Abstract

Three varieties of Nigerian rice grains: CISADANE, OS6 and NERICA 19 were processed to obtain flours and starches. They were evaluated for their proximate composition and physicochemical properties. The grain physical dimension measurements showed that the CISADANE was slender while OS6 and NERICA 19 were bold and thick. The 1,000 grain weight was highest for CISADANE rice followed by OS6 and NERICA 19. CISADANE had the highest protein and amylose contents. Protein contents in samples ranged as follows: 5.6–6.7, 5.2–6.9 and 0.2–0.9 % in brown rice, milled rice and the rice starches, respectively. The amylose content of CISADANE (27.7–36.5 %) and OS6 (19.9–25.6 %) were high compared with NERICA 19 with negligible amylose. Swelling power and solubility generally increased with increasing temperatures (60–90 °C) for all the samples. Cooked CISADANE grain was hardest and OS6 (Faro 11) rice was softest while the stickiness was highest in OS6.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The quality of the end product in any production line depends largely on the quality of raw material. With respect to rice (Oryza sativa L.) production, there are some inherent characters which influence the grain properties. Many compositional and physicochemical tests have been proposed as quality indicators of milled rice [1]. The test may be divided into groups based on but not limited to the following factors: (a) varietal characteristics; (b) apparent amylose content; (c) gelatinization temperature; (d) swelling and solubility properties of whole kernel; and (e) rheological properties of the flour.

It is therefore important that the physical and chemical properties of promising new rice varieties are evaluated based on the above quality criteria. Such information will be invaluable to rice breeders, rice millers and industrialists, who may wish to provide their consumers with acceptable rice varieties. For example, earlier studies have shown that rice consumers in Nigeria have preference for rice varieties with particular physicochemical, cooking and eating qualities such as moderately flaky, fluffy and in-between soft and hard quality [2–4].

There are many varieties of rice grown in Nigeria. Some of these are considered “traditional” e.g. Igbemo and Ofada rice and some other are hybrid rice varieties. Among the hybrid rice varieties produced by the interspecific hybridization project by West Africa Rice Development Association (WARDA) are NERICA 19, CISADANE, and OS6. In the process of developing improved, high yielding varieties of rice, attempts should be made to incorporate acceptable grain with good cooking quality parameters into them.

With the increased availability of rice, it has become part of the everyday diet of many households in Nigeria. It is therefore important to determine the basic physicochemical properties of these rice varieties. Hence, the objective of this work is to determine the physicochemical analysis of the rice grains, rice flours and their respective starches.

Materials and method

Collection of rice samples, preparation and defatting of rice flour

Rough rice samples of CISADANE, OS6 and NERICA 19 were obtained from the International Institute of Tropical Agriculture (IITA) Ibadan, Oyo State, Nigeria. A dehusker (THU-35, Salake, Hiroshima, Japan) was used to dehull 150 g rough rice samples in duplicate. The resultant brown rice was weighed and then milled for 30 s in McGrill No, 2 mill (Rapsco, Brookshine, TX). Head rice was separated from the broken kernels through a double–tray sizing device (Grain Man Machinery Mfg Miami Fl). Flour samples were obtained by grinding with a cyclone sample mill (Udy, Font Collins, Co) fitted with a 100-mesh sieve to get rice flour for further studies. The defatting of the full flours was carried out through solvent extraction technique by using 85 % methanol for 18–24 h. The defatted samples were taken and dried by exposure to air movement at room temperature (25 °C) for 48 h.

Preparation of starch samples

Starch samples were prepared based on alkaline steeping method of Yang et al., 1984 [5]. Rice sample (1 kg) was soaked in 0.05 N sodium hydroxide for 3–4 h. The soaked sample was then washed with water, ground in a mixer, filtered through a 100 mesh sieve and centrifuged at 3000 rpm for 15 min. The supernatant was transferred into a 100 mL volumetric flask while the top brownish layer was carefully scraped out. The leftover starch residue was again ground using a mixer. These operations were repeated several times until the supernatant did not give any whitish filtrate on addition of water. After centrifugation, the residue was taken and the procedure was repeated with 200, 390, and finally 420 mesh sieve. At the end of these operations starch so obtained was treated with toluene and common salt (sodium chloride) solution in the proportion of 3:0.5 by volume and kept in a shaker overnight at 250 rpm. The starch was removed the next day from the shaker and again ground in the mixer and passed through a 420 mesh sieve to take the filtrate. Negligible portion of residue on the top of the sieve was discarded, and the filtrate was filtered using a Buncher funnel. The residue was washed for a minimum of four to five times with deionized water and filtered. The residue so obtained was broken and dried at room temperature (25 °C) for 3 days with occasional stirring. The dried residue so obtained was ground using a Retch ultra-centrifugal mill, using a 1 mm screen.

Proximate composition of samples

Proximate composition of the samples of brown rice, milled rice, and starch were determined by the American Association of Cereal Chemists Approved Methods. AACC (2000) [6].

Moisture content

The moisture content in each sample was determined by drying a known sample in an air forced draft oven maintained at a temperature of 135 °C according to the procedure described in AACC (2000) method No. 44-15 A.

Fat content

The fat content was determined in each rice flour sample by using hexane as a solvent in a Soxhlet apparatus according to the procedure given in AACC (2000) method No. 30-10.

Ash content

The ash content in each rice flour sample was estimated by putting samples in a muffle furnace at a temperature of 550 °C till white grey residue is obtained by following the method described in AACC (2000) method No. 08-01.

Protein content

The nitrogen content in rice flour samples was estimated by following the Kjeldahl’s method according to the procedure described in AACC (2000) method No. 46-10. The protein percentage was calculated by multiplying nitrogen percent with a factor 5.95.

Physicochemical properties analyses

Grain kernel dimension

The length, width and thickness of twenty whole grains, selected randomly from the samples were measured using a vernier calipers. The samples were then classified into shapes based on the length width ratio.

1000-grain weight

Grain (1000 in number) were randomly selected and weighed with electronic Mettler Toledo PB precision balance Model PB 153-S (Mettler-Toledo, Inc.). An average of the three readings were taken.

pH of the starch

pH of the starch was measured by making a 20 % w/v suspension of each sample in distilled water. Each suspension was mixed thoroughly in a Warring micro blender and the pH was determined with Fisher Accumet AP115 Portable pH Meters [7].

Amylose content estimation

The 100 mg sample was treated with 1 ml of ethyl alcohol in a 100 ml conical flask and then 9 ml of sodium hydroxide was added. The mixture was then heated in boiling water bath for 10 min with occasional stirring. The sample was cooled to room temperature and the volume was made up to 100 ml with distilled water. 5 ml portion of the sample was poured in 100 ml volumetric flask, acidified with 1 N acetic acid and then 2 ml of iodine solution was added (0.2 g iodine and 2 g potassium iodide in 100 ml of aqueous solution) and allowed to stand for 20 min. Absorbance of the solutions was measured at a wavelength of 620 nm with a spectrophotometer. Absorbance of each sample solution was taken to prepare a standard graph with absorbance on the y-axis and amylose content on the x-axis. The dilution factor 20 for the sample was included in the conversion formula. Amylose content was determined by the following formula and expressed on dry weight basis. AACC (2000):

Swelling power and solubility

Swelling power and water solubility of rice flour (0.5 g, db) was weighed directly into a centrifuge tube and added 15 ml distilled water. Swelling power and solubility of rice starch were determined at different temperatures (50, 60, 70, 80 and 90 °C) by placing the centrifuge tube in water bath for 30 min. The tube was then centrifuged at 3000 rpm for 15 min at room temperature (25o). The supernatant was decanted and residue was weighed. The supernatant from swelling power determination was dried to get a constant weight in a hot air oven at 100 °C. The swelling power and water solubility index of rice starch were calculated as described by Schoch (1964) [8].

Textual properties of the cooked rice grains

Milled rice grains were cooked in excess water for their optimum cook time with an addition of 2–3 min. The optimum time was determined by cooking the grains in excess water at boiling temperature and testing them at 2–3 min intervals by taking a few grains and pressing them between two glass plates. The time when the chalkiness or white portion disappeared in the cooked grains was considered as the optimum cook time. Afterwards, excess water was decanted, and grains were kept on a filter paper to remove adhering moisture. Cooked-rice grains textural properties were then determined by a uniaxial, single compression method of Keawpeng and Meenune, 2012 [9], using a Texture Analyzer (TA-XT2 plus, Texture Technologies Corp., Scarsdale, N.Y./Stable Micro Systems, Godalming, Surrey, United Kingdom). Ten whole cooked-rice kernels were compressed using a 20 kg load cell to leave a 0.3 mm gap between two compression plates at the bottom of the compression cycle. The maximum compression force was used as an indicator of cooked rice hardness while the adhesion energy measured during the upward travel of the compression plate was used as an indicator of cooked rice stickiness. Rice samples were cooked in duplicate and five measurements were taken for each cook.

Results and discussion

Chemical composition

The results of proximate analysis are presented in Table 1. The demarcation of protein present in brown rice, milled rice, and starch is observed. Highest protein content (6.87 %) was recorded for CISADANE milled rice, NERICA 19 milled rice (6.1 %) and lowest (5.2 %) for OS6. The value for protein content for OS6 falls out of range of 6–11 % reported for rice varieties grown in South East Asia [10]. Protein content of most rice varieties grown in the world have been surveyed and shown to vary from 5 to 17 % with a mean of 10.5 % [10]. A significant correlation between total protein and lysine levels vary significantly in protein content depending on the conditions under which the rice sample is grown. Protein content in starch depends on the method of isolation and it is generally required to be <0.5 % [11]. However, in spite of great care taken during the isolation, we could not offer any explanation on why the protein content of OS6 rice could not be brought down to <0.9 %.

The fat content was highest (1.4 %) in NERICA 19 rice flour followed by OS6 (0.9 %) and CISADANE (0.74 %). The fat content depends to a greater extent on the removal of bran from the outer surface (although all steps had been taken to polish all types of brown rice under identical conditions still some differences existed in these). In starch, the fat was almost negligible in CISADANE (0.08 %) but in OS6 it is 0.24 %. In the case of NERICA 19, all attempts to estimate fat content did not yield any result probably because of its waxy nature. Ash content in rice flours varied from 0.41 to 0.53 %, whereas, in the starch it ranged from 0.10 to 0.22 %. In rice flour, the minerals is concentrated on the surface of the endosperm and hence the ash content was high whereas starch was free from the cell wall material and the ash content was low. The NERICA 19 starch had the least ash content (0.10 %) when compared to the other two varieties whose ash contents were 0.20 and 0.22 % for OS6 and CISADANE, respectively.

Physical dimensions of the rice grain samples

The physical dimension of rice samples are presented in Table 2 for the milled rice. Results showed that the two varieties OS6 and NERICA 19 were almost the same in length and width and can be classified as bold. The CISADANE can be classified as slender, long grain type when comparison is made with US grain type [12]. The thickness was least in CISADANE and highest in NERICA 19. This is clear from the photographs of these three rice varieties shown in Fig. 1.

Physicochemical properties

The results of 1000 grain weight, amylose content, pH and equilibrium moisture content (Emc) of rice samples are presented in Table 3. The 1000 grain weight was highest (20.9 g) in CISADANE rice followed by OS6 rice (19.9 g) and NERICA 19 rice (18.8 g) respectively. The highest value of apparent amylose content was found in CISADANE rice samples 27.7–36.5 % followed by OS6 19.9–25.6 % and negligible amylose content in NERICA 19 rice. In the waxy rice flour as well as the starch, the value of amylose content is shown as zero, which has been found from the standard graph prepared from amylose and amylopectin as described in the Material and Method section. The values of amylose increased after defatting of flours or starches indicating the role of lipids in binding the linear polymer of each type of rice. In waxy rice, a value of zero was seen, probably because NERICA 19 rice starch does not contain lengthy, linear chains in the amylopectin molecule of starch granule, which can freely take a helical form to receive the iodine molecule and by resonance develop a blue colour. As it is well-known that to develop blue colour, a minimum chain length of 40 glucose residue is required.

Although starch was isolated from all the rice varieties under identical conditions, the pH of the starch (20 %) slurry varied. CISADANE rice was fairly acidic (pH 6.6) and the other two starches were alkaline, OS6 (pH 8.5) and NERICA 19 (pH 7.9) implying that the hydrogen ion concentration varies in different starches. In the present study, isolation of starches involves salt treatment, and as a result of Donnan potential between starch and water, the variation in hydrogen ion concentration was observed. It was observed that upon sodium chloride treatment of starch, the pH becomes acidic and the pKa value of a starch suspension in water was 12.6. The Emc (w.b) on soaking of the milled rice in water at room temperature was highest in the NERICA 19 rice (35 %), lowest in CISADANE (27.8 %) and was intermediate in the OS6 rice (30 %). Equilibrium moisture content on soaking rice at room temperature (Emc-s) is inversely related to the amylose equivalent on a broad classification of high-intermediate and low- amylose NERICA 19 rice varieties.

Surface property/overall property

Table 4 shows some of the textural properties of the cooked grains of the rice varieties. With respect to the surface properties, CISADANE, which has the highest amylose content had the highest hardness, while the least was exhibited by NERICA 19. This clearly indicates that the higher the linear component content, the higher will be the hardness. With regard to surface stickiness, OS6 showed the highest stickiness followed by CISADANE and NERICA 19, respectively.

In the overall physical property, overall hardness of the grain (H2) followed the same trend as surface hardness. However, overall stickiness followed a different pattern, where as usual OS6 had the highest stickiness followed by NERICA 19 and then CISADANE, which is different in surface stickiness.

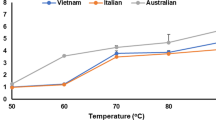

Effect of temperature on swelling power and solubility

The effect of temperature (60–90 °C) on the swelling power of flours and starches of the different rice varieties are shown in Fig. 2a, b, respectively. The most important property of starch in a commercial application is its ability to swell and produce a viscous paste when heated with water. The swelling power of starch indicates the ability of water absorption of starch granules during the starch swelling procedure. The water preferentially breaks down the amorphous region when starch granules are heated with water, because crystalline area is not freely accessible to the water molecules.

From Fig. 2a, it is clear that the swelling power increased in CISADANE flour slowly from 50 to 70 °C and remained almost constant up to 90 °C. However, in its starch (Fig. 2b) this property increased from 50 to 90 °C; the increase was gradual up to 80 °C, and there was a sharp increase in swelling power from 80 to 90 °C. Swelling power was high in CISADANE starch when compared with its flour at 90 °C. Also the swelling power in starch (Fig. 1b) was less from 50 to 60 °C compared to its flour in CISADANE (Fig. 1a). In the flour, a jump occurred from 60 to 70 °C, but in its starch the jump was from 80 to 90 °C.

In OS6 flour, this property increased slowly and reached its highest value at 70 °C and then decline, but in OS6 starch, it continuously rose from 50 to 90 °C. It can also be seen that the jump in CISADANE starch was double from 80 to 90 °C, but the jump in OS6 starch was only one-sixth that from 80 to 90 °C. This increase in swelling power followed a similar pattern with a sharp rise in swelling power between 80 and 90 °C in breadfruit pulp [13].

In NERICA 19 rice flour, the swelling power continuously increase from 50 to 90 °C and reached its highest value at 90 °C, indicating restricted swelling in CISADANE and OS6 flours as well as to some extent in their starch. Under these conditions, it was difficult to measure the swelling power in NERICA 19 rice starch. Among the three flours, the highest swelling power was shown by the NERICA 19 rice flour and the lowest by OS6 and CISADANE flours. Cereal flours are known to swell in two stages, reflecting the properties of the constituent linear and branched polymers. Amylopectin molecules swell to a greater extent along with protein and fat as individual component, but in combination with a linear polymer (i.e. amylose), it is more resistant to swelling as seen in CISADANE and OS6 flours. The effect may be due to either a combination of linear and branched molecules or linear branched molecules along with protein and fat, which demands further studies in these starches. Water absorption capacity ranging from 149.1 to 471.5 % is considered critical in viscous foods such as soups, gravies [14], hence the flours and starches may find use as function ingredients in soups, gravies and baked products [13].

The extent of solubility for rice flour are shown Fig. 3a, b. In CISADANE flour, the solubility increases from 50 to 90 °C, but the extent of solubility in the corresponding starch was comparatively less. In OS6 the solubility in flour increased slowly, but in its starch the increase was sharp from 70 to 80 °C and then decline, which was not so in CISADANE starch. In NERICA 19 rice flour starting from 50 °C, the solubility was very high and almost 4.5 times jump was observed at 70 °C and then decline. This is the peculiarity of NERICA 19 rice flour. Hence it can be deduced that flour and starch of OS6 and CISADANE have less swelling and solubility compared to NERICA 19 rice flour. It is also seen in Fig. 3a that at 70 °C the swelling power was high for OS6 rice flour and at the same time the solubility was high for NERICA 19 flour. Solubility is high in NERICA 19 flour, probably due to leaching of linear portions of branched molecules, and may be this is true if NERICA 19 flour is pregelatinized, which in the present study, is not the case. It is generally documented that pregelatinized flours or starches will have high solubility. It has been proposed that bonding forces within the granules of starch affect its solubility, thus highly associated starch granules with an extensive and strongly bonded micellar structure should display a relatively lower solubility [15].

Conclusion

The physicochemical properties of the grains flours and starches of the Nigeria rice varieties were examined in this study. It was concluded that defatting, protein, fats, nature of amylose and amylopectin molecules among other factors could affect the physicochemical properties of all the rice varieties and their respective flours and starches. It was further concluded that the protein and fat contents play critical role in the solubility and swelling power of rice varieties and their respective starches and flours at different temperatures. Considering the physicochemical properties of CISADANE globally, it could be concluded that this variety is best rice for human consumption while the other varieties, OS6 and NERICA 19 could be converted to other product such as spaghetti, macaroni, pasta and other consumable carbohydrate food.

References

R.J. Priestley, Evaluation of the eating quality of rice with special reference to Ghana. 2. Compositional and physicochemical tests indicative of eating quality. Ghana J agric Sci 11, 65–67 (1978)

Babaleye T, Nwachukwu I (1992) Rice processing in Nigeria In: Proceeding of the MFA workshop in Niger State, IITA, Ibadan, p 5–28

Adeyemi IA (1984) Rice processing in Nigeria-Recent developments. A lecture delivered at Department of Food Science and Brewing, Anambra State University of Technology, Awka

M.T. Ige, I. Fred-Oko, Studies of the factors affecting the local and improved methods of processing rice. Niger J Eng Technol 5(1), 118–126 (1992)

C.C. Yang, H.M. Lai, C.Y. Lii, The modified alkaline steeping method for the isolation of rice starch (Chinese). Food Sci 11, 158–162 (1984)

American Association of Cereal Chemists (AACC), AACC International Approved Methods of Analysis, 11th edn. (AACC International, St. Paul, MN, 2000)

B.O. Okezie, A.B. Bello, Physicochemical and functional properties of winged bean flour and isolate compare with soy isolate. J Food Sci 53, 450–454 (1998)

T.J. Schoch, Methods in carbohydrate chemistry, in Solubility and swelling power of starches, vol. 4, ed. by R.L. Whistler (Academic Press, New York, 1964), pp. 106–109

I. Keawpeng, M. Meenune, Physicochemical properties of organic and inorganic Phatthalung Sungyod rice. Int Food Res J 19(3), 857–861 (2012)

B.O. Juliano, G.B. Cagampanp, L.J. Cruz, R.G. Santiago, Some physicochemical properties of rice in South East Asia. Cereal Chem 41, 275–286 (1964)

F.H.G. Peroni, T.S. Rocha, C.M.L. Franco, Some structural and physicochemical characteristics of tuber and root starches. Food Sci Technol Int 12(6), 505–513 (2006)

B.S. Luh, R.R. Mickus, Rice: products and utilization, in Parboiled rice, ed. by B.S. Luh (AVI Publishing Co. Inc, Westport, 1980)

A.B. Adepeju, S.O. Gbadamosi, A.H. Adeniran, T.O. Omobuwajo, Functional and pasting characteristics of breadfruit (Artocarpus altilis) flours. Afr J Food Sci 5(9), 529–535 (2011)

O. Aletor, A.A. Oshodi, K. Ipinmoroti, Chemical composition of common leafy vegetables and functional properties of their leaf concentrates. Food Chem 78, 63–68 (2002)

M.Z. Sitohy, S.S. El-Seadany, S.M. Labib, M.F.R. Zagazig, Physicochemical properties of different types of starch phosphate monoesters. Starch (Starke) 52, 101–105 (2000)

Acknowledgments

The authors acknowledge the management of International Institute of Tropical Agriculture (IITA) for allowing our student to use their laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Odejobi, O.J., Ige, M.M. & Adeniyi, K.A. Physicochemical properties of the flour and starch from three Nigeria rice (Oryza sativa L.) varieties. Food Measure 9, 61–67 (2015). https://doi.org/10.1007/s11694-014-9210-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-014-9210-7