Abstract

In this research, the protein concentration, the permeate flux, and the predominant fouling mechanisms were investigated during ultrafiltration of different whey samples. The research was carried out at different values of transmembrane pressure and temperature using an experimental design, and a protein concentration of approximately 37 g L−1 was obtained for the bovine whey powder solution, at 60 kPa and 40 °C. The maximum flux observed was 8.9 and 7.9 kg m−2 h−1, respectively, for the bovine whey powder solution and bovine whey, at 50 kPa and 30 °C. Although goat and buffalo whey presented lower permeate flux, probably due to high solutes and calcium contents, protein concentrates of around 40 g L−1 were obtained using the ultrafiltration process. This demonstrates the potential of ultrafiltration to obtain non-bovine protein concentrates. The best fit, verified by Ho and Zydney model, suggests that the fouling for all analyzed whey occurs due to pore blocking and subsequent deposit on the membrane surface.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

World milk production has been growing for several decades. According to FAO data, production increased from 500 million tonnes in 1983 to approximately 830 million tonnes in 2018 (FAO 2018). Cow milk corresponds to 83% of milk produced and buffalo milk to 14%, the rest having its origin in goat, sheep and camel production (Villa et al. 2018). Of the total milk produced in Europe, for example, 37% are destined for the manufacture of cheese (Eurostat 2019).

Most of the milk used in cheese production is processed into whey after protein coagulation. On average 9 L of whey is generated for each kg of cheese produced. In the past it was considered as waste due to its high environmental impact, however, whey has an important nutritional composition coupled with high values of chemical and biochemical oxygen demand (COD and BOD) (Baldasso et al. 2011).

In view of the importance and the large volume of whey, the need has arisen to develop processes to recover and concentrate its nutrients, as well as to avoid its improper disposal and environmental impact. The main target of the processes that use membranes is the recovery of whey proteins. Whey proteins have a nutritional quality widely known, because of their biological value higher than egg, meat and soy protein (Smithers 2015).

Moreover, whey proteins also have functional properties of interest to the industry, such as solubility, emulsifying power, gelling and foaming (Nishanthi et al. 2017). Thus, the whey can be used to obtain various products of high nutritional value, such as fruit beverages (Amaral et al. 2018; Cappato et al. 2018), chocolate beverage (Oliveira et al. 2017), fermented beverages (Lievore et al. 2015; Sabokbar and Khodaiyan 2016), bakery products (Díaz-Ramírez et al. 2016), and dairy products such as yogurts (Mahomud et al. 2017), ice cream, frozen desserts, and popsicles (Gajo et al. 2017; Martins et al. 2018). Although cow milk is one of the most common to the development of these products, milk proteins from other sources also deserve to be researched and applied industrially. Goat milk, for example, presents high nutritional value, has good digestibility, and is well tolerated by individuals with cow milk allergy (Lou et al. 2018; Li et al. 2019). Buffalo milk, in turn, has a higher lipid, protein, lactose and mineral composition than other species (Mahmood and Usman 2010). Due to the growing interest and exploration of buffalo milk for the production of Mozzarella cheese, the resulting whey volume is also increasing (Sameer et al. 2020).

However, the literature regarding fresh whey and the recovery of goat and buffalo whey proteins is scarce. Because the most research uses whey protein concentrate from cow origin to simulate whey solution. So, the literature still lacks studies that report the performance of the ultrafiltration process when non-bovine whey is used. Considering membrane separation processes, the main challenge is still to identify the set of process conditions that minimize the effects of the restrictive phenomena to the flux, known as concentration polarization and fouling. The main parameters that affect the permeate flux are pressure, temperature and feed concentration. Therefore, the present article aimed to study ultrafiltration to recover proteins from commercial whey powder and fresh whey of bovine, goat and buffalo origin, using different temperatures and pressures. The identification of the predominant fouling mechanisms during the ultrafiltration process was also investigated.

Materials and methods

Whey samples

Sweet whey powder from the production of Mozzarella cheese was donated by Alibra Ingredients, Ltda (Campinas, SP, Brazil). For the preparation of the sample, whey powder was reconstituted by manually dissolving it in distilled water at 30 °C, with a soluble solids content of 6% (w/v).

The samples of fresh whey from bovine, goat and buffalo origin were donated by the Technological School of Milk and Cheese of Campos Gerais (Ponta Grossa, PR, Brazil). Bovine and buffalo whey samples were obtained from the production of Mozzarella cheese and a sample of goat origin from Feta cheese. The cheese fines were removed using a 200 mesh sieve, prior to the ultrafiltration.

Ultrafiltration process

The ultrafiltration (UF) process was conducted on a laboratory scale in a Pellicon® Ultrafiltration System from Millipore, which operates with the tangential flow. A membrane cassette composed of polyurethane and polypropylene with a nominal molecular weight limit (NMWL) of 10 kDa and a filtration area of 0.5 m2 was used. A jacketed feed tank (4 L capacity) was used together with an ultra-thermostatic water bath (Thermomix BM, B. Braun Biotech International) for temperature control.

In the first operation mode, the concentrate and permeate were continuously recycled to the feed tank to ensure steady-state conditions in relation to the volume and composition of the feed. The whey powder solution was used in these tests to define the best UF experimental conditions by a Central Composite Rotatable Design (CCRD). In total, 11 experiments were performed using the 22 experimental design with a star configuration (four axial points) and three central points, with varying temperatures in the range of 16–44 °C and a pressure of 10–70 kPa. The levels of the variables were defined based on preliminary experiments and on literature information. All the experiments were carried out in a randomized way.

After evaluation of the effect of the variables pressure and temperature in the process, the bovine, goat and buffalo fresh whey samples were ultrafiltrated under the best experimental conditions in batch mode. In this operation mode, the permeate stream is continuously removed from the system.

The permeate flux was determined by the gravimetric method using Eq. 1:

where \(J\) is the permeate flux (kg m−2 h−1), \(m_{p}\) is the mass (kg)accumulated in the permeate stream during the filtration time \(t\)(h), and \(S\) is the membrane surface area (m2).

Mathematical models

The pore blocking models, proposed by Hérmia (1982) and adapted by Field et al. (1995) is described by Eq. 2:

where \(J_{p}\) is the permeate flux in time \(t,J^{*}\) is the value of steady-state permeate flux in the operating conditions,\(k_{n}\) and \(n\) represent the phenomenological coefficient and the general fouling index, respectively.

According to the value of \(n\), four blocking mechanisms are proposed, which result in different corresponding integrated forms of Eq. 2.

Considering value of \(n = 2.0\), the complete pore blocking model is obtained, represented by Eq. 3.

For \(n = 1.5\) the internal pore blocking model is defined by Eq. 4.

The value \(n = 1.0\) gives the partial pore blocking model, described by Eq. 5.

The four model is the cake filtration, resulted by \(n = 0\), Eq. 6.

where \(J_{0}\) is the flux at time zero and \(J_{lim}\) is the flux measured at the last minute of operation approaching the flux of the stationary region.

However, previous studies have shown that these simple models may be insufficient to describe the fouling in the UF process. Based on this, efforts were made to develop more sophisticated combined mathematical models, which take into account both pore blocking and cake formation. Thus, the model developed by Ho and Zydney (2000), Eq. 7, which considers fouling to be a two-stage process with localized pore blocking prior to the build-up of a surface deposit, was also selected to analyze the flux decrease during whey ultrafiltration.

Assuming a uniform resistance of the cake layer over the fouled membrane surface, an equation for J in time t is proposed:

where α is the pore blockage parameter, ΔP is the transmembrane pressure, Cb is the bulk protein concentration, μ is the solution viscosity, Rm is the resistance of the clean membrane and Rp is the resistance due to the particle deposits on the membrane surface.

The models were adjusted by non-linear least squares regression analysis at a 95% confidence interval. The Statistica software (version 10.0) was used for all of the calculations. The sum of squared residuals (SSR) and the coefficient of determination (R2) were defined as the evaluation criteria for the models.

Physicochemical characterization

The whey samples were characterized by pH using the digital pH meter (Gehaka, model PG 1800); chemical oxygen demand (COD) using colorimetric method with closed reflux (APHA 2005); turbidity was determined using a portable turbidimeter (Policontrol, model AP 2000); protein content was estimated by the Lowry method (Lowry et al. 1951); lactose was measured by the DNS method (3,5-dinitrosalicylic acid) according to the methodology described by Miller (1959); fat content was determined by the Roese–Gottlieb method (AOAC 2005); total solids were estimated by the gravimetric method in a recirculation oven at 105 °C until constant weight (AOAC 2005); minerals Ca, P, K, and Na were determined using AOAC (2005) method. The fractions of concentrates and permeates obtained from UF processes were analyzed in relation to turbidity, protein and lactose content. The permeate samples also were characterized to COD.

Statistical analysis

The processes and analyses were performed in triplicate. The results were expressed as the mean ± standard error. The effects of treatments were analyzed by analysis of variance (ANOVA) followed by the Tukey's test (p value < 0.05). Statistical analyses were performed using Excel and Statistica 10.0 software (Statsoft Inc., Tulsa, USA).

Results and discussion

Physicochemical characterization of whey samples

The results of the physicochemical characterization of whey samples are displayed in Table 1. As can be observed, the whey samples presented the statistical difference between them for almost all the parameters investigated. This is due to the fact that the milk used as raw material originates from different species of animals, which have considerably different nutritional compositions and because of the variation in the traditional processes of cheese manufacturing.

Buffalo milk has a composition traditionally known as superior to the other kinds of milk, mainly in relation to fats, proteins, lactose, and mineral content and consequently, has a higher content of total solids and COD (Shakerian et al. 2016). Thus, the whey generated during the manufacture of buffalo mozzarella cheese also presents higher values in its composition. Besides the content of proteins, lactose and fats measured in this study were higher than that of bovine and goat whey, the composition of the minerals was also higher when compared to the other whey samples, especially the Ca content. These findings are in agreement with data from the literature for buffalo milk that show high Ca content in relation to cow milk (Abd El-Salam and El-Shibiny 2011; Shakerian et al. 2016).

The composition of the goat whey presented a statistical difference in relation to the other whey analyzed. However, it was similar to that found in the literature for this type of whey, with values of protein, lactose, and total solids very close to those observed by Thum et al. (2015).

The two types of bovine whey, whey powder solution and bovine whey, were identified as having a similar composition. The values found for pH, protein, lactose, and total solids are also in agreement with those of other authors, such as the sweet whey used by Marx and Kulozik (2018). COD value is also in accordance with what has been reported in the literature, where values above 60 g L−1 were presented (Smithers 2015).

These results obtained for all samples highlight the importance of recovery and utilization of the nutrients of the whey, mainly due to its rich content of protein, lactose, and minerals. As well as, evidencing the relevance of the application of processes that aim to mitigate its environmental impact, reducing parameters such as turbidity and COD.

Ultrafiltration experimental design

The information regarding the 22 experimental design with a star configuration and three central points is shown in Table 2. The influence of the operation variables, i.e., temperature and transmembrane pressure, on the performance of the ultrafiltration separation process was analyzed and expressed as the protein content in the concentrated stream for the whey powder solution sample.

As for the protein content, it was verified that after UF its value varied between 27.47 and 36.73 g L−1. The highest value was observed in run 4, which used both factors at level 1, temperature of 40 °C and pressure of 60 kPa, while the lowest concentration was observed in run 7, which used temperature at the central point (30 °C) and lower pressure level (10 kPa). The results suggest that lower pressure and temperature conditions, such as 10–20 kPa and 16–20 °C, used in this study, do not favor protein recovery.

The Pareto chart, Fig. 1a, which shows the effective contribution of each parameter to protein concentration, corroborates with these findings. It is noted that both linear terms of the analyzed variables had a positive effect on protein concentration. That is, an increase in pressure or temperature increases the protein content in concentrated stream after UF process. However, it is perceived that the effect of the pressure variable is considerably more expressive. Possibly, this is because the pressure is the driving force behind the process, so its increase is so favourable.

The second-order model that predicts the protein concentration as a function of pressure and temperature, obtained by the regression coefficients, considering only the significant terms, is expressed by Eq. 8. The model proposed was evaluated by means of predicted values versus experimental values graph, the analysis of residues, and ANOVA. Based on the F-test, the model is predictive, since the calculated F-value (36.84) was higher than the listed F (4.53) and the R-squared (0.97) was considered a high value.

where \(z\) is the whey protein concentration (g L−1), \(x\) is the pressure (kPa) and \(y\) is the temperature (°C).

The second-order model was used to generate the contour diagram, Fig. 1b. As can be seen, the conditions in the range from 40 to 75 kPa and from 25 to 40 °C were the best for whey protein concentration. The critical condition, predicted by the experimental design, was around 58 kPa and 33 °C, and the maximum predict value for protein concentration was 37.48 g L−1. Experiments were carried out for external validation of the model using optimal values of the variables and the absolute error verified (5.46%) indicates that the model is adequate to predict protein concentration.

Influence of temperature and TMP on permeate flux

Table 2 also presents the final permeate flux values for the UF process of whey powder solution, where it was observed that runs 6, 9 10 and 11 resulted in the largest permeate flux, with a value around 8.5 kg m−2 h−1, and statistically equal. It is noted that these experiments correspond to the intermediate pressure conditions as well as temperature.

Although the contribution of the temperature to flux increase is discrete, it generates a statistical difference between the values obtained. The fact that higher temperatures favor diffusion and hence, mass transfer, may explain the increase in flux during the UF process. In addition, increasing the temperature reduces the viscosity of the whey solution, which also favors mass transfer and assists in increasing the permeate flux. Similar behavior was observed by Konrad et al. (2012). The authors found that an increase in temperature from 35 to 50 °C resulted in a significant improvement in the permeate flux during the UF of acid whey. However, the authors mentioned that above this temperature, a considerable flux decline was noted, possibly due to thermal precipitation of whey proteins, especially α-La.

It was observed that the effect of transmembrane pressure is more significant for the increase in permeation flow than the effect of temperature. Comparing the tests performed at a fixed temperature of 40 °C, varying the TMP from 20 to 60 kPa, there is an increase of approximately 80% in the permeated flux. Regarding the effect of temperature, comparing the experiments done at 20 and 40 °C, at a fixed 60 kPa, there was an increase of about 6% in the flux value.

The pressure behaviors verified in this paper are similar to those obtained by Baldasso et al. (2011) and Galanakis et al. (2014), which varied the TMP from 0 to 4 bar and observed an increase in the permeate flux, while studying the UF for protein recovery from sweet whey powder solution and from Halloumi whey, respectively. Nath et al. (2014) also noticed an increase in permeate flux as TMP increased during the ultrafiltration process of the whey. However, the authors pointed out that this behavior occurred only up to a certain pressure value, possibly due to the effect of concentration polarization at high TMP. The findings in this work are also consistent in this regard, since run 8 (Table 2), in which 70 kPa was used, results in a lower permeate flux when compared to the values obtained at 40 kPa, for the same temperature. This may be due to the fact that with higher driving force, more solute molecules are transported towards the membrane surfaces, which will result in more deposits and, consequently, higher resistance of the polarized layer.

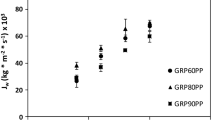

As pressure exerts a strong influence on the separation process, new experiments were conducted in the laboratory to further verify the behavior of the permeate flux against the variation of the pressure. Thus, the temperature was set at 30 °C and the TMP ranged from 10 to 80 kPa. This stage of the study was performed for all samples. Figure 2a shows the variation in the permeate flux for pure water and for each whey sample (whey powder solution and bovine, goat and buffalo whey) for the different transmembrane pressures applied.

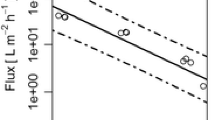

Effect of transmembrane pressure on the behavior of the permeate flux during ultrafiltration of water and whey samples at 30 °C (a); Permeate flux versus time for each whey sample treated by UF in batch mode operation, at 30 °C and 50 kPa (b); Fitting of the pore blocking and Ho–Zydney models for the permeate flux data during ultrafiltration of buffalo whey sample, at 30 °C and 50 kPa (c)

The increase in TMP provided a linear rise in water flux. For the whey samples, a linear increase in the permeate flux was observed only in the region of low pressures, which was verified up to 40–50 kPa. At this point, the values presented a tendency to reach a plateau, followed by a slight decrease in flux in the higher pressures. The decreasing behavior is due to the fact that high TMP intensifies the concentration polarization phenomena and the resistance due to fouling, resulting in a lowering of the permeate flux level. Thus, at lower TMP, permeate flux was controlled by pressure, while at a higher TMP value, mass transfer controls the UF process.

It was found when comparing the permeate flux of the four different whey samples, that whey powder solution and bovine whey samples had better results at 50 kPa, 8.9 and 7.9 kg m−2 h−1, which were slightly higher than those observed for a pressure of 40 kPa, 8.7 and 7.1 kg m−2 h−1, respectively. The goat and buffalo whey samples resulted in maximum flux at 40 kPa, with values of 6.2 and 4.9 kgm−2 h−1, respectively. This may be because of the presence of various solutes in goat and buffalo whey samples, especially at a higher protein rate when compared to the other samples, which contribute strongly to the occurrence of resistive flux phenomena. The lower permeate flux observed for the goat and buffalo whey samples can also be explained by their high calcium content, 448.67 and 949.90 mg kg−1, respectively. According to Barukčić et al. (2015), the influence of calcium was crucial for the decrease of the permeate flux in the UF study of sweet whey, possibly due to the fouling resulting from the interaction between proteins and the mineral.

Batch process operation

The ultrafiltration process carried out in batch mode resulted in permeate with almost complete turbidity removal (Table 3), that is, it was possible to obtain liquid without suspended materials. This is due to the retention of the proteins by the membrane, since these are also responsible for the opalescence and consistency of the whey. After UF, a reduction in the COD value over 50% was also obtained for all permeates. The reason for this is the protein concentration and partial retention of the lactose that occurred. These characteristics observed in the permeate streams tend to facilitate their application in subsequent products or treatments for their disposal.

In the batch process, the behavior of the permeate flux was also evaluated. Figure 2b shows the permeate flux decreasing in time, with an abrupt drop mainly for whey powder solution and bovine whey samples. This was followed by a gradual decline and subsequent stabilization after approximately 10 min within the process for all samples. This may be due to the fact that during the process there is a reduction in the feed mass because of the removal of the permeate stream, promoting the protein concentration, which results in a more severe membrane encrustation and an increase in concentration polarization.

According to the research of Ng et al. (2017), about the ultrafiltration of skim milk, the performance of the UF process is greatly reduced by the decrease in flux resulting from the concentration polarization and fouling, of which aspects are not yet fully understood. However, what is known is that fouling is caused predominantly by whey proteins and in some cases by minerals. When comparing the samples of whey analyzed in the present study, we confirmed that the lowest flux observed was for the buffalo whey sample, which presented the highest values for both protein and calcium content. The pH may also play an important role in flux decline, particularly at the temperatures studied due to calcium phosphate precipitation (Ng et al. 2017).

Fouling resistance measurements

To identify the predominant fouling mechanism during whey ultrafiltration, a comparative study was undertaken to analyze experimental values of permeate flux and different mathematical models. The coefficient of determination (R2), the adjusted coefficient of determination (Radjusted2) and the sum of the square residuals (SSR) between numerical predictions and experimental data were the criteria used to select the best fit model for each assay evaluated (Table 4).

The analyses show that from all conventional models, the cake filtration model had the best experimental flux data results for all whey types. Figure 2c shows the fitting of the four simple pore blocking and Ho–Zydney models for buffalo whey samples. Similar results were reported by Luján-Facundo et al. (2017), who also studied the membrane fouling for different protein model solutions. The authors reported that the cake filtration model was the one that best fit the flux data for the solution tested. However, none of the models studied by the authors accurately defined the behavior of the UF process with all solutions tested.

Despite the aforementioned results, the conventional models of pore blocking did not describe the behavior of the permeate flux completely, which was made possible with the Ho and Zydney model. This model considers fouling as a two-stage process with pore blocking occurring before deposit on the membrane surface. Thus, it can be said that this model combines the models of pore blocking and cake filtration, and the resistance due to the pore blockage initially dominates the whey ultrafiltration, while the resistance due to the cake becomes more expressive at the end of the process.

Therefore, it can be inferred, based on the fouling profile suggested by the models, that in the beginning of the process the whey proteins, obstruct the pores of the membrane, especially the ones that have an average size around 10 kDa. As the process progresses, the high concentration of proteins in the concentrate stream leads to concentration polarization and the protein–protein interaction tends to form a gel on the membrane surface, causing the fouling phenomenon. Another factor that contributes to the growth of the membrane surface obstruction layer is possibly the protein–calcium interaction, which is proper to the filtration regime of the fouling.

Conclusion

The ultrafiltration process made it possible to obtain whey protein concentrate from different whey origins. Potential for recovery of goat and buffalo whey proteins was observed, in addition to the traditionally known bovine whey. However, further studies should be performed to improve permeate flux, especially in the case of goat and buffalo whey. The permeate flux of the whey ultrafiltration was strongly influenced by the protein and calcium content. Thus, whey from goat and buffalo cheese resulted in lower permeate flux during the ultrafiltration process. Furthermore, the Ho and Zydney model was in great agreement with experimental data for the conditions tested as well as it demonstrated a more complete description of the fouling behavior during whey protein ultrafiltration for all samples used.

References

Abd El-Salam MH, El-Shibiny S (2011) A comprehensive review on the composition and properties of buffalo milk. Dairy Sci Technol 91:663–699. https://doi.org/10.1007/s13594-011-0029-2

Amaral GV, Silva EK, Cavalcanti RN et al (2018) Whey-grape juice drink processed by supercritical carbon dioxide technology: physicochemical characteristics, bioactive compounds and volatile profile. Food Chem 239:697–703. https://doi.org/10.1016/j.foodchem.2017.07.003

AOAC (2005) Official methods of analysis. Off Methods Ananlysis AOAC Int 18th edition, 20877–2417

APHA (2005) Standard methods for the examination of water and waste-water, 12th ed. Am. J. Public Heal. Nations Heal. 56

Baldasso C, Barros TC, Tessaro IC (2011) Concentration and purification of whey proteins by ultrafiltration. Desalination 278:381–386. https://doi.org/10.1016/j.desal.2011.05.055

Barukčić I, Božanić R, Kulozik U (2015) Influence of process temperature and microfiltration pre-treatment on flux and fouling intensity during cross-flow ultrafiltration of sweet whey using ceramic membranes. Int Dairy J 51:1–7. https://doi.org/10.1016/j.idairyj.2015.07.002

Cappato LP, Ferreira MVS, Moraes J et al (2018) Whey acerola-flavoured drink submitted Ohmic Heating: bioactive compounds, antioxidant capacity, thermal behavior, water mobility, fatty acid profile and volatile compounds. Food Chem 263:81–88. https://doi.org/10.1016/j.foodchem.2018.04.115

de Oliveira DF, Granato D, Barana AC (2017) Development and optimization of a mixed beverage made of whey and water-soluble soybean extract flavored with chocolate using a simplex-centroid design. Food Sci Technol 38:413–420. https://doi.org/10.1590/1678-457x.07017

Díaz-Ramírez M, Calderón-Domínguez G, García-Garibay M et al (2016) Effect of whey protein isolate addition on physical, structural and sensory properties of sponge cake. Food Hydrocoll 61:633–639. https://doi.org/10.1016/j.foodhyd.2016.06.020

Eurostat (2019) Statistical article: milk and milk product statistics. https://ec.europa.eu/eurostat/statistics-explained/index.php/Milk_and_milk_product_statistics#Milk_products. Accessed 20 May 2019

FAO (2018) Dairy market review. In: Food Agric. Organ. United Nations. https://www.fao.org/economic/est/est-commodities/dairy/milk-and-milk-products/en. Accessed 15 May 2019

Field RW, Wu D, Howell JA, Gupta BB (1995) Critical flux concept for microfiltration fouling. J Memb Sci 100:259–272. https://doi.org/10.1016/0376-7388(94)00265-Z

Gajo AA, de Resende JV, Costa FF et al (2017) Effect of hydrocolloids blends on frozen dessert “popsicles” made with whey concentrated. LWT Food Sci Technol 75:473–480. https://doi.org/10.1016/j.lwt.2016.09.027

Galanakis CM, Chasiotis S, Botsaris G, Gekas V (2014) Separation and recovery of proteins and sugars from Halloumi cheese whey. Food Res Int 65:477–483. https://doi.org/10.1016/j.foodres.2014.03.060

Hérmia J (1982) Constant pressure blocking filtration laws. Applications to power—law non-Newtonian fluids. Trans Ichem E 60:183–187

Ho CC, Zydney AL (2000) A combined pore blockage and cake filtration model for protein fouling during microfiltration. J Colloid Interface Sci 232:389–399. https://doi.org/10.1006/jcis.2000.7231

Konrad G, Kleinschmidt T, Faber W (2012) Ultrafiltration flux of acid whey obtained by lactic acid fermentation. Int Dairy J 22:73–77. https://doi.org/10.1016/j.idairyj.2011.08.005

Li XY, Cheng M, Li J et al (2019) Change in the structural and functional properties of goat milk protein due to pH and heat. J Dairy Sci. https://doi.org/10.3168/jds.2019-16862

Lievore P, Simões DRS, Silva KM et al (2015) Chemical characterisation and application of acid whey in fermented milk. J Food Sci Technol 52:2083–2092. https://doi.org/10.1007/s13197-013-1244-z

Lou X, Li J, Zhang X et al (2018) Variations in fatty acid composition of Laoshan goat milk from partum to 135 days postpartum. Anim Sci J 89:1628–1638. https://doi.org/10.1111/asj.13098

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein Measurement with the folin phenol reagent. Anal Biochem 193:265–275. https://doi.org/10.1016/0304-3894(92)87011-4

Luján-Facundo M, Mendoza-Roca JA, Cuartas-Uribe B, Álvarez-Blanco S (2017) Membrane fouling in whey processing and subsequent cleaning with ultrasounds for a more sustainable process. J Clean Prod 143:804–813. https://doi.org/10.1016/j.jclepro.2016.12.043

Mahmood A, Usman S (2010) A comparative study on the physicochemical parameters of milk samples collected from buffalo, cow, goat and sheep of Gujrat, Pakistan. Pak J Nutr 9:1192–1197. https://doi.org/10.3923/pjn.2010.1192.1197

Mahomud MS, Katsuno N, Nishizu T (2017) Formation of soluble protein complexes and yoghurt properties influenced by the addition of whey protein concentrate. Innov Food Sci Emerg Technol 44:173–180. https://doi.org/10.1016/j.ifset.2017.05.010

Martins CPC, Ferreira MVS, Esmerino EA et al (2018) Chemical, sensory, and functional properties of whey-based popsicles manufactured with watermelon juice concentrated at different temperatures. Food Chem 255:58–66. https://doi.org/10.1016/j.foodchem.2018.02.044

Marx M, Kulozik U (2018) Spore inactivation in differently composed whey concentrates. Int Dairy J 76:1–9. https://doi.org/10.1016/j.idairyj.2017.08.007

Miller GL (1959) Use of dinitrosaiicyiic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Nath A, Chakraborty S, Bhattacharjee C, Chowdhury R (2014) Studies on the separation of proteins and lactose from casein whey by cross-flow ultrafiltration. Desalin Water Treat 54:481–501. https://doi.org/10.1080/19443994.2014.888685

Ng KSY, Haribabu M, Harvie DJE et al (2017) Mechanisms of flux decline in skim milk ultrafiltration: a review. J Membr Sci J 523:144–162. https://doi.org/10.1016/j.memsci.2016.09.036

Nishanthi M, Vasiljevic T, Chandrapala J (2017) Properties of whey proteins obtained from different whey streams. Int Dairy J 66:76–83. https://doi.org/10.1016/j.idairyj.2016.11.009

Sabokbar N, Khodaiyan F (2016) Total phenolic content and antioxidant activities of pomegranate juice and whey based novel beverage fermented by kefir grains. J Food Sci Technol 53:739–747. https://doi.org/10.1007/s13197-015-2029-3

Sameer B, Ganguly S, Khetra Y, Sabikhi L (2020) Development and characterization of probiotic buffalo milk ricotta cheese. LWT. https://doi.org/10.1016/j.lwt.2019.108944

Shakerian M, Kiani H, Ehsani MR (2016) Effect of buffalo milk on the yield and composition of buffalo feta cheese at various processing parameters. Food Biosci 15:110–117. https://doi.org/10.1016/j.fbio.2016.06.002

Smithers GW (2015) Whey-ing up the options—yesterday, today and tomorrow. Int Dairy J 48:2–14. https://doi.org/10.1016/j.idairyj.2015.01.011

Thum C, Cookson A, McNabb WC et al (2015) Composition and enrichment of caprine milk oligosaccharides from New Zealand Saanen goat cheese whey. J Food Compos Anal 42:30–37. https://doi.org/10.1016/j.jfca.2015.01.022

Villa C, Costa J, Oliveira MBPP, Mafra I (2018) Bovine milk allergens: a comprehensive review. Compr Rev Food Sci Food Saf 17:137–164. https://doi.org/10.1111/1541-4337.12318

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) – Finance Code 001. The authors are also grateful for the donations by Alibra Ingredients, Ltda (Campinas, SP, Brazil) and by Technological School of Milk and Cheese of Campos Gerais (Ponta Grossa, PR, Brazil).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Argenta, A.B., De Lima, J.J., Nogueira, A. et al. Evaluation of concentration process of bovine, goat and buffalo whey proteins by ultrafiltration. J Food Sci Technol 58, 1663–1672 (2021). https://doi.org/10.1007/s13197-020-04675-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04675-0