Abstract

Using ultrasound technology for obtaining O/W lycopene emulsions needs analyzing the parameters for the enhanced application. To this end, O/W lycopene emulsions (30:70) were processed using ultrasound with powers of 240 W and 360 W in 5, 10, and 15 min. Afterward, the poly dispersity index, droplet size, ζ-potential, turbidity, phase separation, lycopene concentration, rheological behavior, surface tension, and morphology of emulsions was investigated. The experimental results showed good emulsifying characteristics with respect to droplet size and ζ-potential. If the mean values of the droplet size were significantly reduced and the ζ-potential increased. The ultrasound application had a significant impact on emulsion stability with no phase separation and significantly high lycopene retention. Ultrasound reduced the apparent viscosity by reducing the particle size due to the energy supplied to the system. The final emulsion that was treated at 360 W, and 2160 J/cm3 in 10 min, presented enhanced technological properties appropriate for food products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, natural foods have been increasingly demanded by the consumer (Akhavan Mahdavi et al. 2016). There has been recently high concern regarding the enrichment of foods with bioactive compounds for producing functional foods (Ho et al. 2016).

Lycopene as a fat-soluble carotenoid has health benefits, especially in terms of prevention of cancer, osteoporosis, and coronary heart diseases. Although lycopene has numerous health advantages, its solubility in water is low, and this confines its usage in food industries, particularly in water-based food products.

Emulsion-based delivery systems can be appropriate delivery systems for compounds with low solubility in water, like carotenoids, since it is possible to design them in such a way that increases dispersion in water and enhances bioavailability (Shariffa et al. 2016).

Hence, a large number of studies has been carried out for increasing the bioavailability and solubility of lycopene, including the development of emulsions (Anarjan and Jouyban 2017; Rocha et al. 2012; Shi et al. 2015; Shariffa et al. 2017). Oil-in-Water (O/W) emulsions are regarded as necessary liquids due to their specific characteristics and usages in the food industry. Because of the undesirability of the contact between water and oil molecules for energy, emulsions are unstable thermodynamically.

There are various mechanisms for the characterization of emulsion stability, such as sedimentation or the creaming, flocculation of droplets, phase separation, and droplet cohesion (Gharibzahedi et al. 2013).

Emulsions are often achieved by the application of mechanical energy between the two insoluble phases (Albano and Nicoletti 2017). Systems like high-pressure homogenizers, rotor–stator systems, and stirrers are usually utilized for emulsification (Patil and Gogata 2017). Nevertheless, the energy consumption is high in these devices.

Ultrasound emulsification provides considerable benefits, including achievement of fine droplet size distribution, micron-sized droplets, and emulsions with stability and lower energy consumption in comparison with the conventional emulsions (Silva et al. 2015).

The phenomenon of cavitations created by ultrasound offers faster and more homogenous nucleation, leading to the formation of droplets with smaller size, which decreases their agglomeration by reducing droplet’ contact and having the control over the nuclei number (Cheng et al. 2018; Anarjan and Jouyban 2017). The size of homogenized ultrasonic emulsions is smaller compared to the samples being homogenized by other approaches (Cabrera-Trujill et al. 2018).

Emulsions having carotenoids have already been developed using high-pressure homogenization approaches (Qian et al. 2012). However, the impact of ultrasound on oil/water lycopene emulsion preparation has not been studied very well. The oil in water lycopene emulsions were prepared by ultrasonic emulsification under varying conditions (power, time, amplitude, and energy density) and the effect of ultrasound processing parameters on the qualitative characteristics of emulsions were studied in the current study to obtain the best processing conditions.

Materials and methods

Chemicals and reagents

Methanol, acetone, hexane, and Tween 80 were prepared by Merck (Germany). Corn oil (Oila, Iran) was bought from a local supermarket, which was utilized for dispersed phase. The maltodextrin DE 10–15 was prepared by Laboratory Rasayan (India). Rani Company (Iran) provided apple pectin (AP) with the degree of esterification as72 percent.

Lycopene extraction

In the current study, lycopene extracts were employed. The lycopene extracts were created in the laboratory by supercritical CO2 extraction of tomato powder. The tomato cultivar of H1015 (Heinz, USA) was used in the current work. A Suprex MPS/225 system was employed for the extractions in the SFE mode. A supercritical fluid flow rate of 0.30 ± 0.05 mL/min was utilized in the dynamic extraction phase and the restrictor point was heated in an electrical way so that plugging in the sample is avoided. The extraction vessel was packed with 2.5 g of tomato powder. According to the study previously done by our team, the extraction was done at 55 °C and 35 MPa in 20 min without using any modifier. The lycopene was gathered in a volumetric flask containing hexane. The extract ultimate volume was set to 5 ml with hexane and stored at − 20 °C.

Core emulsion preparation

O/W lycopene emulsion was made using a fixed ratio of oil to the aqueous phase (30:70). A continuous phase component having maltodextrin 10% w/v and pectin 1% w/v was prepared in distilled water separately 24 h prior to the emulsification process so that complete hydration of the biopolymers is gained. They were mixed then in a 1:1 ratio, and the pH was adjusted to 7.0 by the use of 0.1 M NaOH. Then, they were mixed for 2 h by the use of a magnetic stirrer at 500 rpm (MSH-20D, Wise Stir, Germany). The oil phase composed of Tween 80, corn oil, lycopene in ratio 4:25:1 were dissolved for 2 h by the use of a magnetic stirrer at 500 rpm. Then, the oil phase was added in a drop-wise manner to the aqueous phase dispersion using a 1 mL/min flow rate. Simultaneously, this mix was uniform using a magnetic stirrer at 1500 rpm. The oil phase was integrated into the emulsion (after 100 min), the rotational speed was reduced to 500 rpm and, the emulsion was made homogenized for an additional 10 min. Then, the hexane residue (related to lycopene extract) was completely removed in a vacuum rotary evaporator at 50 °C, 5 min, and 200 rpm.

Ultrasound treatments

Ultrasound was used on the O/W lycopene emulsion in an ultrasound system (UP 400s, Hielscher, Germany) in frequency of 24 kHz, as observed in Table 1. The ultrasound probe was put in a sound-reduction box. A 22 mm probe made of a titanium alloy with a cylindrical diameter was utilized. The probe was put 50 mm under the pre-emulsion surface with a 100 ml volume. The duty cycle of 50% was applied. Therefore, the pulse ratio was 1:2. When the powers of 240 W and 360 W were used, wave amplitudes of 126 μm and 189 μm were reported, respectively. The emulsion temperature was kept at 25 ± 2 °C during sonication with an iced water bath. The emulsions were made within two replicates. The emulsions that were prepared freshly were kept in a glass vial, being coated with aluminum foil, and flushed with nitrogen. They were kept at 5 °C in the refrigerator.

Droplet size, ζ-potential, and PDI

A dynamic light scattering (SZ 100, Horiba, Japan) and a zetasizer (Nano-ZS, Malvern, UK) were employed for measuring the particle size, polydispersity index, and ζ-potential of emulsions. The measurement was done based on backscatter angle of 90°. The refractive index parameters were 1.33 for the deionized water and 1.37 for the emulsion particles. The average particle diameters are expressed as “Z-average” diameters. The analysis was done at 25 °C.

Transmittance

A UV–visible spectrophotometer (6405, Jenway, UK) was used for measuring the transmittance of the emulsion. Measurement was performed based on the approach given by Shariffa et al. (2016). The transmittance percent was specified at 600 nm. The test was carried out under low light conditions.

Surface tension

The pendant drop approach was applied for determining the impact of US treatments on the surface tension of emulsions. According to Bagalkot et al. (2018), a drop of emulsion was used to measure the surface tension of oil/water. The drop was created from a needle, the shape of the pendant drop is governed by gravity and the surface tension. The surface tension was calculated from the shadow of the digital image captured by the camera using the drop shape analysis. An image of the drop was recorded with the help of a camera and transferred to the drop shape analysis software. A contour recognition was initially carried out based on a grey-scale analysis of the image and the shape of the drop was then determined (OCA, dataphysics instruments, Filderstadt, Germany). A shape parameter (B) was then adjusted in a numerical method until the calculated drop shape resembles with the actual shape. The surface tension was calculated from below equation from the density difference between two phases and the modified shape parameter (B):

where \(\Delta \rho\) is the density difference between two phases; g is the acceleration due to gravity, and d is the maximum horizontal diameter of the unmagnified pendant drop.

Phase separation

The evaluation of the emulsions’ stability was done on the basis of the approach given by Cabrera-Trujill et al. (2018) for 15 days at temperature of 5 °C. Emulsions were precipitated in plastic Falcon tubes having a 50 ml volume, and by seeing phase separation, a visible mark was used.

Morphology

To investigate the microstructure, the samples were first dried by freeze dryer and the samples were attached to metallic adhesive tapes adhered to metallic stubs. The stubs underwent recovering by a fine layer of gold in an evaporator for 180 s and a current of 40 mA. The observations were made using a field emission scanning electron microscope (FE-SEM) (Mira II, Tescan, Czech) with a voltage of 15 kV and magnification of 1 kx and 2 kx.

Lycopene concentration

The approach described by Shariffa et al. (2017) was used for extracting lycopene from the emulsions with some modifications. Lycopene emulsion (1 mL) was combined with two mL of hexane: acetone: methanol (2:1:1), and it was vortexed at 1000 rpm for 5 min. Afterward, the sample was centrifuged at 500 g for 15 min. A UV–Vis spectrophotometer (6405, Jenway, UK) was used for measuring the concentration of the lycopene at 471 nm.

Rheological analyses

A Physica MCR 301 device was used for evaluating the rheological characteristics of emulsions following the approaches proposed by Motamedzadegan et al. (2018) with some alterations. Concentric cylinders (CC27-SN16194; d50 mm; gap 0.206 mm) were used as the geometric form for all samples. First, the strain sweep test was conducted (strain of 0.1–1000.00%, frequency of 1 Hz and temperature of 20 °C) in order to determine linear viscoelastic range (γLVE). For investigating the viscoelastic behavior in the samples, the frequency sweep experiment was run at the frequency ramp of 0.1–100.0 Hz (at the constant strain of 5%, LVE range) at the temperature of 20 °C. Tan δ, G′, and G″ obtained from the frequency sweep experiment were specified at 1 Hz (6.28 rad/s) frequency for more accurate examination of the rheological behavior. For the investigation of the flow behavior, the dynamic shear test was run in the shear rate range of 0.01–300 S−1. Afterward, power-law (Eq. 1) and Herschel–Buckley (Eq. 2) models were matched against empirical data for describing the flow behavior, and the flow index and coefficient of consistency of samples were specified.

Statistical analysis

All analyses were done three times. The experimental data are given as means ± SD and were analyzed by ANOVA in SPSS 16®software. The significance of the differences (p < 0.05) between the mean values of the treatments was examined by Duncan analysis.

Results and discussion

Droplet size and PDI

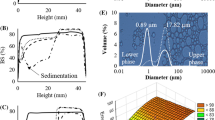

Construction of emulsions with small droplet size and low PDI value is essential. It is also important to analyze droplet size as it specifies the bioavailability, stability, appearance, and texture of the final product (Shariffa et al. 2017). Besides, the system stability was related to PDI values. The ultrasound treatments gave a significant impact (p < 0.05) on the Dz and polydispersity index (PDI) values (Fig. 1). The line graph in Fig. 1 indicates the PDI values of emulsions.

Means of Dz and PDI values of lycopene emulsions a immediately after ultrasound treatments, b after 15 days at 5 °C [line is mean diameter (primary axis), and bars are PDI (secondary axis)]. The treatments details are according to the Table 1

All ultrasound treated emulsions showed a small droplet size (31.53–43.26 nm), which proves that nanoemulsions were constructed (< 100 nm) with PDI values between 0.323 and 0.496. Figure 1 indicates that the PDI values of all the samples were < 0.5, which shows the reliability of the measurements and the uniform distribution of droplets. Coarse emulsion represented a larger PDI value (1.19) and droplet size (62.33 nm) compared to the sonicated emulsion. The results were consistent with Costa et al. (2018). They showed that the emulsions prepared using rotor–stator (coarse emulsion) exhibited larger droplet size and PDI in comparison with the emulsion treated by ultrasound.

Ultrasonic treatment indicated the smallest PDI and Dz values at the fifth run (US360-10). When considering the same application times, the increasing ultrasonic amplitudes led to the significant reduction of Dz values (p < 0.05), with the exception for the sixth run (USP360-15). Nevertheless, when considering the same amplitudes, the increasing ultra-sonication time led to the significant reduction of Dz values (p < 0.05), with the exception for the sixth run (USP360-15). It appeared reduction in Dz values is directly corresponding to the energy transferred to emulsions. The phenomenon that values of Dz gain stability or increase with an increase in the energy input is known as “over-processing effect”. Gul et al. (2018) have also reported the similar results on the particle size for nano-emulsions generated by ultrasound approaches. Costa et al. (2018) indicated significant reduction in emulsion droplet size that with an increase in sonication time and amplitude. These findings were in consistency with our results. Sonicating emulsions for 15 min at 90% power amplitudes with the highest energy density significantly increased PDI and Dz values, in comparison with values taken for the same amplitudes with lower energy density at 10 min sonication. This indicates the incidence of the over processing phenomenon. In this phenomenon, a very intense homogenization process results in the disruption of droplets and increased contact. Hence, their recoalescence happens (Vélez-Erazo et al. 2018). Thus, the uncoated droplets blend with other uncoated droplets in order to create the droplets with the larger size. The effect of coalescence on droplet size distribution was described by Shariffa et al. (2017). As shown by research by Li et al. (2020), ultrasonic emulsification decreases the droplet size of the emulsions to nanometer size. With increasing treatment time, the droplet size is reduced further. In addition, Xiong et al. (2019) showed that ultrasonic treatment at 20 kHz in 12 min reduced the droplet size of emulsion by increasing the ultrasonic power from 150 W to 300 W, and further increase in power to 600 W had the opposite effect, and the emulsion droplet size increased. These results support that, when delivered to the system, energy is utilized for promoting droplet disruption up to a critical point, which beyond this point, there are no additional droplet disruption and higher stability. The additional energy provided for the system is likely depleted as heat because of increasing temperature in the case that a thermostatic bath is not utilized. Application of 90 percent of power amplitude is correspondent to the case in which the high cavitations and estacoustic pressure are achieved. This leads to a greater droplet breakdown and a more homogenous diffusion of the acoustic waves, which causes burst of droplets both in the vicinity of the probe and in all the extent of the fluid (Vélez-Erazo et al. 2018). Following 15 days of storage, an increased was seen in the droplet size, but there wasn’t any significant difference between PDI in emulsion treated by ultrasound after 15 days storage (Fig. 1). The PDI is a parameter for studying the stability of emulsion, the PDI of emulsion didn’t increase during 15 days storage, and it was still below 0.5. Also, there was no visible instability with the naked eye. Qian et al. (2012) showed a negligible rise in the droplet size of the Tween 20 stabilized emulsions during storage, and the mean droplet size increased from 55 nm directly after homogenization to 60 nm following 15 days storage.

ζ-Potential, transition, and surface tension

The ζ-potential analysis is a test that is reliably used for specifying the stability of a colloid system. When zeta potential is higher, the dispersed particles have higher tendency for repelling each other. Hence, the particles are prevented from moving closer to each other and decreasing particle aggregation. Table 2 gives the ζ-potential results for emulsions obtained by ultrasound. The zeta potential of all ultrasound-treated emulsion was higher compared to coarse emulsion (p < 0.05), which shows a stable emulsion system. The emulsion treated at the fifth run (US360-10) showed the most negative ζ-potential value (− 21.43 mV) compared to other emulsions among all the preparations. Its smallest droplet size and stability justifies this. Hence, it is less influenced by gravitational separation. The coarse emulsion and the emulsion prepared at the first run (US240-5) showed the least stable system with the lowest ζ-potential value (− 0.5603 ± 0.3580 and − 13.3 ± 0.6557 mV), which shows that the dispersed lycopene droplets aggregate. This was confirmed by microscopic imaging (Fig. 2). When ultrasonic power increases, the potential change between the emulsions in each group indicated a trend of first rising and then reducing. Thus, ultrasonic emulsification might change the surface charge a little, enhance the interdroplet electrostatic repulsions, prevent more aggregation, and strengthen the lycopene emulsion stability (Gul et al. 2018). Also, this can be related with the energy density in each assay. Also the statistical analysis showed that at the same power, as the energy density increased, the zeta potential increased, but we had an exception in sixth run (USP360-15) that could be attributed to over-processing. Therefore we can attribute this behavior to the energy density in each assay.

Table 2 indicates the transition analyses (%). The ultrasound-treated emulsion showed a higher transition percent compared to not treated emulsion (p < 0.05). It can be assigned to the availability of large droplets in the coarse emulsions. Nevertheless, their transmittance values were smaller than deionized water with 100% transmittance. The availability of lycopene and other components in the system explains this finding. When treating the samples at high power, and energy density (p < 0.05), the significant increase as observed in the transmittance value. Among all the emulsions, the emulsion treated in the fifth run (US360-10) was the least turbid one with the largest transmittance value (76.60%). The turbidity of the lycopene emulsion is associated with the droplet size. It was found by Shariffa et al. (2017) that an increase in the emulsion turbidity is observed with rising concentrations of the droplet. The mean droplet size influences the appearance of an emulsion. The emulsion with the smaller particle size is more translucent. The decreased transmittance value has consistency with the increase in the droplet size. Additionally, Albano and Nicoletti (2017) observed that the emulsion processed by ultrasound at 20 kHz, 120 W for 1 min, showed lower absorbance related to those untreated with ultrasound. The aim of the interfacial tension analysis was evaluating the ability of ultrasound processing for changing the oil–water interfacial tension. Thus, process destabilization is prevented or retarded. If the emulsion has a smaller surface tension of water (72.8 mN/m), the emulsion stability is higher. According to the results, the ultrasonic treatment decreased the surface tension of the emulsions (p < 0.05) (Table 2), and increasing the time of processing to 15 min had no impact on surface tension reduction (p > 0.05). The emulsion made in the fifth run (US360-10) indicated the lowest surface tension (35.03 ± 0.05 mN/m). This shows that this emulsion had the highest stability compared to the others because of surface tension values much smaller than the water. As shown by Xiong et al. (2019), the ultrasound-treated O/W emulsions had lower surface tension compared to untreated samples (34.8 mN/m). Emulsifier adsorption onto the oil–water interface led to the tension reduction between phases that form the films around oil droplets. The large energy utilized in the ultrasound process led to the rapid droplets breakup. Thus, the emulsifier molecules should have the ability of stabilizing the newly formed interface so that the emulsification process efficiency is ensured (Silva et al. 2018).

Morphology

In order to obtain a rapid overview of a colloidal system, microscopic analysis is high. Figure 2 indicates the interaction between droplets emulsions from the coarse emulsion and optimum ultrasound treatment (US360-10).

According to the figures, the lycopene droplets have a spherical shape, and they include large and small lycopene droplets, showing a polydispersed system. These findings are consistent with findings by Shariffa et al. (2016). As reported by these authors, lycopene droplets in nonodispersions had spherical shape. Nevertheless, any droplet aggregation was not seen. The droplets showed good dispersion, and no visible aggregation was observed. It appears that the continuous phase has an irregular shape, i.e., it is not spherical. It is probable that these irregular shapes are due to the interaction between the pectin and maltodextrin that are employed in the stabilization of the oil phase consisting of lycopene droplets. Findings in the current work were consistent with findings by Anarjan and Jouyban (2017). As they reported, the optimal formulated lycopene nanoparticles homogenized by ultrasound were particles with spherical shape and fairly uniform.

Phase separation

Ultrasonic homogenization caused the stabilization of the lycopene emulsions. The emulsions treated with ultrasonic did not present phase separation for 15 days storage at temperature of 5 °C, and creaming phenomenon did not occur. Cabrera-Trujillo et al. (2016) found that the ultrasound-treated emulsions in continuous mode and at 60 μm had stability, and the lowest phase separation happened. Moreover, Cabrera-Trujill et al. (2018) demonstrated that the coarse emulsions homogenized with the rotor–stator and subsequently homogenized by ultrasound had stability for 28 days, and no phase separation happened. As reported by Kaci et al. (2014), emulsions processed by ultrasound showed no phase. Thus, homogenization by ultrasound causes stabilized emulsion because of the small-sized particles and their homogenous distribution.

Lycopene concentration

The concentration of the lycopene was influenced generally by the various ultrasound conditions where the increased time, power, and energy density caused decreased lycopene concentration, which can be seen in Fig. 3.

Means of lycopene concentration and percentage of its retention: a immediately after ultrasound treatments; b after 15 days at 5 °C [line is lycopene concentration (primary axis), and bars are percentage of lycopene retention (secondary axis)]. The treatments details are according to the Table 1

As shown in Fig. 3a, coarse emulsion (control) contained around 1.26 mg lycopene/100gr emulsions. Following the homogenization by ultrasound, the lycopene content in emulsion decreased by about 50%, depending on the treatment conditions, as in the fifth run (US360-10), the lycopene concentration was 0.59 mg/100 g. However, after 15 days of storage at 5 °C, the lycopene content in emulsions showed no change, and they all showed a relative concentration upper 91%, which was correspondent to > 0.5 mg/100 g emulsion (Fig. 3b). The highest relative retention of lycopene was obtained in the fifth run (US360-10) at 93%. The reduction in the lycopene concentration in the emulsions processed by ultrasound is assigned to the impact of ultrasound, causing the propagation medium’s compressions and decompressions, which create the acoustic cavitations, leading to high pressures and temperatures in the environment. This causes the breakdown of lycopene molecules (Cabrera-Trujillo et al. 2016). It is suggested that the transition metal ions from the ultrasound probe might lead to the oxidation of lycopene (Shariffa et al. 2017). According to the studies, an emulsion’s stability was considerably affected by the size of the droplet. The decrease in the particle size might accelerate lycopene degradation (Shariffa et al. 2016; Mohamad et al. 2017). This is in agreement with the finding of Tan and Nakajima (2005). They concluded the beta-carotene degradation in nanodispersions from the decrease of mean particle sizes. Nevertheless, regarding lycopene emulsions treated by ultrasound, though they have a small particle size, the relative retention of lycopene is fairly high, indicating an emulsion with a higher stability.

Rheological behavior

Figure 4 shows the apparent viscosity of emulsions homogenized by ultrasound. All of the emulsions exhibited a non-Newtonian behavior. The viscosity decreased by increasing the shear rate, therefore the emulsion exhibited a shear thinning behavior upon the ultrasound operation.

Strain sweep, frequency sweep, and flow behavior (apparent viscosity-shear rate) curves of lycopene emulsions under different ultrasound conditions. The legend details are according to the Table 1

The shear rate adequately increases for overcoming the Brownian motion. Hence, the more ordered emulsion droplets are obtained along the flow field and, offering lower resistance to flow. Thus, there is less viscosity. The increase in energy density and time reduces the apparent viscosity of emulsions homogenized by ultrasound at 240 W. However, the apparent viscosity increased with increasing energy density and processing time from 10 to 15 min at the power of 360 W. As the emulsions treated according to the sixth run (USP360-15) indicated viscosity higher than the fifth run (US360-10). The emulsion treated in the fifth run (US360-10) showed the lowest apparent viscosity. It can be associated with lower surface tension and small particle size.

The Herschel-Bulkley and Power Law models described flow curves. In order to describe the flow behavior data as a function of shear rate, the experimental data point was fitted to these models. As observed in Table 2, the emulsions showed the highest fit with the power-law model (R2 = 0.99). The flow behavior index of emulsions treated by ultrasound was in the 0.74–0.84 range, corresponding to shear thinning behavior. The consistency index indicates the viscous nature of the emulsion, and it was found that it reduced with ultrasound homogenization compared to the coarse emulsion (control).

In the first stage of oscillatory rheological analyses, i.e. the strain sweep test, the linear viscoelastic domains of the emulsions were determined. The strain sweep diagrams of all the samples are shown in Fig. 4. The strain sweep curve of all the samples can be divided into the general sections of linear and non-linear. In the linear section, the storage modulus (G′) and loss modulus (G″) were almost constant and the structural deformation was reversible (small deformations). In the non-linear section, by increasing the strain, G′ and G″ started to decrease (large deformations). Based on Fig. 4, G″ was larger than G′ in all the samples. This indicates that the samples had a viscose-like behavior in the LVE range. The data belonging to G’LVE, G”LVE, γLVE, tan δ LVE, (G″/G′ at LVE), in the LVE range are presented in Table 2.

The ultrasound-treated emulsions showed a wide range of LVE compared to the coarse emulsion. A wider LVE range means that the sample has a higher viscoelastic property, maintains its structure at higher values of strain sweep and has higher capability for recovering its structure.

The tan δ LVE which is the ratio of G″ to G′ in LVE was also studied (Table 2). Increasing the value of tan δ means a change from the elastic (solid-like) to viscose (liquid-like) nature (Motamedzadegan et al. 2018). The high value of tan δ indicates its low elastic property. The ultrasound homogenization reduced the samples’ elastic property. By increasing the energy density, tan δ LVE was significantly increased (p < 0.05) and the emulsions showed a more liquid like nature.

The frequency sweep rheograms of emulsions are demonstrated in Fig. 4. It is clear that, in general, all the samples had a viscose-like behavior against frequency sweep, as G″ was larger than G′. A liquid-like behavior was observed in all the emulsions at low frequencies in which loss modulus (G”) was larger than storage modulus (G’).

Conclusion

The application parameters of ultrasound at frequency of 24 kHz, powers of 240 W and 360 W in 5, 10, and 15 min with 50:50 pulses on O/W (30:70) lycopene emulsions was defined in the current study. The ultrasound has a significant impact on controlling properties like PDI, the particle size, zeta potential, and turbidity, retention of lycopene, rheological behavior, and surface tension of the lycopene emulsions. The experimental results show great emulsifying characteristics with the obtained values of droplet size, which is significantly lower and higher in ζ-potential. The ultrasound application had a significant impact on the stability of emulsion via higher lycopene retention and no phase separation. Ultrasound decreased the apparent viscosity and led to the creation of shear-thinning behavior. Hence, enhanced technological properties were obtained at the final emulsion that is appropriate for the food products. As a conclusion, using the ultrasound approach in optimum conditions (360 W, 2160 J/cm3, in 10 min), lycopene nanoemulsions can be generated. The little energy required for obtaining ultra-sonicated emulsions in a quicker way. The obtained low energy density (2160 J/cm3) and short time (10 min) are crucial because of the low exposure of the lycopene to the process (preventing potential oxidation) and for preventing extra energy consumption. Moreover, given the scaling-up possibility, it is essential to save energy.

References

Akhavan Mahdavi S, Jafari SM, Asadpoor E, Dehnad D (2016) Microencapsulation optimization of natural anthocyanins with maltodextrin, gum Arabic and gelatin. Int J Biol Macromol 85:379–385. https://doi.org/10.1016/j.ijbiomac.2016.01.011

Albano KM, Nicoletti VR (2017) Ultrasound impact on whey protein concentrate-pectin complexes and in the o/w emulsions with low oil soybean content stabilization. Ultrasonics Sonochem 41:562–571. https://doi.org/10.1016/j.ultsonch.2017.10.018

Anarjan N, Jouyban A (2017) Preparation of lycopene nanodispersions from tomato processing waste: effects of organic phase composition. Food Bioprod Process 103:104–113. https://doi.org/10.1016/j.fbp.2017.03.003

Bagalkot N, Hamouda AA, Isdahl OM (2018) Dynamic interfacial tension measurement method using axisymmetric drop shape analysis. MethodsX 5:676–683. https://doi.org/10.1016/j.mex.2018.06.012

Cabrera-Trujill MA, Filomena-Ambrosio A, Quintanilla-Carvanjal MX, Sotelo-Diaz LI (2018) Stability of low-fat oil in water emulsions obtained by ultra turrax, rotorstator and ultrasound homogenization methods. Int J Gastron Food Sci 13:58–64. https://doi.org/10.1016/j.ijgfs.2018.06.002

Cabrera-Trujillo MA, Sotelo-Díaz LI, Quintanilla-Carvajal MX (2016) Effect of amplitude and pulse in low frequency ultrasound on oil/water emulsions. Dyna 83(199):63–68. https://doi.org/10.15446/dyna.v83n199.56192

Cheng Y, Donkor PO, Ren X, Wu J, Agyemang K, Ayim I, Ma H (2018) Effect of ultrasound pretreatment with mono-frequency and simultaneous dual frequency on the mechanical properties and microstructure of whey protein emulsion gels. Food Hydrocolloids 89:434–442. https://doi.org/10.1016/j.foodhyd.2018.11.007

Costa ALR, Gomes A, Cunha RL (2018) One-step ultrasound producing O/W emulsions stabilized by chitosan particles. Food Res Int 107:717–725. https://doi.org/10.1016/j.foodres.2018.02.057

Gharibzahedi SMT, Razavi SH, Mousavi SM (2013) Ultrasound-assisted formation of the canthaxanthinemulsionsstabilized by arabic and xanthan gums. Carbohydr Polym 96:21–30. https://doi.org/10.1016/j.carbpol.2013.03.085

Gul O, Saricaoglu FT, Besir A, Atalar I, Yazici F (2018) Effect of ultrasound treatment on the properties of nano-emulsion films obtained from hazelnut meal protein and clove essential oil. Ultrasonicssonochemistry 41:466–474. https://doi.org/10.1016/j.ultsonch.2017.10.011

Ho KKHY, Schroem K, Martin-Gonzalez MF, Berton-Carabin CC (2016) Physicochemical stability of lycopene-loaded emulsions stabilized byplant or dairy proteins. Food Struct 12:34–42. https://doi.org/10.1016/j.foostr.2016.12.001

Kaci M, Meziani S, Arab-Tehrany E, Gillet G, Desjardins-Lavisse I, Desobry S (2014) Emulsification by high frequency ultrasound using piezoelectric transducer: formation and stability of emulsifier free emulsion. UltrasonicsSonochemistry 21:1010–1017. https://doi.org/10.1016/j.ultsonch.2013.11.006

Li K, Fu L, Zhao YY, Xue SW, Wang P, Xu XL, Bai YH (2020) Use of high-intensity ultrasound to improve emulsifying properties of chicken myofibrillar protein and enhance the rheological properties and stability of the emulsion. Food Hydrocolloids 98:105–275. https://doi.org/10.1016/j.foodhyd.2019.105275

Mohamad WFW, McNaughton D, Buckow R, Augustin MA (2017) Stability and partitioning of β-carotene in whey protein emulsions during storage. Food Funct 8(11):3917–3925. https://doi.org/10.1039/x0xx00000x

Motamedzadegan A, Naeli MH, Maghsoudlou E, HosseiniBahri SM, Belgheisi S, Babaei ZEA (2018) Effects of basal seed gum and carboxymethyl cellulose gum on rheological properties and flow behavior of pomegranate paste. J Food Meas Charact 13(1):87–96. https://doi.org/10.1007/s11694-018-9921-2

Patil L, Gogata PR (2017) Ultrasound assisted synthesis of stable oil in milk emulsion: study of operating parameters and scale-up aspects. UltrasonicsSonochemistry 40(1):135–146. https://doi.org/10.1016/j.ultsonch.2017.07.001

Qian C, Decker EA, Xiao H, McClements DJ (2012) Physical and chemical stability of b-carotene-enriched nanoemulsions: influenceof pH, ionic strength, temperature, and emulsifier type. Food Chem 132:1221–1229. https://doi.org/10.1016/j.foodchem.2011.11.091

Rocha GA, Favavro-Trindade CS, Ferreira Grosso CR (2012) Microencapsulation of lycopene by spray drying: characterization, stability and application of microcapsules. Food Bioprod Process 90:37–42. https://doi.org/10.1016/j.fbp.2011.01.001

Shariffa YN, Tan TB, Abas F, Mirhosseini H, Nehdi IA, Tan CP (2016) Producing a lycopenenanodispersion: the effectsof emulsifiers. Food Bioprod Process 98:210–216. https://doi.org/10.1016/j.fbp.2016.01.014

Shariffa YN, Tan TB, Uthumporn U, Abas F, Mirhosseini H, Nehdi IA, Wang YH, Tan CP (2017) Producing a lycopene nanodispersion: formulation development and the effects of high pressure homogenization. Food Res Int 101:165–172. https://doi.org/10.1016/j.foodres.2017.09.005

Shi J, Xue SJ, Wang B, Wang W, Ye X, Young Quek S (2015) Optimization of formulation and influence of environmental stresses on stability of lycopene-microemulsion. LWT Food Sci Technol 60:999–1008. https://doi.org/10.1016/j.lwt.2014.10.066

Silva EK, Thereza M, Rosam G, Angela M, Meireles A (2015) Ultrasound-assisted formation of emulsions stabilized by biopolymers. Curr Opin Food Sci 5:50–59. https://doi.org/10.1016/j.cofs.2015.08.007

Silva EK, Costa ALR, Gomes A, Bargas MA, Cunha RL, Meireles MAA (2018) Coupling of high-intensity ultrasound and mechanical stirring for producing food emulsions at low-energy densities. Ultrasonicssonochemistry 47:114–121. https://doi.org/10.1016/j.ultsonch.2018.04.020

Tan CP, Nakajima M (2005) β-Carotenenanodispersions: preparation, characterization and stability evaluation. Food Chem 92(4):661–671. https://doi.org/10.1016/j.foodchem.2004.08.044

Vélez-Erazo EM, Consoli L, Hubinger MD (2018) Mono and double-layer emulsions of chia oil produced with ultrasound mediation. Food Bioprod Process 112:108–118. https://doi.org/10.1016/j.fbp.2018.09.007

Xiong Y, Li Q, Miao S, Zhang Y, Zheng B, Zhang L (2019) Effect of ultrasound on physicochemical properties of emulsion stabilized by fish myofibrillar protein and xanthan gum. Innov Food Sci Emerg Technol 54:225–234. https://doi.org/10.1016/j.ifset.2019.04.013

Acknowledgements

Dr. Yamini at Tarbiat Modares University is highly appreciated for his excellent technical assistance in lycopene extraction by SC-CO2.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflicts of interest regarding the work outlined in this manuscript is confirmed by the authors.

Ethical statement

No animal or human studies are included in this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Belgheisi, S., Motamedzadegan, A., Milani, J.M. et al. Impact of ultrasound processing parameters on physical characteristics of lycopene emulsion. J Food Sci Technol 58, 484–493 (2021). https://doi.org/10.1007/s13197-020-04557-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04557-5