Abstract

The utilization of conventional protein sources like gluten, soy, dairy proteins, and nuts in the development of protein-enriched cereal bars presents a challenge for their consumption by the population suffering from celiac and other food protein allergies. In the present investigation, protein-rich cereal bars were developed using non-conventional protein isolates (alfalfa and dhiancha (API & DPI) and were evaluated for their quality attributes, nutritional composition, and bioactive potential. The incorporation of protein isolates increased the weight, density, and non-enzymatic browning and decreased the water activity in the bars. The hardness of the bar increased with the addition of protein isolates; however, reduced hardness was observed at 7.5 and 10% levels of API. Supplementation with protein isolates enhanced the protein content (7.83–16.71%), total phenols (1642–4956 GAE μg/g), total flavonoids (268–984 QE μg/g), DPPH radical scavenging activity (96.38–114.82 TEAC μmol/100 g) and reducing power (1926–3586 AAE μg/g) of the bars. Cereal bars maintained good sensory score and overall acceptability at 10 and 5% level of incorporation of API and DPI respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The paradigm change in the lifestyle of the consumers has resulted in greater consumption of ‘convenience foods’ owing to the scarcity of time required for culinary preparations. Various Ready to Eat (RTE), Ready to Use (RTU), and Ready to Seve (RTS) foods and beverages are occupying huge market shelves and includes various products like cookies, carbonated and fruit beverages, and snack foods. However, many of the convenience food products have gained bad repo in the nutrition circles owing to their large sugar, salt, and fat content (particularly saturated and trans fats) (Dhir and Singla 2019). Cereal bars are considered a healthy alternative to conventional convenience foods as these can be tailored to suit the needs of the consumer and allow much flexibility in choosing the ingredients for its formulation (Sahni 2015). Growing demands of consumers for convenient and healthy food have perpetuated the development of a variety of cereal bars rich in protein, fibre, and bioactive constituents (Samuel and Peerkhan 2020; Rawat and Darappa 2015; Marques et al. 2015). These bars are positioned as an alternative healthy snack that allows its consumption as meal replacements or as healthy substitutes to usual snacking products. Due to their enhanced nutritive value and high amount of healthful ingredients; cereal bars have become an integral part of the diet of consumers aspiring for healthy and convenient food products (Dutcosky et al. 2006). Popped millets and brown rice are particularly a good choice for the development of cereal bars due to the presence of high amount of dietary fibre, vitamins, minerals, and bioactive constituents (Huang et al. 2018; Kaur et al. 2018; Sahni 2015).

Particularly, extensive research has been carried out for the development of cereal bars rich in proteins (Samuel and Peerkhan 2020; Coelho Das Neves 2016; Rawat and Darappa 2015; Nadeem et al. 2012) due to its popularity among the youth, where it is utilized for its convenience in various weight loss and muscle gain regimes (Sahni et al. 2018). Besides enhancing the nutritional quality of cereal bars, added protein improves quality attributes of the bar by conferring it good binding, structure and strength, and enhancing water holding capacity and Maillard browning (Nadeem et al. 2012). A variety of ingredients like milk proteins, soy, nuts, and gluten have been utilized for protein-rich formulations (Samuel and Peerkhan 2020; Coelho Das Neves 2016; Rawat and Darappa 2015; Nadeem et al. 2012; Singh and Mohamed 2007). However, utilization of aforesaid ingredients presents a challenge for the development of cereal bars due to reluctance in the consumption of these ingredients by a broad spectrum of the population representing celiac patients and those intolerant to dairy products, soy, and nuts.

However, non-dairy, soy, nut, and gluten-free formulations present a challenge of low protein content. Therefore, it is essential to utilize alternative ingredients to develop nutritious formulations for the development of protein-rich cereal bars. The protein content of such formulations can be improved by adding non-conventional protein ingredients. Non-conventional protein ingredients have witnessed an increase in the market share due to increased veganism and high sustainability. Alternative proteins from plant sources have shown substantial growth in recent years. Alfalfa (Medicago sativa) and dhaincha (Sesbania aculeata) seeds have huge potential for their utilization as alternative non-conventional protein sources due to their high protein content, ease in cultivation, resistance to disease and pests (Sharma and Sahni 2021a, b; Sahni et al. 2021). Alfalfa protein isolate can be a good source for protein supplementation in cereal bars owing to its high protein and essential amino acid content, good techno-functionality, and associated bioactive potential (Sahni et al. 2020). Similarly, dhaincha protein isolate can be a good choice for protein-rich formulations due to its high protein and essential amino acid content, antioxidant capacity, and good hydration and gelation properties (Sahni 2020). Thus, the present investigation was carried out to develop protein-enriched cereal bars using popped millets and brown rice, cornflakes, and non-conventional (alfalfa and dhaincha) protein isolates and to evaluate the developed cereal bar for its quality attributes, nutritional composition, and bioactive potential.

Materials and methods

Material

Alfalfa (Medicago sativa) and dhaincha (Sesbania aculeata) seeds were obtained from Punjab Agricultural University, Ludhiana. Seeds were processed by wet heat processing (110 °C for 10 min) prior to milling (Sahni and Sharma 2020; Sahni et al. 2021) Processed seeds were milled and the flour was passed through 60 mesh sieve. Processing was carried out to improve the techno bio-functionality of the resultant protein isolates (Sahni et al. 2020). Sorghum, brown rice, finger millet, corn flakes, honey (Dabur) and cinnamon powder were procured from local market of Ludhiana.

Preparation of non-conventional (alfalfa and dhiancha) protein isolates (API and DPI)

Protein isolates were prepared by the pH-based solubilisation and precipitation method described by Sahni et al. (2020) by following the procedure of Ahmed et al. (2018) with some modifications. Alfalfa and dhaincha flour were dispersed in distilled water (1:20 flour to water ratio) and homogenized for 60 s (120 s for dhaincha) using a T-25 element of Ultra-Turrax homogenizer (IKA®-Werke GmbH & CO. KG, Staufen, Germany). The pH of the homogenate was adjusted to pH 10.0 using 2 M NaOH for solubilisation of protein, followed by its centrifugation at 5000 × g for 30 min at 4 °C to obtain supernatant. pH of the supernatant was adjusted to pH 4.0 using 2 M HCl and allowed to stand for 60 min (90 min for dhaincha) to induce precipitation of the protein, followed by its recovery by centrifugation at 5000 × g for 30 min at 4 °C. Precipitated protein was re-dispersed in deionised water and neutralised using 0.1 M NaOH, followed by freeze drying using a lyophilizer (Macro Scientific works, New Delhi, India). The prepared alfalfa and dhaincha protein isolates were having water absorption capacity 205 and 239% and least gelation concentration of 20 and 14% respectively.

Preparation of cereal bar

Sorghum, brown rice and finger millet were popped using black salt as conduction medium in an open iron pan (temperature of 170 ± 10 °C, 14% grain moisture content). Popped sorghum (35 g), brown rice (20 g), finger millet (10 g) and corn flakes (35 g) were coarsely crushed. Crushed grains were mixed with cinnamon powder (200 mg) and honey was used as a binding agent (60 g). The composite mixture was evenly filled into stainless steel moulds lined with butter paper and baked at 120 °C for 20 min, followed by cooling. Protein isolates were supplemented at 2.5, 5, 7.5 and 10% (w/w of grains).

Physical properties

Weight and volume of the cereal bar were recorded using digital weighing balance and vernier caliper respectively. Weight and the density of the cereal bar were expressed in g and g/cm3 respectively. Water activity was determined using water activity meter (Thermoconstanter Novasina.TH200, Switzerland) at 28 °C. The non-enzymatic browning index was measured as per Hwang et al. (2001) with some modifications. 5 g sample was extracted with 50 mM CaCl2/ 50 mM Tris buffer (pH 7.0), followed by centrifugation at 2000 × g for 15 min to obtain supernatant. The optical density of the supernatant was measured at wavelength 420 and 550 nm (LMSP-V325; Labman Scientific Instruments) which are corresponding to the formation of early and late Maillard reactions products respectively. Water was used as blank and the non-enzymatic browning index was calculated using the following formula.

Texture

The texture of the bar was evaluated using TA.HDplus Texture Analyzer (Stable Micro System Ltd.). Warner Bratzler Blade was used for measuring the hardness and the maximum force required to break the bar was determined using a single bite test with 20 mm/sec of pre-test and post-test speeds; and 75% compression (Sahni et al. 2019).

Colour measurement

Colour was determined as L*, a*, and b* values using Hunter lab colorimeter (CR‐300 Minolta Camera, Japan). L* value represented lightness (ranging from 0 to 100 for lightness to darkness), a* value represented redness ‘ + a’ to greenness ‘-a’ and b* value represented ‘ + b’ yellowness to ‘-b’ blueness.

Nutritional composition

Moisture, crude protein (using the factor 6.25 × N), crude fat, crude fibre and ash were evaluated using standard procedures (AACC, 2000). Nitrogen Free Extract was estimated by subtracting the sum of moisture, crude protein, crude fat, crude fibre, and ash from 100 (Hossain and Becker 2001) as per the following equation. Values were expressed on a dry-matter basis.

Bioactive constituents and antioxidant activity

1 g sample was extracted with 80% (v/v) methanol. Total phenolic content was estimated colorimetrically by Folin–Ciocalteu assay (Flores et al. 2014). 0.5 mL of methanolic extract was mixed with 0.5 mL deionised water, followed by the addition of 5 mL of 10% (v/v) Folin–Ciocalteu reagent. After 5 min, 4 mL of saturated sodium carbonate was added to it and allowed to stand in dark for 15 min. Absorbance was measured at 765 nm using a spectrophotometer and expressed as gallic acid equivalent (GAE μg/g). Total flavonoids and DPPH radical scavenging activity was evaluated as per Kiranmai et al. (2011). For the estimation of total flavonoids to 1 mL methanolic extract added 1.5 mL pure methanol, 0.1 mL 10% aluminium chloride, 0.1 mL potassium acetate solution, and 2.8 mL deionised water and vortex well to allow proper mixing. Absorbance was measured at 415 nm using spectrophotometer and expressed as quercetin equivalent (QE μg/g). For the estimation of DPPH radical scavenging activity, 1 mL methanolic extract was added in a test tube and added 1 mL tris buffer, followed by the addition of 2 mL DPPH (2,2-diphenyl-1- picryl hydrazyl). Test tubes were incubated for 30 min in dark. Absorbance was measured at 517 nm using a spectrophotometer. Deionised water was used as control and values were expressed as Trolox equivalent antioxidant capacity (TEAC μmol/100 g). Reducing power was estimated as described by Sharma and Sahni (2021a). For determining reducing power, to 1 mL extract added 2.5 mL of phosphate buffer (pH 6.6) and 2.5 mL of 1% potassium ferricyanide, followed by incubation for 20 min. 2.5 mL of 10% trichloroacetic acid was added to it and centrifuged at 3000 × g for 20 min. 2.5 mL of the supernatant obtained was mixed with 2.5 mL water and 0.5 mL FeCl3 (0.1%). Absorbance was measured at 700 nm using spectrophotometer and expressed as ascorbic acid equivalent (AEE μg/g). All the results were expressed on dry matter basis.

Sensory evaluation

Samples coded with random three digit numbers were evaluated for sensory attributes (colour and appearance, texture, taste, flavour, and overall acceptability) using 9 point hedonic rating by 30 semi-trained panellists (15 males and 15 females, 23–57 years old). The evaluation was carried out at 27 ± 2 °C and panellists were provided with drinking water in between the samples for cleansing the mouth.

Statistical analysis

Five replications were taken for the evaluation of physical and textural attributes. Ten replications were taken for colour values whereas triplicate values were taken for the rest of the analysis. The data were analyzed statistically using SPSS software (Version 22.0, IBM Corporation) to determine statistical significance at p < 0.05. ANOVA was performed and means were compared by post-hoc Tukey’s test. Values are represented as mean ± standard deviation Sensory data were subjected to analysis by Friedman bilateral variance rank analysis. Principle component analysis (PCA) was done using Statistica v.12.

Results and discussion

Physical properties

The weight of the cereal bar increased significantly (p < 0.05) with the increased level of supplementation of protein isolates (Table 1). An increase in the weight of the bar can be ascribed to the concurrent increase in the moisture content of the bar with the incorporation of protein isolates (Table 2). A higher increase in the weight was manifested with the same level of supplementation for DPI in comparison to API due to the higher water absorption capacity of DPI. A contrary trend was observed for the water activity, where water activity of the bar decreased with the increase in the level of protein isolate. The reduction in the water activity of the bar can be ascribed to the high water binding capacity of proteins (Sahni et al. 2018). In addition, lower water activity was manifested with bars supplemented with DPI in comparison to API. Lower water activity values for DPI supplemented bars can be justified based on the better gelation behaviour of DPI (14% LGC) that resulted in increased binding of water to denatured proteins at the same level of supplementation. Singh and Mohamed (2007) observed a similar trend of decrease in the water activity of protein-rich cookies with enhancement in the level of soy protein. The low water activity of protein-enriched bars exhibited quality improvement of the cereal bar by virtue of the manifestation of low water activity with increased shelf-life stability of the product.

A concurrent increase in the density of the bar was noted with the increase in the level of incorporation of protein isolates and was found to be higher in cereal bars with DPI in comparison to API at the same level of supplementation. The higher density of DPI supplemented bars can be ascribed to an increase in the weight of bar as well as replacement of coarse particles of grains with finely powdered protein isolate that allowed compact filling of bar mixture in the mould. The non-enzymatic browning index increased concurrently with the supplementation of protein isolates and higher browning was manifested with the incorporation of DPI in comparison to API. Coelho Das Neves (2016) observed the increase in the browning index of bar formulation with high protein content.

Textural characteristics

The incorporation of API caused the increase in the hardness of the bar at 5% level of incorporation, however, further addition of API resulted in a decrease in the hardness value (Table 1). However, the addition of DPI resulted in a concurrent increase in the hardness of the bar, and particularly very high value of hardness was observed with 10% level of supplementation. Proteins from different sources behave differently in protein-rich bar formulations depending on the innate nature of the protein, its interaction with other ingredients, and the resultant physico-chemical characteristics of the bar like moisture content and water activity (Nadeem et al. 2012). The increased hardness of the bar with the incorporation of protein isolates can be manifested with the protein–protein association (Sahni et al. 2018). Though, reduced hardness at 7.5 and 10% API can be due to the increased moisture content of the bar. However, high values of hardness for the bars with DPI in comparison to API supplemented bars can be attributed to better gelation properties (LGC 14%) of the DPI resulting in strong protein–protein interaction. Rawat and Darappa (2015) observed linear increase in the hardness of baked energy bars with the increase in the proportion of protein-rich ingredients in the formulation.

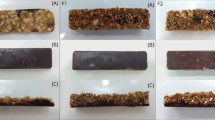

Colour characteristics

L* value of the bar decreased whereas a* value increased with the increase in the protein isolate supplementation (Fig. 1). However, the effect on L* and a* value was more pronounced in bars supplemented with DPI. However, no change in b* value was observed with the supplementation of API whereas incorporation of DPI resulted in the reduction of b* value. The decrease in lightness (L*) and increase in the redness (a*) of bars can be ascribed to the development of Maillard browning products (Sahni et al. 2018). Moreover, the pronounced change in the colour values of DPI supplemented bars in comparison to bars supplemented with API was also concomitant with higher values of the non-enzymatic browning index of DPI as compared to API (Table 1). Coelho Das Neves (2016) also reported similar colour changes in protein bars due to non-enzymatic browning. Overall, bars supplemented with DPI exhibited more pronounced change in the colour in comparison to bars supplemented with API.

Colour characteristics of cereal bars. A (Control), B (AP1 2.5%), C (AP15%), D (AP1 7.5%), E (AP1 10%), F (DP1 2.5%), G (DP15%), H (DP1 7.5%), I (DP1 10%).Values are expressed as mean and error bars represent standard deviation (n = 10). The means with different superscripts are significantly different (p < 0.05). API: Alfalfa protein isolate; DPI: Dhaincha protein isolate

Nutritional composition

A linear increase in the moisture content was observed with the increase in the level of supplementation of protein isolates (Table 2). The moisture content of the bar is based on the cumulative effect of affinity of different ingredients of the bar towards binding water and its loss during baking. In addition, heat-induced gelation of proteins during baking and their consequent improved water binding capacity plays important role in dictating the moisture content of the bar (Sahni et al. 2018). Bars supplemented with DPI exhibited higher moisture content as compared to bars with API due to better water binding capacity and gelation of DPI. A marked increase in the protein content was observed with the incorporation of protein isolates, justifying the utilization of API and DPI for the development of protein-enriched cereal bars. However, no significant (p < 0.05) variation was observed in the protein content of the bar at the same level of supplementation of API and DPI. Ash, fibre, and NFE of bars slightly decreased with the incorporation of protein isolates. Protein isolates majorly contain protein in contrast to grains that have other major constitutes like fibre, minerals, and carbohydrates and therefore can justify aforesaid trend of slight reduction of ash, fibre, and NFE. Rawat and Darappa (2015) reported a similar trend of increase in the moisture and protein content with the addition of protein-rich ingredients in baked energy bars.

Bioactive constituents and antioxidant activity

Table 3 highlights the bioactive potential of developed cereal bars. Cereal bars exhibited a good amount of bioactive constituents and high antioxidant activity attributed to the presence of whole grains. Supplementation of API and DPI further enhanced (p < 0.05) the total phenols, flavonoids, DPPH radical scavenging activity, and reducing power of the bars. An increase in the total phenol content was higher in bars with DPI (1642–4956 GAE μg/g) in comparison to API (1642–4080 GAE μg/g) whereas bars supplemented with API (268–984 QE μg/g) exhibited higher level of flavonoids in comparison to DPI 268–549 QE μg/g). The increase in the bioactive constituents also discerned its effect as a resultant increase in the antioxidant activity of the bars. However, pronounced effect was observed on the reducing power in comparison to DPPH radical scavenging activity. Pronounced effect on reducing power can be attributed to the higher correlation of phenolics and flavonoids with reducing power in contrast to DPPH radical scavenging whereas the increase in the DPPH radical scavenging has been manifested with non-phenolic antioxidants (Al-Laith et al. 2019; Liu et al. 2014; Sharma and Sahni 2021a, b). Cereal bars with DPI exhibited higher increase in the reducing power whereas API supplemented bars showed higher increase in the DPPH radical scavenging activity. Studies have reported the increase in the bioactive constituents and antioxidant potential of cereal bars incorporated with fruit powders (Silva et al. 2016; Marques et al. 2015). The incorporation of API and DPI also exhibited similar enhancement in the bioactive potential of the cereal bars in addition to enhancing the protein content (Table 2).

Sensory characteristics

Incorporation of API exhibited no pronounced effect on the colour and appearance, taste, and flavour score of the bar (Fig. 2a) However, improvement in the texture score was manifested with the 7.5 and 10% level of addition of API with consequent improvement in the overall acceptability of the bar (Fig. 2a). The improvement in the texture score of bars at 7.5 and 10% API can be manifested with the reduced hardness of the bar (Table 1). The incorporation of protein isolates at 7.5 and 10% API improved the bite of the cereal bars. The incorporation of API improved the overall acceptability of the bar, exhibiting high acceptability at 10% API. Contrary to the aforesaid trend, the DPI supplemented bars maintained good sensory quality up to 5% level of incorporation. Marked reduction in all the sensory attributes and low overall acceptability were observed at 7.5 and 10% levels of incorporation of DPI. Particularly, taste and flavour scores exhibited a pronounced decline in the scores due to the manifestation of the typically strong taste and odour of DPI. However, the decline in the texture score of the bar can be correlated with the development of excessive hardness (Table 1).

(a) Quantitative descriptive profile of sensory characteristics of cereal bars (b) Overall acceptability of cereal bars. A (Control), B (AP1 2.5%), C (AP15%), D (AP1 7.5%), E (AP1 10%), F (DP1 2.5%), G (DP15%), H (DP1 7.5%), I (DP1 10%).Values are expressed as mean and error bars represent standard deviation (n = 30). The means with different superscripts are significantly different (p < 0.05). API: Alfalfa protein isolate; DPI: Dhaincha protein isolate

Principle component analysis (PCA)

PCA loading plot (Fig. 3a) depicts the relationship between the different properties of the cereal bars, where properties that lie in the same quadrant are positively correlated whereas properties that lie in the opposite quadrant are negatively correlated to each other. It can be clearly observed that non-enzymatic browning (NEB) and hardness (H) exhibited a negative effect on the overall acceptability (OA) of the cereal bar. It can be discerned from the loading plot that DPPH radical scavenging activity (DPPH RSA) and total flavonoids (TF) are positively correlated whereas reducing power (RP) and total phenols (TP) were positively correlated in cereal bar formulations. PCA score plot (Fig. 3b) reflects the variability in the samples as a function of the distance between different points. It can be observed that samples A, B, F lie in the same quadrant depicting the similarity of 2.5% API and DPI formulation with the control bar. However, the score plot further validates the quality enhancement of protein-enriched bars with 10% API (E) due to high total flavonoids (TF) and DPPH radical scavenging activity (DPPH RSA) without much increase in non-enzymatic browning (NEB) and hardness (H) whereas bar with 5% DPI (G) exhibited a balance of overall acceptability as well as bioactive potential.

Principle component analysis (PCA) showing loading (a) and score plot (b) for cereal bars. H: Hardness, NEB: Non-enzymatic browning, TPC: Total phenols, TF: Total Flavonoids: RP: Reducing Power, DPPH RSA: DPPH Radical Scavenging Activity, MC: Moisture, PC: Protein, Aw: Water Activity, OA: Overall Acceptability, A (Control), B (AP1 2.5%), C (AP15%), D (AP1 7.5%), E (AP1 10%), F (DP1 2.5%), G (DP1 5%), H (DP1 7.5%), I (DP1 10%). API: Alfalfa protein isolate; DPI: Dhaincha protein isolate

Conclusion

Alfalfa and dhaincha protein isolates can be successfully utilized as an alternative non-conventional protein ingredient for the development of protein-enriched non-dairy, gluten, soy, and nut free cereal bars. The addition of protein isolates exhibited improvement in the quality attributes of the cereal bar. The addition of API and DPI not only markedly increased the protein content but also pronouncedly improved the bioactive constituents and antioxidant activity of the bars. Cereal bars with 10% API and 5% DPI maintained good sensory attributes and overall acceptability. Utilization of non-conventional protein isolates for the formulation bars with millets, brown rice, and corn flakes as major ingredient presents an innovative approach to deliver a product with enhanced nutritive value, nutraceutical potential, and suitability for consumption by a broad spectrum of population intolerant to gluten, soy, nuts, and dairy proteins.

References

AACC (2000) Approved methods of the AACC (10th ed). American association of cereal chemists, St. Paul, MN, USA

Ahmed J, Al-Ruwaih N, Mulla M, Rahman MH (2018) Effect of high pressure treatment on functional, rheological and structural properties of kidney bean protein isolate. LWT-Food Sci Technol 91:191–197. https://doi.org/10.1016/j.lwt.2018.01.054

Al-Laith AA, Alkhuzai J, Freije A (2019) Assessment of antioxidant activities of three wild medicinal plants from Bahrain. Arabian J Chem 12(8):2365–2371. https://doi.org/10.1016/j.arabjc.2015.03.004

Coelho das Neves JS (2016) Physical Stability of high protein bars during shelf-life. Instituto Superior Técnico: Lisboa, pp. 39-40

Dhir B, Singla N (2019) Consumption pattern and health implications of convenience foods: a practical review. Curr J Appl Sci Technol 38:1–9. https://doi.org/10.9734/CJAST/2019/v38i630455

Dutcosky SD, Grossmann MVE, Silva RSS, Welsch AK (2006) Combined sensory optimization of a prebiotic cereal product using multicomponent mixture experiments. Food Chem 98(4):630–638. https://doi.org/10.1016/j.foodchem.2005.06.029

Flores FP, Singh RK, Kerr WL, Pegg RB, Kong F (2014) Total phenolics content and antioxidant capacities of microencapsulated blueberry anthocyanins during in vitro digestion. Food Chem 153:272–278. https://doi.org/10.1016/j.foodchem.2013.12.063

Hossain MA, Becker K (2001) Nutritive value and antinutritional factors in different varieties of Sesbania seeds and their morphological fractions. Food Chem 73(4):421–431. https://doi.org/10.1016/S0308-8146(00)00317-4

Huang R, Pan X, Lv J, Zhong W, Yan F, Duan F, Jia L (2018) Effects of explosion puffing on the nutritional composition and digestibility of grains. Int J Food Prop 21(1):2193–2204. https://doi.org/10.1080/10942912.2018.1514634

Hwang JY, Shue YS, Chang HM (2001) Antioxidative activity of roasted and defatted peanut kernels. Food Res Int 34(7):639–647. https://doi.org/10.1016/S0963-9969(01)00083-7

Kaur R, Ahluwalia P, Sachdev PA, Kaur A (2018) Development of gluten-free cereal bar for gluten intolerant population by using quinoa as major ingredient. J Food Sci Technol 55(9):3584–3591. https://doi.org/10.1007/s13197-018-3284-x

Kiranmai M, Kumar CM, Mohammed I (2011) Comparison of total flavanoid content of Azadirachta indica root bark extracts prepared by different methods of extraction. Res J Pharma Bio Chem Sci 2(3):254–261

Liu C, Zhao Y, Li X, Jia J, Chen Y, Hua Z (2014) Antioxidant capacities and main reducing substance contents in 110 fruits and vegetables eaten in China. Food Nutr Sci 5(4):293–307. https://doi.org/10.4236/fns.2014.54036

Marques TR, Corrêa AD, de Carvalho Alves AP, Simão AA, Pinheiro ACM, de Oliveira RV (2015) Cereal bars enriched with antioxidant substances and rich in fiber, prepared with flours of acerola residues. J Food Sci Technol 52(8):5084–5092. https://doi.org/10.1007/s13197-014-1585-2

Nadeem M, Muhammad Anjum F, Murtaza MA, Mueen-ud-Din G (2012) Development, characterization, and optimization of protein level in date bars using response surface methodology. The Sci World J. https://doi.org/10.1100/2012/518702

Rawat N, Darappa I (2015) Effect of ingredients on rheological, nutritional and quality characteristics of fibre and protein enriched baked energy bars. J Food Sci Technol 52(5):3006–3013. https://doi.org/10.1007/s13197-014-1367-x

Sahni P (2015) Cereal bar-your magic bullet for fitness. Small Screen 1(1):46

Sahni P, Sharma S (2020) Influence of processing treatments on cooking quality, functional properties, antinutrients, bioactive potential and mineral profile of alfalfa. LWT-Food Sci Technol 132:109890. https://doi.org/10.1016/j.lwt.2020.109890

Sahni P, Singh B, Sharma S (2018) Functionality of proteins and its interventions in food. IFI Mag 37(3):41–52

Sahni P, Sharma S, Singh B (2019) Evaluation and quality assessment of defatted microalgae meal of Chlorella as an alternative food ingredient in cookies. Nutr Food Sci 49(2):221–231. https://doi.org/10.1108/NFS-06-2018-0171

Sahni P, Sharma S, Surasani VKR (2020) Influence of processing and pH on amino acid profile, morphology, electrophoretic pattern, bioactive potential and functional characteristics of alfalfa protein isolates. Food Chem 333:127503. https://doi.org/10.1016/j.foodchem.2020.127503

Sahni P, Sharma S, Singh B (2021) Impact of different processing treatments on techno and biofunctional characteristics of dhaincha (Sesbania aculeate). Food Sci Technol Int 27(3):251–263. https://doi.org/10.1177/1082013220949812

Sahni P (2020) Quality assessment, characterisation and functionality of forage legumes for food use (Doctoral dissertation, Punjab Agricultural University, Ludhiana)

Samuel KS, Peerkhan N (2020) Pearl millet protein bar: nutritional, organoleptic, textural characterization, and in-vitro protein and starch digestibility. J Food Sci Technol. https://doi.org/10.1007/s13197-020-04381-x

Sharma S, Sahni P (2021a) Germination behaviour, techno-functional characteristics, antinutrients, antioxidant activity and mineral profile of lucerne as influenced by germination regimes. J Food Meas Charact 15(2):1796–1809. https://doi.org/10.1007/s11694-020-00777-7

Sharma S, Sahni P (2021b) Dynamics of germination behaviour, protein secondary structure, technofunctional properties, antinutrients, antioxidant capacity and mineral elements in germinated dhaincha. Food Technol Biotechnol 59(2):238–250. https://doi.org/10.17113/ftb.59.02.21.6922

Silva EPD, Siqueira HH, Damiani C, Boas V, de Barros EV (2016) Physicochemical and sensory characteristics of snack bars added of jerivá flour (Syagrus romanzoffiana). Food Sci Technol 36(3):421–425. https://doi.org/10.1590/1678-457X.08115

Singh M, Mohamed A (2007) Influence of gluten–soy protein blends on the quality of reduced carbohydrates cookies. LWT-Food Sci Technol 40(2):353–360. https://doi.org/10.1016/j.lwt.2005.09.013

Acknowledgements

The award of INSPIRE Fellowship (Sanction Order No. IF170737) by the Department of Science and Technology, India is duly acknowledged.

Funding

INSPIRE Fellowship (Sanction Order No. IF170737) by the Department of Science and Technology (India).

Author information

Authors and Affiliations

Contributions

PS contributed to the conceptualisation of the study, designing and conducting the experiments, statistical analysis, data interpretation, writing the original manuscript draft, and performing critical revision. SS contributed to the supervision, validation, providing resources for the experiments and reviewing the original and revised manuscript drafts. BS contributed to the supervision, validation, providing resources for the experiments. HB contributed to the reviewing of original and revised manuscript drafts.

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflict of interest.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Data availability

All data generated or analysed during this study are included in this article.

Code availability

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sahni, P., Sharma, S., Singh, B. et al. Cereal bar functionalised with non-conventional alfalfa and dhaincha protein isolates: quality characteristics, nutritional composition and antioxidant activity. J Food Sci Technol 59, 3827–3835 (2022). https://doi.org/10.1007/s13197-022-05404-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05404-5