Abstract

Studies on Argentinian soft wheat cultivars are scarce, although the flours obtained from these wheats are the most suitable for cookie making. This work studies the behavior of the flours obtained from 44 adapted soft wheat lines harvested in two consecutive years for cookie making, focusing on starch properties. Starch granule size distribution, and thermal and pasting properties of flour samples were studied. Large variations in flour and starch characteristics were found between all experimental lines, indicating a wide variability among wheat genotypes and a noticeable effect of crop year conditions. Starch granule size distribution showed the typical bimodal distribution observed for wheat. Flours with higher proportion of large A-type granules were associated with lower damaged starch (DS). As expected, the lower the DS content, the lower the solvent retention capacity, gelatinization temperature and enthalpy, with a positive impact on cookie diameter. Flours from soft wheat genotypes with higher proportion of large A-type granules were associated with lower DS content and reduced water absorption capacity. Both genotype and environment exert an effect on soft wheat flour characteristics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Wheat flour is the main ingredient in most cookie formulation; it does not contribute much flavor although contributes strongly to the baked texture, hardness and shape of cookies. Wheat flour consists of starch (ca. 70–75%), water (ca. 14%), and protein (ca. 8–11%), and other minor components such as pentosans (mainly arabinoxylans, ca. 2–3%) (Pareyt and Delcour 2008). A part of starch is damaged during milling, which accounts for 6–12% of flour. The main property of flour affecting cookie quality is water retention capacity, the lower the retention the better the final properties of cookies (Moiraghi et al. 2011). Low retention capacity means that more water is available to dissolve sugar and form a syrup, decreasing dough viscosity during baking and letting the dough to spread further, which in turn results in cookies with larger diameter. Damaged starch (DS) and pentosans are highly hydrophilic components that retain high amounts of water. DS content depends on wheat grain hardness and the milling process, kernels with lower hardness are easier to mill obtaining flours with lower DS content that flours obtained from kernels with higher hardness. Besides containing lower amount of DS, flour obtained from soft wheat contains less protein, and gluten network is usually weaker (Pareyt and Delcour 2008). It has also been suggested that soft wheats have lower amounts of pentosans (Hong et al. 1989). These characteristics make soft wheat flour ideal for the cookie industry.

Although protein, pentosans and DS effect on cookie quality have been widely studied (Pareyt and Delcour 2008), starch structure and properties have not received much attention. In fractionation studies, where flour is separated by aqueous procedures into a large quantity of a low protein prime-starch fraction and lesser quantities of high protein fractions (i.e., gluten, water solubles and starch tailings), Donelson (1988) concluded that physical and chemical properties of starch affected cookie diameter. When the starch fraction used in the formulation resulted in a lowering of the water hydration of dough system, the cookie diameter increased.

Some cereals present different populations of starch granules, differing in their average size and shape. It has been traditionally accepted that wheat grains present two distinct starch granule populations, a large, disk-shaped A-type granules population, and a small, spherical and irregular B-type one (Ao and Jane 2007). However, other authors found wheat to have three different granule populations (Wei et al. 2010), or yet four populations were reported (Li et al. 2008). The wide variability of A and B granule size, composition and properties found in the literature might be attributable to differences in wheat genotypes, starch isolation procedures, granule separation techniques, or the method used for granule size measurement, as well as the cutoff point, as already pointed out by other authors (Li et al. 2008). The properties of wheat starch are related to the structures of A- and B-type granules, swelling, gelatinization, and pasting properties, and are as well affected by the ratio of A/B-type granules (Kim and Huber 2010).

Wheat starch properties seem to widely depend on environmental conditions during grain development; in particular, the temperature during grain filling is perhaps the most significant parameters influencing starch characteristics. High temperatures during this period have been shown to decrease starch production, reduce the final weight of the wheat grain, and diminish yield (Hurkman et al. 2003). High temperatures (> 31 °C) after anthesis may decrease the rate of grain filling, whilst high temperatures imposed before anthesis can also decrease yield (Ferris et al. 1998). On the other hand, deposition of protein appears largely unaffected by elevated temperatures (Jenner et al. 1991).

Considering starch gelatinization during cookie baking, it is usually accepted that gelatinization is restricted due to the low water content and high levels of sugar (Pareyt and Delcour 2008). However, Sciarini et al. (2013) observed a DSC peak at about 60 °C, corresponding to a partial starch gelatinization in sugar-snap cookie dough. Pareyt and Delcour (2008) emphasized that due to the huge diversity of cookie formulations with different water contents, and the scarce literature dealing with starch gelatinization in cookie dough, clear conclusions about the effect of gelatinization cannot be drawn.

In Argentina, soft wheat crop is not extensive and there are only three registered cultivars in the INASE (Argentinian National Seed Institute), thus cookies are made with bread wheat flour added with reducing agents or enzymes in order to allow maximum dough spreading during baking and counteract the shrinkage due to the higher water absorption of gluten proteins. The use of additives cause obviously an extra cost in cookie production.

In the last decades, Argentina cookie industry has grown strongly, and nowadays it demands flours with specific properties that are characteristic of soft wheat. Since little information of Argentinian soft wheat genotypes is available, we decided to analyze flour and starch characteristics from 44 adapted soft wheat lines of different origin, in order to evaluate their performance during cookie making. In previous papers, the relationship between physicochemical characteristics, specially referred to pentosans, DS, protein content and glutenin composition of these wheat flours and cookie quality were studied (Moiraghi et al. 2011). The aim of this work was to gain insight into the behavior of the flours obtained from 44 adapted soft wheat lines for cookie making, focusing on starch properties.

Materials and methods

Materials

Forty-four soft wheat genotypes including advanced lines and cultivars of diverse origins adapted to Argentina’s central wheat region were grown in two consecutive years (2006 and 2007), in Marcos Juarez (32°42′S, 62°07′W, 114 m.a.s.l.) under rainfed conditions. In 2006, the maximum average temperature during anthesis was 27.5 °C, with 6 days prior to anthesis recording temperatures higher than 31 °C, whereas in 2007 maximum average temperature was 25 °C, with only 1 day above 31 °C, as well as the following week registering mild temperatures (Bainotti et al. 2006, 2007).

Genotypes were sown on recommended dates using a 7 × 8 alpha lattice design with three replicates (plot size 5.0 m long × 7 rows wide). Grains were tempered to 15% moisture content for 18 h and then milled on a four-roller laboratory mill (Agromatic AG AQC 109, Laupen, Switzerland). Flour yield was between 54 and 60%. Flour samples were kept in sealed plastic bags at 4 °C during the whole analysis period.

Flour characteristics

Flour particle size analysis (PSA) was performed with a laser diffraction particle size analyzer (Sympatec Helos, Sympatec, Germany), combined with a Rodos dry particle disperser. Approximately 7–10 g of flour were used. The diameter of flour particles was measured based on volume distribution. Average value with standard deviation was informed.

Flours were analyzed for protein content (Method 992.23.32.2.02, AOAC 1998), damaged starch (DS, Approved Method 76-30.02 AACC 2010) and Solvent Retention Capacity profile (SRC, Approved Method 56-11.02, AACC 2010).

The apparent amylose content of flours was determined by enzymatic Amylose/Amylopectin assay procedure utilizing commercial K-Amyl ® (Megazyme International, Ltd., Wicklow, Ireland) kit.

Flour thermal characteristics

The thermal characteristics of flours were measured using a differential scanning calorimeter (DSC 823, Mettler-Toledo, Switzerland) calibrated with indium and zinc. For gelatinization studies, 10.0 mg of flour were weighed into 100 µL aluminum pans, and 20.0 µL of water were added. Pans were sealed and stored for 24 h at 25 °C to allow even water distribution within the sample. Samples were then scanned at 10 °C/min from 30 to 120 °C. Onset temperature (To), peak temperature (Tp) and gelatinization enthalpy (∆H) were calculated using STARe software (Default DB V9.00, Mettler-Toledo, Switzerland).

Pasting properties

Wheat flour pasting properties were measured using a Rapid Visco Analyser (RVA, Tecmaster, Perten Instruments, NSW, Australia), according to AACC method 76-21.01 (AACC 2010). RVA studies were carried out using 3 g of sample (dry basis) and 25 mL of water in an aluminum canister. Pasting temperature, peak viscosity, trough, breakdown, setback and final viscosity were obtained from the pasting curves.

Starch granule size distribution

Starch was isolated following by Bechtel and Wilson (2000) with some modifications. Flour samples were digested using pepsin A (P7012, Sigma, St. Louis, MO), hemicellulase 90 (90,000 U/g activity, Amano Enzyme U.S.A., Lombard, IL), and cleaned further with a detergent mix (5% SDS, 5% Triton X-100, 5% Tween 40, and 5% Triton X-15).

Granule size distributions of starch was determined using a Particle Size Analyser (Horiba LA-950E, Particle Sizing Systems, Japan) with a standard refractive index of 1.32 for water and 1.52 for starch. A 10 µm cutoff was used to differentiate A- from B-type starch granule populations, B granules being smaller than 10 µm. A-type population was further segregated into two groups A1 (10.1–26.1 µm) and A2 (> 26.1 µm), in order to evaluate the influence of larger granules on starch properties, as proposed by Li et al. (2008). Diameter and volume percentage were considered at the peak of each population (Peak A and Peak B).

Cookie making

The ingredients used for cookie making were flour (43.4%), caster sugar (26.0%), shortening (19.3%), powdered milk (2.2%), leavening agent (NaHCO3, 0.5%), NaCl (0.4%), and water (8.2%). Shortening, sugar, milk powder, salt and leavening agent were mixed for 2 min at 700 rpm in a manual mixer (Supermix 130, Moulinex, Argentina) until a cream was obtained. Then water was incorporated and mixed for 1 min. Finally, flour was added and stirred for another 2 min. Cylinders of 45 mm diameter and 7 mm height were cut. Cookies were baked at 200 °C for 10 min. Cookie factor, CF, is used as a parameter to study cookie quality defined as the ratio between the width and the height of four randomly selected cookies. It is assumed that the higher the CF, the better the cookie quality (León et al. 1996).

Statistical analysis

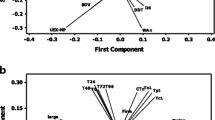

All tests were conducted at least in duplicate within each replicate. Data were subjected to analysis of variance and mean values were compared using by the DGC means-comparison test at a significance level of 0.05. Considering the large number of samples included in this study, tables present the range of minimum–maximum values for each variable. The results for each wheat genotypes are presented in Supplementary material. The relationship between measured parameters was assessed by Pearson’s test. All analyses were performed using the INFOSTAT statistical software (Facultad de Ciencias Agropecuarias, Universidad Nacional de Córdoba, Argentina).

Results and discussion

Flour characteristics

Table 1 shows protein, particle size average (PSA), damaged starch (DS) and apparent amylose contents of the studied flours. It can be observed that PSA, DS and protein contents were strongly affected by crop year, with DS and PSA being significantly higher, and protein being lower in 2007. Regarding protein content, two different groups can be distinguished (p < 0.0001): cultivars with less than 10.5% protein content and cultivars with more than 10.5% proteins, although in general protein contents were rather low (Table S1, Electronic Supplementary Material, ESM). Protein level was significantly higher in cultivars harvested in 2006. Grain filling, the stage in which storage molecules are synthesized and deposited in wheat endosperm, starts 10–15 days after anthesis, and takes place until the physiological maturity is reached (around 30 days after anthesis). In this period, starch and proteins are synthesized, being starch quantitatively more important. As mentioned before, high temperatures during grain filling negatively affects starch synthesis. In 2006 the temperatures during anthesis were higher than in 2007. Thus, it is plausible that starch deposition in 2006 was lower than in 2007, which could contribute to an increase in protein percentage.

Apparent amylose content varied between 25.10 and 31.27% for different cultivars; significant differences between crop year and genotypes were found, being genotype 29 the one with highest amylose content (Table S1, ESM). Raeker et al. (1998) found values between 26.7 and 28.8% for soft wheat starches, whereas Blazek and Copeland (2008) reported values from 35 to 43% for hard wheat. The difference found in this work in apparent amylose content between genotypes (≈ 6%) could be explained by different genetic backgrounds. It has been reported by Zeng et al. (1997) that different dose in waxy genes can explain slight differences of 2% or less in amylose content in wheat. Regarding crop year, amylose content was significantly higher in 2006, when average temperature during grain filling was higher. In agreement, Vignola et al. (2016) reported a significant increase (1.9%) in apparent amylose content with increasing temperatures (4.5 °C).

Regarding damaged starch content, genotypes could be divided into 3 groups (p < 0.0001): genotypes with DS content lower than 5.50%, from 5.51 to 8.01% and higher than 8.01% (Table S1, ESM); moreover, a significant effect of crop year was observed, being lower in 2006 (Table 1). One of the main variables affecting DS level is grain hardness, the harder the grain, the higher the DS content, since hard wheat requires more force to fracture the kernels and as consequence results is flours with higher damaged starch content. Following the same reasoning, it is expected that hard wheat grains result in coarser flours obtained when milled under standard conditions. Thus, grain hardness can be indirectly evaluated by analyzing flour particle size (PSA). A significant correlation was thus found between DS and PSA (r = 0.378, p < 0.05).

The SRC test is a solvation assay developed for wheat flour, based on the differential swelling behavior of individual flour component in selected solvents: water (for all hydrophilic compounds), sodium carbonate (for damaged starch), lactic acid (for gluten), and sucrose (for pentosans). SRC is used to predict the functional contribution of each individual component, with good quality flour for cookie making presenting low absorption capacities in these solvents. In this study, SRC-carbonate (SRC-c) and SRC-water (SRC-w) were evaluated, since these solvents correlate well with starch fraction. As expected, significant correlation was found between DS and SRC-w (r = 0.54, p < 0.0001) and SRC-c (r = 0.50, p < 0.0001) (Table 2).

Flour physicochemical behavior

In order to evaluate thermal and pasting behavior of soft wheat flour, differential scanning calorimetry (DSC) and rapid viscoanalysis (RVA) were carried out. Results are shown in Table 3 and representative curves are collected in Figure S1 (ESM). Significant differences were found between the two crop years for starch gelatinization parameters, i.e. To, Tp and ∆H. For cultivars grown in 2007, To and Tp were lower, and enthalpy was higher than for those grown in 2006. Matsuki et al. (2003) reported a great effect of environmental temperature during wheat grain development on starch synthesis, with a strong influence on starch content, amylopectin structure and gelatinization properties of wheat starch. They found that Tp increased when maturation temperatures were higher, reporting that the crystallite structure of these starches appear to be more ordered. In this same line, Tester et al. (2001) found that elevated growth temperature causes increased registration of amylopectin crystallites with enhanced rigidity of amorphous regions. These events may restrict granule hydration and consequently increase gelatinization temperatures. In our work, other factors may also contribute to increase gelatinization temperatures. Higher growing temperatures lead to a reduction of starch content, which is in agreement with data from Table 1 where it is shown that cultivars grown in 2006 presented higher protein content (related to lower amount of starch in wheat grain). This lower starch content had a direct impact, decreasing gelatinization enthalpy. Furthermore, To and Tp were positively correlated to protein content (Table 2), since proteins compete with starch for water uptake.

Barrera et al. (2012) informed that wheat starch suffers damage during milling resulting in a completely damaged starch fraction (with no birefringence), and a partially damaged fraction with a partial loss of birefringence. These authors claimed that these mechanically damaged starches lose their optical birefringence when suspended in cold water, and that this process, named ‘cold gelatinization’, is similar to gelatinization caused by heating. In agreement with these findings, a negative correlation between DS and To and Tp was found in the present study. Moreover, damaged starch content correlated negatively with gelatinization enthalpy, since wheat with more DS content required lower energy to gelatinize. As expected, both SRC-c and SRC-w (related to high DS content and hydrophilic components, respectively) correlated negatively with To and Tp.

Considering pasting behavior, a wide range in pasting parameters was observed for different flours. A significant effect of crop year and genotype on pasting properties was observed. Flours from 2006 showed higher pasting temperature and lower peak viscosity, breakdown, setback and final viscosity (Table 3). It is known that adverse environmental conditions (higher temperatures, water stress) during grain development can affect pasting properties of flour (Singh et al. 2010).

In general, hydrophilic components, such as gluten and pentosans, and amylose content have a pronounced effect on starch pasting properties. In this work, amylose content was negatively correlated with peak viscosity (r = − 0.31, p < 0.05), in agreement with Zeng et al. (1997). While amylopectin is responsible for the swelling of starch granules, amylose hinders swelling and, consequently, decreases paste viscosity. Other authors have found, on the other hand, lower viscosity development in a rice variety with low amylose content (12.6%) compared to a regular amylose content (27.2%) variety (Dutta and Mahanta 2012). Breakdown was negatively associated with damaged starch (Table 2), in agreement with Barrera et al. (2013), who stated that damaged starch granules swell to a high degree and are consequently weaker during cooking and shear stress, increasing the granule susceptibility to be disrupted. In line with these results, breakdown correlated negatively with SRC-c and SRC-w (Table 2), highly associated with DS content.

Starch granules size distribution

In this work, starch granule size showed a bimodal distribution, with small B- (< 10.1 µm) and large A- (> 10.1 µm) type granules.

Genotype influenced (p < 0.05) the diameter of A and B granules on the peak, whereas crop year only affected the diameter of A granules on the peak (Table 4).

Volume percentage of A1 and A2 subpopulations was also affected by wheat genotype (Table 4). Contribution of the A1 granules population to the total volume was an average of 79.20% for the two crop years, genotypes 5, 8, 26, 31, 32 and 41 had the lowest proportion of A1 granules (Table S1, ESM). Larger A2 granule population was absent in one cultivar (line 50) in 2006, whereas in over 70% of wheat genotypes, it represented less than 10% of the total volume. Contribution of A granules (A1 + A2) to the total volume was an average of 84.46%, whereas B granule average contribution was 13.54% for two crop years.

Both genetic and environmental factors are known to affect starch granules size distribution in wheat grains, as well as starch physicochemical characteristics. Inter-annual variation was significant for %Vol A2 and peak diameter of A-granules, in agreement with Morrison and Scott (1986) who found that the mean volume of A-type granules within a cultivar varied with different growing conditions. Shi et al. (1994) found that the proportion of large A-type granules was reduced with an increase in temperature during grain filling. %Vol A2 was 6.25% for cultivars grown in 2006 (higher temperatures recorded), and 8.28% (p < 0.01) for the same samples harvested in 2007.

Amylose content in large and small granules is a controversial subject on the literature. While most researchers found a higher amylose content in large granules than in small ones (e.g., Ao and Jane 2007), others reported the opposite (e.g., Yin et al. 2012). In this work, amylose content negatively correlated with the %Vol peak A (Table 2), however no correlation between amylose and B granules was found. Blazek and Copeland (2008) found no significant correlation between the size distribution of starch granules and total or free amylose content, whereas Yamamori et al. (2000) found that starch that exhibited a range of A- and B-type granule contents did not differ in their actual amylose content but rather in the state of their amylose (free vs. lipid complexed). In the same line, Eliasson and Karlsson (1983) found that the enthalpy of the endothermic transition due to the amylose–lipid complex was found to be greatest for the small granules.

Gelatinization temperature was also affected by starch granule distribution, To being positively correlated to %Vol peak A (Table 2), and negatively to %Vol peak B. It is known that the large granules (A-type) are laid down in the earliest stage of wheat development and increase in size during the ripening period. The gelatinization temperature is lower for the mature starch than for starch from an early stage of development (Karlsson et al. 1983). Thus, gelatinization temperature decreases when B-type granules increase in volume, this probably being related to the content of amylose–lipid complexes, partly depending on the increasing proportion of B-type granules.

Damaged starch correlated negatively with %Vol A1 and positively with the %Vol B type granules. It has been found that B-granules are more likely to be damaged during milling (D’Appolonia and Gilles 1971), although other authors (Peterson and Fulcher 2001) suggested that large granules are more susceptible. The relationship between size distribution of starch granules and wheat hardness (determining flour DS) has interested several investigators. However, because of the problems associated with sampling, results are not always in agreement (Raeker et al. 1998). Some authors (Zayas et al. 1994) were able to identify hard wheats from soft wheats according to starch morphometric parameters; they found a negative correlation between wheat kernel hardness and starch granule size, with hard wheats being associated to a greater percentage of small granules and fewer large granules than soft wheats.

From Table 3, it can be seen that apparent amylose content was negatively associated with %Vol peak A, while it was also positively correlated with PSA and DS.

Cookie factor

Cookie factor obtained from the 44 experimental wheat lines harvested in two consecutive years are presented in Table 4. As shown, CF was strongly affected by crop year and genotype, with lines 3, 19, 36, 39, 43, 44 and 48 showing the highest CF values (Table S2, ESM). There is some controversy around the role of starch during cookie baking. Some authors consider that the gelatinization of starch is practically zero (Abboud and Hoseney 1984), while others have found evidence of irreversible changes in the structure of the starch during baking, in at least half of the granules (Sciarini et al. 2013).

Cookie spreads during baking due to a decrease in apparent viscosity, which itself results from the increase in temperature and the progressive solubilization of sugar and fat melting. The cookie spreads until the point at which the viscosity suddenly increases (set point). However, the cause for the rapid viscosity increase is yet unclear. Considering that starch is not gelatinized (at least completely), the viscosity increase may be a result of different and combined phenomena. On the one hand, flour protein properties, such as protein aggregation or protein glass transition, might exert an effect on viscosity. On the other, the reduction of water availability to act as a solvent (because of both the presence of the water-binding components of the dough and evaporation during baking) (Pareyt and Delcour 2008). Therefore, the viscosity increases and the cookie spreads at slower rate. Being starch gelatinization not responsible for cookie setting during baking, the positive correlation between CF and To found in this work may be due to an indirect effect of other flour constituents, such as lower content of damaged starch and/or protein, both with high water binding capacity.

Conclusion

In this study, flour from 44 soft wheat experimental lines harvested in two consecutive years were analyzed, mainly focusing on starch properties and related to cookie making performance. Starch characteristics, such as granule size distribution, and flour thermal and pasting properties were affected both by genotype and crop year conditions. Starch particle size distribution influenced gelatinization and pasting properties, with larger granules (A2) being positively related to To and A1-type granules reducing gelatinization temperature. The same trend was true for breakdown. Flours with higher content of apparent amylose produced less viscous and more stable pastes when they were heated in the presence of water. Amylose content negatively correlated with %Vol peak A, and it was also positively associated with DS. The larger the starch granules diameter the lower the To and breakdown viscosity. Lower proportion of A-granules was related to higher damaged starch content which decreased cookie spreading during baking (lower CF).

Thus soft wheat flours with higher proportion of large A-type granules are associated with lower damage starch content and reduced water absorption capacity, with a positive impact on cookie spreading during baking.

References

Abboud AM, Hoseney RC (1984) Differential scanning calorimetry of sugar cookies and cookie doughs. Cereal Chem 61:34–37

American Association of Cereal Chemists (2010) Approved methods of the AACCI. The Association, St. Paul

Ao Z, Jane JL (2007) Characterization and modeling of the A- and B-granule starches of wheat, triticale, and barley. Carbohyd Polym 67:46–55

Association of Official Analytical Chemists (1998) Official methods of analysis of the AOAC international. The Association, Arlington

Bainotti C, Fraschina J, Salines J, Gómez D, Masiero B (2006) Evaluación de cultivares de trigo en la EEA Marcos Juárez Actualización campaña 2006/07. Trigo Actualización 2006. Informe de Actualización Técnica Nº1. INTA EEA Marcos Juárez

Bainotti C, Fraschina J, Salines J, Gómez D, Masiero B (2007). Evaluación de cultivares de trigo en la EEA Marcos Juárez Actualización campaña 2007/08. Trigo Actualización 2007. Informe de Actualización Técnica Nº1. INTA EEA Marcos Juárez

Barrera GN, León AE, Ribotta PD (2012) Effect of damaged starch on starch thermal behavior. Starch/Stärke 116:233–239

Barrera GN, Bustos MC, Iturriaga L, Flores SK, León AE, Ribotta PD (2013) Effect of damaged starch on the rheological properties of wheat starch suspensions. J Food Eng 116:233–239

Bechtel DB, Wilson JD (2000) Variability in a starch isolation method and automated digital image analysis system used for the study of starch size distributions in wheat flour. Cereal Chem 77:401–405

Blazek J, Copeland L (2008) Pasting and swelling properties of wheat flour and starch in relation to amylose content. Carbohyd Polym 71:380–387

D’Appolonia BL, Gilles KA (1971) Effect of various starches in baking. Cereal Chem 48:625–636

Donelson JR (1988) The contribution of high-protein fractions from cake and cookie flours to baking performance. Cereal Chem 65:389–391

Dutta H, Mahanta CL (2012) Effect of hydrothermal treatment varying in time and pressure on the properties of parboiled rices with different amylose content. Food Res Int 49:655–663

Eliasson AC, Karlsson R (1983) Gelatinization properties of different size classes of wheat starch granules measured with differential scanning calorimetry. Starch/Stärke 35:30–133

Ferris R, Ellis RH, Wheeler TR, Hadley P (1998) Effect of high temperature stress at anthesis on grain yield and biomass of field-grown crops of wheat. Ann Bot 82:631–639

Hong BH, Rubenthaler GL, Allan RE (1989) Wheat pentosans. I. Cultivar variation and relationship to kernel hardness. Cereal Chem 66:369–373

Hurkman WJ, McCue KF, Altenbach SB, Korn A, Tanaka CK, Kothari KM, Johnson EL, Bechtel DB, Wilson JD, Anderson OD, DuPont FM (2003) Effect of temperature on expression of genes encoding enzymes for starch biosynthesis in developing wheat endosperm. Plant Sci 164:873–888

Jenner CF, Ugalde TD, Aspinall D (1991) The physiology of starch and protein deposition in the endosperm of wheat. Aust J Plant Physiol 18:211–226

Karlsson R, Olered R, Eliasson AC (1983) Changes in starch granule size distribution and starch gelatinization properties during development and maturation of wheat, barley and rye. Starch/Stärke 35:335–340

Kim H-S, Huber KC (2010) Impact of A/B-type granule ratio on reactivity, swelling, gelatinization, and pasting properties of modified wheat starch. Part I: hydroxypropylation. Carbohyd Polym 80:94–104

León AE, Rubiolo A, Añón MC (1996) Use of triticale flours in cookies: quality factors. Cereal Chem 73:779–784

Li W, Yin Y, Yan S, Li Y, Liang T, Dai Z, Wang Z (2008) Comparison of starch granule size distribution between hard and soft wheat cultivars in eastern China. Agr Sci China 7:907–914

Matsuki J, Yasui T, Kohyama K, Sasaki T (2003) Effects of environmental temperature on structure and gelatinization properties of wheat starch. Cereal Chem 80:476–480

Moiraghi M, Vanzetti L, Bainotti C, Helguera M, León AE, Pérez GT (2011) Relationship between soft wheat flour physicochemical composition and cookie-making performance. Cereal Chem 88:130–136

Morrison WR, Scott DC (1986) Measurements of the dimensions of wheat starch granule populations using a Coulter Counter with 100-channel analyzer. J Cereal Sci 4:13–21

Pareyt B, Delcour JA (2008) The role of wheat flour constituents, sugar, and fat in low moisture cereal based products: a review on sugar-snap cookies. Crit Rev Food Sci 48:824–839

Peterson DG, Fulcher RG (2001) Variation in Minnesota HRS wheats: starch granule size distribution. Food Res Int 34:357–363

Raeker MO, Gaines CS, Finney PL, Donelson T (1998) Granule size distribution and chemical composition of starches from 12 soft wheat cultivars. Cereal Chem 75:721–728

Sciarini LS, Van Bockstaele F, Nusantoro B, Pérez GT, Dewettinck K (2013) Properties of sugar-snap cookies as influenced by lauric-based shortenings. J Cereal Sci 58:234–240

Shi YC, Seib PA, Bernardin JE (1994) Effect of temperature during grain filling on starches from six wheat cultivars. Cereal Chem 71:369–383

Singh S, Gupta AK, Gupta SK, Kaur N (2010) Effect of sowing time on protein quality and starch pasting characteristics in wheat (Triticum aestivum L.) genotypes grown under irrigated and rain-fed conditions. Food Chem 122:559–565

Tester RF, Debon SJJ, Qi X, Sommerville MD, Yousuf R, Yusuph M (2001) Amylopectin crystallization in starch. In: Barsby TL, Donald AM, Frazier PJ (eds) Starch: advances in structure and function. The Royal Society of Chemistry, Cambridge, pp 97–102

Vignola MB, Baroni V, Pérez GT (2016) Genotypic and environmental effects on starch properties of Argentinean wheat flours. Starch/Stärke 68:1–8

Wei C, Zhang J, Chen Y, Zhou W, Xu B, Wang Y, Chen J (2010) Physicochemical properties and development of wheat large and small starch granules during endosperm development. Acta Physiol Plant 32:905–916

Yamamori M, Fujita S, Hayakawa K, Matsuki J, Yasui T (2000) Genetic elimination of starch granule protein, SGP-1, of wheat generates and altered starch with apparent high amylase. Theor Appl Genet 101:21–29

Yin Y, Qi J, Li W, Cao L, Wang Z (2012) Formation and developmental characteristics of A- and B-type starch granules in wheat endosperm. J Integr Agric 11:73–81

Zayas IY, Bechtel DB, Wilson JD, Dempster RE (1994) Distinguishing selected hard and soft red winter wheats by image analysis of starch granules. Cereal Chem 71:82–86

Zeng M, Morris CF, Batey IL, Wrigley CW (1997) Sources of variation for starch gelatinization, pasting, and gelation properties in wheat. Cereal Chem 74:63–71

Acknowledgements

This work was supported by the Consejo Nacional de Ciencia y Técnica (CONICET) and the Agencia Nacional de Promoción Científica y Tecnológica (ANPCyT) (Project PICT-2007-01093).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Moiraghi, M., Sciarini, L.S., Paesani, C. et al. Flour and starch characteristics of soft wheat cultivars and their effect on cookie quality. J Food Sci Technol 56, 4474–4481 (2019). https://doi.org/10.1007/s13197-019-03954-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03954-9