Abstract

The objective of this study was to investigate the effects of different drying processes (microwave, freeze, convective hot air, and vacuum drying) and microwave finish drying (FD + MD and CD + MD) on the physical and powder properties of the red pepper powder. The effect of moisture content on the powder properties and the relationship between microwave output power or drying temperature and physical and powder properties were also determined by using most common mathematical models (linear, power, logarithmic, and quadratic). Results showed that an increase in both microwave output power and temperature (for CD and VD) generally resulted in a decrease in drying time, moisture content, and chroma and an increase in bulk and tapped density values. The drying time, moisture content, and water activity values can be significantly decreased, whereas, the color values can be significantly increased by combining FD and CD with microwave finish drying (P < 0.05). The moisture content (y = − 1.94 ln(x) + 7.6455, R2 = 0.9905), bulk (y = 54.224 ln(x) + 153.71, R2 = 0.9705), tapped (y = 61.7 ln(x) + 225.6, R2 = 0.9994) and particle densities (y = − 327.4 ln(x) + 2260.5, R2 = 0.9966), and porosity (y = − 3.778 ln(x) + 89.806, R2 = 0.9586) values followed a logarithmic trend depending on the increase in the convective hot air drying temperature. The inverse relationship was observed between the moisture content, bulk and tapped densities of the red pepper powders.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Red pepper (Capsicum annuum L.) is a highly consumed vegetable and its powder used as a spice due to its specific aroma, color, and potential health-promoting properties of vitamins, minerals, carotenoid, and phenolic contents, etc. The red peppers of the Bursa variety (Capsicum annuum L.) are rich in phenolic compounds (1011 ± 4.3 mg/kg), vitamin C content (714 ± 7.6 mg/kg), and antioxidant activity (2.94 ± 0.05 mmol Trolox/kg, Frary et al. 2008). Red peppers are generally dried to obtain a spice to use for meat products, instant soups, bakery products, spice mixes, pizzas, seasonings, and sauces in the food industry due to its intense color and strong flavor (Vega-Gálvez et al. 2009; Rayman Ergün et al. 2015; Tekin and Baslar 2018). Besides, drying is one of the most frequently used methods for red pepper processing and preservation due to its high moisture content and perishable structure (Deng et al. 2018). Drying of the red peppers can be accomplished using various techniques including hot air, vacuum, freeze, microwave drying, etc. and drying techniques offer different advantages depending on the drying method. Vacuum drying is a process in which the material is dried under a low-pressure environment which lowers the heat required for rapid drying. Besides, vacuum drying improves the drying rate of fruits and vegetables, and as a result, lower energy consumption values and high-quality powders are obtained (Jaya and Das 2005; Alibas 2009). Freeze drying is the best method for obtaining high-quality (nutritional and commercial value, texture, aroma, rehydration behavior, etc.) food powders or dried fruit and vegetables (Marques et al. 2006). Microwave drying has many unique features related to its selective and volumetric heating compared to traditional drying techniques (Song et al. 2016). The advantages of the previously mentioned dying techniques can be brought together by combining them with microwave finish drying which provides an alternative way to improve the quality of the dehydrated products by increasing the evaporation rate and decreasing the drying time and energy consumption (Alibas 2006; Demiray et al. 2017).

There are several studies on the drying of different forms of red pepper (whole, sliced, shredded, and cubes) such as, hot air drying (Doymaz and Pala 2002; Akpinar et al. 2003; Vega et al. 2007; Di Scala and Crapiste 2008; Vega-Gálvez et al. 2009; Deng et al. 2018), pulse vacuum drying (Deng et al. 2018), ultrasound-assisted vacuum drying (Tekin and Baslar 2018), oven drying (Arslan and Özcan 2011), microwave drying (Arslan and Özcan 2011), atmospheric freeze-drying (Alves-Filho et al. 2007), infrared drying (Nasiroglu and Kocabiyik 2009), infrared-assisted hot air-drying (Deng et al. 2018), solar polytunnel drying (Sharma et al. 2015), etc. These studies generally focused on the drying kinetics, activation energy, and thin layer modeling of red pepper. The determination of powder properties (bulk, tapped, and particle densities, porosity, flowability, cohesiveness, etc.) are important for the economic, functional, and commercial considerations of the powder products (Çalışkan Koç and Dirim 2018). The quality of the obtained powder depends on the selected drying technology, operational conditions, moisture content, and chemical composition (Krokida and Maroulis 2000; Fitzpatrick et al. 2004; Iqbal and Fitzpatrick 2006; Goula and Adamopoulos 2008; Çaliskan Koç and Dirim 2018). From the authors’ knowledge, there is a paucity in the literature investigating the effect of several drying processes on the moisture content, color values, and powder properties of red pepper powder. Therefore, this study aimed to investigate the effects of different drying processes [microwave oven, freeze, convective hot air, and vacuum drying, and also the microwave finish drying methods (FD + MD and CD + MD)], microwave output power and drying temperatures on the moisture content, color values, and powder properties of red pepper powder. Besides, the effect of moisture content on the powder properties of red pepper powder was studied and the relationship between the microwave output power or drying temperature and physical and powder properties of red pepper powders were also investigated to serve as a basis for further design and optimization.

Materials and methods

Raw materials

The red peppers of the Bursa variety (Capsicum annuum L.) were purchased from a local supermarket in Izmir, Turkey. Afterwards, they were washed, the seeds and juice [using a juice extractor (Premier PRJ-607, Turkey)] were removed. Then 50 g of red pepper pulp were placed in a petri dish, with a diameter of 14 cm, as a thin layer (thicknesses of 3 mm). The petri dishes were frozen at − 40 °C until needed for further experiments. The petri dishes were removed from the freezer at least 4 h before the drying experiments and kept in the refrigerator until completely thawed except for freeze-drying experiments. The drying experiments were performed after removing the samples from the refrigerator and reached room temperature.

Methods

Drying of the red pepper pulp

Drying experiments were performed in the microwave oven, freeze dryer, tray dryer, and vacuum oven. The selected dryers and drying conditions were described in detail below. In all drying experiments, the weight losses of the samples (50 ± 2 g) were followed until the constant weight was reached (< 0.01 g). The weight loss was measured every 30 s for MD, 1-h for FD, 10 min for CD, and 30 min for VD until a constant weight was reached (Ohaus AR2140, USA). The red pepper powder was obtained by grinding the dried material (flake) with a mortar and packaged in aluminum polythene bags for further analysis.

Microwave oven drying

The red pepper pulp was dried in a domestic digital microwave oven with the technical feature of 230 V, 2450 MHz, and 2400 W (volume: 26 L, Arçelik Model MD595, Turkey) at 5 different microwave output power settings. The oven had the dimensions of 51 × 44 × 31 cm with a rotating glass plate of 300 mm in diameter. Furthermore, it was able to work at various microwave output powers such as 180 W, 360 W, 540 W, 720 W, and 900 W with a digital control for adjusting the processing time.

Freeze drying

Experiments were performed in a pilot-scale freeze dryer (Armfield, FT 33 Vacuum Freeze Drier, UK). The red pepper pulp samples were frozen at − 40 °C in an air blast freezer (Frigoscandia, Helsinborg, Sweden) for 2 h, then freeze-dried under vacuum (13.33 kPa absolute pressure), at − 48 ± 2 °C condenser temperature. The temperature of the heating plate was set to + 10 ± 2 °C which accelerated the sublimation process, not leading to the melting of the product under working conditions and kept as constant during the drying process.

Convective hot air drying

Drying experiments were performed in a convective hot air dryer (Armfield Lim., Ringwood, Hampshire, UK, dimensions of the tray was 17.5 cm wide × 22.5 cm in length) at 60 ± 2, 70 ± 2, and 80 ± 2 °C air drying temperatures and a 1 m/s air velocity. The samples were located at the center of the convective hot air dryer and the air velocity was measured by an anemometer (MIC Meter Industrial Company, Model:98643) and kept constant during the drying process.

Vacuum drying

The red pepper pulp samples were dried in a vacuum oven (Nuve Laboratory and Sterilization Tech, Model EV018, Turkey, temperature range: 70–200 °C, volume: 15 L, inside diameters: 300 × 250 × 200 mm) combined with a vacuum pump (LAB312, Taiwan) with 20 mbar pressure that was used for the vacuum drying at the 3 different vacuum temperatures (60 ± 2, 70 ± 2, and 80 ± 2 °C).

Microwave finish drying

Freeze drying + microwave finish drying (FD + MD)

The red pepper pulp was dried in a pilot-scale freeze dryer (− 48 ± 2 °C condenser temperature, + 10 ± 2 °C heating plate temperature, 13.33 kPa absolute pressure) for 5 h (where the moisture removal rate decreased). Then the semi-dried red pepper pulp was dried in a microwave oven (540 W microwave output power) until a constant weight was reached.

Convective hot air drying + microwave finish drying (CD + MD)

The red pepper pulp was dried in a convective hot air dryer at 70 ± 2 °C drying air temperature, at a 1 m/s airflow rate for 40 min (after the initial temperature rise period and where the moisture removal rate started to decrease). Then the semi-dried red pepper pulp was dried in a microwave oven (540 W microwave output power) until a constant weight was reached.

Analysis

Physical properties

The moisture content, water activity, and color values (CIE LAB color space, L*, a*, and b*) of the red pepper powders were determined according to AOAC (2000), measurements were made using a Testo-AG 400, Germany water activity measurement device, and a Konica Minolta CR-400, Japan colorimeter, respectively. The Chroma, Hue Angle (°), Total Color Change (ΔE*), Browning (BI), and Yellowness (YI) Index values were calculated according to Pathare et al. (2013).

Powder properties

The bulk, tapped, and particle densities, and porosity values were determined according to the procedure described by Jinapong et al. (2008). The flowability and cohesiveness values of the powders were evaluated in terms of the Carr Index (CI) and Hausner Ratio (HR), respectively. Both CI and HR were calculated from the bulk and tapped density values of the powder according to Jinapong et al. (2008).

Mathematical modeling

In order to determine the relationship between the microwave output power or drying temperature and the physical and powder properties, the linear (y = ax + b, a: slope and b: intercept), power (y = axb, a: proportionality constant and b: power), logarithmic (y = a ln(x) + b, a and b: model parameters), and quadratic (y = ax2 + bx + c, a: indicates the direction of parabola and c: intercept) functions which were basic and most commonly used in the modeling studies were fitted to experimental data using SPSS 20.0 (SPSS Inc., Chicago, IL, U.S.A). The goodness of fit was determined using the coefficient of correlation (R2) that can be described by the equation given by Erbay and Icier (2009).

Statistical evaluation

All experiments were performed in duplicates and measurements were performed in triplicates. All data points shown in graphs represent the mean of the triplicate analysis. Statistically significant differences between samples were determined using ANOVA (analysis of variance), the F-test for multiple samples or two samples with α = 0.05, and SPSS 20.0, (SPSS Inc., Chicago, IL, U.S.A.). Significant differences are indicated by different letters when the P value was below 0.05.

Results and discussion

The results of the physical analyses

In this study, the effect of different drying techniques and microwave finish drying on the physical and powder properties of red pepper pulp were investigated. The microwave energy improves the drying process without damaging the quality of the final product and decreases the drying time and energy consumption. Microwave drying has usually been combined with other drying techniques due to promoting fast and effective drying without significant quality losses (Soysal et al. 2009). For this reason, the microwave oven drying process is applied alone and as a finish drying of FD and CD (at 70 °C). The other drying air temperatures (60 °C and 80 °C) were eliminated due to high water activity values which are related to the stability, quality, and safety of dried foods, and poor flow characteristics. In order to apply microwave finish drying, 540 W microwave output power was chosen. Because, MD-RP at 540 W has the highest bulk density and lowest Carr Index and Hausner Ratio values which has handling, storage, and transportation advantages. In addition, the 900 W microwave output power was eliminated due to higher water activity and ΔE* values (commercial quality of red pepper powder is evaluated based on the strength of the red color) and 180 and 360 W microwave output powers were eliminated due to long drying time.

In this study, the relationships between the microwave output power or drying temperature and the physical and powder properties of red pepper powders were studied by comparing the potential regression models (linear, power, logarithmic, and quadratic) which are the basic and most common mathematical expressions. These models which had the highest R2 values were accepted. The mathematical models will be useful for predicting the changes in the physical and powder properties of the red pepper powders depending on the drying conditions within the range of experimental study, further design, control process, and optimization, etc. In addition, estimation the effects of the process conditions on the physical and powder properties are important for reducing the expenses, saving the energy and time, and obtaining the powders with advantages of low moisture content, water activity, browning index and color change values, wettability and solubility times, etc.

The drying time of red pepper pulp decreased depending on the increase in the microwave output power and drying temperature, for CD and VD, due to a higher heat transfer rate (P < 0.05). The drying times of red pepper pulp ranged between 9.60 min (900 W) and 28.80 min (180 W) for MD, 3.83 h (80 °C) and 6.08 h (60 °C) for CD, 7.5 h (80 °C) and 15 h (60 °C) for VD, and was found to be 9 h for FD, 5.10 h for FD + MD, and 43 min for CD + MD. The higher hot air and vacuum temperatures and microwave output powers accelerated the moisture removal and increased the driving force of heat and mass transfer, which resulted in shorter drying time values. Lower drying time values were observed for MD samples due to promoting the effect of electromagnetic waves (heating energy) that penetrates into the food materials resulting in the removal of water (Jin et al. 2019). Similarly, Michalska et al. (2016) reported that the lowest drying times for plum powder were obtained from microwave vacuum drying compared to FD, VD, and CD and combining CD with MVD resulted in lower drying time (five to eight fold) values compared to CD alone.

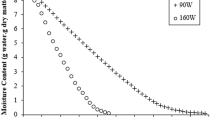

The results of the physical analysis are given in Table 1. The moisture content of red pepper pulp (88.19%) was found to be lower compared to the moisture content of fresh red pepper obtained by Vega-Gálvez et al. (2009), 89.40 ± 1.40%, Arslan and Özcan (2011), 90.06 ± 0.9%, Kaymak-Ertekin (2006), 90.5 ± 0.2%, Nasiroglu and Kocabiyik (2009), 90.0%, and Di Scala and Crapiste (2008), 92.4 ± 0.042% due to the initial removal of the red pepper juice. The red pepper juice was removed in order to use in another application and improve the drying process such as decrease the drying time, energy consumption, moisture content, etc. The moisture contents of red pepper powders (< 7.81%) are below 10% which is sufficient to make foods microbiologically safe (Tze et al. 2012). In several studies, the drying process was stopped when the moisture content of the red pepper decreased to 10–12% (Doymaz and Pala 2002; Akpinar et al. 2003; Nasiroglu and Kocabiyik 2009; Tekin and Baslar 2018; Deng et al. 2018). But, in this study, the drying experiments were conducted until a constant weight was achieved and then the moisture contents of the obtained powders were determined. As expected, increasing the microwave output power and drying temperature (for CD and VD) resulted in a significant decrease in the moisture content of the red pepper powders (P < 0.05). This decrease was found to be suitable for the power function for MD (y = 7.7862x−0.383, R2 = 0.9835) and VD (y = 3.8273x−0.204, R2 = 0.9849) and the logarithmic function for CD (y = − 1.94 ln(x) + 7.6455, R2 = 0.9905). The proportionality constant of power model for MD (a = 7.7862) was found to be higher compared to VD (a = 3.8273). Similarly, Akdoğan et al. (2017) reported that the moisture content values of microwave dried corn husk powders decreased depending on the increasing of the microwave output power due to the high transfer rate at high microwave output power. The high microwave output power and drying temperature resulted in an increase in the driving force of mass transfer and accelerating the rate of water vapor diffusion and this situation may result in the lower moisture content of the red pepper powder. The lowest moisture content values (< 3.85%) were observed for VD-RP compared to other drying techniques, whereas, the highest values were observed for CD-RP (< 7.69%) except for MD-180 W (7.81%, P < 0.05). It may be due to crust formation which prevents the removal of moisture from the red pepper pulp. In addition, the moisture content of FD-RP (6.99%) and CD-RP (5.59–7.69%) can be significantly decreased by combining them with MD (around 33% for FD and 10.5% for CD, P < 0.05). The hot air removed the free water from the surface of the red pepper pulp, and then the microwave energy eliminated the water from the interior part of the pulp (Michalska et al. 2016). In this way, the lower moisture content value was obtained for CD + MD-RP compared to CD-RP.

The water activity value of red pepper pulp was found to be 0.982. A similar water activity value was also obtained by Vega-Gálvez et al. (2009), 0.975 ± 0.002. The water activity values of red pepper powders ranged between 0.226 (for FD + MD-RP) and 0.553 (for CD-RP-60 °C). Similar to the moisture content results, significantly higher water activity values were observed for CD-RP (0.523–0.553, P < 0.05). Lower water activity values were observed for the 70 °C temperature for CD-RP (0.523) and VD-RP (0.289) compared to the other drying temperatures (P < 0.05). The water activity values of CD-RP and VD-RP significantly decreased when the drying temperature increased from 60 to 70 °C, however, a further increase resulted in a significant increase (P < 0.05). These relationships can adequately describe with a quadratic function (CD-RP; y = 0.027x2 − 0.111x + 0.637, R2 = 0.9999, and VD-RP; y = 0.084x2 − 0.309x + 0.571, R2 = 0.9999, convex shape), however, no trend was observed for the water activity values of MD-RP due to low R2 value. Drying at 60 °C may not be effective for heat and mass transfer while 80 °C may cause crust formation due to the fast removal of the water from the surface at the high temperature. Similar to the moisture content results, FD + MD-RP (0.226) and CD + MD-RP (0.381) had lower water activity values compared to FD-RP (0.323) and CD-RP (0.523, P < 0.05). It may be due to eliminating the residual moisture from the interior part of the red pepper pulp by microwave energy (Michalska et al. 2016). It was worth mentioning that, the microwave finish drying may promote the removal of residual moisture in the semi-dried CD-RP and FD-RP which also resulted in lower moisture content and water activity values.

Topuz et al. (2011) reported that the quality of red pepper is evaluated using the intensity of the red color. The color values of red pepper powder are shown in Fig. 1. All samples after drying had higher values of L* (44.77–58.09), and lower values of a* (20.67–33.67) and b* (22.90–38.73, except for FD + MD-RP) when compared to the red pepper pulp values of L* (31.53 ± 0.41), a* (33.95 ± 0.37), and b* (36.60 ± 0.94). The discoloration due to oxidation, thermal degradation, Maillard reaction, etc. may be the reason for the decrease in the values of L*, a*, and b*. In addition, Vega-Gálvez et al. (2009) reported that the Maillard reaction takes place during the drying process because of the high levels of reducing sugars and amino acids in the fresh red pepper. The L* values of the powders dried at higher microwave output power (900 W) and drying air temperature (80 °C) did not exhibit significant differences between each other (P ≥ 0.05). In addition, the results indicated that although the L, a*, and b* values insignificantly changed depending on microwave power bleow 540 W (P ≥ 0.05), a sharp decrease in L*, a*, and b* values were observed above 540 W (P < 0.05) which can be adequately described with a quadratic trend (y = − 0.3868x2 + 0.9832x + 50.185, R2 = 0.9417, y = − 0.932x2 + 3.5628x + 27.182, R2 = 0.9994, and y = − 0.8216x2 + 3.2439x + 29.357, R2 = 0.9556 for L*, a*, and b*, respectively.). Although the L* value of CD-RP followed a quadratic trend depending on the increase of drying air temperature (y = − 2.5198x2 + 8.8733x + 41.309, R2 = 0.9999), the b* value linearly increased (y = 1.51x + 26.157, R2 = 0.9958), and the a* value linearly decreased (y = − 2.4x + 31.597, R2 = 0.9889). The higher L, a*, and b* values were obtained from the MD-RP (P < 0.05). It may be due to the substantial reduction in the drying time of the red peppers compared to other drying techniques. The lowest L* (44.77), a* (20.67), and b* (22.90) were observed for VD-RP at 80 °C which had the longest drying time. Although the vacuum drying process was performed in the absence of the oxygen, the high vacuum temperature and long drying time negatively affected the color values of the red peppers (P < 0.05). These decreases with vacuum temperature were found to be linear for all color values (y = − 2.212x + 51.609, R2 = 0.9745 for L*, y = − 4.355x + 33.969, R2 = 0.9914 for a*, and y = − 4.5425x + 35.842, R2 = 0.9369 for b*). The highest slope (a = 4.5425) and intercept (b = 51.609) values were observed for b* and L* values, respectively. Vega-Gálvez et al. (2009) reported that an increase in drying temperature led to an important amount of brown product formation in the red pepper due to an increase in the kinetic reaction rate. For this reason, it may be due to the high reaction kinetic of pigment degradation and non-enzymatic browning reactions, etc. The L*, a*, and b* values of FD-RP and CD-RP can significantly be increased by combining them with MD (except for the L* value of red pepper powder dried using CD, P < 0.05). The lower drying time of FD + MD and CD + MD may result in less discoloration.

The Chroma, Hue Angle, ΔE*, BI, and YI values of red pepper pulp and red pepper powder are given in Table 1. Chroma is considered the quantitative attribute of colorfulness and higher chroma values can be considered as the higher color intensity of samples perceived by humans (Pathare et al. 2013). The Chroma values of red pepper powder varied between 30.85 and 51.32 and these values showed that the red pepper powders have high color intensity. Similar Chroma values were also obtained by Tekin and Baslar (2018) for ultrasound-assisted vacuum (41.021–41.798), ultrasound-assisted vacuum control (37.233–44.981), vacuum (36.862–41.999), and oven (38.107–44.461) dried red pepper. Similar to changes in the color values of red pepper powder, the low microwave output powers (180–540 W) did not exert a significant effect on the Chroma values of the red pepper powder (P ≥ 0.05), while the high microwave output powers (540–900 W) showed a significant effect (P < 0.05). The Chroma value of red pepper powder insignificantly decreased when the drying temperature increased from 60 to 70 °C (both CD-RP and VD-RP, P ≥ 0.05). On the other hand, a further increase resulted in a significant decrease in the Chroma values of CD-RP and VD-RP (P < 0.05). In addition, the Chroma values of FD-RP and CD-RP significantly increased by combining them with MD (P < 0.05). The Hue angle values of the red pepper powder ranged between 0.76 and 0.86 which can be considered as a red Hue (Pathare et al. 2013). The effect of different drying techniques on the Hue angle value was found to be significant (P < 0.05). The combining of FD with MD resulted in a significant increase in the Hue angle value, while the combining of CD with MD resulted in a significant decrease (P < 0.05).

The results showed that the microwave output powers and drying temperatures (for CD and VD) showed a significant effect on the total color change of the red pepper powder (P < 0.05). In addition, the effect of different drying techniques on the ΔE* value of red pepper powder was found to be significant (P < 0.05). The significantly higher ΔE* values were observed for FD-RP and FD + MD-RP compared to the other drying techniques (P < 0.05). The ΔE* value of FD-RP and FD + MD-RP were not found to be statistically different (P ≥ 0.05), however, the ΔE* value can be decreased by around 12.52% by combining CD with MD (P < 0.05). The ΔE* values of CD-RP and VD-RP generally increased depending on the increase in the drying temperature due to the temperature effect on the heat-sensitive compounds which is related to the loss of the red color in the pepper (P < 0.05). In this study, CD + MD drying provided a shorter drying time compared to CD alone and resulted in a lower color change. No trend was observed for the ΔE* values of MD-RP (R2 values was low), however, the ΔE* value of CD-RP increased linearly (y = 1.195x + 18.043, R2 = 0.9921) with the drying air temperature. The ΔE* value of VD-RP followed a quadratic trend with an increase in the vacuum temperature (y = 0.745x2 − 2.275x + 23.48, R2 = 0.9999, convex shape). The significantly higher BI and YI values were generally observed for MD-RP, FD + MD-RP, and CD + MD-RP (P < 0.05). The BI and YI values of the red pepper powder increased with the increase of the microwave output power up to 540 W (P > 0.05). However, a significant decrease in BI and YI values were noticed by increasing the microwave output power beyond 540 W (P < 0.05). It may be due to shorter drying time at the higher microwave output powers. The changes in BI and YI values depending on the microwave output power followed a quadratic trend (y = − 3.5793x2 + 15.953x + 119.81, R2 = 0.9844, and y = − 1.83x2 + 8.282x − 85.324, R2 = 0.9619, concave shape). The effect of the convective hot air drying temperature was not found to be significant on the BI and YI (except for CD-80 °C) values of the red pepper powder (P ≥ 0.05). An increase in the hot air drying air temperature caused an increase in both BI (y = 1.105x2 − 3.005x + 125.85, R2 = 0.9999) and YI (y = 2.625x + 82.393, R2 = 0.9994) values (P ≥ 0.05), while an increase in the vacuum temperature resulted in a significant decrease (y = − 7.7x2 + 21.34x + 106.49, R2 = 0.9999 for BI and y = − 3.88x2 + 10.26x + 79.11, R2 = 0.9999 for YI, P < 0.05, concave shape). The Maillard reactions or non-enzymatic browning reactions at the high drying temperatures may be the reason for higher BI values at the high convective drying air temperatures. Jaya and Das (2005) reported that oxidative degradation such as browning is low during vacuum drying due to the removal of moisture in the absence of oxygen. Similarly, in this study comparatively lower BI values were obtained for VD-RP. In addition, the YI values of the red pepper powders were found to be significantly lower compared to the red pepper pulp (170.46, P < 0.05).

Powder properties

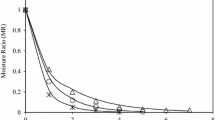

The effect of the different drying processes, drying conditions, and moisture content values on the powder properties of the red pepper powders are shown in Fig. 2a–f. Results showed that the bulk density values of the red pepper powder increased up to 540 W (180.33–233.47 kg/m3), however, a further increase resulted in a decrease (233.47–194.55 kg/m3), and no trend was observed for MD-RP due to low R2 value (Fig. 2a). The microwave output power was found to be significantly effective on the bulk density values (P < 0.05). The bulk density values increased with drying temperatures (followed a logarithmic trend for CD and VD y = 54.224 ln(x) + 153.71, R2 = 0.9705 and y = 23.908 ln(x) + 213.92, R2 = 0.9351), however, the effect of drying temperatures on the bulk density values of CD-RP and VD-RP were generally found to be insignificant (P ≥ 0.05). The lowest bulk and tapped density values were observed for FD-RP and FD + MD-RP (P < 0.05). The findings of this study are in line with Caparino et al. (2012) and Michalska et al. (2016, 2017). The researchers reported that the lowest bulk density values of FD samples related to the porous flat surface of samples with the occulted air content. Similarly, Krokida and Maroulis (2000) also reported that the bulk density values of bananas, apples, carrots, and potatoes were significantly affected by the drying processes (CD, VD, MD, FD, and osmotic dehydration) and the lowest bulk density values were observed for the freeze-drying process. The bulk density values of CD-RP (around 62–125%) and VD-RP (around 128–155%) were significantly higher than FD-RP (P < 0.05). Similarly, Gong et al. (2007) reported that the bulk density values of CD cabbage two times higher than FD cabbage. In addition, researchers reported that bulk density is related to final moisture content and the rate of shrinkage. Higher shrinkage of the CD-RP and VD-RP may be the reason for the higher bulk density values. The combining of FD (93.11 kg/m3) and CD (197.30 kg/m3) with microwave finish drying resulted in lower (86.68 kg/m3) and higher (248.31 kg/m3) bulk density values, respectively. Higher bulk density values are desired because of low packaging and transportation costs (Çaliskan Koç and Dirim 2018). For this reason, VD-RP and CD + MD-RP have advantages of low packaging and transportation costs due to significantly higher bulk density values compared to other techniques (P < 0.05).

The tapped density values ranged between 218.66–268.71 kg/m3 for MD-RP, 225.96–294.00 kg/m3 for CD-RP, and 265.85–322.21 kg/m3 for VD-RP (Fig. 2b). The lowest and highest tapped density values were obtained for FD-RP (127.36 kg/m3) and CD + MD-RP (355.21 kg/m3). The lowest and highest tapped density values of FD-RP and CD + MD-RP indicated the highest (92.34%) and lowest (80.03%) porosity values among all the dried samples. Generally, an increase in both microwave output power and drying temperature (for CD and VD) resulted in an increase in the tapped density values of the red pepper powders, however, these increases generally were not found to be significant (P ≥ 0.05). The tapped density values of MD-RP followed a quadratic trend (y = − 6.7736x2 + 49.978x + 172.97, R2 = 0.964, concave shape) with the increasing microwave output power, whereas, CD-RP and VD-RP followed logarithmic (y = 61.7 ln(x) + 225.6, R2 = 0.9994) and linear (y = 28.18x + 235.88, R2 = 0.9881) trends, respectively. Both FD + MD-RP and CD + MD-RP had significantly higher tapped density values than FD-RP and CD-RP (P < 0.05).

According to Fig. 2a, it can be stated that, when the moisture content value of MD-RP, CD-RP, and VD-RP decreased with an increase of the microwave output power and drying temperature, the bulk density values of the samples generally increased. It may be due to the lower density values of the liquid phase compared to the solid phase. Similarly, Çalışkan Koç and Dirim (2018) reported that the percentage of the solid part decreased with the increase in the moisture content of the powders and the density value of the powders decreased due to bigger density value of the solid part. A similar effect was also observed for tapped density values. In addition, it can be stated that the moisture content values of the red pepper powders have an inverse proportion with the bulk and tapped density values. Similarly, Michalska et al. (2016, 2017) reported that the bulk density values of whole fruit plum powders and blackcurrant pomace powders had an inverse relationship with the moisture content values.

Particle density and porosity are important for the storage stability of powders. Powders with high porosity and low particle density have a greater presence of oxygen which causes oxidation reactions (Zotarelli et al. 2017). The porosity values of the powders depend on the material structure and drying conditions (Krokida and Maroulis 2000). The particle density values of the red pepper powders generally decreased with the increasing drying air temperature for CD and VD (P < 0.05). Generally, the highest particle density value was observed for CD-RP (1908.50–2265.00 kg/m3), where the lowest value was observed for FD-RP (1666.97 kg/m3, P < 0.05, Fig. 2c). No trend was observed for particle density and porosity values for MD-RP, however, the particle density and porosity values of CD-RP followed a logarithmic trend (y = − 327.4 ln(x) + 2260.5, R2 = 0.9966 and y = − 3.778 ln(x) + 89.806, R2 = 0.9586). The particle density and porosity values of VD-RP followed a quadratic trend (y = − 129x2 + 233x + 2115.5, R2 = 0.9999 and y = − 1.66x2 + 2.86x + 86.81, R2 = 0.9999, concave shape). The particle density of FD-RP (1666.97 kg/m3) increased by combining FD with MD (1876.81 kg/m3), however, the opposite effect was observed for the CD-RP (1779.32 kg/m3 for CD + MD-RP). The porosity values of FD-RP (92.34%) and FD + MD-RP (91.99%) were found to be significantly higher compared to other drying techniques (P < 0.05) due to the porous structure of the FD powders with opened pores forming at the surface. In addition, Caparino et al. (2012) reported that the porosity of freeze-dried mango powder was higher than the drum, reflectance window, and spray dried mango powders due to the developed external pores within the internal pores of a single particle. Krokida and Maroulis (2000) also reported that the porosity value of the freeze-dried product is always higher compared to all other dehydration processes (80–90%). According to Krokida and Maroulis (2000), it can be stated that the higher porosity value of FD-RP may be the reason for the low bulk density value. The porosity values FD-RP and CD-RP decreased by combining them with MD (Fig. 2d). Marques et al. (2006) reported that the porosity value of the freeze-dried pineapple, Barbados cherry, guava, papaya, and mango pulps are approximately 0.89 ± 0.01. Achanta and Okos (2000) reported that the high porosity values of the freeze-dried products may be due to the low temperatures (below the glass transition temperature) which cause the material to remain in the glassy state with negligible shrinkage during the freeze-drying process. In addition, Krokida and Maroulis (2000) reported that the vacuum or hot air-dried product has a dense structure (low porosity) due to shrinkage. Similarly, in this study lower porosity values were observed for CD-RP (85.98–89.99%) and VD-RP (80.45–88.01%), and these values decreased depending on the increase of the drying temperature (P < 0.05). Michalska et al. (2016, 2017) also reported that an increase in the hot air temperature resulted in a more compact and rigid product with a lower porosity value. Similar findings were also obtained in this study. The CD-RP and MD-RP have advantages of storage stability due to significantly higher particle density and lower porosity values compared to other techniques (P < 0.05). In addition, the CD + MD-RP has a lower porosity value but also has a higher bulk density. It can also be stated that bulk and tapped density values have generally an inverse relationship with porosity. According to Fig. 2c and d, it can be stated that moisture content and particle density and porosity values of the CD-RP and VD-RP are generally directly proportional, however, no trend was observed between the moisture content, particle density, and porosity values of MD-RP.

The Carr Index and Hausner Ratio values of MD-RP ranged between 12.13–18.78 and 1.12–1.19 which can also be classified as good-very good and low-intermediate, respectively (Fig. 2e and f). Similarly, Akdoğan et al. (2017) reported that the flowability and cohesiveness values of microwave dried corn husk powder ranged between fair-very good and low-intermediate levels, respectively. With regard to other techniques, the microwave drying process resulted in less cohesive and more free-flowing powder (P < 0.05). Opposite to the bulk density values, the HR values of the red pepper powder decreased with the increase of the microwave output power up to 540 W and then increased again. An increase in the drying temperature (60–70 °C) led to a significant decrease in the CI and HR values of CD-RP and VD-RP, however, a further increase (70–80 °C) resulted in a significant increase (P < 0.05). As it can be seen from Fig. 2e and f, the CI and HR values of CD-RP and VD-RP followed a quadratic trend (y = 6.775x2 − 29.305x + 55.72, R2 = 0.9999 and y = 0.14x2 − 0.62x + 2.01, R2 = 0.9999 for CD and y = 4.435x2 − 14.705x + 30.36, R2 = 0.9999 and y = 0.075x2 − 0.245x + 1.42, R2 = 0.9999 for VD). According to the model parameter a which indicates the direction of the parabola, it can be stated that the parabola has a convex shape. The VD-RP has superior properties in flowability, and cohesiveness compared to the FD-RP, CD-RP, FD + MD-RP, and CD + MD-RP due to a lower moisture content which increases the cohesion between powder particles (P < 0.05, Iqbal and Fitzpatrick 2006; Fitzpatrick et al. 2007). Iqbal and Fitzpatrick (2006) and Fitzpatrick et al. (2007) also reported that the moisture content, particle size, and morphology of the powders have an effect on the flow properties of powders. In this study, several drying techniques resulted in different moisture content values, particle morphology, and particle size which related to the flow properties. But, in general, the higher moisture content values were obtained from FD-RP and CD-RP which resulted in low flow properties (Fig. 2e, f). In addition, an inversely proportional relationship was observed between the moisture content values and HR values of VD-RP. The combining of FD and CD with MD resulted in poor flow properties and the Carr Index and Hausner Ratio values of FD + MD-RP (CI 40.53 and HR 1.70) and CD + MD-RP (CI 29.82 and HR 1.43) were found to be as bad and high, and fair and high levels. In order to improve the flow properties of the red pepper powder, several food-grade additives (maltodextrin, gum Arabic, etc.) which improve the flow properties can be added or agglomeration process can be applied to the obtained powders.

Conclusion

This study focused on the effect of different drying processes, drying conditions, and microwave finish drying on the physical and powder properties of the red pepper powder. The drying time of the red pepper pulp decreased with microwave output power and drying temperature due to the higher heat and mass transfer rates (P < 0.05). The lowest moisture content (3.09–3.85%) and BI (101.21–120.13) values were observed for VD-RP whereas, the lowest water activity (0.226) and ΔE* (17.77) values were observed for FD + MD and CD + MD, respectively. The highest bulk density (248.31 kg/m3) and porosity (92.34%) values were observed from CD + MD-RP and FD-RP, respectively. The lowest CI (12.13–18.78), and HR (1.12–1.19) values were observed for MD-RP (P < 0.05). Although combining FD and CD with microwave finish drying has several advantages such as lower drying time, moisture content, and water activity values and higher L*, a*, and b* values, FD + MD-RP and CD + MD-RP have higher BI, CI, and HR values. The inverse relationship was observed between the moisture content and bulk and tapped density values, whereas, the directly proportional relationship was observed between the moisture content and particle density and porosity. Linear models explained the variation in the color values of CD-RP (except for L*) and VD-RP with drying temperature, while the data on water activity, CI, and HR of CD-RP and VD-RP fitted better to the quadratic model. The findings of this study are to give an idea to the producers about the design of the red pepper drying process, the advantages and disadvantages of microwave finish drying, the optimization of the process parameters, and the powder properties of the obtained red pepper powders. This study and mathematical modeling will provide an opportunity for the powder processing industry in selecting a better drying technique that can be utilized for the manufacture of red pepper powder with superior powder properties. The effect of the drying processes and microwave finish drying on the chemical composition of the red pepper powder could be studied in further studies.

Abbreviations

- a, b, c:

-

Constants of models

- a*:

-

Redness/greenness

- ANOVA:

-

Analysis of variance

- b*:

-

Blueness/yellowness

- BI:

-

Browning Index

- CD:

-

Convective hot air drying

- CD-RP:

-

Red pepper dried by convective hot air drying

- CD + MD:

-

Convective hot air drying + microwave finish drying

- CD + MD-RP:

-

Red pepper dried by CD + MD

- cm:

-

Centimeter

- CI:

-

Carr Index

- FD:

-

Freeze drying

- FD-RP:

-

Red pepper dried by freeze-drying

- FD + MD:

-

Freeze drying + microwave finish drying

- FD + MD-RP:

-

Red pepper dried by FD + MD

- g:

-

Gram

- h:

-

Hours

- HR:

-

Hausner ratio

- kg:

-

Kilogram

- L*:

-

Lightness

- mbar:

-

Millibar

- min:

-

Minute

- MD:

-

Microwave oven drying

- MD-RP:

-

Red pepper dried by the microwave oven

- MHz:

-

Megahertz

- mm:

-

Millimeter

- kPa:

-

Kilo Pascal

- R2 :

-

Correlation coefficient

- RP:

-

Red pepper pulp

- s:

-

Second

- VD:

-

Vacuum oven drying

- VD-RP:

-

Red pepper dried by vacuum oven

- W:

-

Watt

- wb:

-

Wet basis

- x:

-

Independent variable (microwave power or drying temperature)

- y:

-

Dependent variable (physical or powder properties)

- YI:

-

Yellowness Index

- ε:

-

Porosity (%)

- ΔE:

-

Total color change

- ρbulk :

-

Bulk density (kg/m3)

- ρtapped :

-

Tapped density (kg/m3)

- ρparticle :

-

Particle density (kg/m3)

References

Achanta S, Okos M (2000) Quality changes during drying of food polymers. In: Mujumdar AS (ed) Drying technology in agriculture and food sciences. Science Publishers, Enfield

Akdoğan A, Çalışkan Koç G, Dirim SN (2017) Mathematical modeling on thin layer microwave drying of corn husk and investigation of powder properties. Bulg Chem Commun 49:986–993

Akpinar EK, Bicer Y, Yildiz C (2003) Thin layer drying of red pepper. J Food Eng 59:99–104. https://doi.org/10.1016/S0260-8774(02)00425-9

Alibas I (2006) Characteristics of chard leaves during microwave, convective, and combined microwave-convective drying. Dry Technol 24:1425–1435. https://doi.org/10.1080/07373930600952776

Alibas I (2009) Microwave, vacuum, and air drying characteristics of collard leaves. Dry Technol 27:1266–1273. https://doi.org/10.1080/07373930903267773

Alves-Filho O, Eikevik T, Mulet A et al (2007) Kinetics and mass transfer during atmospheric freeze drying of red pepper. Dry Technol 25:1155–1161. https://doi.org/10.1080/07373930701438469

AOAC (2000) Official methods of analysis, 17th edn. Assoc Off Anal Chem, Gaithersburg

Arslan D, Özcan MM (2011) Dehydration of red bell-pepper (Capsicum annuum L.): change in drying behavior, colour and antioxidant content. Food Bioprod Process 89:504–513. https://doi.org/10.1016/J.FBP.2010.09.009

Çalışkan Koç G, Dirim SN (2018) Spray dried spinach juice: powder properties. J Food Meas Charact 12:1654–1668. https://doi.org/10.1007/s11694-018-9781-9

Caparino OA, Tang J, Nindo CI et al (2012) Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. J Food Eng 111:135–148. https://doi.org/10.1016/J.JFOODENG.2012.01.010

Demiray E, Seker A, Tulek Y (2017) Drying kinetics of onion (Allium cepa L.) slices with convective and microwave drying. Heat Mass Transf 53:1817–1827. https://doi.org/10.1007/s00231-016-1943-x

Deng LZ, Yang XH, Mujumdar AS et al (2018) Red pepper (Capsicum annuum L.) drying: effects of different drying methods on drying kinetics, physicochemical properties, antioxidant capacity, and microstructure. Dry Technol 36:893–907. https://doi.org/10.1080/07373937.2017.1361439

Di Scala K, Crapiste G (2008) Drying kinetics and quality changes during drying of red pepper. LWT Food Sci Technol 41:789–795. https://doi.org/10.1016/J.LWT.2007.06.007

Doymaz İ, Pala M (2002) Hot-air drying characteristics of red pepper. J Food Eng 55:331–335. https://doi.org/10.1016/S0260-8774(02)00110-3

Erbay Z, Icier F (2009) A review of thin layer drying of foods: theory, modeling, and experimental results. Crit Rev Food Sci Nutr 4:441–464

Fitzpatrick JJ, Iqbal T, Delaney C et al (2004) Effect of powder properties and storage conditions on the flowability of milk powders with different fat contents. J Food Eng 64:435–444. https://doi.org/10.1016/j.jfoodeng.2003.11.011

Fitzpatrick JJ, Barry K, Cerqueira PSM et al (2007) Effect of composition and storage conditions on the flowability of dairy powders. Int Dairy J 17:383–392. https://doi.org/10.1016/J.IDAIRYJ.2006.04.010

Frary A, Doganlar S, Keceli M et al (2008) Water-soluble antioxidant potential of turkish pepper cultivars. HortScience 43:631. https://doi.org/10.21273/HORTSCI.43.3.631

Gong Z, Zhang M, Sun J (2007) Physico-chemical properties of cabbage powder as affected by drying methods. Dry Technol 25:913–916. https://doi.org/10.1080/07373930701372239

Goula AM, Adamopoulos KG (2008) Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: II. Powder properties. Dry Technol 26:726–737. https://doi.org/10.1080/07373930802046377

Iqbal T, Fitzpatrick JJ (2006) Effect of storage conditions on the wall friction characteristics of three food powders. J Food Eng 72:273–280. https://doi.org/10.1016/J.JFOODENG.2004.12.007

Jaya S, Das H (2005) Accelerated storage, shelf life and color of mango powder. J Food Process Preserv 29:45–62. https://doi.org/10.1111/j.1745-4549.2005.00012.x

Jin W, Zhang M, Shi W (2019) Evaluation of ultrasound pretreatment and drying methods on selected quality attributes of bitter melon (Momordica charantia L.). Dry Technol 37:387–396. https://doi.org/10.1080/07373937.2018.1458735

Jinapong N, Suphantharika M, Jamnong P (2008) Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. J Food Eng 84:194–205. https://doi.org/10.1016/j.jfoodeng.2007.04.032

Kaymak-Ertekin F (2006) Drying and rehydrating kinetics of green and red peppers. J Food Sci 67:168–175. https://doi.org/10.1111/j.1365-2621.2002.tb11378.x

Krokida M, Maroulis Z (2000) Quality changes during of food materials. In: Mujumdar AS (ed) Drying technology in agriculture and food sciences. Science Publishers, Enfield, pp 61–106

Marques LG, Silveira AM, Freire JT (2006) Freeze-drying characteristics of tropical fruits. Dry Technol 24:457–463. https://doi.org/10.1080/07373930600611919

Michalska A, Wojdyło A, Lech K et al (2016) Physicochemical properties of whole fruit plum powders obtained using different drying technologies. Food Chem 207:223–232. https://doi.org/10.1016/J.FOODCHEM.2016.03.075

Michalska A, Wojdyło A, Lech K et al (2017) Effect of different drying techniques on physical properties, total polyphenols and antioxidant capacity of blackcurrant pomace powders. LWT 78:114–121. https://doi.org/10.1016/J.LWT.2016.12.008

Nasiroglu S, Kocabiyik H (2009) Thin-layer infrared radiation drying of red pepper slices. J Food Process Eng 32:1–16. https://doi.org/10.1111/j.1745-4530.2007.00195.x

Pathare PB, Opara UL, Al-said FA (2013) Colour measurement and analysis in fresh and processed foods: a review. Food Bioprod Technol 6(1):36–60. https://doi.org/10.1007/s11947-012-0867-9

Rayman Ergün A, Bozkir H, Taştan Ö, Baysal T (2015) Effects of electrical pretreatments on the yield and quality characteristics of red bell pepper puree. J Food Qual 38:396–404. https://doi.org/10.1111/jfq.12156

Sharma R, Joshi VK, Kaushal M (2015) Effect of pre-treatments and drying methods on quality attributes of sweet bell-pepper (Capsicum annum) powder. J Food Sci Technol 52:3433–3439. https://doi.org/10.1007/s13197-014-1374-y

Song Z, Jing C, Yao L et al (2016) Microwave drying performance of single-particle coal slime and energy consumption analyses. Fuel Process Technol 143:69–78. https://doi.org/10.1016/J.FUPROC.2015.11.012

Soysal Y, Ayhan Z, Eştürk O, Arıkan MF (2009) Intermittent microwave–convective drying of red pepper: drying kinetics, physical (colour and texture) and sensory quality. Biosyst Eng 103:455–463. https://doi.org/10.1016/J.BIOSYSTEMSENG.2009.05.010

Tekin ZH, Baslar M (2018) The effect of ultrasound-assisted vacuum drying on the drying rate and quality of red peppers. J Therm Anal Calorim 132:1131–1143. https://doi.org/10.1007/s10973-018-6991-7

Topuz A, Dincer C, Özdemir KS et al (2011) Influence of different drying methods on carotenoids and capsaicinoids of paprika (Cv., Jalapeno). Food Chem 129:860–865. https://doi.org/10.1016/J.FOODCHEM.2011.05.035

Tze NL, Han CP, Yusof YA et al (2012) Physicochemical and nutritional properties of spray-dried pitaya fruit powder as natural colorant. Food Sci Biotechnol 21:675–682. https://doi.org/10.1007/s10068-012-0088-z

Vega A, Fito P, Andrés A, Lemus R (2007) Mathematical modeling of hot-air drying kinetics of red bell pepper (var. Lamuyo). J Food Eng 79:1460–1466. https://doi.org/10.1016/J.JFOODENG.2006.04.028

Vega-Gálvez A, Di Scala K, Rodríguez K et al (2009) Effect of air-drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper (Capsicum annuum, L. var. Hungarian). Food Chem 117:647–653. https://doi.org/10.1016/J.FOODCHEM.2009.04.066

Zotarelli MF, da Silva VM, Durigon A et al (2017) Production of mango powder by spray drying and cast-tape drying. Powder Technol 305:447–454. https://doi.org/10.1016/J.POWTEC.2016.10.027

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Çalışkan Koç, G. The effect of different drying techniques and microwave finish drying on the powder properties of the red pepper powder (Capsicum annuum L.). J Food Sci Technol 57, 4576–4587 (2020). https://doi.org/10.1007/s13197-020-04496-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04496-1