Abstract

In the processing for obtaining acerola juice, a large amount of residues, which is usually discharged, is generated (seeds and bagasse). Adding value to these by-products is of great interest, since their use can enrich human food as a good source of nutrients and dietary fiber. In this study, acerola seed flours (ASF) and acerola bagasse flours (ABF) were used to develop cereal bars (CB) in different combinations with brown oats: CB 1: control - with the addition of 25% brown oats, CB 2: with the addition of 12.5% ASF and 12.5% ABF, CB 3: with the addition of 6.25% ASF and 18.75% ABF, CB 4: with the addition of 12.5% ASF and 12.5% brown oats and CB 5: with the addition of 12.5% ABF and 12.5% brown oats. These bars were sensorially evaluated and CB 1, CB 4 and CB 5 received the highest scores. We conclude that CB 4 and CB 5 can be considered as products with enhanced nutritional value, containing iron with a low energetic value and high levels of dietary fibre, besides being enriched with antioxidants.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The demand for healthy, nutritious and safe food is growing worldwide, and a balanced food intake is the correct way to prevent or even remedy health problems, such as obesity, diabetes, malnutrition, cardiopathies and others, which largely originate from dietary mistakes.

Cereal bars (CB) meet this trend and are elaborated from the mass of grains of sweet and pleasant taste, and are a source of vitamins, mineral nutrients, fibre, protein and complex carbohydrates (Izzo and Niness 2001). These products use a variety of ingredients and cater to various segments of consumers concerned about a healthy life (Palazzolo 2003). Their sensory attributes, added to the demand for health benefits, have enabled the development of CB with new food ingredients, which are also nutritional and functional.

An important constituent found in CB is dietary fibre, mainly derived from oats. Oats are a relatively expensive product, and the search for other cheaper fibre sources becomes relevant to the food industry. Thus, the use of fruit agroindustrial residues could meet this demand, as they are rich in this constituent. The consumption of dietary fibers regulates bowel function, making them relevant to healthy people’s welfare and to the dietary treatment and prevention of many pathologies (Donatto et al. 2006), such as cardiovascular and gastrointestinal diseases, colon cancer, hyperlipidemia, diabetes, obesity, constipation, and hemorrhoids.

Fruit juice processing industries generate large amounts of residues (peel and seeds). These residues are currently used by farmers in the supplementation of animal feed or placed in landfills, causing environmental problems. As this volume corresponds to several tons, adding value to these by-products is of great interest, since these residues are sources of nutrients and fiber.

The use of agroindustrial residues (seed, peel, bagasse) in the manufacturing process of flours as a raw material rich in fibre, for the production of foods that can be included in the human diet, such as acerola residues (seed and bagasse) is considered as an alternative.

Chemical constituents of acerola residues have been reported previously (Aguiar et al., 2010; Marques et al., 2013). Aguiar et al. (2010) studied the chemical composition of acerola seed flour and found, in g 100 g1 dry matter (DM), contents of: proteins (18.70), ether extract (4.33), ash (0.49), total fibre (29.29) and vitamin C (0.08).

Marques et al. (2013) analyzed acerola seed flour and acerola bagasse flour and found high levels (in g 100 g−1 DM) of: insoluble fiber (75.66 and 28.58), soluble fiber (4.76 and 8.74), phenolic compounds (4.73 and 10.82), and vitamin C (12:48 and 10:28), respectively. Furthermore, these flours also showed low levels of antinutritional substances and high levels of minerals. Thus, combining the wealth of constituents and the high volume of discarded residues, they were chosen for the preparation of cereal bars, adding more value to the fruit acerola

Thus, the objective of this study was to use flours of acerola agroindustrial residues (seed and bagasse) by replacing oats in the development of CB and making them more nutritious, with diverse functional properties, as well as verifying their acceptability, with lower prices.

Material and methods

Sample collection and preparation

of Residues (seeds and bagasse) of acerola, Malpighia emarginata DC Variety BRS 238 Frutacor, resulting from pulp extraction, were supplied by a fruit pulp company located in Perdões, State of Minas Gerais, Brazil. Three batches were collected and mixed into a single one to be used in all experiments. The seeds were washed with running water, scrubbed to remove any residual pulp and weighed still wet. The bagasse was frozen at −18 °C, and then seeds and bagasse were dehydrated as described below.

The seeds were placed in ten fine mesh metallic material baskets containing 400 g, and dehydrated at temperature of 45 °C in a forced air oven. Readings for loss of seed weight were performed every 24 hours. The baskets were removed from the oven, weighed on a 3-decimal-place semi-analytical scale and quickly returned to the oven until constant weight. The bagasse was freeze-dried in twelve beakers containing 250 g portions, and protected from light until constant weight.

After dehydration, the seeds were ground in a knife mill (TE 631 Tecnal®) for 3 minutes, packaged in hermetically sealed vials and protected from light in a refrigerator. The lyophilized acerola bagasse from each batch was homogenized in a mortar and subsequently collected and stored the same way as acerola seed flour. Acerola seed flour (ASF) and acerola bagasse flour (ABF) were used in the preparation of cereal bars (CB)

Elaboration of cereal bars

The CB were elaborated containing a liquid phase (50%) and a solid phase (50%). In the liquid phase, the proportions of the binder syrup ingredients were determined by a sequence of preliminary tests, yielding the final formulation for the five cereal bar (CB) treatments in fixed amounts. The amount of each ingredient was determined after preliminary tests.

Brown oats (I-nutri), rice flakes (Harald), honey (Russuel), brown sugar (I-nutri), glucose syrup (Yoki), salt (NaCl) (Cisne), acerola seed flour (ASF) and acerola bagasse flour (ABF) were used for the production of the CB, according to Table 1.

The binder syrup ingredients (brown sugar, glucose syrup and salt), were mixed and heated in a water bath at 90°C for about ten minutes in a stainless steel pot, until reaching soluble solids values from 80° Brix to 85° Brix (Paiva et al. 2012).

The dry phase ingredients (ASF, ABF, rice flakes and brown oats), following the ingredients for each treatment according to Table 1, were manually homogenized in a stainless steel bowl.

After that, the dry phase was added to the binder phase and, during a period of three minutes under heating in a water bath at 90°C, the two phases were mixed, and a uniform mass was obtained. The mass was then distributed in an aluminum form smeared with a thin layer of hydrogenated vegetable fat (Primor) and pressed with a spatula up to a thickness of 1.5 cm.

After cooling at room temperature, the mass was cut to obtain the CBs, which were 2.5 cm wide and 10 cm long, with approximately 25 g each; they were then wrapped with aluminum foil and kept in a sealed plastic container until the beginning of the sensory tests.

Microbiological analyses

Bacteria and yeast counts were made according to Silva et al. (2010), to ensure their microbiological quality. The microorganisms studied were Bacillus cereus, Samonella sp, total and thermotolerant coliforms (fecal ones), besides the fungus Penicillium sp.

Sensory evaluation

The evaluation of the CB acceptance in this study was approved by the Ethics Committee on Human Research of Universidade Federal de Lavras (UFLA—Protocol 0008.0.461.000-11).

The formulations of the cereal bars (Table 1) were evaluated by 80 untrained adult consumers (aged 18–30 years). The attributes evaluated were aspect, texture, flavor, overall appearance and purchase intention. The acceptance test was performed using a 9-point hedonic scale (9 = like extremely, 1 = dislike extremely) and the purchase intention test using a 5-point scale (5 = certainly would buy the product, 1 = certainly would not buy the product).

The tests were conducted in individual booths, under white light, and the samples (CB 1, CB 2, CB 3, CB 4 and CB 5) were presented to the consumers in a balanced way, served in disposable plastic cups and placed on a white bench and coded with three random digits.

Analyses of cereal bars

Four recipes of each bar were prepared, CB 1, CB 4 and CB 5 (which showed a better acceptance, and the one that does not contain ASF and ABF - CB 1), as described in the methodology, and they were submitted to analyses of chemical and mineral composition, soluble solids, phenolic compounds, vitamin C, colour, water activity and texture. For the analysis of chemical and mineral composition, soluble solids, phenolic compounds and vitamin C, the bars were placed in a freezer at −17°C to be frozen and subsequently homogenized in a mortar and stored in a freezer at −17°C. All analyses of CBs were performed in duplicate.

Proximate and mineral composition, soluble solids and caloric value

The chemical composition of the CB (moisture, ether extract, crude protein (NX6.25), ash, dietary fibre and nitrogen-free extract) was performed using the method described by the Association of Official Analytical Chemists - AOAC (2005).

In order to quantify minerals (Ca, P, Mg, S, Cu, Mn, Zn, Fe and Na), the CB were subjected to a nitropercloric digestion in digestion blocks with temperature control. P and S were determined by colorimetry, Na and K by flame photometry and Ca, Mg, Cu, Mn, Zn and Fe by atomic absorption spectrophotometry (Malavolta et al. 1997). The content of soluble solids was determined by the readings performed using an Atago hand-held refractometer, (N-1E) with °BRIX between 0 and 32%, as described by the AOAC (2005).

The calculations of caloric value for the CB were performed using ATWATER coefficients (carbohydrates = 4.0, lipids = 9.0, and proteins = 4.0).

Phenolic compounds and vitamin C

The extraction of phenolic compounds from the CB was performed with 50% methanol in reflux for three consecutive times at 80 °C, in the ratio 1:25 (w/v). The extracts were combined, evaporated to 25 mL and subjected to determination, using the Folin-Denis reagent (AOAC 2005). Tannic acid was used as a standard.

Vitamin C from the CB was determined by the colorimetric method described by Strohecker and Henning (1967). Ascorbic acid was extracted with 0.5% oxalic acid, in the ratio 1:30 (w/v). After filtration, vitamin C was dosed in the extract, using ascorbic acid as a standard.

Color, water activity and texture

For the CB color determination (L*, a* and b*), readings were taken using a spectrocolorimeter, manufactured by Konica Minolta, Model CM-5. L*(lightness), a*(redness) and b*(yellowness) readings were based on the CIELab system, with the following characteristics: 30.0 mm measurement area, 10° angle of view, illuminant D65 with specular component included.

Water activity in the CB was measured with a 3TE AquaLab water activity meter, series 3B, v 3.0 (Decagon Devices Inc. WA, USA) with a standard water activity of 0.500, at 25°C (AOAC 2005).

The CB texture was measured in an SMS TAXT2i texturometer, using a 25 Kg load cell and application program supplied with the equipment (Texture Expert for Windows, version 1.19). To measure shear strength, an HDP/BSK stainless steel blade was used which was adjusted to pierce the sample at a speed of 2 mm s−1. The maximum shear force, in Newtons (N), was automatically determined by the program.

Statistical analysis

Sensory tests were performed using a balanced complete block design (BCBD) and the samples were offered in five treatments (5 CB types) and 80 untrained panelists to represent consumers.

To choose the best bars, sensory data were statistically analyzed by a three-way internal preference map (Nunes et al. 2011), which allows the evaluation of sample acceptability according to the panelists’ hedonic scores, considering the information on the acceptance of several attributes simultaneously. The three-way preference map was obtained by parallel factor analysis (PARAFAC) (Bro 1997) from a three dimensional data set, consisting of 5 bars × 80 panelists x × attributes.

Analyses of chemical and mineral composition, soluble solids, phenolic compounds, vitamin C, water activity and texture in the bars were carried out in a completely randomized design (CRD), with three treatments and eight replicates. The results were evaluated by Analysis of variance with the R software (TEAM 2011), and treatment means were compared by the Tukey test at 5% probability.

Results and Discussion

The microbiological analyses performed in the CB: CB 1, CB 2, CB 3, CB 4 and CB 5 for Bacillus cereus, Salmonella sp, total coliforms, thermotolerant coliforms and Penicillium sp, were in accordance with RDC 12 (ANVISA 2001); the bars are suitable for consumption.

Sensory analysis

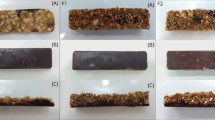

The most accepted bars (Fig. 1) were CB 4 (with the addition of 12.5% ASF and 12.5% brown oats), CB 5 (with the addition of 12.5% ABF and 12.5% brown oats), followed by CB 1 (with the addition of 25% brown oats). Results show that all attributes analyzed had influence on the separation of the bars CB 1, CB 4 and CB 5, since there are a large number of consumers (vectors) towards these samples. The greater preference for these bars can be mainly attributed to higher scores for the attributes aspect, texture, flavor, overall appearance and purchase intention on the hedonic scale (Table 2).

Dispersion of the five cereal bars (CB) in relation to consumer acceptance of various attributes •=samples of the five CBs; /=consumers and =attributes evaluated (aspect, texture, flavour, overall appearance and purchase intention). Cereal bars (CB): CB 1: control - with the addition of 25% brown oats, CB 2: with the addition of 12.5% acerola seed flour (ASF) and 12.5% acerola bagasse flour (ABF), CB 3: with the addition of 6.25% ASF and 18.75% ABF, CB 4: with the addition of 12.5% ASF and 12.5% brown oats and CB 5: with the addition of 12.5% ABF and 12.5% brown oats

For the bars CB 1, CB 4 and CB 5, there was a higher percentage of frequency of scores above 5 for the attributes aspect, texture, flavor and overall appearance, indicating that the panelists liked these bars. While for the attribute purchase intention, the highest percentage of scores was above 3 for the same bars, indicating that the panelists would buy them.

Chemical composition and total caloric value of the cereal bars CB1, CB 4 and CB 5

Moisture determination of very important, as it is the main factor for the development of fungi, yeast and bacteria. In this study, there was a higher moisture content in CB 5 (13.12 g 100 g−1), which differed statistically from those found in CB 1 and CB 4 (Table 3).

Our finding corroborated previous reports that CB are prepared from agroindustrial residues and differed moisture contents in g 100 g−1, ranging from 9.44 to 11.70 (Paiva et al. 2012), 9.73 (Lima et al. 2010) and 4.61 (Fonseca et al. 2011). This variation is probably due to the components used in the preparation of the bars. However, these moisture contents are in with CNNPA Resolution n°12, 1978, which establishes a 15% moisture limit for cereal products (ANVISA 1978).

There was no significant difference (P > 0.05) in ether extract, crude protein and ash among the bars analyzed (Table 3). Paiva et al. (2012) recorded ether extract contents ranging from 6.72 to 9.98 g 100 g−1, crude protein ranging from 8.12 to 12.43 g 100 g−1 and ash varying from 1.11 to 1.63 g 100 g−1 in CB produced with residues of rice, soy, pineapple and brown pequi. Gutkoski et al. (2007) reported an average ether extract levels of 6.57 g 100 g−1, crude protein levels of 11.43 g 100 g−1 in oat-based CB, and Fonseca et al. (2011), studying CB in passion fruit peel jelly, reported ether extract contents of 9.86 g 100 g−1, protein contents of 9.05 g 100 g−1and ash contents of 1.17 g 100 g−1. We observed lower levels of ether extract and crude protein for the bars in the present study. These differences are due to the different residues used, which have different compositions. The consumption of a portion (25 g) of CB 4 or CB 5 provides approximately 0.13 g ether extract; thus, it appears that the CBs in this study, prepared by partially replacing oats with ASF and ABF, present low levels of ether extract (triacylglycerols), being excellent for individuals who consume CBs as a healthy and less caloric snack option.

The ingestion of a portion (25 g) of CB 4 and CB 5 provides 1.45 g and 1.58 g protein, respectively. These levels meet 3.14% and 3.42% of the protein recommended dietary allowance (RDA), respectively, considering that the daily need of an adult male (70 kg) is 46.2 g protein day−1 (IOM - Institute of Medicine of the Natural Academies 2005a).

Regarding the total dietary fiber content, CB 4 and CB 5 showed higher levels (about 75%), when compared to CB 1 (Table 3). CB 5 had the highest content of soluble fiber (about 68% higher than the control bar, CB 1). These results show, it is clear that ASF and ABF increased the levels of dietary fiber, which are essential to maintain a good health and reduce the risk of various diseases, such as cardiovascular diseases and diabetes.

The fiber contents of the CB in this study were higher than those in CB prepared with residues of rice, pequi, soy and pineapple (11.61 to 21.19 g 100 g−1) (Paiva et al., 2012), in passion fruit residue (albedo, peel) based CBs (11.81 g 100 g−1) (Silva et al., 2009), in CB made from baru pulp and almond (14.86 to 16.73 g 100 g−1) (Lima et al., 2010) and in CB made from pineapple peel jelly (5.33 g 100 g−1) (Fonseca et al. (2011). These differences are also due to the constituents present in the residues used in the preparation of the CB.

CB 4 and CB 5 can be classified as rich in dietary fiber, because Brazilian law requires a minimum of 6 g 100 g−1 (for solids) for such classification; thus, they can be claimed as functional food (ANVISA 1998). IOM - Institute of Medicine of the Natural Academies (2005a) recommends an intake of 25 to 38 g fiber per day. Thus, the ingestion of a portion (25 g) of CB 4 or CB 5 provides approximately 11 g fiber, which meets 29-44% of the RDA.

The total soluble solids in CB 4 and CB 5 showed significant differences (P < 0.05) and were lower than that found in CB 1 (Table 3). Paiva et al. (2012), analyzing CB obtained from residues of rice, soy, pineapple and brown pequi, reported soluble solids levels (°Brix) between 55 and 65, which are higher levels. These differences are due to the constituents present in the residues used to obtain CB.

The content of phenolic compounds in CB 4 and CB 5 was high, compared to CB 1 (Table 3), up to about 5 times higher, increasing the antioxidant capacity of these bars. Sampaio et al. (2010) studied CB fortified with iron and found 0.69 g 100 g−1 phenolic compounds, which was lower than that found in this study.

The daily intake of phenolic antioxidants has played an important role in reducing the risk of developing diseases, such as atherosclerosis, cardiovascular diseases, cancer, infections and Alzheimer’s disease. They also present antimicrobial and antiviral action (Fruhwirth and Hermetter 2007) but, depending on the amount ingested, they can cause undesirable effects, such as inhibition of certain digestive enzymes, e. g. trypsin, forming complexes with proteins and decreasing their digestibility (Sathe 2002). In the literature, there is no consensus on the recommended intake of phenolic compounds; therefore, consumption levels considered acceptable were not found (Sathe, 2002; Peuckert et al., 2010; Marques et al., 2013).

In this study, vitamin C levels in CB 4 and CB 5 showed significant differences, and CB 5 showed the highest content (Table 3). Peuckert et al. (2010), analyzed a cereal bar added with textured soy protein and camu-camu and found a vitamin C level of 0.06 g 100 g−1, which was lower than in this study. This difference may be due to the different ingredients used in the preparationof the bar, which have different compositions, as the high content of vitamin C found in ABF (Marques et al. 2013).

The recommended daily intake of vitamin C is 90 mg for adult men and 75 mg for adult womwn (IOM - Institute of Medicine of the Natural Academies 2000). Thus, the consumption of a portion (25 g) of CB 4 and CB 5 provides 17.5 mg and 275.0 mg of vitamin C, respectively. These levels respond for 19% and 23% of the vitamin C RDA in CB 4, and exceed 100% in CB 5. Vitamin C is essential for humans and it acts as an antioxidant and free radical scavenger, besides nourishing cells and protecting them from damage caused by oxidants. Therefore, CB 4 and CB 5 can be classified as a good source of vitamin C, since they meet 20 ~ 100% of the recommended daily intake (IOM - Institute of Medicine of the Natural Academies 2000).

There was no significant differences (P > 0.05) in calories between CB 4 and CB 5 (Table 3). However, there was a reduction in calories whwn compared to CB 1, a fact related to an increase in the levels of dietary fiber and lower levels of carbohydrates present in these formulations. Therefore, the partial replacement of oats by ASF and ABF did not increase the caloric value of the CB, being within the established limits for CB considered as reduced calorie products.

Gutkoski et al. (2007) developed CB with a high dietary fiber content (10-20%), and pointed a caloric variation from 291 to 313 kcal 100 g−1 between the treatments. Paiva et al. (2012) found a caloric variation from 312 to 344.2 kcal 100 g−1 of CB in residue of rice, soy, pineapple and brown pequi while Fonseca et al. (2011) reported 404.86 kcal 100 g−1 of CB in residue of pineapple peel jelly. Therefore, the CB containing ASF and ABF were much less caloric.

We observe calcium only in the bars prepared with a partial replacement of oats with flours, and that iron contents in CB 4, as well as the levels of potassium and sodium in CB 5, were higher than those of CB 1, entailed by the use of ASF and ABF (Table 4).

According to National Health Surveillance Agency (1998)), “a food source of vitamins and minerals” is one with at least 15% of the Dietary Reference Intake (DRI) per 100 grams of solid food, and "a food rich in minerals and vitamins" is one that contains at least 30% of the DRI per 100 grams of solid food.

Results show that a 25 g portion (commercial size) of CB 4 and CB 5 meets the daily recommendation for adults, respectively, of calcium (0.82% and 0.27%) IOM-Institute of Medicine of the Natural Academies (2011)); phosphorus (5.97% and 5.68%), potassium (0.81% and 1.02%), magnesium (3.54% and 3.57%), copper (6.43% and 5.36%), manganese (12.93% and 14.57%), zinc (4.15% and 3.62%) and iron (21.17% and 14.33%) (IOM - Institute of Medicine of the Natural Academies 2005b). Therefore, CB 4 is an iron source.

Paiva et al. (2012), studying CB prepared with residues of rice, soy, pineapple and brown pequi, found higher P, K, Mg, Cu, Mn, Zn and Fe levels (in mg 100 g−1), respectively: 175.0 to 275.0, 242.5 to 495.0, 97.5 to 170.0, 0.53 to 0.91, 1.40 to 1.56, 1.69 to 2.38, 3.33 to 5.58, while Fonseca et al. (2011), analysing CBs elaborated with pineapple peel, found Ca, P, K, Mg, Cu, Mn, Zn and Fe levels (in mg 100 g−1), of respectively: 68, 218, 263, 103, 0.31 2.50, 1.72, 1.87. Only the iron level was lower than that found for the cereal bars of the present study. These differences are probably due to the type of residue used for the preparation of the CB.

Sodium levels, the ones found in CB 1 and CB 4 were statistically equal, and lower than CB 5 (Table 4). Sodium is mineral that should be present in the amount of 2,400 mg day−1 (daily DRI) in human food, which corresponds to 6 g salt (ANVISA 1998), because the excess of this mineral in the diet can bring health risk, e. g. the development of cardiovascular problems, such as hypertension, strokes and renal insufficiency. Thus, the consumption of a 25 g portion of CB 1, CB 4 and CB 5 does not exceed 0.5% of the sodium daily recommended dietary allowance.

Lower sodium contents are positive. Marketed CB has considerably higher sodium levels, which range from 13 to 36 mg in 25 g of product (Fonseca et al. 2011), being higher than the ones found for the bars of this study, which were 10.27 mg, at most. Food sources of minerals and with a low sodium content may be viable options for people who need to increase their intake of these essential nutrients, without consuming excessive sodium (Fonseca et al. 2011). Thus, CB 4 and CB 5 are good choices as a source of minerals with low sodium levels.

Evaluation of color, texture and water activity in the cereal bars CB 1, CB 4 and CB 5

Results show that L* values were between 49.00 and 56.49. L* values define color lightness between 0 (zero), which indicates pure black (no color) to 100 (one hundred), pure white (alb color) (Table 5). Thus, the L* values found in the CB (CB 1, CB 4 and CB 5) are basically intermediate. CB 4 and CB 5 showed a lower lightness, when compared to CB 1 (control).

The color a*, which ranges from green to red (−60 to +60), indicates the existence of red pigments in positive values. CB 4 and CB 5 show a tendency to the green color, that is, they had values that indicate small amounts of red pigments. The color b* refers to the changes from blue to yellow (−60 to +60). In the analyzed CBs, yellow is present with positive values. Thus, a darkening occurred (reduced values of the parameters L* and b*) in CB 4 and CB 5, due to the addition of ASF and ABF in the formulation. These results were similar to those reported by Silva et al. (2009) in CBs developed with passion fruit agroindustrial residues.

Were also observed that the addition of ASF and ABF for the elaboration of CB 4 and CB 5 significantly altered the texture in relation to the control bar (CB 1). The increase in shear strength and hardness in the bars CB 4 and CB 5 can be explained by the compression of the bars, caused by the presence of dietary fibers, besides granulometric differences between brown oats and ASF and ABF, added in the preparation of the bars. These results are in accordance with Silva et al. (2009), who found that the addition of passion fruit residue flour, in replacement to oats, provided high shear strength and hardness.

All bars analysed presented water activity (Aw) below 0.6, indicating food safety. For any kind of bacteria, the minimum Aw value required for growth is 0.75, while osmophilic yeast (which are resistant to mediums with high sugar concentrations), and xerophilic fungi (which survive in mediums with little water) are capable of developing into water activities ranging from 0.61 to 0.65, respectively, using sugars and glucose as substrates (Evangelista 2005, Silva 2000). Thus, these values grant the CB a microbiological safety during storage, under appropriate packaging and temperature conditions.

Nutrition facts table of the cereal bars CB 1, CB 4, CB 5 and of the marketed ones

Glaser (2013) conducted a study comparing 30 types of CB of 10 different brands sold in Brazil. Nutritional information was taken from the labels. Comparing the bars CB 1, CB 4 and BC 5 with the ones recorded by Glaser (2013), it is possible to consider that these CBs presented lower calories, total fat and sodium, and high levels of dietary fiber (Table 6).

From Ordinance n° 27/98 of Secretaria de Vigilância Sanitária do Ministério da Saúde, which deals with complementary nutritional information, the cereal bars CB 1, CB 4 and CB 5 can be classified as products with a reduced caloric value, with a high fiber content, and also as an iron source (ANVISA 1998). Moreover, due to the high contents of phenolic compounds and vitamin C of the residue flours used in the preparation of CB 4 and CB 5, there was an increase in the levels of these constituents, which are antioxidants.

Therefore, the partial replacement of oats (25%) by ASF and ABF in the proportion of 12.5% for the preparation of the cereal bars CB 4 and CB 5 led to improvements in the sensory attributes and consumer preference.

Conclusion

The use of ASF and ABF in the formulation of the cereal bars CB 4 (with the addition of 12.5% ASF and 12.5% brown oats) and CB 5 (with the addition of 12.5% ABF and 12.5% brown oats) provided products with a higher nutritional value, meeting the demands of the current consumer market, with low sodium and energetic value contents, and high levels of dietary fiber and iron; they are also enriched with phenolic compounds and vitamin C, which are antioxidants, being an alternative for consumers of healthy and functional food. In addition, the partial replacement of oats with acerola flour residues may result in a cheaper product, adding value to these by-products and avoiding their disposal into the environment.

References

Aguiar TM, Rodrigues FS, Santos ER, Sabaa-Srur AUO (2010) Chemical characterization and evaluation of the nutritional value of Malpighia punicifolia seeds. J Brazilian Soc Food Nutr 35:91–102

AOAC (2005) Official methods of Analysis. Association of Official Analytical Chemists, 18 th ed. Washington, USA.

Bro R (1997) PARAFAC. Tutorial and applications Chemometr Intell Lab 38:149–171

Donatto FF, Pallanch A, Cavaglieri CR (2006) Dietary Fibers: therapeutic effects and in exercise. Health R 8:65–71

Evangelista J (2005) Food Technology. Atheneu, São Paulo

Fonseca RS, Del Santo VR, Souza GB, Pereira CAM (2011) Preparation of cereal bar with peel pineapple. ALAN 61:216–223

Fruhwirth GO, Hermetter A (2007) Seeds and oil of the Styrian oil pumpkin: components and biological activities. Eur J Lipid Sci Tech 109:1128–1140

Glaser Y (2013) Comparison of the nutritional values of cereal bars. http://www.mundotri.com.br/arquivos. Accessed 8 Jan 2013

Gutkoski LC, Bonamigo JMA, Teixeira DMF, Pedó I (2007) Development of oat based cereal bars with high dietary fiber content. J Brazilian Soc Food Nutr 27:355–363

IOM - Institute of Medicine of the Natural Academies (2000) Dietary Reference Intakes for vitamin C, vitamin E, selenium and carotenoids. National Academy Press, Washington

IOM - Institute of Medicine of the Natural Academies (2005a) Dietary Reference Intakes for Energy, Carbohydrate, Fiber, Fat, Fatty Acids, Cholesterol, Protein and Amino Acids. National Academies, Washington

IOM - Institute of Medicine of the Natural Academies (2005b) Dietary reference intakes for energy. National Academy, Washington

IOM-Institute of Medicine of the Natural Academies (2011) Dietary Reference Intakes for Vitamin D and Calcium. National Academy Press, Washington

Izzo M, Niness K (2001) Formulating nutrition bars with inulin and oligofructose. C Food World 46:102–105

Lima JCR, Freitas JB, Czeder LP, Fernandes DC, Naves MMV (2010) Microbiological quality, acceptability and nutritional value of cereal bars made with squash and almond baru. B CEPPA 28:331–343

Malavolta E, Vitti GC, Oliveira AS (1997) Assessment of nutritional status of plants: principles and applications. POTAFOS, Piracicaba (in Portuguese)

Marques TR, Corrêa AD, Lino JBR, Abreu CMP, Simão AA (2013) Chemical components and functional properties of acerola (Malpighia emarginata dc.) residue flour. J Food Sci Technol 33:526–531

ANVISA - National Health Surveillance Agency (1978) Resolution CNNPA n° 12. 1978. http://www.anvisa.gov.br/legis/resol/12_78.pdf. Accessed 10 Dec 2012

ANVISA - National Health Surveillance Agency (1998) Technical regulation concerning disclosure nutritional supplementary. Ordinance n° 27 de 13 de jan de1998. http://portal.anvisa.gov.br/wps/wcm/connect/9180ca00474581008d31dd 3fbc4c6735/PORTARIA_27_1998.pdf?MOD=AJPERES. Accessed 27 Jan2013

ANVISA National Health Surveillance Agency (2001) Technical Regulation on microbiological standards for foods. Resolution RDC no12, de 02 de jan de 2001.http://portal.anvisa.gov.br/wps/wcm/connect/a47bab8047458b909541d53fbc4c6 735/RDC_12_2001.pdf?MOD=AJPERES. Accessed 27 Jan 2013

Nunes CA, Pinheiro ACM, Bastos SC (2011) Evaluating consumer acceptance tests by three-way internal preference mapping obtained by parallel factor analysis (PARAFAC). J Sens Stud 26:167–174

Paiva AP, Barcelos AFP, Pereira JAR, Ciabotti EBF (2012) Characterization of food bars manufactured with Agroindustrial by-products and waste. R Ciênc Agrotec 36:333–340

Palazzolo G (2003) Cereal bars: they’re not just for breakfast anymore. Cereal Food World 48:70–72

Peuckert YP, Viera VB, Hecktheuer LHR, Marques CT, Rosa CS (2010) Characterization and acceptability of cereal bars added soy protein and Camu - camu (Myrciaria Dúbia). Alim Nutr 21:147–152

Sampaio CRP, Ferreira SMR, Canniatti-Brazaca SG (2010) Physico-chemical characterization and composition of cereal bars fortified with iron. Alim Nutr 21:607–616

Sathe SK (2002) Dry bean protein functionality. Crit Rev Biotechnol 22:175–223

Silva JA (2000) Topics of food technology. Livraria Varela, São Paulo (in portuguese)

Silva IQ, Oliveira BCF, Lopes AS, Pena RS (2009) Obtaining cereal bar added the industrial waste passion. Alim Nutr 20:321–329

Silva N, Junqueira VCA, Silveira NFA (2010) Manual of methods for the microbiological examination of foods. Livraria Varela, São Paulo (in portuguese)

Strohecker R, Henning HM (1967) Analisis de vitaminas: metodos comprobados. Madrid, Paz Montalvo

TEAM, R DEVELOPMENT CORE (2011) A language and environment for statistical computing R Foundation for Statistical Computing, Viena

Acknowledgements

We would like to thank Fundação de Amparo a Pesquisa de Minas Gerais - FAPEMIG, Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - CAPES and Conselho Nacional de Desenvolvimento Científico e Tecnológico - CNPq.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marques, T.R., Corrêa, A.D., de Carvalho Alves, A.P. et al. Cereal bars enriched with antioxidant substances and rich in fiber, prepared with flours of acerola residues. J Food Sci Technol 52, 5084–5092 (2015). https://doi.org/10.1007/s13197-014-1585-2

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-014-1585-2