industrial waste, could be used as a natural preservative in turkey patties, but further studies are required on extracts, obtained by different extraction methods, and used with different addition levels and forms (essential oil, powder, etc.), to obtain better results in meat products.

Availability of data and material

Not Applicable.

Code availability

Not Applicable.

Abbreviations

- C:

-

Control

- CE:

-

Catechin equivalents

- DPPH:

-

2,2-Diphenyl-1-picrylhydrazyl

- GA:

-

Turkey patty samples including albedo extract of grapefruit

- GAE:

-

Gallic acid equivalents

- GF:

-

Turkey patty samples including flavedo extract of grapefruit

- PA:

-

Turkey patty samples including albedo extract of pomelo

- PF:

-

Turkey patty samples including flavedo extract of pomelo

- TBARS:

-

Thiobarbutiric acid

- TFC:

-

Total flavonoid content

- TPC:

-

Total phenolic content

References

Bhat Z, Pathak V (2012) Quality evaluation of mutton Harrisa during one week refrigerated storage. J Food Sci Technol 49:620–625

Binsi P, Shamasundar B, Dileep A (2007) Physico-chemical and functional properties of proteins from green mussel (Perna viridis) during ice storage. J Sci Food Agric 87:245–254

Chen G, Chen H (2011) Extraction and deglycosylation of flavonoids from sumac fruits using steam explosion. Food Chem 126:1934–1938

Davies MJ, Fu S, Dean RT (1995) Protein hydroperoxides can give rise to reactive free radicals. Biochemical J 305:643–649

Diab KA (2016) In vitro studies on phytochemical content, antioxidant, anticancer, immunomodulatory, and antigenotoxic activities of lemon, grapefruit, and mandarin citrus peels. Asian Pac J Cancer Prev 17:3559–3567

Disha M, Hossain M, Kamal M, Rahman M, Hashem M (2020) Effect of different level of lemon extract on quality and shelf life of chicken meatballs during frozen storage. SAARC J Agric 18:139–156

Dua S, Bhat Z, Kumar S (2015) Effect of oleuropein on the oxidative stability and storage quality of Tabaq-Maz, fried mutton ribs. Food Biosci 12:84–92

Fernandez-Lopez J, Zhi N, Aleson-Carbonell L, Pérez-Alvarez J, Kuri V (2005) Antioxidant and antibacterial activities of natural extracts: application in beef meatballs. Meat Sci 69:371–380

Gálvez F, Domínguez R, Pateiro M, Carballo J, Tomasevic I, Lorenzo JM (2018) Effect of gender on breast and thigh turkey meat quality. Br Poult Sci 59:408–415

Hagenmaier R (2002) The flavor of mandarin hybrids with different coatings. Postharvest Biol Technol 24:79–87

Hashmi SH, Ghatge P, Machewad GM, Pawar S (2012) Studies on extraction of essential oil and pectin from sweet orange. Open Access Scientific Reports 1:1–3

Ibrahim HM, Hassan IM, Hamed AA (2018) Application of lemon and orange peels in meat products: quality and safety. Int J Curr Microbiol App Sci 7:2703–2723

Inserra L, Priolo A, Biondi L, Lanza M, Bognanno M, Gravador R, Luciano G (2014) Dietary citrus pulp reduces lipid oxidation in lamb meat. Meat Sci 96:1489–1493

Jamwal A, Kumar S, Bhat Z, Kumar A, Kaur S (2015) The quality and storage stability of chicken patties prepared with different additives. Nutrition Food Sci 45:728–739

Joglekar SN, Pathak PD, Mandavgane SA, Kulkarni BD (2019) Process of fruit peel waste biorefinery: a case study of citrus waste biorefinery, its environmental impacts and recommendations. Environ Sci Pollut Res 26:34713–34722

Kalem IK, Bhat Z, Kumar S, Noor S, Desai A (2018) The effects of bioactive edible film containing Terminalia arjuna on the stability of some quality attributes of chevon sausages. Meat Sci 140:38–43

Kaur S, Kumar S, Bhat Z, Kumar A (2015) Effect of pomegranate seed powder, grape seed extract and tomato powder on the quality characteristics of chicken nuggets. Nutrition Food Sci 45:583–594

Lee SK, Mbwambo Z, Chung H, Luyengi L, Gamez E, Mehta R, Kinghorn A, Pezzuto J (1998) Evaluation of the antioxidant potential of natural products. Comb Chem High Throughput Screen 1:35–46

Levine RL, Williams JA, Stadtman EP, Shacter E (1994) Carbonyl assays for determination of oxidatively modified proteins. Methods Enzymol 233:346–357

Munekata PES, Rocchetti G, Pateiro M, Lucini L, Domínguez R, Lorenzo JM (2020) Addition of plant extracts to meat and meat products to extend shelf-life and health-promoting attributes: an overview. Curr Opin Food Sci 31:81–87

Nishad J, Koley TK, Varghese E, Kaur C (2018) Synergistic effects of nutmeg and citrus peel extracts in imparting oxidative stability in meat balls. Food Res Int 106:1026–1036

Ockerman HW (1985) Quality control of post-mortem muscle tissue. Ohio State University, Dept. of Animal Science

Papuc C, Goran GV, Predescu CN, Nicorescu V (2017) Mechanisms of oxidative processes in meat and toxicity induced by postprandial degradation products: a review. Comprehensive Rev Food Sci Food Safety 16:96–123

Puglisi I, De Patrizio A, Schena L, Jung T, Evoli M, Pane A, Van Hoa N, Van Tri M, Wright S, Ramstedt M (2017) Two previously unknown Phytophthora species associated with brown rot of Pomelo (Citrus grandis) fruits in Vietnam. PLoS One 12: e0172085.

Rodríguez-Carpena JG, Morcuende D, Estévez M (2012) Avocado, sunflower and olive oils as replacers of pork back-fat in burger patties: effect on lipid composition, oxidative stability and quality traits. Meat Sci 90:106–115

Sabu S, Ashita T, Stephy S (2020) Chitosan and lemon peel extract coating on quality and shelf life of yellowfin tuna (Thunnus albacares) meat stored under refrigerated condition. Indian J Fish 67:114–122

Singh PK, Kumar S, Bhat Z, Kumar P (2014a) Effect of clove oil on the storage quality of aerobically packaged fiber-enriched chevon cutlets. J Meat Sci 10:36–43

Singh PK, Kumar S, Kumar P, Bhat Z (2014b) Effect of mincing on the quality characteristics of chevon cutlets. J Anim Res 4:193–200

Singh PK, Kumar S, Bhat Z, Kumar P, Kumar A (2015) Effect of processed oats and clove oil on the characteristics and storage quality of aerobically packaged chevon cutlets. Indian J Small Rumin 21:76–84

Toh J, Khoo H, Azrina A (2013) Comparison of antioxidant properties of pomelo [Citrus grandis (L) Osbeck] varieties. Int Food Res J 20(4):1661–1668.

Veberg A, Olsen E, Nilsen A, Wold J (2007) Front-face fluorescence measurement of photosensitizers and lipid oxidation products during the photooxidation of butter. J Dairy Sci 90:2189–2199

Viji P, Binsi PK, Visnuvinayagam S, Bindu J, Ravishankar CN, Gopal TKS (2015) Efficacy of mint (Mentha arvensis) leaf and citrus (Citrus aurantium) peel extracts as natural preservatives for shelf life extension of chill stored Indian mackerel. J Food Sci Technol 52:6278–6289

Xi W, Zhang G, Jiang D, Zhou Z (2015) Phenolic compositions and antioxidant activities of grapefruit (Citrus paradisi Macfadyen) varieties cultivated in China. Int J Food Sci Nutr 66:858–866

Yerlikaya P, Gokoglu N, Topuz OK, Gumus B, Aydan Yatmaz H (2016) Antioxidant activities of citrus albedo and flavedo fragments against fish lipid oxidation. J Aquat Food Prod Technol 25:1339–1347

Yoo KM, Lee KW, Park JB, Lee HJ, Hwang IK (2004) Variation in major antioxidants and total antioxidant activity of Yuzu (Citrus junos Sieb ex Tanaka) during maturation and between cultivars. J Agric Food Chem 52:5907–5913

Zain NM, Yusop SM, Ahmad I (2014) Preparation and characterization of cellulose and nanocellulose from pomelo (Citrus grandis) albedo. J Nutr Food Sci 5:334–338

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors. The authors would like to thank Esra Korkmaz, Amira Sato, Büşra Özdemir, Elifnur Sarısoy and Nurgül Yılmazer for contributions in laboratory studies.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

ASB designed the study, supervised the experiments, and contributed to reviewing and editing of the manuscript; TA contributed to laboratory studies, collection of data, and in the writing of the manuscript; HÖ made contributions in the collection, analyses and interpretation of data and in the writing of the manuscript; MK made reviewing and editing of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethics approval

There is no ethics.

Consent to participate

Not Applicable.

Consent for publication

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Babaoğlu, A.S., Ainiwaer, T., Özkan, H. et al. Grapefruit and pomelo peel extracts as natural antioxidants for improved storage stability of Turkey patties during refrigerated storage. J Food Sci Technol 59, 4067–4074 (2022). https://doi.org/10.1007/s13197-022-05458-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05458-5